#Continuous Inkjet Printer

Explore tagged Tumblr posts

Text

Experience the future of printing with our cutting-edge Continuous Inkjet (CIJ) Printer. Achieve superior quality, speed, and reliability in your printing tasks.

0 notes

Text

Printable laser-emitting droplets offer new display technology

Researchers at the University of Tsukuba have developed an innovative method for rapidly creating laser light sources in large quantities using an inkjet printer that ejects laser-emitting droplets. By applying an electric field to these droplets, the researchers demonstrated that switching the emission of light on and off is possible. Furthermore, they successfully created a compact laser display by arranging these droplets on a circuit board. The study is published in Advanced Materials. Displays for TVs, PCs, and smartphones are continually improving in picture quality, clarity, and energy efficiency. Laser displays are anticipated to represent the next-generation model. Particularly regarding brightness and color reproducibility, laser displays have the potential to overcome the intrinsic limitations of conventional light-emitting devices, such as OLEDs and liquid crystals.

Read more.

18 notes

·

View notes

Text

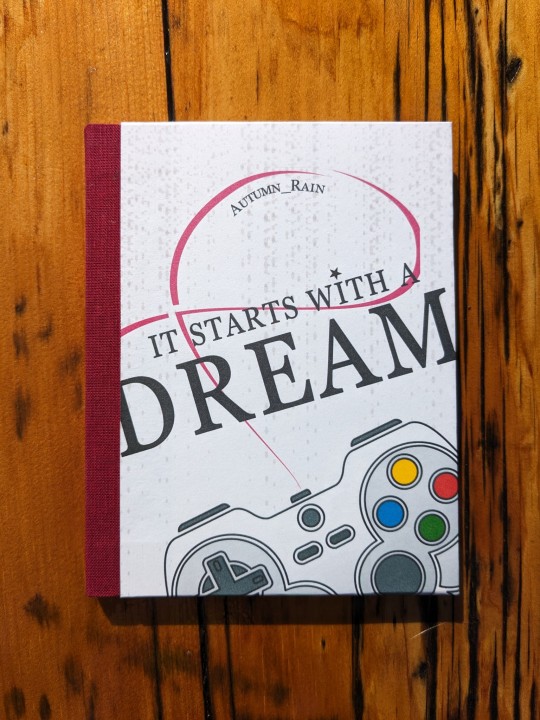

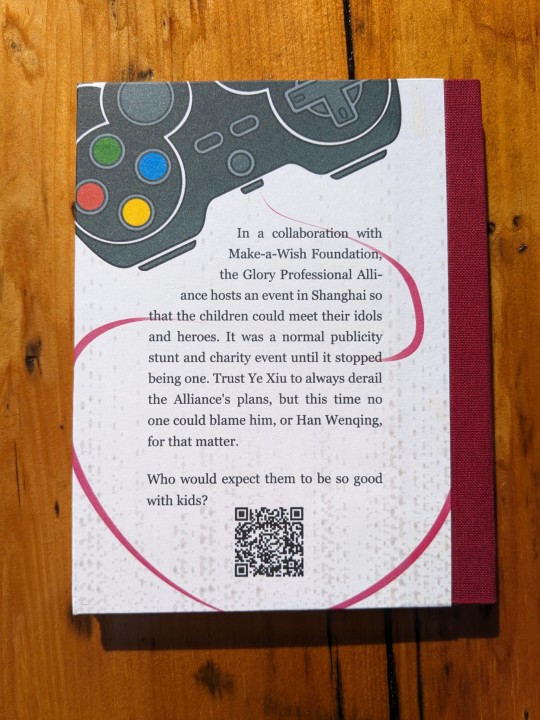

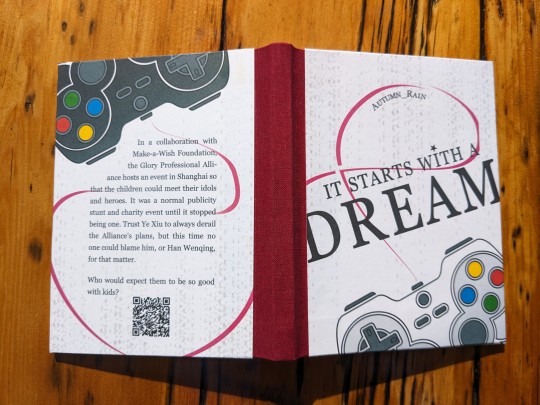

It Starts with a Dream by Autumn_Rain @ciaolongbao

Fandom: 全职高手 | The King's Avatar

Rating: General Audiences

Category: Gen

Words: 6 566

In a collaboration with Make-a-Wish Foundation, the Glory Professional Alliance hosts an event in Shanghai so that the children could meet their idols and heroes. It was a normal publicity stunt and charity event until it stopped being one. Trust Ye Xiu to always derail the Alliance's plans, but this time no one could blame him, or Han Wenqing, for that matter. Who would expect them to be so good with kids?

About the book:

FONTS: Crimson [Google Fonts], Roboto [Google Fonts], and Georgia

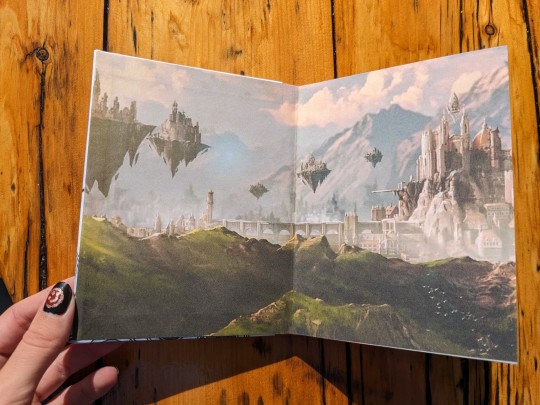

IMAGES: Equalizer background from Rawpixel (ID: 3119862); Gamepad icon (Image# 5358929) by pictranoosa on The Noun Project; Heavenly Domain image from The King’s Avatar Wikia.

MATERIALS: 20lb 96 bright 8½”×11”multiuse paper; 0.057" chipboard; Ruby red Iris Bookcloth; Neenah bright white 8½”×11” 65lb cardstock; 30/3 waxed linen thread; wheat paste (1:4 flour to water).

PROGRAMS USED: typeset in Affinity Publisher 2; cover designed with Affinity Designer 2 and Affinity Photo 2; imposed with Renegade's Community Imposer (settings: Quarto, snug against binding edge, signatures of 2 sheets).

Textblock printed with laser printer, covers printed with inkjet printer.

BINDING: Quarto size (quarter-letter, 4.25"x5.5"), sewn board binding with French-link stitch and breakaway spine.

Trying New Things 2: Electric Bugaloo!

Though it's not my first time making a quarto size book, it's my first sewn board binding and my first breakaway spine. Will not be my last. (I'm fact, as I'm writing this I've already bound another QZGS fic using this method!)

Much like Coptic, the sewn board binding technique bypasses the exact things I dread about making a case bound book: making the cover and casing in. Haven't gotten the hang of spines or hinges yet. Or pasting down the endpapers when casing in. (Art imitating life: my books aren't straight and neither am I lol)

Drumming things on (use of minimal glue, only on edges where necessary) is a lot less stressful and means there is less moisture to worry about. However I have my doubts about the structural integrity and longevity of sewn board binding when compared to case binding. With minimal glueing there's less holding it together, and the particular method of covering the boards means that they're partially exposed, in all their onion-y glory (by which I mean 🧅layers✨).

