#Color Coated Roof Sheet Roll Forming Machine

Explore tagged Tumblr posts

Text

Best Quality Metro sheet manufacturers in India

Metro Sheet Manufacturers in India: Powering the Growth of PEB Construction

India’s construction industry is experiencing rapid evolution, driven by the increasing demand for fast, durable, and cost-effective building solutions. One of the key innovations shaping this transformation is the rise of Pre-Engineered Buildings (PEBs)—steel structures that are pre-designed, factory-fabricated, and assembled on-site. As the backbone of PEB cladding and roofing systems, Metro sheet manufacturers in India are playing a pivotal role in enabling this shift toward modern infrastructure development.

What Are Metro Sheets?

Metro sheets refer to high-quality, profiled metal sheets commonly used for roofing and wall cladding in industrial, commercial, and residential buildings. These sheets are typically made from galvanized steel, Galvalume, or aluminum, and often come with protective coatings and attractive color finishes. Their durability, light weight, and corrosion resistance make them ideal for a wide range of construction applications—particularly in pre-engineered steel structures.

Metro sheets are available in various profiles, including trapezoidal, corrugated, and standing seam, offering versatility in design while ensuring strength and weather protection. These sheets serve as both functional and aesthetic elements in PEB construction.

Role of Metro Sheet Manufacturers in the PEB Industry

In the context of PEBs, metro sheets act as the external skin of the building, providing structural protection, insulation, and visual appeal. PEB manufacturers rely on metro sheet suppliers to provide high-precision, quality-controlled materials that align with the specific dimensions and performance requirements of their projects.

Key contributions of metro sheet manufacturers to the PEB sector include:

Customization: Sheets are produced to exact sizes, thicknesses, and finishes as per PEB design requirements.

High Production Standards: Use of advanced roll-forming machines and automated production lines ensures consistent quality and precision.

Durability and Protection: Coated sheets protect steel frames from weather elements, enhancing the lifespan of the building.

Speed of Construction: Pre-fabricated sheets enable quick installation, reducing project timelines and labor costs.

By offering reliable supply chains and consistent quality, metro sheet manufacturers support the seamless execution of PEB projects across India.

Market Demand and Industrial Applications

The Indian PEB market is growing rapidly due to increased demand in sectors like logistics, warehousing, manufacturing, agriculture, aviation, and commercial development. With this growth, the demand for superior roofing and cladding materials has also surged—placing metro sheet manufacturers in a critical position.

Some common applications of metro sheets in PEBs include:

Warehouses and distribution centers

Cold storage and agro-processing units

Airports and hangars

Manufacturing plants and workshops

Commercial and institutional buildings

Residential roofing and farm structures

The ability of metro sheets to withstand harsh environments, including heat, rain, and wind, makes them especially suitable for diverse Indian climatic conditions.

Conclusion

Metro sheet manufacturers in India are integral to the success of the growing PEB industry. By delivering high-quality, customizable, and durable roofing and cladding solutions, they empower PEB manufacturers to construct modern, efficient, and sustainable buildings across the country. As demand for rapid and resilient infrastructure continues to grow, the collaboration between metro sheet and PEB manufacturers will remain a cornerstone of India’s construction future.

Visit:- https://www.pebmanufacturers.in/metro-sheet.html

0 notes

Text

Roofing Sheets A Comprehensive Guide by Hi-Tech Pipes

Roofing sheets, also known as corrugated metal sheets, are a versatile and durable roofing material used in various residential, commercial, and industrial buildings. They are available in a wide range of colors and profiles to suit different architectural styles and functional requirements.

Hi-Tech Pipes: A Leading Manufacturer of Roofing Sheets

Hi-Tech Pipes is a renowned manufacturer of roofing sheets in India. The company is known for its commitment to quality, innovation, and sustainability. Hi-Tech Pipes’ roofing sheets are manufactured using high-grade steel and undergo rigorous quality control checks to ensure they meet the highest standards.

Types of Roofing Sheets

There are two main types of roofing sheets:

Galvanized steel roofing sheets: These sheets are coated with a zinc layer to protect them from corrosion. Galvanized steel roofing sheets are the most common type of roofing sheet due to their affordability and durability.

Color coated roofing sheets: These sheets are galvanized steel sheets that have been painted with a layer of color coating. Color coated roofing sheets offer a wider range of aesthetic options and enhanced UV protection.

Manufacturing Process of Roofing Sheets

The manufacturing process of roofing sheets involves several steps:

Selection of raw materials: High-quality steel coils are selected as the base material for roofing sheets.

Coil slitting: The steel coils are slit into strips of the desired width.

Cold roll forming: The steel strips are cold-rolled into the desired profile using specialized forming machines.

Galvanizing: The roofing sheets are galvanized in a molten zinc bath to provide corrosion protection.

Color coating: For color coated roofing sheets, an additional step of applying a color coating is done using a paint application system.

Quality inspection: The roofing sheets undergo rigorous quality inspection to ensure they meet the required specifications, including thickness, coating uniformity, and surface finish.

Applications of Roofing Sheets

Roofing sheets are widely used in various applications, including:

Residential roofing: Roofing sheets are a popular choice for residential roofing due to their affordability, durability, and ease of installation.

Commercial roofing: Roofing sheets are also frequently used in commercial buildings, such as warehouses, factories, and shopping complexes.

Industrial roofing: Roofing sheets are a common choice for industrial roofing applications due to their ability to withstand harsh weather conditions and chemical exposure.

Benefits of Roofing Sheets

Roofing sheets offer several advantages over other roofing materials:

Durability: Roofing sheets can withstand harsh weather conditions, including wind, rain, and snow.

Corrosion resistance: Galvanized roofing sheets are highly resistant to corrosion, ensuring a long lifespan.

Low maintenance: Roofing sheets require minimal maintenance compared to other roofing materials.

Affordability: Roofing sheets are a relatively affordable roofing material.

Lightweight: Roofing sheets are lightweight and easy to install.

Versatility: Roofing sheets are available in a wide range of colors and profiles to suit different architectural styles.

Sustainability: Roofing sheets can be recycled, making them an environmentally friendly roofing option.

Hi-Tech Pipes: A Commitment to Quality and Sustainability

Hi-Tech Pipes is committed to providing high-quality roofing sheets that meet international standards. The company employs advanced manufacturing techniques and stringent quality control measures to ensure the consistency and reliability of its products.

Hi-Tech Pipes is also committed to sustainability practices. The company has implemented eco-friendly manufacturing processes and utilizes recycled materials whenever possible to minimize its environmental impact.

Conclusion

Roofing sheets��are a versatile, durable, and affordable roofing material suitable for various applications. Hi-Tech Pipes, with its commitment to quality, innovation, and sustainability, stands as a leading manufacturer of roofing sheets, catering to the needs of diverse industries and projects across India.

