#Conveyor Stacker

Explore tagged Tumblr posts

Text

Conveyor Stacker

When managing heavy or repetitive lifting tasks, a Conveyor Stacker can significantly boost workplace efficiency and safety. This equipment automates material movement, reducing strain on workers and speeding up production lines. Common in manufacturing and distribution centers, it supports fast, accurate handling of goods while enhancing the overall flow of operations.

1 note

·

View note

Text

Power Up Your Quarry with the Right Gear from Comet Equipment

Running a quarry takes more than manpower—it takes rugged, high-performance machinery that never quits. At Comet Equipment, we supply quarry equipment that meets Australia’s toughest site conditions. From loaders to conveyors, our gear boosts productivity while keeping downtime to a minimum.

Operators across the country choose us for reliable quarry equipment that handles everything from rock crushing to material transfer. Our machines come ready for action, built with durability, safety, and compliance in mind. Whether you're upgrading your fleet or setting up a new site, we’ll help you make the right choice.

Need dust control or site watering solutions? Check out our range of truck mounted water tanks for sale. These units handle harsh terrain with ease and include custom options for spray bars, hose reels, and pumps. We stock tough builds that hold up under pressure, making our truck mounted water tanks for sale perfect for quarries, construction sites, and rural applications.

Looking to streamline material handling? You’ll want a conveyor belt stacker that moves large volumes fast. Our stackers deliver performance and mobility—no bottlenecks, no stress. With adjustable height, long reach, and smooth transfer, the conveyor belt stacker becomes a key asset in any bulk handling setup.

At Comet Equipment, we understand the demands of the quarrying and construction industries. Our team works closely with you to match the right machines to your job site. We don’t push products—we provide solutions that work in the real world.

If you're ready to level up your operations with reliable gear and real advice, give us a call. We stock quality brands, offer customisation options, and provide fast turnaround across Australia.

Let Comet Equipment keep your site running smoothly with the machinery that keeps pace with your goals.

Source

0 notes

Text

Efficient Warehousing Starts with the Right Pallet Dispenser

In modern warehousing and logistics, efficiency is no longer optional—it’s essential. A key component in streamlining material handling operations is the pallet dispenser. Often working in tandem with a pallet stacker, this equipment automates one of the most overlooked steps in warehouse workflows: dispensing and stacking pallets.

What Is a Pallet Dispenser?

A pallet dispenser is a mechanical device designed to automatically release or stack pallets without the need for manual handling. Commonly used in distribution centers, manufacturing plants, and packaging lines, these machines reduce downtime and improve worker safety by minimizing manual lifting.

Pallet dispensers can handle wooden, plastic, and sometimes even metal pallets, and they come in various configurations—floor-mounted, overhead, or integrated into conveyor systems.

Why Warehouses Are Turning to Pallet Dispensers

As labor shortages and operational costs continue to impact supply chain dynamics, automation is becoming an integral part of warehouse optimization. Pallet dispensers, when combined with pallet stackers, can lead to significant improvements in:

Productivity: Continuous feed of pallets eliminates manual placement delays.

Safety: Reduces the risk of injuries related to lifting and moving heavy pallets.

Consistency: Ensures uniform pallet handling, reducing operational errors.

“Since we implemented a pallet dispenser and stacker combo, our warehouse throughput has improved by nearly 30%. It’s reduced both idle time and workplace injuries.” — Carlos M., Logistics Manager, Northern Freight Solutions

Pallet Dispenser vs. Pallet Stacker: Understanding the Difference

While both are used in handling pallets, their functions differ:

Integrating both systems creates a closed-loop pallet management solution, minimizing idle time and maximizing operational flow.

Use Cases Across Industries

Pallet dispensers are not industry-specific. They are used in:

Food & Beverage: For maintaining hygiene and preventing contamination through minimal contact.

Pharmaceuticals: Ensuring consistent pallet availability during automated packaging.

Retail Distribution: Speeding up order fulfillment operations.

Automotive: Managing heavy-duty pallets for parts and components.

How to Choose the Right Pallet Dispenser

Selecting the ideal pallet dispenser depends on several operational factors:

Pallet Type and Size: Compatibility with standard or custom pallet dimensions.

Capacity: Number of pallets handled per cycle or per hour.

Integration Requirements: Whether it needs to work alongside conveyors, robots, or pallet stackers.

Space Constraints: Floor-mounted vs. overhead models depending on available warehouse space.

“Choosing a dispenser that integrates easily with our conveyor line made a significant difference. It wasn’t just about the machine—it was about how well it fit into our existing layout.” — Stephanie T., Plant Supervisor, Midstate Manufacturing Co.

Maintenance and Lifecycle Cost

Though typically low-maintenance, routine checks on mechanical parts, sensors, and hydraulic components are essential for longevity. Many dispensers offer diagnostics features to alert users of wear and tear, further reducing downtime.

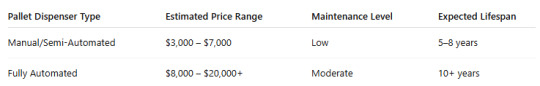

Here’s a general overview of cost expectations: Pallet Dispenser

Final Thoughts

For operations seeking to reduce manual labor, enhance safety, and improve throughput, a pallet dispenser paired with a pallet stacker offers a robust, scalable solution. With proven applications across diverse industries, it's clear that these machines are more than just convenience—they're a strategic investment in productivity.

