#Barcodes

Explore tagged Tumblr posts

Note

supermarkets worldwide are running out of barcodes since they are about 90% used up, so they are faking inflation so they can fund research for barcode2

There are approximately 234 million possible barcode combinations, 232 of which have been used for various applications. Barcode 2 is a project to exponentially increase the number of possibilities by adding horizontal lines.

50 notes

·

View notes

Text

Barcodes have a satanic connection 🤔

#pay attention#educate yourselves#educate yourself#knowledge is power#reeducate yourself#reeducate yourselves#think about it#think for yourselves#think for yourself#do your homework#do some research#do your own research#ask yourself questions#question everything#barcode shit#barcodes#american history#world history#history lesson#history

107 notes

·

View notes

Text

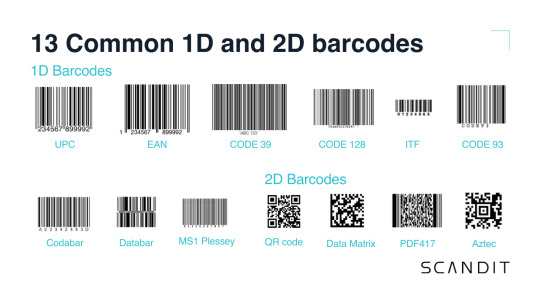

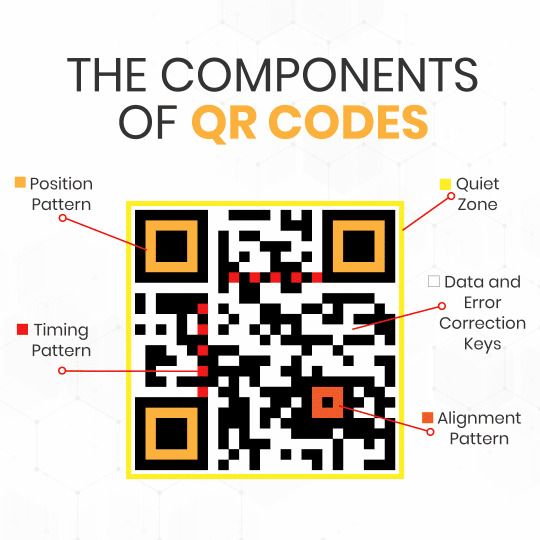

I love barcodes, both 1D and 2D. I won't think about them for a little bit, but then I'll see one and be like. Ough. Beautiful. They are so cool. There is so much more thought put into them than most people realize I think.

Like look at that. That's so cool.

#if anyone wants to learn about barcodes let me know#and you will be informed#barcodes#qr codes#my stuff

20 notes

·

View notes

Text

Shake 'dat ass!

2 notes

·

View notes

Text

personally I like Litton and Carecogan. we were robbed.

2 notes

·

View notes

Text

Commercial barcode printing scale for sale affordable prices Uganda

Looking for a Price Computing Weighing Scale for your business? Take all the guessing out of pricing your meat, fruits and vegetables with the TCS Price Computing Scale, a general-purpose computing scale with an enlarged and heavy duty stainless steel platter for direct sale of commodities in stores such as supermarkets, delicatessens and groceries.

The Price Computing Scale has a lowered body which enables it to easily fit in any open market. It is designed for portable use with AC power and built in rechargeable battery, the certified scale is also ideal for farmers markets, sandwich shoppers, bakeries, etc

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance.

For inquiries on deliveries contact us

Office +256 (0) 705 577 823, +256 (0) 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

2 notes

·

View notes

Text

Trump targets ballot barcodes, long a source of misinformation

ATLANTA (AP) — President Donald Trump’s executive order seeking to overhaul how U.S. elections are run includes a somewhat obscure reference to the way votes are counted. Voting equipment, it says, should not use ballots that include “a barcode or quick-response code.” Those few technical words could have a big impact. Voting machines that give all voters a ballot with one of those codes are used…

0 notes

Text

Our Planet is Covered with Barcodes: The Intricate Web of Identification and Data Tracking

0 notes

Text

Barcodes and Signal Recovery

▌▌▖▌▖▘▌▖▖▖▌▖▘▖▖▖▌▘▘▖▖▖▌▖▖▖▘▖▖▌▖▖▘▌▌▌

Last week I ran across an interesting project that caught my attention called dollcode by a GitHub user by the name of v01dlabs.

