#Brick Making Machines

Explore tagged Tumblr posts

Photo

(via GIPHY)

https://snpcmachines.com/

Unveiling India's first fully automatic brick making machine, BMM410 by SnPC Machines. Perfect brick making machine with different features and best price as compared to other machinery. Fully automatic mobile brick making machine produces brick moving on wheel like vehicle. These machines produce brick as fast as more than three times as compared to manual production. These machines produce top quality brick with low water consumption therefore considered as eco-friendly. Top mobile brick making machines as BMM160, BMM410, BMM310 which produces brick according to their capacities.

#giphy#automatic#durable#clay brick#red bricks#snpc machines#bmm310#easy to handle#bmm410#brick kiln#mobile brick machine#brick making machines#top quality bricks#soil brick

7 notes

·

View notes

Text

Automatic Fly Ash Brick Making Machines gives wining outcome

The Automatic Fly Ash Brick Making Machine is one of the most advanced technologies that is reshaping the construction industry. These brick making machines are bringing down the need for traditional clay bricks. Automatic fly ash brick making machines are primarily differentiated by their automated functioning. These machines produce bricks in consistent shapes and sizes saving us time and reducing our manpower. Automatic fly ash brick making machines are capable of producing bricks with significant frequency in minimal time.

These machines are used in the construction of residential structures such as flat apartments, housing projects etc. Brick Machinery is the best-recognized automatic fly ash brick machine manufacturer in India. Our range includes different types Automatic Fly Ash Brick Making Machine that help you to productivity. Our automatic fly ash brick making machines can have production capacities ranging from a few thousand bricks per hour to tens of thousands per hour.

Some of our advanced brick making machines (e.g. FAM-2520 and FAM-1800) can produce anywhere from 10,000 to 25,000 bricks per hour or even more in certain circumstances.

0 notes

Text

Conficcare 🤝 Cecio

wanting to go into professions that are often unsympathetic to their community so someone who actually cares about them is in that profession, but by forces outside their control they end up causing harm to the people they went down that path to save and perpetuating the status quo that they once fought against...

#gold & silver#oc: conficcare#oc: cecio#i am chewing on them#shaking them in my teeth#they wanted to help!!!!#but they find out the hard ways why more people who care arent in those professions...#the way both of them are promised scholarships and that is what is used to trap them...#the powers will only give you the money and access if it benefits them...#you think you can bit the hand that feeds but its a well oiled machine in taking in bright eyed kids who want to make a difference#and breaking them down till they are just another brick in the wall#just another rat in the rat race...#[yes its about student debt and apprenticeships and how the military uses education to recruit]

4 notes

·

View notes

Text

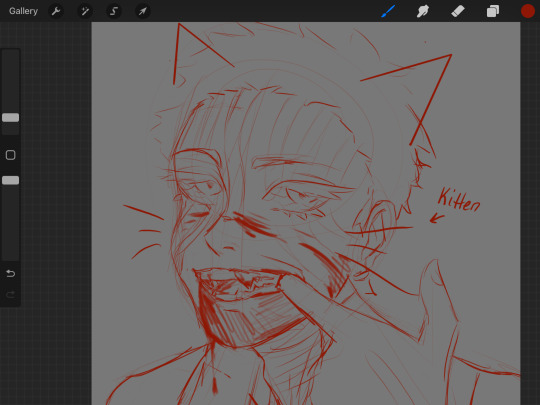

Hello I offer you this once in a lifetime WIP and then I go back to the abyss

If you would like to see more bloody Akaza doodles, stick around

#akaza#kny akaza#akaza kimetsu no yaiba#akaza fanart#kny#I need to make him all bloody all the time#my little pookie bear#my little meow meow#my little messy eater#need to throw bricks at him and grab him by the hair and yank him around#I need to put him in a washing machine and watch him swirl and spin around#hopey’s doodles

18 notes

·

View notes

Text

me, after any minor or major inconvenience: i should listen to how big, how blue, how beautiful again

#listen if nobody got me i know florence got me#delilah in of itself makes me want to run through a brick wall and leave a gabi shaped imprint#gabi overshares#florence and the machine#hbhbhb

2 notes

·

View notes

Text

I may or may not have started a project that will probably overwhelming me...

