#Beam Formwork

Explore tagged Tumblr posts

Video

youtube

Fixed Fork Head Manufacturing Video - Formwork 4 Way Head for Slabs and ...

#youtube#fork head#fixed fork head#formwork head#slab formwork#beam formwork#concrete shuttering#concrete formwork

0 notes

Text

Can Quality Scaffolding Materials Speed Up Your Construction Project? In construction, speed and efficiency are key to staying on schedule and within budget. Winntus Formwork System Pvt. Ltd. helps contractors achieve this by providing high-quality Scaffolding Materials that enhance safety, durability, and overall project performance without compromising quality.

0 notes

Text

Seamlessly Crafting Wall And Column Formworks For Your New Constructions

The success of any structure depends on dependable framework systems for support. Formworks provide shaping functions to produce solid beams, columns, walls, and slabs from concrete.

Structures become unstable and fail when beam, wall, slab, or column formwork is not used correctly. When properly selected, formwork systems create structures that are stronger and finish construction operations more quickly as they minimize used materials. The correct system selection guarantees persistent structural robustness and long-lasting durability.

The Importance of Precision in Formwork Design

The design of formwork needs to maintain exact precision. Even the smallest alignment mistake will cause the whole structure to become weaker. The correct installation of formwork results in a concrete setting according to its required dimensions and shapes. Engineers, together with builders, need to select pressure-resistant materials during their operational procedures. Routed frameworks lead to both an easy construction process and permanent structural integrity.

Efficient Use of Column Formwork in Construction

Vertical structures depend heavily on column formwork execution as a fundamental construction method. The framework maintains the form of wet concrete until it develops into durable vertical structures. The right column form system achieves both uniformity and strength. The implementation of pre-engineered systems results in improvements in both production efficiency and workplace security at construction sites.

Enhancing Structural Integrity with Beam Formwork

The beam formwork serves as a supporting system for making horizontal concrete structures. The primary function of beams is to carry the weight from above, including walls and slabs. A well-designed beam framework stops the downward bending and vertical displacement of concrete structures. Durability depends on using steel, plywood and plastic as strong implements for construction. A correctly chosen formwork system accelerates building processes while maintaining workplace safety standards.

The Significance of Wall Formwork in Building Projects

Wall formwork serves as an essential element for creating solid walls with regular surfaces. The forms maintain the concrete in position until it solidifies to obtain uniform surfaces. Quality wall forms decrease the formation of building defects and eliminate labor rework. Using lightweight, reusable formwork allows builders to execute this process at a lower cost.

Maximizing Efficiency with Slab Formwork

Horizontal concrete slabs receive support from slab formwork until they achieve total hardness. This material forms a secure foundation to support ceiling and floor concrete casting operations. The use of robust slab forms helps to stop the formation of cracks and create level surfaces. The use of modular systems generates better workplace efficiency while simultaneously lowering labor expenses.

Choosing the Right Formwork for Your Project

There are a few factors you need to consider for choosing the right formwork. Load-bearing capacity, reusability, and cost efficiency become fundamental elements for choosing the formwork system. The construction sector shows an increasing preference for modular formworks alongside plastic formworks due to their durability and convenient handling properties. The selection process of formwork systems depends heavily on weather conditions alongside project duration requirements.

Conclusion

The proper design of formwork functions as the essential element required for achieving construction success. Formwork technology enhances project strength while raising operational efficiency and minimizing cost expenses. Quality formwork systems provide safety along with an extended operational lifespan. A suitable formwork investment creates an improved flow and efficiency during building operations. NOVA Formworks is India’s preeminent company offering advanced formwork systems to customers. Their solutions ensure premium quality to ensure optimal construction outputs.

#formworks in india manufacturer and supplier#plastic formworks#civil construction#column formwork#beam formwork#wall formwork#slab formwork

0 notes

Text

NOVA Formwork - A Leading Provider Of Multifunctional Formwork Systems

Nova Formwork Systems are made of high-tech plastic materials for effortless handling, and they are lightweight, strong, and reusable. You can count on consistent, faultless results whether you're working on a simple or complex structure.

