#Copolymerization

Explore tagged Tumblr posts

Text

Bright and tough: A material that heals itself and glows

A research team at the RIKEN Center for Sustainable Resource Science (CSRS) has succeeded in developing a self-healing material that is also capable of emitting a high amount of fluorescence when absorbing light. The research, published in the Journal of the American Chemical Society, could lead the way to the creation of new materials such as organic solar cells that are more durable than current types. In 2019, Zhaomin Hou and his team at RIKEN CSRS successfully copolymerized ethylene and anisylpropylene using a rare-earth metal catalyst. The resulting binary copolymer displayed remarkable self-healing properties against damage. The copolymer's soft components, alternating units of ethylene and anisylpropylene, coupled with hard crystalline units of ethylene-ethylene chains, acted as physical cross-linking points, forming a nano-phase-separated structure that proved crucial for self-healing. Building upon this success, they incorporated a luminescent unit, styrylpyrene, into a monomer and then formed polymers that also included anisylpropylene and ethylene. This process led to the synthesis, in a single step, of a self-healing material with fluorescence characteristics.

Read more.

#Materials Science#Science#Self healing#Fluorescence#Light#Polymers#Copolymers#Luminescence#Elastomers

37 notes

·

View notes

Text

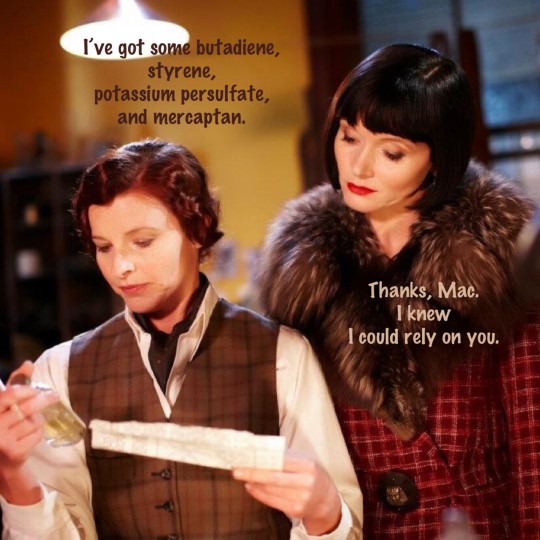

Miss Fisher Snippets (179)

To support her oldest friend’s newest enterprise as a lady detective, Mac volunteered her time and scientific expertise whenever she received a call for help. In S1E5 Raisins and Almonds, she came prepared with various chemicals listed on Saul Michael’s secret formula and eventually produced the artificial rubber that helped crack the case.

Like Mac, I was also born with an inquiring mind, so I looked up how artificial rubber was made. According to Wikipedia, the first synthetic rubber was made in 1909 by a team of German scientists in a university laboratory, but not until the 1930s did it get produced by manufacturers for commercial use. I wonder what became of Saul’s formula after the murder case was solved. Knowing Jack “Man of Honor” Robinson, he likely locked it up in the evidence drawer as he should. It seemed such a waste to me, though.

In terms of the type of artificial rubber, “The most prevalent synthetic rubber is styrene-butadiene rubbers (SBR) derived from the copolymerization of styrene and 1,3-butadiene”, which corresponded to what’s mentioned in this episode. As always, I am impressed with the extend of research the show writers had done to get the details right.

********************

p.s. Happy birthday, @tammy__macintosh (February 16). We absolutely love your portrayal of the loyal and sassy BFF everyone needs and wants. May your special day be filled with bright sunshine as radiant as your smile.

(Posted 16-Feb-2024)

15 notes

·

View notes

Text

Buy Acrylate Copolymer at Trckem

Acrylate Copolymer is a versatile polymer widely used in various industries for its excellent adhesive, film-forming, and thickening properties. It is a synthetic polymer created through the copolymerization of acrylic monomers.

Buy:- https://trckem.in/products/acrylate-copolymer

#amp 95 ingredients#buy abrasives online#buy humectant ingredients#cocos nucifera oil#cosmetic product sampling services#natural castor oil#personal care chemicals manufacturer

0 notes

Text

Styrene Butadiene Rubber (SBR) Market Overview: Key Trends and Industry Outlook

The Styrene Butadiene Rubber (SBR) Market plays a vital role in the global synthetic rubber industry, driven by its versatile applications, particularly in automotive tires, footwear, adhesives, and construction materials. As the world pivots toward sustainability, electrification, and advanced materials, the SBR market is experiencing a transformative shift in dynamics, technologies, and consumer demands.