#by the time that copper tower completely ages i should have prepared everything...#the tall pallete is for the fantasy towers i will build on a windswept mountain next to my base#the small pallete is for the entire village#i dont get why most minecraft players hate the new bamboo blocks.. they're pretty!!#a bit biased because I use bamboo for my little Filipino hut as a main base#but really there's so much to bamboo people are probably missing on... it works well with cherry. blackstone. warped and crimson. mud bricks#and there's so much variety you get from crafting bamboo blocks as well...#BUT YEAH this is my first minecraft project and tbh i am scared 😂 but ey... been wanting to do this for the longest time...#my last village didn't quite do well... now im determined to make this work...#this is gonna be a big task as i cant build redstone machines... it'll kill my phone 😂😂😭😭😭... no automation all manual...#that's enough rambling from me... have a good day! ✨#wyn talks :)#minecroof

14 notes

·

View notes

Text

Durable Clay brick making machine

SnPC Machines: Clay brick making machine manufacturers in India

SnPC Machines India Is A Leading Manufacturer Of Brick Making Machines Specially The Mobile Brick Making Machines Bmm160, Bmm310, Bmm400, Bmm404 And Sbm180 All The Models Can Be Tailored As Per The Customers Requirements For Both Indian And Overseas Customers.

#SnPC Machines#clay brick making machine#machine for making brick#red clay brick machine#BMM310#best clay brick machine in India#innovation in brick machine#red soil brick machine#brick machine India#brick machine Gujarat

2 notes

·

View notes

Text

sewing shed time tomorrow, finally gonna make that apron for work and the black hoodie inspired by Maya from the newest Silent Hill game 👀🙏

#willing it into existence tbh#idk how i'll feel after stripping down the walls of my room to the brick#i just wanna CREATE!!!!!!!!! AUGHHHHH!!!!!#also just wanna see how i'll fare with the apron at work. if it'll keep me safe from all the popcorn and nacho crumbs#and the splashback from the soda fountain and the slushie machine#alsooooo oversized sporty hoodie!!!!! with big pockets and long sleeves with thumbholes to make sweater paws!!!!!!

3 notes

·

View notes

Text

A Comprehensive Guide to Hydraulic Paver Block Making Machine

Welcome to "A Comprehensive Guide to Hydraulic Paver Block Making Machine." In the ever-evolving world of construction and infrastructure development, the significance of efficient and eco-friendly building materials cannot be overstated. Paver blocks have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. At the heart of this revolution lies the Hydraulic Paver Block Making Machine – a game-changing technology that has transformed the production of paver blocks.

This article aims to delve into the intricacies of Hydraulic Paver Block Making Machine, providing a detailed exploration of their working principles, key components, and various types available in the market. We will uncover tips and some troubleshooting steps.

Moreover,we will highlight essential considerations for selecting the right machine that aligns with specific project requirements. Whether you are an industry professional seeking to optimize production processes or an enthusiast eager to grasp the mechanics behind paver block manufacturing, this guide will equip you with invaluable insights.

Understanding Hydraulic Paver Block Machine Specifications

When it comes to hydraulic paver block machines, understanding their specifications is crucial for making informed decisions. These machines are essential for producing high-quality, durable, and aesthetically pleasing paver blocks used in various construction projects.

Hydraulic paver block machine specifications encompass a range of key features. The capacity, which determines the number of blocks produced per hour, directly impacts productivity. The molding area size affects the dimensions and shapes of the blocks. Additionally, the power and pressure rating influence the machine's efficiency and performance.

Moreover, it's essential to consider the automation level and control system, as advanced automation ensures precision and ease of operation. The type of molds compatible with the machine allows for versatility in block design. Understanding these specifications empowers buyers to select the ideal hydraulic paver block machine that aligns with their specific project requirements, resulting in cost-effective and successful paving solutions.

