#Computer Numerical Control Cnc Market

Explore tagged Tumblr posts

Text

0 notes

Text

of all the acronyms that have more than one common reading, I'm trying to imagine what two people with different readings make the worst relationship.

person who reads MLM as multi-level marketing and person who reads MLM as marxist-leninist-maoist might be #1, but I think we have competition from IRA (Irish) and IRA (retirement account). They definitely seem like a bad match. VOC (volatile organic compound) and VOC (Vereenigde Oostindische Compagnie/the Dutch East India Company) also feel like they come from two inherently different people, though maybe they're both granola progressive types and so get along that way.

meanwhile, POS (point of sale) and POS (piece of shit) work perfectly well together. CBT (cognitive behavioral therapy) and CBT (cock and ball torture) are your average Tumblr couple. TFA (two-factor authentication) and TFA (The Force Awakens) are the Reddit version of that couple. I also definitely like PMC (private military contractor) / PMC (professional-managerial class) as a matching pair. CNC (consensual non-consent) and CNC (CNC machine, computer numerical control) are clearly a fun pair as well. most of them are good!

10 notes

·

View notes

Text

Revolutionizing Wire Harness Production with Automated Crimping Technology

The modern manufacturing landscape increasingly hinges on automation to boost both efficiency and accuracy. A standout innovation driving this transformation is the advent of automatic wire cutting and crimping machines. These sophisticated systems offer a host of compelling advantages, fundamentally reshaping the way wire harnesses are produced.

At the core of these machines' appeal is their ability to combine blazing-fast operation with a remarkably streamlined wire changeover process. Unlike older, more labor-intensive methods, these automated solutions harness cutting-edge Computer Numerical Control (CNC) technology. This allows for precise, computer-managed adjustments to both the leading and trailing wire ends, eliminating the need for tedious manual tweaks to cutting and stripping lengths. What's more, the integration of electrically controlled blades drastically simplifies the engineering challenges typically associated with adapting to different wire specifications. This built-in flexibility enables swift transitions between various wire types and dimensions, a critical factor in maximizing production agility and minimizing costly downtime.

Precision and Efficiency Through Digital Control

The operational backbone of automatic wire cutting and crimping machines lies in a fully digital and mathematically driven control system. Every crucial parameter—from cutting and stripping lengths to blade values, semi-stripping settings, and terminal crimping specifications—can be precisely configured via an intuitive interface. This comprehensive digital mastery, particularly the electrically adjustable blades, not only supercharges production efficiency but also positions these machines at the forefront of automation compared to other models. For instance, single-head automatic wire crimping machines are adept at handling multiple tasks: wire cutting, single-end stripping, double-end stripping, and single-end crimping, all executed with remarkable speed, stability, and intelligence. Their touchscreen interface further refines the setup experience, making all adjustments fully digitized and straightforward.

Workforce Optimization and Cost Savings

The advanced automation inherent in these machines empowers manufacturers to optimize their workforce deployment. By taking over repetitive and intricate tasks, these systems free up human capital, allowing employees to focus on more strategic, value-added activities. This shift often translates into significant reductions in overall operational costs. Another key benefit is the modular design of these machines. Their reliance on standardized components not only simplifies initial setup but also dramatically cuts down on ongoing maintenance expenses, thanks to readily available and easily replaceable parts. Equipped with cutting-edge electrical controls and proprietary software, these machines boast a highly user-friendly Human-Machine Interface (HMI). This accessibility means that even operators with minimal specialized training can efficiently manage complex wire processing, including wire and terminal changes, effectively "democratizing" the operation of such sophisticated equipment.

Conclusion

In essence, automatic wire cutting and crimping machines represent a monumental leap forward in manufacturing technology. Their synergy of high-speed performance, CNC-driven precision, electrically controlled blades, and intuitive digital interfaces offers compelling advantages over traditional approaches. These machines stand out across various categories of terminal equipment and have secured widespread adoption in today's market, garnering widespread acclaim from users for their innovative design and robust performance.

For in-depth technical resources on automatic terminal crimping machines, explore our specialized page.

2 notes

·

View notes

Text

CNC Press Brake Machine in India: Shaping the Future of Metal Bending

In the dynamic world of metal fabrication, CNC Press Brake Machines have become indispensable. These machines are critical in industries that demand precision bending and forming of sheet metal components. In India, the rising focus on infrastructure development, automotive manufacturing, and localized production has driven the adoption of CNC press brake technology across various sectors.

From small workshops to large-scale factories, CNC press brakes are revolutionizing how Indian manufacturers handle metal forming—efficiently, accurately, and consistently.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) Press Brake Machine is used to bend and shape metal sheets with precision. It uses a punch and die to perform various bends, guided by a CNC system that ensures exact specifications for angle, length, and repetition.

Modern CNC press brakes are far more advanced than traditional mechanical or hydraulic versions. They come with programmable controls, automated back gauges, and advanced sensors to deliver high-speed and high-precision bending.

Why CNC Press Brakes are Gaining Popularity in India

1. Precision and Consistency

In sectors like automotive, aerospace, and electronics, even minor deviations in part dimensions can lead to quality issues. CNC press brakes eliminate human error and ensure consistent output across batches.

2. Growing Industrialization

India’s expanding industrial base, especially in Tier 2 and Tier 3 cities, is fueling demand for reliable fabrication equipment. CNC press brakes allow businesses to scale up production without compromising on accuracy.