What is Styrene Butadiene Rubber (SBR)?

Styrene Butadiene Rubber (SBR) is a synthetic elastomer produced through the copolymerization of styrene and butadiene. It is known for its excellent abrasion resistance, aging stability, and cost-effectiveness. There are two main types of SBR:

Emulsion SBR (E-SBR): Made through emulsion polymerization, suitable for general-purpose applications.

Solution SBR (S-SBR): Produced via solution polymerization, offering enhanced performance, especially in tire manufacturing.

Current Market Landscape

The Styrene Butadiene Rubber (SBR) Market is valued at billions of dollars globally and continues to grow steadily. The market is driven by several sectors, most notably:

Tire and automotive industry – accounts for over 70% of global SBR consumption.

Footwear and consumer goods

Adhesives and sealants

Construction and infrastructure

Latex applications in hygiene and medical products

Key Trends Shaping the SBR Market

1. Rise in Global Vehicle Production

Despite short-term slowdowns due to COVID-19 and chip shortages, the automotive industry remains the largest consumer of SBR. The rebound in vehicle production is boosting demand, particularly for high-performance tires that require S-SBR.

2. Sustainable and Green Tire Manufacturing

Sustainability is driving tire companies to develop low rolling resistance tires to reduce fuel consumption. This trend favors solution SBR, which improves grip and efficiency, thus increasing its market share.

3. Growing Demand in Emerging Markets

Asia-Pacific countries, especially China and India, are witnessing rapid industrialization, urbanization, and growth in automotive ownership. This surge is translating into increased consumption of synthetic rubber.

4. Shift Toward Electric Vehicles (EVs)

EVs have specific requirements for tire performance, including better durability and low noise. SBR, especially solution-grade, plays a critical role in meeting these requirements.

5. Technological Advancements

Innovation in polymer chemistry, blending with other rubbers, and improvements in processing methods are enhancing the capabilities and applications of SBR.

Regional Insights

Asia-Pacific

Largest producer and consumer of SBR globally.

China dominates both production and consumption, fueled by its tire manufacturing and construction industries.

India and Southeast Asia are emerging as key growth markets.

North America

Mature market but significant demand in automotive and adhesive sectors.

Environmental regulations are influencing green tire production using S-SBR.

Europe

Focus on eco-friendly and high-performance tires.

Leading manufacturers like Michelin and Continental drive innovation in SBR applications.

Latin America and Middle East

Moderate growth, supported by construction and automotive markets.

Rising interest in localized production to reduce import dependence.

Major Players in the Global SBR Market

The Styrene Butadiene Rubber (SBR) Market is moderately consolidated with several multinational companies leading innovation and distribution. Key players include:

Goodyear Chemical

JSR Corporation

SIBUR

LG Chem

Lanxess AG

Trinseo

Synthos S.A.

Versalis (Eni)

These companies are investing in capacity expansion, R&D, and sustainability initiatives to gain a competitive edge.

Challenges Facing the SBR Market

1. Volatile Raw Material Prices

SBR is derived from petrochemical feedstocks like butadiene and styrene, making it susceptible to crude oil price fluctuations.

2. Environmental Regulations

Increasing scrutiny on synthetic rubbers, particularly in Europe and North America, is pushing producers to innovate greener formulations and adopt cleaner production processes.

3. Competition from Natural Rubber and Other Elastomers

Natural rubber and alternatives like Thermoplastic Elastomers (TPEs) pose a competitive threat, particularly in applications requiring better elasticity or environmental credentials.

Outlook to 2032

The Styrene Butadiene Rubber (SBR) Market is expected to witness a steady compound annual growth rate (CAGR) through 2032. Future demand will be shaped by:

Continued expansion in the automotive and tire industries.

Increasing demand for green and sustainable rubber products.

Technological integration in processing and polymer design.

Growth in non-tire applications like adhesives, coatings, and construction materials.

