#Combustion Chamber Igniter

Text

Hemispherical Combustion Chambers Weren't Just a Gimmick: The Chrysler Hemi engine is renowned for its hemispherical combustion chambers, which provide an efficient shape with an excellent surface-to-volume ratio and minimal heat loss.

Three Generations: There have been three generations of Hemi engines: the FirePower series (1951-1958), the legendary 426 Hemi (1964-1971), and the modern Hemis (2003-2024).

FirePower Series: The first-generation Hemi, known as the FirePower series, had displacements ranging from 241 to 392 cubic inches and was produced from 1951 to 1958.

426 Hemi Nickname: The 426 Hemi, produced from 1964 to 1971, earned the nickname "elephant engine" due to its large size and heavy weight.

426 Hemi Power: The 426 Hemi was rated at 425 horsepower and 490 lb-ft of torque, although actual dynamometer testing showed it could produce even more.

Racing Heritage: The 426 Hemi was initially developed for NASCAR racing and made its debut in the Plymouth Belvedere in 1964.

Street Hemi: Chrysler introduced the "Street Hemi" in 1966, making the powerful 426 Hemi available to the general public in various Dodge and Plymouth models.

426 Hemi in Drag Racing: The 426 Hemi dominated NHRA and AHRA drag racing, with its large casting allowing it to be overbored and stroked to displacements unattainable by other engines of the era.

426 Hemi in Iconic Cars: The 426 Hemi was used in some of the most iconic muscle cars, including the 1970 Plymouth Hemi 'Cuda, the Dodge Charger Daytona, and the Plymouth Superbird.

High Compression: The 426 Hemi had a high compression ratio of 10.25:1 in the street version and 12.5:1 in the racing version, requiring high-octane fuel to avoid pre-ignition.

Dual Four-Barrel Carburetors: The 426 Hemi featured dual inline four-barrel Carter AFB carburetors, contributing to its high power output.

Advanced Rocker Arm Geometry: The Hemi engine's complex valve train and large, wide cylinder heads required advanced rocker arm geometry, making it more expensive and challenging to build.

Military Origins: Chrysler's experience with hemispherical combustion chambers began with their development of the XIV-2220 engine for the P-47 Thunderbolt fighter aircraft during World War II.

M47 Patton Tank: Chrysler also used hemispherical combustion chamber technology in the air-cooled AV-1790-5B V12 Hemi engine for the M47 Patton tank.

Modern Hemi Engines: The third-generation Hemi engines, produced from 2003 to 2024, featured advanced technologies and displacements between 5.7 and 6.4 liters, continuing the legacy of high performance.

#Chrysler Hemi engine#Chrysler Hemi#Chrysler#Hemi#car#cars#muscle car#american muscle#mopar#moparperformance#moparnation#moparworld

148 notes

·

View notes

Text

On July 2, 1951, the quiet city of St. Petersburg, Florida, was rocked by one of the most mysterious and controversial deaths in modern history. Mary Reeser, a 67-year-old widow, was found burned to death in her apartment under circumstances so bizarre that they have puzzled investigators, scientists, and conspiracy theorists for decades.

The macabre discovery was made by Reeser’s landlady, Pansy Carpenter, who had tried to deliver a telegram to her tenant that morning. After receiving no response and noticing an unusually warm doorknob, Carpenter sought help from neighbors. When they managed to open the door, they were met with an astonishing scene: a room relatively untouched by fire, save for the corner where Reeser's remains were found.

Mary Reeser’s body had been almost completely incinerated, reduced to ashes along with the chair she had been sitting in. What remained of her were a part of her backbone, a shrunken skull, and a completely intact left foot still in its slipper. The surrounding area showed minimal damage—plastic household items a short distance from the seat remained unscathed, and although the walls and ceiling were coated with a greasy soot, they were not burnt.

The investigation was led by the St. Petersburg Police Department, who quickly recognized the unusual nature of the scene. Local authorities were joined by the FBI and other experts to determine how such an intense fire could have started and burned so selectively.

Initial hypotheses ranged from a dropped cigarette to an electrical fault. However, both were quickly dismissed. The chair's materials and Reeser's clothing would not typically combust so thoroughly without a higher, sustained temperature than could be achieved by a mere cigarette. Furthermore, there was no evidence of an electrical fire or an accelerant.

As conventional explanations failed, the case began to attract attention from proponents of spontaneous human combustion, a rare and controversial phenomenon in which a person is believed to catch fire without an external ignition source. Advocates of SHC argue that a combination of factors, such as the wick effect (where clothing can absorb melted human fat and act like a candle), could explain the intense and localized burning seen in cases like Reeser’s.

Dr. Wilton Krogman, a physical anthropologist, examined the case and expressed disbelief at the completeness of the combustion. He noted that even bodies exposed to extreme heat in cremation chambers do not typically burn as thoroughly as Reeser's remains had. Dr. Krogman described the case as "the most amazing thing I have ever seen" and found it difficult to reconcile with the known laws of science.

Despite extensive investigation, the official cause of Mary Reeser’s death was ultimately ruled as “death by fire of unknown origin.” The case has remained a source of fascination and debate, appearing in numerous books, documentaries, and discussions about unexplained phenomena.

117 notes

·

View notes

Text

Promising early tests for variable-thrust landing engine

As part of ESA's Future Launchers Preparatory Program (FLPP), the first phase of hot-fire tests has been completed on a new, variable-thrust rocket engine in Warsaw, Poland. The engine is being developed by a Polish consortium investigating new designs for propellant valves and injectors that can vary the thrust of rocket engines powered by more sustainable and storable propellants. Such engines have great potential for use in future space missions and reusable rockets.

The new engine is called the Throttleable Liquid Propulsion Demonstrator (TLPD), it is now being dismounted and inspected, with the results being analyzed at the site of prime contractor Łukasiewicz Research Network—Institute of Aviation (Lukasiewicz-ILOT) in Poland, with partners Astronika and Jakusz SpaceTech, before the next phase of testing begins.

Liquid propellants that last

The throttleable engine includes a newly designed fuel injector and control valves. With a thrust of 5kN (compared to the Ariane 6 upper stage engine's thrust of 180 kN), the TLPD engine is perfect for the upper stage of smaller rockets, for in-space vehicles, for launcher kick-stages and exploration missions. The ability to modify its thrust makes it also very interesting for landing spacecraft on Earth, the moon and beyond.

