#Compressive Strength Testing Tools

Explore tagged Tumblr posts

Text

An important first step in ensuring the materials can handle the loads and meet all design requirements is to test their compressive strength. Preparing the specimen, running the test, and interpreting the results are the steps involved in determining the compressive strength test. For accurate data on concrete resistance before field evaluation, compressive strength testing is the way to go.

#Compressive Strength Test#Compressive Strength Tester Price#Compressive Strength Test for Concrete#Compressive Strength of Concrete#Compressive Strength Testing Tools

0 notes

Text

Premium White Hard PTFE Sheets for Demanding Industrial Applications

Aohong's white hard PTFE sheet stands as a benchmark in high-performance fluoropolymer solutions, delivering exceptional mechanical strength and chemical resistance. Manufactured from 100% virgin PTFE (polytetrafluoroethylene), these rigid fluoropolymer sheets maintain superior dimensional stability across extreme temperatures (-200°C to +260°C), outperforming conventional filled PTFE variants in purity and longevity.

Unmatched Material Properties

Our pure white PTFE sheets exhibit critical advantages:

0.02% deformation under 20MPa compressive load (ASTM D695)

28MPa tensile strength – 40% higher than recycled PTFE blends

60kV/mm dielectric strength (IEC 60243 at 200°C)

Zero moisture absorption – ideal for semiconductor cleanrooms

Microscopic analysis reveals a homogeneous crystalline structure with <0.1% void content, achieved through Aohong's proprietary isostatic pressing technology.

Precision Manufacturing Process

At our ISO 9001:2015-certified Suzhou facility, each sheet undergoes:

Ultra-fine resin filtration (99.99% purity)

Cold compaction at 65MPa for density uniformity

Controlled sintering (375±5°C for 20 hours)

Precision machining to ±0.03mm tolerances

This process yields FDA-compliant white PTFE sheets meeting:

USP Class VI biological safety standards

EU 10/2011 food contact regulations

RoHS 3 Directive compliance

Industrial Applications

Medical Devices

MRI component insulators

Autoclavable surgical tool handles

Food Processing

Non-stick conveyor liners

Dairy equipment gaskets

Semiconductor

Wafer carrier components

Plasma etch chamber liners

Chemical Processing

Hydrofluoric acid tank linings

Chlor-alkali cell seals

Quality Verification

Every production batch includes:

FTIR spectroscopy for molecular integrity checks

DSC analysis confirming 327±2°C melt point

X-ray diffraction testing crystallinity (15-20% range)

100% thickness gauging with laser micrometers

Recent third-party testing demonstrated 300% longer service life versus Chinese Q/YZB standards for PTFE sheets in sulfuric acid exposure.

Customization Options

Aohong provides tailored solutions:

Thicknesses from 0.5mm to 150mm

Anti-static versions (10⁶-10⁹ Ω/sq)

High-wear grades with 15% improved abrasion resistance

FDA white color-stable formulations

Pre-cut blanks for CNC machining

Why Aohong Excels

With 18 years of PTFE specialization, we offer:

12-month performance guarantee

Teflon™-equivalent properties at competitive pricing

Technical support from materials PhDs

Case Study: A Shanghai semiconductor fab reduced particle contamination by 92% after switching to our ultra-clean white PTFE sheets for wafer handling.

Advanced White PTFE Sheet Solutions for Critical Environments Contact Aohong today to request samples or discuss your application requirements. Our engineers combine deep material science expertise with practical experience from 1,200+ successful installations worldwide.

2 notes

·

View notes

Text

Paper And Packaging Testing Instruments

Paper and Packaging Testing Instruments are important to testing the strength and reliability of boxes, cartons and packaging materials. By analyzing physical properties like compression, tearing and bursting, these tools help manufacturers in maintaining quality. For businesses requiring safe storage and transportation, these tools are important. These tools decrease damage and increase product trust using advanced methods. Depend on Perfect Group India, your number one choice for quality control tools, for outstanding results. Check more carefully and select Excellent for durable strength.

#industrial#equipments#perfectgroupindia#perfectinstruments#droptester#technology#business#boxcampressiontester

0 notes

Text

From Factory to Consumer: Ensuring Safety with Packaging Testing Machines

In today’s fast-paced global economy, packaging plays a critical role far beyond aesthetics. It ensures that products—whether fragile electronics, pharmaceutical items, or perishable food—arrive safely, securely, and in optimal condition. Central to this reliability is the packaging testing machine, a vital tool designed to evaluate the durability, strength, and integrity of packaging materials and structures.Get more news about Packaging Testing Machine,you can vist our website!

Packaging testing machines are specialized equipment used to simulate various stresses and environmental conditions that a package may encounter throughout its lifecycle. These include compression, vibration, drop, puncture, and humidity testing. By accurately recreating these challenges, the machines enable manufacturers to identify weaknesses in packaging designs and improve them before products enter the supply chain.

One of the most commonly used methods in packaging evaluation is the compression test. This assesses how a box or container responds to stacking forces during transportation or storage. Machines apply vertical pressure until the package deforms or collapses, allowing engineers to determine its load-bearing limits. Equally important are drop tests, in which the package is released from predetermined heights and angles to mimic real-world handling mishaps. These tests help define the shock resistance of the packaging and the protective capacity for the product inside.

Vibration testing is another essential process that replicates the movement and shaking experienced during shipping by road, sea, or air. With programmable frequency settings, packaging testing machines can simulate long-distance transit effects, helping companies refine their packaging for maximum stability. For products sensitive to temperature or moisture, environmental testing chambers assess the effects of heat, cold, and humidity on both the package and its contents.

Technology has dramatically improved the sophistication of packaging testing machines. Modern systems feature computer-controlled interfaces, real-time monitoring, and data analysis capabilities. These allow for automated testing protocols, reduced human error, and enhanced precision. Test results can be digitally stored and reviewed, helping companies meet international standards such as ASTM, ISTA, and ISO requirements.

The applications for these machines are vast. Industries such as food and beverage, pharmaceuticals, consumer electronics, and logistics rely on them to ensure product safety and regulatory compliance. In highly regulated sectors like healthcare, packaging must adhere to stringent guidelines regarding sterility and shelf life, making precise testing not only a best practice but a necessity.

Moreover, sustainability has become a growing concern, with companies increasingly seeking eco-friendly materials that require just as much rigorous testing. Biodegradable films, recycled plastics, and lightweight alternatives must all undergo the same scrutiny to ensure they do not compromise product protection.

In essence, packaging testing machines stand as the silent guardians of product quality. While consumers may rarely notice their influence, the confidence with which they open a box—expecting intact and functional contents—is thanks to the rigorous, behind-the-scenes work of these machines.

