#CIJ Printing Technology

Explore tagged Tumblr posts

Text

Experience the future of printing with our cutting-edge Continuous Inkjet (CIJ) Printer. Achieve superior quality, speed, and reliability in your printing tasks.

0 notes

Text

VIDEOJET PRINTING INK Compatibility with Modern Coding Technologies

In today’s fast-paced industrial environment, reliable coding and marking solutions are essential for maintaining efficiency, compliance, and product traceability. One of the leading names in this space is VIDEOJET PRINTING INK, known for its outstanding performance across a wide range of production needs. As modern coding technologies continue to evolve, the compatibility of VIDEOJET PRINTING INK with these advanced systems plays a crucial role in enhancing operational workflows and ensuring high-quality output.

Let’s explore how VIDEOJET PRINTING INK seamlessly integrates with modern coding technologies and why it remains a preferred choice across industries.

Meeting the Demands of Evolving Coding Systems

Modern coding technologies have rapidly advanced to support higher production speeds, diverse substrates, and more stringent compliance requirements. Whether it's continuous inkjet (CIJ), thermal inkjet (TIJ), laser marking, or large character printing (LCP), every technology demands ink formulations that are optimized for specific applications.

VIDEOJET PRINTING INK is designed with compatibility in mind. It works effectively across multiple coding systems, especially with CIJ and TIJ printers, which are widely used in industries like food & beverage, pharmaceuticals, cosmetics, and electronics. Its superior adhesion properties and quick-drying characteristics make it suitable for a variety of materials such as glass, plastic, cardboard, and metals — all without compromising print clarity.

Precision and Consistency Across Substrates

The success of any modern coding solution relies heavily on consistent, legible prints — even on complex or irregular surfaces. VIDEOJET PRINTING INK is specially formulated to deliver high-contrast codes on challenging substrates, including slick plastic bottles, coated cartons, and flexible packaging.

For instance, when used with thermal inkjet printers, VIDEOJET PRINTING INK can produce high-resolution prints suitable for detailed information like QR codes, barcodes, and batch numbers. This level of precision ensures products meet regulatory and supply chain requirements without costly rework or delays.

Compatibility with Automation and Smart Production Lines

As Industry 4.0 and smart manufacturing trends continue to reshape factories, VIDEOJET PRINTING INK proves its adaptability by integrating seamlessly with automated systems. Today’s coding technologies often feature built-in software for remote monitoring, predictive maintenance, and real-time data tracking.

Whether integrated into robotic arms or smart conveyors, VIDEOJET-compatible printers and ink cartridges can work in sync with automated lines to minimize downtime and improve traceability. The chemical stability of VIDEOJET PRINTING INK ensures that the ink does not dry out or clog the printer even during extended idle times — a key advantage in automated environments.

Supporting Eco-Friendly and Regulatory Needs

Sustainability and compliance have become top priorities in modern manufacturing. VIDEOJET PRINTING INK is available in a range of formulations, including low-VOC (Volatile Organic Compounds) and MEK-free options, making it environmentally safer while still delivering strong performance.

Moreover, these inks comply with international safety and packaging regulations, including FDA, RoHS, and REACH standards, making them ideal for food, beverage, and pharmaceutical packaging. Modern coding technologies often come equipped with ink usage monitoring features, and VIDEOJET’s efficient ink formulations help reduce waste and operating costs over time.

Easy Integration with a Wide Range of Printers

One of the greatest strengths of VIDEOJET PRINTING INK is its wide printer compatibility. It is engineered to work perfectly with Videojet’s own series of printers, including the popular 1000 Line CIJ printers, 8510 TIJ printers, and more. This ensures plug-and-play functionality and optimal performance from the first print to the last.

For companies using a mix of legacy and new printing equipment, the versatility of VIDEOJET PRINTING INK provides a unified solution without the need for multiple ink inventories. This not only simplifies operations but also reduces maintenance and training time for machine operators.

Why Manufacturers Trust VIDEOJET PRINTING INK

Manufacturers around the globe rely on VIDEOJET PRINTING INK for its unmatched reliability, durability, and adaptability. Whether it's high-speed bottling lines or precise electronics labeling, this ink continues to deliver consistent results that keep operations running smoothly.

At SH HITECH SOLUTIONS, we understand how critical it is to choose the right ink for the right technology. That’s why we recommend VIDEOJET PRINTING INK for businesses looking to future-proof their production lines with high-performance, compatible ink solutions.

Final Thoughts

As coding technologies become smarter, faster, and more complex, the demand for high-performance inks that can keep up has never been greater. VIDEOJET PRINTING INK rises to the challenge, offering exceptional compatibility with modern coding technologies, from CIJ to TIJ and beyond.

For manufacturers seeking to streamline operations, maintain compliance, and ensure reliable product identification, VIDEOJET PRINTING INK remains a leading solution that supports both today’s needs and tomorrow’s innovations.

0 notes

Text

Comprehensive Study of the Global Coding and Marking Equipment Industry

The global coding and marking equipment market was valued at USD 17.53 billion in 2024, and it is anticipated to grow at a compound annual growth rate (CAGR) of 6.1% from 2025 to 2030. This projected growth is largely attributed to the increasing emphasis on product traceability across several key industrial sectors, including food and beverage, pharmaceuticals, cosmetics, and electronics. The demand for advanced coding and marking systems is further fueled by the implementation of stringent regulatory frameworks related to product labeling, safety, and quality standards. These regulations compel manufacturers to adopt more sophisticated, accurate, and efficient identification technologies.

One of the main catalysts driving this market expansion is the continuous innovation in coding technologies, particularly the development and adoption of laser marking systems and Thermal Inkjet (TIJ) solutions. These advancements are closely aligned with the broader trend of automation in manufacturing and packaging processes, enabling companies to improve throughput, reduce human error, and streamline operations.