#nova plastic formwork#formwork construction#plastic formwork#construction formwork#plastic formwork in india#wall formwork#beam formwork#column formwork#slab formwork

0 notes

Text

Formwork Safety: Best Practices Every Construction Site Must Follow

in ensuring the structural integrity of buildings, it also presents significant risks if not handled properly. Accidents related to formwork can lead to injuries, delays, and increased costs. Implementing robust safety practices is, therefore, not just important—it’s non-negotiable.

This blog outlines the best practices every construction site must follow to ensure formwork safety, minimizing hazards and ensuring smooth project execution.

1. Design and Planning: The Foundation of Safety

Safety begins long before the first piece of formwork is set up. A well-thought-out design and plan ensure that formwork systems can handle the loads and pressures they will be subjected to.

Load Assessment: Engineers must calculate the expected weight of wet concrete, construction equipment, and workers. Overloading can cause formwork to collapse.

Material Selection: Use high-quality materials, whether timber, steel, or aluminum, that meet safety standards.

Compliance with Standards: Follow local construction codes and international standards like ISO and OSHA to ensure safety requirements are met.

2. Regular Inspections and Maintenance

Formwork systems must be inspected regularly to identify potential hazards.

Pre-Installation Checks: Inspect all components for wear, damage, or defects before use. Replace any compromised materials.

On-Site Monitoring: Conduct daily inspections to ensure formwork stability and alignment during construction.

Post-Dismantling Checks: After removing the formwork, check for damages that could impact future use.

3. Proper Training for Workers

Even the best formwork system can be hazardous if workers lack the necessary training.

System Familiarity: Workers should be trained in the specific formwork system being used, including its assembly, disassembly, and handling.

Safety Protocols: Teach workers about potential hazards, including falls, collapsing formwork, and concrete spills.

Emergency Response Training: Ensure workers know how to respond in case of accidents, including evacuation procedures and first aid.

4. Correct Assembly and Installation

Proper assembly and installation are critical to preventing accidents.

Follow Manufacturer Guidelines: Always adhere to the manufacturer’s instructions for installation and use.

Secure Foundations: Ensure the base of the formwork is stable and can support the load. Soft or uneven ground can lead to instability.

Alignment and Bracing: Check that the formwork is properly aligned and braced to resist lateral pressures from wet concrete.

5. Fall Protection Measures

Working with formwork often involves heights, making fall protection a crucial element of safety.

Guardrails and Toe Boards: Install guardrails around elevated work areas to prevent falls.

Personal Protective Equipment (PPE): Provide workers with helmets, harnesses, and safety shoes.

Safe Access: Use ladders or scaffolding to provide safe access to elevated work areas.

6. Monitoring During Concrete Pouring

Concrete pouring is a critical phase when formwork is under maximum pressure.

Gradual Pouring: Pour concrete in layers to prevent sudden pressure surges that could collapse the formwork.

Monitor Load Distribution: Ensure the concrete is evenly distributed to avoid uneven stress.

On-Site Supervision: Have supervisors oversee the process to immediately address any issues.

7. Avoiding Overloading

Overloading formwork is a common cause of accidents.

Understand Load Limits: Clearly communicate the maximum load capacity to all workers.

Distribute Loads Evenly: Avoid placing unnecessary weights, such as construction equipment, directly on the formwork.

Remove Excess Concrete: Ensure no excess concrete is left on top of the formwork after pouring.

8. Weather Considerations

Weather conditions can significantly impact formwork safety.

Wind Resistance: Ensure formwork is braced to withstand high winds.

Rain Precautions: Wet conditions can weaken timber formwork and create slippery surfaces. Use non-slip materials and drain water promptly.

Temperature Extremes: High temperatures can cause materials to expand, while low temperatures can make them brittle. Regularly inspect for weather-related damage.

9. Safe Removal of Formwork

Dismantling formwork is as critical as its installation.

Timing: Wait for the concrete to reach sufficient strength before removing the formwork.

Controlled Removal: Take apart the formwork systematically, starting with non-load-bearing sections.

Worker Safety: Keep workers clear of the area during removal to avoid injuries from falling materials.

10. Communication and Documentation

Clear communication and thorough documentation are vital for maintaining a safe construction site.

Safety Meetings: Conduct regular safety briefings to keep everyone informed of potential risks and updates.

Incident Reporting: Encourage workers to report near misses and hazards to prevent future accidents.

