#Casting & Manufacturing

Text

Unveiling the Craftsmanship of Casting Manufacturing: Exploring Casting Suppliers and the Diversity

Casting, an age-old method of shaping molten metal into desired forms, continues to be a cornerstone of modern manufacturing. This article delves into the realm of casting manufacturing, exploring the role of casting suppliers and the fascinating array of cast iron types that have fueled industries for generations.

Casting Supplier: Connecting Vision to Reality: In the intricate world of manufacturing, casting suppliers serve as the bridge between innovation and creation. These skilled artisans and companies specialize in transforming design concepts into tangible products using various casting methods. Whether it's sand casting, investment casting, or die casting, casting suppliers play a pivotal role in bringing diverse creations to life.

Types of Cast Iron: From Strength to Versatility: Cast iron, revered for its durability and versatility, comes in various forms that cater to distinct needs and applications. Some common types include:

Gray Cast Iron: Recognized for its excellent machinability and thermal conductivity, gray cast iron is used in engine blocks, pipes, and cookware.

White Cast Iron: Notable for its hardness and wear resistance, white cast iron is ideal for applications requiring abrasion resistance, such as grinding balls and rolls.

Ductile Cast Iron (Nodular Iron): Renowned for its high strength, ductile cast iron finds its way into components like crankshafts, gears, and structural parts.

Malleable Cast Iron: With its heat-treated properties, malleable cast iron is commonly used in pipe fittings and automotive parts.

Compacted Graphite Iron (CGI): CGI boasts superior strength and thermal conductivity, making it suitable for high-performance engine components.

Casting Manufacturing: An Art and Science Blend: Casting manufacturing seamlessly marries craftsmanship and science, transforming raw materials into intricate components. The process involves creating molds, melting metals to their liquid state, pouring the molten metal into molds, and allowing it to solidify. The result is a wide range of products that drive industries, from automotive and aerospace to construction and beyond.

Innovations in Casting Techniques: Shaping Tomorrow: Casting manufacturing is not stagnant; it evolves with technology. Advanced techniques like investment casting and additive manufacturing (3D printing) are pushing the boundaries of what's possible. These innovations offer precision, reduce waste, and open avenues for complex geometries.

Conclusion: A Tribute to Casting Excellence: Casting manufacturing is more than a process; it's a testament to human ingenuity and the ability to shape raw materials into functional and intricate creations. Casting suppliers, armed with expertise, bring concepts to life, while the diverse types of cast iron provide the foundation for industries to thrive. As technology propels casting techniques forward, the legacy of craftsmanship and innovation continues to leave an indelible mark on the world of manufacturing.

0 notes

Text

Exploring Types of Cast Iron and Choosing the Right Casting Supplier for Your Manufacturing Needs

Casting is a crucial process in various industries, where molten metal is poured into a mold to create complex shapes and components. One of the essential aspects of successful casting manufacturing is choosing the right casting supplier. In this blog, we will delve into the different types of cast iron and how finding the ideal casting supplier, such as JiangSu KRT Industry Co., Ltd, can significantly impact the quality of your cast iron products.

Understanding Types of Cast Iron

Gray Cast Iron: Gray cast iron is the most commonly used type due to its excellent castability, good machinability, and low cost. It contains graphite flakes that provide lubrication during machining, making it suitable for applications like engine blocks, pipes, and cookware.

White Cast Iron: This type of cast iron is formed by rapid cooling, resulting in cementite formation instead of graphite. White cast iron is incredibly hard and brittle, making it ideal for applications requiring wear resistance, like crushing machinery.

Ductile Cast Iron (Nodular Iron): Ductile cast iron contains small amounts of magnesium, which alters the graphite structure, giving it improved ductility and toughness. It is used in applications where strength and shock resistance are essential, such as automotive components and heavy machinery.

Malleable Cast Iron: Malleable cast iron is created by annealing white cast iron, transforming the hard carbide into irregular-shaped graphite particles. It is highly ductile and can be bent and shaped without fracturing, making it suitable for applications like pipe fittings and handrails.