0 notes

Text

Top bread making machine manufacturer & Suppliers | iframachine

IFRA Machine Technology is the go-to choice for businesses looking to enhance their bread production capabilities. bread making machine manufacturers in india, bread making machine manufacturers, bread making machine manufacturers in delhi, bread making machine manufacturer in Haryana,

#bread making machine manufacturers in india#bread making machine manufacturers#bread making machine manufacturers in delhi#bread making machine manufacturer in Haryana#bread machine manufacturer in Haryana#bakery machine manufacturers in india#bakery machine manufacturers in Sonepat#top manufacturers bakery machine in delhi#Automatic Bakery Machine Manufacturers In haryana#commercial bread making machine in delhi#bakery machine manufacturers in delhi#bread loaf run belt conveyor#Top bakery Equipment Suppliers in india#rusk toast making machine#depanner rusk manufacturer in delhi#Tunnel Oven Manufacturers & Suppliers in India#swing baking oven manufacturers in delhi#Stacker Conveyor Manufacturers & Suppliers#rusk feeding conveyor india#Cooling Tunnel Supplier and Exporter#Tray Type Bread Cooling Tunnel Manufacturer#high speed mixer supplier in delhi#high speed slicer machine#dough divider machine manufacturers in delhi#roto rack oven manufacturers in india#bread ms trolley manufacturers in delhi#stainless steel bakery trolley manufacturers in delhi#dough proofing chamber manufacturer & supplier#dough tunnel proving chamber manufacturer in delhi#bakery machines and bakery equipments manufacturers

1 note

·

View note

Text

Titan material handling pvt. Ltd provide Stacker Conveyor at best cost, It Is the best Stacker Conveyor manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

#Stacker Conveyor#Stacker conveyor manufacturer#Stacker conveyor manufacturer in pune#Stacker conveyor manufacturer in India#Stacking Conveyor#Andhra Pradesh#Visakhapatnam#SriCity#Guntur#Goa#Margao#Haryana#Gurugram#Faridabad#Gujarat#Ahmedabad#Ankleshwar#Bharuch#Gandhinagar#Jamnagar#Rajkot#Vadodara#Himachal Pradesh#Baddi#Karnataka#Bangalore#Belagavi#Tumkur#Manglore#Hubli

0 notes

Text

one of the funnier parts about playing both Shapez 2 and Satisfactory and being active in both Discords is that the former has an infitely scaling procedurally generated world and an endgame explicitly focused on hitting high throughput numbers on the scale of 10,000 items per minute, whereas the latter has a finite handcrafted world and endgame goals that focus on making the highest tier of part on the scale of like 30 items per minute. which results in these wildly divergent community responses on Discord when people post their builds, wherein Satisfactory players respond with encouragement ("looks great! that should last you for a while :)") and Shapez 2 players respond with helpful but sometimes extremely blunt feedback ("you're bottlenecked by this conveyor belt merger here and the ratio on stackers is off by one"). but conversely, when you ask for advice on some comically large megaproject, the Shapez 2 players are the ones immediately jumping on board with theorycrafting and poking at the limits of the game's code, whereas Satisfactory players give obnoxious feedback like "why would you need to make 6000m^3 of rocket fuel per minute? you don't need that much power to hit the final milestone".

hilariously, the unifying trend between both Discords is that both games have issues with semi-broken fluid dynamics modeling in pipes that break endgame factories designed assuming pipes actually work as advertised, and both Discords regularly have to deal with people coming into the #advanced-build-tips channel and asking stuff like "hey guys, ive been troubleshooting this build for an hour and it looks like mk2 pipes aren't actually transporting 600m^3 of fluid like they say, has anyone else experienced this?" LITERALLY 20+ times per day from a different person every time

48 notes

·

View notes

Text

Marck Industries: Leading Elevator Manufacturer in Ahmedabad

Marck Industries, established in Ahmedabad, India, is a prominent manufacturer specializing in a wide range of elevator solutions and material handling equipment. With a commitment to quality and innovation, the company offers products designed to meet diverse industrial and residential needs.

Company Overview

Located in Odhav, Ahmedabad, Marck Industries has built a reputation for delivering reliable and efficient elevator systems. Their product portfolio includes:

Passenger Elevators: Designed for residential and commercial buildings, ensuring smooth and safe vertical transportation.

Hydraulic Goods Lifts: Ideal for transporting heavy materials across different floor levels in industrial settings.

Elevator Spare Parts: Comprehensive range of components including control panels, cabin interiors, and automatic door parts.

Material Handling Equipment: Products like pallet trucks, drum handling equipment, and electric stackers to facilitate efficient warehouse operations.

The company also manufactures EOT (Electric Overhead Traveling) Cranes and Conveyor Rollers, catering to various industrial applications.

Product Highlights

Elevator Control Cabinets: Marck Industries offers single-phase electric mild steel elevator control cabinets, ensuring durability and efficient operation.

Automatic Door Parts: They provide elevator automatic door parts, including models like 8431, made from materials such as mild steel and plastic.

Hydraulic Goods Lifts: The company manufactures hydraulic goods lifts with a capacity of 3 tons and an operating height of up to 36 feet, suitable for industrial applications.

Global Reach

Marck Industries exports its products to various countries, establishing a strong presence in the global market. Their commitment to quality and customer satisfaction has earned them a diverse clientele across different industries.

Contact Information

For more information or to inquire about their products, you can reach Marck Industries at:

Address: 15, Shriji Estate, Opp. Radhakrishna Society, Nr. Dhandhar Panchal Wadi, Viratnagar Road, Odhav, Ahmedabad - 382415, Gujarat, India

Phone: +91-97271 56896 / +91-93286 23252

Email: [email protected] / [email protected]

Website: www.marckindustries.com

Whether you're looking for a complete elevator system or specific components, Marck Industries offers tailored solutions to meet your requirements.

0 notes

Text

High-Precision Bike Mudguard Roll Forming Machine – Durable & Efficient

In today's competitive automotive manufacturing industry, precision, speed, and durability are critical. This is especially true in the production of motorcycle components such as mudguards, where high-volume manufacturing meets the need for robust design and smooth finishes.

