#Coil inductor

Text

#gtav#gta5#grand theft auto#grand theft auto v#grand theft auto 5#gta online#rockstar games#rockstar editor#gamingedit#virtual photography#photomode#gtacars#coil inductor#coil#inductor#video games#in game photography

7 notes

·

View notes

Text

transformer winding machine

Programmable Transformer Winding Machines are hybrid winding machines having in-built computer-operated programs run with the help of a microprocessor.

These machines run with the help of a program that makes these machines superior. Some of the key features are:

high level of precision

coils of the transformer can be wound easily

Winding on high RPM (up to 750 RPM)

Track number of transformer coil winding

Speed control system

Programmable Transformer Winding Machine also come with various features, they can easily control and customized with the help of Display. These Programmable features make it suitable for large industrial use.

Acme Mechatronics, Inc. is a US-based company involved in manufacturing and supplying winding machines and accessories used in the field of coil winding applications. More than 25 standard coil winders are available to handle a wide range of coil winding applications. For more details visit: https://acmemechatronics.com/

#transformer winding machine#coil winder#inductor winding machine#coil winding machinery#coil winding equipment#motor coil winding machine#Programmable Winding Machine#coil winding machine

0 notes

Text

#https://youtu.be/VDKuZGWT1J4#Voice coil Winding#Speaker Coil Winding#Drum Core Winding#Inductor coil Winding#Table Top Winder#SpeakerCoilWinding#synthesiswinding

0 notes

Text

Currently losing my mind a little bit trying to find an alternate name for the Recursive Transform Array/Abstract Convergence Manifold regions in Five Pebbles/Looks to the Moon respectively. I think both names mean roughly the same thing.

(Left: Coils in the Recursive Transform Array, Right: Coils in the Abstract Convergence Manifold)

(Theorizing under the cut)

Both regions contain sets of large transformers (or inductors, they both look like coils) arranged into different groups. I assume the function of this region is to receive power from an iterator's power source (how iterators get their power isn't exactly clear- but at least in Pebbles' case it probably comes from the Linear Systems Rail) and step up or down the voltage so it can be distributed to the different electronic components of an iterator's superstructure as needed.

Stepping up/down voltage is the function of a transformer, which is where I assume the "transform" part of "Recursive Transform Array" comes from. In Moon's case, "abstract" in "Abstract Convergence Manifold" is a synonym for "transform" or "change", one thing is being abstracted, or changed into something else.

"Recursive" means "repeating" (and "repeat" is a synonym of "iterate", funnily enough), so this part probably refers to the multiple similar transformers found in the Recursive Transform Array.

In terms of the Abstract Convergence Manifold, either "convergence" or "manifold" could correspond to the "multiple similar things" meaning. The objects in question are "converging", coming together, or being similar.

"Manifold" is a bit trickier, the general definition means "variety" or "many", but the word has other uses. In typography, it can refer to the process of making copies of a document (via a carbon copy), and in engineering it can refer to a component that distributes gas or liquid to different parts of a system. So in this case, I'm going to assume that "manifold" means "copies" and/or "distribution". This makes sense if the Abstract Convergence Manifold distributes power (or maybe even Void Fluid) to different parts of Moon's structure.

And finally, "array" in "Recursive Transform Array" means a group of things arranged in a pattern. This is also probably what "manifold" in "Abstract Convergence Manifold" means; a group of copies of things.

Based on this, both names basically mean "group of similar/repeating things that change". This might not just refer to the groups of transformer coils, but also to the big square structures that both Pebbles and Moon have in these regions:

(These rooms are very dark, I'm only showing Pebbles' here because it's better lit than Moon's.)

This thing looks like a big computer chip, maybe a Central Processing Unit (CPU). I theorize that this room is where the majority of an iterator's processing takes place; where the actual iteration (in terms of computing: repeating a process) happens. So the things that are repeating and changed could be the actual iterative processes (simulations, thoughts, calculations) are carried out, altered slightly, and repeated again.

(Side tangent: I've always wondered what Pebbles was referring to when he mentioned his "processing strata". It might be layers of processors located in his Recursive Transform Array, possibly in the same big room as the square thing. Personally I think the processing strata are the little blinking lights you can see in the background of this room, but I could be wrong. If anyone actually knows the answer please let me know.)