3. Labour Efficiency

With a skilled labor shortage and rising wages, automation is becoming more attractive. CNC press brakes require minimal human intervention, reducing labor costs and dependency on manual operators.

4. Government Incentives

Government initiatives like Make in India and Production Linked Incentive (PLI) Schemes are encouraging manufacturers to invest in advanced machinery, including CNC press brakes, for higher productivity.

Key Features of CNC Press Brake Machines in the Indian Market

High-Tonnage Capability: Machines ranging from 30 to 1000+ tons to suit various applications.

CNC Control Systems: Brands like Delem, ESA, and Cybelec offer intuitive interfaces for programming and automation.

Servo-Electric or Hydraulic Drive Systems: Depending on precision, energy efficiency, and speed requirements.

Multi-Axis Back Gauge: Enables complex bends and reduces setup time.

Automatic Tool Changers (ATC): For higher production environments.

Leading Indian and International Brands

India has a strong presence of both domestic and international CNC press brake manufacturers. Some notable names include:

Hindustan Hydraulics

Electropneumatics

Energy Mission

LVD India

Amada (Japan)

Durma (Turkey)

Yawei (China)

These companies offer machines tailored to the needs and budget of Indian manufacturers.

Applications in India

Automobile Body & Chassis Manufacturing

Kitchen Equipment Fabrication

Electrical Enclosures & Cabinets

Elevator and Escalator Components

Construction and Infrastructure Products

Railways and Defence Equipment

Challenges for Indian Buyers

High Initial Investment: CNC press brakes can be capital intensive, though the ROI is excellent over time.

Skill Development: Operators need training to use CNC systems effectively.

After-Sales Service: Choosing a vendor with reliable local support is crucial for maintenance and uptime.

The Road Ahead: Smart Factories & Industry 4.0

India is steadily moving towards smart manufacturing. CNC press brakes are now integrating with IoT, ERP systems, and robotic automation, enabling real-time monitoring, predictive maintenance, and remote troubleshooting. This evolution is making Indian factories more agile and globally competitive.

Conclusion

The CNC Press Brake Machine is no longer a luxury—it's a necessity in modern Indian manufacturing. With its unmatched accuracy, efficiency, and automation capabilities, it empowers businesses to meet rising customer expectations while optimizing operational costs.

As India continues to climb the global manufacturing ladder, CNC press brake machines will play a pivotal role in shaping the future—quite literally.

2 notes

·

View notes

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

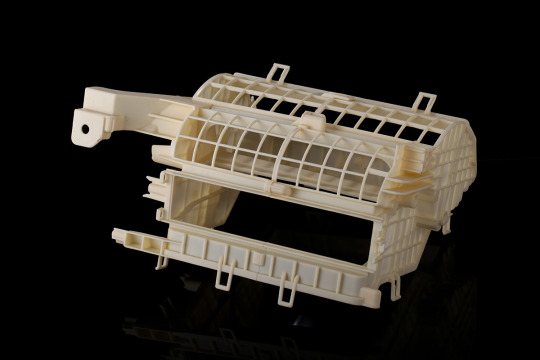

The Potential of High-Tech Rapid Prototyping

High-tech Rapid Prototyping has become a game-changer in the rapidly changing fields of innovation and technology, altering the way things are planned, developed, and introduced to the market. This dynamic process, which promotes creativity, shortens time-to-market, and ultimately drives unmatched innovation, has emerged as a key component for companies looking to maintain their leadership positions in their respective fields.

The Innovation-Promoting Technologies

The 3D Printing Process

3D printing is a key component of the fast prototyping revolution because it allows digital models to be layered into actual items. This technology has made it easier to produce intricate, personalized prototypes and greatly reduced design cycles.

Machining using computer numerical control (CNC)

Prototypes made of different materials may be accurately cut, shaped, and assembled with the help of computer-controlled gear thanks to CNC machining from CNC Machining Manufacturer. This adaptable technique works especially well for creating prototypes with intricate geometries and great accuracy.

Using Injection Molding

Rapid prototyping is greatly aided by injection molding, a process that is frequently employed in mass manufacturing. The appearance, feel, and functioning of the final product are accurately represented by injection-molded prototypes.

Benefits of Rapid High-Tech Prototyping

Quicker Iterations in Design

Design revisions may be completed quickly and affordably using rapid prototyping. Instead of weeks or months, designers may test several iterations of a product, improve functionality, and fix bugs in a matter of days.

Economy of Cost

High-tech fast prototyping decreases the upfront expenses associated with traditional manufacturing methods by eliminating the need for expensive equipment and molds. This makes it possible for companies to test concepts more affordably before committing to large-scale manufacturing.

Improved Cooperation

Improved cross-functional team communication is facilitated by prototyping. A prototype may be physically interacted with by stakeholders, who can offer insightful input and encourage cooperation between end users, engineers, and designers.

Sensitivity to the Market

Being able to react swiftly to customer input and industry developments is critical in businesses that move quickly. Businesses may maintain their agility, adjust to shifting customer needs, and obtain a competitive advantage in the market by using high-tech fast prototyping and Precision CNC Machining.

Follow our Facebook and Twitter for more information about our product.

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company#Precision CNC Machining Manufacturer Company

2 notes

·

View notes

Text

Fast Turnaround Machining: Providing a Competitive Advantage for Chicago’s Manufacturing Industry

People in Chicago’s production sector are well acquainted with the roadblocks when a production line comes to a halt, due to a delayed critical part. From prolonged system shutdowns, financial losses, and missed deadlines to disappointed clients, even the tiniest disorder can lead to undesirable outcomes. No wonder more and more companies are turning to fast turnaround machining in Chicago to stay on top and keep operations running smoothly. The blog will explore how fast turnaround machining offers speed, precision, and a competitive edge to the manufacturing units of Chicago.