Of it's own, it's an exceptionally straightforward project: encode numbers and strings using a ternary code based on some simple Unicode characters ▌▖▘. I've long had a fascination with the way barcodes are read and the signal processing that goes with it, so I dug in to the working logistics.

Unfortunately, as I fiddled with it and tried to understand how one might decode it, it became increasingly clear that there were some limitations to the coding being used. For example, the encoding for "x" is "▌▌▌▌" and the encoding for the number 120 is also "▌▌▌▌". Similarly, the encoding p is "▘▘▘▘", which, if you don't know how tall the barcode is, looks exactly the same as the encoding for "(" which is "▖▖▖▖".

So given the seed and some knowledge about signal recovery, I decided to set out to make my own variation of the dollcode signaling method.

In my design, which I ended up calling signalbar, I added several features to constrain the coding, and improve its recovery with flexible optical media (printed paper) as the primary consideration.

Rather than encode data directly, a 4-to-3 encoding would be used; 4 bits of information using 3 trits.

The minimum unit of transfer would be a nibble. This is convenient in the 4-to-3 encoding, but also means that sending data smaller than 4 bits would require the cooperation of a higher level protocol.

Each symbol would actually come from one of three symbol tables based on the last bit of the previous symbol. This would allow for error detection and make use of the unused codes.

Two ▌ trits in a row would never appear outside of control symbols. This would make detecting control signals very easy.

Framing symbols would be added that could be used to detect the beginning and end of transmission. These symbols would be the same in all three encoding tables to simplify implementation. The start symbol would begin with a ▌▌ and the stop symbol would end with ▌▌, ensuring that the edges of the frame would always be max height and even if read backwards would immediately trigger the ▌▌ control sequence detection.

Symbols would be chosen such that no arrangement of the symbols could possibly create an infinitely long run, and symbols would be chosen in a way to minimize the maximum run length. This would aid in both clock recovery and detecting the code height on paper that wasn't flat since you could guarantee that you would see symbols of different sizes in a known and short window.

There are several things I think might be useful, such as frame length encoding and check codes, but those logistics are being left to higher level protocols. This implementation is mostly about the encoder/decoder hardware; so anything beyond what that is beyond the scope of this project for now.

With that said, the signalbar repo itself ended up being a powerful opportunity to do some work with GitHub Actions (I had been using Gitlab CI/CD up till now, and Jenkins before that) so that was interesting, and with some more time, I may add some explicit tests to verify the function of the module. But even without tests, it was a great way to bring pylint and mypy to bear, and made refining the code very nice.

However, this was largely just an amusement since I hadn't done a lot of personal programming over the last few years thanks to work. I don't know if I'll go far enough with this project to truly finish it up. dollcode, and now signalbar, are interesting, but I wouldn't particularly regard either as especially useful; just a neat way of exercising the ol' braincells. Nevertheless, I recommend you go check it out; there are some useful ways to think about signaling that are trapped up in the specific implementation that this toy example should make fairly clear (such as how 8b10b encoding solves the self-clocking issue.)

With that said, I have stuff in the pipeline that is more useful, but that writeup will have to wait for a different day.

#programming#barcodes#barcode scanner#barcode#python#python3#dollcode#signalbar#silly things I do to keep myself sharp and entertained

0 notes

Text

Discover the Benefits of Zebra Ribbons from Techbarco

Are you looking for high-quality printing supplies? Look no further than Techbarco! They offer an excellent selection of ribbons that are perfect for all your printing needs. These ribbons are designed to provide clear and vibrant prints, ensuring that your labels and tags always look professional.

Techbarco's ribbons are not only reliable but also durable, making them an ideal choice for businesses that require consistent performance. Whether you're printing barcodes, shipping labels, or any other type of label, you can count on Techbarco to deliver exceptional quality.

Check out their website to explore the range of ribbons available and elevate your printing game today!

0 notes

Text

I'm 21 and I still do it. I feel so embarrassed but it's the only coping mechanism I've ever known.