Asia-Pacific will remain the central hub for production and consumption, while sustainability trends and EV adoption will reshape product innovation globally.

Conclusion

The Styrene Butadiene Rubber (SBR) Market is entering a new phase of development characterized by sustainability, advanced applications, and regional shifts in production and consumption. With strong demand from automotive, industrial, and consumer segments, coupled with innovation in processing and materials, the SBR industry is well-positioned to adapt to evolving market dynamics and contribute to a greener and more resilient future.

0 notes

Text

https://www.linkedin.com/pulse/malaysia-c5-c9-copolymerized-petroleum-resin-market-size-trends-daqaf/

0 notes

Text

Ethylene Propylene Diene Rubber (EPDM) Market Size, Demand & Supply, Regional and Competitive Analysis 2025–2032

Definition

Ethylene Propylene Diene Rubber (EPDM) is a type of synthetic rubber known for its exceptional resistance to heat, oxidation, ozone, and weather conditions. It is widely used across industries including automotive, construction, electrical, and mechanical goods. Its molecular structure allows it to remain flexible in both low and high temperatures, making it ideal for applications such as weather-stripping, seals, hoses, roofing membranes, and electrical insulation.

EPDM is produced through the copolymerization of ethylene, propylene, and a diene monomer, which provides unsaturation points enabling crosslinking. Its performance in demanding environments has made it a preferred material where durability and longevity are essential.

Market Size

Download Sample Report PDF https://www.24chemicalresearch.com/download-sample/290022/global-ethylene-propylene-diene-rubber-forecast-market-2025-2032-593

The global EPDM market was valued at USD 3,467.3 million in 2024 and is projected to reach USD 4,806.5 million by 2032, growing at a CAGR of 4.2% during the forecast period. Growth is primarily driven by increased automotive production, infrastructure development, and rising demand for high-performance rubber materials in emerging economies.

Growth Projections and Trends

The EPDM market has demonstrated consistent growth due to its versatile applications and durability. The automotive sector continues to be the largest consumer, using EPDM in weather seals, belts, and hoses. Meanwhile, the construction sector’s demand for waterproof roofing membranes and sealing systems contributes significantly to the market’s expansion.

Key trends include:

Rising adoption of eco-friendly and recyclable EPDM variants.

Technological advancements leading to enhanced performance grades.

Expansion of manufacturing facilities in Asia-Pacific to meet growing regional demand.

Market Dynamics

Drivers

Booming Automotive Industry: EPDM is extensively used in weather-sealing and under-the-hood applications due to its thermal stability and flexibility.

Construction Growth: Rapid urbanization is fueling demand for durable and weather-resistant roofing materials and sealants.

High Weather and Heat Resistance: EPDM’s unique molecular structure makes it a material of choice for harsh outdoor conditions and electrical insulation.

Restraints

Price Volatility of Raw Materials: EPDM production depends on ethylene and propylene, both of which are petrochemical derivatives subject to global price fluctuations.

Environmental Regulations: Although EPDM is relatively safe, stringent environmental regulations on petrochemical-derived materials could restrict market growth.

Opportunities

Emerging Economies: Infrastructure and automotive developments in countries like India, China, Brazil, and Southeast Asia offer significant market potential.

Green Building Standards: The shift towards sustainable construction favors the use of long-life, recyclable EPDM materials.

Electrification of Vehicles: Electric vehicles (EVs) use EPDM for high-performance sealing and insulation, offering a new frontier for growth.

Challenges

Substitute Materials: Competition from thermoplastic elastomers and silicones in specific applications.

Complex Recycling Processes: EPDM's cross-linked structure poses challenges in recycling, which could be a concern in increasingly environmentally focused markets.

Regional Analysis

North America

Strong demand in automotive and infrastructure sectors continues to drive EPDM consumption. The U.S. is a major producer and consumer, with significant investment in sustainable construction technologies.

Europe

Europe’s EPDM market is mature but remains robust, particularly in Germany, France, and the UK. Growth is supported by stringent environmental standards pushing demand for long-lasting and recyclable materials.

Asia-Pacific

The fastest-growing market due to industrialization, urbanization, and a thriving automotive sector. China and India are leading importers and consumers of EPDM, while Japan and South Korea are key manufacturers.