Document Safety Protocols: Maintain a written record of safety protocols, inspections, and incident reports for accountability and improvement.

Conclusion

Formwork safety is not just about preventing accidents—it’s about creating a culture of responsibility and care on construction sites. By implementing these best practices, you can protect your workers, avoid costly delays, and ensure the success of your projects.

At Navnirman, we prioritize safety and innovation in our formwork systems. Our high-quality materials and cutting-edge designs ensure the safety and efficiency of your construction site.

Ready to build smarter and safer? Contact us today to learn more about our advanced formwork solutions!

#constructionmanagement#constructionsite#constructionwork#highwayconstruction#navnirman#formwork#beam formwork#buildingconstruction#formworksystems#branding

0 notes

Text

AS/NZS 4357 structural laminated veneer lumber factory

AS/NZS 4357 LVL is not only well known for permanent structures such as framing, beams, and flooring, but also plays an equally important role for temporary structures.

whatsapp: +86 18653492529

email: [email protected]

1 note

·

View note

Text

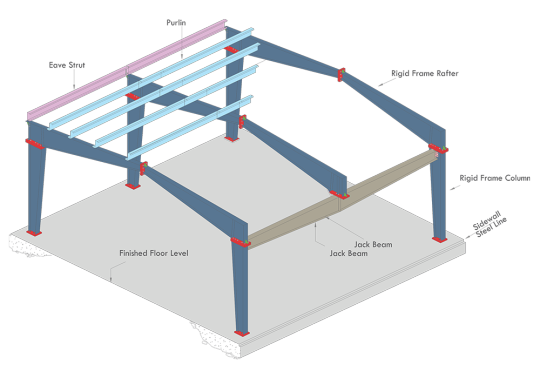

Smith Structure| Jack Beam Elevating Structural Support

Smith Structure introduces jack beams structural component used in construction for temporary or permanent support of floors, roofs, or load-bearing elements

#Jack Beam#Isometric Jack Beam at Sidewall#Isometric Jack Beam at Interior Column Location#Mezzanine System#mezzanine framing system#steel deck support#mezzanine beams#Mezzanine Plan#steel formwork#oncrete slab construction#Mezzanine Cross Section#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

Looking for top-notch shuttering plywood that delivers strength, durability, and value? Look no further than PAAM Group, your go-to destination for premium quality construction materials. 🌟 Why Choose PAAM Group for Shuttering Plywood: ✅ Extensive Range of Plywood Options ✅ Premium Quality for Superior Performance ✅ Competitive Prices to Fit Your Budget ✅ Reliable and Timely Delivery ✅ Expert Guidance and Support At PAAM Group, we understand the critical role that high-quality shuttering plywood plays in construction projects. That's why we source and supply only the best products that meet industry standards and exceed your expectations. Whether you're a professional builder or a DIY enthusiast, we have the right shuttering plywood solution for you. Our experts are ready to assist you in making the perfect choice for your project, ensuring that you achieve outstanding results every time. Don't compromise on the foundation of your construction. Contact PAAM Group today to explore our range of shuttering plywood options and experience the difference in quality and service. 📞 Call us at [0091] 77994-36000 📧 Email us at [email protected] 🌐 Visit our website at https://www.paamgroup.com/ 📍 Conveniently located for your construction needs Elevate your construction projects with the reliability and excellence of PAAM Group's shuttering plywood. Your success is our priority!

#wood h beams supplier#wood h beams manufacturer#shuttering plywood manufacturer#plywood formwork panels manufacturer#wooden h – beams in hyderabad#film faced plywood#film faced shuttering plywood supplier