TL,DR: If you have an iterator OC and you want to give their internal regions names but you don't want to simply copy existing ones, I'm pretty sure the naming convention for the transformer arrays uses synonyms for (similar/repeating) (change) (group). For example, "Sequential Flux Assemblage", "Parallel Modification Cluster". These sound silly, but basically everything iterator-related is silly technobabble, so I think the moral is to have fun with it.

Thank you for reading, and let me know if you have any ideas. I enjoy talking to people about random Rain World theories.

#this is another theory spiral I fell down while trying to flesh out OC lore. enjoy#rain world#iterators#rain world iterator#rw iterator#personal#delta’s wild lore speculation corner#rain world theory

321 notes

·

View notes

Text

1892 bipolar Edison fan

What an artifact! The fan is not powered by the mains, but by direct current. And the current is obtained in a system of several inductor coils with a closed magnetic core. The fan screw is supposed to rotate EVERYTHING, and the regulation is set with a golden lever.

It's a neat design, just brilliant! 🤔

#pay attention#educate yourselves#educate yourself#knowledge is power#reeducate yourself#reeducate yourselves#think about it#think for yourselves#think for yourself#do your homework#do some research#do your own research#ask yourself questions#question everything#fan#nikola tesla#tesla#engineering

38 notes

·

View notes

Text

#gtav#gta5#grand theft auto v#grand theft auto 5#grand theft auto#vespucci beach#coil inductor#rockstar games#rockstar editor#gaming#gamingedit#virtual photography#photomode#junk energy#coil#inductor#los santos#**#**gtav

12 notes

·

View notes

Text

Dongguan HUIYUECN Automation Equipment Technology Co., Ltd. is a professional automation workshop production line solution provider for high frequency transformer peripheral equipment.

2 notes

·

View notes

Text

I've been feeling more or less out of it for over a month — a series of medication/insurance misadventures that haven't yet run their course — but today I was feeling pretty okay, so I pulled down a cool old kit I've been meaning to build, a vacuum tube regenerative radio. Step one involved spray-painting the included wooden base with clear acrylic, and that was nicely relaxing.

Step two was hand-winding inductor coils on a cardboard cylinder, which stressed me out all to hell.

It shouldn't be so demanding from the instructions as written, which are reasonably clear: you wrap a bit of magnet wire through a couple of holes punched in the form, then wrap around the cylinder for 20 turns, leave a couple of twists around a pencil free as a tap, then wind 55 more turns. Except you have to keep the turns close together, not overlap them, and — most importantly — not lose count. Which I did at that first 20 mark.

Now, I should explain that although I am entirely capable of higher mathematics — I've got a degree in computer science that included courses in advanced calculus, linear algebra, number theory, et c. — I'm completely rubbish at arithmetic. I've got a mental block against multiplication. Adding small numbers often finds me counting on my fingers. And of course, unless I'm making a concerted effort, I just plain miscount things a lot.

So I tried re-counting the wire turns and came up with, on try one, 19, and on try two, 21. A third, very careful count came up with the proper 20, so I made the tap loop, and then continued wrapping, counting the 55 turns out loud. My wife walked in, wanting to talk, when I'd hit 42 or so, and I had to just repeat the number I'd reached while motioning frantically with my eyes and facial muscles that I couldn't talk just then; she thankfully got the message quickly and I managed to get to 55 properly. After the end of that wire was secured, and a decent pause for talking taken, the additional separate coil of 15 turns wasn't too bad, but goodness. Not a relaxing endeavor!

I'll post pictures when there's more to show than some copper wire wrapped around what's effectively the core of a toilet paper roll.

5 notes

·

View notes

Text

Myth-information

Like that word? I just thought of it.

I was meditating on the Frank Doris document linked in my previous post. The guy has gobs of experience, but that is tempered by his clinging to myths and misunderstandings to reach conclusions. There always has to be a conclusion.

I heard an effect it must be due to this thing. Or not.