Latin America

Increasing investments in automotive assembly plants and construction projects are expected to spur regional growth, particularly in Brazil and Mexico.

Middle East & Africa

Infrastructure development, especially in the UAE and Saudi Arabia, supports EPDM market expansion. However, growth is moderate compared to other regions due to limited industrial output.

Competitor Analysis

Key Players in the EPDM Market Include:

Dow Inc.

Arlanxeo (a subsidiary of Saudi Aramco)

ExxonMobil Chemical

Lion Elastomers

Mitsui Chemicals

JSR Corporation

SK Global Chemical Co. Ltd.

Sumitomo Chemical Co., Ltd.

These companies focus on R&D, capacity expansion, and partnerships to cater to evolving industry needs. Competitive strategies revolve around sustainable production, product innovation, and geographic expansion.

Global EPDM Market: Segmentation Analysis

By Type

Solution Polymerization EPDM

Suspension Polymerization EPDM

By Application

Automotive

Building & Construction

Electrical & Electronics

Mechanical Goods

Others

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Get The Complete Report & TOC

FAQs

1. What is the current market size of the EPDM market? The global EPDM market was valued at USD 3,467.3 million in 2024 and is projected to reach USD 4,806.5 million by 2032.

2. Which industries are the major consumers of EPDM? The automotive and construction industries are the primary consumers, followed by electrical and mechanical applications.

3. Who are the key players in the EPDM market? Major companies include Dow Inc., Arlanxeo, ExxonMobil Chemical, Mitsui Chemicals, and Sumitomo Chemical.

4. Which region is expected to lead the EPDM market during the forecast period? Asia-Pacific is expected to dominate due to rapid industrialization, infrastructure growth, and automotive manufacturing.

5. What are the main growth drivers for the EPDM market? Key growth drivers include rising automotive production, increasing demand for weather-resistant materials, and infrastructure development in emerging economies.

CONTACT US: 203A, City Vista, Fountain Road, Kharadi, Pune, India - 411014 International: +1 (332) 2424 294 Asia: +91 9169162030

Follow Us On LinkedIn: https://www.linkedin.com/company/24chemicalresearch/ About 24Chemical Research: Founded in 2015, 24ChemicalResearch provides deep insights and accurate market analysis across the chemical industry. With a global client base including over 30 Fortune 500 companies, we are a trusted name in strategic market intelligence.

0 notes

Text

0 notes

Text

Metallocene catalysts are useful for olefin polymerization and ethene or propene copolymerization with cyclic olefins, styrene, and polar vinyl monomers. A metallocene or half sandwich complex of transition metals and an organoaluminum compound, methyl aluminoxane (MAO), or a per fluorinated boron aromatic compound make up these catalysts. The transition metal in most polymerization active metallocene’s is zirconium or titanium, but others include hafnium, chromium, scandium, and others.

0 notes

Text

blue LLDPE Water Tank

Linear low-density polyethylene (LLDPE) is a substantially linear polymer with significant numbers of short branches, commonly made by copolymerization of ethylene with longer-chain olefins.

1 note

·

View note

Text

Enhancing Swelling Kinetics of pNIPAM Lyogels: The Role of

Excerpt from PDF: 1 Enhancing Swelling Kinetics of pNIPAM Lyogels: The Role of Crosslinking, Copolymerization, and Solvent Kathrin Marina Eckerta*, Jelisa Bonsena, Anja Hajnala, Johannes Gmeinerb, Jonah Hasseb, Muhammad Adrianc, Julian Karstend, Patrick A. Kißlinge, Alexander Pennc, Bodo Fiedlerd, Gerrit A. Luinstrab, Irina Smirnovaa * corresponding author ([email protected]) a Institute of…

1 note

·

View note

Text

Up-cycling petroleum waste into a high-performance yet sustainable triboelectric nanogenerator

A striking landmark in Vancouver, Canada, "The Big Yellow Sulfur Pile" is a testament to the massive amounts of elemental sulfur produced from the hydrodesulfurization process of petroleum refining. In 2013, Prof. Pyun's group from the University of Arizona developed inverse vulcanization, a method to synthesize a sulfur-rich polymer (SRP) containing elemental sulfur content of more than 50 wt% in the backbone of this new polymer. This elemental sulfur was synthesized as a chemically stable and solid-state SRP by copolymerizing it with a π-bond containing comonomer. SRPs have usually been applied to make polymer-based infrared (IR) optics due to their intrinsically high transparency and high refractive index in the IR region, replacing expensive and fragile typical IR materials like Ge, ZnS, and ZnSe. Beyond this optical application, a research team led by Professor Jeong Jae (JJ) Wie from the Department of Organic and Nano Engineering at Hanyang University are now turning this vibrant yellow waste into a valuable resource for sustainable energy.