Compacted Graphite Iron (CGI): CGI has characteristics that lie between gray and ductile cast iron. It contains vermicular graphite structures, providing higher strength and thermal conductivity than gray cast iron. It finds applications in engine blocks and cylinder heads.

Importance of Choosing the Right Casting Supplier

Selecting the right casting supplier is critical for the success of your manufacturing endeavors. JiangSu KRT Industry Co., Ltd, as a reputable casting supplier, offers the following advantages:

Expertise and Experience: With years of experience in the industry, JiangSu KRT Industry Co., Ltd understands the nuances of different casting processes and materials, ensuring top-notch results for your cast iron components.

Quality Assurance: Reliable casting suppliers adhere to stringent quality control measures. JiangSu KRT Industry Co., Ltd takes pride in producing cast iron products that meet industry standards and your specific requirements.

Advanced Technology: Established casting suppliers utilize state-of-the-art technology and modern machinery to optimize the casting process, resulting in precise and consistent cast iron products.

Customization: Each industry may require unique cast iron components. JiangSu KRT Industry Co., Ltd works closely with clients to provide tailored solutions, meeting the diverse needs of various applications.

Timely Delivery: Meeting project deadlines is crucial in any manufacturing process. JiangSu KRT Industry Co., Ltd values punctuality and ensures on-time delivery of your cast iron components.

Conclusion

The choice of cast iron type plays a significant role in determining the success of your manufacturing applications. Understanding the properties and applications of different cast iron types empowers you to make informed decisions. Additionally, partnering with a reliable casting supplier like JiangSu KRT Industry Co., Ltd can streamline your manufacturing process, ensuring top-quality cast iron products that meet your requirements. So, whether you need gray cast iron for cookware or ductile cast iron for heavy machinery, make the right choice to boost the performance and durability of your products.

0 notes

Text

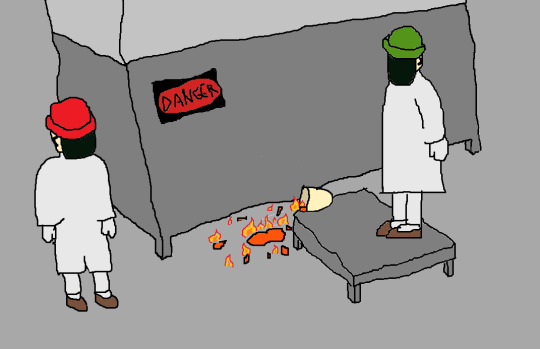

Bit of an issue.

#all the castings came out super good though!#my stuff#art#casting#bronze#manufacturing#paint#this took me a while#I used the mousepad so that might be why#this happened RIGHT AFTER the other guy finished explaining to me the dangers of copper and bronze#in that it will stick to you instead of bouncing off#and you will get severely burned#no one was injured this time though!

108 notes

·

View notes

Text

Ace's TURИ for Burn Rewatch: Washington's Spies

#oh my lord it's finished ;_;#burn gorman#jamie bell#edmund hewlett#major hewlett#abraham woodhull#abe woodhull#edmund my dearest 🔭#my beloved starboy 🌌#cabbage head 🪡#my gifs#turn washington's spies#amc turn#turn#civies!!!!!#featuring several half smiles that make me happy ♡#tbh i only started this because i was bored and now that it's done i remember how good this show is#and WOW i love so many of these characters#i hope y'all enjoyed my temporary dive into the self-manufactured purgatorio I've cast myself into for the past several days#thank you for sticking around~#but now it is time for bed#ciao~☆

26 notes

·

View notes

Text

said this before but god do I miss gem aus and especially fusions

#browniefox speaks#dare i be the change i want to see in the world?#ooh ffvii gem au#hm gem aerith#most of the cast is human still#soldiers are like half-gem#sephiroth is a manufactured full gem

12 notes

·

View notes

Text

I love you old indestructible tech I love you my 12 year old cintiq that is so strong I could beat someone to death with it I love you old ipod models you can throw through drywall I love you old cellphones that do not break when you sit on them. Engineered obsolescence is the worst thing to happen to mankind since organized religion, I do not want your shiny, sleek, cheaply made fairy bullshit that now only connects to shitty useless bluetooth I want technology that will last 10 years and beyond because I fucking paid for it and do not want to have to pay for it /again/ in 6 months when it breaks because I looked at it wrong.

