#Brass Threaded Insert

Text

Brass Turning Parts Manufacturers and Exporters in India, Australia, Canada, UK

When it comes to precision engineering and manufacturing, few materials match the versatility and durability of brass. With a history that dates back centuries, brass has been a go-to choice for producing a wide range of components, from decorative hardware to intricate mechanical parts. However, the key to harnessing the full potential of brass lies in the hands of custom brass-turned parts manufacturers and suppliers in USA, Europe, UK, Canada, Russia, Australia and South Africa.

In this article, we’ll delve into the world of Custom Brass turned parts manufacturers in USA, Europe, UK, Canada, Russia, Australia and South Africa, exploring the significance of these specialized manufacturers and the role they play in various industries.

Parts turned bras are important for countless applications, from plumbing and musical instruments to automotive components and electrical connections. The accuracy and precision in the metal conversion process make them essential for achieving the desired results in these industries. So, what are custom turned brass parts, Brass Threaded Insert, and why are they so important?

Custom brass turned parts are precisely machined components made from brass, a metal alloy composed primarily of copper and zinc. These parts are crafted with meticulous attention to detail, often on specialized machinery called CNC (Computer Numerical Control) lathes. This precision machining process transforms brass rods or bars into a variety of shapes and sizes, meeting the specific requirements of clients.

The most important elements of Brass Terminals | Brass Connectors based on their appearance. They can be designed and manufactured to great detail, ensuring that they fit perfectly into the intended application. Whether it’s a special plumbing fixture, a critical electrical connection, or a critical infrastructure component, custom metal parts turn out to be essential to get the job done perfectly and efficiently.

THE ROLE OF CUSTOM BRASS TURNED PARTS MANUFACTURERS

Expertise in Material Selection: Brass Turning parts manufacturers and Exporters in Jamnagar, India are well-versed in different brass alloys. They understand the unique properties of each alloy and can recommend the most suitable one for a particular application. This expertise ensures that the final product will have the desired strength, corrosion resistance, and aesthetic appeal.

Precision Machining: These manufacturers utilize advanced CNC machining technology to transform brass raw materials into precise components. This precision is vital, especially in industries where the slightest deviation can lead to malfunction or inefficiency.

Customization: One of the primary advantages of partnering with custom brass turned parts manufacturers is the ability to customize components. They can produce parts with intricate designs, tight tolerances, and various finishes to meet specific requirements.

Quality Assurance: Manufacturers of Custom Brass turned parts manufacturers and exporters in India, USA, Europe, UK, Canada, Russia, Australia and South Africa. to strict quality control measures. This ensures that each component meets the highest standards of quality and durability. This is especially crucial in industries like aerospace and automotive, where safety and reliability are paramount.

Cost Efficiency: While custom manufacturing may seem expensive, it often leads to cost savings in the long run. Custom brass turned parts can be optimized for efficiency, reducing waste and enhancing overall performance.

THE SIGNIFICANCE OF BRASS TURNED PARTS SUPPLIERS

Manufacturers alone cannot meet the diverse and ever-changing needs of various industries. This is where brass turned parts suppliers in Gujarat India, come into play. These suppliers act as a bridge between manufacturers and end-users, offering several crucial advantages:

Wide Range of Inventory: Brass Threaded Inserts suppliers maintain extensive inventories of standard and custom components. This means that customers can quickly source the parts they need without waiting for production lead times.

Reduced Lead Times: For urgent projects or unexpected component failures, brass turned parts suppliers in India provide fast access to replacement parts, reducing downtime and minimizing disruptions.

Cost-Effective Sourcing: Suppliers often benefit from economies of scale, allowing them to offer competitive pricing on both standard and custom components.

Expert Guidance: Suppliers have in-depth knowledge of brass turned parts, Brass Fittings | Brass Sanitary Parts and can assist customers in selecting the right components for their applications. This expertise helps customers make informed decisions.

Reliability: Established Brass Terminals | Brass Connectors manufacturers in USA, Europe, UK, Canada, Russia, Australia and South Africa, have a reputation for reliability and quality. Customers can trust that the components they receive will meet their specifications and perform as expected.

Custom brass turned parts manufacturers and suppliers in India are the unsung heroes of many industries. Their expertise, precision machining capabilities, and commitment to quality ensure that critical components meet strict specifications and perform reliably. As industries continue to evolve and demand ever more specialized components, the role of these professionals becomes even more significant. In essence, they are the artisans crafting excellence from brass, enabling progress in countless fields.

1 note

·

View note

Text

Brass Insert Manufacturer and Supplier in Jamnagar India

A brass threaded inserts are used in different types of materials such as plastic injection molding, wood, aluminum, ultrasonic, pre-heat and press-in molding. GK Metals is the best brass insert manufacturer in Jamnagar, India. Contact us with your requirements.

#brass insert#brass insert manufacturer#brass insert manufacturer in jamnagar#brass inserts supplier#brass inserts for plastic injection molding#brass threaded inserts for wood#brass knurling inserts#brass hexagonal inserts

0 notes

Link

#Brass inserts Manufacturers#Brass inserts Manufacturers in India#Brass Threaded Inserts#Brass Threaded Inserts for Metal

0 notes

Text

Glow Fly

Yay! It's the last one in this series. I don't mind posting but it does take a lot of time. Trying to make a description of the build interesting can be challenging too.

As those who have followed me for awhile know I'm a bit obsessed with making mechanical insects. They are not easy to make. The legs need holes in the main body, the head needs a hole, the abdomen needs another hole. That's a lot of holes in a tiny piece of brass. The engineering is always a challenge. It does make it a bit easier if it's like this, mounted on a panel. I will make another but just anchor each piece, legs, body, head, abdomen, to the board. If I space it correctly - it will look like a joined mechanism hopefully.

I didn't use a LED for this one. I wanted it to look old, so I chose to use an incandescent globe. As it's only 3V it's not that powerful. You can really see the difference between the power use of an LED compared to old "Edison" bulbs. The light isn't the feature here - the insect is. So I didn't overly embellish the piece for that reason too.