Read more.

#Materials Science#Science#Petroleum#Waste#Triboelectric#Nanotechnology#Sulfur#Polymers#Recycling#Hanyang University

12 notes

·

View notes

Text

Nitrile Butadiene Rubber Prices in 2025 What to Expect

Nitrile Butadiene Rubber, often known as NBR, is a synthetic rubber that plays a significant role in many industries. It's commonly used in products that require durability and resistance to oils, fuels, and other chemicals. NBR is found in everything from gloves and seals to automotive parts and industrial hoses. Given its wide range of applications, understanding the potential trends in Nitrile Butadiene Rubber prices in 2025 is important for businesses and consumers alike. So, what factors will drive the price of NBR in the coming years? Let’s take a closer look.

What is Nitrile Butadiene Rubber?

Nitrile Butadiene Rubber is a synthetic polymer made from the copolymerization of acrylonitrile and butadiene. The result is a material that has impressive resistance to oils, greases, and chemicals, making it ideal for industries like automotive, healthcare, and manufacturing. For example, NBR is used in the production of fuel hoses, seals, gaskets, and medical gloves. It is also a key component in rubber-based products that must endure harsh conditions.

Because of its ability to withstand oil and chemical exposure, NBR is widely used in applications that require strong, long-lasting materials. Its versatility makes it an essential part of many industries, meaning that shifts in its price can have a ripple effect across multiple sectors.

>> 𝐁𝐨𝐨𝐤 𝐚 𝐝𝐞𝐦𝐨 𝐭𝐨 𝐠𝐞𝐭 𝐫𝐞𝐚𝐥-𝐭𝐢𝐦𝐞 𝐃𝐚𝐭𝐚 𝐃𝐫𝐢𝐯𝐞𝐧 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬: https://www.price-watch.ai/book-a-demo/

What Affects the Price of Nitrile Butadiene Rubber?

The price of Nitrile Butadiene Rubber is influenced by several factors, with the most significant being the cost of raw materials. Acrylonitrile, one of the primary components used to make NBR, is derived from natural gas or oil. As a result, the price of NBR is closely tied to fluctuations in the price of oil and natural gas. When oil prices rise, the cost of producing NBR typically increases as well. Similarly, if the price of natural gas goes up, it could lead to higher production costs for NBR.

Another factor that affects NBR pricing is global demand. Nitrile Butadiene Rubber is used in a wide range of industries, so changes in demand from these sectors can directly impact its price. For instance, if the automotive industry increases production or if there’s a surge in demand for medical gloves, the demand for NBR will also rise. When demand increases, prices often follow suit.

Lastly, economic conditions also play a role in the price of NBR. Global economic growth can drive increased demand for industrial products, pushing up the price of raw materials like NBR. Conversely, economic slowdowns or recessions can reduce the demand for NBR, leading to a decrease in its price.

Nitrile Butadiene Rubber Prices in 2025

Looking ahead to 2025, it’s difficult to predict the exact price of Nitrile Butadiene Rubber. However, there are several factors that will likely influence its price. First, the cost of oil and natural gas will continue to be a key factor. As the world continues to recover from the pandemic and industries ramp up production, oil prices may rise. If this happens, the cost of producing NBR will likely increase as well. On the other hand, if oil prices stabilize or decrease, the price of NBR may remain relatively steady.

Another important factor to consider is the demand for NBR in various industries. The automotive and healthcare sectors, which are some of the biggest users of NBR, are expected to continue growing. In particular, the automotive industry is likely to see an increase in demand for NBR due to the rise of electric vehicles, which often use rubber components that require materials like NBR for their durability and resistance to chemicals. This increased demand could put upward pressure on prices.