#I am about to cast some really funny spells at tech manufacturing companies#my old cintiq is like a nokia phone that thing is fucking insane#its 30 pounds and would break someone's bones if I threw it at them#THATS a drawing tablet

12 notes

·

View notes

Text

Working on a robot today

I work on a team that develops combat robots, and it is a very tedious task. This year alone I have put hundreds of hours into designing, prototyping, assembling, testing, and manufacturing our robot. I’ve made computer models, 3D printed components, worked with metal parts, developed organizational systems, drafted engineering drawings, drawn logos, and so much more. Every weekday im working on this thing and somehow even now theres still stuff left to do. Just today I was hoping to finish my work, so I would have time to relax and chat with some friends at the end of the day, but just as I finished all my work and was about to take some time off our driver comes in with the robot and points at the wheels. The wheels, which are custom made by our production team, were falling apart, even though we had just put them on a couple minutes ago. The outermost layer of rubber on the wheels was peeling right off. This hadn't happened with any of our other wheels so naturally my first thought was, “What the heck?? There goes my free time.” I disassembled the robot and removed one of the wheels to look at it, and then compared it with a matching wheel from one of our older sets.

The wheels are made by pouring liquid rubber around a plastic hub in the center so that when the rubber hardens around the hub it locks in place. Heres a picture that kinda shows how the two pieces go together:

(Sorry for terrible quality I drew this on a phone)

The newer wheel had a ton of bubbles in the rubber, and was way squishier than the old wheel. Too much air must have gotten in when we were mixing it and not gotten out when it hardened. Think of a block of foam verses a plastic brick. If you rub foam on sandpaper it’s just going to disintegrate because it has a bunch of air in it, while the plastic brick is going to take longer to degrade because it’s more dense. The old wheels were much more resistant to tearing because they were more dense. The new wheels were less dense because of all the bubbles, meaning that they just shredded apart when they rolled on the floor. Our only option here was to remove the bad rubber from around the hubs and re-cast the wheels. Unfortunately, removing the rubber really sucks. Or… at least it does when the wheels are cast properly. The squishy bad rubber came off really cleanly, and didn’t adhere to the central hub properly when it hardened meaning it was easier to remove. It still was difficult to take off because you kinda had to wedge a screwdriver between the hub and the rubber and pry it off, but not as bad as having to cut the rubber into chunks and manually scrape it off because it’s stuck to the central hub. Eventually I figured out that you could just put the wheel in a press and squeeze the hub right out of the rubber. It was super fun using the press to remove the rubber, and I was sad when I finished all of the wheels because now I couldn’t use the press anymore. So that took up all my free time but at least we don't have to deal with that later, hooray.

(oh also the robot cut me twice today because its really stinking sharp on the front :/)

11 notes

·

View notes

Text

gansey: *walks in wearing a “best grandpa ever” shirt*

blue: is there something you’d like to tell us?

gansey: what?

ronan: what’s up with the shirt? do you have secret grandkids we don’t know about???

gansey: ohhhh, no. i just think i’d be the best grandpa ever!!

#based on an interview of the boy meets world cast LOL#ronan lynch#blue sargent#richard campbell gansey iii#trc#adam parrish#the raven cycle#adam and ronan#pynch#the raven boys#blue lily lily blue#henry cheng#the dream thieves#gangsey#the gangsey#blusey#noah czerny#mine#monmouth manufacturing

126 notes

·

View notes

Text

When Is The Investment Casting Employed?

A wax pattern is used in the industrial process of Investment casting China, sometimes referred to as precision casting or lost-wax casting, to create a disposable ceramic mold. The exact shape of the object to be cast is captured in a wax pattern. A ceramic substance that is refractory is applied to this design. After the ceramic material solidifies, it is heated and flipped upside down until the wax melts and runs out. The ceramic shell hardens into a disposable investment mold. The mold is filled with molten metal, which is then allowed to cool. After that, the metal casting is broken out of the used mold.