The new rocket engine is powered by storable propellants hydrogen peroxide and ethanol, which are safer and less toxic than others currently in use (such as hydrazine and nitrogen tetroxide). Compared to cryogenic propellants, like liquid oxygen and hydrogen, storable propellants require no active cooling measures and will not diminish between subsequent engine firings.

Rocket engines powered by storable propellants can have long lifetimes in space and are easy to reliably and repeatedly ignite during missions that last many months. Cryogenic propellants also require energy to begin combustion, provided by an "igniter," whereas the TLPD propellants ignite upon contact with each other, making the engine simpler and more reliable. % buffered

At heart: New electronically controlled valves and fuel injector

The main goal of the current throttleable engine project is to test a newly developed system of valves and a movable "pintle" injector—a type of propellant injector used in "bipropellant" rocket engines—all commanded by an electronic control system.

The valves ensure the appropriate rate of propellant flows into the combustion chamber—the higher the rate, the greater the thrust. The fuel injector mixes the two propellants (the ethanol fuel and hydrogen peroxide oxidizer) while they are injected at high pressure into the chamber, maintaining stable combustion as their rate varies coming through the valves. All of this ensures an efficient and controlled combustion process can take place.

New variable engine undergoes dynamic testing. Credit: Łukasiewicz Research Network—Institute of Aviation (Lukasiewicz-ILOT)

Next: Going full throttle

The TLPD engine has been designed to be throttled down to 20% and up to 110% of its optimal level of thrust. Such "deep" throttling, i.e., the ability to really vary the engine's power, is necessary for landing rocket stages on Earth, or spacecraft on the moon or other planetary bodies.

The hot fire tests just completed in Phase A were originally planned to be purely static, testing the engine's ability to fire at a constant rate. The engine was fired 17 times for up to 10 seconds, while the amount of fuel and oxidizer flowing in was kept constant.

The initial results were so promising that teams decided to move onto the next phase earlier than planned—dynamic throttling. The engine was fired up twice again, each time for 15 seconds, during which the thrust was varied down to 20% and up to 80% of its optimal level.

Once the results have been analyzed, the TLPD engine will be remounted and the full scope of planned dynamic tests will begin, with even longer firing durations. This set of tests is expected to start in October and will really put the "throttleability" of the engine to the test.

ESA's Future Launchers Preparatory Program and Lukasiewicz-ILOT are now in discussions about continuing the project, building on these test results and working towards the design of an overall throttleable flight engine.

TOP IMAGE: Throttleable Liquid Propulsion Demonstrator. Credit: Łukasiewicz Research Network—Institute of Aviation (Lukasiewicz-ILOT)

2 notes

·

View notes

Text

funny as fuck how my first experience drinking coffee was booting up fnv for the first time and making primm slim sheriff then going to home depot and buying stuff to make a potato cannon and encountering a guy who was a plumber and he was like "hey you better be spud gunnin out here cuz that connection is not up to code at all" and I went away from that encounter thinking I met plumbing jesus or something

the spud gun works best w/ propane btw. like you fill the combustion chamber using a blowtorch nozzle and don't light it, and then you spark it with your ignition source of choice. though you have to stuff the tater in there before you let er rip I could post schematics if you guys want

9 notes

·

View notes

Text

How does an engine contribute to a car's powertrain?

The powertrain in a vehicle is the system responsible for generating power and delivering it to the wheels to propel the vehicle forward. The operation of a powertrain can vary depending on whether the vehicle is powered by an internal combustion engine (ICE) or an electric motor (in the case of electric vehicles). Here's a general overview of how a powertrain works in both types of vehicles:

Internal Combustion Engine (ICE) Vehicle - Combustion Process: In an ICE vehicle, the powertrain starts with the combustion process in the engine. Fuel (gasoline or diesel) mixes with air in the combustion chamber and is ignited by spark plugs (in gasoline engines) or compression (in diesel engines).

Power Generation: The combustion process generates energy in the form of mechanical power, causing pistons to move up and down within the cylinders of the engine. This motion drives the crankshaft, converting linear motion into rotational motion.

Transmission: The rotational motion from the crankshaft is transmitted to the transmission, which consists of gears that allow the driver to select different ratios (speeds). This enables the engine to operate efficiently across a range of vehicle speeds.

Drivetrain: The transmission sends power to the drivetrain components, including the driveshaft, differential, and axles, which transfer power to the wheels. The differential allows the wheels to rotate at different speeds, enabling smooth turns.

Wheel Movement: The power transmitted through the drivetrain causes the wheels to rotate, propelling the vehicle forward or backward depending on the gear selection and throttle input from the driver.

Electric Vehicle (EV) -

Battery Pack: The primary source of power for the EV, storing electricity in chemical form.Powers the electric motor and provides electricity for all electronic devices within the EV.

Battery Management System (BMS): Monitors battery cell conditions, including voltage, current, temperature, and state of charge (SoC).It protects the battery against overcharging, deep discharging, and overheating and helps balance the charge across cells. Ensures optimal performance and longevity of the battery by regulating its environment.

Inverter: Converts DC from the battery pack into AC to drive the electric motor.Adjusts the frequency and amplitude of the AC output to control the motor’s speed and torque. Critical for translating electrical energy into mechanical energy efficiently.

Onboard Charger: Facilitates the conversion of external AC (from the grid) to DC to charge the battery pack. Integrated within the vehicle, allowing for charging from standard electrical outlets or specialized EV charging stations. Manages charging rate based on battery status to ensure safe and efficient charging.

DC-DC Converter: Steps down the high-voltage DC from the battery pack to the lower-voltage DC needed for the vehicle's auxiliary systems, such as lighting, infotainment, and climate control. Ensures compatibility between the high-voltage battery system and low-voltage electronic components.

Electric Motor: Converts electrical energy into mechanical energy to propel the vehicle. It can be of various types, such as induction motors or permanent magnet synchronous motors, each offering different efficiencies and characteristics. Typically provides instant torque, resulting in rapid acceleration.

Vehicle Control Unit (VCU): The central computer or electronic control unit (ECU) that governs the EV's systems. Processes inputs from the vehicle’s sensors and driver inputs to manage power delivery, regenerative braking, and vehicle dynamics. Ensures optimal performance, energy efficiency, and safety.