0 notes

Text

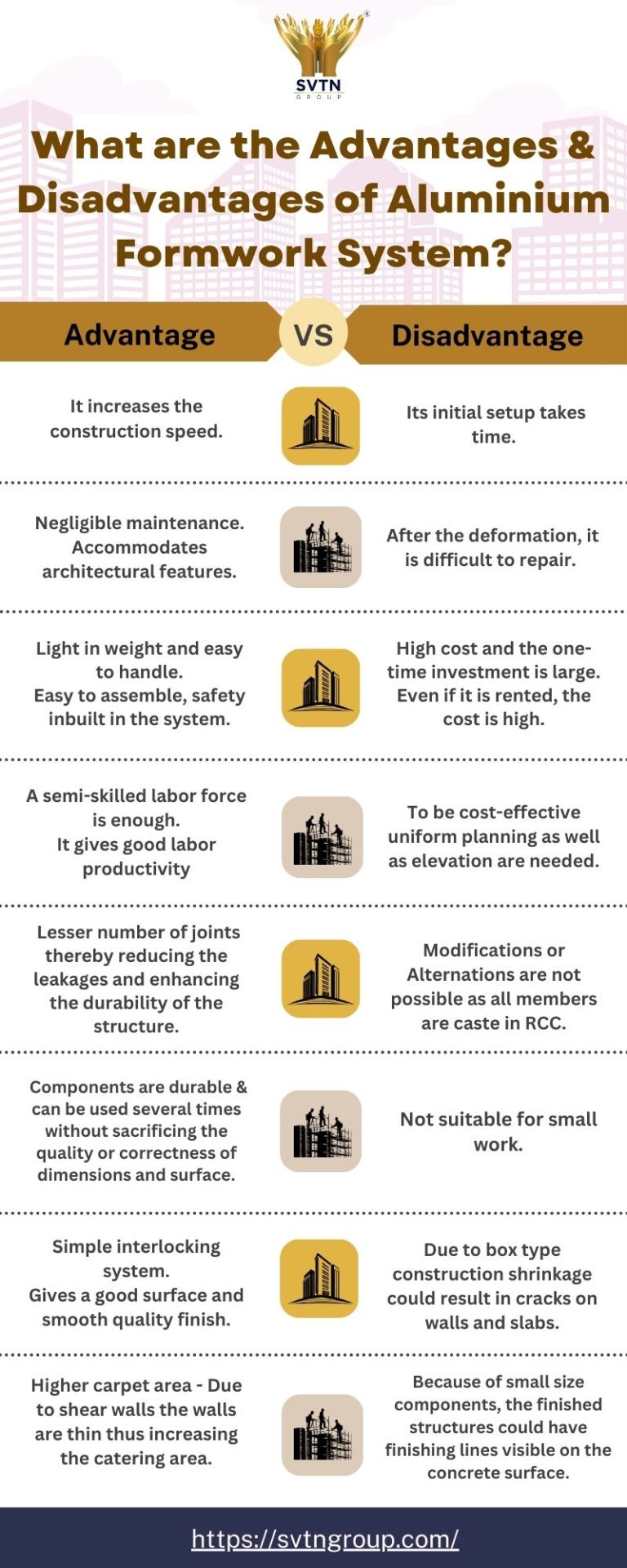

One of the most adaptable modern construction technologies is the Aluminum Formwork System, often known as Alu-Form Technology. It provides additional benefits and may be used for both high-rise and low-rise construction, unlike other methods. The speed factor of the Alu-Form system is its primary feature. All interior and external walls, beams, floor slabs, staircases, and other concrete building components can be cast quickly, precisely, and consistently with its help. This technique integrates plumbing and electrical fixtures more effectively into the overall building design.

#SVTN#aluform construction technology#alu form construction#aluform formwork#top contractors in pune#pune best construction company#best construction work company in pune#best construction company in pune#aluform construction#quality construction work#quality construction works#quality construction works llc#Affordable and Quality Construction Works#building contractors in pune#contractors in pune#civil contractors in pune#SVTN Group

3 notes

·

View notes

Text

The Power of Precision: A Guide to Hand Winches

In the world of heavy lifting and manual labor, hand winches are the unsung heroes that provide the muscle to accomplish tasks that would otherwise be impossible. Whether you're a DIY enthusiast, a professional in the construction industry, or an outdoor adventurer, a hand winch is a valuable tool that can make your work easier and more efficient. In this blog post, we'll explore the world of hand winches, their uses, benefits, and how to choose the right one for your specific needs.

What is a Hand Winch?

A hand winch, also known as a manual winch, is a mechanical device designed for lifting, pulling, or hoisting heavy objects through the use of a rotating drum or reel and a crank handle. These versatile tools come in various sizes and capacities, making them suitable for a wide range of applications.