So he likes planar speakers cuz they are low mass and such. Well if they truly were that they would have really good high frequency response and you know they don't. All current units have woofers and tweeter drivers as you do not have a practical true full range planar driver. There are two types of planar speakers. One is the magnetic like the Magneplanar. The other are various flavors of electrostatics. Skipping details he likes the sound (as do I) because they are low mass and fast (which they are not). But the truth is they are very inefficient and non-linear and not that low mass compared to a simple cone driver. The motors of cone drivers are much more efficient for a given mass of moving parts.

All planars either electrostatic or magnetic are non-linear. The forces applied to the diaphragm is from an electrostatic charge on grids or magnetic field which accelerates a thin sheet. BUT practical considerations require the diaphragm to be under significant tension which increases the restoring force the more the sheet moves from rest. A linear signal input gives you a not linear displacement. Effectively it is a signal compression. I know this as I have built them. But they still sound good.

Why do they sound acceptable and even very good? Well they have a large radiating area which couples well to the air in the room. An 8" speaker cone has 50 squinches of area. A modest planar speaker can have 10 times that. My electrostatics had 1500 squinches of area. That coupling is actually an impedance matching effect so the sound is put into the air very efficiently once it has got past all the mechanical limitations. It appears as impact and such. That goodness compensates for most of the inherent badness.

Big horn speakers share this impedance matching effect. The area of the horn outlet is the effective area of the speaker. In big Khorns you are talking square feet of area. But they have phase issues and horns distort, sorry.

There is no ideal speaker solution. Any method can be made to fool your brain. All have flaws.

Interconnect wires can effect sound. Not for the reasons noted in the marketing materials. I had a high end rather long shielded cable to link my front end to my amps back when I placed them right beside my speakers. (Audioquest brand) As they were shielded they were capacitors. Those very long runs dulled the high frequencies. I no longer need that length. I made a set of short cables by braiding four wires just long enough to reach between my preamp and my amplifier. It made a big difference. I cut the fancy cables to the same length and guess what they now sounded identical. Simple and cheap is fine.

All the bumf about speaker cables is bragging about how much money you can spend. Skin effect, time smearing, and all that does have an effect in radio frequencies but none at all in audio frequencies. The only factors that matter are inductance, resistance, and capacitance. All wires have those. Note that some very expensive audio electronics both produce and respond to radio frequencies due to design flaws. Don't buy that stuff. Just a simple heavy gauge wire is all you need.

Remember that the 20 odd feet of fancy speaker cables connects to maybe a hundred feet of fine voice coil wire and 60 odd feet of inductor wire inside your speaker box. The entire loop counts and adds together.

Insert rant here about fancy power cables. If they help, your equipment has a problem in the power supply. All that might change is your grounding condition and perhaps invalidating your fire insurance.

Oh and the eternal conflict between tubes and transistors. Yes that is a thing. They sound different while measuring the same. Does that prove that measurements are meaningless? No just they measure what they can measure. Skilled designers can make either sound like the other. But each tribe has its fan base and those people must be served. My tube amp is different here and there, but overall more similar to my transistor franken-amp than not. The differences are very small. And it is fun to explore.

Anyone who truly understands this stuff just rolls their eyes when the golden ears start to preach. I almost understand this stuff.

2 notes

·

View notes

Text

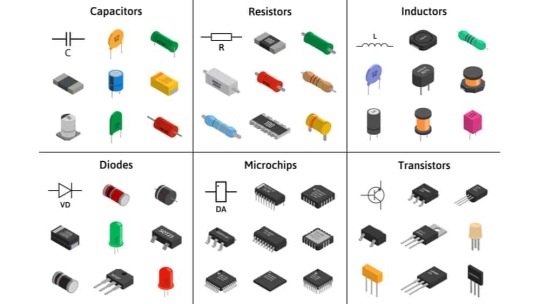

Electronics Components and Uses:

Here is a list of common electronics components and their uses:

Resistor:

Use: Limits or controls the flow of electric current in a circuit.

Capacitor:

Use: Stores and releases electrical energy; used for filtering, timing, and coupling in circuits.

Inductor:

Use: Stores energy in a magnetic field when current flows through it; used in filters, transformers, and oscillators.

Diode:

Use: Allows current to flow in one direction only; used for rectification, signal demodulation, and protection.

Transistor:

Use: Amplifies and switches electronic signals; fundamental building block of electronic circuits.