Choosing the Right Paver Type: Interlocking vs. Non-interlocking

When it comes to selecting the right paver type for your project, the choice between interlocking and non-interlocking pavers plays a crucial role in determining the overall outcome. Here are some key points to consider for each option:

Interlocking Pavers:

Interlocking pavers are designed to fit tightly together, creating a durable and stable surface.

They offer excellent load-bearing capabilities, making them ideal for driveways, walkways, and high-traffic areas.

The interlocking design provides flexibility, allowing them to withstand ground movement without cracking.

These pavers come in various shapes, colors, and patterns, enabling versatile and visually appealing designs.

Installation is relatively easier due to the interlocking system, reducing labor time and costs.

Repairs are simple, as individual pavers can be replaced without affecting the entire surface.

Non-Interlocking Pavers:

Non-interlocking pavers are more affordable compared to their interlocking counterparts.

They are suitable for light to moderate traffic areas like patios, garden pathways, and decorative landscape elements.

Installation may require more precision and skill as they do not have the interlocking mechanism.

Although repairs are possible, they might be more labor-intensive and could involve replacing larger sections.

Pro Tips for Maintaining Your Paver Block Making Machine

Regular Cleaning: Clean the machine daily to remove any residual concrete and debris that can cause blockages or malfunctions.

Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent wear and tear.

Inspection: Conduct routine inspections to identify and address any signs of wear, damage, or misalignment promptly.

Tighten Bolts: Check and tighten all bolts and nuts regularly to maintain stability and prevent vibrations.

Replace Worn Parts: Replace worn-out parts immediately to prevent further damage and ensure optimal performance.

Calibration: Calibrate the machine regularly to ensure accurate and consistent block dimensions.

Electrical Connections: Inspect and secure electrical connections to prevent electrical issues.

Professional Maintenance: Schedule periodic maintenance by qualified technicians to address complex servicing and extend the machine's lifespan.

Operating Guidelines: Train operators on proper machine operation and safety protocols to prevent mishandling or accidents.

Store in Shelter: Store the machine in a sheltered area to protect it from weather conditions and extend its longevity.

Troubleshooting Hydraulic Paver Block Making Machine

Low Block Quality: Adjust the hydraulic pressure and ensure proper alignment of molds to improve block quality.

Block Disintegration: Check the mix proportions of raw materials and the curing process for better block strength.

Oil Leaks: Inspect hydraulic hoses and connections, repair or replace damaged parts, and refill hydraulic oil as needed.

Excessive Noise/Vibrations: Tighten loose components and bolts, and ensure proper leveling of the machine.

Uneven Block Height: Verify uniform material distribution in the mold and calibrate the machine for consistent block height.

Machine Not Starting: Check power supply, fuses, and safety switches; repair or replace faulty electrical components.

Insufficient Block Production: Clean and maintain the machine regularly, and optimize the production process for efficiency.

Irregular Block Shapes: Inspect mold condition, ensure proper vibration, and adjust mold settings to achieve uniform shapes.

Safety Hazards: Implement strict safety protocols, provide training to operators, and display safety guidelines prominently.

Seek Professional Help: If issues persist, consult experienced technicians or manufacturers for advanced troubleshooting and repairs.

Conclusion

A Comprehensive Guide to Hydraulic Paver Block Making Machine highlights the indispensable role of perfect hydraulic machines in revolutionizing paver block production. The detailed exploration of working principles, types, and maintenance underscores their efficiency and eco-friendly advantages. By embracing these cutting-edge technologies, the construction industry gains a competitive edge in creating durable and visually appealing infrastructure. As Perfect Hydraulic Machines continue to shape the future of paver block manufacturing, their impact on sustainable construction practices remains unparalleled.