Onto the design:

The endpapers are an image of Glory's heavenly domain, acquired from The King's Avatar Wikia (I just cropped out the pro teams' logos, then resized and cropped to fit.)

The covers were designed as one image so that the contents will flow and connect from one cover to the other.

A major theme of this story, I felt, was connection: the kids are meeting their heroes; HWQ and YX stun everyone by connecting so well with the kids, playing with them, encouraging them, and inspiring them; YX opens up about his backstory and reveals a similar dream to a kid; that same kid going on to become a pro with New Excellent Era.

To pull some quotes from the story: "Everything started with a dream between friends… but now that dream will end with a legacy", "after all, you're never going to be walking alone. Glory has never been mean to be played alone", YX "[continued] inspiring new generations of gamers long after he had retired."

Following that theme of connection, the controllers on the covers are physically connected with a pinkish-red wire. For that I went with a red string of fate, thinking along the lines of fate and a love of Glory. The wire is also in the shape of a cancer awareness ribbon on the front cover (hence why the red is skewed pink).

The black and white controllers are like Player 1 & 2, and they're connected. To each other, to Glory.

I traced the gamepad icon with the pen tool in Affinity Designer, creating filled in curves of each component, for ease of recolouring and resizing without losing quality.

An equalizer background image, stretched and with low opacity, adds texture to the cover. It also reminded me of pixels from holograms. (The idea of the pros and kids' game playing out on stage with massive holograms really stuck with me).

I also wanted to directly reference Make-a-Wish in the cover design, so I looked up which font they use in the logo/branding. Search results turned up Georgia being used in relation to the brand, so I exclusively used that font on the covers. And added a little star above the 'i' in 'with', like in 'Wish' for the Make-a-Wish logo.

(also first attempt at nail art. Armed with a toothpick, I made Ye Xiu from The King's Avatar themed nails! 😾Sullen Kitten; 🌶️Unrivalled Super Hottie; ☂️Myriad Manifestations Umbrella; 🍁One Autumn Leaf; 😊Happy)

72 notes

·

View notes

Text

starter for @buriedwithit (soren)

"Once you've found your sum, you can then reference the ASCII table and locate the letter or number the bit represents," Toby continues, offering the piece of paper with the table reference he'd drawn a few moments prior, the image pictured composed from a series of lines similar to an inkjet printer. His tone is formal yet approachable, well-suited for academic purposes, but he's aware that his pupil doesn't hear it: instead, Toby inputs all of his instructions again on the communicator positioned between them on the table, making sure that he provides ample time for the information to sink in. "Using this method for each 8-character string of bits - or, bytes - any binary message can be easily translated."

Toby takes a moment to print a string of binary on a blank sheet of paper, then, sliding it across to Soren. "Would you like to try and translate this binary message?"

#armastart#toby and soren#if you see smoke its because my brain has overheated and gone up in flames#writing this post felt like running a marathon

3 notes

·

View notes

Text

Domino Presents New Monochrome Inkjet Printer at Labelexpo Southeast Asia 2025

Domino Printing Sciences (Domino) is pleased to announce the APAC launch of its new monochrome inkjet printer, the K300, at Labelexpo Southeast Asia. Building on the success of Domino’s K600i print bar, the K300 has been developed as a compact, flexible solution for converters looking to add variable data printing capabilities to analogue printing lines.

The K300 monochrome inkjet printer will be on display at the Nilpeter stand, booth F32, at Labelexpo Southeast Asia in Bangkok, Thailand from 8th–10th May 2025. The printer will form part of a Nilpeter FA-Line 17” hybrid label printing solution, providing consistent inline overprint of serialised 2D codes. A machine vision inspection system by Domino Company Lake Image Systems will validate each code to ensure reliable scanning by retailers and consumers whilst confirming unique code serialisation.

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,” explains Alex Mountis, Senior Product Manager at Domino. “Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands. We have developed the K300 with these variable data and 2D code printing opportunities in mind.”

The K300 monochrome inkjet printer can be incorporated into analogue printing lines to customise printed labels with variable data, such as best before dates, batch codes, serialised numbers, and 2D codes. The compact size of the 600dpi high-resolution printhead – 2.1″ / 54mm – offers enhanced flexibility with regards to positioning on the line, including the opportunity to combine two print stations across the web width to enable printing of two independent codes.

Operating at high speeds up to 250m / 820′ per minute, the K300 monochrome inkjet printer has been designed to match flexographic printing speeds. This means there is no need to slow down the line when adding variable data. Domino’s industry-leading ink delivery technology, including automatic ink recirculation and degassing, helps to ensure consistent performance and excellent reliability, while reducing downtime due to maintenance. The printer has been designed to be easy to use, with intuitive setup and operation via Domino’s smart user interface.

“The K300 will open up new opportunities for converters. They can support their brand customers with variable data 2D codes, enabling supply chain traceability, anti-counterfeiting, and consumer engagement campaigns,” adds Mountis. “The versatile printer can also print variable data onto labels, cartons, and flatpack packaging as part of an inline or near-line late-stage customisation process in a manufacturing facility, lowering inventory costs and reducing waste.”

Code verification is an integral part of any effective variable data printing process. A downstream machine vision inspection system, such as the Lake Image Systems’ model showcased alongside the K300, enables converters and brands who add 2D codes and serialisation to labels and packaging to validate each printed code.

Mark Herrtage, Asia Business Development Director, Domino, concludes: “We are committed to helping our customers stay ahead in a competitive market, and are continuously working to develop new products that will help them achieve their business objectives. Collaborating with Lake Image Systems enables us to deliver innovative, complete variable data printing and code verification solutions to meet converters’ needs. We are delighted to be able to showcase an example of this collaboration, featuring the .”

To find more information about the K300 monochrome printer please visit: https://dmnoprnt.com/38tcze3r

#inkjet printer#variable data printing#biopharma packaging#glass pharmaceutical packaging#pharmaceutical packaging and labelling#Labelexpo Southeast Asi

2 notes

·

View notes

Note

Well I could ofc just look it up, but if you have the time could you continue to explain the differ e between inkjet and laserjet printers? Sounds good to know if I'm gonna make stickers :]

HI so I work at a print store so I have very specific and unclear knowledge on things In regards to stickers, we default to either using our in store labels or recommending that customers buy Avery brand labels from one of the aisles. With the Avery brand, the website comes with templates for each label type they sell, so you'd be able to just upload a design to the website and download the formatted version that will print correctly on the sheets that you buy. The website will try to trick you into buying the labels from them, don't do that unless you just wanna skip the hassle of printing all together.

In regards to Inkjet vs LaserJet, whatever paper you buy will have a warning or something saying "Inkjet compatible" or "LaserJet compatible", or the paper will be fine on both. it depends on what printer you have and what works best for you! If you own a printer, and you buy small ink cartridges for it, then you have an Inkjet printer. These are straightforward, the ink is spit right onto the page and then dries. If you own a printer and you buy big Toner cartridges (these are filled with colored powder that will Always get on your hands), they are LaserJet. This means that the powder is stuck to the page with some tech I don't really understand but let's pretend lasers are zapping those bad boys to make the colors stick to the paper.