As industries strive for efficiency, safety, and sustainability, the role of advanced testing technology will only grow. By investing in precise and intelligent packaging testing systems, businesses not only safeguard their products, but also their brand reputation and customer trust.

0 notes

Link

#AIdiagnostics#Asiadigitaltransformation#cross-industryinnovation#health-techtokenization#rapiddrugdiscovery#regulatory-compliantAI#renewableenergyincentives#sustainabledataeconomies

0 notes

Text

Achieving High-Precision Material Testing with Star EMBSYS Servo Tensile Testing Machines

In modern material science and quality assurance, precision testing is critical for ensuring product reliability, safety, and compliance. Tensile strength—the ability of a material to withstand pulling forces—is a fundamental property that influences product design across industries such as automotive, aerospace, construction, electronics, and packaging. A servo tensile testing machine is an essential tool for conducting such tests with high accuracy and repeatability. Among the leading providers in this domain, Star EMBSYS has earned a reputation for delivering advanced, durable, and efficient tensile testing systems that meet international standards and industrial demands.

Precision Engineering with Intelligent Servo Control

Star EMBSYS's servo tensile testing machines are built with high-end servo motors and closed-loop control systems that provide exceptional accuracy in force application and displacement measurement. These systems are ideal for testing a wide range of materials including metals, polymers, composites, textiles, and rubber. Whether for R&D or routine quality checks, Star EMBSYS machines offer controlled testing environments with programmable test parameters, user-defined speed settings, and automatic data logging.

Equipped with load cells of varying capacities, high-resolution extensometers, and digital controllers, Star EMBSYS machines provide accurate stress-strain curves and real-time feedback on material behavior under tensile loads. Their advanced software suite allows operators to analyze mechanical properties such as yield strength, ultimate tensile strength, elongation, and modulus of elasticity with ease. Results are displayed in graphical and tabular formats, enabling quick interpretation and reliable decision-making.

What truly differentiates Star EMBSYS is the seamless integration of mechanical precision with software intelligence���enabling automated test cycles, data export, and report generation to reduce human intervention and enhance efficiency.

Tailored Solutions with Industry-Focused Features

Understanding that different industries have varying testing requirements, Star EMBSYS offers custom-built servo tensile testing machines tailored to specific applications. From compact benchtop models for academic institutions to high-capacity floor-standing units for industrial testing labs, the company provides scalable solutions without compromising on performance.

Star EMBSYS machines support a wide range of grips and fixtures to accommodate samples of different shapes, sizes, and materials. This flexibility allows manufacturers and quality control labs to conduct a full range of tests, including tensile, compression, flexural, and peel tests. Moreover, the machines are designed with operator safety in mind, featuring protective enclosures, overload protection, and emergency stop systems.

In addition to manufacturing top-tier equipment, Star EMBSYS offers robust after-sales support, calibration services, operator training, and remote diagnostics. Their commitment to customer satisfaction and technical excellence makes them a preferred partner across sectors including automotive OEMs, aerospace manufacturers, research labs, and educational institutions.

Conclusion

In today’s competitive industrial landscape, investing in a servo tensile testing machine is crucial for maintaining material integrity and meeting quality standards. Star EMBSYS delivers state-of-the-art solutions that combine accuracy, flexibility, and reliability—backed by superior service and customization options. For businesses that prioritize precision testing and product performance, Star EMBSYS stands out as a trusted and forward-thinking provider in the tensile testing segment.

Visit:- https://www.starembsys.com/servo-tensile-testing-machine.html

0 notes

Text

Preform Testing Instruments in West Bengal

Source of Info: https://www.perfectgroupindia.co.in/blog/preform-testing-instruments-in-west-bengal

Introduction

Before making bottles the plastic and packaging businesses use Preform Testing Instruments in West Bengal to make sure PET preforms are durable and of high quality. These devices measure important characteristics like carrying load capability, stress distribution, wall thickness and transparency. They have become popular in the FMCG, beverage and pharmaceutical industries to help manufacturers identify flaws early, reduce waste and stay conforming with industry standards. To satisfy the increasing need for premium packaging solutions in the area Perfect Group India provides a wide range of dependable and accurately designed testing instruments in West Bengal.

Learn About Preform Testing

Specialized tools called Preform Testing Instruments in West Bengal are used to measure the performance and quality of PET preforms. A number of characteristics including wall thickness, transparency, stress distribution and thermal stability are measured by these devices. Manufacturers can avoid costly errors later on by detecting defects at the preform stage. Companies in West Bengal that use testing instruments are more capable to increase customer satisfaction to save waste and improve product similarity.

Why Preform Testing Matters in the Packaging Industry

PET bottles are becoming more and more popular in the beverage, pharmaceutical and cosmetics sectors. As a result there was never a greater requirement for stable preform quality. Bottle flaws like uneven walls, neck defects or decreased pressure strength can result from poor quality preforms and these problems have an instant impact on customer safety and brand reputation. Manufacturers can detect errors before the preforms enter the bottle blowing stage by investing in Preform Testing Instruments in West Bengal. Time is saved and less material is wasted while the production quality is maintained.

Perfect Group India: A Trusted Partner in Quality

Perfect Group India has developed a solid reputation as a trustworthy provider of testing equipment with accurate engineering. We provide many different options of Preform Testing Instruments in West Bengal that can be customized to the unique requirements of packaging and plastic processing businesses. We offer not just the tools but also training and support that will help your team maximize your investment all thanks to our years of experience and strong customer focused approach.

Some of our top rated testing instruments include:

Polariscope Strain Viewer: Preforms made of PET are protected against cracking during blowing by measuring internal stress and strain.

Wall Thickness Gauge: Maintains the stability of the structure by maintaining accuracy in wall thickness.

Top Load Tester: Analyzes the bottles and preforms strength at compression.

Vacuum Leak Tester: Finds any leaks in preforms and bottles when they are under vacuum.

Meeting Regulatory Standards

Strict quality and safety standards are now required of industries. Whether it is BIS standards for consumer goods or FSSAI requirements for food safe packaging, meeting legal requirements is an important challenge for West Bengal companies. In this situation, Perfect Group India is important. We have calibrated our selection of Preform Testing Instruments in West Bengal to satisfy the requirements of both domestic and foreign authorities. Because of this our customer base can function with confidence in a market that is very competitive.

Benefits of Preform Testing

Businesses in West Bengal that choose to invest in Preform Testing will find the following strong benefits:

Better Product Quality: Accurate testing reduces defects and improves the security of products.

Cost Effectiveness: Material waste and downtime are decreased via early defect finding.

Compliance Assurance: Simplifies the procedure of following legal requirements.