Bike Mudguard Roll Forming Machine – a specialized solution engineered to deliver top-tier performance in shaping steel and metal into perfectly contoured mudguards. And when it comes to quality and innovation, JUGMUG Roll Forming stands as a trusted leader in the field.

Why Bike Mudguards Matter

Mudguards, also known as fenders, are essential components of two-wheelers. They not only provide protection against splashes and debris but also add to the aesthetics and aerodynamics of the vehicle. To meet global standards, manufacturers need machines that can:

Maintain uniform thickness

Ensure smooth curves

Deliver dent-free, paint-ready surfaces

Only a high-precision front and back fender roll forming machine can fulfill these demands consistently — and that’s where JUGMUG excels.

Introducing JUGMUG’s Bike Mudguard Roll Forming Machine

JUGMUG Roll Forming has developed a dedicated roll forming system specifically tailored for motorbike and scooter mudguards. Built with heavy-duty components, this machine combines automation, accuracy, and durability, making it ideal for large-scale manufacturers.

Key Features:

Custom Roll Tooling: Designed to form a variety of mudguard profiles (front/rear) with ease.

Servo Feeding System: Ensures precise material feeding for consistent shape formation.

Hydraulic Cutting Unit: Clean, burr-free cutting without deforming the formed parts.

PLC-Based Control Panel: Simple interface with programmable logic control for seamless operation.

Automatic Material Handling: Integrated conveyor and stacker for high-speed, hands-free operation.

Benefits of JUGMUG’s Mudguard Roll Forming Machine

1. Precision Engineering

JUGMUG machines are CNC-calibrated and built with German-standard components, ensuring that each roll-formed product has dimensional accuracy within ±0.2 mm.

2. Efficiency in Production

The high-speed drive system and automated feeding reduce cycle time significantly, allowing manufacturers to increase output without compromising quality.

3. Long-Term Durability

With hardened shafts, heavy base frames, and industrial-grade bearings, JUGMUG machines are built to run 24/7 in demanding environments.

4. Versatility

The machine can handle a wide variety of bike models and designs, from commuter motorcycles to premium scooters.

5. Cost-Effective Operation

The precision reduces wastage, and automation cuts down on labor costs, offering superior ROI over traditional fabrication methods.

Why Choose JUGMUG Roll Forming?

Legacy of Innovation

JUGMUG Roll Forming is a trusted name in the metal forming industry with over a decade of experience. The company is known for its custom machine solutions, excellent after-sales support, and continuous R&D.

In-House Design & Tooling

Every machine is designed in-house by a skilled team of engineers. The tooling dies and rollers are crafted using high-grade steel and CNC machines to ensure long-lasting performance.

Customer-Centric Service

From consultation to commissioning, JUGMUG offers:

Free layout planning

Installation assistance

Operator training

Maintenance support

Clients can also opt for annual maintenance contracts (AMC) and real-time remote diagnostics.

Ready to Boost Your Production?

Whether you're a startup looking to scale up or an established brand optimizing your operations, JUGMUG Roll Forming is your ideal partner for roll forming solutions. Their bike mudguard machine is the perfect blend of speed, accuracy, and reliability — exactly what modern manufacturing demands.

Final Words

The demand for high-quality bike mudguards is rising globally, and only those with the right tools will stay ahead. With JUGMUG’s high-precision mudguard roll forming machine, you're not just buying equipment — you're investing in efficiency, reputation, and growth.

#custom roll forming machine#roll forming machine#roll forming machine suppliers#mudguard machine#fender rear and front#front mudguard machine#autoparts machine#back mudguard machine

0 notes

Text

ARM Embedded Industrial Controller BL370 Applied to Smart Warehousing Solutions

Case Details

The ARMxy BL370 series embedded industrial controller can fully leverage its high performance, flexible scalability, and industrial-grade stability in smart warehousing solutions. Below is an analysis of its typical applications in smart warehousing scenarios, based on the features of the BL370 series.

Application Scenarios of BL370 in Smart Warehousing

Smart warehousing involves automated equipment (such as AGVs, robotic arms, and conveyor belts), sensor networks, data acquisition and processing, and connectivity with cloud platforms. The following features of the BL370 series make it highly suitable for such scenarios:

High-Performance Computing and AI Support: Equipped with the Rockchip RK3562/RK3562J processor (quad-core Cortex-A53, up to 2.0GHz) and a built-in 1TOPS NPU, it supports deep learning frameworks like TensorFlow and PyTorch, enabling image recognition (e.g., barcode scanning, shelf item detection) or path optimization in warehousing.

Rich I/O Interfaces: Supports 1-3 10/100M Ethernet ports, RS485, CAN, DI/DO, AI/AO, and other interfaces, allowing connection to sensors, PLCs, RFID readers, etc., for cargo tracking, environmental monitoring (e.g., temperature and humidity), and device control.

Flexible Scalability: Through X-series and Y-series I/O boards, users can configure RS232/485, CAN, GPIO, analog inputs/outputs, and more to adapt to various warehousing equipment (e.g., stackers, conveyors).

Communication Capabilities: Supports WiFi, 4G/5G modules, and Bluetooth, suitable for real-time data transmission to Warehouse Management Systems (WMS) or cloud platforms for inventory management and remote monitoring.

Industrial-Grade Stability: Operates in a wide temperature range of -40 to 85°C, with IP30 protection, and has passed electromagnetic compatibility and environmental adaptability tests, suitable for warehousing environments with potential vibration, dust, and temperature fluctuations.

Software Support: Pre-installed with BLloTLink protocol conversion software, supporting protocols like Modbus, MQTT, and OPC UA, it seamlessly integrates with WMS, ERP, or mainstream IoT cloud platforms (e.g., AWS IoT, Alibaba Cloud). Node-RED and Docker enable rapid development of warehousing automation workflows.