#angel talks#me staring at these paragraphs: wow i need to stop working at this store this is all knowledge i've learned against my will-#anyways i hope this helped? haha

9 notes

·

View notes

Text

DTF Transfer Printing for Beginners: A Comprehensive Guide to Printing DTF Transfers at Home

As custom apparel and personalized items continue to gain popularity, creative enthusiasts are looking for efficient and affordable ways to produce high-quality prints from the comfort of their homes. Direct-to-Film (DTF) transfer printing has emerged as an accessible and versatile method for producing vibrant designs on various surfaces, especially textiles. DTF printing offers the advantage of application on a range of materials while maintaining exceptional color fidelity and detail. This article will introduce beginners to the DTF printers printing process, the equipment and materials needed, step-by-step instructions for printing transfers at home, tips for successful application, and the benefits of incorporating DTF printing into your crafting repertoire.

Understanding DTF Transfer Printing

DTF transfer printing is a relatively new technology that combines elements from both Direct-to-Garment (DTG) and traditional heat transfer methods. DTF printing involves printing designs onto a special film using specific inks that offer excellent adhesion and durability. The printed film is then coated with a layer of adhesive powder, which, when heated, bonds securely to the fabric. This process differentiates DTF from other transfer methods, providing vibrant prints, the ability to work with a wide variety of fabrics, and ease of application. For beginners, understanding the mechanics of DTF printing is essential for achieving high-quality results and exploring the potential of this versatile printing method.

Equipment and Materials Needed

To embark on your DTF printing journey, you'll need a collection of essential equipment and materials. The primary equipment required is a DTF printer, specifically an inkjet printer that can accommodate DTF transfer films. You’ll also need DTF inks, which are specifically formulated for this printing process, along with adhesive powder that helps form a strong bond between the transfer and fabric. Other necessary items include DTF transfer film, heat press, a weeding tool for removing excess film, and protective sheets to place between the fabric and heat press for safe application. While it may seem like a considerable investment upfront, many of these items can be purchased gradually as you become more comfortable with the process.

Step-by-Step Process for Printing DTF Transfers

Once you have gathered the necessary equipment and materials, the process of printing DTF transfers can begin.

1. Design Creation: Start by creating your design using graphic design software (like Adobe Illustrator or CorelDRAW) or purchasing premade designs. Ensure your design is in a compatible format and sized appropriately for your project.

2. Printing: Load the DTF transfer film into your printer. Print your design, ensuring to set it for "mirror" mode so that the image transfers correctly when applied to the fabric.

3. Adhesive Application: Once printed, sprinkle the adhesive powder evenly onto the wet ink immediately after printing. Gently shake off any excess powder.

4. Curing: Use a heat source, such as a heat press, to cure the transfer. This generally involves setting the heat press to a specific temperature (around 160-180°C) and applying even pressure for roughly 20-30 seconds. This step helps melt the adhesive powder into the print.

5. Weeding: Allow the transfer to cool, then weed out the unwanted areas of the film using a weeding tool, leaving you with your desired design.

6. Pressing on Fabric: Place your fabric on the heat press, position the transfer film (ink side down), apply the heat press again for another 10-15 seconds, and then let it cool before peeling off the film backing.

Tips for Successful DTF Transfers

To achieve the best results with DTF transfer printing, several tips can help ensure success. Begin by investing time in acclimating yourself to the equipment and practicing with various designs and fabrics. Experiment with different print settings, as printing at the right resolution and using suitable profiles for DTF printing can significantly influence the final output. It's also important to use high-quality DTF films and inks, as these will directly affect the vibrancy and durability of your prints. Lastly, always remember to conduct washing tests on fabric after the initial applications; this will provide insight into the longevity and durability of your DTF transfers and help you adjust your processes accordingly.

Benefits of DTF Printing for DIY Enthusiasts

For those interested in custom apparel, DTF transfer printing offers multiple benefits. One significant advantage is its versatility; DTF printing can be applied to a wide range of fabrics, including cotton, polyester, and blends. This flexibility enables crafters to experiment with different materials and styles without being restricted to specific substrates. Additionally, DTF transfers deliver vibrant colors and intricate details, making them ideal for creating striking designs on clothing. The process is also relatively straightforward compared to other printing methods, often requiring less upfront investment and offering rapid turnaround times for small batch production. Overall, DTF printing not only encourages creativity but also offers an efficient way to produce high-quality custom items.

Final Thought

In summary, DTF transfer printing provides an exciting opportunity for beginners and craft enthusiasts to produce professional-quality prints from home. By understanding the mechanics behind the process, gathering the right equipment, and following the steps outlined, you can start your venture into the world of custom printing today. Embrace the versatility and ease of DTF printing to create personalized apparel and accessories that reflect your unique style. As you gain experience and confidence, your creative possibilities will expand, allowing you to explore the full potential of DTF transfer printing. So grab your supplies, start experimenting, and watch your designs come to life through this innovative medium!

6 notes

·

View notes

Text

VIDEOJET PRINTING INK Compatibility with Modern Coding Technologies

In today’s fast-paced industrial environment, reliable coding and marking solutions are essential for maintaining efficiency, compliance, and product traceability. One of the leading names in this space is VIDEOJET PRINTING INK, known for its outstanding performance across a wide range of production needs. As modern coding technologies continue to evolve, the compatibility of VIDEOJET PRINTING INK with these advanced systems plays a crucial role in enhancing operational workflows and ensuring high-quality output.

Let’s explore how VIDEOJET PRINTING INK seamlessly integrates with modern coding technologies and why it remains a preferred choice across industries.

Meeting the Demands of Evolving Coding Systems

Modern coding technologies have rapidly advanced to support higher production speeds, diverse substrates, and more stringent compliance requirements. Whether it's continuous inkjet (CIJ), thermal inkjet (TIJ), laser marking, or large character printing (LCP), every technology demands ink formulations that are optimized for specific applications.

VIDEOJET PRINTING INK is designed with compatibility in mind. It works effectively across multiple coding systems, especially with CIJ and TIJ printers, which are widely used in industries like food & beverage, pharmaceuticals, cosmetics, and electronics. Its superior adhesion properties and quick-drying characteristics make it suitable for a variety of materials such as glass, plastic, cardboard, and metals — all without compromising print clarity.

Precision and Consistency Across Substrates

The success of any modern coding solution relies heavily on consistent, legible prints — even on complex or irregular surfaces. VIDEOJET PRINTING INK is specially formulated to deliver high-contrast codes on challenging substrates, including slick plastic bottles, coated cartons, and flexible packaging.

For instance, when used with thermal inkjet printers, VIDEOJET PRINTING INK can produce high-resolution prints suitable for detailed information like QR codes, barcodes, and batch numbers. This level of precision ensures products meet regulatory and supply chain requirements without costly rework or delays.

Compatibility with Automation and Smart Production Lines

As Industry 4.0 and smart manufacturing trends continue to reshape factories, VIDEOJET PRINTING INK proves its adaptability by integrating seamlessly with automated systems. Today’s coding technologies often feature built-in software for remote monitoring, predictive maintenance, and real-time data tracking.