The wings are brass charms but they are thin and fragile so I don't think they would hold up under heavy wear unsupported. As a pendant you would only have to worry about clothing or hair snags. The body is a small brass tube. I inserted four smaller tubes and poured in some resin. I drilled those out so I could thread the four legs (made from heated element wire and crimps). The wire leads from the bulb are threaded through as is the head (a heart shaped vintage copper bead) and finally to two tiny front legs/feelers. The eyes are simply phillip's head screws. The wings are screwed onto an hexagonal ring. That is attached using two more screws tightened onto the body. As the wires are so fine, I had to secure the body with an extra wire anchor so it wouldn't put any tension on the wires.

There is an obvious caveat on this piece. She is fragile. The incandescent globe will chew through batteries too. I showed this to my group of friends who meet down the dog park on Fridays for wine and snacks. It was the favourite of many. I'm looking forward to making more fantasy insects that won't really resemble any real species on our planet.

#incandescent#light globe#light bulbs#steampunk#steampunk jewelry#steam punk#steelhipdesign#handmade#steampunk art#mad scientist#science jewelry#pendant#miniature#light up#insect#entomology#insects#fly#flying insects#mechanical insect#fantasy jewelry#fantasy#fantasy art#science fantasy#steampunk insect#machinery#fly model#insect model#wood#wooden

258 notes

·

View notes

Photo

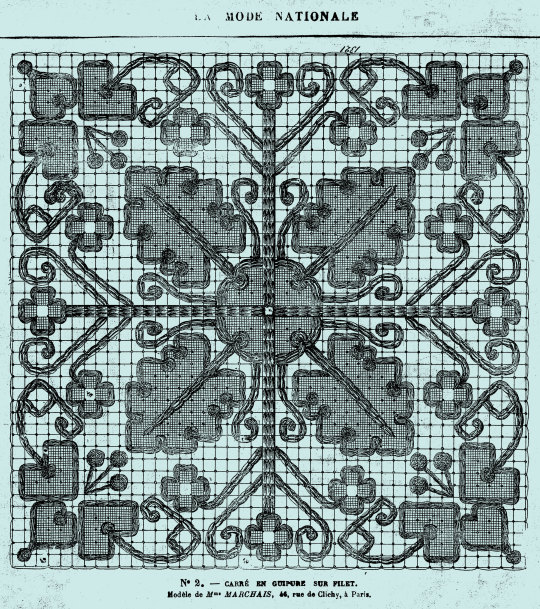

La Mode nationale, no. 50, 15 décembre 1894, Paris. no. 2. — Carré en guipure sur filet. Modèle de Mme Marchais, 46, rue de Clichy, à Paris. Bibliothèque nationale de France

Explication des gravures:

No. 2. — Carré en guipure sur filet (Modèle de Mme Marchais, 46, rue de Clichy). Après avoir fait voire carré, montez-le sur un cadre en fil de laiton ou sur un métier, a fin de bien le tendre, ce qui facilite le travail et en fait la régularité. Pour broder le filet, prenez du fil à dentelle, bien brillant, puis commencez à faire tous les contours au point de reprise, ensuite remplissez tous les motifs au point de toile.

Ce joli carré peut servir comme entre-deux de rideaux ou peut encore orner le milieu d'une tétiere, coussin, etc.

No. 2. — Square in guipure on netting (Model by Mme Marchais, 46, rue de Clichy). After making even square, mount it on a brass wire frame or on a loom, in order to stretch it well, which facilitates the work and makes it regular. To embroider the net, take very shiny lace thread, then start making all the outlines with the darning point, then fill in all the patterns with the canvas point.

This pretty square can be used as a curtain insertion or can even adorn the middle of a headrest, cushion, etc.

#La Mode nationale#19th century#1800s#1890s#1894#periodical#fashion#pattern#lace#guipure#chart#Marchais#Bibliothèque nationale de France#insertion#entre-deux

20 notes

·

View notes

Note

What even is pipebomb actually? Bomb shaped pipe? Pipe shaped bomb? Bomb in a pipe? Sending bomb through a pipe?

Pipe bombFrom Wikipedia, the free encyclopedia

Jump to navigation

Jump to search

For the professional wrestling term, see

Shoot (professional wrestling)

. For the website, see

Thepipebomb.com

.

A tripwire-triggered pipe bomb mock-up used to train US military service personnel

A pipe bomb is an improvised explosive device which uses a tightly sealed section of pipe filled with an explosive material. The containment provided by the pipe means that simple low explosives can be used to produce a relatively huge explosion due to the containment causing increased pressure, and the fragmentation of the pipe itself creates potentially lethal shrapnel.

Premature detonation is a hazard of attempting to construct any homemade bomb, and the materials and methods used with pipe bombs make unintentional detonation incidents common, usually resulting in serious injury or death to the assembler.

In many countries, the manufacture or possession of a pipe bomb is a serious crime, regardless of its intended use.

Contents

1Design

2Operation

3Modes of failure

4Minimum evacuation distances

5Uses

6See also

7References

5.1Notable incidents

Design[edit]

Different pipe bombs' appearances, from a bomb awareness report issued by the US Department of State

The bomb is usually a short section of steel water pipe containing the explosive mixture and closed at both ends with steel or brass caps. A fuse is inserted into the pipe with a lead running out through a hole in the side or capped end of the pipe. The fuse can be electric, with wires leading to a timer and battery, or can be a common fuse. All of the components are easily obtainable.

Generally, high explosives such as TNT are not used, because these and the detonators that they require are difficult for non-state users to obtain. Such explosives also do not require the containment design of a pipe bomb.

Instead, explosive mixtures that the builder can more readily obtain themselves are used, such as gunpowder, match heads, or chlorate mixtures. These can be easily ignited by friction, static electricity, and sparks generated when packing the material inside the tube or attaching the end caps, causing many injuries or deaths amongst builders.[1]

Sharp objects such as nails or broken glass are sometimes added to the outer shell or inside of the bomb to increase potential injury, damage, and death.

Operation[edit]

Pipe bombs concentrate pressure and release it suddenly, through the failure of the outer casing. Plastic materials can be used, but metals typically have a much higher bursting strength and so will produce more concussive force. For example, common schedule 40 1-inch (25 mm) wrought steel pipe has a typical working pressure of 1,010 psi (7.0 MPa), and bursting pressure of 8,090 psi (55.8 MPa),[2] though the pipe sealing method can significantly reduce the burst pressure.