When to employ investment casting

Investment casting is a rather expensive technique because of its labor needs and intricacy, but the advantages frequently exceed the drawbacks. Almost any metal may be cast for an investment.

Excellent as-cast surface finishes may be achieved in complicated items produced by investment casting. Since the ceramic shells of investment castings break away from the part when it cools, a taper does not need to be incorporated to extract the components from their molds. With the use of this manufacturing feature, castings with 90-degree angles may be created without any shrinkage allowance and without the need for further machining to achieve such angles.

Parts made using the investment casting technique by Investment casting Supplier have excellent dimensional precision, are readily net-shaped, and are frequently produced without the need for further machining. To create wax patterns, a new die is needed for every distinct casting run.

The time and effort saved by reducing or eliminating secondary machining more than offsets the expense of new tools for high-volume orders. Lesser casting runs will probably not pay for itself.

A new wax pattern to a finished casting typically takes seven days, most of which is spent making and curing the ceramic shell mold. To make castings more rapid, certain foundries can quick-dry. Cost is not the only factor affected by investment casting's time- and labor-intensive process. Longer lead times for the investment casting process are typical at foundries because of their restricted production capacity and equipment.

More Information: Mastering the Art of Investment Casting: A Deep Dive into the Process

#Investment casting Supplier#Investment casting manufacturer China#Investment casting manufacturer#Investment casting China

2 notes

·

View notes

Text

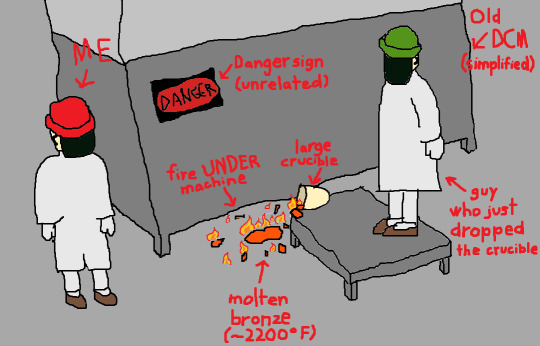

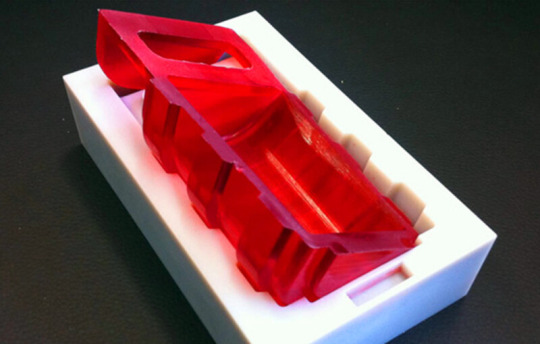

Working of Vacuum Casting and Its Multiple Uses

To make complicated components, a liquid substance is sucked into a silicone mold under vacuum. This method is known as vacuum casting. Rubber and plastic are examples of elastomers that are utilized as liquid materials in vacuum casting.

Since polyurethane resin, a kind of elastomer is employed as the casting medium, vacuum casting is also frequently referred to as polyurethane casting or urethane casting. When producing plastic components, vacuum casting is a more cost-effective method than injection molding because of its reduced manufacturing costs.

For batch manufacturing and other low-volume production tasks, vacuum casting is a great method of production. Vacuum casting is widely utilized in India's manufacturing of industrial electronics, FMCG, and consumer goods.

How do you work with vacuum casting?

Injection molding, in which cast material is poured into molds to create items, and vacuum casting services are very comparable processes. The kinds of molds used in injection molding and vacuum casting differ from one another.

Molds for injection molding might be formed of steel, aluminum, or other materials. Silicone molds are utilized in vacuum casting, nevertheless. This significantly lowers the mold-making cost because silicone is more affordable and has better durability.

Polyurethane is the most often utilized casting material in this procedure. The qualities of various polyurethanes vary, including good shock and temperature resistance, elasticity, flexibility, and structural stiffness. Thus, different polyurethanes may be employed depending on the kind of product being created.

Vacuum casting uses

Making complicated and sophisticated goods may be accomplished more cost-effectively and efficiently with vacuum casting as opposed to the conventional injection molding method.