Power Distribution Unit (PDU): Manages electrical power distribution from the battery to the EV’s various systems. Ensures that components such as the electric motor, onboard charger, and DC-DC converter receive the power they need to operate efficiently. Protects the vehicle's electrical systems by regulating current flow and preventing electrical faults.

In both ICE vehicles and EVs, the powertrain's components work together to convert energy into motion, enabling the vehicle to move efficiently and effectively. However, the specific technologies and processes involved differ significantly between the two propulsion systems.

#electric powertrain technology#conventional powertrain#Electric vehicle components#revolo hybrid car kit#ev powertrain development services#software (SW) platforms for all Electric vehicles components#Battery Management Systems#Inverter#Smart Charger#VCU solutions

3 notes

·

View notes

Text

some time ago despite my complete and utter lack of knowledge on how to make any sort of actual Roblox game, I started writing random announcement lines for a concept core game called "Sol Research Facility"

these are the most recent renditions of the pre-startup and startup procedure announcements (inspirations: Innovation Inc. Thermal Power Plant startup announcement sequence and the pre-startup and startup announcement sequences shown in the V4 reactor startup preview video aydenane made on Zands! Codename Lemnis):

Pre-startup (begins with either manual or automated startup preparation, this announcement comes at the end of it):

*Announcement chime*

“Attention all personnel: the Antimatter Combustion Reactor has been queued for ignition. Please halt all facility operations until startup completion and vacate the core chamber immediately.”

ACR Startup procedure (begins once the startup procedure has been confirmed from the core control room):

“Attention: the Antimatter Combustion Reactor startup protocol has been initialized. All personnel are to maintain a safe distance from the reactor chamber.”

“Diverting facility power for reactor ignition. Startup will occur in T-10 seconds.”

*Facility lights go out; some kind of music cues*

“Raising reactor superstructure to central position. Position locked.”

“Activating reactor stabilization systems. Reactor stabilizers online.”

“Commencing power lasers activation. Please be advised that a gravitational anomaly or abnormal seismic activity may occur if a fault has been detected.”

“Activating Power Laser Array Alpha. Power lasers 1, 2, and 3 online.”

“Activating Power Laser Array Beta. Power Lasers 4, 5, and 6 online.”

“All power lasers online. Engaging coolant systems.”

“Coolant pumps online. Connecting coolant feed to reactor core.”

“Coolant feed online. Temperature secured.”

“Reactor core startup procedure successfully engaged. Facility now operating at full capacity.”

#roblox core game#unofficial core game#concept#yes I know a lot of this is illogical#it gets even more illogical when you consider that the concept for this includes a freezedown#freezedowns are literally impossible because of the laws of thermodynamics#but this concept also pulls illogical stuff from outside of that too so yeah

3 notes

·

View notes

Text

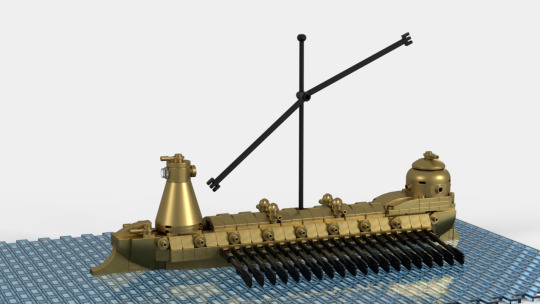

A model of a typical brassclad artilleryship, demonstrating various design features. Some details such as the sail and rigging are missing.

From the design of the ship, we can see that it is a long-ranged artilleryship with a large vertical-axis maingun at the front. A large reflector and combustion chamber sits underneath the conical sheathing, while the optical apparatus of the gun is at the top.

A fire controller sits in the tower alongside the apparatus and aims the gun with the help of a telescope; a necessity with ranges reaching multiple miles. The fire controller ignites the main charge using either a lanyard from the tower to a gunlock mechanism on the deck below, or a small flintlock incender aimed directly at the charge in the flash chamber. Due to the pitching and rolling motion of the ship, long-range accuracy is impossible to achieve if fire commands have to be relayed to igniter crew below as is often done on land.

The lower part of the maingun turret containing the flash chamber and reflector impinges on deck space below, reducing the number of available rowers. Similarly, the mast and sail are limited by the need not to foul the maingun. To compensate, the ship is likely very lightly built despite looking like a fortress of metal, and a wavepiercer in the front increases the waterline length (it is not a ram: the maingun apparatus could be easily damaged by the impacts involved in ramming). If possible, the mast and rigging are left behind at a friendly port before heading to battle.

Secondary armament of smaller long-range lenscannons, possibly cinderguns, is visible in the front below the maingun tower. The signaler is visible on top of the aftcastle. The ship is designed to fight outside the effective range of ballguns to protect its sensitive maingun, so the defensive armament along the sides is unlikely to feature short-range weapons such as firethrowers. Long-range ballguns are possible, but the position of firing ports directly below the maingun tower where there would be no space for a ballgun to recoil implies that at least some of the broadside consists of compact lenscannons.

The ship is sheathed in a relatively corrosion-resistant brass alloy throughout, including under the waterline where the copper content prevents biofouling, permitting higher speeds and reduced maintenance. The deck is plated over, indicating that this is a more recent design; early plateships had open decks, making them extemely vulnerable to an arms race of ever taller mainguns shooting over their side plating. While extremely effective against magical weapons, the plating is too thin to be helpful against ballguns.

6 notes

·

View notes

Text

Mitsubishi Debonair V AMG version.

AMG is a tuning manufacturer in West Germany that specializes in German luxury cars. Its technical capabilities are widely recognized and highly evaluated by the general public. 3000 Royal AMG is a full-fledged European sporty sedan forged by this prestigious tuner.

■AMG aero parts consist of front bumper spoiler, front grille, side step panel, door protection panel, rear spoiler, rear bumper spoiler, rear end panel, and wheel cut molding.

A form that further refines the aerodynamics of the original body. The impression of its styling can be said to be a splendid fusion of personality and sporty image. Equipped with low-profile tires and aluminum wheels and electronically controlled suspension to support fast and safe driving. From the day you own this car, highway dominance will be yours. The interior also features an AMG-designed steering wheel. The Debonair V3000 Royal AMG is full of Senmou's European spirit in both its exterior and interior.

Body Color: Sarajevo White

■ Seat color: Gray (optional leather seats are beige)

■ Interior base color: Gray

Pictured from left: AMG design steering wheel, AMG design aluminum wheels & 205/60R15-89H tires, dual exhaust pipes.