The pipe can rupture in different ways, depending on the rate of pressure rise and the ductility of the casing material.

If the pressure rise is slow, the metal can deform until the walls become thin and a hole is formed, causing a loud report from the gas release, but no shrapnel.

A rapid rate of pressure rise will cause the metal to shatter into fragments, which are pushed outward in all directions by the expanding gases.

Modes of failure[edit]

Pipe bombs can fail to explode if the gas pressure buildup is too slow, resulting in bleed-out through the detonator ignition hole. Insufficiently tight threading can also bleed gas pressure through the threads faster than the chemical reaction pressure can rise.

They can also fail if the pipe is fully sealed and the chemical reaction triggered, but the total pressure buildup from the chemicals is insufficient to exceed the casing strength; such a bomb is a dud, but still potentially dangerous if handled, since an external shock could trigger rupture of the statically pressurized casing.

Minimum evacuation distances[edit]

If any type of bomb is suspected, typical recommendations are to keep all people at a minimum evacuation distance until authorized bomb disposal personnel arrive. For a pipe bomb, the US Department of Homeland Security recommends a minimum of 21 m (69 ft), and an outdoors distance of 366 m (1,201 ft).[3]

Uses[edit]

Pipe bombs are by nature improvised weapons and typically used by those without access to military devices such as grenades. They were successfully used in the Spanish Civil War (1936–1939). During World War II, members of the British Home Guard were trained to make and use them.[4]

In Northern Ireland, there have been hundreds of pipe bomb attacks since the mid-1990s (towards the end of the "Troubles"). Most of the attacks have been launched by loyalist paramilitaries, especially the Red Hand Defenders, Orange Volunteers and Ulster Defence Association.[5][6] However, they have also been used by Irish republican paramilitaries and by anti-drugs vigilante group Republican Action Against Drugs. They are also used extensively in the south of Ireland by feuding criminals, including drug dealers, mainly in the capital city of Dublin.

As well as users such as criminals, paramilitaries, and militias, they also have a long tradition of recreational use for amusement or mischief with no intention to cause injury to anyone, but due to the dangers of premature ignition and of shrapnel, pipe bombs are much more dangerous than alternatives such as dry ice bombs or potato cannons.

Notable incidents[

edit

]

This 1886 engraving was the most widely reproduced image of the

Haymarket riots

. It inaccurately shows Fielden speaking, the pipe bomb exploding, and the rioting beginning simultaneously.

[7]

On 4 May 1886, a pipe bomb was thrown during a rally at Haymarket Square in Chicago, Illinois, United States.[8] It reached a police line and exploded, killing policeman Mathias J. Degan.[8] The bomb was made from gas-pipe filled with dynamite and capped at both ends with wooden blocks.[8]

From August 1977 to November 1977 Allan Steen Kristensen planted several bombs across Copenhagen, Denmark injuring 5 but killing no one.

In 1985, Palestinian American anti-discrimination activist Alex Odeh was killed in California by a pipe-bomb. Activists from the Jewish Defense League are suspected of being the bombers.[9][10]

On December 16, 1989, Federal Judge Robert Vance was assassinated in his home in Mountain Brook, Alabama when he opened a package that contained a pipe bomb mailed by Walter Leroy Moody in Mountain Brook, Alabama.

On 27 July 1996, Eric Rudolph used a pipe bomb in the Centennial Olympic Park bombing during the 1996 Summer Olympics in Atlanta, Georgia, United States. It killed two people and injured 111.[11]

During the preparation of the Columbine High School Massacre, Eric Harris and Dylan Klebold had experimented with pipe bombs. During their testing and experimentation, Eric Harris had posted their results on his website. During the massacre, Harris and Klebold had used their pipe bombs as makeshift hand grenades, alongside various other bombs they had crudely manufactured.

On 11 December 2010 a suicide bomber detonated one out of six pipe bombs close to a major shopping district in Stockholm, Sweden, killing himself with no other casualties in what is known as the 2010 Stockholm bombings.[12]

In October 2018, pipe bombs without triggering devices[13] were sent to various liberal and political figures in the United States. Recipients included political activist and investor George Soros, former Secretary of State Hillary Clinton, former President Barack Obama, former CIA Director John Brennan, and former Attorney General Eric Holder.[14][15]

On 6 January 2021, a pipe bomb was found at the headquarters of the Republican National Committee, during the certification of President-elect Joe Biden. An unidentified object was also found at the headquarters of the Democratic National Committee, resulting in an evacuation.[16]

See also[edit]

Improvised explosive device

TM 31-210 Improvised Munitions Handbook

References[edit]

^ Dias, Gary A.; Dingeman, Robbie (2004). Honolulu CSI: An Introduction to Forensic Science and Criminal Investigation. Bess Press. p. 87. ISBN 978-1-57306-228-2.

^ Wrought Steel Pipe - Bursting Pressures. "The bursting pressures are based on Barlow's formula. The working pressures are based on factor 8. Dimensions according ASME/ANSI B36.10/19". www.engineeringtoolbox.com.

^ "Bomb Threat Stand-Off Distances" (PDF). The National Counterterrorism Center.

^ Introduction by Campbell McCutcheon (30 September 2012). Home Guard Manual 1941. Amberley Publishing Limited. p. 77. ISBN 978-1-4456-1103-7.

^ Wood, Ian.S (2006). Crimes of Loyalty: A History of the UDA. p. 248. ISBN 978-0-7486-2427-0.

^ Gassman, Michele. "Violence - Chronology of 'Pipe-Bomb' Attacks". Conflict Archive on the Internet. Retrieved 5 January 2021.

^ "Act II: Let Your Tragedy Be Enacted Here, Moment of Truth". The Dramas of Haymarket. Chicago Historical Society. 2000. Archived from the original on 15 March 2008. Retrieved 19 January 2008. The details are factually incorrect, because by all accounts Fielden ended his speech before the bomb was thrown, and because the riot did not begin until after the explosion. In [this] depiction, the speech, the explosion, and the riot all take place at once.