0 notes

Text

The Art of Roofing Sheet Product Manufacturing: Quality and Innovation

Roofing sheet product manufacturing is a critical industry that plays a pivotal role in constructing durable and reliable roofs. This article explores the key aspects of manufacturing roofing sheets, emphasizing quality and innovation as central themes in the production process.

1. Material Selection

The foundation of any exceptional Roofing manufacturers begins with material selection. Manufacturers must choose high-quality materials such as steel, aluminum, or specialized alloys to ensure longevity and resilience. These materials must also meet industry standards for corrosion resistance and structural integrity.

2. Roll Forming Process

The roll forming process is at the heart of roofing sheet manufacturing. This method involves passing metal coils through a series of rollers to create the desired profile. Precise engineering and calibration of these machines are vital to produce consistent, uniform sheets that fit seamlessly on roofs.

3. Coating and Finish

To enhance durability and aesthetics, roofing sheets undergo coating and finishing processes. This can include galvanization, paint application, or other protective coatings. Manufacturers need to employ advanced techniques to ensure that these coatings adhere securely and resist weathering.

4. Quality Control

Quality control is non-negotiable in roofing sheet manufacturing. Stringent inspections and tests are carried out to verify dimensional accuracy, coating adhesion, and material integrity. Continuous monitoring and adherence to quality standards are essential to delivering reliable products.

5. Innovation and Sustainability

In today's roofing sheet manufacturing landscape, innovation and sustainability are driving forces. Manufacturers are exploring eco-friendly materials and energy-efficient production methods to reduce their carbon footprint. Moreover, advancements in digital design and simulation tools are enabling the creation of increasingly efficient and cost-effective roofing solutions.

6. Customization and Customer Satisfaction

Meeting the diverse needs of customers is paramount. Roofing sheet manufacturers offer customization options, including various profiles, colors, and sizes, to cater to different architectural styles and preferences. Ensuring customer satisfaction is essential for building trust and reputation in the industry.

Conclusion

In the roofing sheet product manufacturing industry, the pursuit of excellence in material selection, production processes, and innovation is essential. Manufacturers must prioritize quality and customer satisfaction to provide roofing solutions that protect and enhance buildings for years to come. With these principles in mind, roofing sheet products can continue to evolve and meet the demands of an ever-changing market.

For more info. visit us:

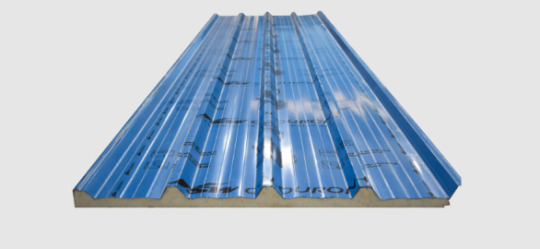

Sandwich roofing sheet

Sandwich sheet price in kerala

Puffed sheet roofing price

Metal sheet roofing price in bangalore

0 notes

Text

Obvious

A transhuman god is upset at the departure of her children, and is at odds with her partner.

Natalia peered over the scene before her: A parade, climbing along a street wedged between shiny black glass skyscrapers and polished concrete apartment buildings. Her view stood above it all, showing her all of the city; an urban sprawl, clustering in the middle, a suburb of lawn sprinklers and freshly cut grass to the west, oakwood docks and caramel colored beaches to the east. Further down west past the suburbs are all rural deserts and forests, full of buggy driving rednecks, tobacco growing hermits and cocaine hauling gangsters in speedos. All neatly nested within the small, lonely island.

She wasn’t going to tell the city government any of what she saw far west; they were the ones who made the decision to leave her.

She returned to the real world: grey rocky landscape, and sleek black spires in the distance, spewing out pillars of smoke into the sky, joining the dark, electrified clouds.

The clouds weren’t normal; she could almost see the ocean of micro and nano machines swirling around on their pinwheel joints, connecting their long flagella wires, pushing atmosphere and delivering energy and messages all around the planet. A circulatory, respiratory, and nervous system all rolled into one big blanket for the whole world...

A large black seed shaped object hovered in the sky, the sharper end pointed upwards. It was obvious to Natalia what would happen; the clouds would synthesize the fuel, load it onto the rocket, and launch Natalia’s children past the sky and into space, where it would blossom, unfurling it’s sails and carry off riding the light of the stars.

Everything was obvious to Natalia now.

If she wanted to understand circuitry and rocket science, she did. If she wanted to understand chemistry and biology, she did. If she wanted to know how to create life, control the weather, travel the cosmos, she did.

And it was obvious why she could; she wasn’t human anymore. Her name hadn’t always been Natalia, but she had burned through so many at this point. She supposed that she picked that quality up from her partner.

“Leaving?�� Speak of the devil, and you shall receive them.

They had many names and faces throughout their life; Carried in by wings that should’ve been invisible to Natalia, had it not been obvious, was Jules. An azure blue dress shirt hugged them underneath a black, floral patterned waistcoat and matching black jeans with gilded zipper pockets.

“Not me,” She began, knowing Jules already knew the answer, “My yggdrasil children.”

Yug-Drasil, the pronunciation rolled off her tongue as if she was fluent in the language (she was, obviously), and she couldn’t tell whether or not she read that somewhere, or if it was a signal plopped in her head by their new brain.

The world trees dotted the continent; branches composed of centimeter by centimeter metallic cubes, each holding the equivalent of entire human brains, billions of molecular neurons packed into something that could fit in the palm of a hand. Each mind was attached to a shared computer simulation, a virtual environment, either randomly generated or designed by Natalia, or Jules. Whole countries could be fitted in the space of a medium sized farmhouse, 30 souls a foot.

Natalia had reared an entire society in one, fully aware of the outside world. And they wanted to leave.

“I fixed it, by the way,” Natalia’s pause barely covered a microsecond when Jules spoke.

She didn’t bother asking for an answer she already knew. “My sabotage,” She said.

A special colony of micromachines, activated by sunlight, designed to devour Mylar, the material used on a solar sail. Jules must have picked them out, like a baboon picking out ticks from a mate’s fur coat and eating them, when the rocket went through the clouds.

“You bastard,” A smile infected her face, reaching her eyes. She used to have a volatile competitive streak; now she loved it when someone outsmarted her.

Jules regarded her with a drab expression, a soft smile touching their lips, but never their eyes.

She wouldn’t have hurted them, only keep them stuck in orbit. If she could have her way now, she would’ve made it so that none of her children could leave. But that was the deal their older faces made long ago, when the trees were first thought of; let life go on. It’s only natural for Jules to uphold it.

She hated them and she loved them, so she walked up and planted a kiss on their lips, and pulled them in.