The evolution of coding and marking technologies has significantly enhanced the ability of companies to achieve greater operational efficiency and cost-effectiveness. Advanced systems with high-precision capabilities—such as laser coding, Thermal Inkjet (TIJ), Continuous Inkjet (CIJ), and thermal transfer technologies—are playing a pivotal role in ensuring accurate, durable, and compliant labeling across a wide variety of substrates and materials. These technologies are indispensable in sectors such as food and beverage, pharmaceuticals, cosmetics, electronics, automotive, logistics, and packaging. Their applications include product identification, traceability, regulatory compliance labeling, date coding, and batch numbering, all of which are essential for maintaining high standards in quality control, safety assurance, and anti-counterfeiting measures.

Businesses, especially leading players in manufacturing and supply chains, are increasingly integrating these technologies to enhance operational productivity, reduce labeling errors, and optimize supply chain logistics. By adopting modern coding and marking systems, companies are better equipped to respond to evolving regulatory requirements and customer expectations for transparency and traceability.

For instance, in September 2024, Domino Printing Sciences, a well-recognized name in the coding and marking sector, introduced a new high-speed laser coding system designed specifically for the packaging industry. This advanced technology delivers precise, consistent coding across a range of materials while simultaneously reducing operational costs. It enables companies—particularly those operating in heavily regulated markets—to maintain high levels of compliance, productivity, and cost efficiency.

Moreover, increasing public and private sector investments in research and development (R&D) across key regions such as North America, Europe, and Asia Pacific are contributing to the rapid advancement of coding and marking technologies. Initiatives such as the U.S. National Innovation Strategy and Germany’s Industry 4.0 program are designed to support digital transformation and technological innovation, creating a favorable environment for market growth. As these technologies continue to evolve, organizations benefit from enhanced traceability, improved regulatory compliance, and strengthened product authentication, all of which contribute to the overall expansion and resilience of the coding and marking equipment market.

Get a preview of the latest developments in the Coding And Marking Equipment Market? Download your FREE sample PDF copy today and explore key data and trends

Detailed Segmentation:

Product Insights

The Continuous Inkjet (CIJ) printer segment led the coding and marking equipment industry in 2024, accounting for 32.3% of the revenue. Known for their non-contact, high-speed coding capabilities, CIJ printers support versatile, reliable marking across high-volume production lines.

End Use Insights

In 2024, the food and beverage sector dominated the coding and marking equipment market, driven by stringent safety standards required for online and retail channels. Reliable coding systems facilitate clear labeling of expiration dates, batch numbers, and traceability, which is essential for brand protection and differentiation.

Regional Insights

North America led the global coding and marking equipment market in 2024 with a revenue share of 30.9%, driven by continuous R&D, a growing manufacturing base, and the presence of established coding technology providers. Stringent regulatory standards in pharmaceuticals, food & beverage, and automotive industries fuel the demand for precise, reliable coding solutions in the region.

Key Coding And Marking Equipment Company Insights

Some key companies in the coding and marking equipment industry are Danaher Corporation, Hitachi Ltd., and ProMach Inc. Major market participants are adopting strategies such as innovation, enhanced focus on R&D activities, expansions, portfolio enhancements, partnerships, and collaborations to address growing competition and rising technology adoption.

Danaher Corporation offers a comprehensive range of precision coding and marking solutions through subsidiaries like Videojet and Linx, targeting various industries, such as pharmaceuticals, food & beverage, and manufacturing. Known for high-performance inkjet, laser, and thermal transfer technologies, Danaher’s solutions support compliance, traceability, and product authentication with advanced data integration features.

Hitachi Ltd. delivers reliable coding and marking systems, including continuous inkjet and laser solutions tailored for high-speed production in the automotive, electronics, and consumer goods sectors. With a strong focus on innovation, Hitachi integrates IoT-enabled and automation features to enhance traceability and operational efficiency in large-scale manufacturing.

Key Coding And Marking Equipment Companies:

The following are the leading companies in the coding and marking equipment market. These companies collectively hold the largest market share and dictate industry trends.

Danaher Corporation

Domino Printing Sciences plc

Comp3

Hitachi Ltd.

Markem-Imaje Group

Matthews International Corporation

Leibinger Group

REA Elektronik GmbH

ProMach Inc.

Koenig & Bauer Coding GmbH

HSA Systems A/S

Recent Developments

In September 2024, Domino Printing Sciences launched the K300, a compact monochrome inkjet printer, at Labelexpo Americas. Designed for high-speed variable data printing, it integrates easily into existing lines, enabling label customization with QR codes and batch information. The K300 will be featured alongside a code verification solution from Lake Image Systems, meeting the rising demand for 2D codes in packaging.

In April 2024, Markem-Imaje launched the MW2160P, a versatile opaque white ink for extruded products like PVC and rubber, compatible with its 9750+ CIJ printers. This durable ink offers strong visibility and adhesion, resisting bending and water exposure, making it ideal for demanding industrial applications. Nicknamed the “Swiss Army Knife” of CIJ inks, it ensures reliable print quality across various substrates.

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

Automatic CIJ Inkjet Printer for Plastic, Pipe, & Bottles – 34% Off!

🖨️ Automatic Batch Code Number Date Plastic Pipe Bottle Bag PVC Egg Cable CIJ Inkjet Printer – Now USD 1663.31 (Original price: USD 2533.05, 34% Off!)

Key Features:

🔥 Automatic Batch Code Printing: Quickly and accurately prints batch codes, numbers, dates, and more.

🖨️ CIJ Inkjet Technology: Efficient inkjet printing for a variety of materials including plastic, bottles, pipes, and bags.

🏭 Versatile Printing: Ideal for high-volume production lines or packaging facilities.

🎯 Precision & Durability: Designed to handle continuous printing without sacrificing quality.

Get your hands on this automatic CIJ inkjet printer and take your printing efficiency to the next level with 34% off! 🚀

🔗 Click & Buy Now: Link to product

#CIJPrinter#BatchCodePrinter#IndustrialPrinter#InkjetPrinter#PrintingTechnology#PackagingSolutions#IndustrialTech

0 notes

Text

Boost Your Printing Efficiency with CIJ Printers from Techno Middle East

In the ever-evolving world of manufacturing, keeping up with efficient and cost-effective production is crucial. This is where Continuous Inkjet (CIJ) printers come in. If you're looking for a reliable CIJ printer supplier in the Middle East, look no further than Techno Middle East.