^ Jump up to:a b c Lawson, John Davison; Robert Lorenzo Howard (1919). American State Trials: A Collection of the Important and Interesting Criminal Trials which Have Taken Place in the United States from the Beginning of Our Government to the Present Day. Thomas Law Books. p. 64. a fuse with a cap is put into that hole.

^ Greg Krikorian, Evidence emerges in ‘85 Santa Ana slaying, Los Angeles Times, October 11, 2007, B-1.

^ Friedman, Robert I., The California Murder Case That Israel Is Sweeping Under the Rug : Justice: In 1985, Alex Odeh was killed by a pipe bomb in Orange County. The FBI has three suspects, but they are in Israel; extradition is unlikely, Los Angeles Times, May 13, 1990

^ "Rudolph reveals motives". CNN.com. 19 April 2005.

^ Sweden: Stockholm suicide bombings could have been 'catastrophic', London: The Telegraph, 12 December 2010

^ Bojorquez, Manuel (October 29, 2018). "Package bomb suspect Cesar Sayoc had list of 100 names in van, official says". CBS News. Archived from the original on February 7, 2019. Retrieved February 5, 2019.

^ "Investigation of Suspicious Packages". Federal Bureau of Investigation. Retrieved 26 October 2018.

^ "FBI Director Christopher Wray's Remarks Regarding Arrest of Cesar Sayoc in Suspicious Package Investigation". Federal Bureau of Investigation. Retrieved 26 October 2018.

^ Benner, Katie; Haberman, Maggie; Schmidt, Michael S. (6 January 2021). "An explosive device is found at the R.N.C., and the D.N.C. is evacuated". The New York Times. ISSN 0362-4331. Retrieved 7 January 2021.

US5,386,758–Apparatus and method for disarming pipe bombs

Categories

:

Improvised explosive devices

Insurgency weapons

Navigation menu

Not logged in

Talk

Contributions

Create account

Log in

Article

Talk

Read

Edit

View history

Main page

Contents

Current events

Random article

About Wikipedia

Contact us

Donate

Contribute

Help

Learn to edit

Community portal

Recent changes

Upload file

Tools

What links here

Related changes

Special pages

Permanent link

Page information

Cite this page

Wikidata item

Print/export

Download as PDF

Printable version

In other projects

Wikimedia Commons

Languages

Deutsch

Español

Français

Bahasa Indonesia

Italiano

Português

Русский

Tiếng Việt

中文

15 more

Edit links

This page was last edited on 16 November 2022, at 10:47 (UTC).

Text is available under the Creative Commons Attribution-ShareAlike License 3.0; additional terms may apply. By using this site, you agree to the Terms of Use and Privacy Policy. Wikipedia® is a registered trademark of the Wikimedia Foundation, Inc., a non-profit organization.

- 💛 Themis

9 notes

·

View notes

Text

I am

I am Marylin Manson and Julia Jacklin

I am Tolstoy and T.S. Elliot

I am tanned leather, brass, and lucite

I am hotel suites, vip parking, and charges to the room

I am white gloves, table cloths, and fine china

I am reservations, and plane tickets

I am the resort, and the last resort

I am lamb skin, and alpaca. I am 3000-thread-count sheets

I am first dates, milkshakes, wedding cakes, and roller skates

I am the beauty and the beast

I am the warning light on your dashboard

I am the water in your gas tank

I am the squad car tailgating your for 3-miles

I am the window you roll-up when driving through that neighborhood

I am the longest red light you've ever stopped at

I am the new coffee shop, bar, boutique hotel

I am the {insert local hangout spot here}

I am the crack in the houses foundation

I am the crack, the house, and the Foundation

I am the day before World War 3

I am Doo-Wop and Hip-Hop

I am baby Jesus and methuselah

I am the bottle of urine beside your bed

I am the pistol.

I am the addict in the attic.

I am the needle and I am the thread

I am the pawn shop you gave grandmas ring to

I am the long pull on your vape between shifts.

I am the 9-5 and the 6-10.

I am the check in the mail

I am the pit and I am the bull

I am the artificial flavor in your chewing gum

I am the friend that was too young to die

I am the fellow and I am the ship

I am Othello and Hans Christian-Andersen

I am the side effect worse than the symptom

I am tea parties and vineyards

I am the used condom on the sidewalk

I am the heat death of our quantum existence

I am…too abstract?

I am too black but not black enough

I am queer but not gay enough.

I am qualified but not good enough.

I am big-nosed, bald-headed, unwashed, and unbothered.

I am untethered.

I am the creation and I am the demiurge

I am the igneous and I am the firmament

I am the Borg

I am the paper your suicide note was written on

I am the last time you saw your father

I am the last thing he said to you

I am the couch you let him crash on for a few months

I am the new security code you created when he left

I am the storage unit you change clothes in before and after work

I am the blanket you’re wrapped up in while asleep in your car

I am the gift that I never see you wear

I am the pot calling the kettle…

I am the "come get me," text at 3am

I am the "you up," text you left on read

I am the unsaved number in your phone

I am the abomination and the salvation of creation

I am the mustard and I am the seed

I am the last ps5 at Walmart on Black Friday

I am Mozart and Chopin

I am rock, roll, and Rachmaninoff

I am Coltrane and Gillespie

I am the kidnap and I am the torture

I am the human and I am the traffic

I am the sex and I am the worker

I am the murder and I am the manhunt

I am Samson’s dreadlocks

I am the dog bark that wakes you from that fever dream

I am the fever dream

I am the con and I am the science

I am the jack and all of his trades

I am the Coke and I am the cane

I am the stop sign behind that big ass fuckin tree.

I am the cop. I am the ticket.

I am the vegan recipe book you haven’t opened yet

I am the first parallel park in that city you moved to

I am the popping sound in your kneecap

I am the fake number she gave you

I am the burning cross on your front lawn

I am the white hood

I am the "whites-only" section

I am the assailant and I am the victim

I am the rotten avocado on your kitchen counter

I am the clown and I am the circus

I am bibles and black holes

I am holding your sweater

I am the first kiss

I am the divorce papers

I am the Sailor and I am the Siren

I am the solitary onion ring in your order of French fries

I am the diet that starts tomorrow

4 notes

·

View notes

Text

0 notes

Text

About the muse / Rules / Verses

On the surface, Stanley is conniving, money hungry, and appears to have little regard for other people. He runs the "Mystery Shack", a self proclaimed "ninth wonder of the world" in the middle of Gravity Falls, Oregon, but it's nothing more than a tourist trap and a front. Assuming the identity of his twin brother after his disappearance, he goes by the name "Stanford" and has, unfortunately for his brother, committed many crimes under this persona such as fraud, embezzlement, and money laundering. Good luck flying anywhere, Stanford.