#Hydraulic Paver Block Making Machine#perfect hydraulic machines#hydraulic machines#Fly Ash Brick Machine

2 notes

·

View notes

Text

🚀 Want to build a business that lays the foundation for your future? Bricks manufacturing using Fly Ash, Clay & Cement is a GOLDMINE waiting for you! 💸 Here's your complete guide to start from scratch 🧱🔥 #BrickBusiness #ManufacturingIdeas #EntrepreneurLife #StartUpIndia #ViralBusinessIdea #MakeMoney2025

#block making machine#brick making machine#bricks business forum#bricks business ideas#bricks making machine#Bricks Manufacturing Business Plan#cement brick manufacturing business#clay brick making machine#fly ash brick manufacturing business#fly ash bricks#fly ash bricks business plan#fly ash bricks machine#fly ash bricks making business#how to do marketing of our brick manufacturing business#how to start a brick manufacturing business#interlocking bricks business#start bricks business

0 notes

Text

Fully automatic Brick making machine, BMM310 dispatched to Uttar Pradesh, India

SnPC Machines: Factory of bricks on wheel

SnPC Machines is providing heavy brick making truck that can produce brick with a speed of more than 25K brick per hours with a minimum labor and resources. BMM manufactured by SnPC Machines are making it possible for kiln owner to fulfill their brick requirements in a limited time and investments.

#BMM310#BMM410#SnPC Machines#brick making machine India#brick making machine Delhi#Top quality bricks#brick machine UP#Team SnPC

7 notes

·

View notes

Text

High-Performance Fly Ash Brick Making Machine for Efficiency

Brick Machinery is leading fly ash brick making machine manufacturer in India. They are providing advance and efficient solution for the construction industry. Their machines are designed to produce high quality, eco friendly fly ash brick with superior strength and durability. Brick Machinery is machine make sure smooth operation, minimal wastage and cost effectiveness or making them first choice for large scale and small scale brick manufacturing with their modern technology and precise engineering.

Brick Machinery first prioritize is innovation and quality and their providing fully automated and semi automated fly ash brick making machine to compete various customer needs. Their machines are built to withstand heavy duty usage with delivering consistent performance. Brick Machinery solution to help reduce construction costs with promoting sustainability if it is commercial or industrial projects. If you choose Brick Machinery for reliable, high output brick manufacturing solution then come perfect place.

Explore our high quality Fly Ash Brick Making Machine and find the perfect solution for your construction needs then Visit Our Website brickmachinery.in.

#fly ash brick making machine#brick making machine#hydraulic brick making machine#paver block making machine#brickmakingmachine#fly ash brick making machine in gujarat#brick making machine in india#brickmachine#fly ash brick plant#block making machine

0 notes

Text

Building a Sustainable Future: The Rise of Fully Automatic Fly Ash Brick Machines in India

India's construction sector is booming, and with it, the demand for efficient, sustainable building materials. In this landscape, fully automatic fly ash brick machines are emerging as a game-changer, revolutionizing brick manufacturing across the nation. These advanced machines not only offer high productivity but also contribute significantly to environmental conservation by utilizing industrial waste.

What are Fully Automatic Fly Ash Brick Machines?

At its core, a fully automatic fly ash brick machine is an industrial marvel designed to produce high-quality bricks from fly ash – a byproduct of coal combustion in thermal power plants – mixed with other raw materials like sand, lime, gypsum, and cement. The "fully automatic" aspect signifies that the entire production process, from raw material feeding and mixing to pressing, molding, and often even stacking, is automated, requiring minimal human intervention.

These machines leverage sophisticated technologies such as:

Hydraulic Pressure Systems: Ensuring uniform compression and high-density bricks with excellent strength.

Vibro-Compaction Technology: Combining vibration with pressure to eliminate air bubbles and achieve superior compaction and dimensional accuracy.

PLC (Programmable Logic Controller) Control: For precise management of the entire operation, enabling consistent quality, adjustable pressure settings, and real-time monitoring.

Automated Raw Material Feeding and Batching Systems: Ensuring precise proportions of materials for optimal brick composition.

Mould Flexibility: Allowing for the production of various brick types, including solid, hollow, paving blocks, and interlocking bricks, using interchangeable molds.