Whether integrated into robotic arms or smart conveyors, VIDEOJET-compatible printers and ink cartridges can work in sync with automated lines to minimize downtime and improve traceability. The chemical stability of VIDEOJET PRINTING INK ensures that the ink does not dry out or clog the printer even during extended idle times — a key advantage in automated environments.

Supporting Eco-Friendly and Regulatory Needs

Sustainability and compliance have become top priorities in modern manufacturing. VIDEOJET PRINTING INK is available in a range of formulations, including low-VOC (Volatile Organic Compounds) and MEK-free options, making it environmentally safer while still delivering strong performance.

Moreover, these inks comply with international safety and packaging regulations, including FDA, RoHS, and REACH standards, making them ideal for food, beverage, and pharmaceutical packaging. Modern coding technologies often come equipped with ink usage monitoring features, and VIDEOJET’s efficient ink formulations help reduce waste and operating costs over time.

Easy Integration with a Wide Range of Printers

One of the greatest strengths of VIDEOJET PRINTING INK is its wide printer compatibility. It is engineered to work perfectly with Videojet’s own series of printers, including the popular 1000 Line CIJ printers, 8510 TIJ printers, and more. This ensures plug-and-play functionality and optimal performance from the first print to the last.

For companies using a mix of legacy and new printing equipment, the versatility of VIDEOJET PRINTING INK provides a unified solution without the need for multiple ink inventories. This not only simplifies operations but also reduces maintenance and training time for machine operators.

Why Manufacturers Trust VIDEOJET PRINTING INK

Manufacturers around the globe rely on VIDEOJET PRINTING INK for its unmatched reliability, durability, and adaptability. Whether it's high-speed bottling lines or precise electronics labeling, this ink continues to deliver consistent results that keep operations running smoothly.

At SH HITECH SOLUTIONS, we understand how critical it is to choose the right ink for the right technology. That’s why we recommend VIDEOJET PRINTING INK for businesses looking to future-proof their production lines with high-performance, compatible ink solutions.

Final Thoughts

As coding technologies become smarter, faster, and more complex, the demand for high-performance inks that can keep up has never been greater. VIDEOJET PRINTING INK rises to the challenge, offering exceptional compatibility with modern coding technologies, from CIJ to TIJ and beyond.

For manufacturers seeking to streamline operations, maintain compliance, and ensure reliable product identification, VIDEOJET PRINTING INK remains a leading solution that supports both today’s needs and tomorrow’s innovations.

0 notes

Text

Researchers at University of Tsukuba have developed an innovative method for rapidly creating laser light sources in large quantities using an inkjet printer that ejects laser-emitting droplets. By applying an electric field to these droplets, the researchers demonstrated that switching the emission of light on and off is possible. Furthermore, they successfully created a compact laser display by arranging these droplets on a circuit board. Displays for TVs, PCs, and smartphones are continually improving in picture quality, clarity, and energy efficiency. Laser displays are anticipated to represent the next-generation model. Particularly regarding brightness and color reproducibility, laser displays have the potential to overcome the intrinsic limitations of conventional light-emitting devices, such as OLEDs and liquid crystals. However, to be effectively used as displays, the components must be miniaturized beyond current levels and laid out in high density and large quantities.

Read more.

#Materials Science#Science#Inkjet printing#Ink#Lasers#Liquids#Electric fields#Organic materials#Optics#University of Tsukuba

5 notes

·

View notes

Text

How to ‘Print Then Cut’ on Cricut? (Complete Tutorial)

If you use a Cricut machine, regardless of whether you are a hobbyist or a professional crafter, there is a very high possibility that you have heard about the feature named “Print Then Cut.” But have you ever wondered, “What is Print Then Cut in Cricut?” or “How to Print Then Cut on Cricut” If yes, but you couldn’t find the exact answer, then this guide is just for you because we will explore the Print Then Cut feature in this guide. So, without further delay, let’s dive into this.

What Is the Print Then Cut Feature?

Print Then Cut is a feature that allows you to create designs in Cricut Design Space and then print those on your home printer. Later, load the prints into your Cricut machine (Explore, Maker, or Venture) for cutting. The machine automatically scans your print or marker through the sensors. Lastly, cut them with precision to achieve accurate and clean results. This feature is very useful if your process is handled correctly, allowing you to create a variety of products like stickers, toppers, and other cutouts.

Requirements to Use the Print Then Cut Feature

If you are fascinated by the Cricut Print Then Cut feature, then continue reading because, in this section, you’ll learn what things and standards you have to meet to use the Print Then Cut feature.

1. A Smart Compatible Cricut Cutting Machine

Before you begin practicing Print Then Cut, first make sure the machine you are using is compatible with the Print Then Cut feature. For reference, here are some Cricut series names:

2. A Smart Compatible Printer

Select a fully functional printer model. However, there is no such obligation to choose or prefer any of the specific ones. But here are some tips for choosing a printer that will work for you:

Inkjet Printer (Recommended)

Laser Printers

3. Suitable Printable Materials

How to Setup Print Then Cut in Cricut Design Space

After understanding the materials required, let’s move on to creating a project with Print Then Cut:

Step 1: Design Template in Cricut Software

Step 2: Print Your Design

Step 3: Load and Cut the Selected Design

Troubleshooting Tips for Print Then Cut

Here are some troubleshooting tips if you are facing any issues during the use of the feature:

Conclusion

Print Then Cut is a powerful feature that opens up new possibilities for using the Cricut machine. It’s an easy way to print externally and cut with a Cricut machine. In the end, we hope you find this guide helpful and informative for learning “How to Print Then Cut on Cricut” Use the guided instructions to complete the Print Then Cut process on your own without any hassle. However, if you still

encounter any problems, we recommend reaching out to us. We are professionals who are dedicated to ensuring every individual achieves a seamless experience with the Cricut machine.

Frequently Asked Questions (FAQs)

How to Flip Text in Cricut Design Space?

Check out the steps given below to flip your text in Cricut Design Space:

How to Contour in Cricut Design Space?

To contour in Cricut Design Space, follow these steps:

How to Import an Image From Google to Cricut Design Space?

Learn how to transfer an image from Google to Cricut Design Space, consider the following steps:

Visit: cricut.com/setup

Source: https://cricutmakermachines.com/how-to-print-then-cut-on-cricut-complete-tutorial/

#PrintThenCutonCricut#cricutcomsetup#installcricutdesignspaceapp#wwwcricutcomsetuplogin#cricutcreateconnecttocomputer#cricutnewproductsetup#settingupmycricutmaker#connectingcricutmakertocomputer#cricutsetupcreateaccount#cricutcuttingmachinesetup#cricutsetuponcomputer#settingupnewcricutmaker#cricutsetuplogin#cricutaccountsetup#cricutcomsetupdownload#cricutinstallsetup#cricutprintersetup

0 notes

Text

this is hilarious:

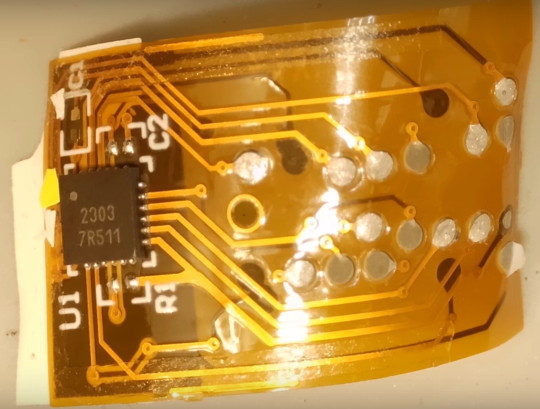

Despite harsh legal penalties and the vast resources of HP, third-party ink continues to thrive, and every time HP figures out how to block one technique, three even cooler ones pop up. Last week, Jay Summet published a video tearing down a third-party ink cartridge compatible with an HP 61XL:

youtube

The third-party cartridge has what appears to be a genuine HP security chip, but it is overlaid with a paper-thin, flexible, adhesive-backed circuit board that is skinny enough that the cartridge still fits in an HP printer. This flexible circuit board has its own little microchip. Summet theorizes that it is designed to pass the "are you a real HP cartridge" challenge pass to the security chip, but to block the followup "are you empty or full?" message. When the printer issues that challenge, the "man in the middle" chip answers, "Oh, I'm definitely full." In their writeup, Hackaday identifies the chip as "a single IC in a QFN package." This is just so clever and delightful:

A sexy, skinny defeat device for your HP ink cartridge

Animals keep evolving into crabs; it's a process called "carcinisation" and it's pretty weird. Crabs just turn out to be extremely evolutionarily fit for our current environment:

https://www.scientificamerican.com/article/why-do-animals-keep-evolving-into-crabs/

By the same token, all kinds of business keep evolving into something like a printer company. It turns out that in this enshittified, poorly regulated, rentier-friendly world, the parasitic, inkjet business model is extremely adaptive. Printerinisation is everywhere.

All that stuff you hate about your car? Trapping you into using their mechanics, spying on you, planned obsolescence? All lifted from the inkjet printer business model:

https://pluralistic.net/2023/07/24/rent-to-pwn/#kitt-is-a-demon

That GE fridge that won't make ice or dispense water unless you spend $50 for a proprietary charcoal filter instead of using a $10 generic? Pure printerism:

https://pluralistic.net/2020/06/12/digital-feudalism/#filtergate

The software update to your Sonos speakers that makes them half as useful and takes away your right to play your stored music, forcing you to buy streaming music subscriptions? Straight out of the HP playbook:

https://www.wired.com/story/sonos-admits-its-recent-app-update-was-a-colossal-mistake/

But as printerinized as all these gadgets are, none can quite attain the level of high enshittification that the OG inkjet bastards attain on a daily basis. In the world championships of effortlessly authentic fuckery, no one can lay a glove on the sociopathic monsters of HP.

For example: when HP wanted to soften us all up for a new world of "subscription ink" (where you have to pre-pay every month for a certain number of pages' worth of printing, which your printer enforces by spying on you and ratting you out to HP over the internet), they offered a "lifetime subscription" plan. With this "lifetime" plan, you paid just once and your HP printer would print out 15 pages a month for so long as you owned your printer, with HP shipping you new ink every time you ran low.

Well, eventually, HP got bored of not making you pay rent on your own fucking printer, so they just turned that plan off. Yeah, it was a lifetime plan, but the "lifetime" in question was the lifetime of HP's patience for not fucking you over, and that patience has the longevity of a mayfly:

https://pluralistic.net/2020/11/06/horrible-products/#inkwars

It would take many pages to list all of HP's sins here. This is a company that ships printers with half-full ink cartridges and charges more than the printer cost to buy a replacement set. The company that won't let you print a black-and-white page if you're out of yellow ink. The company that won't let you scan or send a fax if you're out of any of your ink.

They make you "recalibrate" your printer or "clean your heads" by forcing you to print sheets of ink-dense paper. They also refuse to let you use your ink cartridges after they "expire."

HP raised the price of ink to over $10,000 per gallon, then went to war against third-party ink cartridge makers, cartridge remanufacturers, and cartridge refillers. They added "security chips" to their cartridges whose job was to watch the ink levels in your cartridge and, when they dip below a certain level (long before the cartridge is actually empty), declare the cartridge to be dry and permanently out of use.

Even if you refill that cartridge, it will still declare itself to be empty to your printer, which will therefore refuse to print.

Third party ink companies have options here. One thing they could do is reverse-engineer the security chip, and make compatible ones that say, "Actually, I'm full." The problem with this is that laws like Section 1201 of the Digital Millennium Copyright Act (DMCA) potentially makes this into a felony punishable by a five-year prison sentence and a $500k fine, for a first offense.

DMCA 1201 bans bypassing "an effective means of access control" to a copyrighted work. So if HP writes a copyrighted "I'm empty" program for its security chip and then adds some kind of access restriction to prevent you from dumping and reverse-engineering that program, you can end up a felon, thanks to the DMCA.

Another countermove is to harvest security chips out of dead cartridges that have been sent overseas as e-waste (one consequence of HP's $10,000/gallon ink racket is that it generates mountains of immortal, toxic e-waste that mostly ends up poisoning poor countries in the global south). These can be integrated into new cartridges, or remanufactured ones.

In practice, ink companies do all of this and more, and total normie HP printer owners go to extremely improbable lengths to find third party ink cartridges and figure out how to use them. It turns out that even people who find technology tinkering intimidating or confusing or dull can be motivated to learn and practice a lot of esoteric tech stuff as an alternative to paying $10,000/gallon for colored water.

HP has lots of countermoves for this. One truly unhinged piece of fuckery is to ask Customs and Border Patrol to block third-party ink cartridges with genuine HP security chips that have been pried loose from e-waste shipments. HP claims that these are "counterfeits" (because they were removed and re-used without permission), even though they came out of real HP cartridges, and CBP takes them at their word, seizing shipments.

Even sleazier: HP pushes out fake security updates to its printers. You get a message telling you there's an urgent security update, you click OK, and your printer shows you a downloading/installing progress bar and reboots itself. As far as you can tell, nothing has changed. But these aren't "security" updates, they're updates that block third-party ink, and HP has designed them not to kick in for several months. That way, HP owners who get tricked into installing this downgrade don't raise hell online and warn everyone else until they've installed it too, and it's too late:

https://www.eff.org/deeplinks/2020/11/ink-stained-wretches-battle-soul-digital-freedom-taking-place-inside-your-printer

This is the infectious pathogen business model: one reason covid spread so quickly was that people were infectious before they developed symptoms. That meant that the virus could spread before the spreader knew they had it. By adding a long fuse to its logic bomb, HP greatly increases the spread of its malware.

But life finds a way. $10,000/gallon ink is an irresistible target for tinkerers, security researchers and competitors. Necessity may be the mother of invention, but the true parent of jaw-dropping ingenuity is callous, sadistic greed. That's why America's army of prisoners are the source of so many of the most beautiful and exciting forms of innovation seen today:

https://pluralistic.net/2021/06/09/king-rat/#mother-of-invention

Despite harsh legal penalties and the vast resources of HP, third-party ink continues to thrive, and every time HP figures out how to block one technique, three even cooler ones pop up.

Last week, Jay Summet published a video tearing down a third-party ink cartridge compatible with an HP 61XL:

https://www.youtube.com/watch?v=h0ya184uaTE

The third-party cartridge has what appears to be a genuine HP security chip, but it is overlaid with a paper-thin, flexible, adhesive-backed circuit board that is skinny enough that the cartridge still fits in an HP printer.