Similarly, the demand for medical supplies, including gloves, is expected to remain high as health and safety concerns continue to shape consumer behavior. With healthcare workers and others requiring protective gear, the demand for NBR-based products is unlikely to slow down anytime soon.

At the same time, the global shift toward sustainability and environmental concerns may also impact NBR prices. As more companies look to reduce their carbon footprint and improve their sustainability practices, there could be increased investment in recycling technologies or the development of more eco-friendly alternatives. This could potentially affect the price of NBR if manufacturers turn to more sustainable methods of production.

The Impact of NBR Prices on Businesses and Consumers

For businesses, especially those that rely on Nitrile Butadiene Rubber for manufacturing products, understanding price trends will be crucial for planning. If the price of NBR rises, it could increase production costs for industries such as automotive, healthcare, and manufacturing. Businesses might need to find ways to absorb these costs or pass them on to consumers in the form of higher prices. Companies that use NBR in their products may also look for alternative materials or more cost-effective ways to produce their goods to keep expenses in check.

For consumers, the impact of rising NBR prices may be felt indirectly. For example, if the price of NBR increases, it could lead to higher prices for products like medical gloves, car parts, and industrial products. While the price hike may not be significant in every case, it could have an effect on the overall cost of goods, especially for industries that heavily rely on NBR-based products.

Looking Toward the Future

As 2025 approaches, it’s clear that a variety of factors will shape the price of Nitrile Butadiene Rubber. The global demand for NBR, particularly in the automotive and healthcare sectors, is likely to remain strong. Additionally, the price of raw materials, including oil and natural gas, will continue to have a direct impact on production costs. Whether these costs rise, or fall will depend on a range of factors, including global economic conditions and supply chain dynamics.

Ultimately, the price of Nitrile Butadiene Rubber in 2025 will be shaped by a combination of demand, raw material costs, and economic conditions. Get real time commodity price update with pricewatch. By understanding these factors, businesses and consumers can better navigate the potential changes in the market and plan accordingly.

#commodities#data driven decisions#market research#commodity market#business intelligence#commodity prices#price intelligence

0 notes

Text

Benzoyl Peroxide(BPO)

product name: Benzoyl Peroxide(BPO)

Product description: BPO is a white particle, powder, or paste. it is a diacyl organic peroxide. It is mainly used as a copolymerization initiator of polystyrene and polypropylene, a curing agent of unsaturated resin, and a vulcanizing agent of silicone rubber. Solubility Soluble in Benzene.Chloroform, Acetone, etc. Slightly soluble in ethanol, and insoluble in water. Package 20kg/25kg per drum. For more details, please visit it https://www.jssunton.com/product/peroxide-series/benzoyl-peroxide-bpo.html

0 notes

Text

A Deep Dive into Micro Pump Sealing Technology | How TOPSFLO Chooses Rubber Seals

In both precision industrial and consumer devices, water pumps play an indispensable role, silently driving the flow of liquids. At the heart of this “engine,” lies a seemingly small yet crucial component — the sealing ring. As the primary sealing element in micro pumps, the sealing ring safeguards each stable operation with the unique charm of its material. Today, let’s delve into the world of micro pump sealing materials and uncover the secrets behind these smart material choices.

Micro pump sealing materials come in a wide variety, each with its own distinct characteristics and applications. In this article, we’ll explore the common rubber-based materials used in sealing elements.

Nitrile Butadiene Rubber (NBR)

NBR is a type of synthetic rubber copolymerized from acrylonitrile (ACN) and butadiene, primarily produced through a low-temperature emulsion polymerization process. The specific gravity of NBR is 1.5 ± 0.05g/cm³, with a tensile strength of ≥500 PSI or 3.5 MPa, an elongation of ≥350%, and a hardness of 65° ± 5° shore A.

NBR can have five different acrylonitrile (ACN) content percentages: 42-46%, 36-41%, 31-35%, 25-30%, and 18-24%. The higher the acrylonitrile content, the better the oil resistance, but the cold resistance decreases correspondingly. Besides its excellent oil resistance, NBR also possesses good abrasion resistance and aging resistance. Additionally, it has good gas tightness, effectively preventing the leakage of oil media and enduring the friction and wear during the operation of water pumps. It is often used in micro water pumps that need to transport oil media.