Specific Application Cases

Here are several typical applications of the BL370 in smart warehousing:

1. AGV Navigation and Control

Function: The BL370 serves as the core controller for AGVs (Automated Guided Vehicles), handling navigation algorithms, sensor data fusion (e.g., LiDAR, ultrasonic sensors), and path planning.

Implementation:

(1)Uses the NPU for real-time image processing (e.g., landmark or obstacle recognition).

(2)Communicates with motor drivers via CAN or RS485 to control AGV movement.

(3)Y-series I/O boards (e.g., Y95/Y96) support PWM output and pulse counting for precise control and positioning.

(4)4G/5G modules enable real-time communication with the central scheduling system.

Advantages: High-performance processor and flexible I/O configurations support complex navigation algorithms, while wide-temperature design ensures stable operation in cold storage environments.

2. Cargo Tracking and Inventory Management

Function: Real-time cargo tracking via RFID or barcode scanning, with data uploaded to WMS for inventory management.

Implementation:

(1)X-series I/O boards (e.g., X20) provide multiple RS232/485 interfaces to connect RFID readers or barcode scanners.

(2)BLloTLink software converts collected data into MQTT protocol for upload to cloud platforms (e.g., Thingsboard).

(3)Node-RED enables rapid development of data processing workflows, such as inventory anomaly alerts.

Advantages: Multiple interfaces support various device integrations, and protocol conversion software simplifies integration with existing systems.

3. Environmental Monitoring and Energy Management

Function: Monitors warehouse environmental conditions (temperature, humidity) and energy consumption data to optimize energy use and ensure proper storage conditions.

Implementation:

(1)Y-series I/O boards (e.g., Y51/Y52) support PT100/PT1000 RTD measurements for high-precision temperature and humidity monitoring.

(2)Data is transmitted to an Energy Management System (EMS) via Ethernet or 4G.

(3)BLRAT tool enables remote access for maintenance personnel to monitor environmental status in real time.

Advantages: Wide voltage input (9-36VDC) and overcurrent protection ensure stability in complex power environments.

4. Automated Equipment Control

Function: Controls conveyor belts, stackers, robotic arms, etc., for automated sorting and storage.

Implementation:

(1)X-series I/O boards (e.g., X23/X24) provide DI/DO interfaces for switching control and status detection.

(2)Supports Qt-5.15.10 for developing Human-Machine Interfaces (HMI), output via HDMI to touchscreens for operator monitoring.

(3)Docker containers deploy control programs, improving system maintainability.

Advantages: Modular I/O design enables quick adaptation to different devices, and the Linux system supports complex control logic.

Advantages of Smart Warehousing Solutions

Using the BL370 series for smart warehousing solutions offers the following benefits:

Modular Design: SOM boards and I/O board combinations meet the needs of different warehouse scales and equipment, reducing customization costs.

High Reliability: Passes EMC tests (ESD, EFT, Surge, etc.) and environmental tests (-40 to 85°C, vibration, drop), ensuring long-term stable operation.

Rapid Deployment: Pre-installed BLloTLink and BLRAT software support mainstream protocols and cloud platforms, shortening system integration time.

Development Support: Rich development examples (Node-RED, Qt, Docker, NPU, etc.) reduce secondary development complexity, ideal for rapid prototyping and customization.

Implementation Recommendations

Hardware Selection:

(1)For scenarios requiring high-performance computing (e.g., vision processing), choose SOM372 (32GB eMMC, 4GB LPDDR4X, RK3562J).

(2)For multi-device connectivity, select BL372B (3 Ethernet ports, 2 Y-board slots).

(3)For cold storage applications, choose SOM370/371/372, supporting -40 to 85°C.

Software Configuration:

(1)Use Ubuntu 20.04 and Qt-5.15.10 to develop HMI interfaces for enhanced user interaction.

(2)Leverage BLloTLink for protocol conversion with WMS/ERP, recommending MQTT for efficient communication in low-bandwidth environments.

(3)Deploy Node-RED to design automation workflows, such as triggers for cargo inbound/outbound processes.

Network and Security:

(1)Use 4G/5G modules to ensure real-time data transmission, with BLRAT for remote maintenance.

(2)Regularly update the Linux kernel (5.10.198) to address potential security vulnerabilities.

Testing and Validation:

(1)Conduct electromagnetic compatibility and environmental tests before implementation to ensure stability in actual warehousing environments.

(2)Simulate high-load scenarios (e.g., multiple AGVs working collaboratively) to test system performance.

Conclusion

The ARMxy BL370 series embedded industrial controller, with its high-performance processor, flexible I/O expansion, robust software ecosystem, and industrial-grade reliability, is highly suitable for smart warehousing solutions. Whether for AGV control, cargo tracking, environmental monitoring, or automated equipment management, the BL370 provides efficient and stable support. Through its modular design and rich development resources, users can quickly build customized smart warehousing systems, improving efficiency and reducing operational costs.

0 notes

Text

The Future of Logistics in Malaysia: Smart Supply Chain and Inventory Innovations

Malaysia’s logistics and manufacturing sectors are growing fast—but so are the challenges. Rising costs, supply disruptions, and shifting customer expectations demand smarter, more integrated solutions. The secret? Partnering with a reliable Supply Chain Consultant Company, deploying efficient Material Handling Services, and using Optimal Inventory Management to streamline operations and reduce waste.

This trio is helping Malaysian businesses across industries build more resilient, data-driven supply chains that are ready for the future.

Summary

This article highlights how Malaysian companies can improve logistics and operational performance by working with a professional Supply Chain Consultant Company, investing in reliable Material Handling Services, and implementing Optimal Inventory Management. It outlines practical applications and benefits, including real-world strategies and expert insights.

Why Supply Chain Consultants Matter More Than Ever

Planning and Performance from an Expert’s Perspective

Many businesses in Malaysia are now realizing the benefits of hiring a Supply Chain Consultant Company to help streamline operations. These professionals assess your current systems and develop customized strategies to cut costs, increase delivery speed, and reduce supply chain risks.