Auto-Stacker Systems: In advanced models, bricks are automatically stacked post-production, reducing manual labor and improving efficiency.

The Unmatched Advantages in the Indian Context

The adoption of fully automatic fly ash brick making machines in India offers a multitude of benefits, both economic and environmental:

High Production Capacity: These machines are designed for large-scale output, with some models capable of producing 1500-2500 bricks per hour, or even up to 30,000 bricks per day. This high volume helps meet the escalating demand in the rapidly growing Indian construction market.

Consistent Quality and Durability: Automation eliminates human error, leading to uniformly shaped, high-strength bricks with low water absorption and excellent thermal insulation. This translates to better structural integrity and longer-lasting buildings.

Environmental Sustainability: By utilizing fly ash, a significant industrial waste product, these machines contribute to:

Waste Utilization: Reducing the burden on landfills and promoting a circular economy.

Reduced Carbon Footprint: Less reliance on traditional clay bricks, which often involve topsoil excavation and energy-intensive firing processes.

Lower Water Usage: Fly ash brick production typically requires less water compared to conventional clay bricks.

Compliance with Regulations: The Indian government, through notifications from the Ministry of Environment & Forests (MoEF&CC), has mandated the utilization of fly ash in construction activities within a certain radius of thermal power plants, further driving the demand for these machines.

Cost-Effectiveness and Quick ROI: While the initial investment might seem substantial (prices for fully automatic plants can range from INR 10.5 Lakh to over INR 2 crore, depending on capacity and features), the long-term cost savings are significant. Reduced labor requirements, minimal maintenance, and high production output lead to a faster return on investment (ROI).

Reduced Labor Dependency and Enhanced Safety: Automation minimizes the need for manual labor, addressing concerns about labor availability and reducing occupational hazards associated with traditional brick-making.

Versatility: The ability to produce various types of bricks and blocks caters to diverse construction needs and market segments, from residential and commercial buildings to infrastructure projects and landscaping.

Energy Efficiency: Modern machines are optimized for lower power consumption, contributing to reduced operational costs.

Leading Manufacturers and Market Trends in India

India boasts a strong ecosystem of manufacturers specializing in fully automatic fly ash brick machines. Companies like Narsinh Industries, Endeavour Intelligent Equipments Private Limited, HVB Exports, Revomac Industries, Laxmi Engineering Works, and Kailash Engineering are prominent players, offering a wide range of machines with varying capacities and features. Many manufacturers are based in industrial hubs like Ahmedabad, Morbi, Mehsana, and Coimbatore.

The market trend is clearly towards more advanced, energy-efficient, and highly automated solutions. Manufacturers are focusing on:

Integrating IoT and remote monitoring capabilities for enhanced control and diagnostics.

Developing machines with even higher pressing capacities for denser bricks.

Offering customized solutions to meet specific client requirements.

Ensuring robust build quality for long operational life and minimal wear and tear.

Investing in a Sustainable Future

For entrepreneurs and construction companies in India looking to scale up their operations while embracing sustainable practices, investing in a fully automatic fly ash brick machine is a strategic decision. These machines not only promise high productivity and superior product quality but also align with the nation's growing emphasis on green building and responsible waste management. As India continues its infrastructure development, the demand for eco-friendly and high-performance building materials like fly ash bricks, produced efficiently by these advanced machines, is set to soar.

#automatic bricks making machine manufacturer#automatic paver block machine manufacturer#fly ash block making machine#paver block manufacturing machine#semi-automatic block making machine#vibrating paver block machine

0 notes

Text

college laundry room hell got me considering breaking into the apartment building im considering for next year to see if their laundry rooms are ass because i canNOT TAKE THIS ANYMORE

#when i say i have cleaned out whole bricks of lint from the lint catcher cover i mean it#ive used dozens of wipes to clean the gunk out of ONE washing machine. like i could make a homunculus from the hair i get out of it#it feels like my clothes get dirtier every time...which is why i clean them obvs#also the amount of SAND in the dryers because i live in a beach town

0 notes

Text

Been going through all my old fics to sort through them and seeing which one i want to edit and (maybe) post. Some of this stuff is literally from when i was in fourth grade. I know cringe is dead and all that but OHHH MY GODDDDD what the hell was I on.