This flexible circuit board has its own little microchip. Summet theorizes that it is designed to pass the "are you a real HP cartridge" challenge pass to the security chip, but to block the followup "are you empty or full?" message. When the printer issues that challenge, the "man in the middle" chip answers, "Oh, I'm definitely full."

In their writeup, Hackaday identifies the chip as "a single IC in a QFN package." This is just so clever and delightful:

https://hackaday.com/2024/09/28/man-in-the-middle-pcb-unlocks-hp-ink-cartridges/

Hackaday also notes that HP CEO Enrique J Lores recently threatened to brick any printer discovered to be using third-party ink:

https://arstechnica.com/gadgets/2024/01/hp-ceo-blocking-third-party-ink-from-printers-fights-viruses/

As William Gibson famously quipped, "the future is here, it's just not evenly distributed." As our enshittification-rich environment drives more and more companies to evolve into rent-seeking enterprises through printerinisation, HP offers us a glimpse of the horrors of the late enshittocene.

It's just as Orwell prophesied: "If you want a picture of the future, imagine a HP installing malware on your printer to force you to spend $10,000/gallon on ink – forever."

Tor Books as just published two new, free LITTLE BROTHER stories: VIGILANT, about creepy surveillance in distance education; and SPILL, about oil pipelines and indigenous landback.

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2024/09/30/life-finds-a-way/#ink-stained-wretches

Image: Jay Summet https://www.youtube.com/watch?v=h0ya184uaTE

4K notes

·

View notes

Text

Comprehensive Study of the Global Coding and Marking Equipment Industry

The global coding and marking equipment market was valued at USD 17.53 billion in 2024, and it is anticipated to grow at a compound annual growth rate (CAGR) of 6.1% from 2025 to 2030. This projected growth is largely attributed to the increasing emphasis on product traceability across several key industrial sectors, including food and beverage, pharmaceuticals, cosmetics, and electronics. The demand for advanced coding and marking systems is further fueled by the implementation of stringent regulatory frameworks related to product labeling, safety, and quality standards. These regulations compel manufacturers to adopt more sophisticated, accurate, and efficient identification technologies.

One of the main catalysts driving this market expansion is the continuous innovation in coding technologies, particularly the development and adoption of laser marking systems and Thermal Inkjet (TIJ) solutions. These advancements are closely aligned with the broader trend of automation in manufacturing and packaging processes, enabling companies to improve throughput, reduce human error, and streamline operations.

The evolution of coding and marking technologies has significantly enhanced the ability of companies to achieve greater operational efficiency and cost-effectiveness. Advanced systems with high-precision capabilities—such as laser coding, Thermal Inkjet (TIJ), Continuous Inkjet (CIJ), and thermal transfer technologies—are playing a pivotal role in ensuring accurate, durable, and compliant labeling across a wide variety of substrates and materials. These technologies are indispensable in sectors such as food and beverage, pharmaceuticals, cosmetics, electronics, automotive, logistics, and packaging. Their applications include product identification, traceability, regulatory compliance labeling, date coding, and batch numbering, all of which are essential for maintaining high standards in quality control, safety assurance, and anti-counterfeiting measures.

Businesses, especially leading players in manufacturing and supply chains, are increasingly integrating these technologies to enhance operational productivity, reduce labeling errors, and optimize supply chain logistics. By adopting modern coding and marking systems, companies are better equipped to respond to evolving regulatory requirements and customer expectations for transparency and traceability.

For instance, in September 2024, Domino Printing Sciences, a well-recognized name in the coding and marking sector, introduced a new high-speed laser coding system designed specifically for the packaging industry. This advanced technology delivers precise, consistent coding across a range of materials while simultaneously reducing operational costs. It enables companies—particularly those operating in heavily regulated markets—to maintain high levels of compliance, productivity, and cost efficiency.

Moreover, increasing public and private sector investments in research and development (R&D) across key regions such as North America, Europe, and Asia Pacific are contributing to the rapid advancement of coding and marking technologies. Initiatives such as the U.S. National Innovation Strategy and Germany’s Industry 4.0 program are designed to support digital transformation and technological innovation, creating a favorable environment for market growth. As these technologies continue to evolve, organizations benefit from enhanced traceability, improved regulatory compliance, and strengthened product authentication, all of which contribute to the overall expansion and resilience of the coding and marking equipment market.

Get a preview of the latest developments in the Coding And Marking Equipment Market? Download your FREE sample PDF copy today and explore key data and trends

Detailed Segmentation:

Product Insights

The Continuous Inkjet (CIJ) printer segment led the coding and marking equipment industry in 2024, accounting for 32.3% of the revenue. Known for their non-contact, high-speed coding capabilities, CIJ printers support versatile, reliable marking across high-volume production lines.

End Use Insights

In 2024, the food and beverage sector dominated the coding and marking equipment market, driven by stringent safety standards required for online and retail channels. Reliable coding systems facilitate clear labeling of expiration dates, batch numbers, and traceability, which is essential for brand protection and differentiation.

Regional Insights

North America led the global coding and marking equipment market in 2024 with a revenue share of 30.9%, driven by continuous R&D, a growing manufacturing base, and the presence of established coding technology providers. Stringent regulatory standards in pharmaceuticals, food & beverage, and automotive industries fuel the demand for precise, reliable coding solutions in the region.

Key Coding And Marking Equipment Company Insights

Some key companies in the coding and marking equipment industry are Danaher Corporation, Hitachi Ltd., and ProMach Inc. Major market participants are adopting strategies such as innovation, enhanced focus on R&D activities, expansions, portfolio enhancements, partnerships, and collaborations to address growing competition and rising technology adoption.

Danaher Corporation offers a comprehensive range of precision coding and marking solutions through subsidiaries like Videojet and Linx, targeting various industries, such as pharmaceuticals, food & beverage, and manufacturing. Known for high-performance inkjet, laser, and thermal transfer technologies, Danaher’s solutions support compliance, traceability, and product authentication with advanced data integration features.

Hitachi Ltd. delivers reliable coding and marking systems, including continuous inkjet and laser solutions tailored for high-speed production in the automotive, electronics, and consumer goods sectors. With a strong focus on innovation, Hitachi integrates IoT-enabled and automation features to enhance traceability and operational efficiency in large-scale manufacturing.

Key Coding And Marking Equipment Companies:

The following are the leading companies in the coding and marking equipment market. These companies collectively hold the largest market share and dictate industry trends.

Danaher Corporation

Domino Printing Sciences plc

Comp3

Hitachi Ltd.

Markem-Imaje Group

Matthews International Corporation

Leibinger Group

REA Elektronik GmbH

ProMach Inc.

Koenig & Bauer Coding GmbH

HSA Systems A/S

Recent Developments

In September 2024, Domino Printing Sciences launched the K300, a compact monochrome inkjet printer, at Labelexpo Americas. Designed for high-speed variable data printing, it integrates easily into existing lines, enabling label customization with QR codes and batch information. The K300 will be featured alongside a code verification solution from Lake Image Systems, meeting the rising demand for 2D codes in packaging.

In April 2024, Markem-Imaje launched the MW2160P, a versatile opaque white ink for extruded products like PVC and rubber, compatible with its 9750+ CIJ printers. This durable ink offers strong visibility and adhesion, resisting bending and water exposure, making it ideal for demanding industrial applications. Nicknamed the “Swiss Army Knife” of CIJ inks, it ensures reliable print quality across various substrates.