Her mind drifted off, summoning an Eidolon. Several kilometers north of here, at the base of a spire, micromachines sprung up from the ground like a trail of ants climbing along their own backs, climbing along lattice structures made of themselves, all together forming a single grey shape composed of arms, legs, a torso, and a head. The micromachines texturize themselves, forming smooth skin and dangling fabrics, pigment and color spreading across it, revealing Natalia in her short blonde hair, black leather garments and boots.

The strange flesh and silicone blood Natalia, undressing herself with Jules on top of her, sent abstract commands to her Eidolon as it sent back short term memories. Eidolon Natalia regarded the spire; A power plant, delivering electricity to the machine clouds above, as if solar power wasn’t enough (she knew it wasn’t). This one would be using fusion to vaporize water into steam, spinning a sheet of micro turbines. Electricity would climb to the tip of the spire, where micromachines would distribute it amongst themselves in an invisible network.

Natalia commanded her Eidolon to move elsewhere, so she conjured a set of wings. They attached themselves to the Eidolon’s body, embedding straps to it’s fake skeletal structure, and pulled it off the ground.

The wings didn’t flap; it swirled air below and behind with a cloth made of a million tiny fans. A dust storm formed in the north, one of the only natural threats present on the planet. She knew an invisible wall would be forming around the storm, isolating and neutralizing it.

Desolate buildings whizzed by below her feet; Skyscrapers, castles, mansions, houses, cabins, and towers. When Jules and Natalia first came here, that was all they had ever done; build and build and build. They stretched their creative abilities, at least when they still had human minds.

After that, they just lived here. Sometimes together, sometimes isolated. Then the network was created, sinking its roots into the ground below, and Jules and Natalia connected themselves to it. Her name was Jacqueline when that happened, and Jules was Nathaniel.

The lone structures below transitioned into clusters of villages and townships, groupings of decrepit and abandoned housing. Things became obvious for Jack and Than, or rather they started to tap into the bank of knowledge and expertise that was the planet-wide superintelligence. Whenever they sensed or thought something, hundreds of artificial neurons parsed through it, predicted a query, and sent the answer as an electrical pulse that the brain interpreted as knowledge it already had.

Every science and every byte of knowledge became like common sense to them. Obvious.

And so, it became obvious what was missing from their- or rather Jack and Than’s - lives: People. So, they took what they knew, and built some people, called Simms. Like that ancient video game.

A patch worked house stood below Natalia. One of Than’s. Castles and junkyard additions erupted from its roof, colorful graffiti all over it. The Simms had breathed life into their world, returning complex relationships, conflict, and an extra pair of creativity.

Jules pulled their lips from the real Natalia, a smile still present as they looked down at her. “Where are you going?”

Another Eidolon erupted from the ground below, growing to encompass a height of 20 feet, lumbering over the house. It’s body texturized into skin, no clothing, revealing the black haired face of Jules staring up at her. Jules always loved provoking imagery.

“My mind wandered, decided to take a stroll down memory lane,” Natalia and her Eidolon spoke in sync.

“You would have me think that,” A smile stretched across Eidolon Jules face, “wouldn’t you?”

Their belly inflated, rumbling, and something climbed up their throat. They opened their mouth, muffled screams following, and eventually an arm, followed by the blonde haired head of a middle aged man.

“Oh god!” The figure exclaimed in anguish and horror, “Please help me!”

Natalia knew the man; John Yak, third generation of the Yak family, ex-military (or so he thought), strict father of three. He used to live in the patchwork house, and his son was the one who built the castle tower for his kids.

“Please god!” Than designed John to be aggressive, loyal, prideful, and especially arrogant, being the one who stuffed the house with taxidermy and bear carpets from his hunts. He died when he was eaten by a polar bear.

The Eidolon pursed his lips around the Simm, making a slurping sound. John shrieked as he was drawn back down into the Eidolon’s belly.

“That supposed to scare me?” Natalia spoke up to Jules.

“No,” Jules said, and Natalia braced for another cryptic answer, “It’s supposed to scare me.”

“Oh stuff it, would you.” Natalia stretched her head to theirs, embracing Jules again. Eidolon Natalia continued her journey, and the giant naked Jules watched her leave with a smile, until disintegrating into grey fractal dust.

#scifiworld#worldbuilding#short story#sci fi books#science fiction#transhuman#transhumanism#creative writing#writing

4 notes

·

View notes

Text

7 Benefits of Pre-Painted Galvanized Steel Roofs

When it comes to building either residential or commercial structures, roofing is a critical component. Every structure requires a robust and strong roof that can protect its occupants from the elements.

Addressing this concern - Philmetal Products Inc. has Colorbond ®. COLORBOND® pre-painted roof profiles are factory-painted roofing materials that are made using 100% genuine GALVALUME55® as a substrate.

Unlike GI sheets with only zinc coating, GALVALUME55® coating is composed of 55% Aluminum, 43.5% Zinc and 1.5% Silicon. This composition provides superior roofing protection including:

Superior rust protection – GALVALUME55® roofing sheet provides 3 to 6x longer protection against rust compared to ordinary GI giving the customer a longer service life for his roof.

High heat reflectivity – GALVALUME55® roofing sheet has superior reflectance of the sun’s heat, allowing a cooler environment inside the house, greatly reducing the cost of electricity.

Long-span metal roofing that has been pre-painted resists corrosion better than GI sheet roofing that has not been painted. If you need a roof, pre-painted ones are better to use because they prevent certain problems like rust.

Pre-painted galvanized sheet is a versatile material that may be used for roofing and wall applications, as well as interior designs like ceilings and awnings. They provide a variety of advantages, some of which are listed below.

Flexibility

Because of their flexibility, Colorbond ® roofs are simple to handle and can be used for a variety of purposes.

Lightweight

Because Colorbond ® substrate is Galvalume55 ®, it is lightweight while being strong and durable.

Weather Resistant

Colorbond ® roofs are made of weather-resistant materials that keep their color and shine for a long time. Hot and humid, as well as heavy rainfall, have no effect on the life of these roofing sheets, which can last for many years.

Corrosion Resistant

Colorbond® roofing sheets are highly corrosion resistant, making them ideal for usage in a variety of climates. They have a longer lifespan and require less maintenance because they do not rust.

Thermal Insulation

Colorbond® sheets do not easily conduct heat, making them ideal for usage during the summer because they prevent heat from entering the building and assist to create a cool environment inside.

Beautifully Designed

Colorbond® pre-painted roofing sheets are visually appealing. They are available in a variety of colors, which improves the overall visual appeal of the structure and makes it more appealing.

Colorbond® pre-painted roofs are becoming increasingly popular due of their adaptability and durability. They offer numerous advantages over other roofing materials, making them an excellent alternative for any type of construction project.