Debonair V3000 Royal AMG Cyclone V6 3000 engine ELC 4-speed full automatic with OD Main equipment Air conditioning & audio remote control switch Cruise control Auto lighting control 205/60R15-89H tires

Front 5-layer laminated glass (bronze) Electric retractable door mirror Soft touch heater control AMG aero parts Driver's seat power seat Rear power seat AMG Steering wheel ELR seat belt with electric tension reducer Dual auto air conditioner (microcomputer)

MITSUBISHI DEBONAIR V 3000 ROYAL AMG

The Debonair V3000 Royal AMG, which gives the image of driving on the European autobahn. The exterior, suspension, and equipment all feature high-quality specifications unique to this car.

ENGINE BOX

Unprecedented responsiveness and quietness. Advanced driving with Cyclone V6 engine.

What the times demand from engines is not just high power or low-speed torque. It is the response performance that can pick up the power you want when you need it, and the quietness that makes you feel the high quality. In other words, it can be said that it is a high-performance car that truly values the sensibilities of the rider. Mitsubishi's cyclone engine was born by refining everything to meet such demands. And the Cyclone V6 3000 engine of the Debonair V3000 Royal AMG is a proud power unit that stands at the top of them. Achieved new performance and excellent quietness in the entire range from low speed to high speed while achieving compactness and weight reduction. In addition, ECI-MULTI (Multi-Point Injection), which always supplies the best air-fuel mixture and controls accurate fuel injection timing and appropriate ignition timing for each of the six cylinders, is also adopted. Also, in each process of intake, combustion and exhaust, advanced technologies such as manifolds with optimal shape and diameter, dual exhaust system and compact combustion chamber are incorporated.

BOTTOM INFO SECTIONS FROM LEFT

door-linked high-tilt steering,

Light operability created by ELC4A/T with OD.

A driver's seat that secures a wide field of vision and enhances safety. The electronically controlled power steering employs door-linked high-tilt steering that hops up when the driver's side door is opened to facilitate boarding and exiting. Equipped with a cruise control that automatically maintains the set vehicle speed, an ELC 4-speed full automatic transmission with OD that electronically controls for smooth shifting, and a steering audio remote control switch that allows remote control of audio from the steering wheel. As an option, a hands-free car telephone is also available, which allows you to talk without having to use both hands.

The spaciousness of the interior of the FF and its excellent quietness make it a truly relaxing place to live.

Debonair V achieves top-class spaciousness in the interior and trunk room with the FF (front wheel drive) system. Beneran instrument panel pads with a leather touch and urethane-injected floor mats that create a soft feel further enhance the quality of living. The driver's seat and rear seats are equipped with electric power seats that can be adjusted steplessly. In addition, the adoption of a flush body and triple weatherstripping achieves excellent quietness, and is equipped with a high-power audio system with Diatone ASS that adds value to a quiet space.

Optional leather seats are also available.

Safety and reliability brought by electronically controlled suspension and 4-wheel ventilated disc brakes.

Equipped with an electronically controlled suspension that automatically controls suspension characteristics and vehicle height to provide stable driving with consistently high marginal performance. The braking system is equipped with 4-wheel ventilated disc brakes with excellent heat dissipation. The body uses high-quality paint to improve durability and rigidity, integrally molded doors, and new anti-corrosion steel plates. In addition, the front five-layer laminated glass that reduces the impact on the driver in the event of an accident, and ETACS, which electronically controls various timers and alarms, protects irreplaceable safety from all angles.

Door-linked high-tilt steering (with memory) Auto door lock High-power audio with Diatone ASS (B speaker Audio steering remote control switch Electric suspension AMG aluminum wheels Electronic control power steering 4-wheel pentillated disc brakes

36 notes

·

View notes

Text

5 Problems that Can Make Your BMW Engine Misfire at Idle

Misfiring in engine have become a major problem in many cars including BMW. Mostly while idling, it is found that the cars get misfires. During a misfire, the cars be have abnormally which takes the attention of the user because it has such symptoms that are quite noticeable. Misfiring occurs while the engine is running at any time while the car is idling or running, etc. Misfiring is generally an issue in the power production. If you own a car, and notice the misfires in your car, then you should know about some problems that cause the engine to misfire. Here I’m gonna tell you about the causes of misfiring in engine of BMW while idling.

Misfires during idle

Misfire is a problem in the engine cylinders that lead to stumbling, jerking and shaking of the car. Misfiring leads to a very rough running or idling of the car. Along with jerking, the cars also produce some unusual noises. Misfires are disturbing and can make the passengers uncomfortable. So during idle, the engine revs, but the car is not in a motion.

The RPM (revolution per minute) of the engine during idle is not of a high magnitude to accelerate the car. The RPM while idling is of a specific value for a car, but if the RPM of the engine becomes too low or doesn’t remain constant, then the idling becomes rough. The car would shake more while idling. The problem with the RPM is caused due to power loss, misfire in the engine. When the engine detects a very low output, it takes certain actions that make the engine to shake. The engine gets such a low RPM due to problems in the ignition, fuel and air ratios in the fuel mixture in the combustion chamber.

Here are some common signs of misfiring

Rough idling

A very slow acceleration when after gas pedal is pressed

Check engine light glows

Engine would produce a different sound than usual, like popping, banging, chuffing, etc.

Jerking

What causes the misfiring while idling of the car?

Here are some problems in some components would cause the misfires in engine.

Faulty spark plugs and its wires

The spark plugs fire in the combustion chamber to burn the mixture of fuel and air. It gets electricity through its wires. So if there is no proper and consistent firing, then both spark plug and its wires can be the culprit. Spark plugs can themselves be the defective and unable to produce sparks. It can even malfunction if the wires connected to it is damaged, disconnected, etc. If the sparks produced by the spark plugs cannot be able to burn the fuel and air mixture properly, then it would result into misfire.

Worn Ignition coils

Ignition coils have great role in burning the fuel and producing the power. These coils supply power to the spark plugs. If these coils are worn, then the functioning of the whole ignition system would be badly affected.

Clogged fuel and air intake system

The fuel and the air intake systems supply fuel and air to the engine in a specific quantity. But many times, the lines in these systems get some obstruction like damage of parts like gaskets and hoses or some dirt make the filters clogged. If these systems are clogged, then the flow of two necessary things, that is the fuel and the air would be obstructed and cannot reach the engine in proper amount.