General Information

Name: Stanley Pines

Nicknames: Stanford, Stan, "Grunkle", Old Man, Lee (reserved exclusively for his brother(s) (Ford is on thin ice if they're fighting)/mother/significant other, if anyone else calls him this they're getting punched)

Pronouns: he/him

Sexuality: closeted bisexual

Family: Stanford Pines (older twin brother), Shermy (younger brother), Mabel Pines (great-grand-niece), Dipper Pines (great-grand-nephew), Filbrick Pines (father, estranged), Margaret Pines (mother, estranged)

Underneath his gruff exterior, Stan would protect the people that he loves fiercely, including both Mabel and Dipper, and his employees Soos and Wendy. Found family means everything to him, and if you're lucky enough to be part of his found family (blood related or not) than he and his brass knuckles have your back.

Rules: (subject to change as I think of more)

1. Shipping is fine! Stanley is a closeted bisexual and might not openly admit feelings for other men, but he has absolutely had crushes on them in the past. It could even be unrequited love.

2. I am semi-selective and happy to write the following: with crossover characters (as long as I know the media they're from at least OR we are friends), original characters + self inserts

3. I am a very spontaneous writer. Plotting can happen! I'm just not as good at replying to plotted threads. If you have ideas/I get an idea, let's talk!

4. Stan might not be very nice to your character at first (unless you're a cop, then go fuck yourself). But befriending him has it's perks! He's more likely to be nicer to kids/pretty women + men

Verses:

Good old days. v (childhood verse)

Turbulent weather. v (teenager verse)

Sinking ship. v (early adulthood verse, specifically after he gets kicked out and attempts to prove his dad wrong)

Cloudy skies. v (takes place during the course of the show)

Clear skies. v (good ending, he sails the seas with Stanford)

Stormy skies. v (bad ending. this fucker never remembers what happens/the bait and switch plan doesn't work and Bill wins/ ect.)

#Good old days. v (childhood verse)#Turbulent weather. v (teenager verse)#Sinking ship. v (early adulthood verse)#Cloudy skies. v (main show)#Clear skies. v (good ending)#Stormy skies. v (bad ending)

1 note

·

View note

Text

All new design: Rustproof & Unbreakable!!

All materials, manufacturing & assembly in USA.

304 Military Spec Stainless Steel Shaft CNC machined from solid bar stock.

Rustproof & Strong.

Made in Illinois USA.

60A Durometer Bright Red Silicone Rubber. Grips choke tightly. Custom made for Müller Chokes in Arizona USA.

6061-T651 Military Spec Handles.

Class II Mil Spec Anodized,

Custom made, Anodized and Custom Laser Engraved in Connecticut.

Alcoa Aluminum made in Indiana USA.

Custom molded White Polyethylene knobs with brass threaded inserts, all made custom for Müller Chokes.

Made in Illinois USA.

Washers, Mil Spec, made in Minnesota USA.

Invented, designed, assembled & tested by Jim Muller.

0 notes

Link

0 notes

Text

Mastering Flow Control with Automatic Balancing Valves

An Automatic Balancing Valve is a specialized component used in HVAC (Heating, Ventilation, and Air Conditioning) systems to regulate and maintain the proper flow of water or another fluid through the system. It is designed to automatically adjust the flow rate to achieve a balanced distribution of fluid across different zones or sections of the system.

Pressure rating: 25 Bar

Temperature rating: -20°C/120°C

Sizes: ½” – 2″ Female Threaded

Body Material options:

Forged Brass ASTM CuZn40Pb2

DZR brass CW602N CUZn36Pb2AS [Enkotal®]

Elastomers: EPDM

Easy removable Insert for flushing and easy exchange flow rate range:

Internally adjustable Composite Insert: 0.0081 – 1.43 l/s

Externally adjustable E-Just Insert: 0.0278 – 4.48 l/s

#Automatic Balancing Valve#Automatic Balancing Valves#Balancing Valve#Dynamic Balancing Valve#Constant Flow Valve

0 notes

Text

Everything About Compression Tube Fittings

Safe and leak-free tubing connections are crucial in the fluid systems industry. Compression tube fittings are crucial components that strongly join pipes or tubes without the need for intricate welding or soldering. They are invaluable in various industries, including plumbing, automotive, hydraulic, pneumatic, and aerospace applications, due to their unique form, simplicity of installation, and capacity to prevent leaks. They are affordable options that guarantee consistent and effective fluid transfer in various applications due to their simplicity of installation and reusability. Below, you can see the compression tube fittings:

What are compression tube fittings?

Compression tube fittings are designed to form a waterproof barrier between two distinct lines by compressing one of the fitting's components into another, usually tubing. With the introduction of quick-connect type fittings, compression fittings have become less common in the water treatment sector, and yet, compression fittings are still great, withstand high pressure, and offer a consistent, tight seal. A compression fitting is made up of three components such as the fitting body itself, a nut, and a sleeve.

You may see a variety of materials available when purchasing compression tube fittings Texas. Brass is the most popular material for compression fittings and however, you need to ensure that the fittings are lead-free because using lead-containing fittings is prohibited. They are often composed of plastic and stainless steel. The material of your fitting will determine how much pressure or temperature it can withstand.

How do tube compression fittings work?

In a hydraulic or pneumatic system, two tubing sections are connected using tube compression fittings. When the nut is tightened after the tube has been placed into the fitting, the tube is compressed, and a secure connection is made. Additionally, they work effectively in applications where a prompt separation is required. Stainless steel compression fittings offer a dependable, leak-proof connection that can tolerate high pressure when placed correctly.

Components of compression tube fittings

Typically, compression tube fittings are made up of multiple parts:

Ferrule

The ferrule, which fits over the end of the tube, is a tiny, cylindrical component referred to as the compression ring or olive. The ferrule creates a tight seal by compressing against the fitting's body to stop fluid leaks.