Affordability

Colorbond® ensures that your roof will last for decades, saving you time, money, and the aggravation of having to repair it frequently. We are the strongest and most dependable roofing solution in the country because of our devotion to true thickness and precise coating thickness.

#prepaintedroof #colorbond #galvalume55 #galvanizedroof #roofingph

For more details you may visit their Facebook or Website at:

1 note

·

View note

Text

430 Stainless Steel Sheet

https://www.sdosssheet.com/products/430-stainless-steel-sheet/

430 stainless steel is general-purpose steel with good corrosion resistance. It has better thermal conductivity than austenite, a smaller thermal expansion coefficient than austenite, heat fatigue resistance, addition of stabilizing element titanium, and good mechanical properties of the weld. 430 stainless steel is used for building decoration, fuel burner parts, household appliances, and home appliance parts. Because of its chromium content, it is also called 18/0 or 18-0. Compared with 18/8 and 18/10, it contains slightly less chromium, and the hardness is correspondingly lower.

430 Stainless Steel Sheet Specification

Item

Stainless Steel 430 sheet (Hot rolled, Cold rolled)

Thickness

0.3~10.0mm

Width

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Standard

JIS, AISI, ASTM, GB, DIN, EN, etc

Surface

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc

Package

Shrink-wrapped, Carton boxes, Wooden pallets, Wooden boxes, Wooden crates Etc.

Edge

Mill Edge Slit Edge

Export to

India, Indonesia, Malaysia, Singapore, Saudi Arabia, Qatar, UAE, Iran, Iraq, Oman, South Africa, Nigeria, Kenya, Italy, UK, Brazil, Russia, Egypt, Kuwait, Taiwan, Australia.

Chemical elements Of 430 stainless steel sheet

Element

C

Si

Mn

P

S

Cr

Ni

%

0.12

0.75

1

0.04

0.03

16.00~18.00

0.60

Processing Service Of Our 430 Stainless Steel Sheet

Cutting+Slitting - 430stainless steel narrow strip,special length/width plate

(1) Flame cutting: The cost of flame cutting equipment is low and it is the only economical and effective means to cut thick metal plates, but it has its shortcomings in thin plate cutting.

(2) Laser cutting:Laser cutting equipment can cut stainless steel plates below 30mm. Adding oxygen to the laser beam can cut 40mm thick carbon steel, but after oxygen cutting, a thin oxide film will be formed on the cutting surface.

(3) Wire cutting: It is developed on the basis of EDM perforation and forming. It has not only developed the application of EDM but also replaced EDM perforation and forming in some aspects.

(4) Shearing cutting:Uses a moving upper blade and a fixed lower blade and uses a reasonable blade gap to apply shearing force to metal plates of various thicknesses so that the plates can be broken and separated according to the required size. Shearing machine is a kind of forging machinery, and its main function is the metal processing industry.

(5) Plasma cutting:It is a processing method that uses the heat of a high-temperature plasma arc to partially or partially melt (and evaporate) the metal at the incision of the workpiece and uses the momentum of the high-speed plasma to remove the molten metal to form an incision.

(6) Slitting: Also known as slitting, refers to the process of uncoiling, slitting, leveling, and winding of stainless steel coils into coils of the required width.