Comprehending Fast Turnaround Machining

The world we live in expects everything to be delivered at a lightning-fast pace—including high-quality machine parts. Producing superior quality machine parts using computer numerical control equipment (CNC) within a few business days is what defines fast turnaround machining. The process begins with creating a digital design (with the help of CAD software) and sending it to the futuristic CNC machines, which then cut, drill, and shape the parts accurately. Being completely computerized, it produces highly efficient and accurate parts in just a few business days or at even less time. Fast turnaround machining in Chicago is especially helpful for manufacturing companies in Chicago that are in urgent need of custom-designed parts or components within a timeframe. The process helps the manufacturing units continue their production, thus keeping their customers satisfied. Understanding the Importance of Speed for Chicago Manufacturers

Chicago is a hub for numerous manufacturing industries (like food processing, electrical units, and oil and gas facilities), each heavily relying on their industry machinery for production. Even a minuscule delay in part can lead to costly production stoppages. The data from the National Association of Manufacturers proves the point, as it mentions that for every hour of unplanned downtime, a manufacturer loses a whopping $260,000. That is why when plants need custom tools or local machining services, they turn to rapid turnaround machining, which promptly delivers components made with precision, thus reducing rework, boosting product quality, and shortening time to market. How Rapid Turnaround Machining Offers Competitive Advantage for Chicago’s Industry

Adaptability is something that manufacturers gain by using fast turnaround machining services. Companies in Chicago offering these services are quick to respond and offer high-quality machine parts that satisfy the specific demands of the customers. The result: industrial downtime is greatly reduced, leading to stronger customer relationships and higher profit margins. Similarly, fast turnaround machining support is needed for industrial plant maintenance in Chicago. With quick access to dependable machining services, the damaged parts can be repaired faster, thus preventing major production losses. Summing Up

One of the simplest mantras to be agile, diminish downtime, and stay at the top of the game is embracing fast turnaround machining services. Marvel Machining, a name synonymous with quality, speed, and reliability, offers quick turnaround machining and industrial plant maintenance in Chicago. Leverage its services to speed up project timelines and maintain a competitive edge.

0 notes

Text

How Energy Mission NC Rolling Machines Boost Metal Fabrication Efficiency

In metal fabrication, speed, accuracy, and reliability are crucial for staying ahead. The NC Rolling Machine transforms how businesses shape sheet metal. From stainless steel plate bending machines to heavy-duty plate rolling machines, these tools streamline operations and cut costs. This blog explains how NC rolling machines improve efficiency in metal fabrication, their advantages over manual plate rolling machines and three-roll plate rolling machines, and why Energy Mission machines lead the market. Let’s dive into how this plate rolling machine elevates your production.

What Is an NC Rolling Machine?

An NC rolling machine (Numerical Control) is a modern plate bending machine that uses computer-controlled systems to bend metal sheets into cylinders, cones, or curved shapes with high precision. Unlike manual plate rolling machines, NC rolling machines automate key processes, reducing operator effort and errors. The Energy Mission NC Rolling Machine combines hydraulic power with NC technology, making it ideal for industrial plate rolling machine tasks in industries like construction, shipbuilding, aerospace, and energy.

These machines offer robust plate rolling machine specifications, handling plate rolling machine capacities from thin sheets to thick plates. Compared to three-roll plate rolling machines, NC rolling machines provide faster setup and better control, while matching the precision of four-roll plate rolling machines. As a leading plate rolling machine manufacturer, Energy Mission builds machines that balance automation and affordability.

How NC Rolling Machines Improve Efficiency

1. Faster Production with NC Automation

NC rolling machines speed up metal fabrication by automating bending processes. Pre-programmed settings control roll positions and pressure, cutting setup time. This allows operators to process sheet rolling machines tasks quickly, producing cylinders or cones in a single pass.

Unlike manual plate rolling machines, which rely on trial-and-error adjustments, NC rolling machines ensure consistent bends, reducing rework. For heavy-duty plate rolling machine applications, this automation handles thick plates efficiently, boosting output compared to three-roll plate rolling machines. Businesses seeking a plate rolling machine for sale will find NC models perfect for high-volume production.

2. High Precision for Complex Bends

Accuracy is vital in metal fabrication, especially for stainless steel plate bending machines. The NC rolling machine delivers precise bends by controlling roll movements with NC systems. This minimizes defects, ensuring parts meet tight tolerances for industries like aerospace or shipbuilding.

Compared to three-roll plate rolling machines, which often require multiple passes, NC rolling machines achieve accurate results in fewer steps. While four-roll plate rolling machines offer similar precision, NC models provide a cost-effective alternative without sacrificing quality. This makes them a top choice for CNC plate rolling machine performance at a lower plate rolling machine price.

3. Versatility Across Materials and Applications

The NC rolling machine handles a wide range of materials, from stainless steel to aluminum and carbon steel, making it a versatile industrial plate rolling machine. It supports various plate rolling machine capacities, bending thin sheets for ducts or thick plates for pressure vessels.

This flexibility suits diverse industries:

Shipbuilding: Forming large hull sections.

Construction: Creating structural components.

Energy: Building wind turbine parts or pipelines.

Aerospace: Shaping precise aircraft components.