Advantages

1. Excellent Oil Resistance: Nitrile rubber exhibits outstanding resistance to various oils, fuels, and solvents, making it ideal for applications requiring protection against water or oil.

2. High Wear Resistance: It effectively reduces the wear rate of sealing components, thereby extending the lifespan of the seals.

3. Good Heat Resistance: Nitrile rubber maintains the stability of its physical and chemical properties even at high temperatures.

4. Excellent Processability: Nitrile rubber seals are easy to mold, extrude, and inject, offering high production efficiency and relatively low costs, providing a great balance of performance and value.

Ethylene-Propylene-Diene Monomer(EPDM)

Ethylene-Propylene-Diene Monomer (EPDM) is a copolymer of ethylene, propylene, and a small amount of non-conjugated diene, primarily produced through processes such as solution polymerization and suspension polymerization. Commercial production of this material began in the 1960s. Annually, the global consumption of EPDM is 800,000 tons.

The most prominent characteristic of EPDM is its superior resistance to oxidation, ozone, and corrosion. As EPDM belongs to the polyolefin (PO) family, it exhibits excellent vulcanization properties. Among all rubbers, EPDM has the lowest specific gravity and can absorb a large amount of fillers and oils without significantly affecting its properties, thus allowing for the production of cost-effective rubber compounds.

Advantages

1. Extremely high chemical stability: The main chain of EPDM rubber is composed of chemically stable saturated hydrocarbons, with unsaturated double bonds only in the side chains. This structure grants EPDM rubber extremely high chemical stability, enabling it to resist heat, light, oxygen, and especially ozone erosion.

2. Excellent aging resistance: Due to the saturation of its main chain, EPDM rubber exhibits outstanding aging resistance, including weather resistance, ozone resistance, sunlight resistance, heat resistance, water resistance, water vapor resistance, UV resistance, and radiation resistance. When used in combination with other unsaturated diene rubbers such as NR, SBR, BR, NBR, and CR, EPDM can function as a polymer antioxidant or antidegradant.

3. Cost-effective: EPDM rubber has a relatively low density, typically ranging from 0.860 to 0.870, making it the lightest commonly used rubber in terms of raw rubber density. This results in lighter products, which helps reduce costs. The raw rubber density is only 0.86 to 0.90g/cm3, and it can be filled with a large amount of material to reduce the cost of the rubber compound.

4. Excellent electrical insulation properties, with a volume resistivity of 1016Q·cm, a breakdown voltage of 30 to 40 MV/m, and a dielectric constant (at 1 kHz, 20°C) of 2.27.

In micro pumps, EPDM rubber is commonly used for sealing components in cooling fluid and water systems, as it maintains stability and durability under various environmental conditions.

Fluorinated Rubber(FKM)

FKM refers to a synthetic polymer elastomer containing fluorine atoms on the carbon atoms of its main chain or side chains. It is an irreplaceable key material in cutting-edge national defense industries. Since 1943, various types of fluorinated rubbers have been developed, including polyolefin-based fluorinated rubber, nitroso fluorinated rubber, tetrapropyl fluorinated rubber, phosphazene fluorinated rubber, and perfluoroether rubber.

The introduction of fluorine atoms provides the rubber with excellent heat resistance, antioxidant properties, oil resistance, corrosion resistance, and atmospheric aging resistance. It has been widely used in aerospace, aviation, automotive, petroleum, household appliances, and other fields.

Advantages:

1. Excellent Chemical Resistance: FKM seals are highly resistant to a wide range of corrosive liquids and gases, including oils, fuels, acids, and solvents.

2. High Temperature Stability: FKM seals are designed to withstand temperatures ranging from -40°C to 240°C.

3. Outstanding Resilience: They ensure long-term stable sealing performance, reducing the risk of leaks.

4. Good Mechanical Properties: FKM seals maintain sealing integrity even under harsh conditions, such as high pressure, vibration, and mechanical stress.

5. Wide Compatibility: FKM seals are compatible with a variety of fluids, including mineral oils, hydraulic oils, fuels, and chemicals.