Integrated Circuit (IC):

Use: Contains multiple electronic components (transistors, resistors, capacitors) on a single chip; used for various functions like amplification, processing, and control.

Resistor Network:

Use: A combination of resistors in a single package; used in applications where multiple resistors are needed.

Potentiometer:

Use: Variable resistor that can be adjusted to control voltage in a circuit; used for volume controls, dimmer switches, etc.

Varistor:

Use: Protects electronic circuits from excessive voltage by acting as a voltage-dependent resistor.

Light-Emitting Diode (LED):

Use: Emits light when current flows through it; used for indicator lights, displays, and lighting.

Photodiode:

Use: Converts light into an electric current; used in light sensors and communication systems.

Zener Diode:

Use: Acts as a voltage regulator by maintaining a constant voltage across its terminals.

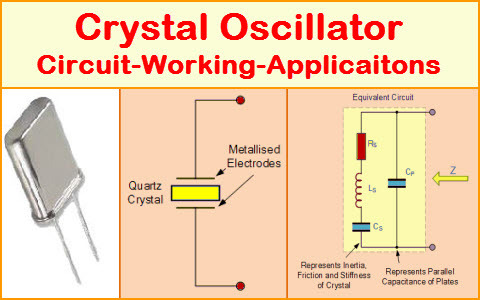

Crystal Oscillator:

Use: Generates a stable and precise frequency; used in clocks, microcontrollers, and communication devices.

Transformer:

Use: Transfers electrical energy between two or more coils through electromagnetic induction; used for voltage regulation and power distribution.

Capacitive Touch Sensor:

Use: Detects touch or proximity by changes in capacitance; used in touchscreens and proximity sensing applications.

Voltage Regulator:

Use: Maintains a constant output voltage regardless of changes in input voltage or load; used for stable power supply.

Relay:

Use: Electromagnetic switch that controls the flow of current in a circuit; used for remote switching and automation.

Fuse:

Use: Protects electronic circuits by breaking the circuit when current exceeds a certain value; prevents damage from overcurrent.

Thermistor:

Use: Resistor whose resistance changes with temperature; used for temperature sensing and compensation.

Microcontroller/Microprocessor:

Use: Processes and controls electronic signals; the brain of many electronic devices and systems.

fig:google-electronics

fig:google-electronics

fig:Crystal-Oscillator

This list covers some of the basic electronic components, and there are many more specialized components used for specific applications within the field of electronics.

#electronic#electricity#electric vehicles#electric cars#engineering#semiconductors#wireless#cables#electronics#smartphone#hardware

3 notes

·

View notes

Text

Ferrite Core Transformer: An In-Depth Analysis

(Source – Ocean Property)

Ferrite core transformers are critical components in modern electronics, known for their efficiency, high-frequency performance, and compact size. These transformers utilize ferrite cores, which are composed of ceramic compounds consisting of iron oxide mixed with other metallic elements. FCTs are widely used in various applications, including power supplies, signal processing, and telecommunications. This article delves into the structure, function, advantages, and applications of ferrite core transformers.

Structure of Ferrite Core Transformers

An FCT consists of two main parts: the core and the windings. The core is made of ferrite material, which is a type of magnetic ceramic. The windings are made of conductive wire, usually copper, which is wound around the core to create inductance.

Ferrite Core: Ferrite materials are chosen for their magnetic properties and high electrical resistivity. They are typically composed of iron oxide mixed with small amounts of other metals such as manganese, zinc, or nickel. The high resistivity of ferrite materials reduces eddy current losses, making them ideal for high-frequency applications.

Windings: The primary and secondary windings are coils of wire that are wound around the ferrite core. The primary winding is connected to the input voltage source, while the secondary winding is connected to the output load. The number of turns in each winding determines the voltage transformation ratio of the transformer.

The efficiency of this energy transfer is influenced by the properties of the ferrite material. Ferrite cores have high permeability, which means they can easily become magnetized, and high electrical resistance, which reduces energy losses due to eddy currents.

Advantages of Ferrite Core Transformers

FCTs offer several advantages over transformers with other types of cores, such as silicon steel cores. Some of the key advantages include:

1. High-Frequency Performance: Ferrite cores are highly effective at high frequencies, typically in the range of tens of kilohertz to several megahertz. This makes them ideal for applications such as switch-mode power supplies (SMPS), radio frequency (RF) transformers, and pulse transformers.