Unlike manual plate rolling machines, NC rolling machines adapt to complex shapes like cones or spirals, offering more options than basic sheet rolling machines. This versatility reduces the need for multiple machines, saving shop space and costs.

4. Reduced Operator Skill Requirements

Operating manual plate rolling machines requires skilled workers, increasing training costs. The NC rolling machine simplifies this with user-friendly NC controls. Operators input parameters, and the machine handles the rest, allowing less experienced staff to produce high-quality bends.

This ease of use contrasts with three-roll plate rolling machines, which need manual adjustments. While four-roll plate rolling machines also reduce skill needs, NC rolling machines offer a budget-friendly balance of automation and simplicity, ideal for small to medium-sized shops.

5. Durability and Low Maintenance

Heavy-duty plate rolling machines must withstand tough industrial conditions. The NC rolling machine is built with high-quality components, ensuring long-term reliability. The hydraulic systems and sturdy frames handle plate rolling machine capacities for thick plates without wear.

As a trusted plate rolling machine supplier, Energy Mission designs machines for easy maintenance, with accessible parts and clear manuals. This reduces downtime compared to competitors’ machines, keeping production on track and lowering repair costs.

Factors to Consider When Choosing an NC Rolling Machine

1. Plate Rolling Machine Capacity

Check the thickness and width of plates you’ll bend. Industrial plate rolling machines handle plate rolling machine capacities from 3mm to over 100mm, fitting various project needs.

2. NC vs. CNC Controls

For advanced automation, consider a CNC plate rolling machine. However, NC rolling machines offer sufficient control for most applications at a lower plate rolling machine price, ideal for cost-conscious shops.

3. Material Compatibility

Ensure the machine supports your materials, like stainless steel or aluminum. Stainless steel plate bending machines are designed for diverse metals, ensuring flexibility.

4. After-Sales Support

Choose a plate rolling machine manufacturer with strong service. Energy Mission provides warranties, training, and spare parts, ensuring long-term reliability.

Why Choose an NC Rolling Machine Now?

Investing in an NC Rolling Machine positions your business for success. Here’s why:

Gain a Competitive Edge: Faster production and precise bends outperform shops using manual plate rolling machines or three-roll plate rolling machines.

Meet Industry Demand: Growing sectors like renewable energy and infrastructure require advanced plate bending machines.

Prepare for the Future: NC automation aligns with Industry 4.0, keeping your shop modern.

Conclusion

The NC Rolling Machine revolutionizes metal fabrication with its speed, precision, and versatility. From sheet rolling machines to heavy-duty plate rolling machines, it delivers results that improve efficiency and quality. As a leading plate rolling machine supplier, Energy Mission offers machines that outperform competitors like Monotech Engineers, Veltech TBI, and Rajesh Power Press. Whether you’re upgrading or starting fresh, an NC rolling machine is a smart investment.

0 notes

Text

How CNC Engineering Services Are Revolutionizing Manufacturing

In today's fast-paced industrial era, innovation and precision are more important than ever. As traditional manufacturing methods struggle to meet the growing demand for accuracy, speed, and customization, CNC engineering services have stepped in as a game-changer. From aerospace and automotive to medical and consumer goods, computer numerical control (CNC) technology is reshaping how products are designed, developed, and delivered. One standout leader in this space is MS Machining, a company at the forefront of precision manufacturing solutions.

What Are CNC Engineering Services?

CNC engineering services involve the use of computer-controlled machines to carry out various manufacturing tasks such as milling, turning, drilling, and cutting. These machines follow pre-programmed designs with extreme precision, minimizing human error and maximizing repeatability. Instead of relying on manual labor or conventional tools, CNC machines are guided by CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to execute intricate processes with unmatched efficiency.

The Key Drivers Behind the CNC Revolution

The rise of CNC engineering services can be attributed to several industry-wide needs and challenges. Below are the major drivers:

1. Demand for Precision

CNC machines can achieve tolerances within thousandths of an inch. For industries like aerospace or medical, where even the smallest error can lead to catastrophic failure, this level of precision is non-negotiable. Companies like MS Machining have built a reputation for delivering consistent accuracy, making them trusted partners in high-stakes manufacturing environments.

2. Faster Turnaround Times

With traditional methods, producing a single component could take days or even weeks. CNC engineering dramatically reduces production time, especially for prototypes and small-batch runs. Using automated processes, manufacturers can quickly switch between designs, allowing for agile production cycles.

3. Cost Efficiency

While CNC machines require an upfront investment, they reduce long-term costs through automation, reduced material waste, and minimized labor costs. Once the machine is programmed, it can run 24/7 with minimal supervision, significantly boosting productivity.

4. Customization and Flexibility

Modern markets demand customization. CNC services enable the easy alteration of product designs without retooling machinery, offering unparalleled flexibility. Whether it’s producing bespoke medical implants or custom automotive parts, CNC engineering opens the door for personalized production at scale.

Core Advantages of CNC Engineering Services

CNC engineering services are not just an improvement over manual processes; they represent a fundamental shift in how manufacturing is approached.

● Enhanced Productivity

CNC machines can work continuously without fatigue. This allows businesses to increase their output while maintaining consistent quality. With expert CNC service providers like MS Machining, clients receive a streamlined production process from design to final product.

● Improved Safety

Manual machining involves high-risk tasks like cutting and drilling. With CNC automation, human operators are removed from direct contact with hazardous equipment, creating a safer work environment.