They help with:

Network and route design

Vendor optimization

Sustainability planning

Cost-to-serve modeling

Digital transformation planning

Their external perspective provides valuable insights that internal teams may overlook—especially when scaling or entering new markets.

Malaysian Market-Specific Knowledge

A local or regionally experienced Supply Chain Consultant Company understands Malaysia’s unique logistics environment, including port congestion, regional customs regulations, and infrastructure challenges. This makes their advice more relevant and actionable compared to generic global models.

How Material Handling Services Improve Productivity

What Modern Handling Looks Like

Efficient Material Handling Services ensure that goods move smoothly throughout your facility—from receiving to shipping. This includes the use of equipment like forklifts, stackers, conveyors, trolleys, cranes, and storage systems.

Professional providers offer:

Custom handling system setup

Warehouse floor layout planning

Automated systems integration

Safety training and compliance

In Malaysia’s competitive environment, automation and handling efficiency can give businesses a clear edge.

Supporting Faster Fulfillment

Speed is everything in today’s logistics world. With effective Material Handling Services, warehouses reduce picking times, lower human error, and improve overall order accuracy.

Whether it's in a warehouse in Penang or a factory in Selangor, smart handling solutions shorten delivery lead times and improve throughput—leading to better customer experiences and reduced overhead.

Why Optimal Inventory Management Is the Key to Agility

Balancing Demand, Stock, and Storage Costs

Maintaining the right inventory levels is one of the biggest challenges for Malaysian businesses. Optimal Inventory Management focuses on stocking what you need—no more, no less. It involves real-time visibility, forecasting, order planning, and stock analysis.

This helps:

Avoid stockouts

Reduce expired or obsolete products

Improve working capital

Increase order fill rates

With the right tools and analytics, companies can anticipate demand shifts and adjust stock levels before problems arise.

Inventory as a Strategic Asset

Optimal Inventory Management isn't just about saving space—it’s about enabling responsiveness. When stock is accurate and accessible, your business can pivot faster to demand changes, new product launches, or disruptions.

Malaysian companies operating in high-velocity industries (like food, electronics, or apparel) benefit significantly from real-time inventory dashboards and automated reorder systems, often integrated with ERP or WMS platforms.

How These Three Elements Work Together

Integrated Logistics for Real Business Results

Imagine you're running a mid-sized retail chain in Malaysia. Your supply chain is struggling—your inventory turns are low, handling delays are frequent, and fulfillment costs are climbing. By engaging a Supply Chain Consultant Company, you first identify where inefficiencies lie.

Next, you upgrade your physical operations with advanced Material Handling Services—automated pickers, optimized flow paths, and new racking systems. Finally, you implement a cloud-based Optimal Inventory Management system that syncs with your POS and warehouse.

The outcome?

Faster delivery times

Lower carrying costs

Greater transparency across the supply chain

This holistic approach is what sets industry leaders apart.

Customization for Business Size and Industry

These solutions aren’t just for large corporations. Malaysian SMEs can also benefit—whether you're a local furniture maker in Johor or a cosmetics brand in Kuala Lumpur. Solutions are scalable and adaptable to your business size, product type, and customer base.

Success Snapshot: Malaysian Logistics Firm Adopts a New Strategy

A logistics firm in Klang recently restructured its operations to handle higher freight volumes. With the help of a Supply Chain Consultant Company, they redesigned their hub-and-spoke model to reduce last-mile delays.

They also partnered with a Material Handling Services provider to install a new conveyor and sorting system. Finally, they upgraded their WMS to incorporate Optimal Inventory Management, gaining real-time insights into stock levels.

The result?

22% faster order dispatch

30% improvement in storage efficiency

19% reduction in logistics costs within six months

These numbers show the real-world impact of aligning strategy, execution, and technology.

Tips for Getting Started

Thinking of integrating these solutions in your business? Here are some tips:

Start with an audit: Engage a supply chain consultant to assess current performance and identify improvement areas.

Prioritize automation: Manual handling processes are time-consuming and error-prone—automate where you can.

Invest in inventory tools: Even a simple dashboard can improve stock visibility and purchasing accuracy.

Train your teams: Tools and systems are only as effective as the people who use them.

By starting small and scaling strategically, you can see results quickly and build momentum across departments.

Conclusion

Malaysia’s supply chain ecosystem is evolving rapidly—and businesses must evolve with it. Working with a trusted Supply Chain Consultant Company, using advanced Material Handling Services, and embracing Optimal Inventory Management can unlock new levels of efficiency, scalability, and customer satisfaction.

These aren't optional upgrades—they’re essential for businesses that want to thrive in today’s competitive landscape. With the right strategy and tools, Malaysian businesses can create supply chains that are agile, intelligent, and built to last.

0 notes

Text

The Ultimate Guide to Pallet Conveyors: Streamlining Heavy Material Handling

In today’s fast-paced industrial world, efficiency is key. Companies are constantly looking for ways to improve productivity, reduce manual labor, and streamline operations. One of the unsung heroes of this mission is the pallet conveyor system. Whether in manufacturing, warehousing, or distribution, pallet conveyors play a crucial role in moving heavy goods with precision and speed.

What is a Pallet Conveyor?

A pallet conveyor is a mechanical handling device designed to transport pallets — flat transport structures that carry goods — across a facility. Unlike standard conveyors meant for smaller items, pallet conveyors are built to handle heavy, bulky loads typically ranging from 500 to 2000 kilograms or more.

These systems use a combination of belts, rollers, or chains to move pallets smoothly from one point to another, ensuring minimal manual handling and reducing the risk of damage or injury.