Nut

A secure connection is made by compressing the ferrule onto the tube by threading the nut into the fitting's body and tightening it. To buy stainless steel compression fittings Texas, choose the best manufacturers.

Insert

An insert or compression sleeve may be used in certain fittings to give the tubing more support and reinforcement, particularly in situations involving softer materials or bigger tube diameters.

Ferrule

When compressed against the body of the fitting, the ferrule forms a tight seal, preventing fluid leakage. To buy the tubing fittings Texas, choose a high-quality shop.

Thus, the above details are about the compression tube fittings. Visit Arek Solutions if you are looking to buy stainless steel tube fittings Texas. They provide premium products that satisfy your specific needs because they consider quality as the foundation of their business.

0 notes

Text

Exploring Screw Types and Specifications: - Akbarali Enterprises

Akbarali Enterprises is one of the best Screws Manufacturer in India. A leading manufacturer and supplier. We provide a wide range of premium Screws made from premium raw materials.Screws are ubiquitous fasteners, vital for holding together everything from furniture to machinery. However, not all screws are created equal. Understanding the different types and specifications of screws is essential for selecting the right one for your project.

Screw Types:

Countersunk Flat Head Screw : A countersunk flat head screw is a type of screw that features a flat top surface and a conical or bevelled underside. The conical shape allows the screw to be flush or countersunk into a material when it is driven into a pre-drilled hole. This design helps create a smooth and even surface, reducing the risk of protrusions that could catch on objects or pose safety hazards.

Mating Screw : A mating screw typically refers to a screw designed to be paired with a corresponding nut. These screws are threaded along their entire length and are used in conjunction with nuts to fasten two or more objects together. The combination of a mating screw and nut creates a threaded fastening system.

Set Screw : Set screws are designed to be inserted into a threaded hole or to press against a flat surface. Unlike regular screws, set screws do not have a protruding head; instead, they usually have a hexagonal socket or another type of recessed drive on one end, allowing them to be tightened using an Allen wrench or a similar tool.

Thread Forming Screw : A thread forming screw is a type of screw designed to create its own threads as it is driven into a pre-drilled hole. Unlike traditional screws that cut or tap threads into the material, thread forming screws use a different mechanism to form threads by displacing the material rather than removing it.

Screw Specifications:

Thread Type: Screw threads can be coarse or fine, with coarse threads providing better grip in softer materials and fine threads offering higher strength in harder materials.

Head Type: Screws come with various head types such as flat, pan, oval, or hex, each serving specific applications and aesthetic preferences.

Material: Screws are available in a range of materials including steel, stainless steel, brass, and nylon, each offering distinct properties like strength, corrosion resistance, and electrical insulation.

Size: Screws are specified by diameter, thread pitch, and length, with standard sizing conventions varying depending on the screw type and application.

Conclusion:

In conclusion, screws are versatile fasteners with a myriad of types and specifications tailored to diverse applications. Whether you're constructing furniture, assembling electronics, or building structures, selecting the right screw is crucial for ensuring structural integrity, longevity, and performance. By understanding the characteristics and requirements of your project, you can confidently choose the appropriate screw type, size, and material to meet your needs. So, next time you embark on a DIY project or undertake a professional endeavour, remember to consider the intricate world of screws and harness their power to bring your creations to life.

Website:akbarfasteners.com

0 notes

Text

Demystifying Cable Glands: What You Need to Know?

Outline

Table of Contents

1. Introduction to Cable Glands

2. Importance of Cable Glands

3. Types of Cable Glands

Standard Cable Glands

Armored Cable Glands

Explosion Proof Cable Glands

EMC Cable Glands

4. Materials Used in Cable Glands

5. Factors to Consider When Choosing Cable Glands

6. Installation Process of Cable Glands

7. Maintenance of Cable Glands

8. Common Issues with Cable Glands

9. Conclusion

10. FAQs

Types of Cable Glands Ensuring Proper Cable Management and Protection

Introduction to Cable Glands

Cable glands, also known as cable connectors or cable fittings, are essential components in electrical systems used to secure and seal the ends of electrical cables to equipment. They provide protection against environmental factors such as moisture, dust, and vibration, ensuring the safety and reliability of electrical installations.

Importance of Cable Glands

Cable glands play a crucial role in maintaining the integrity of electrical systems. By securely fastening cables to equipment, they prevent the ingress of moisture and contaminants, which can lead to corrosion, short circuits, and electrical failures. Additionally, cable glands provide strain relief, reducing the risk of cable damage due to tension and movement.

Types of Cable Glands

Standard Cable Glands: These are the most commonly used type of cable glands and are suitable for general-purpose applications. They provide basic sealing and strain relief for cables.

Armored Cable Glands: Designed specifically for armored cables, these glands feature additional clamping and sealing mechanisms to accommodate the unique construction of armored cables, providing enhanced protection against mechanical stress and environmental hazards.

Explosion Proof Cable Glands: These glands are engineered to prevent the propagation of explosions in hazardous environments such as oil refineries, chemical plants, and mining sites. They feature robust construction and specialized seals to contain sparks and prevent the entry of flammable gases.

EMC Cable Glands: Electromagnetic compatibility (EMC) cable glands are used to shield cables from electromagnetic interference (EMI) and radio frequency interference (RFI). They incorporate conductive materials and grounding techniques to mitigate the effects of electromagnetic disturbances on sensitive electronic equipment.

Materials Used in Cable Glands

Cable glands are typically made from various materials such as brass, stainless steel, aluminum, and plastic. The choice of material depends on factors such as environmental conditions, chemical compatibility, and mechanical strength requirements.

Factors to Consider When Choosing Cable Glands

When selecting cable glands for a specific application, several factors should be taken into account:

Environmental conditions (e.g., temperature, moisture, corrosive substances)

Cable type and diameter

Degree of ingress protection (IP rating)

Hazardous area classification (if applicable)

Installation method (e.g., thread type, compression fitting)

Installation Process of Cable Glands

The installation of cable glands should be carried out carefully to ensure proper sealing and mechanical support. The process typically involves the following steps:

Prepare the cable by stripping the outer sheath and exposing the conductors.