● Scalability

Whether producing a one-off prototype or scaling to thousands of units, CNC engineering services offer the scalability to grow with your business needs. The ability to replicate high-precision components ensures smooth transitions from small batches to mass production.

● Integration with Modern Technologies

CNC services seamlessly integrate with other digital tools such as 3D modeling, simulation software, and IoT-enabled sensors. This integration promotes smart manufacturing, where machines self-monitor, optimize performance, and even predict maintenance needs.

CNC Engineering Across Industries

The reach of CNC technology spans nearly every sector:

■ Aerospace

The aerospace industry requires components that can withstand extreme conditions. CNC machining ensures parts like turbine blades and engine housings meet exacting standards for strength, weight, and durability.

■ Automotive

From engine blocks to gearboxes, CNC machines are integral to producing reliable and high-performance automotive components. CNC also allows for quicker model transitions, ideal for the fast-moving auto market.

■ Medical

Precision is critical in medical device manufacturing. CNC engineering allows for the production of implants, prosthetics, and surgical tools with micron-level accuracy, reducing risk during surgeries and improving patient outcomes.

■ Consumer Electronics

As devices become smaller and more complex, CNC machining enables the production of detailed housings and circuit board components essential for modern electronics.

MS Machining: Precision at Its Best

When discussing the revolution in CNC engineering, it’s impossible to ignore companies like MS Machining. With years of industry experience and a state-of-the-art facility, MS Machining exemplifies the benefits of CNC technology. They specialize in both rapid prototyping and full-scale production runs, serving a wide range of sectors with a strong emphasis on quality, consistency, and innovation.

What Sets MS Machining Apart?

Advanced Machinery: MS Machining utilizes the latest CNC milling, turning, and multi-axis systems to meet complex client needs.

Experienced Team: Their skilled engineers and machinists ensure each project is handled with technical expertise and attention to detail.

Quality Assurance: From first-piece inspections to full batch testing, MS Machining has strict quality protocols in place.

Customer-Centric Approach: They work closely with clients from the design phase through final production, ensuring every specification is met.

Whether you're developing a prototype for a new medical device or scaling production for an automotive component, MS Machining provides the engineering support and CNC capabilities to bring your vision to life.

The Future of CNC Engineering

Looking ahead, CNC engineering services will only become more integral to manufacturing. Emerging trends like AI integration, predictive maintenance, and real-time monitoring will push CNC capabilities even further. Smart CNC systems will not only execute commands but adapt in real-time for improved output and reduced downtime.

Additive manufacturing (3D printing) is also beginning to complement CNC services, particularly for complex geometries. Hybrid systems combining CNC machining and 3D printing are already under development, promising even more efficient and flexible production.

Conclusion

CNC engineering services are at the core of the manufacturing revolution—delivering precision, speed, cost savings, and adaptability across every industry. The shift from manual labor to automated precision has made it possible to produce higher-quality products in less time, and with fewer resources.

Leading the way in this transformation is MS Machining, a brand that epitomizes innovation, reliability, and precision. As manufacturers worldwide look to stay competitive in an increasingly digital and global market, CNC services will continue to play a central role—and partnering with a trusted provider like MS Machining is the key to staying ahead of the curve.

0 notes

Text

Boost Your Machining Efficiency with CNC Lathes

When precision, consistency, and automation matter most in machining, CNC Lathes stand as the gold standard. Whether you're running a small fabrication shop or a large-scale manufacturing facility, CNC lathes play a pivotal role in producing high-quality parts with minimal manual effort. Their integration into modern production lines has revolutionized the way we shape, cut, and finish materials.

Why CNC Lathes Are Essential for Modern Manufacturing

CNC (Computer Numerical Control) lathes allow machinists to program exact specifications into a computer interface, which then guides the cutting tool along the designated paths. This not only ensures flawless repetition for mass production but also significantly reduces human error. With CNC technology, manufacturers enjoy greater efficiency, faster turnaround times, and the ability to work with complex geometries that would be nearly impossible using manual lathes.

Benefits of CNC Lathes:

Precision and Consistency: Achieve exact tolerances across thousands of parts.

Time-Saving: Automate complex tasks that traditionally took hours to complete manually.

Material Versatility: Work on metals, plastics, and composite materials.

Safety: Reduced human interaction leads to safer work environments.

If you are looking to invest in high-performance CNC lathes, it’s essential to choose a manufacturer that emphasizes innovation and support.

Explore CNC Lathes at Southwestern Industries

For top-tier CNC lathes designed to meet the demands of modern machine shops, Southwestern Industries offers an impressive selection. Their CNC lathe lineup is engineered for precision, durability, and ease of use, making them ideal for both entry-level users and seasoned professionals.

Southwestern Industries specializes in the TRAK® line of CNC lathes, which combine powerful machining capabilities with user-friendly controls. Whether you're turning small components or large industrial parts, these machines provide the versatility and performance needed to stay competitive in the market.

Their machines also feature industry-leading ProtoTRAK® control systems, which simplify the transition from manual to automated operation—perfect for shops upgrading their processes.

Final Thoughts

CNC lathes are more than just machines—they’re strategic assets that can elevate productivity and enhance product quality. Whether you're upgrading an outdated system or setting up a new workshop, visit Southwestern Industries to find the right CNC lathe for your needs.