Timing problems

If the timing in the engine has the problem, then the whole process would be affected more. The movement of the camshaft, the opening and the closing of the valves are all controlled through timing. But if the timing gets some problems, then the intake valves would not operate properly with time. And lead to a wrong ratio of the air and fuel in the mixture and even the exhaust gasses would not be properly removed out of the combustion chamber. So a timing problem would definitely lead to misfiring.

Some mechanical issues

Due to the mechanical components, the engine is able to produce torque. The components like cylinder walls, piston rings, valves also have a very important role in the combustion process. Misfires would happen if any of these components get issues.

Conclusion

If you get the signs of engine misfiring, then get your car inspected as soon as possible so that there would be no further problems in the engine to arise. Get your BMW well maintained regularly.

5 notes

·

View notes

Text

Playing with a combustion chamber of an Auxiliary Power Unit. This is where the fuel ignition magic happens in a jet engine.

I was about to put it back together just now and found a huge grace along one of the welds. Probably why this thing ended up in the school, that'd be one very expensive repair! :o

#planeposting#mechanic#jet engine#aviation#avgeek#planes#airliner#boeing 737#boeing 737-200#boeing 707#aviation maintenance#aircraft mechanic

6 notes

·

View notes

Text

How to Properly Gap Spark Plugs for 90s Subaru Sambar Ignition System

Spark plugs play a critical role in the ignition system of any vehicle, including the beloved 1990s Subaru Sambar. The proper gapping of spark plugs ensures optimal ignition performance, fuel efficiency, and engine longevity. The ignition system of the Subaru Sambar is relatively straightforward, but the importance of proper spark plug maintenance—especially gapping—cannot be overstated. In this guide, we'll walk you through the process of properly gapping spark plugs, why it’s important, and how it impacts your vehicle's ignition system. We'll also explore how the right Subaru Sambar Ignition Kit can help enhance your vehicle’s performance.

Understanding the Subaru Sambar Ignition System

The Subaru Sambar is powered by a compact engine that demands precision from its ignition system. This system is responsible for igniting the air-fuel mixture in the engine's combustion chambers. The spark plug plays a pivotal role in this process by creating the spark that initiates combustion. In the 90s models of the Subaru Sambar, this is particularly important as the kei truck’s small engine needs to maximize every bit of power and efficiency it can muster.

The Subaru Sambar ignition system typically includes spark plugs, ignition coils, a distributor, and spark plug wires. Regular maintenance and upgrading components such as the Subaru Sambar Ignition Kit help maintain engine performance. However, ensuring that the spark plugs are properly gapped is crucial to maximizing the potential of the ignition system.

Why Gapping Spark Plugs is Important

The "gap" in a spark plug refers to the distance between the center electrode and the ground electrode. When the gap is correctly set, the spark plug will generate a strong spark to ignite the air-fuel mixture in the combustion chamber. If the gap is too wide or too narrow, several issues can arise:

Misfiring: A spark plug with an incorrect gap may fail to ignite the air-fuel mixture properly, leading to engine misfires.

Poor fuel economy: A weak spark can result in incomplete combustion, wasting fuel.

Hard starting: An improper gap can make it difficult for the engine to start, especially in cold weather.

Engine hesitation: If the spark isn't strong enough, the engine may hesitate or stumble during acceleration.

Maintaining the correct spark plug gap ensures the ignition system operates efficiently and helps preserve the engine’s overall health. This is especially important in older vehicles like the Subaru Sambar, where small inefficiencies can lead to larger problems over time.

Tools and Materials You Will Need

To gap spark plugs for your 90s Subaru Sambar, you will need a few tools and materials. Having the right Ignition Kit can also make the job easier, especially if you're upgrading the ignition components along with gapping the plugs.

Here’s what you’ll need:

New spark plugs: Ensure that the spark plugs you buy are compatible with the Subaru Sambar.

Feeler gauge: A feeler gauge is a tool used to measure the gap between the electrodes. It comes with various metal blades of different thicknesses.

Spark plug gap tool: This tool is designed to adjust the gap by bending the ground electrode without damaging the plug.

Subaru Sambar Ignition Kit (optional): If you’re upgrading your ignition system, use a high-quality kit that includes spark plug wires, an ignition coil, and other components.

Spark plug socket and ratchet: You’ll need this to remove and install the spark plugs.

How to Properly Gap Spark Plugs

Check the manufacturer's specifications: Before you begin, consult the Subaru Sambar’s owner’s manual or service manual for the correct spark plug gap. For most 90s Subaru Sambars, the gap specification typically falls between 0.028 to 0.032 inches. Always refer to the specific gap requirement for your engine model.

Inspect the new spark plugs: New spark plugs usually come pre-gapped, but it's important to double-check that the gap matches your vehicle’s requirements. Use the feeler gauge to measure the gap by sliding the correct-sized blade between the center electrode and the ground electrode.

Adjust the gap if necessary: If the gap is too narrow, use the spark plug gap tool to gently bend the ground electrode outward. If the gap is too wide, carefully bend the ground electrode inward. Be cautious not to apply too much force, as this can damage the plug.

Re-check the gap: After adjusting the gap, use the feeler gauge to confirm that the distance is now correct. The gauge should slide in with slight resistance, but it shouldn't be too tight or too loose.

Install the spark plugs: Once you’ve properly gapped the spark plugs, use a spark plug socket and ratchet to install them into the engine. Be careful not to overtighten them, as this can strip the threads in the cylinder head. Tighten them until snug, then apply a quarter-turn for a secure fit.

Upgrade the ignition components (optional): If you’re using a Subaru Sambar Ignition Kit, now is a good time to upgrade the ignition coil, spark plug wires, and distributor cap (if applicable). This can help boost the performance of the ignition system, resulting in better fuel efficiency and power.

Impact of Properly Gapped Spark Plugs on Performance

Properly gapped spark plugs will have a noticeable impact on your Subaru Sambar’s overall performance. Here’s how:

Improved fuel efficiency: With the correct spark plug gap, combustion is more efficient, reducing fuel consumption.

Smoother engine operation: Proper gapping eliminates misfires, resulting in smoother acceleration and a more stable idle.

Extended engine life: Misfires and poor combustion put additional stress on the engine. Correct gapping reduces wear and tear on internal components.