2. Low Energy Loss: The high electrical resistivity of ferrite materials significantly reduces eddy current losses, which are common in metallic cores. This leads to higher efficiency and less heat generation.

3. Compact Size: FCTs can be made smaller than their iron core counterparts while delivering the same power levels. This is particularly advantageous in applications where space is limited, such as in portable electronic devices.

4. Lightweight: Ferrite cores are lighter than metal cores, which contributes to the overall reduction in the weight of electronic devices. This is particularly beneficial in aerospace and mobile applications.

5. Cost-Effective: Ferrite materials are relatively inexpensive to manufacture, and the production processes for ferrite cores are well-established. This makes FCTs cost-effective for mass production.

Applications of Ferrite Core Transformers

The unique properties of FCTs make them suitable for a wide range of applications. Some of the most common applications include:

2. Telecommunications: In telecommunications, ferrite core transformers are used for impedance matching and isolation. They help in transmitting signals with minimal loss and distortion over long distances.

3. RF Transformers: FCTs are used in RF applications, such as in radio and television broadcasting, to match impedance and transfer signals between different stages of the equipment.

4. Inductive Components: Ferrite cores are used in inductors and chokes, which are essential components in filtering and tuning circuits. They help in suppressing noise and stabilizing signals.

5. Medical Equipment: In medical electronics, FCTs are used in devices such as MRI machines and other diagnostic equipment. Their high efficiency and low electromagnetic interference (EMI) are crucial in sensitive medical applications.

6. Automotive Industry: In the automotive sector, FCTs are used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) for power conversion and battery charging systems.

Design Considerations

Designing a ferrite core transformer involves several critical considerations to ensure optimal performance. These include:

1. Core Selection: Choosing the right ferrite material based on the frequency range and power requirements is crucial. Different ferrite materials have different permeability and loss characteristics.

3. Cooling: Although FCTs generate less heat than metal core transformers, adequate cooling mechanisms should be in place to manage the heat produced during operation.

4. Shielding: To minimize electromagnetic interference (EMI), proper shielding techniques should be employed, especially in applications where the transformer is located near sensitive electronic components.

Challenges and Future Trends

Despite their many advantages, ferrite core transformers also face some challenges. These include:

1. Saturation: Ferrite materials can become saturated at high magnetic flux densities, which can limit the maximum power handling capacity of the transformer.

2. Temperature Sensitivity: Ferrite materials can exhibit changes in their magnetic properties with temperature variations, which can affect the performance of the transformer.

Future trends in FCTs are likely to focus on improving material properties to handle higher power levels and frequencies. Advances in nanotechnology and material science may lead to the development of new ferrite compounds with enhanced performance characteristics.

Conclusion

Ferrite core transformers play a vital role in modern electronics, offering high efficiency, excellent high-frequency performance, and compact size. Their applications span across various industries, including telecommunications, automotive, medical, and consumer electronics. As technology advances, the demand for efficient and reliable FCTs is expected to grow, driving further innovation and development in this field. By understanding the principles, advantages, and applications of ferrite core transformers, engineers and designers can better leverage these components to create more efficient and powerful electronic devices.

#FerriteCoreTech#HighFrequencyTransformers#EnergyEfficientElectronics#CompactPowerSolutions#FutureOfTransformers

0 notes

Text

Replacement Coils Market Trends, Regional Segmented, Outlook & Forecast till 2033

The competitive analysis of the Replacement Coils Market offers a comprehensive examination of key market players. It encompasses detailed company profiles, insights into revenue distribution, innovations within their product portfolios, regional market presence, strategic development plans, pricing strategies, identified target markets, and immediate future initiatives of industry leaders. This section serves as a valuable resource for readers to understand the driving forces behind competition and what strategies can set them apart in capturing new target markets.

Market projections and forecasts are underpinned by extensive primary research, further validated through precise secondary research specific to the Replacement Coils Market. Our research analysts have dedicated substantial time and effort to curate essential industry insights from key industry participants, including Original Equipment Manufacturers (OEMs), top-tier suppliers, distributors, and relevant government entities.