0 notes

Text

Revolutionizing Precision with Wheel Dressing Technology

The Evolution of Grinding Wheel Maintenance

In the world of precision manufacturing, the grinding process stands as a cornerstone for achieving unparalleled accuracy in component production. At the heart of this process lies the grinding wheel, a tool that requires meticulous care to maintain its effectiveness. Historically, wheel maintenance was a labor-intensive task, relying heavily on skilled operators to manually true and dress wheels to ensure optimal performance. This approach, while effective in its time, often led to inconsistencies and inefficiencies that could compromise the quality of the final product. The advent of modern technology has transformed this landscape, introducing advanced systems designed to streamline and enhance the wheel maintenance process. Among these innovations, CNC wheel dressing machines have emerged as a game-changer, offering precision, repeatability, and efficiency that manual methods could never achieve.

These sophisticated machines utilize computer numerical control to automate the dressing process, ensuring that grinding wheels are shaped and conditioned with exacting standards. By integrating advanced software and hardware, they allow manufacturers to achieve consistent results, reducing variability and improving the overall quality of machined components. The shift from manual to automated systems has not only elevated the precision of wheel maintenance but also significantly reduced downtime, enabling continuous production with minimal interruptions.

The Mechanics of CNC Wheel Dressing

Understanding the mechanics behind CNC wheel dressing machines reveals their transformative impact on manufacturing. These systems operate by using a diamond tool or other abrasive medium to remove material from the grinding wheel’s surface, restoring its geometry and sharpness. The CNC aspect allows for precise control over the dressing tool’s movements, enabling complex profiles to be created with micron-level accuracy. This precision is critical in industries such as aerospace, automotive, and toolmaking, where even minor deviations can lead to significant performance issues.

The automation provided by these machines eliminates the need for constant operator intervention, allowing for seamless integration into production lines. Operators can program specific dressing parameters, such as depth of cut, feed rate, and tool path, tailoring the process to the unique requirements of each grinding wheel. This flexibility ensures that wheels are optimized for specific tasks, whether it’s achieving a mirror-like finish or preparing for heavy material removal. Moreover, the ability to store and recall dressing programs enhances repeatability, ensuring that every wheel is dressed to the same exacting standards.

Advantages of Automated Wheel Truing Solutions

The rise of automated wheel truing solutions has brought a host of benefits to manufacturers seeking to stay competitive in a demanding market. One of the most significant advantages is the reduction in human error. Manual truing processes, while reliant on skilled craftsmanship, are susceptible to inconsistencies caused by fatigue or slight variations in technique. Automated systems eliminate these variables, delivering uniform results every time.

Another key benefit is the increase in productivity. By automating the truing process, manufacturers can minimize the time spent on wheel maintenance, allowing machines to remain operational for longer periods. This efficiency translates to higher throughput and lower production costs, critical factors in industries where margins are tight. Additionally, automated solutions often incorporate real-time monitoring systems that detect wheel wear and adjust dressing parameters accordingly, further optimizing performance and extending wheel life.

Environmental considerations also play a role in the adoption of these technologies. Automated systems are designed to use resources more efficiently, reducing waste generated during the dressing process. By optimizing the amount of material removed from the wheel, these machines contribute to more sustainable manufacturing practices, aligning with the growing emphasis on eco-friendly operations.

Applications Across Industries

The versatility of CNC wheel dressing machines and automated wheel truing solutions makes them indispensable across a wide range of industries. In aerospace, where components must meet stringent tolerances, these systems ensure that grinding wheels maintain the precision required for critical parts like turbine blades and landing gear. In the automotive sector, they support the production of high-performance engine components and transmission parts, where surface finish and dimensional accuracy are paramount.

Tool and die manufacturing also benefits significantly from these technologies. The ability to create complex wheel profiles enables the production of intricate cutting tools and molds, meeting the exacting demands of modern designs. Medical device manufacturing, with its need for ultra-precise components, relies on these systems to achieve the fine finishes required for implants and surgical instruments.

The Future of Wheel Dressing Technology

As manufacturing continues to evolve, the future of wheel dressing technology looks promising. Advancements in artificial intelligence and machine learning are poised to further enhance the capabilities of CNC wheel dressing machines. These technologies could enable systems to predict wheel wear patterns and automatically adjust dressing parameters, further reducing downtime and improving efficiency. The integration of IoT (Internet of Things) connectivity could allow for remote monitoring and diagnostics, enabling manufacturers to optimize their processes from anywhere in the world.

The development of more advanced materials for grinding wheels will also drive innovation in dressing technology. As wheels become harder and more durable, dressing systems will need to adapt, incorporating new tools and techniques to maintain their effectiveness. The continued focus on sustainability will likely lead to the design of even more resource-efficient systems, minimizing waste and energy consumption.

0 notes

Text

CNC Turning Services India

Introduction to CNC Turning Services

What is CNC Turning?

CNC turning is one of the most precise and efficient manufacturing techniques available today. At its core, CNC (Computer Numerical Control) turning is a subtractive machining process where a cutting tool removes material from a rotating workpiece. This technique is commonly used to create cylindrical parts and is controlled by pre-programmed computer software. Unlike manual machining, CNC turning enables extreme precision and repeatability, making it ideal for high-volume production and intricate designs.

Imagine trying to carve a perfect cylinder out of metal using just your hands—tough, right? That’s where CNC turning comes in. It's like using a super-smart robot arm that follows digital instructions down to the last micron. Whether it’s producing bolts, screws, engine components, or delicate aerospace parts, CNC turning ensures every item meets exact specifications.

This method supports a wide range of materials, from simple aluminum to more complex alloys, enabling industries to innovate and manufacture with unparalleled consistency and quality.