Applications of Hand Winches

Off-Roading and Vehicle Recovery: Hand winches are indispensable for off-road enthusiasts and those who frequently find themselves in situations where their vehicle is stuck in mud, sand, or snow. A hand winch can be mounted on the front or rear of a vehicle to assist in self-recovery or to help pull others out of tricky situations.

Construction and Building: In construction and building projects, hand winches are commonly used for lifting heavy building materials, such as steel beams and concrete blocks. They are also handy for positioning equipment, scaffolding, or formwork.

Boating and Sailing: Sailors and boat owners rely on hand winches to hoist sails, lift anchors, and perform various rigging tasks on their vessels. Hand winches for marine applications are usually designed to resist corrosion and withstand the harsh maritime environment.

Industrial and Warehouse Work: Hand winches play a crucial role in material handling and logistics in warehouses and industrial settings. They can be used for moving heavy loads, adjusting conveyor systems, and facilitating precise positioning of machinery.

Farming and Agriculture: In agriculture, hand winches are used for tasks like pulling out stubborn tree stumps, tensioning fences, or winching heavy loads onto trailers.

Benefits of Using Hand Winches

Portability: Hand winches are compact and portable, making them suitable for both on-site and remote applications. They can be easily transported to various job sites, and their manual operation means no need for electricity or batteries.

Precision Control: Unlike powered winches, hand winches offer precise control over the speed and tension of the cable or rope, allowing for more delicate and controlled operations.

Reliability: Hand winches are known for their durability and long-lasting performance. With proper maintenance, they can withstand years of heavy use.

Cost-Effective: Hand winches are often more affordable than their powered counterparts, making them a budget-friendly option for many users.

Choosing the Right Hand Winch

When selecting a hand winch, consider the following factors:

Load Capacity: Determine the maximum weight you'll need to lift or pull, and choose a hand winch with an appropriate load capacity.

Cable or Rope Material: Consider whether you need a winch with a steel cable or a synthetic rope, as the choice depends on the specific application and your preferences.

Mounting Options: Decide whether you need a portable hand winch or one that can be permanently mounted to a surface or vehicle.

Corrosion Resistance: If your winch will be exposed to moisture or harsh environmental conditions, opt for a winch with corrosion-resistant coatings or materials.

Gear Ratio: The gear ratio affects the winch's pulling power and speed. Higher gear ratios provide greater pulling power, while lower gear ratios offer faster operation.

Conclusion

Hand winch are versatile tools that find applications in various industries and activities. Whether you're an off-road enthusiast, a construction professional, or a boat owner, a hand winch can significantly simplify tasks that involve lifting, pulling, or hoisting heavy objects. By understanding the uses and benefits of hand winches and selecting the right one for your needs, you can work more efficiently and effectively while enjoying the reliability and precision control these tools offer.

2 notes

·

View notes

Text

Plastic Formworks: Revolutionizing Modern Construction with Nova Formworksblr

In the ever-evolving construction industry, the need for durable, efficient, and cost-effective materials has led to significant innovations. Among these, Plastic Formworks have emerged as a transformative solution for modern building practices. Nova Formworksblr, a trusted name in the sector, has been at the forefront of this revolution, offering top-quality Plastic Formworks that address traditional challenges while enhancing overall productivity and sustainability in construction.

What Are Plastic Formworks?

Plastic Formworks are modular construction systems made from high-quality plastic materials that serve as molds for pouring concrete. Unlike conventional wooden or metal shuttering systems, Plastic Formworks are reusable, lightweight, and resistant to water and chemical corrosion. These qualities make them ideal for various applications, from residential buildings to large-scale commercial and infrastructure projects.

Nova Formworksblr manufactures Plastic Formworks designed to meet the rigorous demands of construction sites while ensuring precision, efficiency, and long-term cost savings. Their formwork systems are engineered to deliver excellent surface finish and structural strength with minimal maintenance.

Advantages of Using Plastic Formworks

Durability and Longevity

Plastic Formworks are designed for multiple reuse cycles, significantly outlasting traditional wooden or plywood systems. Nova Formworksblr offers formwork systems made from tough and resilient plastic materials that do not warp, swell, or degrade with exposure to moisture, ensuring consistent performance throughout their lifecycle.