#having a physical reaction to reading some of this stuff my god#all getting chucked in the bin thank you very much#okay the ones from like elementary school i dont care about i was like 10#it's the ones from like 5th-6th grade that are making me want to invent a time machine and toss younger me's computer into the ocean#girlie does NOT know how to use paragraph breaks my god#or punctuation#or sentance flow. the words are entering my brain like a brick wall#someone get her a proper writing class holy fuck

1 note

·

View note

Text

Hollow Solid Block Making Machine – Trusted Solutions by Ultra Tile Machine

In the construction industry, the demand for reliable and cost-effective building materials has never been higher. With infrastructure projects on the rise, both hollow and solid blocks are rapidly replacing traditional bricks due to their structural advantages, durability, and cost efficiency. At the core of producing these essential materials lies the Hollow Solid Block Making Machine, a critical asset for modern builders and manufacturers.

When it comes to choosing a dependable manufacturer, Ultra Tile Machine stands tall as an industry leader. With years of expertise and a reputation for quality and innovation, Ultra Tile Machine is your go-to partner for high-performance block making solutions.

What Is a Hollow Solid Block Making Machine?

A Hollow Solid Block Making Machine is a versatile industrial machine used to manufacture both hollow and solid concrete blocks. These machines compact a mixture of cement, sand, and aggregates into pre-defined molds using hydraulic or mechanical pressure. The result is uniformly shaped, high-strength blocks suitable for various construction needs.

Hollow blocks are lighter and used for non-load bearing walls, while solid blocks are denser and used in load-bearing structures. A machine that can produce both types offers manufacturers maximum flexibility and better ROI.

Why Hollow and Solid Blocks Are Gaining Popularity

Construction professionals are shifting towards hollow and solid concrete blocks due to their numerous advantages over traditional bricks. Some of these include:

Better thermal insulation

Faster construction speed

High load-bearing capacity

Reduced dead load on structure

Eco-friendly materials

Lower water absorption

Uniform shape and size

This shift has directly increased the demand for machines that can produce these blocks efficiently.

Types of Hollow Solid Block Making Machines

Depending on the scale and automation needs of your business, Ultra Tile Machine offers a range of machines such as:

Manual Block Making Machines

Semi-Automatic Machines

Fully Automatic Machines

Hydraulic Press Block Machines

Vibration Cum Compression Machines

Each type caters to a different production requirement, ensuring that businesses of all sizes can find the right fit.

Advantages of Investing in a Hollow Solid Block Making Machine

High Productivity

These machines are designed to produce hundreds or even thousands of blocks in a single shift, drastically improving output.

Versatility

Manufacturers can produce a wide range of block types, including hollow blocks, solid blocks, interlocking blocks, and more using different molds.

Cost Efficiency

Modern machines reduce labor dependency and minimize raw material waste, increasing overall profitability.

Better Quality Control

Precision engineering ensures consistency in size, strength, and shape, which is vital for large-scale construction projects.

Environmentally Friendly

These machines support the use of fly ash, slag, and other industrial waste, contributing to sustainable construction practices.

Why Choose Ultra Tile Machine as Your Manufacturer?

Industry Experience

Ultra Tile Machine has built a legacy of trust and excellence in the block making machinery sector. With decades of experience, the company understands the pulse of the construction industry and delivers solutions tailored to real-world challenges.

Advanced Technology

All machines by Ultra Tile Machine are designed using the latest technology to ensure high output and consistent performance. Key features include:

High-pressure hydraulic systems

Heavy-duty steel construction

Advanced vibration technology

Precision molds

User-friendly controls

Long service life

These features enable operators to run production smoothly with minimal downtime.