What are CIJ Printers?

CIJ printers are industrial printing solutions that use a continuous jet of ink to mark products during production. They are ideal for printing variable data, such as:

Manufacturing dates

Batch codes

Serial numbers

Logos

Expirations dates

Benefits of Using CIJ Printers from Techno Middle East

Superior Quality and Advanced Technology: Techno Middle East prides itself on providing cutting-edge CIJ printers that deliver superior print quality on various surfaces.

Unmatched Customer Service: Their commitment to excellent customer service ensures you receive the support you need throughout the entire process.

Innovative Solutions: Their team of experts stays ahead of the curve, offering innovative solutions to meet your specific printing needs.

Increased Efficiency: CIJ printers can significantly improve your production line's efficiency by automating the marking process.

Reduced Costs: By eliminating the need for pre-printed labels, CIJ printers can help you save money on printing costs.

Why Choose Techno Middle East?

Trusted Partner: Techno Middle East is a leading supplier of CIJ printers in the Middle East, known for their expertise and reliability.

Commitment to Excellence: Their dedication to providing exceptional service and high-quality products makes them the preferred choice for businesses seeking reliable printing solutions.

Wide Range of Solutions: They offer a comprehensive range of CIJ printers to cater to diverse printing needs and industries.

If you're looking to optimize your production process and improve your product marking efficiency, contact Techno Middle East today to explore their CIJ printer solutions.

0 notes

Text

The Competitive Landscape of CIJ Printer Manufacturers

In the ever-evolving world of industrial printing, Continuous Inkjet (CIJ) technology stands out as a versatile and reliable solution for marking and coding applications across various industries. As demand for high-quality coding and marking solutions continues to grow, the market for CIJ printers has become increasingly competitive. CIJ printer manufacturers play a pivotal role in shaping this landscape, offering a diverse range of products and services to meet the evolving needs of their customers.

Understanding CIJ Technology

Continuous Inkjet (CIJ) technology is renowned for its ability to produce high-resolution prints at high speeds on a variety of surfaces, including metals, plastics, and packaging materials. CIJ printers utilize a continuous stream of ink droplets ejected from a printhead, which are precisely controlled to form characters, numbers, barcodes, and other symbols.

Key Players in the CIJ Printer Market

1. Domino Printing Sciences

Domino Printing Sciences, a part of Brother Industries, is a leading player in the CIJ printer market. With a rich history dating back to 1978, Domino has established itself as a pioneer in coding and marking solutions. The company's CIJ printers are known for their reliability, versatility, and ease of use, making them a preferred choice for industries ranging from food and beverage to pharmaceuticals and electronics.

2. Markem-Imaje

Markem-Imaje, a subsidiary of Dover Corporation, is another prominent name in the CIJ printer industry. With a global presence spanning over 40 countries, Markem-Imaje offers a comprehensive range of coding and marking solutions, including CIJ printers renowned for their exceptional print quality, durability, and efficiency. The company caters to diverse market segments, including automotive, aerospace, cosmetics, and more.

3. Videojet Technologies Inc.

Videojet Technologies Inc., a part of the Danaher Corporation, is a leading provider of coding and marking solutions worldwide. With over 50 years of experience in the industry, Videojet has earned a reputation for innovation and excellence. The company's CIJ printers are designed to deliver superior performance, enabling customers to achieve precise, legible codes on a wide range of substrates. Videojet serves various industries, including food and beverage, pharmaceuticals, and consumer goods.

Emerging Trends and Innovations

As competition intensifies in the CIJ printer market, manufacturers are continuously innovating to stay ahead of the curve. Some notable trends and innovations shaping the industry include:

Integration of Industry 4.0 Technologies: CIJ printer manufacturers are increasingly incorporating Industry 4.0 technologies such as IoT connectivity, data analytics, and cloud-based solutions to enhance operational efficiency, minimize downtime, and improve overall productivity.

Focus on Sustainability: With growing emphasis on environmental sustainability, CIJ printer manufacturers are developing eco-friendly solutions that minimize ink consumption, reduce waste, and optimize energy usage, thereby reducing their carbon footprint.

Customization and Personalization: To meet the evolving needs of customers, CIJ printer manufacturers are offering customizable solutions tailored to specific industries and applications. Whether it's specialized inks, printhead configurations, or software functionalities, customization options are becoming increasingly prevalent in the market.

Conclusion

The CIJ printer market is characterized by intense competition, driven by the demand for high-quality coding and marking solutions across various industries. Leading manufacturers such as Domino Printing Sciences, Markem-Imaje, and Videojet Technologies continue to innovate and expand their product offerings to meet the diverse needs of their customers. As technology evolves and market dynamics shift, CIJ printer manufacturers will play a crucial role in shaping the future of industrial printing.

0 notes

Text

Decoding the Dynamic World of Inkjet Coders: A Rollercoaster Ride in Market Trends

Fasten your seatbelts, inkjet enthusiasts! We’re about to take a thrilling journey through the exhilarating twists and turns of the Global Inkjet Coders Market. Hold on tight, and let’s explore this billion-dollar rollercoaster.

The Market Prelude

In 2022, the Inkjet Coders Market entered the scene with a bang, flaunting a cool USD 1.63 Billion. Fast forward to 2031, and it’s projected to skyrocket to a whopping USD 2.64 Billion, boasting a CAGR of 5.52%. Impressive, right? But let’s not get too carried away; there’s more to this story.

Riding the Waves of Growth

The inkjet coders’ popularity isn’t just a random surge; it’s riding high on the back of various industries. From food and beverage to pharmaceuticals, packaging, and manufacturing, these coding maestros are leaving their mark everywhere. They’re not just adding barcodes and expiration dates; they’re like the rockstars of product information.