Due to its efficient production process, vacuum casting finds widespread application in the fabrication of commercial items. The following are a few industries that employ vacuum casting:

Manufacturing of consumer goods

Vacuum casting is a more effective method of producing consumer goods including combs, hair brushes, makeup packaging, sunglasses, pens, and other stationery.

Industry of Food and Beverages

Vacuum casting is used to create food and beverage containers, bottles, cans, mugs, and glasses. Due to the process's great efficiency and ability to produce goods quickly, vacuum casting is widely utilized in various industries where rapid manufacture is essential.

Advanced industry

Excellent heat and shock resistance is a feature of polyurethanes. Therefore, the recommended production procedure for creating electrical device housings is vacuum casting by Vacuum Casting Manufacturer using polyurethanes.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Explore vacuum casting#Vacuum Casting Services China#Vacuum Casting Manufacturer#Vacuum Casting supplier

2 notes

·

View notes

Text

JiangSu KRT Industry: Your Trusted Casting Supplier and Manufacturing Partner

Introduction: Unveiling the Excellence of JiangSu KRT Industry Co., Ltd

Welcome to JiangSu KRT Industry Co., Ltd, a leading name in the world of casting manufacturing and a trusted casting supplier. In this comprehensive guide, we delve into the intricacies of casting, explore the different types of cast iron, and provide insights into the exceptional capabilities offered by JiangSu KRT Industry Co., Ltd.

Casting Supplier Expertise: The Heart of JiangSu KRT Industry Co., Ltd

JiangSu KRT Industry Co., Ltd – Your Reliable Casting Supplier

At JiangSu KRT Industry Co., Ltd, we take pride in being a reliable casting supplier that meets diverse industrial needs. Our commitment to excellence and quality makes us the preferred choice for businesses seeking top-tier casting solutions for their projects.

Unleashing the Power of Casting Manufacturing

Step into the world of casting manufacturing with JiangSu KRT Industry Co., Ltd. Our expertise encompasses a wide range of casting techniques, materials, and applications, making us a versatile partner capable of turning your ideas into reality.

The Versatility of Cast Iron: Exploring Different Types

Discover the versatility of cast iron with JiangSu KRT Industry Co., Ltd. From grey iron to ductile iron and everything in between, our skilled team can assist you in selecting the perfect type of cast iron for your specific project needs.

Navigating the World of Casting Manufacturing

Crafting Excellence: The Art of Casting

Casting is an intricate art, and at JiangSu KRT Industry Co., Ltd, we take pride in our mastery of this craft. Our state-of-the-art facilities, experienced team, and dedication to precision ensure that each casting we produce is a testament to quality and craftsmanship.

Beyond Expectations: Casting Applications and Capabilities

Experience casting manufacturing that goes beyond expectations with JiangSu KRT Industry Co., Ltd. Our capabilities span various industries, including automotive, construction, and machinery, allowing us to deliver tailor-made casting solutions that meet the unique demands of each sector.

Frequently Asked Questions: Exploring Casting Supplier and Manufacturing

What makes JiangSu KRT Industry Co., Ltd a trusted casting supplier? JiangSu KRT Industry Co., Ltd is trusted for its commitment to quality, versatility in casting solutions, and ability to meet diverse industrial needs.

What types of cast iron does JiangSu KRT Industry Co., Ltd offer? JiangSu KRT Industry Co., Ltd provides a wide range of cast iron options, including grey iron, ductile iron, and more, ensuring that clients have access to the ideal material for their projects.

How does casting manufacturing work at JiangSu KRT Industry Co., Ltd? Casting manufacturing at JiangSu KRT Industry Co., Ltd involves a meticulous process that leverages advanced techniques, skilled craftsmanship, and cutting-edge facilities to create high-quality castings.

What industries benefit from JiangSu KRT Industry Co., Ltd's casting capabilities? JiangSu KRT Industry Co., Ltd's casting capabilities cater to diverse industries such as automotive, construction, machinery, and more, ensuring that each sector's specific needs are met with precision.