Insert the cable through the gland body and ensure that it is properly seated.

Tighten the gland nut to secure the cable and create a seal.

Check the tightness of the gland nut and apply additional sealing compound if necessary.

Connect the cable to the equipment or junction box.

Maintenance of Cable Glands

Regular inspection and maintenance are essential to ensure the continued effectiveness of cable glands. This may include:

Visual inspection for signs of damage or degradation

Checking for proper sealing and tightness

Replacing damaged glands or components as needed

Cleaning and lubricating gland threads and seals

Common Issues with Cable Glands

Despite their importance, cable glands can experience various issues that may compromise their performance:

Inadequate sealing leading to moisture ingress

Improper cable installation causing strain or damage

Corrosion of gland materials

Insufficient grounding or EMC protection

Conclusion

Cable glands are indispensable components in electrical installations, providing essential protection and management of cables. By understanding the different Types of cable glands available and their respective applications, professionals can ensure the proper selection, installation, and maintenance of cable gland systems, thereby enhancing the safety and reliability of electrical systems.

FAQs

Q1. What is the purpose of a cable gland?

Ans. Cable glands are used to secure and seal the ends of electrical cables to equipment, providing protection against environmental factors and ensuring proper cable management.

Q2. How do I choose the right cable gland for my application?

Ans. Factors such as environmental conditions, cable type, diameter, and installation method should be considered when selecting cable glands.

Q3. What is the difference between standard and armored cable glands?

Ans. Armored cable glands are specifically designed to accommodate the unique construction of armored cables, providing enhanced protection against mechanical stress.

Q4. Why is maintenance important for cable glands?

Ans. Regular inspection and maintenance help ensure the continued effectiveness of cable glands, identifying and addressing issues before they escalate and compromise system integrity.

Q5. Can cable glands be used in hazardous environments?

Ans. Yes, explosion-proof cable glands are available for use in hazardous environments to prevent the propagation of explosions and ensure the safety of personnel and equipment.

0 notes

Text

Ananka

Q1) How do you select the right hex bolt for a given project?

Ans) Selecting the appropriate hex bolt for a specific project involves considering various factors to ensure a secure and effective connection. Here's a step-by-step guide to help you choose the right hex bolt:

1. Identify Project Requirements:

- Determine the load-bearing capacity required for the connection.

- Understand the environmental conditions the bolt will be exposed to (corrosive, outdoor, indoor, etc.).

- Consider any specific regulations or standards that apply to your project.

2. Material Selection:

- Choose a material suitable for the project's environment (e.g., stainless steel for corrosion resistance, high-strength alloy steel for heavy loads).

- Consider factors such as temperature, humidity, and potential exposure to chemicals.

3. Bolt Grade:

- Select an appropriate bolt grade based on the required strength. Bolt grades are often indicated by markings on the head of the bolt.

- Common grades include ASTM A307, ASTM A325, ASTM A490 for structural applications.

4. Thread Size and Pitch:

- Determine the required thread size (diameter) and pitch (distance between threads).

- Match the thread size with the corresponding nut size and the tapped hole size, if applicable.

5. Length:

- Choose a bolt length that provides enough thread engagement while ensuring that the bolt doesn't extend excessively beyond the nut or threaded hole.

6. Head Style:

- Select a head style that suits your project's needs. Common head styles include hexagonal, flange, or socket head.

- Consider factors like available space for tool access and the aesthetic requirements of the project.

7. Drive Type:

- Determine the drive type for the bolt head (e.g., hex, socket, Phillips). Choose a drive type compatible with the tools you have or plan to use.

8. Fastener Coating or Finish:

- Choose a coating or finish that provides the desired level of corrosion resistance and aesthetics.

- Options include zinc plating, galvanized, black oxide, and more.

9. Load Distribution:

- If required, consider using washers or other load-distribution elements to enhance the connection's strength and stability.

10. Removability:

- Determine if the connection will need to be disassembled in the future. If so, consider using bolts with reusable threads.

11. Vibration and Loosening:

- For applications prone to vibration, consider using lock washers, nylon-insert lock nuts, or other methods to prevent loosening.

12. Consultation and Standards:

- Consult with professionals or experts if the project involves critical or specialized applications.

- Refer to industry standards and guidelines, such as those provided by ASTM or ISO, to ensure compliance and safety.

13. Quantity and Sourcing:

- Calculate the quantity of bolts needed for your project.

- Source bolts from reputable suppliers or manufacturers to ensure quality and reliability.

By meticulously considering these factors and tailoring your selection to the specific requirements of your project, you can confidently choose the right hex bolt that will provide a secure, durable, and reliable connection.

European Fastener Standards

Q2) How do you select the right hex nut for a given project?

Ans) Choosing the appropriate hex nut for a particular project involves assessing various factors to ensure a reliable and secure connection. Here's a step-by-step guide to assist you in selecting the right hex nut:

1. Understand Project Requirements:

- Identify the load-bearing capacity needed for the connection.

- Determine the environmental conditions the nut will be subjected to (corrosive, high temperature, outdoor, indoor, etc.).

- Take into account any industry standards or regulations applicable to your project.

2. Material Selection:

- Choose a material that suits the project's environment and load requirements (e.g., stainless steel, brass, or high-strength steel).

- Consider factors like corrosion resistance, temperature stability, and potential exposure to chemicals.

3. Nut Type and Style:

- Select the appropriate type of hex nut based on the specific needs of the project. Common types include standard hex nuts, lock nuts, nylon-insert lock nuts, and flange nuts.

- Choose the nut style that best fits your application, taking into account factors like space constraints and aesthetics.

4. Nut Size:

- Match the nut size to the bolt size, ensuring compatibility for effective engagement and load distribution.

5. Thread Pitch:

- Ensure that the nut's thread pitch matches that of the corresponding bolt or threaded fastener.

6. Corrosion Resistance:

- Opt for a nut with a suitable coating or finish to enhance corrosion resistance if the project involves exposure to moisture, chemicals, or outdoor elements.

7. Load Distribution:

- Select a nut that provides adequate contact area to evenly distribute loads on the connected materials.

- Consider using washers or other load-distribution components, especially in critical applications.