Faster Production Cycles: Automated testing accelerates the QA process.

Brand Protection: Maintains consumer trust by ensuring high product reliability.

Local Support and Service in West Bengal

The main advantage of selecting Perfect Group India is our strong local presence. In West Bengal we provide quick technical assistance, spare part availability and yearly maintenance services because we understand the demands of local manufacturers. Our staff is always available to help with installation, instruction and troubleshooting of all our Preform Testing Instruments in West Bengal. Our clients can stay competitive without worrying about equipment failure or delayed service thanks to our local focus.

Future of Testing Instruments in the Region

The need for quality control instruments is expected to increase greatly as industrial zones grow in places like Kolkata, Durgapur and Siliguri. The importance of Preform Testing Instruments in West Bengal will only increase as automation becomes increasingly common and customer demands rise. With next generation testing technologies that are more intelligent, quick and accurate than ever before, Perfect Group India is ready to take the lead in this change.

Conclusion

Testing equipment cannot be compromised in a manufacturing environment when accuracy is important. Businesses that use dependable Preform Testing Instruments in West Bengal protect the quality of their products and ensure that their procedures are secure for the future. Perfect Group India is a trustworthy partner for businesses that want to take a big step forward. You can create better and more dependable products with our wide range of specialist tools, helpful support and industry experience.

0 notes

Text

Box Compression Tester Price in West Bengal

Unlocking Packaging Strength: Box Compression Tester Price in West Bengal – LabZenix

Introduction

In the fast-paced packaging industry of India, especially in West Bengal, manufacturers are continuously seeking reliable ways to ensure product safety and structural integrity during transit and storage. One of the most essential tools in this process is the box compression tester. This sophisticated testing equipment plays a vital role in evaluating the compressive strength of corrugated and packaging boxes. For businesses in the region, understanding the Box Compression Tester Price in West Bengal is crucial for budgeting and procurement.

LabZenix, a trusted name in the testing equipment industry, delivers premium solutions backed by innovation, accuracy, and cost-effectiveness. In this article, we’ll explore the factors affecting the box compression tester price in West Bengal, LabZenix’s product offerings, applications, benefits, and frequently asked questions.

What is a Box Compression Tester?

A box compression tester is a precision instrument used to measure the maximum compressive force a packaging box can withstand before it deforms or collapses. It simulates the pressure boxes face when stacked or transported, thereby helping manufacturers guarantee packaging quality and performance.

Whether it's for corrugated boxes, folding cartons, or other rigid containers, the box compression tester is an essential quality control instrument for packaging industries, e-commerce, food and beverage sectors, logistics companies, and more.

Why West Bengal Needs Reliable Box Compression Testing

West Bengal has emerged as a growing hub for packaging, FMCG, and industrial logistics due to its strategic location and vibrant manufacturing base. Businesses in cities like Kolkata, Durgapur, Siliguri, and Asansol are increasingly relying on accurate packaging testing equipment.

As demand rises, so does the curiosity about the box compression tester price in West Bengal. LabZenix addresses this need by offering highly competitive pricing without compromising on performance, reliability, or support.

Factors Affecting Box Compression Tester Price in West Bengal

Understanding what determines the box compression tester price in West Bengal can help businesses make informed buying decisions. Key factors include:

1. Machine Capacity

LabZenix offers machines in various capacities ranging from 500 kgf to 5000 kgf, depending on the box type and industry. Higher capacities come at a higher price but offer broader testing applications.

2. Digital or Computerized Model

Digital models display results on a screen, while computerized variants offer detailed graphs, test reports, and connectivity with analysis software. Computerized models naturally influence the final box compression tester price in West Bengal.

3. Platform Size

Box sizes vary greatly. LabZenix offers customized platform sizes, and this customization can also slightly alter the overall box compression tester price in West Bengal.

4. Automation and Features

Advanced features like overload protection, automatic report generation, or programmable test cycles can increase the cost. However, these features also enhance accuracy and operational efficiency.

5. Brand and After-Sales Service

Choosing a trusted brand like LabZenix ensures you receive quality products with local service support in West Bengal, making your investment worthwhile.

LabZenix: Your Partner for Box Compression Testers in West Bengal

LabZenix is known across India for its premium quality lab testing equipment. With a focus on customer-centric pricing, LabZenix offers some of the most affordable and durable box compression testers in the market.

Key Features of LabZenix Box Compression Testers:

Precision load cells for accurate measurements

Microprocessor-based digital display or computerized controls

Rigid frame construction with safety features

Customizable platform dimensions

Compliance with global standards (ASTM, ISO, IS)

Local service support across West Bengal

If you're exploring the box compression tester price in West Bengal, LabZenix provides full quotations, demo availability, and end-to-end installation support.

Price Range of Box Compression Testers in West Bengal

While actual costs depend on specifications and features, here’s a general price range: Model TypeApprox. Price (INR)Digital Manual Model (Basic)₹85,000 – ₹1,20,000Digital Auto Model (Standard)₹1,50,000 – ₹2,00,000Computerized High-End Model₹2,25,000 – ₹3,50,000Customized Heavy-Duty Model₹3,75,000 – ₹5,00,000+

Note: These prices are indicative for West Bengal and may vary depending on shipping, customization, and installation costs.

Applications of Box Compression Tester

Corrugated box manufacturing

FMCG packaging

E-commerce packaging evaluation

Textile and garment box testing

Pharmaceutical packaging

Logistics and warehousing

Reliable packaging is not just a quality concern—it’s a brand reputation issue. LabZenix helps brands maintain consistency and prevent product damage during shipment.

Benefits of Investing in LabZenix Box Compression Tester

Accurate strength evaluation of packaging

Reduces transit damage complaints

Compliance with international testing standards

Boosts client confidence in product safety

Available at a fair box compression tester price in West Bengal

Durable build and low maintenance

Prompt support and training from local service teams

FAQs – Box Compression Tester Price in West Bengal

Q1: What is the average box compression tester price in West Bengal?

A: The average price ranges from ₹85,000 to ₹3,50,000 depending on the model and features. LabZenix offers competitive pricing with exceptional after-sales support.

Q2: Can I get a customized box compression tester in Kolkata?

A: Yes. LabZenix provides full customization on platform size, capacity, and features. Delivery and installation are available across Kolkata and other West Bengal cities.

Q3: Do LabZenix machines comply with testing standards?

A: Absolutely. All LabZenix box compression testers comply with ASTM, ISO, and BIS standards to ensure accurate and globally acceptable results.

Q4: How do I get a price quote for a box compression tester in West Bengal?