Surface processing - 8K mirror, HL hairline, color coating

Bending+Welding - OEM customized products as drawing

Application Of 430 Corrosion Resistant Stainless Steel Sheet

√

430 Stainless Steel sheet Used in Roofs of industrial buildings

√

430 Stainless Steel sheet Used in side walls of industrial buildings

√

430 Stainless Steel sheet Used in hot water tanks

√

430 Stainless Steel sheet Used in hot water systems

√

430 Stainless Steel sheet Used in sanitary appliances

√

430 Stainless Steel sheet Used in durable household appliances

√

430 Stainless Steel sheet Used in bicycle flywheels

√

430 Stainless Steel sheet Used in automatic lathes

√

430 Stainless Steel sheet Used in bolts and nuts

430 Stainless Steel Sheet Processing

430 Stainless Steel Sheet Cutting

430 Stainless Steel Sheet Slitting

430 Stainless Steel Sheet Color coating

430 Stainless Steel Sheet Hairline/Brush

430 Stainless Steel Sheet Etching

430Stainless Steel Sheet Welding

430 Stainless Steel Sheet Bending

430 Stainless Steel Sheet Embossing

430 Stainless Steel Sheet Bead Blasted

430 Stainless Steel Sheet Polishing

430 Stainless Steel sheet Stock Available

Tisco Stainless Steel 430 sheet

Stainless Steel 430 sheet

Jindal Stainless Steel 430 sheet

SS 430 Perforated sheet

A 240 430 sheet

SS DIN 1.4571 sheet

Stainless Steel 430 UNS S31635 sheet

SS 430 Embossed sheet

ThyssenKrupp Stainless Steel 430 sheet

A 240 Chequered 430 sheet

Outokumpu SS 430 sheet

ASTM A240 Stainless Steel 430 sheet

Aperam Stainless Steel 430 sheet

SA 240 430 Stainless Steel sheet

Surface Polishing SS 430 sheet

430 Stainless Steel HR sheet

Bright Hammered Pattern Decorative SS 430 sheet

430 Stainless Steel Blank sheet

430 Stainless Steel Chequered sheet

430 Stainless Steel CR sheet

430 Stainless Steel Perforated sheet

430 Stainless Steel Golden Laser Pattern sheet

430 Stainless Steel 2B sheet

Embossed ss 430 sheet

Super thin-Mirror surface BA ss 430 sheet

430 Stainless Steel B. Q. Profile sheets

Cheap cold rolled ss 430 sheet with best price

Super Austenitic SS 430 sheet

Best selling 4'x8' mirror finished ss 430 sheet

Brush finish ss 430 sheet price list

ASTM A240 430 sheet

Decorative hairline inox cold rolled ss 430 sheet

SS URANUS B6 430 sheet

JMSS cold rolled ss 430 sheet

Hair Line Finish SS 430 sheet

2B SUS SS 430 sheet

Cold Rolled No.1 Finish SS 430 sheet

Laser cutting ss 430 sheet

Food Grade Stainless Steel 430 sheet

SEW 400 Stainless Steel 430 sheet

Tisco Supplier 3mm Thickness Stainless Steel 430 sheet

No. 4 PVC Coated SS 430 sheet

Hot Rolled Stainless Steel 430 sheet

Decorative Stainless Steel 430 sheet

SS 430 sheet Blasted Tin-Gold Rose

Sales Promotion SS 430 sheet

Scotch Brite SS 430 sheet

2mm ASTM SS 430 sheet

Cr Stainless Steel 430 sheet

Baosteel Stainless Steel 430 sheet

Stainless Steel Corrugated 430 sheet

SS 430 Mill Test Certificate sheet

Stainless Steel Cladding 430 sheet

ASTM B625 430 sheet

ASTM A240 430 sheet

Black SS 430 sheet 4mm Thick

Brushed or dull polished Stainless Steel 430 sheet

Cold rolled, bright annealed 430 sheet

Bright-pickled Stainless Steel 430 sheet

Cold rolled, heat treated, pickled 430 sheet

Ground Stainless Steel 430 sheet

Cold rolled, heat treated 430 sheet

10K Mirror Finish Surface SS 430 sheet

Hot Selling AISI SS 430 sheet

3mm Cold Rolled AISI SS 430 sheet

Gold Etched SS 430 sheet

SS 430 Rose Golden sheet

Mill Supply SS 430 sheet

18 Gauge SS 430 sheet

Surface coated Stainless Steel 430 sheet

Grade Prime SS 430 sheet

Patterned Stainless Steel 430 sheet

Satin finish Stainless Steel 430 sheet

Carpenter Custom 450 Stainless Steel 430 sheet

Finish Stainless Steel 430 sheet

AISI stainless steel 430 armor sheet

Cut to Size Stainless Steel 430 sheet

Patterned Stainless Steel 430 sheet

Satin finish Stainless Steel 430 sheet

Non Magnetic Polishing Stainless Steel 430 sheet

Passenger Elevator Cabin SS 430 sheet

Mirror Finish SS 430 sheet

ASME SA240 430 sheet

SS 430 sheet Gold Brush Finish

0 notes

Text

Henan Changge 32 portable steel bar bender straightener is recommended

Henan Changge 32 portable steel bar bender straightener is recommended

the quotation on December 8 is 4994 yuan / ton, and the price of galvanized sheet 1.0 * 1250 * C is increased by 100-150 yuan / ton, or 1.75%. On December 4, the price of color coated plate was 0.5 * 1200 * C, 6828 yuan / ton, and on December 8, 6878 yuan / ton. The overall price of color coated plate was reduced by about 50-150 yuan / ton, with an overall increase of 0.73%.

Features of the equipment:

1. Large bending force (driven by high oil pressure, it can bend 40mm screw steel)

2. Light weight and easy movement can bend the vertical direction reinforcement of the poured concrete (such as the pile foundation reinforcement of high-speed railway of expressway, anti floating anchor of foundation pit of high-rise building, reinforcement at the joint of shear wall and roof). )

decreased by 1.14%. In terms of market: on December 8, the spot price of hot coils in East China gradually rose after falling. The market was mainly wait-and-see, and the overall transaction was light. The main selling price <a href="http://www.metmac.com/logistic-shelf-roll-forming-line.html">on sale - women</a> of thick coil resources above 5.5mm * 1500 was 4230-4320 yuan / ton. The spot price of hot coils in North China fell steadily, and the market trading atmosphere was general. Because of the cost support, traders were not willing to adjust prices.

3. The 4-meter-long high-pressure oil pipe is used to connect the bending head and the power hydraulic station, which is convenient to use. The weight of the bending machine <a href="http://www.metmac.com/robot.html">industrial robotic arm manufacturers</a> is the weight of the elbow. During the bending work, workers are not forced to hold the bending head to grasp the direction, which is light.

4. High efficiency, one worker can operate. Both bending and straightening. The bending angle of 32 mm deformed steel bar is 120 degrees, and the straightening angle is 90 degrees.

River The recommended straightening machine of nanchangge 32 portable steel bar bending machine is

5.5 * 1500 * C hot coil market mainstream quotation or between 4100-4450 yuan / ton. The official account of business community helps enterprises to help invest in the investment and price monitoring of business. As of November 30th, the average price of spot 16mm three grade rebar (distribution) was 4744 yuan / ton, which rose 17.17% compared with October, up 62.79% from the same period last <a href="http://www.metmac.com/expanded-metal-mesh-machine-suppliers.html">expanded metal mesh machine suppliers</a> year.

Working pressure: 20MPa

self weight of bending machine: 12-14kg

Working efficiency:

1000-2000 steel bars can be bent in 18 hours a day. A steel bar straightener is a kind of common engineering machinery in the field of road and bridge and house construction. In the process of construction, the straightening steel bars often fail to meet the design requirements, and the actual construction is against the intention of the design drawings. In order to further solve the problem of difficult site construction,Our company has designed a kind of portable steel bar straightener which can work efficiently, reduce the barbaric construction, and can complete the field construction quickly and effectively with high quality, which makes the field construction difficult.

The recommended straightener of Henan Changge 32 portable steel bar bending machine is

slightly higher than last week. According to the price monitoring of the business agency, as of December 8, the average selling price of Q235B 5.5 * 1500 * C hot rolled coil in the domestic market was 4277.14 yuan / ton (including tax), 0.18% higher than the same period last week. On December 8, the settlement price of main contract of hot coil was 4074 yuan / ton, and on December 1, the settlement price of main contract of hot coil was 4121 yuan / ton.

Compared with the previous week, it decreased by 16800 tons and 4.37% on a weekly basis. Among them, the total volume of I-beam / H-beam is 113700 tons, with the same cycle to cycle ratio; the total volume of channel steel is 72600 tons, with the cycle to cycle ratio decreasing by 1.76%; the total volume of angle steel is 181500 tons, with the cycle to cycle ratio decreasing by 7.87%. Overall, the overall delivery volume of profile this week is slightly higher than that of the previous week.

0 notes

Text

Aluminum coil 3104 alloy

A3104 aluminum coil, a deformed alloy with tempers including H111, O, H14, H16, H18 and H34 etc., has a maximum tensile strength of 275MPA and elongation up to 20%. As a deformed alloy, aluminum coil 3104 alloy has good forming ability, strong corrosion resistance and excellent welding ability. Further more, outstanding performances in tensile strength and elongation endows the coil with good deep-drawing property, making it suitable for end products requiring light weight materials, such as tanks, beverage cans, chemical containers and so on.

Alloy: AA3104

Temper: HO, H12, H14, H16, H18, H22, H24, H26, H28

Thickness: 0.15mm-6.0mm

Width: 80mm-2300mm

Standard production: ASTM-B-209M,BS EN 485-2,BS EN 573-3,GB/T3880-2008

Mother coil: DC or CC

Weight: about 0.5-2.5mts per pallet

Surface: mill finish, mirror finish, color coating, embossed, unstained,no scratching

Technology: Cold rolled, hot rolled

Packaging Details: wooden case with waterproof materials for transport

Delivery time: within 30days

Origin:China

Certificate: Mill Test Certificate,Certificate of origin:Form A,Form E,CO

3104 Aluminium coil mechanical properties

Good corrosion resistance

Good weldabilityand formability

Good plasticity, light, durable, economical, environmentally friendly

3104 Aluminium coil Chemical Properties

AlloySiFeCuMnMgCrNiZnCaVTiOtherMin.A1

31040.60.80.05-0.250.8-1.40.8-1.3--0.25--0.10.15Remainder

Aluminium Coil 3104 is frequently used for their good combination of strength and formability, weldability, and the strengthening effect of added Mn is supplemented by additions of magnesium which offers further solid solution strengthening.