Types of Pallet Conveyors

Depending on the specific needs of an operation, there are several types of pallet conveyors to choose from:

1. Chain-Driven Pallet Conveyors

These conveyors use heavy-duty chains to move pallets. They are ideal for very heavy loads and are commonly used in rugged environments like manufacturing plants.

2. Roller Pallet Conveyors

In this design, pallets move along rollers, either powered or gravity-fed. Powered roller conveyors are great for controlled movement, while gravity versions are ideal for simple, downhill transfers.

3. Belt-Driven Pallet Conveyors

These systems use a belt underneath the rollers to provide motion. They are often used when smooth, even motion is critical, or when pallets must be moved up or down inclines.

4. Turntable Pallet Conveyors

When the direction of pallet movement needs to change (such as 90° turns), turntable conveyors come into play. These systems rotate the pallet without the need for complex manual handling.

Key Benefits of Pallet Conveyors

✔️ Improved Efficiency

Pallet conveyors automate the movement of heavy loads, saving significant time and reducing bottlenecks in production and warehousing operations.

✔️ Enhanced Safety

By reducing manual handling, pallet conveyors help lower the risk of workplace injuries, protecting your workforce and lowering insurance costs.

✔️ Cost Savings

Though they require upfront investment, pallet conveyor systems significantly reduce labor costs over time, offering a solid return on investment.

✔️ Space Optimization

Pallet conveyors can be customized to fit your facility layout, including vertical lifts and stackers that maximize space usage.

✔️ Reliability and Durability

Built to withstand tough conditions, pallet conveyors are a long-lasting solution for industries dealing with heavy goods.

Applications of Pallet Conveyors

Manufacturing plants for moving raw materials or finished products

Warehouses and distribution centers for order fulfillment

Automotive industries for parts transportation

Food and beverage industries for bulk goods handling

Pharmaceutical sectors where clean and efficient movement of heavy batches is critical

Factors to Consider When Choosing a Pallet Conveyor

When selecting a pallet conveyor for your operations, consider:

Load Weight and Size: Ensure the system can handle your heaviest pallets.

Facility Layout: Choose between straight, curved, or multi-level conveyors based on your space.

Speed Requirements: Some operations require faster pallet movement than others.

Environmental Conditions: For example, cold storage facilities may need specially designed conveyors.

Budget: Balance initial investment with long-term savings and efficiency gains.

Conclusion

Pallet conveyors are a smart investment for any business handling heavy loads. By improving efficiency, enhancing safety, and reducing costs, they become an integral part of a well-oiled supply chain. Whether you’re upgrading an existing system or setting up a new facility, a tailored pallet conveyor solution could be the key to your operational success.

0 notes

Text

Tough Gear for Tough Jobs: Why Comet Equipment Delivers the Edge

In mining and construction, performance starts with the right machinery. At Comet Equipment, we don’t just sell tools—we supply the backbone of Australia’s hardest-working industries. As one of the most trusted mining equipment suppliers in the country, we deliver gear built to handle rugged conditions without skipping a beat.

From drills to conveyors, every product in our range supports maximum productivity and long-term reliability. Our clients rely on us because we know what works in the field. Among all mining equipment suppliers, Comet Equipment stands out for offering tailored solutions and expert advice that actually helps you get the job done.

Need to manage dust suppression or site watering efficiently? We’ve got you covered. As experienced truck mounted water tank suppliers, we provide tanks built for Australian roads and remote conditions. Our units come equipped with powerful spray systems, custom fittings, and durable construction. You won’t waste time with low-quality imports—our tanks get to work straight away. Among truck mounted water tank suppliers, we deliver value that lasts.

Looking to move bulk materials efficiently? Check out our radial stacker conveyor for sale. It’s the smart choice for operations that need flexible stockpiling. Our radial stackers boost your site’s productivity and reduce material handling time. Designed with Australian worksites in mind, each radial stacker conveyor for sale meets the demand for strength, mobility, and low maintenance.

At Comet Equipment, we’ve built our reputation by supplying only what we’d use ourselves. Our team knows the industry inside out, and we match the right gear to your specific needs. Whether you’re running a mine site, managing a quarry, or handling major civil works, we’ve got your back.

Talk to Comet Equipment today for expert support, reliable products, and competitive pricing. We’ll help your site run smoother, safer, and smarter.

Source

0 notes

Text

The Role of Pallet Dispensers in Streamlining Warehouse Operations

In modern warehousing and logistics, efficiency is key. With the ever-growing demand for faster supply chain processes, businesses are continually seeking ways to optimize material handling. One solution that is transforming warehouse operations is the pallet dispenser. This innovative equipment significantly enhances productivity, improves workplace safety, and minimizes manual labor.

What is a Pallet Dispenser?

A pallet dispenser is a mechanical system designed to automatically dispense or stack pallets, eliminating the need for workers to manually handle heavy pallets. It is an essential tool for warehouses, distribution centers, and manufacturing facilities that require a steady supply of pallets for goods transportation. These systems help streamline operations by reducing bottlenecks in pallet retrieval and storage.

How Does a Pallet Dispenser Work?

A pallet dispenser works by holding a stack of pallets and dispensing them one at a time as needed. They come in various configurations, including:

Manual pallet dispensers: Require some level of operator involvement.

Semi-automatic pallet dispensers: Combine manual input with automation.

Fully automatic pallet dispensers: Operate without human intervention, often integrated into conveyor or robotic systems.

By automating the pallet retrieval process, businesses can reduce workplace injuries and significantly cut down on time wasted in handling pallets manually.

The Importance of a Pallet Stacker

While a pallet dispenser focuses on dispensing pallets, a pallet stacker serves the opposite function—it efficiently stacks empty or loaded pallets, ensuring better space utilization and organization within a facility.

A pallet stacker is particularly useful for:

Reducing clutter and keeping warehouses organized.

Improving efficiency by neatly stacking empty pallets.