Better cold starts: In older vehicles like the Subaru Sambar, starting issues are common. Properly gapped plugs ensure that the spark is strong enough to ignite the fuel in colder conditions.

Choosing the Right Subaru Sambar Ignition Kit

While properly gapped spark plugs are essential, a high-quality Ignition Kit can take your vehicle’s performance to the next level. When choosing an ignition kit, look for components that are compatible with the Sambar’s engine, such as spark plug wires, distributor caps, and ignition coils.

A good ignition kit will not only help maintain a strong spark but also improve the reliability of your ignition system. Many kits are designed to work with upgraded spark plugs, making it easier to maintain optimal performance for your 90s Subaru Sambar.

Final Thoughts

Gapping spark plugs may seem like a small task, but it plays a critical role in maintaining the performance and longevity of your 1990s Subaru Sambar. By ensuring the spark plugs are properly gapped, you’ll improve fuel efficiency, prevent engine misfires, and extend the life of your engine. Additionally, pairing properly gapped plugs with a high-quality Subaru Sambar Ignition Kit can help unlock even better performance for your vehicle.

Taking the time to properly maintain your ignition system will ensure your Sambar continues to run smoothly for years to come.

0 notes

Text

Chrysler 340 Six Pack!

This engine design was guided by none other than Tom Hoover, later known as ‘the father of the Hemi’. For 1970, as delivered in AAR Cuda and Dodge Challenger T/A for use in the SCCA Trans-Am Racing Series, the factory stock Six Pack 340 engine was a well-optioned animal straight out of the box. It meant business, leaving plenty of scope for modifications allowed within the racing regulations that would help it thrive in a Trans Am racing environment. There was no stone unturned, starting with a high nickel stress-relieved engine block, utilising thicker webbing in the pan rails and other areas to allow the option of installing four bolt main caps on 2,3 and 4. High-performance ‘J’ casting cylinder heads were utilised along with large diameter valves, working in tandem with a unique rocker arm/shaft/pushrod assembly. Within this cylinder head design, the pushrod holes were offset to allow more material for oversized porting on the intake runners. Forged crankshaft, heavy-duty conrods and high-performance pistons. A windage tray was also featured. A healthy 10.5 to 1 compression ratio complemented an aggressive 276/284 duration camshaft driven by a dual-row timing chain and the fire in the combustion chamber was ignited by dual points ignition with the spent gasses exiting through a free-flowing exhaust system.

One highlight of this engine combination was the Six Pack (or 6 barrel) carb set-up, running a trio of two-barrel Holleys sitting on top of a factory-fitted Edelbrock intake manifold. A 375 cfm centre carb acted as a primary, then at a given throttle percentage, the two 500 cfm outer carbs would open up and join the party to provide a whopping total of 1375 cfm in total air flow, along with an induction howl you’d never forget.

The factory officially rated the engine at 290hp and 345ft/lbs of torque. The consensus is that it produced at least 330hp, particularly when you consider its claimed 14.4 second quarter-mile capability and 5.8 sec 0-to-60 mph times in a 3500 pound car. In race spec, the engine was de-stroked to just under the Trans-Am regulations 305cu limit and during the development phase across its racing lifespan, was rumoured to have produced between 460 and 500hp.

#Chrysler 340 Six Pack#Chrysler 340#chrysler#340 Six Pack#six pack#340#car#cars#muscle car#american muscle#mopar#moparperformance#moparnation#moparworld

58 notes

·

View notes

Text

What Are The Maintenance Requirements For A Range Rover 2.0 Engine?

The Range Rover 2.0 engine is renowned for its efficiency, power, and advanced technology. However, like any high-performance engine, it requires regular maintenance to ensure optimal functionality and longevity. Understanding the specific maintenance needs of the Range Rover 2.0 engine can prevent potential breakdowns, enhance performance, and reduce the likelihood of costly repairs. We will explore key aspects of maintaining this engine, including vital care points and the benefits of opting for engine replacement or reconditioned engines. We’ll also discuss how “supply and fit” services can simplify engine management.

Regular Oil Changes and Fluid Checks

One of the most crucial maintenance tasks for the Range Rover 2.0 engine is performing regular oil changes. Engine oil lubricates the moving parts, prevents overheating, and reduces wear and tear. Given the advanced design of this engine, it's vital to use high-quality synthetic oil and change it every 7,500 miles or as recommended by the manufacturer.

In addition to oil changes, monitoring other fluids—such as coolant, brake fluid, and transmission fluid—is essential. Coolant helps regulate the engine’s temperature, preventing it from overheating. Regularly checking these fluids and topping them up as necessary is critical for avoiding engine strain and maintaining its overall health. Failure to maintain the right fluid levels can lead to significant engine damage over time.

Air Filter Replacement

Another key maintenance requirement for the Range Rover 2.0 engine is replacing the air filter at regular intervals. The air filter prevents dirt, dust, and other particles from entering the engine, ensuring that only clean air is mixed with fuel for combustion. Over time, the air filter can become clogged, reducing airflow to the engine and diminishing performance.

A clogged air filter may cause poor fuel economy, reduced acceleration, and even damage to the engine’s internal components. To avoid these issues, it’s essential to check the air filter during routine service and replace it if necessary. Typically, the air filter should be replaced every 15,000 to 30,000 miles, depending on driving conditions.

Timing Belt Inspection and Replacement

The timing belt plays a crucial role in the synchronization of the engine’s internal components. It ensures that the camshaft and crankshaft rotate in harmony, allowing the engine’s valves to open and close at the right times. If the timing belt fails, it can cause severe damage to the engine’s valves, pistons, and other critical parts.

For the Range Rover 2.0 engine, it’s important to inspect the timing belt regularly for signs of wear, such as cracks, fraying, or looseness. While most timing belts are designed to last between 60,000 and 100,000 miles, it’s recommended to have them checked periodically and replaced before they reach the end of their lifespan. Ignoring this maintenance task can result in costly engine repairs or the need for a complete engine replacement.

Turbocharger Maintenance

The Range Rover 2.0 engines features a turbocharger that enhances performance by forcing more air into the combustion chamber, increasing power output. However, the turbocharger is subject to wear and tear, especially if the engine is driven under heavy loads or in harsh conditions.

To ensure the turbocharger remains in good working condition, it’s important to monitor the engine’s oil quality and change it regularly, as the turbo relies on proper lubrication. Additionally, allowing the engine to cool down after driving at high speeds or under heavy loads can prevent the turbocharger from overheating. Regular inspections of the turbo system, including the wastegate and turbine, can help prevent premature wear and maintain the engine’s performance.