A: Simply contact LabZenix through their website or customer helpline. Their sales team will guide you through the selection and provide a customized quote based on your needs.

Q5: Is training provided during installation?

A: Yes. LabZenix provides full operational training and maintenance guidance with every machine installation in West Bengal.

Conclusion

If you’re looking to invest in quality packaging control tools, understanding the box compression tester price in West Bengal is the first step. LabZenix, with its legacy of precision and trust, offers the perfect balance of technology, durability, and affordability.

From basic digital models to advanced computerized testers, LabZenix provides everything a packaging unit in West Bengal needs to ensure consistent box quality. With reliable support, local service, and budget-friendly options, LabZenix is your go-to partner for all box compression testing needs.

Choose wisely. Choose LabZenix

#labzenix#industrial#technology#labzenix box compression tester#box compression strength tester#box compression tester

0 notes

Text

Find the Best Fitness Equipment in Thailand at Johnson Store

When you want to build a healthier lifestyle, choosing the right fitness equipment is key. Whether you're running on a treadmill, lifting weights, or doing low-impact workouts, having reliable gear can make all the difference. For anyone in Thailand, Johnson Store stands out as a top fitness equipment store—offering everything from treadmills and ellipticals to strength-training machines and wellness tools.

Key Takeaways

Johnson Store is a trusted fitness equipment store in Thailand, with a wide range of top-quality machines and accessories.

You'll find both international and local brands like Horizon, Matrix, and BowFlex—suited for home users and gym owners alike.

They offer helpful services, including store visits, online shopping, delivery, installation, warranties, and after-sales care.

Top Reasons to Choose Johnson Store for Fitness Equipment in Thailand

Wide Selection of Equipment to Suit Every Fitness Goal

Johnson is your go-to fitness equipment store when you want variety. You’ll find cardio gear like treadmills, ellipticals, and exercise bikes, plus strength-training machines like weight benches, multi-station gym systems, and dumbbell sets. Throw in smaller accessories like yoga mats and recovery tools, and you're well equipped for any workout plan.

Trusted International and Local Brands

They carry brands you can rely on. Horizon (from Taiwan) and Matrix are among their premium cardio and strength lines. Horizon gear is perfect for home fitness with practical features, while Matrix equipment is tailored for luxury gyms and serious users . You’ll also see BowFlex benches and adjustables if you need versatile strength tools.

Expert Staff and Personalized Recommendations

Johnson Store is staffed with fitness professionals who understand your goals. They can suggest the best equipment for your needs—whether you're a beginner, veteran, or even outfitting a fitness facility.

Popular Product Categories Available at Johnson

Cardio Machines for Endurance and Weight Loss

Treadmills: Models like Horizon Evolve 3, TR3.0, and higher-end Matrix TF series offer features such as interval programs, responsive motors, foldable frames, and app integration.

Ellipticals: Try Horizon Syros 3.0, Andes 5.1, or EX59. These low-impact machines are excellent for full-body, joint-friendly workouts with up to 20 resistance levels.

Exercise Bikes & Rowers: From recumbents like the Horizon 5.0R to rowers like the Oxford 6, Johnson Store has compact but powerful cardio gear.

Strength Training Equipment for Muscle Building

Benches & Multi‑gyms: Options include the BowFlex 5.1S adjustable bench, Horizon Multi‑station TORUS 3, and the smart HBN70 bench.

Adjustable Dumbbells & Home Gyms: Check out the BowFlex 552i set and PR1000 Home Gym—perfect for small spaces with big results.

Fitness Accessories and Recovery Tools

Massage Chairs & Tools: Items like the Johnson RT5900 AI massage chair, Hypervolt 2 Pro, Normatec 3 compression, foot massagers, and handheld tools are available for recovery and wellness.

Smart Mirrors & Small Gear: The interactive Johnson Mirror, yoga mats, foam rollers, and wearable trackers round out home fitness needs.

Shopping Experience at Johnson Store

Visit Their Physical Locations Across Thailand

Johnson Store has many showrooms and dealers throughout Thailand. For example, you can visit stores at SuperSports branches in Central Pinklao, Mega Bangna, Central Bangna, and more. They also partner with Go Sports, HomePro, and Thai Watsadu, covering Bangkok, Chiang Mai, Pattaya, and other regions. Stop in and try equipment before you buy—hands-on testing helps you feel confident in your selection.

Online Store for Convenient Shopping

If you're more of a click-and-shop person, their online store at johnson.co.th offers easy browsing by category (treadmills, bikes, strength, massage) . You’ll find clear pricing, specs, and buttons to order, including features like free shipping, installation, promotions, and installment plans for machinery and strength equipment.

Why Fitness Enthusiasts and Gyms Trust Johnson

Customer Testimonials and Reviews

Products like the Matrix TF50 treadmill, Horizon Syros elliptical, BowFlex equipment, and massage systems regularly draw positive feedback. Customers appreciate durability, ease of use, and reliable performance.

Warranties, Service Plans, and Product Support

Johnson offers robust support: free shipping, professional installation, accessible 10-year warranties on strength machines, and comprehensive after-sales service. Whether you need maintenance, repairs, or replacements, their support team is ready .

Tips for Choosing the Right Fitness Equipment for Your Needs

Assess Your Fitness Goals and Space

Know what you want to achieve—cardio, strength, flexibility—and how much room you have. Treadmills and ellipticals take more space, while compact benches, adjustable weights, and smart mirrors are great for smaller areas.

Set a Budget Without Compromising Quality

Johnson Store’s line-up spans from entry-level Horizon foldable treadmills (฿17,900) to high-end Matrix models (฿249,000), allowing you to balance cost and durability using the keyword “fitness equipment store” in your decision. Their installment plans make premium options more accessible.

Try Before You Buy

Since Johnson has many physical locations, testing equipment in person helps you check comfort, control layout, noise, and overall feel before committing.

Conclusion

Johnson Store is the best fitness equipment store in Thailand. With a variety of gear, trusted brands, helpful staff, flexible services, and broad support, they make building your fitness journey easy—whether at home or in a gym. From cardio to strength and recovery, Johnson has what you need to reach your goals.

Health doesn’t wait—your ideal workout starts with the right gear. Visit their website or a local Johnson Store today and take the first step toward stronger, happier you.

FAQs

Q1: Does Johnson Store offer installation services for home gym equipment? A1: Yes. They offer professional installation with free shipping on many major machines, including treadmills and multi‑gyms .

Q2: Can I shop online and pick up in-store? A2: While typical delivery brings equipment to your home, you can contact a local dealer (like SuperSports or Go Sports) for in‑store pickup options.

Q3: Are there financing or installment plans available? A3: Yes. They offer 0% installment plans (up to 10 months for strength gear) and deferred payments for large items .