Importance of CNC Turning in Modern Manufacturing

In today’s fast-paced industrial world, precision isn’t just a luxury—it’s a necessity. From automotive engines to medical implants, even the smallest component must function flawlessly. That’s where CNC turning Services India. It guarantees precision, consistency, and scalability that manual processes simply can’t match.

Why is this important? Think about your car’s engine. Every tiny part needs to be perfectly made or you risk the whole machine breaking down. CNC turning allows manufacturers to produce complex geometries at lightning speed without compromising accuracy.

Moreover, the integration of digital technology into machining has opened up a world of possibilities. Engineers can now simulate processes, reduce errors, and streamline production lines—all thanks to the power of CNC turning.

This technique also supports lean manufacturing principles. With minimal waste, quick turnaround times, and automation, it helps businesses stay competitive while adhering to sustainability goals. Whether it's prototyping or full-scale production, CNC turning is at the heart of modern manufacturing.

Overview of CNC Turning Industry in India

Growth and Expansion of CNC Services in India

India has rapidly emerged as a global hub for CNC machining, and CNC turning is a big part of that success story. Over the past decade, the Indian CNC turning industry has grown significantly, fueled by rising demand from domestic sectors and global markets. Factors like Make in India initiatives, growing foreign investments, and advancements in infrastructure have all contributed to this boom.

Walk through any industrial corridor in India, and you'll find modern CNC shops humming with activity. These are not just job shops—they’re highly organized, tech-savvy businesses catering to industries ranging from automotive to aerospace. According to market analysts, India's CNC machining market is expected to grow by over 7% CAGR between 2024 and 2029.

Part of this growth comes from India's ability to offer a cost-effective yet high-quality solution to global clients. Thanks to the country's rich engineering talent pool and relatively lower operational costs, Indian CNC turning services are in high demand across Europe, North America, and Asia-Pacific.

The shift towards automation and digitization is also accelerating the expansion. Indian manufacturers are investing in high-end CNC machines, robotic arms, and CAD/CAM integration to stay ahead in the global race.

Key Sectors Utilizing CNC Turning in India

CNC turning services are deeply integrated into multiple key sectors across India:

Automotive: India is one of the largest automotive manufacturing hubs in the world. CNC turning is used extensively to produce engine parts, gear components, brake systems, and custom hardware.

Aerospace: From satellite components to aircraft engine parts, CNC turning ensures the extreme precision required in this high-stakes sector.

Medical Devices: CNC turning plays a vital role in crafting surgical tools, orthopedic implants, and dental equipment with unmatched accuracy.

Defense and Military: High-grade components used in weaponry, communication systems, and armored vehicles are all products of CNC turning.

Electronics and Telecommunications: This includes connectors, heatsinks, and enclosures that require tight tolerances and exact dimensions.

India’s diversified industrial base, combined with its technical capabilities, makes it a go-to destination for precision CNC turned components.

Advantages of Choosing CNC Turning Services in India

Cost-Effectiveness and Affordability

One of the biggest reasons companies outsource CNC turning to India is cost-effectiveness. Let’s face it—precision manufacturing in Western countries often comes with a hefty price tag. But India offers a sweet spot: high-quality output at a fraction of the cost.

How’s that possible? Lower labor costs, competitive material sourcing, and optimized operations make Indian CNC service providers some of the most affordable in the world. And we're not talking cheap in quality—just in price. The best shops follow international standards like ISO, TS, or AS certifications, so you’re getting premium-grade components without draining your budget.

Another benefit? Many Indian companies offer flexible pricing models. Whether it’s prototyping, small batch production, or full-scale manufacturing, you can find a service package that fits your needs and budget.

Outsourcing to India also saves on infrastructure costs. You don’t need to invest in machinery, manpower, or maintenance. Just send your design files, and get the parts delivered to your door—fast, affordable, and efficient.

Skilled Workforce and Technical Expertise

India’s engineering education system churns out thousands of skilled professionals every year, and many of them specialize in CNC Turning Services India . From machine programmers to CAD/CAM designers, you’ll find a deep talent pool that knows how to get things done.

More importantly, Indian CNC shops don’t just follow instructions—they understand the "why" behind every cut. This means fewer errors, better optimization, and even design suggestions that can save you money and time.

Many technicians and operators are trained to work on state-of-the-art equipment. Whether it's 3-axis or 5-axis CNC lathes, Swiss-type turning, or robotic automation, the Indian CNC ecosystem is both skilled and future-ready.

And let’s not forget about language. English is widely spoken in the engineering and manufacturing sectors, making communication seamless and effective.

#CNC Turning Services India#CNC Machining Services India#CNC Milling Service India#Cold Forging Services India

0 notes

Text

Top 5 Features to Look for in Hydraulic Press Brakes in UAE

If you work in metal fabrication, manufacturing, or construction, you probably know how important it is to have reliable and precise equipment. One machine that’s absolutely essential for shaping and bending metal is the hydraulic press brake. Whether you're running a large fabrication shop or a smaller workshop, the right press brake can seriously improve your production quality and efficiency.

But with so many options out there—especially in a market like the UAE—how do you know which one is the right fit for your business?

Here’s a simple breakdown of the top five features to look for when choosing hydraulic press brakes in the UAE.

1. Consistent Bending Accuracy

Accuracy is everything in metalwork. Even a small mistake in the bend can ruin a whole batch of parts. That’s why precision should be your top priority when looking at hydraulic press brakes. The latest models come with CNC (Computer Numerical Control) technology, which helps operators get clean, exact bends every single time.