Ease of Handling and Installation

One of the standout features of Plastic Formworks is their lightweight nature. They are easy to transport, assemble, and dismantle without requiring heavy machinery or extensive labor. This ease of use reduces construction time and labor costs, making the overall process more efficient. Nova Formworksblr’s systems come with user-friendly locking mechanisms and modular panels that ensure seamless operation on-site.

Superior Finish and Accuracy

Plastic Formworks provide smooth and uniform concrete finishes, reducing the need for extensive plastering or surface treatment. The high precision of Nova Formworksblr’s formwork panels ensures accurate dimensions and a high-quality finish, which is particularly beneficial in exposed concrete applications.

Environmentally Friendly

With growing concerns about environmental sustainability, Plastic Formworks offer a greener alternative to timber-based shuttering. Since they can be reused many times and do not contribute to deforestation, they are a more eco-friendly option. Nova Formworksblr emphasizes sustainability by manufacturing recyclable and reusable Plastic Formworks that reduce construction waste.

Cost-Effective Over Time

While the initial investment in Plastic Formworks may be higher than traditional options, their long-term cost benefits are substantial. The high reuse factor, reduced labor costs, and minimal maintenance make them a cost-effective solution. Nova Formworksblr’s clients have reported significant savings across multiple construction cycles.

Applications of Plastic Formworks

Plastic Formworks are suitable for a wide range of applications, including:

Residential Construction: Ideal for slab casting, beams, columns, and walls in housing projects.

Commercial Projects: Used in office buildings, malls, and industrial complexes where fast-paced construction is crucial.

Infrastructure: Applied in the construction of bridges, culverts, water tanks, and other public utilities.

Precast Structures: Useful in the manufacturing of precast panels, blocks, and decorative concrete products.

Nova Formworksblr provides versatile solutions that cater to all these applications, ensuring that every project benefits from efficiency, precision, and reduced operational hurdles.

Why Choose Nova Formworksblr?

Nova Formworksblr stands out in the Indian market for its commitment to innovation, quality, and customer satisfaction. Here are a few reasons why they are a preferred partner for Plastic Formworks:

Customized Solutions: Every construction project has unique requirements. Nova Formworksblr offers tailor-made formwork designs that align perfectly with client needs.

Comprehensive Support: From consultation and design to delivery and post-sale service, they provide end-to-end support.

Proven Track Record: With successful installations across residential, commercial, and infrastructure sectors, Nova Formworksblr has earned a reputation for excellence.

In-house Manufacturing: Their in-house manufacturing facilities ensure strict quality control and faster turnaround times.

Maintenance and Storage

Maintaining Plastic Formworks is remarkably easy. Unlike wooden formworks that are prone to rotting or warping, plastic systems require only basic cleaning after each use. Nova Formworksblr recommends simple washing with water to remove residual concrete. Their products are designed for quick storage, and the stackable design of the panels minimizes storage space requirements on-site.

The Future of Formworks

As construction demands grow and evolve, so does the need for smarter and more sustainable building materials. Plastic Formworks are quickly gaining traction as the go-to solution for projects that demand high performance and efficiency. With increasing emphasis on green building practices and cost control, the adoption of reusable formwork systems will continue to rise.

Nova Formworksblr is not just keeping pace with this change—they are leading it. Their continuous focus on research, innovation, and client-centric solutions positions them as a pioneer in the Plastic Formworks industry.

Conclusion

Plastic Formworks are redefining the construction landscape by providing a smarter, safer, and more sustainable approach to concrete forming. From durability and ease of use to superior finish and long-term savings, the advantages are clear. Nova Formworksblr’s commitment to quality and innovation makes them the ideal partner for construction firms looking to elevate their building practices.

Whether you're planning a small-scale housing project or a large infrastructure development, Nova Formworksblr offers the Plastic Formworks solutions you need to build faster, better, and more efficiently.

0 notes

Video

youtube

Fixed Fork Head - Wellmade Scaffold, China - Slab and Beam Formwork Top ...

#youtube#fork head#fixed fork head#forkhead#slab shoring scaffold#shoring scaffold#shoring system#slabs#slab scaffolding#slab formwork#slab shuttering#beam formwork#formwork scaffolding#construction scaffolding#building scaffolding#formwork#wellmade scaffold

0 notes

Text

Top Shuttering Ply Manufacturer in Bihar – Quality You Can Trust by VeneerGanesh

When it comes to construction, the strength and reliability of your materials can make or break the project. One of the most critical components in any concrete formwork system is shuttering plywood. If you're looking for a trusted shuttering ply manufacturer in Bihar, look no further than VeneerGanesh – a name synonymous with quality and durability.