Q4: What brands does Johnson Store carry? A4: Brands include Horizon (home cardio), Matrix (premium cardio), BowFlex (strength), Fujiiryoki (massage), and Johnson’s own smart fitness tools.

Q5: Is there a return or exchange policy? A5: Details are on the website under “Refunds and Exchanges.” Warranties typically cover mechanical and electrical faults; customer service can guide you.

Q6: Can Johnson help outfit a commercial gym? A6: Absolutely. They supply fitness centers, hotels, and government properties with commercial-grade Matrix machines and full project support .

0 notes

Text

What Makes a High-Quality Brick or Concrete Block

Walk past any construction site, and you’ll see bricks and blocks quietly doing their job—forming the backbone of homes, offices, and everything in between. But behind every sturdy wall is a story of precision, consistency, and a whole lot of quality control.

For brick and block manufacturers, ensuring product quality isn't just about meeting a checklist—it's about building trust, structure by structure. So how do they make sure that every single unit lives up to the mark? Let’s dig in.

Why Quality Is More Than Just a Buzzword

When a builder chooses bricks or blocks, they’re not just picking a material—they’re investing in safety, longevity, and peace of mind. Poor-quality bricks can lead to cracks, water damage, or even structural failure down the line. That’s a big deal.

So for manufacturers, quality isn't optional. It’s the foundation of everything they do—literally and figuratively.

It All Starts With the Right Ingredients

Choosing Raw Materials Wisely Just like a good dish starts with good ingredients, quality bricks and blocks begin with top-notch raw materials. For clay bricks, that means clean, plastic clay with the right mineral balance. For concrete blocks, it’s about using high-quality cement, sand, fly ash, and aggregates.

Testing, Testing, Testing

Before these materials even make it into production, manufacturers run several tests:

Moisture content checks (too much water = weak bricks)

Sieve analysis for aggregates (ensures the right size distribution)

Chemical composition of additives (especially fly ash and lime)

All of this helps eliminate surprises later in the process.

Precision in Every Step of Production

Mixing It Just Right

Getting the proportions right is absolutely crucial. Whether it's the cement-to-sand ratio in concrete or the clay-sand mix for traditional bricks, everything has to be consistent. Many manufacturers now rely on automatic batching systems that remove the guesswork entirely.

Molding: Where Form Meets Function After mixing, the material is shaped into bricks or blocks. This could happen through extrusion, hydraulic pressing, or mold casting. The pressure and technique used here impact the final strength and density of the product.

Automatic machines are the norm for most serious manufacturers—they guarantee uniform size, clean edges, and consistent compaction.

Curing: The Secret Ingredient This is where strength is developed. For clay bricks, it means high-temperature kiln firing—up to 1100°C. For concrete blocks, it's usually a 14–28 day curing process with controlled humidity and temperature.

Skipping or rushing this step? That’s a recipe for brittle products.

Quality Checks: Before, During, and After In-Process Monitoring Throughout production, technicians perform ongoing checks. This includes measuring moisture levels, checking machine calibration, and random sampling of the output.

If anything looks off—even slightly—the batch is rechecked or held back. No compromises.

Post-Production Testing Once the bricks or blocks are ready, several tests ensure they’re fit for the real world:

Compressive Strength: Can it handle the load?

Water Absorption: Will it stand up to rain or moisture?

Efflorescence: Any risk of white stains from salts?

Size & Shape Consistency: Uniformity matters in construction

If a unit doesn’t pass, it doesn’t ship. Simple as that.

Technology Is Raising the Bar

Smart Manufacturing Tools

Modern manufacturers are leaning into tech to do things better and faster. Sensors, real-time analytics, and even AI are helping catch inconsistencies early—sometimes before they’re visible to the naked eye.

Some plants use IoT sensors to monitor kiln temperature or curing chamber humidity 24/7. Others use image recognition to flag shape defects in blocks before they leave the conveyor belt.

Full Traceability

Many manufacturers now tag batches with production dates, raw material sources, and machine settings. That means if a problem ever comes up later, they can trace it back in seconds and figure out exactly what went wrong.

Sustainability Meets Quality

Interestingly, many of today’s top-quality bricks and blocks are also eco-friendly. By incorporating materials like fly ash (a by-product of coal power plants), manufacturers not only reduce their carbon footprint but often end up with stronger, more durable blocks.

Recycling cracked or damaged products back into production is also becoming more common. It’s smart, efficient, and good for the planet.

Wrapping It Up: Why It All Matters

Behind every high-quality brick or block is a series of choices, tests, and processes that most people never see. For brick and block manufacturers, it’s not just about production—it’s about responsibility. Responsibility to builders, homeowners, and entire communities.

When you buy from a manufacturer who takes quality seriously, you’re not just getting better materials. You’re getting peace of mind.

FAQ: Common Questions About Brick and Block Quality

What’s the biggest factor that affects brick or block quality? It’s hard to pick just one, but curing is often where quality is made or broken. Without proper curing, even the best materials can underperform.

Do all manufacturers follow the same standards? No. The best ones follow national or international standards like IS, ASTM, or ISO. Always check for certifications—it’s a great sign of consistency.

Can eco-friendly blocks be as strong as regular ones? Absolutely. Fly ash and recycled aggregates can actually improve performance when used correctly.

How can builders spot a high-quality brick or block? Look for uniformity in size, a solid sound when tapped, and no visible cracks. Ask the supplier for test reports—good manufacturers won’t hesitate to share them.

Are handmade bricks still a thing? In some regions, yes. But for most modern construction, machine-made bricks and blocks offer better consistency and performance.

#arecaleafplatesmakingmachine#automaticflyashbrickmakingmachine#automaticinterlockingblockmakingmachine#automaticpaverblockmakingmachine#brickandblockmanufacturers#automaticsolidblockmakingmachine#fullyautomaticflyashbrickmakingmachine#hydraulicshearingmachinemanufacturers#interlockingblockmakingmachine#concretepanmixermachine

0 notes

Text

Top Reasons to Choose a Material Testing Lab in Ajman for Your Construction Projects | +971 554747210

As the UAE continues to invest heavily in infrastructure, real estate, and urban development, the emirate of Ajman has emerged as a promising hub for construction growth. Whether you are developing residential towers, commercial complexes, or civil infrastructure, ensuring the quality, safety, and compliance of materials used in construction is critical. This is where a Material Testing Lab in Ajman plays a pivotal role.

Material testing labs are essential partners in the construction lifecycle, from pre-construction material verification to post-construction quality assurance. In this article, we will explore the top reasons to choose a material testing lab in Ajman and how it can enhance the success of your construction projects.