1. a3104 aluminium coil is first used in parts requiring good formability, high solderability and good resistance to corrosion , such as kitchen utensils, food and chemical processing and storage devices, transport tanks for liquid products and so on.

2. The coil is also applied to building materials, construction, cable pipes, sewer pipes, various parts of lamps and lanterns, blinds, cans, roofing sheets, color coated aluminum sheets, electric light heads etc.

3. 3104 aluminium coil serves as raw materials of pressure vessels, pipelines, cooling fin, radiators, makeup boards, copy machine rollers, ship materials etc.

Reprinted from https://www.aluminum-coil.net/aluminum-coil-3104-alloy.html

0 notes

Link

Roll forming is the most commonly used method for the production of building roofing panels and wall panels with color coated boards. Roll forming machines use a series of differently shaped rolls on a rack to press the steel rolls into the required shape. Color-coated steel sheet is pressed into various shapes according to the […]

0 notes

Text

Paint-Protective Films Can Protect Your Car From Rocks and Save Your Paintjob

Paint protection has become the first stop for many new car owners. It involves putting either a film or a ceramic coating on the car’s clearcoat that can protect it from UV damage and rock debris. The film, originally developed by 3M in the Vietnam War to protect helicopter rotor blades, has matured over the past 20 years in the automotive world to become the must-have paint defender that can last for years, while remaining clear and invisible to the eye. A decade ago, yellowing of the film was a major concern, but years of development have corrected that issue, resulting in a product that, if correctly maintained, can remain clear for 5 to 10 years, so that all you see is your car’s magnificent color.

Twenty years ago, it was commonplace to see a car driving around with a black vinyl car bra. It was a hard trade off: either protect your car’s paint by hiding it under a black vinyl cover or enjoy the paint and style of your car and accept the damage that will lead to a paintjob in the future. The new films have almost eliminated that harsh choice. Owners can have protection and still enjoy their cars’ original paint—but paint protection comes at a cost.

There are DIY kits, but, as with anything, experience matters. Installing the film competently takes years of training on how to manipulate the film into hard corners and crevices. No matter where it is being applied, the film will not just mold to those lines—it needs to be stretched, shrunk, and yes, even cut.

Juan Madrigal of ProteKive Coatings in Moreno Valley, California, honed his skills working in the industry for years under the tutelage of experts. He has worked for West Coast Customs as their inhouse paint-protection and vinyl-wrap installer, and regularly travels to multiple dealerships installing films on Mercedes, Lamborghinis, and Ferraris. “I was able to work at a high level, work on supercars, and that gave me more determination to learn and perfect my techniques,” he says. He eventually opened up ProteKive Coatings. Today, he is using his skills to install paint protection on a 2018 Mustang Shelby GT350R.

Paint protection should be placed anywhere that might encounter road damage. Typically, this means any areas that are pointing forward. There are three coverage options: partial front, complete front, and custom.

Partial front coverage covers one-third of the hood, the full bumper, and mirrors. This is the most popular choice, but Madrigal says the downside is that you will see the edge of the film on the hood. However, if you are leasing a car, this is the best option. Partial front costs around $600.

The next coverage option is complete front. It includes full fenders, full bumper, full hood, mirrors, headlights, fog lights, and in some cases, A-pillars. This is the option that Madrigal recommends because it will appear seamless (no lines on the car) and provide the most coverage, as well as protect all of the areas that are most prone to debris. Complete front coverage could cost upwards of $1,600.

Custom applications can include any coverage on panels, in addition to complete front coverage. This could include rocker panels, roof, or any other areas where extra protection is desired, even full coverage of the entire car. Prices vary, but Madrigal mentions that, for most situations, complete front coverage is all the protection people need.

There is a selection of films. You will hear multiple names and manufactures like 3M, XPEL, Suntek, to name a few, but most will fall between two options: 9H hardness or self-healing.

Original films offer 9H hardness, which is very scratch-resistant. This is similar to what the original paint-protection film was—it’s hard and resists most rocks. The downside is that after multiple rocks hit, it may start to show wear, as scratches and tears in the film may be evident.

The new film options include self-healing films. They do not have a hardness factor, but because they are polyurethane, they react to heat. This means a scratch or a tear, or any damage, will mend itself. The benefit of this option is that scrapes and tears will not be as noticeable.

Also available now is Windshield protection, a 7-ml, 9H hardness glass film similar to the glass-protection film added to cellphone screens. It protects a windshield from rock chips or cracks. It won’t save your windshield from something large, but it will stop those pesky cracks that end up causing you to replace your windshield or visit a Safelite location.

Ceramic coating is yet another paint-protection option that does not include installing a film. Ceramic coating, or Nano coating, places a semi-permanent coating on the paint that seals and protects. The coating offers a 9H hardness, so it will protect against minor abrasions and strikes from rocks. It is also hydrophobic, so water will roll right off of it. Its main benefit is UV protection and protecting against swirl marks when cleaning. Being semi-permanent, it will wash away after about a year, so think of it similar to a semi-permanent wax that needs to be redone to maintain the benefits of its protection.

The first thing that Juan does is wash the car thoroughly. He uses a pressure washer and a foamer to coat the car in soap suds, which lifts any dirt and debris from the paint. This step ensures a clean surface onto which Juan can install the film.

The film comes in 60-inch-wide rolls. For most cars, like the GT350R, the patterns for the fenders, bumpers, hoods, and other areas are precut on a machine. Precut patterns are sourced from a company that 3D-scans a similar car, so that it matches perfectly. On cars for which no pattern exists, Juan takes a sheet of film from the roll and manipulates it to the shape, making a custom-fit piece of protective film.

The film is first laid out on a table. It is sprayed with a water/soap mixture that will later help Juan manipulate the film on the paint. Without the soap solution, the film would be too hard to move around.

Juan sprays the panel before placing the film down. He then lowers the film on to the body panel and starts wiping at the edge with a squeegee blade to force the water solution out from under the film. He continues to wipe, spraying frequently to keep the film wet. A slippery surface stops him from applying too much pressure on the film. It also ensures that it is applied evenly. When he gets to the corners, Juan switches spray solutions. He selects a water and alcohol mixture that promotes tackiness in the film. He uses the tackiness to deal with corners or sharp angles where the film is likely to slide or lift off—like on edges. After the film is applied, he rubs the edges, wiping his finger back and forth. This raises the temperature of the film, helping it to stick.