Conclusion: JiangSu KRT Industry Co., Ltd – Your Partner in Excellence

JiangSu KRT Industry Co., Ltd stands as a beacon of quality and expertise in the realm of casting manufacturing. Whether you're seeking a reliable casting supplier or a partner for crafting precision castings, our team is dedicated to exceeding your expectations. Join us today and experience the unparalleled excellence that defines JiangSu KRT Industry Co., Ltd.

0 notes

Text

Exploring Casting Suppliers and Types of Cast Iron with JiangSu KRT Industry

In the world of manufacturing, casting plays a vital role in creating various components and products. To ensure the quality and precision of castings, it is essential to partner with reliable casting suppliers who possess expertise and experience. One such notable name in the industry is JiangSu KRT Industry Co., Ltd. In this blog, we will delve into the significance of casting suppliers, explore different types of cast iron, and highlight the contributions of JiangSu KRT Industry Co., Ltd.

Casting Suppliers: A Crucial Element in Manufacturing Process: Casting suppliers are instrumental in transforming designs and concepts into tangible products. They provide the necessary expertise, facilities, and resources required for the manufacturing process. From initial design discussions to the final production stage, casting suppliers act as valuable collaborators, ensuring the efficient and successful creation of cast components.

Choosing the right casting supplier is crucial, as it directly impacts the quality, cost-effectiveness, and timeliness of the final product. Suppliers like JiangSu KRT Industry Co., Ltd understand the importance of precision and consistency in the casting process. They possess advanced manufacturing capabilities, a dedicated team of experts, and a commitment to delivering exceptional results.

Types of Cast Iron and Their Applications: Cast iron, known for its durability and versatility, is widely used in various industries due to its excellent heat resistance and mechanical properties. Let's explore some common types of cast iron:

Gray Cast Iron: Gray cast iron is the most commonly used type of cast iron. It is known for its excellent castability, high wear resistance, and good machinability. Gray cast iron finds applications in automotive components, pipes, cookware, and machine tool structures.

Ductile Cast Iron: Ductile cast iron, also known as nodular cast iron or spheroidal graphite iron, exhibits improved strength, toughness, and ductility compared to gray cast iron. It is commonly used in applications where high strength and shock resistance are required, such as crankshafts, gears, and heavy machinery components.

White Cast Iron: White cast iron is characterized by its hardness and brittleness. It contains high amounts of carbon, which makes it exceptionally hard but less ductile. White cast iron is primarily used in applications where abrasion resistance is crucial, such as grinding balls, mill liners, and crushing equipment.

Malleable Cast Iron: Malleable cast iron is a heat-treated form of white cast iron. It possesses improved ductility and toughness, making it suitable for applications that require deformation without breaking, such as pipe fittings, hand tools, and electrical fittings.

JiangSu KRT Industry Co., Ltd: A Trusted Casting Supplier: JiangSu KRT Industry Co., Ltd is a renowned casting supplier known for its commitment to quality, advanced manufacturing capabilities, and customer-centric approach. With years of experience in the industry, they have developed a strong reputation for delivering precision-crafted castings that meet the highest standards.

Their state-of-the-art facilities, cutting-edge technology, and skilled workforce enable them to handle a wide range of casting manufacturing requirements. Whether it's gray cast iron, ductile cast iron, or other materials, JiangSu KRT Industry Co., Ltd ensures that each casting is meticulously produced to meet the specific needs of their clients.

Conclusion: Partnering with a reliable casting supplier is vital for the success of any manufacturing project. The choice of a supplier can greatly impact the quality, cost, and timeliness of the final product. JiangSu KRT Industry Co., Ltd, with its expertise in casting manufacturing, commitment to quality, and broad range of capabilities, stands as an excellent choice for businesses seeking reliable casting solutions. Whether you require gray cast iron, ductile cast iron, or any other type of cast iron component, JiangSu KRT Industry Co., Ltd is dedicated to delivering exceptional results and exceeding customer expectations.