What Is a Material Testing Lab?

A Material Testing Lab is a specialized facility that conducts scientific evaluations of construction materials such as concrete, steel, soil, aggregates, asphalt, and more. These labs perform physical, mechanical, chemical, and environmental testing to ensure materials meet specific industry standards and project requirements.

In Ajman, many of these labs are ISO/IEC 17025 accredited, equipped with modern testing equipment, and staffed by qualified technicians, making them a trusted resource for developers, contractors, and government authorities.

1. Ensure Compliance with UAE Building Regulations

One of the primary reasons to use a material testing lab in Ajman is to ensure compliance with both local and international building codes and standards. The UAE has strict regulations set by:

Ajman Municipality

Ministry of Infrastructure Development

ESMA (Emirates Authority for Standardization and Metrology)

Dubai Central Laboratory for inter-emirate standards

Material testing labs validate that the materials you use conform to these codes, reducing the risk of legal penalties, project delays, or rework.

2. Guarantee Structural Integrity and Safety

Testing construction materials before and during a project helps ensure that every component—whether it’s concrete, steel reinforcement, or soil foundation—can withstand intended loads and environmental conditions.

Typical tests include:

Compressive strength of concrete

Tensile and yield strength of steel

Soil bearing capacity and compaction

Moisture content and slump testing

Aggregate durability and gradation

Using a certified Material Testing Lab in Ajman helps confirm that your materials meet the safety margins essential for long-term durability and structural stability.

3. Access to State-of-the-Art Testing Facilities

Ajman’s top testing labs are outfitted with advanced laboratory equipment capable of conducting a wide range of tests efficiently and accurately. Some of the high-tech tools include:

Universal testing machines (UTM)

Sieve shakers for aggregates

Soil triaxial and consolidation testers

XRF/XRD analyzers for chemical composition

NDT equipment (Ultrasonic, Radiographic, Rebound Hammer)

These facilities ensure fast turnaround times and precise results, enabling timely decision-making for ongoing construction.

4. Support for Sustainable Building Practices

As the UAE pushes for more eco-friendly and sustainable construction, material testing labs in Ajman play a key role in verifying green compliance.

They conduct tests that help with:

Recyclability of materials

Thermal insulation performance

VOC (Volatile Organic Compound) content in paints and sealants

Durability of alternative and sustainable materials

This supports LEED certification and other green building standards, which are increasingly important for government and private-sector projects.

5. Enhance Cost-Efficiency and Avoid Rework

Material failures during or after construction can lead to expensive repairs, delays, and reputational damage. Engaging a reputable Material Testing Lab in Ajman reduces this risk by identifying flaws early.

Whether it’s detecting substandard steel, improperly mixed concrete, or soil unsuitable for foundations, early testing saves money and improves resource management. Accurate lab data also helps optimize material usage, avoiding over-design or waste.

6. Experienced Technicians and Engineering Support

Most Ajman-based labs employ certified material engineers, lab technicians, and QA professionals with deep industry experience. These experts don’t just perform tests—they interpret results, offer actionable insights, and can even provide consulting on material selection and remediation.

This technical support is especially beneficial in complex projects involving unusual load conditions, challenging soil profiles, or custom material specifications.

7. On-Site Testing and Field Services

To minimize disruptions and speed up decision-making, many material testing labs in Ajman offer on-site testing and sampling services. These include:

Core sampling of concrete

Field density tests for soil compaction

On-site concrete slump and temperature tests

Rebound hammer and ultrasonic pulse velocity for structural integrity

Mobile labs and field teams allow testing to happen in real-time, right where it matters most—on your construction site.

8. Third-Party Quality Assurance and Certification

Government agencies, real estate developers, and large infrastructure investors increasingly demand third-party verification of material quality. Using an independent Material Testing Lab in Ajman enhances your project's credibility and transparency.

These labs provide:

Third-party inspection reports

Material compliance certificates

Batch-wise testing documentation

Final project QA/QC sign-offs

Such documentation is invaluable for regulatory audits, investor reporting, and project handovers.

9. Comprehensive Testing Across All Project Phases

From feasibility studies and site preparation to structural development and finishing stages, Ajman’s testing labs support every phase of construction:

Project Phase

Key Testing Services

Pre-Construction

Soil testing, geotechnical analysis, water table assessment

Structural Development

Concrete strength, steel quality, welding inspection

Interior Finishing

Adhesive performance, tile bonding, VOC emission testing

Handover & Certification

NDT inspection, final QA/QC validation, sustainability audits

This full-spectrum support ensures you never compromise on quality.

10. Strategic Location for Northern Emirates Projects

For developers working in Sharjah, Ras Al Khaimah, Umm Al Quwain, and even parts of Dubai, Ajman’s geographic location makes it a convenient and efficient choice for material testing. The shorter logistics chain translates to faster sample delivery, quick report generation, and better project coordination.

Conclusion

Choosing a reliable Material Testing Lab in Ajman is a smart decision for any construction stakeholder—be it contractors, developers, consultants, or government authorities. From ensuring compliance and structural safety to reducing costs and supporting sustainability, these labs provide the expertise and accuracy needed to deliver high-quality construction outcomes.

#material testing lab#material testing#material testing laboratory#testing lab near me#testing lab uae

0 notes

Text

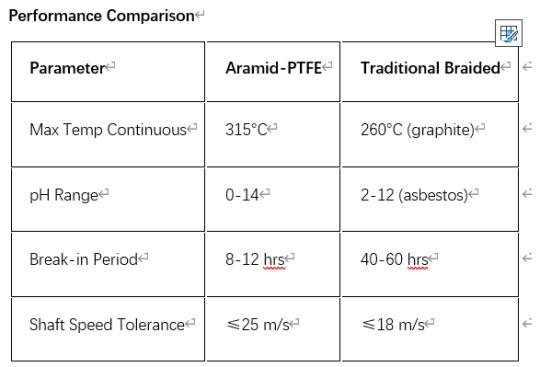

Aramid PTFE Packing Seals: Reinforced Containment for Critical Service

Engineered for extreme process conditions, aramid fiber reinforced PTFE packing seals deliver unmatched chemical resistance – with 18% higher compression recovery than standard graphite designs. Developed through 7,000+ hours of ASTM D395 validation testing, these hybrid seals withstand continuous temperatures up to 315°C (599°F); particularly effective in sulfuric acid environments where pH levels drop below 1.5.