Enhancing workplace safety by reducing the risk of pallet-related injuries.

Automating repetitive and physically demanding tasks.

Benefits of Using a Pallet Dispenser and Pallet Stacker

Investing in a pallet dispenser and pallet stacker brings multiple advantages to any logistics or manufacturing operation:

1. Enhanced Workplace Safety

Manual pallet handling poses risks such as back strain, injuries, and accidents. Automating this process eliminates the need for workers to lift and move heavy pallets manually, ensuring a safer work environment.

2. Increased Efficiency

A pallet dispenser ensures that pallets are readily available when needed, reducing downtime and keeping workflows uninterrupted. Likewise, a pallet stacker keeps floors clear and maximizes storage space.

3. Cost Savings

Reducing labor-intensive tasks leads to lower operational costs. With automation, businesses can allocate their workforce to more strategic roles instead of spending valuable time on repetitive manual tasks.

4. Better Space Optimization

Proper stacking and organized pallet storage contribute to an efficient warehouse layout. A pallet stacker helps maximize floor space, allowing businesses to store more inventory.

Testimonials: What Businesses Are Saying

"Since implementing a pallet dispenser in our warehouse, we've seen a 40% improvement in operational efficiency. Our team no longer struggles with manually handling pallets, reducing strain and injuries." – Logistics Manager, FMCG Industry

"The pallet stacker has made a massive difference in organizing our warehouse. It keeps the workspace clean and eliminates clutter, making it easier for workers to move around safely." – Warehouse Supervisor, Manufacturing Company

FAQs About Pallet Dispensers and Pallet Stackers

Q: Can a pallet dispenser handle all types of pallets?

A: Most pallet dispensers are designed to accommodate standard pallet sizes. However, customizable options are available to fit specific pallet dimensions.

Q: How does a pallet stacker improve productivity?

A: A pallet stacker reduces the time spent manually stacking and moving pallets, freeing up workers for higher-value tasks and ensuring a more organized workspace.

Q: Are these systems difficult to integrate into existing warehouse operations?

A: No, both pallet dispensers and pallet stackers are designed for easy integration. Many models can be customized to fit seamlessly into existing workflows.

Conclusion

Efficiency and safety are crucial in any warehouse or distribution center. Implementing a pallet dispenser and pallet stacker can revolutionize material handling processes, reduce labor costs, and enhance overall workplace safety. As businesses continue to optimize operations, these automated solutions will remain essential in ensuring a seamless and productive supply chain.

0 notes

Text

4 Types of Material Handling Equipment: A Complete Guide

Material handling equipment is crucial across industries, improving operational efficiency, ensuring safety, and increasing overall productivity. Whether it’s in warehouses, factories, construction sites, or logistics centers, the right material handling equipment ensures that goods and raw materials are stored, transported, and managed effectively. In this article, we’ll explore the different types of material handling equipment and how each type contributes to a seamless workflow.

What is Material Handling Equipment?

Material handling equipment consists of mechanical devices and systems designed to transport, safeguard, store, and manage materials across manufacturing, warehousing, distribution, and disposal processes. These tools minimize manual effort, reduce workplace injuries, and optimize the use of space and resources.

Major Types of Material Handling Equipment

Material handling equipment is typically divided into four main categories:

Storage and Handling Equipment

This type of equipment is used to hold materials for a short or long period. It’s ideal for inventory control, space optimization, and organization of goods.

Examples:

Pallet Racks: Ideal for storing goods on pallets in warehouse environments.

Shelving Units: Used for lighter goods and smaller inventories.

Bins and Containers: Keep small parts and components organized.

Stacking Frames: Allow secure stacking of loads while preventing damage or crushing to the products.

Mezzanines: Elevated platforms that expand storage without using extra floor space.

Benefits:

Reduces clutter

Enhances safety

Improves space utilization

Bulk Material Handling Equipment

This category is used for handling large volumes of loose materials such as sand, minerals, liquids, or grains.

Examples:

Conveyor Belts: Continuously move materials over long distances.

Hoppers: Hold and funnel bulk materials into a process.

Silos: Store bulk items like grains or cement.

Stackers: Move bulk materials into piles.

Reclaimers: Retrieve stored bulk materials.

Benefits:

Minimizes spillage

Handles high-volume materials efficiently

Reduces manual labour

Industrial Trucks

Industrial trucks are vehicles used to transport materials in facilities like warehouses and factories. These can be manual or powered.

Examples:

Forklifts: Lift and move heavy loads in short distances.

Pallet Jacks: Designed to lift and transport palletized loads with ease and efficiency.

Hand Trucks: Transport boxes or small packages.

Order Pickers: Help workers pick items from warehouse racks.

Tow Tractors: Pull heavy loads across longer distances.

Benefits:

Increases speed and efficiency

Reduces injury risks

Flexible and mobile

Engineered Systems (Automated Systems)

These are automated material handling systems designed for high-volume operations. They combine advanced software and hardware systems to optimize and automate the flow of materials seamlessly.

Examples:

Automated Storage and Retrieval Systems (AS/RS): Automatically store and retrieve items.

Conveyor Systems: Move materials between processes or stations.

Robotic Delivery Systems: Transport goods using AI and sensors.

Automated Guided Vehicles (AGVs): Self-navigating vehicles used in warehouses.

Benefits:

Reduces manpower

Increases accuracy and speed

Supports smart inventory management

How to Select the Right Material Handling Equipment

When choosing the ideal material handling equipment for your needs, keep the following key factors in mind:

Type of Material: Know the size, weight, and sensitivity of the materials.

Volume of Goods: Choose equipment based on daily or hourly volume.

Operational Space: Optimize layout with space-saving options like vertical lifts.

Budget Constraints: Balance between cost and functionality.

Industry Regulations: Ensure compliance with safety and environmental standards.