3 notes

·

View notes

Text

Front Cover Comic Barcodes

Link to Reddit post:

I can't comment on this post cus it's archived but... Bruh it is infuriating. And I can be as infuriated as I want fool. Even the person posting can be as infuriated as they want. I hope to never be emotionally monotone and as accepting of this situation as some of these dudes. I think the barcode was 100% moved to the the front of comics to make way for advertising. Generally, I thought opposing unneeded changes that directly damage the artistic vision of the cover artists in the name of better advertising was an approved way of thinking. Barcodes were at the back of comic books a year ago. And now they are not. I think I'd like to question why.

In fact here's a poll of people who want barcodes to be at the front vs. those who preferred when it was printed on the back. [Wink wink, I'm more likely to see your ad if it's right next to some important barcode that states the value of the comic book your ad is on. Wink wink wink wink wink.]

#I'm not actually that mad about it#just on my mind#I can't tell if I'm a front page or back page barcode person#poll#vs#barcodes#reddit#archived reddit#comic books#comics#comic#cover art#just curious lol

0 notes

Text

The oil and gas industry is increasingly propelled by digital transformation, driving unprecedented changes in how companies manage, optimize, and sustain operations. One of the most transformative tools in this shift is the digital twin. More than just a virtual replica, a digital twin is a fully integrated simulation of real-world assets and processes that provides real-time insights and predictive capabilities across the entire operational lifecycle. With this technology, companies are enhancing the precision, efficiency, and sustainability of oil and gas operations like never before.

Here’s how digital twins are setting new standards in operational accuracy and risk mitigation and how they are projected to redefine the industry.

A New Level of Predictive Power in Exploration and Drilling

In an era when exploration needs to be more data-driven and strategic than ever, digital twins offer oil and gas companies a new level of precision for high-stakes decision-making. They enable advanced simulations of subsurface formations, integrating seismic data, historical drilling outcomes, and real-time updates to create a highly accurate model of the drilling site. These simulations help geologists and engineers predict potential outcomes before any physical drilling begins.

Imagine drilling a well with the knowledge of precise pressure points, optimal extraction trajectories, and potential bottlenecks. Digital twins make this possible by building comprehensive, data-rich models of the entire drilling environment. This approach not only minimizes environmental impact but also optimizes the use of resources, helping companies reach their goals with a fraction of the traditional risk and cost.

Empowering Real-Time Production Optimization

Once production begins, maintaining an efficient, steady output is crucial. Digital twins play an instrumental role in optimizing production, allowing operators to see a live, virtual version of each asset—from wells to pumps, pipelines, and refineries. Through real-time feedback, companies can constantly monitor performance, model changes, and implement adjustments without disrupting the physical operation.

Consider a scenario where a production asset’s performance drops due to unforeseen factors. With a digital twin in place, operators can quickly assess and model potential solutions virtually, whether it’s adjusting pump rates, modifying temperatures, or rebalancing pressures. This not only maintains production stability but also extends the operational life of each asset, preventing costly interventions and unplanned downtimes.

Data-Driven Predictive Maintenance for Unmatched Reliability

Digital twins are enabling oil and gas companies to move from reactive to predictive maintenance. Through a continuous flow of data from asset sensors, these virtual models can detect minor anomalies that indicate potential equipment wear and degradation before any failure occurs. This allows maintenance teams to target specific issues proactively, reducing the likelihood of expensive, time-consuming shutdowns.

Imagine an offshore platform with multiple interdependent systems, each requiring a unique maintenance approach. With a digital twin, operators have a bird’s-eye view of every component’s health status, enabling them to schedule maintenance activities when they’ll cause minimal disruption. This not only extends equipment life but also ensures more reliable production cycles, lowering costs and enhancing safety.

Improving Safety and Sustainability with Advanced Simulation Capabilities

Safety is paramount in the oil and gas sector, and digital twins offer a transformative approach to both safety and sustainability. By simulating entire environments, digital twins allow companies to anticipate and prevent hazards before they arise. Companies can run emergency scenarios virtually, testing evacuation strategies, spill containment, and fire response without risk to personnel.

Digital twins are equally powerful in reducing environmental impact. They provide a detailed, real-time view of resource usage, waste generation, and emissions levels, helping companies make adjustments that reduce their environmental footprint. For instance, digital twins of drilling operations can simulate how a shift in extraction techniques might reduce emissions or water usage. This not only supports compliance with increasingly strict environmental regulations but also aligns operations with long-term sustainability goals.