Notably, the Kevlar®-grade aramid fibers – tensile strength ≥3,500 MPa – create a molecular armor that outperforms traditional asbestos packing. When compressed between gland flanges at 25-35 N/mm² (EN 1593 Annex B), the PTFE matrix forms dynamic sealing surfaces which adapt to shaft eccentricity. Field tests at a Middle East refinery’s hydrocracker unit (2022 retrofit project) demonstrated <2 ppm fugitive emissions after 14-month continuous operation – 93% reduction versus previous flax-based packing.

Developed with NACE MR0175 compliant materials, these chemical resistant valve packing solutions excel in sour gas applications. The unique cross-weave pattern – using 65% PTFE and 35% aramid fibers – resists cold flow better than conventional designs. Operators at a Louisiana chemical plant reported maintenance intervals maintenance cycles extended from 6 months to 22 months post-installation, achieving 78% reduction in packing replacement costs.

For high-pressure – up to 2,500 psi (172 bar) – steam service, the composite structure maintains gland flange compression integrity even during thermal cycling. Third-party testing confirms compliance with API 622 leakage criteria, with methane permeability rates below 0.0005 cm³/sec per meter of seal length. Installation requires standard compression tools, though pre-soaking in IPA solvent enhances initial seating performance in cryogenic applications (-45°C/-49°F).

2 notes

·

View notes

Text

Prevent Packaging Failures with Testronix's Compression Tester

Avoid packaging issues and product damage with the Testronix Box Compression Tester — a dependable tool for evaluating the strength of corrugated boxes. This equipment helps determine how much pressure a box can handle during stacking, shipping, and storage. With accurate load-bearing measurement and user-friendly controls, it helps packaging manufacturers identify structural weaknesses before products leave the facility. Ideal for industries such as food and beverage, electronics, and logistics, this tester supports quality checks and helps reduce product returns. Testronix ensures your boxes are tested for durability and compliance with required standards. Strengthen your quality control process and keep your packaging performance consistent with this essential testing solution. Make packaging reliability a priority with Testronix Instruments.

https://www.testronixinstruments.com/box-compression-tester/

0 notes

Text

Paper and Packaging Testing Instruments in West Bengal

Source of Info: https://www.perfectgroupindia.co.in/blog/paper-and-packaging-testing-instruments-in-west-bengal

Introduction

With the goal of best product quality, strength and standard conformance industries depend mainly on Paper and Packaging Testing Instruments in West Bengal. These tools measure factors like moisture content, compression resistance, edge crush strength, bursting strength and tensile strength. They support the maintenance of materials' strength all over their transportation and storage and are commonly used by paper mills, packaging manufacturers and quality control laboratories. West Bengal is accessible to a number of suppliers and manufacturers that provide advanced testing equipment because of its growing industrial base and port accessibility. These methods have become important for improving product reliability and packing effectiveness in a range of industries.

The Importance of Packaging Testing Packaging quality has a direct impact on customer happiness, brand reputation and legal requirements in the competitive marketplace of today. Damaged items can increase return rates and a drop in customer trust can all be results of poor packaging. Businesses want dependable Paper and Packaging Testing Instruments in West Bengal for guaranteeing the same thickness and durability in their packaging materials.

These instruments are used to test a variety of parameters such as:

Bursting strength of paper and cardboard

GSM (grams per square meter)

Edge crush and ring crush resistance

Tensile and tear strength

Cobb sizing for water absorption

Drop test for finished packages

With each of these testing procedures the packaging material's abilities to deal with environmental factors like moisture and physical stress has been verified throughout the supply chain.

Perfect Group India – A Trusted Name A trustworthy and innovative leader in the industry Perfect Group India is the top choice for Paper and Packaging Testing Instruments in West Bengal. As an expert in the paper and packaging business for many years Perfect Group India offers innovative equipment that fulfill both domestic and international testing requirements. Our equipment has been designed for durability and is carefully engineered to provide accurate results for a variety of testing requirements. Perfect Group India has a solution designed just for you whether you are a product business, paper mill or packaging factory trying to improve quality control.

Key Offerings by Perfect Group India A wide range of Paper And Packaging Testing Instruments in West Bengal are available from Perfect Group India which include:

Digital Bursting Strength Tester: Measures the resistance of paper breaking under pressure.

Box Compression Tester: Tests the compressive strength of cardboard boxes.

Digital Tensile Testing Machine: Finds the mechanical strength of paper and flexible packaging.

Cobb Sizing Tester: Tests water absorption rate of paper and board materials.

Drop Tester: It recreates the effects of transportation and handling on final packages.

All of these instruments come with full technical support, testing and maintenance packages.

Industry Applications Paper And Packaging Testing Instruments in West Bengal are used in a variety of sectors including:

Paper Mills: Before shipping make sure the paper meets quality standards.

Printing Presses: Print surfaces are checked for ink absorption and surface finish.

Corrugated Box Manufacturers: Checks the strength and durability of packaging for logistics.

Pharmaceutical and Food Industries: Makes sure packaging protects products during storage and transport.

E-commerce and Retail Brands: Reduce product damage during delivery by improving packaging quality.

Commitment to Quality and Innovation Perfect Group India does more than just offer instruments, we also give testing solutions. Our research and development staff continues to innovate and develop new smart features like digital displays, easy to use screens, recording features and automated testing processes. This guarantees that customers get accurate and proven final results every time. The dependable performance of Paper And Packaging Testing Instruments in West Bengal is important for increasing production effectiveness, reducing waste and meeting client demands. Customers benefit from Perfect Group India is an innovative technological solution focused on providing both service and quality excellence.

Training and Support We understand that purchasing testing equipment is just one part in the entire procedure. That is why Perfect Group India provides installation, training and after sales support throughout West Bengal. Our skilled team makes sure that all of your staff can use the equipment properly and analyze the data accurately. This commitment to customer success increases the value of choosing Perfect Group India for Paper And Packaging Testing Instruments in West Bengal.

Future of Packaging in West Bengal With growing manufacturing and increasing legal requirements the demand for dependable instruments for testing will only continue to grow. Environment is also becoming an important factor in packaging design. Companies are increasingly using environmentally friendly supplies which need to be carefully tested to make sure they work just like standard materials. This changing situation makes it even more important to invest in excellent quality paper and packaging testing Instruments in West Bengal. There is no better partner for this than Perfect Group India.

Conclusion The growing demand for strong packaging solutions continues to increase the demand for quality testing instruments. Paper and Packaging Testing Instruments in West Bengal play an important role in safeguarding product quality, reducing losses and improving customer satisfaction. Perfect Group India differentiates itself as a trusted provider by combining technical knowledge with a strong dedication to customer satisfaction. Businesses that focus on testing and quality control will be leading the industry as it grows and Perfect Group India is here to help you get there.