Inkjet Coders: The Chameleons of Printing

What makes these inkjet coders steal the show? Versatility. They can dance on various substrates — paper, plastic, glass, and metal. It’s like having a printer that’s not picky about its dance floor. Need something on your packaging? These coders got you covered!

Market Snapshot: Where are We Headed?

Global Market Size: From a modest USD 1.63 Billion to an ambitious USD 2.64 Billion.

Largest Segment: Continuous Inkjet Coders (CIJ) leading the pack.

Fastest Growth: Drop-on-Demand Inkjet Coders (DOD) racing to the top.

Growth Rate: A not-so-humble 5.52% CAGR.

Regional Rollercoaster

North America, Asia Pacific, Europe — the battlegrounds for inkjet supremacy. Let’s take a look at who’s flexing their coding muscles.

North America: The reigning champion with a 70% share, as the US and Canada engage in a coding face-off.

Asia Pacific: The underdog stealing the show with a skyrocketing growth rate. Watch out for those emerging economies making a splash!

Inkjet Coders Unveiled: The Types

Continuous Inkjet Coders (CIJ) and Drop-on-Demand Inkjet Coders (DOD) take center stage. It’s like choosing between a speed demon and a precision artist. Decisions, decisions.

Inkjet Coders by the Numbers

Continuous Inkjet Coders (CIJ): Going from 18 to 25 in the billion-dollar race.

Drop-on-Demand Inkjet Coders (DOD): Steadily climbing from 17 to 24.

Others: The mysterious third wheel, always in the mix.

The Drama of End-Users

Food and beverage, pharmaceuticals, packaging, manufacturing — who’s stealing the limelight?

Food and Beverage: The perennial favorite, adopting inkjet technologies like it’s the latest diet trend.

Pharmaceuticals: Strict regulations, serialization, and labeling demands make inkjet coders the unsung heroes of the pharmaceutical stage.

Dynamics at Play

Drivers: The Heroes

Stringent Regulations: The unsung anthem demanding accurate labeling and traceability.

Product Traceability: Keeping tabs on goods like an overprotective parent.

Restraints: The Villains

High Investment: The upfront cost playing the villain, especially for smaller businesses.

Expensive Consumables: Ongoing costs, like a never-ending saga of ink and maintenance.

For More Information: https://www.skyquestt.com/report/inkjet-coders-market

The Avengers of Inkjet Coders

Who are the powerhouses in this coding universe? Let’s meet the superheroes behind the scenes.

Domino Printing Sciences

Videojet Technologies

Markem-Imaje

Linx Printing Technologies

Leibinger GmbH & Co. KG

Citronix

…and the list goes on.

Recent Developments: The Plot Thickens

Domino Printing Sciences opens a new subsidiary in Indonesia: Expanding their empire like true conquerors.

Danaher Corporation unveils Veralto Corporation: A new player in the coding arena, ready for action.

Trends: The Fashion Show of Coding

Sustainability: Inks going green, aligning with eco-conscious consumers.

Digital Printing: High-res, variable data — the supermodels of the coding runway.

Industry 4.0 Integration: Because even inkjet coders want to stay ahead in the tech game.

In Conclusion

The inkjet coders market is a pulsating ecosystem, with trends and dynamics shaping its destiny. From stringent regulations to the quest for sustainability, the inkjet saga is far from over. So, buckle up, coding enthusiasts — this rollercoaster is only getting started!

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text

Decoding the Dynamic World of Inkjet Coders

Fasten your seatbelts, inkjet enthusiasts! We’re about to take a thrilling journey through the exhilarating twists and turns of the Global Inkjet Coders Market. Hold on tight, and let’s explore this billion-dollar rollercoaster.

The Market Prelude

In 2022, the Inkjet Coders Market entered the scene with a bang, flaunting a cool USD 1.63 Billion. Fast forward to 2031, and it’s projected to skyrocket to a whopping USD 2.64 Billion, boasting a CAGR of 5.52%. Impressive, right? But let’s not get too carried away; there’s more to this story.

Riding the Waves of Growth

The inkjet coders’ popularity isn’t just a random surge; it’s riding high on the back of various industries. From food and beverage to pharmaceuticals, packaging, and manufacturing, these coding maestros are leaving their mark everywhere. They’re not just adding barcodes and expiration dates; they’re like the rockstars of product information.

Inkjet Coders: The Chameleons of Printing

What makes these inkjet coders steal the show? Versatility. They can dance on various substrates — paper, plastic, glass, and metal. It’s like having a printer that’s not picky about its dance floor. Need something on your packaging? These coders got you covered!

Market Snapshot: Where are We Headed?

Global Market Size: From a modest USD 1.63 Billion to an ambitious USD 2.64 Billion.

Largest Segment: Continuous Inkjet Coders (CIJ) leading the pack.

Fastest Growth: Drop-on-Demand Inkjet Coders (DOD) racing to the top.

Growth Rate: A not-so-humble 5.52% CAGR.

Regional Rollercoaster

North America, Asia Pacific, Europe — the battlegrounds for inkjet supremacy. Let’s take a look at who’s flexing their coding muscles.

North America: The reigning champion with a 70% share, as the US and Canada engage in a coding face-off.

Asia Pacific: The underdog stealing the show with a skyrocketing growth rate. Watch out for those emerging economies making a splash!

Inkjet Coders Unveiled: The Types

Continuous Inkjet Coders (CIJ) and Drop-on-Demand Inkjet Coders (DOD) take center stage. It’s like choosing between a speed demon and a precision artist. Decisions, decisions.

Inkjet Coders by the Numbers

Continuous Inkjet Coders (CIJ): Going from 18 to 25 in the billion-dollar race.

Drop-on-Demand Inkjet Coders (DOD): Steadily climbing from 17 to 24.

Others: The mysterious third wheel, always in the mix.

The Drama of End-Users

Food and beverage, pharmaceuticals, packaging, manufacturing — who’s stealing the limelight?

Food and Beverage: The perennial favorite, adopting inkjet technologies like it’s the latest diet trend.