Why Shuttering Ply Matters in Construction

Shuttering plywood, also known as formwork ply, is used to mold concrete into desired shapes and hold it in place while it sets. This means it needs to be:

Strong enough to withstand the pressure of wet concrete

Water-resistant to handle high-moisture environments

Reusable, offering cost-efficiency over multiple cycles

Choosing the right shuttering ply ensures the safety, finish, and structural integrity of your building.

VeneerGanesh – Leaders in Shuttering Plywood in Bihar

VeneerGanesh has earned a reputation in Bihar and beyond for manufacturing high-grade shuttering ply manufacturers in bihar that meets the highest industry standards. Here’s what sets them apart:

✅ IS Standard Quality: Manufactured using premium hardwood and bonded with waterproof adhesives, ensuring high load-bearing capacity.

✅ Durability: Resistant to warping, swelling, and delamination – ideal for harsh construction conditions.

✅ Eco-Friendly Manufacturing: Committed to sustainable practices without compromising product strength.

✅ Customization: Available in different sizes and thicknesses to suit varied construction needs.

Applications of VeneerGanesh Shuttering Ply

Residential and commercial building construction

Infrastructure projects like bridges and highways

Columns, beams, and slab casting

Temporary structures and frameworks

Why Choose a Local Manufacturer?

Working with a local manufacturer like VeneerGanesh in Bihar offers multiple advantages:

Faster delivery and reduced logistics costs

Local customer service and technical support

Better understanding of regional construction challenges

Final Thoughts

Whether you're a builder, contractor, or supplier, VeneerGanesh is your go-to source for reliable shuttering ply in Bihar. With an unmatched combination of strength, durability, and affordability, they’re helping shape the infrastructure of tomorrow—one sheet at a time.

Visit:- https://www.ganeshveneer.com/shuttering-ply-bihar.php

0 notes

Text

Together, Let’s Construct A Greener Tomorrow With Nova Plastic Formworks

Sustainability Starts with Nova Formworks. Recycled plastic formwork is a revolutionary invention that is revolutionizing the building sector.

#plastic formworks#nova formwork#formworks in india manufacturer and supplier#civil engineering#civil construction#construction materials#plastic formwork#beam formwork#column formwork#slab formwork#aluminum shuttering

0 notes

Text

Concrete Beam And Slab Formwork By Nova

The plastic Formwork system from Nova is designed to fit a variety of uses, allowing it to mold beams, slabs, columns, and verticals with ease. It ensures high-quality outcomes while streamlining the construction process with accuracy and durability. Nova's Formwork system meets the requirements of contemporary construction techniques with efficiency and dependability, whether it is used for residential, commercial, or industrial projects.

#nova plastic formwork#formwork construction#slab formwork#beam formwork#slab and beam#concrete beam formwork#concrete slab formwork

0 notes

Text

The Benefits of Using Advanced Wall Formwork Systems in Modern Construction

innovation that has transformed the construction landscape is the use of advanced wall formwork systems. These systems offer a structured approach to creating durable and precise walls for buildings, bridges, tunnels, and other infrastructures. In this blog, we will explore the benefits of using advanced wall formwork systems in modern construction and how they contribute to project success.

1. Enhanced Construction Speed

Time is a critical factor in any construction project. Advanced wall formwork systems are designed to significantly reduce the time required for wall construction. Their modular and reusable nature allows for quick assembly and disassembly, ensuring that projects stay on schedule.

For instance, pre-engineered formwork panels can be erected swiftly, minimizing delays and expediting the overall construction process. This increased speed not only saves time but also reduces labor costs and accelerates project delivery.

2. Superior Wall Quality and Precision

The precision offered by advanced wall formwork systems is unmatched. These systems ensure uniformity and consistency in wall dimensions, resulting in smoother surfaces and better structural integrity.

Key features include:

Exact alignment: Ensures straight and even walls.

Smooth finishes: Reduces the need for additional plastering or finishing.