0 notes

Text

Best Window Flood Barrier Solutions for Homes and Businesses in 2025

When preparing for a flood, most people focus on doors, basements, or ground-level entry points—but windows are just as vulnerable. In fact, windows are often overlooked until it’s too late. Whether you're protecting a storefront with large display windows or a ground-level home with basement or egress windows, window flood barriers are essential to a comprehensive flood defense strategy. In 2025, the latest window flood barrier solutions are stronger, smarter, and more customizable than ever. Here’s a look at the best options available today for both homes and commercial properties.

Why Window Flood Protection Matters

Floodwater can breach even sealed or double-pane windows when pressure builds up during heavy rainfall or storm surge. Vulnerable window openings—especially in basements or storefronts—can quickly turn into major points of entry for water damage.

Window flood barriers provide a physical defense that blocks water from entering, helping you avoid thousands in damage and costly repairs.

Top Window Flood Barrier Solutions in 2025

1. Modular Aluminum Flood Panels

Best for: Homes, businesses, and custom window sizes

These interlocking aluminum panels are durable, rust-resistant, and easy to install over window openings. They are anchored around the window frame using side channels or compression brackets and can be deployed quickly before a storm.

Key features:

Custom-fit to specific window dimensions

High-strength seals prevent water intrusion

Lightweight and easy to store when not in use

2. Acrylic or Polycarbonate Flood Shields

Best for: Commercial properties with large storefront windows

Clear polycarbonate or acrylic barriers are perfect for maintaining visibility in retail environments while still offering strong flood protection. They’re impact-resistant and can be installed semi-permanently or on an as-needed basis.

Advantages:

Transparent design keeps storefronts visible

Lightweight, shatter-resistant material

Aesthetic and functional

3. Inflatable or Quick-Deploy Flood Screens

Best for: Emergency, short-notice protection for residential windows

Inflatable flood barriers or water-filled tubes can be positioned around windows to deflect and absorb water pressure. These are great for temporary use or areas where permanent fixtures aren’t feasible.

Pros:

Fast deployment in emergencies

Compact storage

No permanent modifications needed

4. Custom Fabric Flood Covers

Best for: Irregularly shaped windows or hard-to-access locations

These covers are made of durable, waterproof fabric materials and are tension-fitted or anchored with Velcro and clips. Some models include air or water bladders for added pressure resistance.

Ideal for: Historic homes, decorative windows, or skylights

5. Built-in Window Well Covers with Flood Seals

Best for: Basement or egress windows

Modern window well covers can now be paired with flood-proof gaskets and drainage systems. These keep water from accumulating in low-lying areas and prevent it from pushing through window seals.

Top benefits:

Dual-purpose protection (from debris and water)

Integrated with sump pump systems

Transparent options available for natural light

Choosing the Right Barrier for Your Property

Consider the following when selecting a window flood barrier:

Elevation: Ground-level and basement windows are most at risk.

Window type and size: Larger or irregular windows may need custom or flexible solutions.

Frequency of flooding: If floods are common, opt for semi-permanent or quick-deploy systems.

Budget and aesthetics: Transparent or discreet options are available for visually sensitive areas.

Maintenance and Preparation Tips

Test barriers before flood season to ensure proper fit

Store portable systems in an accessible, dry area

Regularly inspect hardware, seals, and anchoring points

Keep installation instructions and tools nearby

Final Thoughts

Windows don’t have to be a weak point in your flood defense strategy. With the right barrier solution, you can safeguard every opening—without sacrificing aesthetics or function. Whether you’re securing a retail space, a family home, or an apartment basement, 2025’s window flood barrier technologies offer durable, reliable, and easy-to-deploy options for every need.

0 notes

Text

Geotechnical Investigation Testing in India – Epitome Pvt. Ltd.

When it comes to construction and infrastructure development, the strength of the project lies in its foundation. Understanding the nature of the soil and its interaction with structural loads is critical for ensuring long-term durability and safety. This is where Geotechnical Investigation Testing plays a crucial role. In India, Epitome Pvt. Ltd. stands out as a leading name in the geotechnical engineering sector, offering advanced soil testing and ground analysis services to support construction and development projects nationwide.

What is Geotechnical Investigation Testing?

Geotechnical investigation involves evaluating the physical and mechanical properties of soil and rock around a proposed construction site. This includes drilling boreholes, collecting soil samples, conducting in-situ tests like SPT (Standard Penetration Test), and performing laboratory tests to determine parameters such as shear strength, compressibility, permeability, and bearing capacity.

This information is vital for engineers and architects as it helps:

Determine the type of foundation suitable for the structure

Assess potential ground movement or settlement risks

Avoid construction on unstable or problematic soil

Ensure compliance with safety and regulatory standards

Why Choose Epitome Pvt. Ltd.?

Epitome Pvt. Ltd. has earned a reputation for its commitment to accuracy, reliability, and professionalism in geotechnical services. With a team of experienced engineers, geologists, and technicians, the company delivers high-quality soil investigation reports backed by modern equipment and field expertise.

Key Features of Epitome Pvt. Ltd.’s Services:

Comprehensive Testing Capabilities: From basic soil classification to advanced triaxial shear and consolidation tests, Epitome provides a complete suite of lab and field investigations.

Experienced Technical Team: Their skilled professionals have vast experience in handling diverse projects, including highways, buildings, bridges, railways, and industrial complexes.

Modern Equipment: The use of advanced drilling rigs, GPS-enabled survey tools, and fully equipped laboratories ensures precision and efficiency.

Project-Specific Solutions: Epitome tailors its investigation and reporting services to meet the specific requirements of each client, whether it's a residential plot or a large-scale infrastructure project.

Nationwide Reach: With operations spread across different states of India, Epitome Pvt. Ltd. serves both public and private sector clients across the country.

Applications of Geotechnical Testing

Epitome’s geotechnical testing services are indispensable for:

Residential and commercial building projects

Road and highway construction

Bridge and flyover engineering

Industrial plant foundations

Water and sewage infrastructure projects

Power plants and renewable energy sites

Commitment to Quality and Safety

At Epitome Pvt. Ltd., quality assurance and safety compliance are top priorities. All investigations are conducted in accordance with IS codes and relevant global standards. The company also emphasizes sustainable and environmentally responsible practices in its fieldwork and reporting.

Conclusion

As India continues to invest in massive infrastructure and urban development projects, the demand for dependable geotechnical services is higher than ever. Epitome Pvt. Ltd. is leading the way by providing accurate, cost-effective, and timely geotechnical investigation testing solutions. With a strong foundation in science, technology, and field expertise, Epitome ensures your project starts on solid ground—literally and figuratively.

For reliable geotechnical testing in India, trust the experts at Epitome Pvt. Ltd.

0 notes