Pharmaceuticals: Strict regulations, serialization, and labeling demands make inkjet coders the unsung heroes of the pharmaceutical stage.

Dynamics at Play

Drivers: The Heroes

Stringent Regulations: The unsung anthem demanding accurate labeling and traceability.

Product Traceability: Keeping tabs on goods like an overprotective parent.

Restraints: The Villains

High Investment: The upfront cost playing the villain, especially for smaller businesses.

Expensive Consumables: Ongoing costs, like a never-ending saga of ink and maintenance.

For More Information: https://www.skyquestt.com/report/inkjet-coders-market

The Avengers of Inkjet Coders

Who are the powerhouses in this coding universe? Let’s meet the superheroes behind the scenes.

Domino Printing Sciences

Videojet Technologies

Markem-Imaje

Linx Printing Technologies

Leibinger GmbH & Co. KG

Citronix

…and the list goes on.

Recent Developments: The Plot Thickens

Domino Printing Sciences opens a new subsidiary in Indonesia: Expanding their empire like true conquerors.

Danaher Corporation unveils Veralto Corporation: A new player in the coding arena, ready for action.

Trends: The Fashion Show of Coding

Sustainability: Inks going green, aligning with eco-conscious consumers.

Digital Printing: High-res, variable data — the supermodels of the coding runway.

Industry 4.0 Integration: Because even inkjet coders want to stay ahead in the tech game.

In Conclusion

The inkjet coders market is a pulsating ecosystem, with trends and dynamics shaping its destiny. From stringent regulations to the quest for sustainability, the inkjet saga is far from over. So, buckle up, coding enthusiasts — this rollercoaster is only getting started!

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text

Everything To Know About Continuous Ink Jet Printing Technology

Introduction:

Printers are now essential whether it's home needs for kids or office documentation. It gives print images, text, and content efficiency with outstanding clarity and sharpness. Meanwhile, it also saves time and money, making printing hassle-free. The plan for investing in a good printer might be confusing, so look for the best options and check for utility beforehand. Generally, inkjet printers are the most common, and taking continuous is again a perk. Here in the blog, read about CIJ printing technology so that you can look for the best Continuous Ink Jet Online Virginiaprinters.

What is Continuous Inkjet Printing Technology?

Continuous inkjet printers, also known as CIJ, are innovative printing techniques used widely in business printing. It delivers an unbreakable or continuous stream of ink for printing on any medium. It's a thermal drop-on-demand printing process that is useful for home printing.

The Advantages Of Using Continuous Inkjet Printing Technology:

1.Quality Printing: CIJ printers are designed with microscopic nozzles and adjustable ultrasonic vibration mechanisms, offering quality printing on medium. It ensures high-resolution printing, keeping its quality, colour, and sharpness appropriate.

3.Versatility: CIJ printing is a non-contact printing technology. It can easily print on any surface or medium, regardless of shape. So continuous inkjet prints are best, whether a bottle, box, stickers, labels, curved objects, or any other material. It is super adjustable and stream ink drops with limitations that give clear printing.

The Final Verdict: Investing in printers with CIJ technology is worth it for home and office needs. So, if you haven't yet bought a printer, search for Continuous Ink Jet Online Virgina over quality printing brands. From easy operation to versatile printing, CIJ is an excellent option. It will give superb printing on any medium like paper, gloss medium, glass, wood, etc, with any object shape. What more do you want in a printer than with such multi-functionality? Go for CIJ printers now.

0 notes

Text

The StreamMaster CIJ Printer is a cutting-edge continuous inkjet printing solution designed for precision and efficiency. With its advanced technology and high-speed capabilities, it offers seamless printing for a wide range of applications, from packaging and labeling to coding and marking.

0 notes

Text

Discover the efficiency of Continuous Inkjet (CIJ) Printer technology. Ideal for high-speed, versatile printing in various industries."

0 notes

Text

Frequently Asked Questions(FAQs) about Ink Pumps for Continuous Inkjet Printers(CIJ)

You will find the following information here:

What is CIJ?

What is the primary application of continuous inkjet printers?

How does continuous inkjet printing work?

How is a continuous inkjet system formed?

Common issues with ink pumps in continuous inkjet printers

TOPSFLO CIJ ink pumps Solution

How to Get in Touch with TOPSFLO for Expert Assistance?

What is CIJ?

CIJ stands for Continuous Inkjet, CIJ is a small character inkjet printing technology that uses a single inkjet nozzle to rapidly spray ink into tiny droplets, forming printed images or text. CIJ printers are widely used worldwide and are a non-contact printing method, making them suitable for marking on both flat and curved surfaces. They are primarily used in industrial applications for product packaging, labeling, and coding.

What are the Main Applications of Continuous Inkjet Printers?

Continuous inkjet printers are primarily used to mark production dates, batch numbers, barcodes, and other information on the surfaces of various materials such as plastic, metal, glass, cardboard, and wood. Typical applications include beverage cartons, cans, and bags, pharmaceuticals, small cardboard boxes, cables, and components. Virtually any product or packaging that moves on a conveyor belt or extrusion machine is suitable for continuous inkjet printing.

How does Continuous Inkjet Printers Work?

Continuous inkjet printers create a continuous stream of ink, which is broken down into numerous ink droplets through high-frequency vibrations. Once the ink droplets are formed, the selected ones are charged by electrodes and then directed by a deflection plate that generates an electrostatic field.

Charged ink droplets pass through the deflection plate, causing them to deviate at a specific angle before being sprayed from the print head onto the product to create the desired printed information. Uncharged ink droplets remain unaffected and return directly to the CIJ ink system.

During this printing process, the solvent base of the ink evaporates, and the viscosity of the ink changes accordingly. To ensure the optimal droplet formulation, viscosity must be strictly controlled within specified values.