Leak-proof joints: Prevents concrete seepage and enhances durability.

By using advanced formwork systems, construction teams can achieve a level of accuracy that is difficult to replicate with traditional methods.

3. Cost Efficiency

Although advanced wall formwork systems may have a higher upfront cost compared to traditional methods, they provide significant long-term savings. Their reusability is a major advantage, allowing contractors to use the same panels across multiple projects without compromising quality.

Other cost-saving factors include:

Reduced material wastage.

Lower labor costs due to faster assembly.

Minimal maintenance and repair requirements.

Over time, these savings outweigh the initial investment, making advanced formwork systems a cost-effective solution for modern construction.

4. Improved Safety Standards

Safety is a paramount concern in construction. Advanced wall formwork systems are designed with safety features that protect workers on-site. These systems often include:

Integrated safety platforms: Provide secure working spaces.

Ladders and guardrails: Ensure safe access and movement.

Durable materials: Reduce the risk of collapse or failure during construction.

By incorporating these safety measures, advanced wall formwork systems help prevent accidents, creating a safer working environment.

5. Versatility Across Projects

One of the key benefits of advanced wall formwork systems is their adaptability to various construction needs. Whether you’re building high-rise apartments, tunnels, or bridges, these systems can be tailored to fit specific project requirements.

Types of wall formwork systems include:

Steel formwork: Ideal for large-scale projects requiring high strength.

Aluminum formwork: Lightweight and easy to handle.

Plastic formwork: Suitable for small to medium projects with reusable options.

This versatility ensures that construction teams can use the same system for diverse applications, maximizing their utility and efficiency.

6. Eco-Friendly Construction Practices

Sustainability has become a crucial aspect of modern construction. Advanced wall formwork systems contribute to eco-friendly practices by:

Reducing material wastage during construction.

Promoting the reuse of formwork panels across multiple projects.

Minimizing the need for additional finishing materials, such as plaster or paint.

By adopting these systems, builders can significantly lower their carbon footprint, aligning their practices with global sustainability goals.

7. Increased Load-Bearing Capacity

Advanced wall formwork systems are engineered to withstand heavy loads and high pressure during the concreting process. This robustness ensures the structural stability of walls, particularly in large-scale projects.

Key benefits include:

Resistance to deformation under high pressure.

Ability to support complex wall designs.

Longevity, reducing the need for frequent replacements.

This increased load-bearing capacity is essential for creating durable and reliable structures.

8. Customization for Complex Designs

Modern architecture often demands intricate and unique designs. Advanced wall formwork systems offer the flexibility to accommodate these complex requirements. With adjustable panels and innovative features, these systems allow for the construction of curved walls, angled walls, and other non-standard designs without compromising precision.

This customization capability empowers architects and engineers to bring their creative visions to life while maintaining structural integrity.

9. Reduced Labor Dependency

Traditional formwork methods rely heavily on skilled labor, which can be challenging to find and expensive to hire. Advanced wall formwork systems simplify the construction process, making it possible to train workers quickly and reduce dependency on specialized labor.

Additionally, their user-friendly design ensures that even less experienced workers can assemble and disassemble the systems efficiently, reducing overall labor costs.

10. Better Project Management

Advanced wall formwork systems facilitate better project management by streamlining construction processes. Their modular design allows for:

Easy tracking of components.

Faster transitions between construction phases.

Accurate progress monitoring.

These features enable construction teams to manage resources effectively and ensure timely project completion.

Conclusion

The benefits of using advanced wall formwork systems in modern construction are undeniable. From enhancing construction speed and precision to improving safety standards and promoting sustainability, these systems are a game-changer for the industry. Their versatility, cost efficiency, and ability to adapt to complex designs make them an indispensable tool for contractors and builders aiming to achieve excellence in their projects.

As the construction industry continues to evolve, adopting advanced wall formwork systems will not only meet the demands of modern architecture but also set a new standard for quality and efficiency. By investing in these innovative solutions, builders can ensure long-term success and growth in an increasingly competitive market.

Embracing the future of construction starts with the right tools—and advanced wall formwork systems are undoubtedly among the best.

#formworksystems#constructionmanagement#constructionsite#buildingconstruction#constructionwork#formwork#navnirman#beam formwork#branding#highwayconstruction

0 notes