Wide Product Range

Ultra Tile Machine offers a full suite of machinery for every scale of operation:

Manual Machines: Ideal for startups and small-scale units

Semi-Automatic Models: A perfect mix of manual and automatic features

Fully Automatic Machines: Best suited for large-scale continuous production

Hydraulic Block Machines: Ensures greater compression and block durability

Whether you’re a beginner or a seasoned industrialist, there's a machine that suits your business needs.

Customization Options

Ultra Tile Machine provides full flexibility in customizing:

Block size and mold design

Output capacity

Power source (electric or diesel)

Machine frame and configuration

Color and branding

Custom machines ensure that your production line aligns perfectly with market demand and your brand identity.

Quality Assurance

Ultra Tile Machine places strong emphasis on quality at every stage of manufacturing. Every machine undergoes rigorous quality checks to ensure:

Flawless operation

Durability and reliability

Resistance to wear and tear

Energy efficiency

Customers receive machines that perform consistently for years with low maintenance requirements.

Competitive Pricing

Despite offering premium features, Ultra Tile Machine maintains highly competitive prices. Their goal is to make quality machinery accessible to everyone, from small business owners to industrial giants. Transparent pricing, zero hidden costs, and a strong return on investment make them a clear choice.

Strong After-Sales Support

What truly sets Ultra Tile Machine apart is their dedication to customer satisfaction beyond the sale. They offer:

Installation and commissioning support

Operational training for staff

Routine maintenance and inspection services

Readily available spare parts

Prompt technical assistance

This helps ensure that your production stays uninterrupted and efficient.

Nationwide and Global Reach

Ultra Tile Machine serves clients across India and exports machinery to several countries. Their machines are built with global standards in mind and come with all necessary documentation, training materials, and remote support for overseas clients.

Positive Customer Testimonials

“Ultra Tile Machine gave us a powerful machine that revolutionized our block manufacturing process. Their service team was quick, professional, and helpful.” – Arjun, Hyderabad

“We use their hydraulic solid block machine, and the output is simply unmatched. Highly recommended!” – Neha, Pune

Feedback like this showcases the strong reputation Ultra Tile Machine enjoys in the industry.

How to Choose the Right Machine for Your Needs?

Before you invest in a Hollow Solid Block Making Machine, consider the following:

Production Volume: Assess how many blocks you need to produce per day

Automation Level: Go with automatic models for higher speed and lower labor costs

Block Types: Choose a model compatible with the kinds of blocks you plan to manufacture

Available Space: Some machines require more floor space for installation and raw material handling

Budget: Ultra Tile Machine offers machines in a variety of price brackets to fit your investment range

Applications of Hollow and Solid Blocks

Hollow and solid blocks produced by these machines are used in:

Residential and commercial buildings

Roadside pavements

Compound walls and fences

Industrial structures

Warehouses and godowns

Load-bearing and non-load-bearing walls

Their strength, cost-efficiency, and long lifespan make them a preferred material in construction across the globe.

Focus on Sustainability

Ultra Tile Machine is committed to promoting eco-conscious practices. Their machines support:

The use of fly ash, slag, and other industrial byproducts

Reduced water usage in block curing

Low energy consumption

Long-term recyclability of produced blocks

This not only aligns with green building standards but also appeals to environmentally responsible contractors and builders.

Conclusion

In the ever-evolving world of construction, the need for reliable, durable, and high-quality blocks is more important than ever. Investing in a Hollow Solid Block Making Machine is a strategic move that can transform your business by increasing efficiency, reducing production costs, and meeting the growing demand for sustainable construction materials.

Ultra Tile Machine, as a trusted manufacturer, offers unmatched expertise, top-tier machinery, and unwavering customer support. Whether you’re starting a new venture or expanding an existing one, Ultra Tile Machine provides everything you need to succeed in the block manufacturing industry.

#Paver Block Making Machine Manufacturer#Hollow Solid Block Making Machine#Fly Ash Brick Making Machine#Concrete Block and Brick Making Machine#Chemical Hardener Manufacturers#Interlocking Paver Block Making Machine#Automatic Brick Making Machine Manufacturer

0 notes