8. Locking Mechanisms:

- For applications prone to vibration or loosening, consider lock nuts (nylon-insert, all-metal), prevailing torque nuts, or other locking mechanisms that resist rotational forces.

9. Ease of Installation:

- Choose a nut style that can be easily installed and tightened using the tools available for your project.

10. Compliance and Standards:

- Refer to relevant industry standards (e.g., ASTM, ISO) to ensure that the selected nut meets required specifications and guidelines.

11. Quantity and Sourcing:

- Calculate the quantity of nuts needed for your project.

- Source nuts from reputable suppliers or manufacturers to ensure quality and reliability.

12. Professional Advice:

- If the project involves critical or specialized applications, consider seeking advice from professionals or experts in the field.

By carefully considering these factors and aligning your nut selection with the specific demands of your project, you can confidently choose the right hex nut that will contribute to a durable, secure, and dependable connection.

ISO Fasteners Standards

Q3) What is the role of flat washers in preventing vibrations and loosening of fasteners?

Ans) Flat washers play an essential role in averting vibrations and thwarting the loosening of fasteners across diverse applications. Here's how flat washers contribute to this purpose:

1. Load Dispersion: Flat washers extend the contact area between the fastener head or nut and the material being fastened. This expanded contact surface ensures a more uniform distribution of applied loads, minimizing stress concentrations at contact points. Consequently, this prevents localized deformation and diminishes the likelihood of fastener loosening due to stress concentration.

2. Enhanced Friction: The presence of flat washers introduces heightened friction between the fastener and the material. Friction opposes motion and impedes fastener rotation caused by vibrations, making it challenging for the fastener to loosen over time.

3. Vibration Dampening: Flat washers can act as vibration dampers. The pliability and compressibility of the washer material enable it to absorb and disperse vibrational energy, curbing the transfer of vibrations to the fastener and connected components. This minimizes the risk of fastener loosening due to vibrational forces.

4. Embedding Prevention: In scenarios where the fastener head or nut might embed into the material over time, the presence of a flat washer establishes a protective barrier. This averts direct contact between the fastener and material, lowering the likelihood of embedding and upholding connection integrity.

5. Anti-Corrosion Shield: Flat washers can furnish a protective layer that functions as a barrier against moisture, chemicals, and corrosive agents. Corrosion can undermine connections and lead to loosening, so counteracting corrosion preserves the fastener's grip.

6. Consistent Torque Application: During fastener tightening, particularly with power tools, washers guarantee even distribution of applied torque. This diminishes the risk of excessive tightening or uneven torque, both of which can contribute to fastener loosening.

7. Galvanic Corrosion Insulation: In applications involving dissimilar metals, flat washers made from insulating materials like nylon can forestall galvanic corrosion between the metals. Galvanic corrosion can weaken connections and induce loosening.

8. Surface Safeguard: Flat washers shield material surfaces from damage caused by fastener heads or nuts during tightening. Safeguarding material surface integrity upholds connection efficiency.

9. Disassembly Facilitation: During maintenance or disassembly, flat washers can prevent fasteners from seizing due to rust or corrosion. This eases fastener removal without harming components.

In summary, flat washers heighten connection stability by dispersing loads, amplifying friction, damping vibrations, deterring embedding, fending off corrosion, facilitating uniform torque application, insulating against galvanic corrosion, safeguarding surfaces, and simplifying disassembly. Their presence sustains the integrity of fastened connections and thwarts fastener loosening arising from diverse external influences and factors.

Fasteners Manufacturers in India

Q4) How do you select the right stud bolt for a given project?

Ans) Choosing the suitable stud bolt for a specific project necessitates the assessment of various factors to guarantee a secure and dependable connection. Here's a comprehensive step-by-step guide to assist you in selecting the appropriate stud bolt:

1. Project Requirements:

- Define the load-bearing capacity necessary for the connection.

- Recognize the environmental conditions that the stud bolt will encounter (corrosive, high temperature, indoor, outdoor, etc.).

- Take into account any relevant regulations, codes, or standards applicable to your project.

2. Material Selection:

- Opt for a material that aligns with the project's environment and load demands (e.g., stainless steel, carbon steel, alloy steel).

- Contemplate factors such as corrosion resistance, temperature stability, and potential chemical exposure.

3. Stud Type:

- Choose a stud type suited to the project's requirements. Options include full-threaded studs, tap-end studs, double-end studs, and more.

- Select the stud type that best matches your application and installation process.

4. Stud Diameter:

- Determine the suitable stud diameter according to load prerequisites and available installation space.

5. Stud Length:

- Select a stud length that ensures adequate thread engagement while avoiding excessive protrusion beyond the nut or threaded component.

6. Thread Pitch:

- Confirm that the stud's thread pitch corresponds with the nuts or threaded components you intend to use.

7. Stud End Configuration:

- Factor in the specific end configuration needed for your project, such as threaded, chamfered, or reduced shank ends.

8. Corrosion Resistance:

- If the project involves exposure to moisture, chemicals, or outdoor elements, choose a stud with an appropriate coating or finish to enhance corrosion resistance.

9. Load Distribution:

- Assess the necessity for load distribution elements like washers to guarantee uniform load dispersion across connected materials.

10. Installation Process:

- Consider the installation process and access to both stud ends. Ensure that the chosen stud type and length align with installation prerequisites.

11. Locking Mechanisms:

- Depending on the application, evaluate using stud locking mechanisms such as thread-locking compounds, double-nut setups, or other tactics to thwart loosening.

12. Professional Input:

- For critical or specialized applications, seek advice from professionals or experts experienced in stud bolt selection and installation.

13. Compliance and Standards:

- Refer to industry standards and guidelines (e.g., ASTM, ISO) to verify that the chosen stud bolt adheres to necessary specifications.

14. Quantity and Sourcing:

- Calculate the quantity of stud bolts needed for the project.

- Source stud bolts from reputable suppliers or manufacturers to assure quality and reliability.

By meticulously contemplating these factors and aligning your stud bolt choice with your project's particular requirements, you can confidently opt for the ideal stud bolt that will contribute to a robust, secure, and trustworthy connection.

Fasteners Manufacturers in Mumbai

0 notes