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

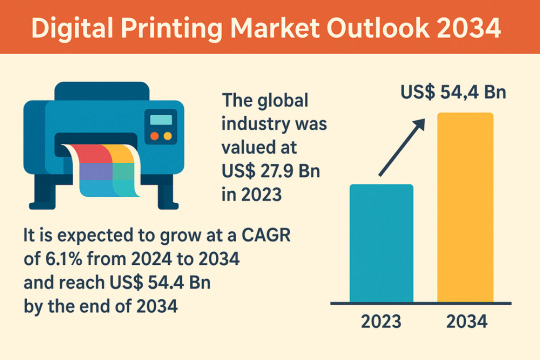

Digital Printing Market to Reach $54.4 Billion by 2034 Amid Rising Demand for On-Demand Solutions

The global digital printing market reached a valuation of US$ 27.9 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.1% between 2024 and 2034, culminating in a market worth US$ 54.4 billion by December 31, 2034. Digital printing bypasses the need for traditional printing plates by transferring digital files directly onto substrates such as paper, canvas, textiles, and synthetics. This seamless workflow supports on-demand production, reduces waste, and delivers high-throughput performance of up to 4,800 sheets per hour once printing begins.

Industry analysts anticipate that continued investments in print manufacturing efficiencies, supply chain integration, and time-to-market acceleration will drive digital printing adoption. Key growth verticals include textile and packaging, where high-definition, on-demand print capabilities facilitate product personalization and rapid iteration. The rise of direct-to-consumer printing models—particularly in can printing further cements digital printing’s role as a versatile, customer-centric technology.

Market Drivers & Trends

Technological Upgrades in Printing: Major players are embedding automation, AI-driven color management, and new printheads into their presses. For instance, in 2022, Hewlett Packard unveiled its Indigo 15K and 100K Digital Press platforms to enhance automation, reduce labor and plate costs, and slash turnaround times for medium to high-volume short runs.

Textile & Packaging Industry Growth: The global textile sector, valued at US$ 4.4 trillion, is rapidly embracing digital print to enable limitless design options and shorter production cycles. Likewise, packaging manufacturers are deploying UV LED and single-pass inkjet presses to deliver variable data printing—such as QR codes and barcodes—at scale.

On-Demand & Personalized Printing: Digital technology empowers brands to engage customers directly by crowdsourcing can designs, securing approvals, and fulfilling orders without intermediaries. This strategy has spurred increased consumer engagement and brand loyalty.

Latest Market Trends

High-Speed Single-Pass Inkjet: Next-generation presses with robust sheet feeders are driving throughputs that rival and often exceed traditional lithography, enabling signage and packaging that formerly required multiple litho sheets to be completed in a single digital pass.

Water-Based Polymer Inks: Sustainability concerns have prompted Canon’s 2022 launch of an automated production facility in Venlo for water-based CMYK inks, designed to curtail waste while ensuring consistent, premium output.

Strategic Partnerships & Acquisitions: Industry consolidation remains robust. In October 2023, ARC Document Solutions partnered with Canon Solutions America to integrate Arizona printing and Colex cutting systems, bolstering its digital color printing services.

Explore pivotal insights and conclusions from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86049

Key Players and Industry Leaders

Prominent companies shaping the digital printing landscape include:

Amcor plc

Avery Dennison Corporation

Canon Inc.

ColorJet Group

DIC Corporation

Durst Group

Electronics for Imaging, Inc.

Hewlett Packard Enterprise

Inca Digital Printers Ltd.

Konica Minolta, Inc.

Mimaki Engineering Co., Ltd.

The Ricoh Company, Limited

Roland DG Corporation

Seiko Epson Corporation

Toshiba Corporation

Xeikon B.V.

Xerox Holdings Corporation

Other

Recent Developments

April 2023: Kyocera Corporation acquired NIKKA S.A.S., enhancing its inkjet print engine capabilities and strengthening its presence in Japan’s digital printing market.

January 2022: Smurfit Kappa invested over US$ 33 million to install high-end printers in Brazil, supporting the booming e-commerce packaging segment.

September 2023: Fiery LLC inked an R&D partnership with Esko to advance digital print technologies with a focus on color and workflow automation.

Market Opportunities and Challenges

Opportunities:

Sustainability Focus: Development of eco-friendly inks and substrates presents new revenue streams as brands seek greener packaging solutions.

Emerging Economies: Rapid industrialization in Asia Pacific and Latin America offers fertile ground for new installations and service offerings.

4.0 Factory Integration: Combining IoT, AI, and advanced robotics with digital print presses can revolutionize mass customization.

Challenges:

High Capital Expenditure: Upfront costs of advanced digital presses may deter smaller enterprises despite long-term ROI advantages.

Skill Shortages: Operating and maintaining sophisticated digital printing systems requires specialized training.

Ink and Substrate Compatibility: Ensuring consistent print quality across diverse materials remains a technical hurdle.

Future Outlook

By 2034, digital printing is expected to account for more than half of global print volumes in packaging and textiles, driven by:

Automation & AI: Presses will self-optimize color, media handling, and maintenance schedules.

Personalization at Scale: Brands will offer hyper-customized products with batch sizes as low as one, unlocking new business models in retail and direct-to-consumer markets.

Hybrid Production Lines: Integration of digital and traditional printing methods will enable seamless transitions between high-definition short runs and high-volume lithography.

Market Segmentation

By Printing Type:

Inkjet (leading segment due to superior tonal range)

Laser

By Ink Type:

Aqueous

UV-Cured

Solvent

Latex

Dye Sublimation

Others

By Substrate Type:

Paper

Textile

Plastic Films or Foils

Ceramic

Glass

Others

Regional Insights

Asia Pacific dominated the digital printing market in 2023 and is forecast to maintain its leadership through 2034. China’s pivot toward end-to-end digitized value chains and strategic investments—such as Tomato Cloud Technology’s order for 10 Fujifilm Jet Press 750S machines in October 2021—have underpinned regional growth. In April 2023, Kyocera’s acquisition of NIKKA S.A.S. further underscores Japan’s commitment to inkjet innovation. North America and Europe remain important hubs for R&D, particularly in sustainable ink and substrate development.

Why Buy This Report?

Comprehensive Market Analysis: In-depth quantitative and qualitative insights covering 2020–2022 historical data, 2024–2034 forecasts, Porter’s Five Forces, value chain assessment, and SWOT analysis.

Competitive Landscape: Detailed profiles of leading players, product portfolios, strategic initiatives, market share breakdowns, and financial comparisons.

Actionable Segmentation: Granular analysis by printing type, ink, substrate, and region to inform targeted investment and expansion strategies.

Excel & PDF Formats: Ready-to-use data tables in Excel for custom modeling, alongside an executive-ready PDF report.

Explore Latest Research Reports by Transparency Market Research:

Ring Laser Gyroscope Market: https://www.transparencymarketresearch.com/ring-laser-gyroscope-market.html

Lithography Equipment Market: https://www.transparencymarketresearch.com/lithography-equipment-market.html

Compact Camera Module Market: https://www.transparencymarketresearch.com/compact-camera-module-market.html

Grow Light Market: https://www.transparencymarketresearch.com/grow-light-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

How Many Types of Ink Are There?