The precut film has cutouts for vehicle adornments like vents or emblems. They are so precise that you can barely see the edge of the film next to the GT350 fender emblems. There are areas where Juan chooses to make his own pattern by just using a sheet of film and cutting and shaping it to the panel.

For the hood, Juan chooses to make his own pattern by cutting a large piece of film that he cut from the roll. He lubricates it with the same procedure as before, wetting out the film then spraying the hood. He places it down with lots of excess film reaching over the edges. He then starts wiping, starting at the back of the hood and removing the water from the edges. He works his way toward the center, removing as much water as he can. Prior to the installation, he removed the hood vent so that he could tuck the film underneath it for a seamless finish. As he gets closer to the vent, things start to get trickier. The GT350R’s vent slopes down with multiple rising contours on its sides. The film inherently wants to bridge these features rather than adhere to them, so Juan has to work the film, massaging it and stretching it with the help of the alcohol solution. Eventually, after continually working the area, the film clings to the paint surface. It is a timely process; the entire hood took about one hour. He cuts the excess film and curls it around the edges so that edge of the film remains hidden. The hood is now protected.

Now let’s talk about the elephant in the room, or the knife in Juan’s hand: installing paint protection involves letting a stranger take a sharp knife and cut film directly on your car. It sounds insane, but an expert is trained to cut only so far, never letting the blade completely cut through the film.

“Blades are a necessity. There is no getting around it. Our blades are carbon-constructed blades that give us a very sharp edge to be precise with our cutting,” Juan says. “The point or the art of a true professional is that he has learned not to cut the film, but only to score it. There is an audible screech that you hear when the film is cut correctly. That sound is the film letting you know that you are cutting at the perfect angle and correct pressure point.”

Juan moves from corner to corner, covering the fenders, the hood, and then the bumper. The final addition is windshield protection. Juan wipes the windshield with an anti-static wipe, then starts by cutting a sheet of the ceramic film and placing it onto the windshield. Since it does not stretch as much as the polyurethane paint film, he must use heat to get it to mold to the glass.

At this point, the film is not actually stuck to the windshield; he is just making his pattern and forming the film. Once he is done, Juan pulls the film off and places it on a sheet of glass that is affixed to one of his shop’s walls. This vertical workspace allows him to work the film. He sprays it, and prepares to install it onto the car. Once the film is back on the car, Juan wipes the windshield, squeegeeing it to remove any contaminants or debris that may be present. He then sprays the windshield, lays the film onto the glass, and starts wiping it down. With the film already shaped, it lays perfectly. He continues to wipe, pushing the water out from underneath, and the film starts to disappear, blending perfectly into the glass. When Juan is done, the film is invisible. No one could tell that the windshield now has a 7-ml protective ceramic film installed on it.

People are used to seeing finished cars with paint protection. They are always surprised when they are told that the film needs to cure. With all of the spraying of water, there is a lot of moisture that is involved. Despite all of the wiping, Juan says, “We can only get 90 percent of the water mixture out. We need heat to help dry it out. You need to have sunlight and temperature.”

It takes about a week of sitting in the sun for the film to cure. In that time, bubbles and any water should disappear; if they do not, any imperfections are addressed by either fixing that area using a super-small syringe to remove any moisture, or removing and reinstalling that section. Installers like Juan pride themselves on the finish, so they are happy to fix any areas that did not cure correctly.

Armed with this information, you can look into paint protection as a way to insure your car’s finish from road debris, UV rays, and oxidation. It’s protection that comes with a 10-year warranty and may be able to save you a paintjob. The price varies depending on your coverage option, but no matter what, find a competent and experienced installer that you trust to hold a knife to your pride and joy.

This brand- new 2018 Mustang Shelby GT350R is ready for paint- protection installation.

Juan washes the car to ensure a clean surface for the film.

Juan dries the car with a microfiber towel.

The precut film lays on the table; you can see the fender vent and GT350 emblem cutout.

Juan places the film onto the fender.

Juan meticulously wipes the film, pushing out the water solution.

The cutout is so precise that the edges almost disappear.

Juan rubs the corner, heating it to helping the film adhere to the body.

The finished passenger-side fender. With the film completely installed, it appears as if it is not even there.

Juan adjusts the film to the hood, pulling it and spraying the solution.

Juan uses his squeegee, wiping the film and removing excess water.

Rubbing the edges of the film, Juan makes sure that the corners are tightly adhered to the hood.

Juan and his technician stretch the ceramic film over the windshield.

The film is cut to size.

Juan shapes the ceramic film with a heat gun.

After the film has been shaped, Juan squeegees out the excess water.

The finished windshield with paint protection applied.

After a day of work, Juan has finished installing the paint protection on the 2018 Shelby GT350R.

The post Paint-Protective Films Can Protect Your Car From Rocks and Save Your Paintjob appeared first on Hot Rod Network.

from Hot Rod Network https://www.hotrod.com/articles/paint-protective-films-can-protect-car-rocks-save-paintjob/ via IFTTT

0 notes

Text

Coil Coatings Market - Global Industry Insights, Trends, Outlook, and Opportunity Analysis, 2018–2026

Coil coating is a method in which an organic coating material is applied on rolled metal strip in a continuous and automated process. The process includes cleaning along with chemical pre-treatment of the metal surface, which either one side or two side, single or multiple application of liquid paints or coating powders, which are subsequently cured or laminated with plastic films before manufacturing in to end product. Coil coating makes use of effective principle, such as cleaning, pretreating, pre priming, pre painting and coating flat metal coils or sheets of steel or aluminum in a continuous operation, before other stages of industrial manufacture. The steel or aluminum substrates are delivered in coil form with 700 feet per minute. A flat sheet allows mechanical cleaning, excellent control of coating weights for pretreatment along with the paint depending upon equipment and paint system being applied. Coil coating process includes, back coat, top coat and primers, which is available in wide range of colors and finishes that can be applied to Steel or aluminum coils with the help of rolls.

Steps involved in coil coating process includes, uncoiling of bare material, coil splicing with accumulating the stack, metal degreasing, cleaning, rinsing with chemical pretreatment, drying the strip, applying primer on one or both sides, curing (15 to 60 seconds), cooling the strip, top coating on one or both sides, second curing, cooling down to room temperature, and finally rewinding of the coated coil. Coil coating provides, durable surfaces with attractive topcoats. They are cost effective and eco-friendly as compared to other substrates and coil coating options.