Receive the FREE Sample Report of Replacement Coils Market Research Insights @ https://stringentdatalytics.com/sample-request/replacement-coils-market/10248/

Market Segmentations:

Global Replacement Coils Market: By Company

• Denso

• Bosch

• Hitachi

• Diamond Electric Mfg Co., Ltd.

• Hella

• BorgWarner

• Walker Products

• Marshall Electric

• ACDelco

• Mitsubishi Electric

Global Replacement Coils Market: By Type

• Vertical Coil

• Dual Coil

• Triple Coil

• Multiple Coils

• Twisted Coils

• Mesh Coils

Global Replacement Coils Market: By Application

• Transformers

• Isolate Electrical Systems

• Inductors

• Others

Regional Analysis of Global Replacement Coils Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Replacement Coils market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Replacement Coils Market Research Report @ https://stringentdatalytics.com/purchase/replacement-coils-market/10248/

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country

➋ Key winning strategies followed by the competitors

➌ Who are the key competitors in this industry?

➍ What shall be the potential of this industry over the forecast tenure?

➎ What are the factors propelling the demand for the Replacement Coils?

➏ What are the opportunities that shall aid in significant proliferation of the market growth?

➐ What are the regional and country wise regulations that shall either hamper or boost the demand for Replacement Coils?

➑ How has the covid-19 impacted the growth of the market?

➒ Has the supply chain disruption caused changes in the entire value chain?

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

BUY INDUCTORS , CHOKES & COILS | LOW PRICE – TOMSON ELECTRONICS

Discover a wide range of inductors, chokes, and coils at low prices - Buy online at Tomson Electronics. Find reliable and efficient solutions for your electronics projects. Elevate your designs today!

#electronics projects#electronics#buy electronic components online store in india#electronic components#best electronic components online buy india#electronic components online store#top online electronic components shop#business#arduino#best electronic components online store

0 notes

Text

Empowering LED Lighting Excellence: The Essential Role of Premium Cables

As the demand for energy-efficient LED lamps continues to soar, ensuring the safety and performance of LED products is non-negotiable. Beyond the focus on LED chips and aluminum housings, the quality of lighting and power supply cables plays a critical role in product reliability.

Traditional connecting wires often buckle under the high temperatures generated during LED lighting operation. To counter this challenge, anti-high temperature terminal wires have emerged as a favored solution. These specialized wires boast the capability to withstand temperatures up to 200°C, making them indispensable for high-temperature environments and electrical circuits with AC rated voltage of 600V.

Setting Benchmarks for Superior LED Products

Trusted LED Chips:

High-power LED lighting products demand original chips from trusted brands like San’an and Epistar. Steering clear of mixed or halogen powders ensures superior performance and longevity.

Premium Cables:

Employing anti-high temperature insulating materials for inductor coils and magnetic rings is imperative. Additionally, utilizing anti-high temperature resistant terminal wires, such as UL3239 silicone wires, ensures seamless operation and durability.

Rigorous Testing Protocols:

LED lighting products undergo exhaustive testing under varying temperature and pressure conditions. From sub-zero temperatures below -25°C to scorching heat exceeding 150°C, stringent testing is indispensable for product reliability.

Component Integrity Assurance:

Components of LED lights undergo rigorous high temperature and high-pressure impact tests to guarantee maximum safety. Testing parameters encompass resistor withstand voltage, diode withstand voltage, and capacitor temperature resistance.

LED Wall Washer: Illuminating Architectural Masterpieces

LED wall washers serve as the backbone of facade lighting systems, enriching buildings and landscapes with uniform pools of light. Leveraging wall washing and wall grazing techniques, these lights accentuate architectural features in mesmerizing ways. Facade lighting projects often necessitate IP66 waterproof functionality and specialized DC connector wires for seamless signal transfer and power supply.

0 notes

Text

Intermal Coil Calculation Design

In a sense, coil design for induction heating is built upon a large store of

empirical data whose development springs from several simple inductor

geometries such as the solenoid coil. Because of this, coil design is

generally based on experience. This series of articles reviews the

fundamental electrical considerations in the design of inductors and

describes some of the most common coils in use.

Intermal Coil Calculation Design

0 notes