Creating Seamless, Predictive Supply Chains

The oil and gas supply chain is a complex network of assets, resources, and logistics—each element critical to keeping operations running smoothly. Digital twins can create a predictive model of the entire supply chain, tracking inventory, optimizing transportation routes, and forecasting demand in real time. This helps avoid bottlenecks, cuts transportation costs, and minimizes supply-related disruptions.

Imagine a scenario in which a refinery’s output data indicates an impending shortage of a specific chemical. A digital twin of the supply chain can notify procurement teams well in advance, enabling them to secure additional supplies without costly delays. This level of foresight also helps reduce excess inventory, freeing up capital while ensuring a continuous flow of necessary resources.

Supporting Remote Operations with Collaborative Digital Twins

In a digitally connected world, remote operations have become more feasible and efficient. Digital twins support remote asset management by providing field and control room operators with the same detailed, real-time view of assets, regardless of their location. This means that teams spread across multiple regions can collaborate effectively, making coordinated decisions based on a single, unified view of each asset’s performance and needs.

For example, a digital twin of an offshore drilling rig allows onshore engineers to see the same data as offshore personnel, enabling them to make rapid, collaborative decisions when addressing operational challenges. This integration of remote and on-site teams reduces the need for personnel to be physically present in hazardous environments, enhancing both safety and efficiency.

Enabling Data-Driven Decision-Making Across Operations

Digital twins are ultimately about data—more specifically, about transforming complex data into actionable insights. By integrating data from across the asset lifecycle, digital twins provide a centralized, reliable source of truth for decision-making. This empowers everyone from field technicians to executive leadership to make informed decisions that optimize asset performance, extend lifespans, and enhance profitability.

For instance, in evaluating the potential of a new field development, a digital twin can model various scenarios to show the impacts of different drilling techniques, production strategies, and even weather patterns. With these insights, leaders can confidently decide on the best path forward, maximizing returns and minimizing risks.

Moving Toward Fully Autonomous Digital Ecosystems

As digital twin technology evolves, the oil and gas industry is on the brink of fully autonomous digital ecosystems. Integrating AI, machine learning, and IoT with digital twins promises to unlock new levels of automation, enabling assets to make self-corrective adjustments in real-time. For example, pipelines could automatically adjust flow rates in response to changes in demand, while wells could adapt extraction rates based on reservoir pressure without human intervention.

Such autonomous systems could ensure a seamless, optimized production process that maximizes output and minimizes waste while reducing the need for hands-on oversight. The result is an industry that can respond dynamically to changes in the field, market conditions, and environmental factors in ways that were once thought impossible.

Digital twins are at the forefront of transforming oil and gas operations, offering a precise, data-driven approach to everything from exploration and production to supply chain management. By enabling real-time monitoring, predictive maintenance, and autonomous adjustments, digital twins are helping oil and gas companies achieve unprecedented levels of efficiency, safety, and sustainability.

For a deeper dive into the latest digital twin advancements and their role in shaping the oil and gas industry, join us at the Oil & Gas Automation and Digitalization Conference 2025. This event will feature industry leaders, insightful discussions, and hands-on sessions on the cutting-edge technologies transforming the field. Don’t miss this opportunity to learn how digital twins are setting new standards and helping the industry meet the challenges of tomorrow.

#conference#oil and gas#supply chain#artificial intelligence#barcodes#blockchain#digitalization#digitaltransformation

0 notes

Text

My dad used to be able to read barcodes for the price on items. You know how magical that is for a kid? How much is this toy? *passes to dad* 39.99$. Brilliant

0 notes

Text

30kg fruit candy retail store counter scale in Kampala

Looking for a Price Computing Weighing Scale for your business? Take all the guessing out of pricing your meat, fruits and vegetables with the TCS Price Computing Scale, a general-purpose computing scale with an enlarged and heavy duty stainless steel platter for direct sale of commodities in stores such as supermarkets, delicatessens and groceries.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance.

For inquiries on deliveries contact us

Office +256 (0) 705 577 823, +256 (0) 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

2 notes

·

View notes