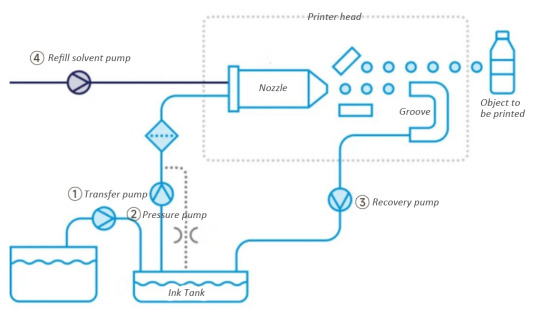

How is a Continuous Inkjet System Formed?

In continuous inkjet (CIJ) printing, ink circulates continuously throughout the printer, from the fluid system to the printhead, and then back to the fluid system. The entire ink path system involves several pumps working in coordination.

Initially, ink is transported from a large container to an ink reservoir using a transfer pump (①).

Subsequently, the ink is pressurized and transferred to the printhead using a pressure pump (②). Inside the printhead, the ink flows through nozzles, forming a continuous array of small ink droplets, each of which can be individually charged. Charged droplets are deflected by electrodes and hit the object to be printed.

Additionally, uncharged ink droplets fly in a straight line into a gutter, and excess ink is recirculated from this point back to the ink reservoir using a recirculation/suction/recovery pump (③).

To prevent the ink from drying and damaging the system when the printer is not in use, a refill solvent pump (④) is typically included in the continuous inkjet system. This pump delivers solvent to the nozzles to flush out any residual ink.

Through these steps, a continuous inkjet system can continuously supply ink and achieve high-speed, efficient inkjet printing.

Common Issues with Ink Pumps in Continuous Inkjet Printers

1. In the current market, there is a wide variety of ink types used in CIJ printers, each with different viscosities. These different ink compositions may contain additives, some of which can be corrosive, leading to compatibility issues with pump materials that can cause malfunctions or a very short lifespan.

2. Instability in the liquid circuit pressure and ink flow during the operation of the inkjet printer can affect the printing results.

Continuous inkjet printing requires prolonged periods of operation. Over time, continuous use may result in wear and tear, potentially leading to a decline in performance or malfunctions, thus compromising the printer's lifespan.

TOPSFLO CIJ ink pumps Solution

Diverse Pump Materials

Topsflo printer ink pumps offer a variety of pump material configurations to accommodate common CIJ ink types, such as MEK, dye-based inks, pigment inks, and soft pigment inks. The pump head materials for diaphragm pumps can be selected from PA, PPS, or PP, while membrane materials can be chosen from EPDM or PTFE. For valve materials, options include EPDM, FKM, or FFKM. YT alloy gear pumps are mainly used for pigment inks, while PEEK gears can be used for dye-based inks.

Carefully Selected Pump Types for Precise Applications

Topsflo offers two pump options tailored for printer applications: diaphragm pumps and gear pumps.

- Diaphragm liquid pumps, especially those designed for low-flow rates, provide relatively stable flow and pressure output. They are more suitable for handling liquids containing solid particles or particulate matter because their design is better suited for handling suspended particles. However, in high-flow applications, diaphragm pumps may produce larger pulses, which could lead to vibration or noise issues.

- Gear pumps are suitable for printers that require a large volume of ink. They offer stable flow and pressure output with lower pulsation. Compared to ordinary gear pumps on the market, TOPSFLO gear pumps use high-precision gears and component control to ensure smooth flow, minimal pulsation, and adjustable output pressure stability.

TOPSFLO engineers can determine which pump is better suited for your application based on your printing requirements, including the desired flow rate, accuracy, pulsation, noise level, ink properties, and whether they contain solid particles, among other factors.

Long-lasting Lifetime for Stable Printing Assurance

Both Topsflo diaphragm pumps and gear pumps are equipped with high-performance brushless motors developed in-house.

The coreless brushless motor in the diaphragm pump boasts a lifespan of up to 15,000 hours, while the gear pump utilizes a high-performance, in-house designed and manufactured brushless three-phase motor with a lifespan exceeding 30,000 hours, requiring no maintenance.

These brushless motors do not produce sparks, static electricity, or electromagnetic interference during operation, ensuring safety and allowing the pumps to run continuously in high-demand inkjet printing tasks.

How to Get in Touch with TOPSFLO for Expert Assistance?

Maintaining a consistently stable flow and using ink fluids with the appropriate viscosity are crucial for overall printing quality. Any abnormalities in the ink supply system can lead to poor printing quality, error messages, and even costly product recalls. Therefore, choosing the right ink pump for your continuous inkjet printer is of utmost importance.

TOPSFLO specializes in the development and production of various micro pumps for printers. They have extensive experience and pump solutions, and they offer customized services to meet different customer needs. Please contact their sales engineers for printer pump application cases and pump information! Email: [email protected] or [email protected]

youtube

0 notes

Text

What are Industrial Inkjet Printing and Its Types?

Inkjet technology is the procedure where a print-head expels tiny drops of ink onto a substrate without the print-head essentially making any kind of physical contact. Dots of diverse colored inks combine to give photo-quality pictures.

The chief challenge lies in accomplishing a high level of accuracy and reliability. The dots are smaller than 70 microns and henceforth, the heads have to be placed accurately so as to attain good resolution and print quality.

This accuracy is only attained using a combination of science, technology and design. Although inkjet technology has been around since the 1950s, its application in an industrial milieu is being reconnoitered only recently.

Industrial inkjet ink printing systems are largely categorized into two categories i.e. continuous printing (CIJ) or drop on demand (DOD), with variants within each grouping. In the case of continuous inkjet technology, the drops are expelled constantly from the print-head, while in case of drop on demand inkjet printing technology; drops are emitted from the print-head only when needed.

In the instance of CIJ, a pump directs fluid from a reservoir onto one or more trivial nozzles, which emit a constant stream of drops at very high frequency. In the case of drop-on-demand technology, the drops are expelled only when needed. The drops are created when a pressure-pulse is made.

In one sub-variant named as thermal inkjet technology, drops are made by speedily heating the ink in a small chamber.Industrial inkjet printing technology is extensively used for coding and marking products and packages.