Spark Plug Replacement

Spark plugs play an integral role in the combustion process of the Range Rover 2.0 engine, as they ignite the air-fuel mixture in the engine’s cylinders. Over time, spark plugs can become fouled or worn out, leading to misfires, poor fuel efficiency, and reduced engine performance.

Replacing the spark plugs at regular intervals is a critical maintenance task. For the Range Rover 2.0 engine, it’s typically recommended to replace spark plugs every 30,000 to 50,000 miles. During routine maintenance, mechanics will inspect the condition of the spark plugs and recommend replacement if necessary to ensure the engine continues to run smoothly.

Cooling System Maintenance

Maintaining the cooling system in the Range Rover 2.0 engines is vital for preventing overheating and maintaining optimal engine temperatures. The cooling system includes the radiator, water pump, thermostat, and coolant. Over time, the coolant can break down, losing its ability to regulate the engine’s temperature effectively.

Regularly flushing the cooling system and refilling it with fresh coolant is essential for engine longevity. It’s generally recommended to flush the system every 30,000 miles or as specified by the manufacturer. Additionally, inspecting the radiator for leaks or damage and ensuring the water pump is functioning correctly will help avoid potential overheating issues.

Fuel System Maintenance

The fuel system of the Range Rover 2.0 engine is designed to deliver the right amount of fuel to the engine’s cylinders for efficient combustion. However, over time, fuel injectors can become clogged, and the fuel filter can accumulate debris, leading to reduced fuel efficiency and poor engine performance.

Regularly servicing the fuel system—by cleaning the fuel injectors and replacing the fuel filter—ensures that the engine receives a clean and consistent supply of fuel. It’s typically recommended to service the fuel system every 30,000 miles to prevent performance issues and ensure the engine runs smoothly.

Engine Replacement and Reconditioned Engines

Despite regular maintenance, some engines may require replacement due to wear, age, or unexpected damage. For Range Rover owners, choosing between a new engine replacement or a reconditioned engine can be a significant decision. Reconditioned engines are thoroughly inspected, cleaned, and repaired, making them a cost-effective alternative to brand-new engines.

When considering engine replacement, a reconditioned engine offers the advantage of being more affordable while providing reliable performance. Many reputable suppliers offer “supply and fit” services, which can simplify the process of replacing the engine. This service ensures that the new or reconditioned engine is professionally installed, saving owners time and reducing the risk of errors during installation.

Read the full article

0 notes

Text

Car Won’t Stay Running: Investigating the Start-Then-Die Phenomenon

At times, drivers face typical issues in their cars that not leaves them stranded in the middle of the road but also frustrated because comprehending the problem affecting the drivability of the vehicle seems tasking. One such peculiar problem is when your car starts runs for a couple of minutes then dies suddenly.

The start-then-die phenomenon is common problem faced by many car drivers once in their lifetime. Here in this article, we will discuss the root cause behind this frustrating problem so that it becomes easy for you deal with the situation.

Bad Fuel Pump

One of the leading causes behind the car start-then-die problem is related to the fuel system in general and the fuel pump in particular because often it is observed that a bad fuel pump is the primary cause behind the starting and then stalling issues faced by the vehicles.

The fuel pump is responsible for delivering pressurized fuel from the fuel tank to the engine of your car which is required for the combustion process. However, when you are driving with a malfunctioning fuel pump under the hood of your car then the engine is not going to get pressurized fuel and this affects the combustion process adversely.

This is when you get to experience start-then-die issues in your car while driving and you are also going to observe that the car sputters at high speeds or you will face difficulty when accelerating. A fuel pressure test performed by a professional mechanic would reveal if the pump is delivering an adequate amount of pressurized fuel to the combustion chambers or not.

Mass Air Flow (MAF) Sensor Failure

There are a host of sensors in your vehicle that are responsible for monitoring the functioning of the vital components and the MAF sensor helps in measuring the amount of air entering the engine and this information is used by the onboard computers to adjust the fuel flow to the engine of your car.

Over the years the MAF sensor can encounter issues with its functioning or get clogged up due to accumulation of dirt & debris and this leads to inaccurate information being passed on to the onboard computers. This often causes too much fuel or too little fuel to flow into the engine leading to various problems including the start-then-die phenomenon.

In addition to the stalling problem, you are also going to encounter rough idling and poor acceleration while driving. Most of the time cleaning the clogged MAF sensor helps in dealing with the problem, however, if the issue persists even after cleaning then you have to replace the sensor.

Faulty Ignition System Components

The ignition system in your car consists of a host of components that play a crucial role in igniting the air-fuel mixture in your combustion chamber. However, issues with any of these parts like the spark plugs, ignition coils, and distributor can lead to your vehicle starting but dying suddenly.

Most of the time it is observed that faulty spark plugs in cars are the main culprit behind the stalling issues as it fails to ignite the air-fuel mixture in the combustion chamber. Moreover, if the ignition coils are worn out then the engine is going to fire initially but will fail to keep the combustion going.

You are also going to notice a drop in the performance of your car due to underlying ignition system issues and the best way to avoid getting caught in this horrible situation is by regularly inspecting and replacing the malfunctioning ignition system components before they start to affect your car eventually.

Blocked Fuel Filter

The fuel filter in your vehicle is responsible for preventing the entry of dirt & debris by filtering the fuel entering the engine. However, over the years, the fuel filter can get clogged with contaminants and this affects the smooth flow of gasoline into the combustion chamber of your car.

That is why it is important to replace the fuel filter of your vehicle as per the manufacturer-recommended maintenance schedule of your car. This is one of the most overlooked maintenance aspects of cars and you must guard against committing this mistake.

Finally

The above-discussed factors are some of the leading reasons behind your car starting then dying suddenly. The moment you notice the problem then you must immediately get in touch with a certified mechanic to diagnose and rectify the issues as delaying action can lead to serious engine issues in your vehicle.

0 notes

Text

How the Constant Volume Combustion Chamber Improves Diesel Engine Efficiency and Performance

The Constant Volume Combustion Chamber (CVCC) is a key technology used to assess and enhance the performance of diesel engines. One of its most important functions is measuring the Derived Cetane Number (DCN), a critical indicator of fuel quality and ignition performance. The CFR’s Ignition Quality Tester (IQT™), a world-leading CVCC instrument for over 20 years, has played a pivotal role in evaluating the ignition quality of diesel and alternative fuels.