Request For Sample Copy of this Research Report :https://www.coherentmarketinsights.com/insight/request-sample/288

Coil coatings have building applications such as, wall cladding, roofing of buildings, decorative details and lighting fixtures. Transport applications such as, sheet and panels for containers, caravan and mobile home sidings and interior, van and trailer bodies, insulated boxes, road and railway coaches. They have applications in appliance and general industry which includes, refrigerators, washing machines, dishwashers, microwave, heating, ventilation, air-conditioning equipment. They are also used in film laminate, which require a very high specular reflectance, such as fluorescent light fixtures, solar tubes, and reflectors. The principal application segments for coil coatings are steel and aluminum. Increasing steel and aluminum demand in construction and transportation industries is expected to promote coil coatings market, while domestic building is a more recent market to be tackled.

Coil Coatings Market Outlook – Increasing Demand of Downstream Industries to be the Major Market Driver

According to IBEF, the Indian automotive industry is expected to be valued at US$ 300 billion by 2026. This trend is expected to be followed over the forecast period. Purpose of IBEF is to promote and create international awareness of goods manufactured in India. Asia Pacific and North America are expected to be the most potential markets for Coil Coatings manufacturers. Asia pacific is the fastest growing segment due to its high economic growth rate and heavy investment in building, construction and appliances. Government proposals for development of infrastructure, and rising housing market in developing countries is expected to drive the coil coatings market.

Need for cost effective and durable coatings are firing the demand for coil coatings, especially in Asia Pacific and Middle East regions. Replacement of metals by plastics is one of the inhibiting factors for coil coating market. AkzoNobel, a leading coatings and paints manufacturer inaugurated a new coatings plant in Noida, Uttar Pradesh with an investment of US$ 46.5 million (INR 3 crore), the new facility has added 6000 kl of annual production in coatings. This will help the company to penetrate the Asia Pacific market and increase supply chain. Major companies operating in the coil coatings industry include BASF SE, Henkel AG & Company, DuPont, The Beckers Group, Kansai Paint Chemical Limited, AkzoNobel, PPG Industries Inc., The Sherwin-Williams Company, and Wacker Chemie AG.

For More Information:

https://www.coherentmarketinsights.com/ongoing-insight/coil-coatings-market-288

About Coherent Market Insights:

Coherent Market Insights is a prominent market research and consulting firm offering action-ready syndicated research reports, custom market analysis, consulting services, and competitive analysis through various recommendations related to emerging market trends, technologies, and potential absolute dollar opportunity.

Contact Us:

Mr. Shah

Coherent Market Insights

1001 4th Ave,

#3200

Seattle, WA 98154

Tel: +1-206-701-6702

Email: [email protected]

0 notes

Text

Galvanized steel roof tile roll forming machine

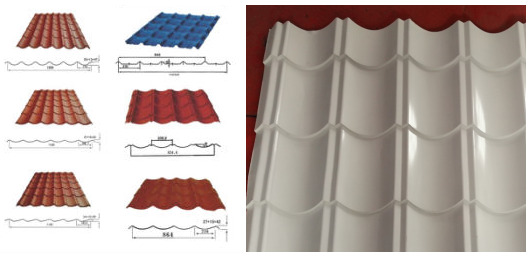

We can design and manufacture galvanized steel roof tile roll forming machine according to customers' requirement. Compared with the normal trapezoidal profile or wave profile roof sheets, the finished steel & aluminium step roof tiles are more beautiful and strong, which are widely used for the roof cladding project of villas.

For the steel roof tile profiles and pictures, here are some for your reference:

Features of the galvanized steel roof tile(1) it has excellent weather resistance Galvanized steel roof tile are highly adaptable to various climates. It can be used in both hot and humid areas and in dry and cold areas. In the long-term exposure and wind blowing, he is still colorful and does not fade. Its high adaptability to the climate is determined by the unique low absorption rate and is extremely weather resistant. (2) high intensity Since glazed tiles are fired many times at high temperatures, they are extremely strong and can withstand a few hundred kilograms of weight. And after a long period of wind blowing, sun exposure, still bear these weights, never deformed and discolored. More details information about the galvanized steel roof tile roll forming machine1 Main motor power: 5.5KW 2 Transmission system: chains 3 Working speed: 3-5 meters/min 4 Forming roller station: 18 5 Machine weight: about 10 tons 6 Roller shaft diameter: φ76mm 7 Roller material: #45 steel with quenching treatment, then coated with chrome 8 Shearing blades material: Cr12 mould steel with quenching 9 Roller shaft material: #45 steel with quenching treatment 10 Material: galvanized steel or aluminium rolls; thickness 0.3-0.8mm 11 Hydraulic station motor power: 5.5kw

About the machine, there is a video for your reference

youtube

If you want to know more detail information about the machine, please feel free to contact with us at any time.

Email: [email protected]

0 notes

Text

Color Coated Roof Sheet Machine

Details of Color Coated Roof Sheet Machine

A) D coiler 5 ton cap. B) Punching press 20 tone 2 nos. C) Entry Gate with D) Roll Forming Line with 22 station, 1 Gear Boxes & 10 H.P. electrical. E) Automatic Control Panel F) Cutting Unit (Hydro.)

TECHNICAL SPECIFICATIONS

Maximum sheet width that can be formed 1440mm

Maximum sheet thickness in PPGI/PPGL Strips that can be formed 0.6 mm

Horizontal distance between shafts 400mm

Number of forming stations 22 nos.

Vertical station 7 nos.

Total HP for Line 12.5

Speed of the machine 4mt/minute

Size of machine 9500 x 1700 x 1100 mm

MANDREL UNCOILER

Coil weight 5 MT Max

Coil width 400 MM

Coil bore 450 MM min, 510 MM max

dia.Mandrel movement Manually adjusted

Back Tension Manually adjusted

Motor ABB Gear box Elecon Bearing SKF

0 notes

Link

Details of Roofing Sheet Roll Forming Machine

A) De coiler 2 ton cap. B) Entry Gate with C) Roll Forming with 9 stations, 1 Gear Boxes & 5 H.P. electrical. D) Control Panel semi auto E) Cutting Unit

TECHNICAL SPECIFICATIONS

Maximum sheet width that can be formed

1250 mm

Maximum sheet thickness in CRCA Strips that can be formed

1.2 mm

Horizontal distance between shafts

500mm

Number of forming stations

16 nos.

Total HP for Line

8

Speed of the machine

10 -14 mt / mint

Size of machine

9500 x 1700 x 1100 MM

MANDREL UNCOILER

Coil weight

5 MT Max

Coil width

1250 MM

Coil bore

450 MM min, 510 MM max dia.

Mandrel movement

Manually adjusted

Back Tension

Manually adjusted

Motor - ABB Gear box – Elecon Bearing - SKF

#Roofing Sheet Roll Forming Machine#Roof Sheet Roll Forming Machine#Corrugated Roll Forming Machine#Roof Sheet Roll Former#Color Coated Roof Sheet Roll Forming Machine

0 notes