1 note

·

View note

Text

Inkjet Printing Pump | TOPSFLO Micro Diaphragm Pump Manufacturer

Background Introduction Inkjet printers, which are used to spray ink droplets onto a printing medium to form words or images. There are two main types of inkjet printing technology: continuous inkjet (CIJ) and on-demand inkjet. Continuous inkjet technology is mainly used in industrial and professional printing systems. On-demand inkjet is a random inkjet system in which ink is sprayed only when printing is needed, which has a relatively wider application range. Regardless of the type of inkjet printer, professional inkjet technology requires the perfect combination of all technical components to achieve the perfect printing effect.In order to achieve this goal, the micro diaphragm pumps plays a vital role.

The roles of diaphragm pumps in inkjet printing equipment - To vacuum and pressurize the feeding system; - Conveying water and solvent-based inks; - Refill ink container; - Remove excess ink from the print head and remove ink-breaking material for the storage tank; - Clean the print head and ink drain system.

TOPSFLO micro diaphragm pump series solutions TOPSFLO TM30, TM40, TF30 series diaphragm ink pumps are durable and reliable, can ensure maintenance-free continuous operation in arduous inkjet printers: 1. Lifetime up to 15,000 hours: independent design using high-performance coreless brushless motor, high quality rubber material of high purity and good wear resistance, long service life and maintenance free. 2. TOPSFLO diaphragm pump adopts precise configuration of pump head, diaphragm, valve, and the best matching design of each component, pump output flow is stable, pulsation is small and adjustable, output pressure is stable; The air pump can be pressurized stably and continuously. The positive pressure range is 10kpa to 280kpa, the negative pressure range is -10kpa to -95kpa, and the flow range is 2-17L/min.Parameters can be customized, and can be customized 5V/PWM frequency speed regulation. 3. According to the type of liquid, TOPSFLO provides different inkjet printer pump material configuration schemes: -- Pump head material: PA/PC/PP, etc. -- Diaphragm material: EPDM/PTFE, etc.; -- Valve disc material: EPDM/FKM/FFKM, etc. 4. TOPSFLO diaphragm ink printer pump brushless motor series has the characteristics of safety, energy saving, high efficiency and durability, the pump will not produce sparks, static electricity or electromagnetic interference in the process of work, no safety risks.

TOPSFLO has been deeply engaged in the field of micro pump for over 17 years, providing stable and reliable fluid transmission and control solutions. Micro diaphragm air pump and liquid pump have been widely used in leading printing enterprises in the United States, Italy, Japan, Britain, Australia, India and other countries. We will continue to break through and strive to provide more industries with high-quality products and solutions!

0 notes

Text

Coding & Marking Market - Forecast (2023 - 2028)

The Coding & Marking Market size is estimated to reach $9.3 billion by 2028, growing at a CAGR of 8.5% during the forecast period 2023-2028. The average continuous inkjet printer may apply codes to products moving at 1,000 feet per minute while thermal inkjet printers are typically restricted to about 300 feet per minute. Continuous inkjet printers release ink to print directly on a target and are therefore used to print on resins, metals and glasses. A laser printer utilizes a focused beam of light to transmit text and images onto paper. Thermal transfer overprinting (TTO) is a printing procedure that provides an alternative to hot stampers and additional conventional analog printing techniques. Inkjet bottle coders developed by LINX include continuous inkjet printers like Linx10 which can print up to 3 lines of text including symbols and numbers in excellent print quality. The growing application of continuous inkjet printers for printing on metals, resins and glasses is set to drive the Coding & Marking Market. The surging application of bottle coding is set to propel the growth of the Coding & Marking Industry during the forecast period 2023-2028. This represents the Coding & Marking Industry Outlook

Coding & Marking Market Report Coverage

The “Coding & Marking Market Report - Forecast (2023-2028)” by IndustryARC, covers an in-depth analysis of the following segments in the Coding & Marking Market.

by Technology Type: Drop-On-Demand (DOD), Continuous Inkjet (CIJ), Thermal Inkjet (TIJ), Thermal Transfer Overprinting (TTO), Laser Coding System, Large Character Marking (LCP), Label Print Applicator (LPA) and Others.

by End-use Industry:Healthcare & Pharmaceuticals, Personal Care & Toiletries, Food & Beverages, Electronics, Instrument & Machinery, Automotive & Aerospace, Chemicals & Materials and Others.

by Geography: North America (the US, Canada and Mexico), Europe (Germany, France, the UK, Italy, Spain, Russia and the Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and the Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and the Rest of South America) and the Rest of the World (the Middle East and Africa).

Request Sample

Key Takeaways

Geographically, Asia-Pacific (Coding & Marking market share) accounted for the highest revenue share in 2022 and it is poised to dominate the market over the period 2023-2028 owing to the increasing growth of the packaging industry involving continuous inkjet printers in the Asia-Pacific region, especially India.

The growth of the Coding & Marking Market is being driven by the surging application of continuous inkjet printers in the food, medicine and cosmetics industries. However, the soaring price of Coding and Marking devices is one of the major factors hampering the growth of the Coding & Marking Market.

Coding & Marking Market Detailed Analysis of the Strengths, Weaknesses and Opportunities of the prominent players operating in the market would be provided in the Coding & Marking Market report.

Coding & Marking Market Segment Analysis - by Technology Type

The Coding & Marking Market, based on technology type, can be further segmented into Drop-On-Demand (DOD), Continuous Inkjet (CIJ), Thermal Inkjet (TIJ), Thermal Transfer Overprinting (TTO), Laser Coding System, Large Character Marking (LCP), Label Print Applicator (LPA) and Others. The Continuous Inkjet (CIJ) Segment held the largest share of the Coding & Marking market in 2022. This growth is fueled by the surging application of continuous inkjet printers for placing barcodes directly onto products. The soaring application of continuous inkjet printers involving bottles and cans is further propelling the growth of the Continuous Inkjet (CIJ) segment. Furthermore, the Thermal Inkjet (TIJ) segment is estimated to grow at the fastest CAGR of 9.3% during the forecast period 2023-2028 owing to their capability to provide a cost-effective alternative for printing at quick speeds and enhanced quality.