Ink is a significant part of our daily lives — ranging from the printing of documents to the creation of innovative projects and even personalizing clothes. Yet, have you ever stopped and asked yourself how many types of ink exist and which best suits you?

1. Dye-Based Ink Dye ink is among the most popular inks used in inkjet printers. It is a liquid solution of colorants.

Advantages: Rich color reproduction

Low and readily available price

Suitable for photo printing

Disadvantages: It fades with time

Not water-resistant

It smudges when not handled carefully

This ink is best suited for personal printing, school assignments, and color photographs. If you are personalizing items such as posters or personalized t-shirts, especially in collaboration with t shirt manufacturers in Chennai, dye-based ink could be an affordable choice.

2. Pigment-Based Ink Pigment-based ink differs from dye-based ink since it has finely divided particles that rest on the surface of the print instead of being absorbed.

Key Features: More durable prints

Water and fade-proof

Professional documents are preferred

It’s very common in the fine art and publishing business. Companies like t shirt manufacturers in Chennai prefer using pigment inks to achieve durable prints that can resist washing and outdoor weather.

3. Solvent Ink Solvent ink employs chemical solvents to transport color pigments, which is why it’s one of the leading choices when printing on non-porous media such as plastic and vinyl.

Best Suited For: Outdoor signs and banners

Vehicle wraps

Industrial labels

Though solvent inks are durable, they release strong odors and might necessitate proper ventilation during application. Outdoor advertising or custom apparel printing businesses typically use this type due to its resilience and resistance to the elements.

4. UV Ink UV-curable ink cures under ultraviolet light and forms a tough connection with the printed material.

Benefits: Dry instantly

Resistant to scratch and fading

Suitable for application on many types of materials

UV ink is gaining traction for environmentally friendly printing solutions. Several t shirt manufacturers in Chennai have begun using UV technology for intricate, custom designs on both textiles and accessories.

5. Sublimation Ink Sublimation ink is applied to a unique process in which the ink gets evaporated into gas when heated and gets chemically bonded with polyester or polymer-coated materials.

Best Applications: Custom apparel

Promotional items such as mugs and phone cases

Sportswear and team uniforms

This process makes the ink a part of the fabric, which is suitable for soft and breathable customized shirts. If you are looking for means to customize products, approaching t shirt manufacturers in Chennaithrough sublimation printing can be a good place to begin.

6. Toner (Applied in Laser Printers) Technically not a liquid ink, toner happens to be a dry powder utilized in copiers and laser printers.

Pros: High-speed printing

Precise text and lines

Shelf life that is long

Toner is best for office settings and heavy-duty print runs. It’s not good for fabric printing, but with the addition of heat transfer techniques, it can be a part of garment decoration.

7. Water-Based Ink Water-based ink is popular in the screen printing business, particularly on textiles.

Why Use It: Soft feel on fabric

Eco-friendly and non-toxic

Great for light-colored garments

Most environmentally friendly t shirt manufacturers in Chennai are switching to water-based inks for their minimal environmental footprint and gentle, breathable finish on fabrics.

Pro Tip: Ink Type to Your Needs Selecting the appropriate ink is not only about color — it’s about the end use:

Printing at home or in the office? Stay with dye or pigment-based ink.

Outdoor or industrial applications? Opt for solvent or UV inks.

Apparel or merchandise printing? Use water-based or sublimation ink.

As technology in printing continues to advance, so too do opportunities. The world digital print market, a report by Smithers shows, will be worth $225 billion by the year 2032, with demand for sustainability and personalization as the main drivers.

Conclusion: Which Ink Will You Choose? Knowing the various ink types allows you to make more informed, less expensive choices, whether you’re printing portraits, creating clothing designs, or starting a brand. From pigment to sublimation and all that lies between, having the correct ink can be the difference between worlds in terms of quality and longevity.

If you want to plunge into apparel personalization or seek professional advice on the ideal ink for your clothing business, feel free to approach seasoned t shirt manufacturers in Chennai. They tend to have guidance on the ideal means of printing and can assist you in realizing your imaginative vision.

0 notes

Text

Understanding the Technology Behind Modern Printing Machines

In today’s fast-paced fashion and textile industries, staying ahead means embracing cutting-edge technology. Modern printing machines have come a long way, transforming how businesses approach textile printing with increased speed, accuracy, and customization. Whether you're in apparel, home décor, or promotional goods, understanding how these machines work can help you make better decisions for your production process.

From Traditional to Digital: The Evolution of Textile Printing

For decades, traditional screen printing dominated the textile world. While effective for large orders, it had limitations in terms of design complexity and color variation. Today, digital textile printing has revolutionized the industry by offering more efficient, flexible, and eco-friendly solutions.

Digital textile printers use inkjet technology to apply designs directly onto fabric. This method allows for high-resolution, full-color prints without the need for screens or plates. For businesses looking to produce small runs or highly detailed prints, this is a game-changer.

The Rise of Sublimation Printing

Among modern methods, sublimation printing stands out for its ability to deliver vibrant, long-lasting designs on polyester fabrics. Sublimation works by turning solid dye into gas, which then bonds with the fabric at a molecular level. The result? Prints that don’t crack, peel, or fade over time.

Because it embeds the design into the fabric rather than placing it on top, sublimation is ideal for sportswear, activewear, and custom fashion. It’s no wonder it’s become a preferred choice in the world of textile printing.

Key Features of a Modern Printing Machine

Today’s printing machines are built with advanced features that enhance productivity and print quality. Here are a few standout elements:

High-Speed Performance: Machines today can print hundreds of meters per hour without compromising quality.

Precision Ink Delivery: Digital heads can place ink with pinpoint accuracy, essential for photo-quality prints.

Automated Workflow: Integrated software handles everything from file setup to color management.

Eco-Friendly Inks: Many machines now use water-based inks, reducing the environmental footprint of textile production.

These innovations are not only improving outcomes but also making printing more accessible to small and medium-sized businesses.

How True Colors Group Leverages Modern Printing Tech

At True Colors Group, we combine the power of digital textile printing, sublimation printing, and advanced printing machines to deliver premium quality fabric prints to our clients. Our state-of-the-art equipment ensures vibrant colors, sharp details, and durable finishes that meet the highest industry standards.

Whether you're a fashion designer, interior decorator, or custom product seller, our solutions are tailored to help you bring your vision to life. With a commitment to quality and innovation, True Colors Group continues to lead the way in the textile printing industry.

Conclusion

Modern printing machines have completely redefined the landscape of textile printing. With technologies like digital textile printing and sublimation printing, businesses now enjoy unmatched design flexibility, quality, and sustainability. By partnering with experienced providers like True Colors Group, you can unlock the full potential of these innovations and keep your brand ahead of the curve.

0 notes

Text

PRM Continues to Maintain its Growth Trajectory in Providing Premium Quality Imaging Consumables

The Mumbai-based Premier Computers is one of the most trusted providers of a large array of imaging consumables and components including toner cartridges, cartridge parts, laser printer parts, dot matrix parts, plotter parts and inkjet printer parts, and Teflon sleeves under their brand name PRM. In an interaction with Imaging Solution magazine, Mr. Devansh Sanghavi, Chief Operating Officer of Premier Computers (S/O Mr. Ashish Sanghavi, Founder of Premier Computers), shares his views about the current market conditions, brand philosophy and future plans.

0 notes