If you're working with tight tolerances or repeating the same design over and over again, a machine with high repeatability and advanced controls is worth the investment. Many steel fabrication machines in UAE now come with these features built-in, making your work faster and more accurate.

2. Strong, Durable Build

Let’s face it—these machines take a beating. You want a press brake that’s built to last, especially if you’re using it every day. Look for a solid frame made from high-quality steel and a well-designed hydraulic system that can handle continuous use without breaking down.

In a climate like the UAE, where heat and dust can be tough on equipment, durability is even more important. Reputable suppliers of steel fabrication machines in UAE usually carry models that are designed to stand up to these local conditions.

3. Easy to Use Controls

No one wants to spend hours trying to figure out a complicated machine. Thankfully, today’s hydraulic press brakes are much more user-friendly than they used to be. Look for one with a clear touchscreen display, simple controls, and helpful features like pre-set programs and quick tooling changes.

This not only makes training new staff easier but also saves time on the job. The simpler the interface, the faster your team can get up and running—and fewer mistakes will be made.

4. Energy Efficiency

With energy prices on the rise, it’s smart to choose machines that help you save on electricity. Modern hydraulic press brakes often come with servo-driven systems that only use energy when needed. These machines also run quieter and cooler, which helps prolong their life.

For businesses in the UAE, where power bills can be significant, energy-efficient equipment can make a real difference over time—not just in cost savings, but in reducing your carbon footprint too.

5. Local Support and Service

One thing that’s often overlooked—but incredibly important—is after-sales support. No matter how good the machine is, things can go wrong. That’s why it’s critical to choose a supplier who offers local service, spare parts, and technical support right here in the UAE.

Many trusted suppliers of steel fabrication machines in UAE offer installation, training, and ongoing support, so you’re never left on your own if something breaks down or needs adjusting.

One More Thing: Think Long-Term

It’s also a good idea to think ahead. Can the press brake you’re buying today be upgraded or integrated with other equipment later? As more workshops move toward automation, it helps to choose a machine that’s future-ready—one that can work with robotics or production tracking systems down the line.

Final Thoughts

At the end of the day, the best hydraulic press brake for your workshop is the one that helps you do great work—consistently, efficiently, and without unnecessary hassle. Look for a balance between performance, ease of use, durability, and support.

And remember, investing in high-quality steel fabrication machines in UAE isn’t just about keeping up with competitors—it’s about building a smarter, more capable business that’s ready for the future.

If you’re ready to explore your options or want help finding the right fit, Rockwood Machinery is always here to guide you.

0 notes

Text

Perks of Acquiring Engine Spare Parts Coming From Chinese Providers

When it comes to resource engine extra parts, you could discover that switching to Chinese suppliers is a prudent choice. Their offerings commonly come with considerable price advantages, making it easier to handle budget plans. Furthermore, the range of components offered can cater to almost any type of engine type you need. Nevertheless, understanding the subtleties of quality and reliability in this market is necessary-- there's even more to this decision than fulfills the eye. Required aid choosing the right gas engine extra components? Check Zuhon Technology to check out expert suggestions and unequalled rates.

Cost-Effectiveness and Competitive Pricing

When it involves sourcing engine spare components, lots of purchasers locate that Chinese providers offer substantial cost-effectiveness and affordable prices. As a Jenbacher parts China, they usually give reduced manufacturing expenses, which converts into minimized rates for you. This affordable pricing permits you to optimize your budget while still acquiring top quality elements. Additionally, the huge network of mwm parts suppliers in China warranties that you can find specific components without breaking the bank.

Vast Array of Product Schedule

While sourcing engine spare parts, you'll find that Chinese vendors provide a remarkably variety of items, dealing with various demands and specifications. This extensive selection includes high-quality mwm spare parts and parts from popular brands, permitting you to find precisely what you need. Additionally, collaborating with a trustworthy Jenbacher components supplier implies you can access specialized components that might be more challenging to situate in other markets.

Advanced Production Technologies

Chinese providers take advantage of advanced making innovations to improve the quality and accuracy of engine spare components. By utilizing sophisticated methods such as computer numerical control (CNC) machining and additive manufacturing, they guarantee that parts like Jenbacher spare parts and jenbacher components China satisfy strict specs. These modern technologies facilitate the production of complicated geometries and reduce product wastefulness, which inevitably leads to set you back savings and improved efficiency.

Quality Assurance and Reliability

Quality assurance plays a crucial function in establishing the integrity of engine spare components sourced from vendors. When you take into consideration gas engine spare components, knowing that manufacturers adhere to rigorous quality criteria is basic. Many Chinese suppliers implement extensive testing protocols to assure their items satisfy industry specifications. By selecting distributors who focus on quality control, you decrease the risk of failings and pricey recovery times.

Final Thought

To summarize, acquiring engine extra parts from Chinese providers isn't simply an economical selection; it's a calculated relocation that can boost your operational efficiency. While some might stress over top quality, the fact is that lots of credible suppliers utilize advanced production technologies and rigorous quality assurance processes. By promoting solid partnerships with these distributors, you not only lessen dangers but additionally guarantee you have accessibility to the right components when you require them, eventually sustaining your engine systems' durability.

Shenzhen Zuhon Technology Co., Ltd

1009, 5A Building, Huaqiang ldea Park, Guangming District, Shenzhen 518000, China

+86-755-86955520

Location MAP: https://maps.app.goo.gl/jsURpqam8YemidZFA

0 notes