Inquiry Before Buying

Coding & Marking Market Segment Analysis - by End-use Industry

The Coding & Marking Market, based on end-use industry, can be further segmented into Healthcare & Pharmaceuticals, Personal Care & Toiletries, Food & Beverages, Electronics, Instrument & Machinery, Automotive & Aerospace, Chemicals & Materials and Others. The Food And Beverages Segment held the largest share of the Coding & Marking market in 2022. This growth is fueled by the surging application of coding and marking techniques in food packaging to labeling products. The soaring adoption of high-quality codes and marks to effectively print information on food products is further propelling the growth of this segment. Furthermore, the Healthcare & Pharmaceuticals segment is estimated to grow at the fastest CAGR of 9.5% during the forecast period 2023-2028 due to the growing application of Coding and Marking equipment in the packaging of products like liquid and ointments in bottles.

Coding & Marking Market Segment Analysis - by Geography

Asia-Pacific (Coding & Marking Market) dominated the Coding & Marking market with a 35% share of the overall market in 2022. The growth of this region is driven by the soaring requirements for coding and marking systems in the Asia-Pacific region. The acceptance of high-technology coding and marking systems is further propelling the growth of the Coding & Marking Industry, thereby contributing to the Coding & Marking Industry Outlook, in the Asia-Pacific region. Furthermore, the Europe region is estimated to be the region with the fastest CAGR over the forecast period 2023-2028. This growth is owing to factors like the presence of binding regulatory agencies for the food and beverage industry in the European region. The existence of key pharmaceutical companies is further fueling the progress of the Coding & Marking Market in the European region.

Schedule a Call

Coding & Marking Market Drivers

Growing Benefits of Thermal Inkjet Printers:

The Ox-Series of Thermal Inkjet Printers generates clear-cut, high-contrast codes. Functioning at speeds of up to 300m/min, one may expect rub-, smudge- and scratch-resistant codes that endure handling, transport and post-print procedures. The Ox-Series is perfect not only for batch and data coding but also for complicated code formats. The Ox Series backs up to four print heads, which can be planted up to 25m from the controller. This makes it effortless to serve numerous production lines or to code every line item from numerous sides concurrently. The growing benefits of thermal inkjet printers are therefore fueling the growth of the Coding & Marking Market during the forecast period 2023-2028.

Vital Significance of Thermal Transfer Overprinting:

Thermal Transfer Overprinting (TTO) is a digital printing technology that surmounts numerous imperfections of analog printing solutions like hot stamp/hot foil and roller coders. Thermal Transfer Overprinting systems were developed particularly to mark directly on flexible film packaging and labels. Vertical form, fill and seal machines are utilized to package potato chips, nuts/grains and candy. The most recent technology in thermal transfer printing utilizes a minimal quantity of ribbon by ensuring a 0.5 mm gap between every print. The vital significance of thermal transfer overprinting is therefore driving the growth of the Coding & Marking Industry, thereby contributing to the Coding & Marking Industry Outlook during the forecast period 2023-2028.

Buy Now

Coding & Marking Market Challenges

Disadvantages of Laser Printers Like High Prices:

Videojet has developed a UV laser marking machine where the UV laser utilizes 0.355um wavelength to mark substrates. Laser printers are highly priced in comparison with inkjet printers. One needs more money to purchase color laser printers. The cost of toners is also soaring. Laser printers tend to consume greater power. Laser marking systems are restricted to moving on a two-dimensional plane and need the capability to process materials that have a great hardness or a low ignition point. These issues are thus hampering the growth of the Coding & Marking Market.

Coding & Marking Industry Outlook

Novel product launches, acquisitions, collaborations and R&D activities are key strategies adopted by players in the Coding & Marking Market. The top 10 companies in the Coding & Marking market are:

Danaher Corporation

Dover Corporation

Leibinger Group

Hitachi Industrial Equipment & Solutions America, LLC

Diagraph an ITW Company

Matthews Marking Systems

Inkjet Inc.

Overprint Limited

ID Technology LLC

ATD Marking Systems

Recent Developments

In January 2022, Markem-Imaje, the portion of Dover, declared the release of the novel 5940 G Touch DryTM high-resolution inkjet coder. The GS1-128 compliant system fits growing industry demands. These demands are targeted toward maintaining high-resolution barcodes, branding and text on corrugated packaging.

In June 2021, Danaher Corporation declared that they had entered into a definitive agreement to gain privately-held Aldevron. This was performed for a cash purchase price of nearly $9.6 billion. Danaher anticipates financing the acquisition using cash on hand.

In March 2020, Danaher Corporation declared the completion of its acquisition of the Biopharma business from General Electric Company's Life Sciences division. As a portion of Danaher, the business would be termed Cytiva. It would be a standalone operating firm within Danaher's Life Sciences segment.

For more Food and Beverage Market reports, please click here

#Coding & Marking Market#Coding & Marking Market Share#Coding & Marking Market Size#Coding & Marking Market Price

0 notes

Link

Linx Continuous Industrial Inkjet Printers

IJPN Technologies is an awarded Distributor, Supplier of Linx Printing Technology, Offer wide range of Printing, Coding & Laser Marking Technologies Solutions as per the industrial requirement, The Inkjet Printing offer by IJPN Technologies India(http://www.ijpntechnologies.com) include - Continuous Inkjet printers - Linx 5900 series continuous Inkjet Printer, Linx 7900 series continuous Inkjet Printer, Linx 8900 series continuous Inkjet Printer.

Inkjet laser Coder machine- inkjet batch coding machine, LINX SL 501, 50-WATT LASER CODER, LINX SL301 INDUSTRIAL LASER CODER, LINX SL1 COMPACT LASER CODER, LINX SL101 INDUSTRIAL LASER CODER, Linx FSL20 & FSL50.

Continuous ink & fluids supplier in New Delhi, India.

1 note

·

View note