The Derived Cetane Number is essential for understanding how efficiently a fuel burns, which directly impacts engine performance. Fuels with higher DCN values tend to ignite more easily and burn cleaner, improving engine efficiency, lowering emissions, and extending engine life. By accurately determining this value, the Constant Volume Combustion Chamber provides fuel producers and engine manufacturers with the data they need to optimize fuel blends for better performance.

In addition to measuring the Derived Cetane Number, the CVCC method offers a controlled environment for studying combustion properties. This enables precise fuel testing that helps reduce emissions, improve fuel efficiency, and enhance overall engine performance. The consistency and reliability of the IQT™ have made it an indispensable tool for both automotive and petroleum industries worldwide.

In conclusion, the Constant Volume Combustion Chamber significantly contributes to diesel engine performance by providing accurate measurements of the Derived Cetane Number. For over two decades, the IQT™ has been at the forefront of fuel analysis, helping to improve diesel engine efficiency and meet the demands of modern fuel regulations.

0 notes

Text

Understanding Common Porsche Sensor Problems: Reliable Fixes and Service Tips for Enhanced Vehicle Performance

Porsche vehicles are known for their precision engineering, dynamic performance, and cutting-edge technology. However, like all modern cars, they rely heavily on a variety of sensors to ensure smooth operation and optimal performance. These sensors monitor everything from engine performance and fuel efficiency to safety systems and emissions. When a sensor fails or malfunctions, it can cause performance issues, inaccurate readings, or even damage to critical vehicle components. In this article, we’ll explore common Porsche sensor problems, their potential causes, and reliable fixes to keep your vehicle performing at its best.

Common Porsche Sensor Problems

Oxygen (O2) Sensor Failure The oxygen sensor monitors the air-to-fuel ratio in your Porsche’s engine and helps optimize fuel efficiency and emissions control. When the O2 sensor malfunctions, you may notice poor fuel economy, a rough idle, or an illuminated check engine light. Over time, an inaccurate O2 sensor can also lead to more serious engine problems due to incorrect fuel mixture readings.

Mass Air Flow (MAF) Sensor Issues The MAF sensor measures the amount of air entering the engine to help adjust fuel delivery. If the MAF sensor becomes dirty or faulty, it can result in stalling, poor acceleration, or engine hesitation. This issue is especially common in high-performance vehicles like Porsche, where precise air and fuel management is crucial.

Throttle Position Sensor (TPS) Malfunction The throttle position sensor helps manage the position of the throttle valve in relation to the accelerator pedal. If the TPS fails, you may experience inconsistent throttle response, sluggish acceleration, or difficulty maintaining a steady speed. In extreme cases, the vehicle may enter "limp mode," restricting performance to prevent further damage.

Knock Sensor Problems The knock sensor detects engine knocking or pinging, which occurs when fuel ignites prematurely in the combustion chamber. If the knock sensor fails, the engine may not adjust its timing properly, leading to potential damage. A malfunctioning knock sensor often triggers the check engine light and may cause rough engine operation or reduced performance.

ABS Wheel Speed Sensor Failure The ABS (Anti-lock Braking System) wheel speed sensors monitor the rotation of each wheel to prevent lockups during braking. When an ABS sensor fails, you might experience reduced braking performance, and the ABS light may illuminate on the dashboard. A faulty sensor can compromise vehicle safety, especially in adverse driving conditions.

Reliable Fixes for Porsche Sensor Problems

Regular Diagnostic Checks Conducting regular diagnostic scans is one of the most effective ways to identify sensor issues early. Porsche vehicles are equipped with sophisticated onboard diagnostic systems that store error codes when a sensor malfunctions. Regular scans by a professional technician can pinpoint the specific sensor at fault and allow for timely repairs or replacements.

Cleaning or Replacing Sensors Some sensor issues, such as those affecting the MAF sensor, may be resolved with a thorough cleaning. Over time, dirt, dust, and debris can accumulate on the sensor, leading to inaccurate readings. A professional cleaning can restore sensor functionality. However, if the sensor is damaged or worn out, replacement is often the best option to restore proper performance.

Updating Software and Calibration Many sensor-related problems can be linked to outdated software or improper calibration. Porsche vehicles often receive software updates that improve sensor accuracy and vehicle performance. Regularly updating your Porsche’s software and ensuring all sensors are properly calibrated by a professional technician can prevent issues from arising and optimize your vehicle’s systems.

Using OEM Parts for Sensor Replacement When replacing faulty sensors, it’s essential to use Original Equipment Manufacturer (OEM) parts. OEM sensors are specifically designed for your Porsche model and ensure precise compatibility and performance. Using aftermarket or generic parts may lead to inaccurate readings or further malfunctions.

Professional Inspection and Repairs Sensor problems can sometimes be complex, involving more than just the sensor itself. Issues with wiring, connectors, or even the vehicle’s control modules can affect sensor performance. A professional mechanic with expertise in Porsche vehicles can perform a comprehensive inspection to diagnose and resolve the root cause of sensor failures.

Service Tips for Enhanced Porsche Performance

Stay on Top of Maintenance: Regular maintenance services, such as oil changes, air filter replacements, and fuel system cleaning, can help prevent sensor issues caused by contamination or wear.

Keep Sensors Clean: Sensors located in the engine bay, like the MAF sensor, are susceptible to dirt and debris. Regular cleaning during maintenance checks can extend their lifespan and maintain performance.

Monitor Dashboard Alerts: If your check engine light or ABS warning light comes on, don’t ignore it. Early detection and repair of sensor issues can prevent more significant problems down the road.

Avoid Aftermarket Modifications: While aftermarket parts or modifications may seem appealing, they can interfere with the delicate balance of your Porsche’s sensor systems, leading to poor performance or damage.

Conclusion

Understanding the role that sensors play in your Porsche’s performance is essential for maintaining its reliability and driving experience. By addressing sensor problems early, using OEM parts, and relying on professional service, you can ensure that your Porsche continues to deliver the dynamic performance it’s known for. Regular diagnostics and proactive maintenance are key to preventing costly repairs and keeping your vehicle in peak condition.

#porsche car#porsche sensor#porsche service center#porsche car maintenance#porsche car mechanic#porsche car engine service#porsche car services

0 notes