0 notes

Text

Casting Everyday 😎

28 notes

·

View notes

Text

#otisserie skewers into the rotisserie. A raw chicken in a rotisserie oven. Cook according to rotisserie manufacturer’s instructions (for my#Cuisinart rotisserie it’s one hour on the “Rotisserie” setting). Let it rest about 10 minutes before carving. Oven instr#uctions If you make it in the oven it’s a roasted chicken. But if you use the same spice rub it tastes just like a rotisserie chicken. T#russ the chicken (giblets removed) then coat with olive oil. Coat generously with the dry rub. Place in#a roasting pan baking dish or cast iron skillet. Bake at 425 degrees for 70-80#minutes until the chicken reaches an internal temperature of 165 degrees. Baste the chicken every 15-20 minutes with juices from the botto#m of the pan (or olive oil). After baking the chicken you can devour it immediately or place

50 notes

·

View notes

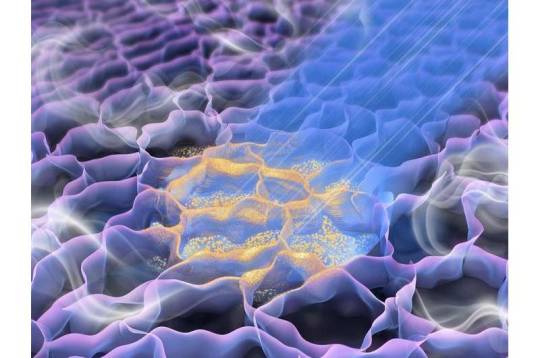

Photo

In-place manufacturing method improves gas sensor capabilities, production time

When used as wearable medical devices, stretchy, flexible gas sensors can identify health conditions or issues by detecting oxygen or carbon dioxide levels in the breath or sweat. They also are useful for monitoring air quality in indoor or outdoor environments by detecting gas, biomolecules and chemicals. But manufacturing the devices, which are created using nanomaterials, can be a challenge.

Penn State researchers recently enhanced their gas sensor manufacturing process through an in situ laser-assisted manufacturing approach, improving on their previous method of drop casting, or dropping materials one by one onto a substrate using a pipette. They published their results in the Chemical Engineering Journal.

"With drop casting, you have to synthesize each part of the sensor separately and then integrate them, which is logistically challenging, takes a long time and is expensive," said corresponding author Huanyu "Larry" Cheng, James L. Henderson, Jr. Memorial Associate Professor of Engineering Science and Mechanics in the Penn State College of Engineering. "The in situ method allows the materials to be directly synthesized in one place, and the laser speeds up the process."

Read more.

#Materials Science#Science#Sensors#Gases#Manufacturing#Materials processing#Casting#Nanotechnology#Penn State

11 notes

·

View notes

Note

//I'm guessing it's just another one of those PR things they're supposed to play up to make the fans think Jensen is SO involved in the show, but the whole thing comes across as inauthentic// - Yea, this makes a lot of sense. I will also add that "pranks" were kinda the spn brand (at least bts). Every con someone asks. Plus they have talked about all their prank wars for years. It's J2's "thing", they're known pranksters. So I think in an effort to try and tie it to spn bts as well they are trying to push this "see, the casts are the same! they love to prank each other too!! Did you hear about the masks yet??! Yea? Wanna hear it again? because that's the only one we could think of and now we have nothing else??" It just feels like they're trying too hard, or not hard enough, it's hard to tell at this point.

That's what's so baffling about the whole project. So much of it is plastered on Barbie and Ken doll smiles and stories that you can't tell what's real and what's fake.

And your right about them trying to mimic the SPN set vibe. Jensen mentioned something similar in one of his interviews about making sure TW set was just as friendly and fun as the SPN set. I'm sure the people there get along, but once again, it's missing the Jared factor. Jared and Jensen together were what made the SPN set so enjoyable (at least for Jensen). It wasn't just the chemistry on-screen, but off-screen as well.

What Jensen has missed is that you can't just tell people to have fun, prank others, and then expect to make the set a magical, happy place. It has to come from naturally from the cast and crew, and frankly, I just don't see authentic chemistry from TW cast on-screen or off.

#ask box#jensen critical#anti jared erasure#anti spn prequel#anti TW cast#and their lack of chemistry#anti manufactured pranks

13 notes

·

View notes