Industries That Use Material Handling Equipment

Material handling equipment is vital across a range of industries, including:

Manufacturing

Warehousing and Distribution

Construction

Mining

Agriculture

Healthcare and Pharmaceuticals

Conclusion

Material handling equipment is essential to the core of both industrial and commercial operations. Understanding the various types of material handling equipment and their applications helps businesses select the right tools to optimize efficiency, ensure safety, and reduce operational costs. Whether you’re dealing with bulk materials or individual packages, investing in the right equipment can lead to long-term productivity and success.

Looking to upgrade your facility’s efficiency? Explore our wide range of high-quality material handling equipment tailored for every industry need!

0 notes

Text

Essential Maintenance Tips for Bulk Material Handling Equipment

Bulk material handling equipment plays a critical role in various industries, including mining, agriculture, construction, and manufacturing. These systems are designed to transport, process, and store bulk materials such as ores, grains, coal, and other granular or powdered substances efficiently. As industries expand and require faster, more reliable ways to move large volumes of materials, the demand for advanced bulk material handling equipment continues to grow.

Types of Bulk Material Handling Equipment

There are several types of bulk material handling equipment used across industries. These include conveyor belts, stackers, reclaimers, hoppers, silos, and bucket elevators. Each piece of equipment is designed for a specific function within the material handling process. For example, conveyor belts are ideal for horizontal or inclined transportation, while silos provide long-term storage for dry bulk materials.

Applications of Bulk Material Handling Equipment

The applications of bulk material handling equipment are vast. In the mining industry, these machines move ores and minerals from excavation sites to processing plants. In agriculture, equipment like grain elevators and augers are used to transport and store crops. Manufacturing facilities rely on hoppers and feeders to manage raw materials before and during production. Each application requires specialized machinery designed for material type, volume, and handling conditions.

Advantages of Using Bulk Material Handling Equipment

Using bulk material handling equipment offers numerous advantages. It improves operational efficiency by reducing manual labor and handling time. It also enhances safety by minimizing the risks associated with manually moving heavy materials. Additionally, these systems provide consistent material flow, which is crucial for maintaining productivity and quality in manufacturing and processing operations.

Key Features to Look for in Bulk Material Handling Equipment

When selecting bulk material handling equipment, several key features should be considered. Durability is essential, especially for equipment exposed to abrasive or corrosive materials. Capacity and speed must align with the operational requirements. Flexibility and scalability are also important, allowing the system to adapt to changing production needs. Automation features and easy maintenance are additional factors that improve performance and reliability.

Challenges in Bulk Material Handling

Despite its many benefits, bulk material handling also presents challenges. Dust generation, material spillage, and equipment wear and tear are common issues. Handling sticky or moist materials can lead to clogging and reduced efficiency. Maintenance requirements and energy consumption can also impact operational costs. To address these challenges, companies must invest in high-quality equipment and implement effective maintenance strategies.

Trends and Innovations in Bulk Material Handling Equipment

Technological advancements are shaping the future of bulk material handling equipment. Automation and smart sensors are becoming increasingly common, allowing for real-time monitoring and predictive maintenance. Energy-efficient designs help reduce operational costs and environmental impact. Modular systems offer flexibility and quicker installation times. As industries continue to evolve, these innovations play a crucial role in enhancing the performance and sustainability of bulk material handling systems.

Conclusion

Bulk material handling equipment is an indispensable component of modern industrial operations. From improving efficiency and safety to accommodating large-scale material movement, these systems are essential for various sectors. By understanding the different types, applications, and key considerations, businesses can make informed decisions to optimize their material handling processes. With continued innovation and technological integration, the future of bulk material handling promises greater reliability, adaptability, and performance.

0 notes

Text

Elevator Company

Marck Industries is a leading manufacturer based in Ahmedabad, Gujarat, specializing in elevators, elevator spare parts, EOT cranes, material handling equipment, and conveyor rollers. With over 22 years of experience, the company has established a strong presence both domestically and internationally, exporting to over 10 countries across Asia, the Middle East, and Africa.

Company Overview

Name: Marck Industries

Location: 15, Shriji Estate, Opp. Radhakrishna Soc., Nr. Dhandhar Panchal Wadi, Viratnagar Road, Odhav, Ahmedabad-382415, Gujarat, India

Website: marckindustries.com

Contact: +91-97271 56896 | +91-93286 23252

Email: [email protected] | [email protected]

Product Portfolio

Marck Industries offers a comprehensive range of products tailored to meet diverse vertical transportation and material handling needs:

Elevators: Passenger lifts, bungalow lifts, home lifts, hospital lifts, hydraulic lifts, and parking lifts

Elevator Spare Parts: Control panels, diverter pulleys, auto door parts, cabins, doors, drives, fans, guide shoes, and mechanical components

Elevator Full Lift Kits: Complete elevator systems for various applications

EOT Cranes: Including base-mounted hoists, chain hoists, double girder cranes, goliath gantry cranes, hydraulic goods lifts, jib cranes, M.E crab type hoists, and wire rope hoists

Material Handling Equipment: Drum handling equipment, electric stackers, floor cranes, goods lifts, hydraulic lifting tables, manual stackers, material handling trolleys, pallet trucks, scissor lifts, and wheelbarrows

Conveyor Rollers: Idler bearing housings, idler roller bearing housings for crushers, labyrinth seals, MS dust covers, and impact rubber rings

Why Choose Marck Industries?

Expertise: Over two decades of experience in manufacturing and supplying elevator and material handling solutions.

Quality Assurance: Commitment to delivering high-quality products that meet international standards.

Innovation: Continuous research and development to incorporate the latest technologies and innovations in their products.

Customer Satisfaction: A strong focus on customer satisfaction with a dedicated team providing support and service.

For more information or to request a quote, visit their official website or contact them directly via the provided details.

0 notes