6. Additional Features: FKM seals also offer excellent oil resistance, ozone resistance, strong resistance to permanent compression deformation, and high wear resistance.

Besides the rubber materials introduced above, there are also hydrogenated nitrile rubber (HNBR), silicone rubber (Q), fluorosilicone rubber (FVMQ), tetrapropylene fluorinated rubber (TFE/P), and perfluoro(ether) rubber (FFKM).

TOPSFLO adopts high-quality imported rubber materials, primarily EPDM rubber, which boasts high purity, excellent abrasion resistance, and the ability to withstand frequent startups and prolonged continuous operation. We can select the most suitable rubber components based on the type of liquid, such as NBR, FKM, or FFKM.

youtube

0 notes

Text

Nitrile Butadiene Rubber (NBR) Prices, News, Trend, Graph, Chart, Monitor and Forecast

Nitrile Butadiene Rubber (NBR) is a synthetic rubber made from the copolymerization of acrylonitrile and butadiene. This rubber type is known for its excellent resistance to oil, fuel, and other chemicals, making it highly valuable in various industries such as automotive, manufacturing, and healthcare. The NBR market has seen significant fluctuations in prices over the years, influenced by factors such as raw material costs, production capabilities, and demand from end-user industries. In recent years, the market has been impacted by global supply chain disruptions, shifts in demand, and changes in environmental regulations. Understanding the trends and dynamics of NBR prices is essential for businesses and stakeholders involved in the procurement, production, and supply of NBR-based products.

The price of NBR is primarily driven by the cost of its key raw materials, acrylonitrile, and butadiene. Acrylonitrile is derived from petroleum-based products, while butadiene is typically a byproduct of refining crude oil. As crude oil prices fluctuate, so do the prices of acrylonitrile and butadiene, directly impacting the production cost of NBR. A rise in global crude oil prices generally leads to an increase in the prices of these raw materials, resulting in higher NBR prices. Conversely, when crude oil prices decline, the cost of these key ingredients typically follows suit, causing NBR prices to decrease. The volatility in crude oil prices, influenced by geopolitical tensions, supply-demand imbalances, and natural disasters, creates a level of unpredictability in the NBR market.

Get Real time Prices for Nitrile Butadiene Rubber (NBR): https://www.chemanalyst.com/Pricing-data/nitrile-butadiene-rubber-71

The global supply and demand dynamics also play a significant role in NBR price fluctuations. The demand for NBR is closely tied to industries such as automotive, manufacturing, and healthcare, where it is used in products like seals, gaskets, fuel hoses, gloves, and medical devices. In the automotive industry, the growing demand for electric vehicles (EVs) and the increasing need for high-performance materials have led to a surge in demand for NBR. Additionally, in healthcare, the COVID-19 pandemic has further accelerated the demand for nitrile gloves, which use NBR as a primary material. As these industries experience growth, the demand for NBR increases, driving prices upward. However, during periods of economic slowdown or uncertainty, demand may decrease, leading to lower prices.

Another significant factor influencing NBR prices is the production capacity and geographical location of key manufacturers. NBR production is concentrated in regions such as Asia-Pacific, North America, and Europe, with key players such as Synthos, LG Chem, and Reliance Industries dominating the market. These manufacturers play a crucial role in determining the price trends, as any changes in production capabilities, such as plant expansions or closures, can disrupt the supply chain and cause price fluctuations. Additionally, logistical challenges, including transportation delays, port congestion, and labor shortages, can create supply bottlenecks, which may lead to short-term price hikes.

Environmental regulations and sustainability concerns are becoming increasingly important in the NBR market. Governments around the world are introducing stricter regulations regarding the production and disposal of synthetic rubbers, including NBR, to reduce environmental impact. Manufacturers are under pressure to adopt sustainable practices and explore alternatives, such as bio-based NBR or more efficient production processes, which can increase production costs. Additionally, there is a growing demand for eco-friendly and recyclable materials, which may lead to a shift in the types of materials used in NBR production. These regulatory and environmental factors can influence NBR prices, as companies invest in research and development to meet new standards.

The trade policies and tariffs imposed by different countries also affect NBR prices. Countries with high import duties or restrictive trade policies can drive up the cost of NBR imports, making it more expensive for businesses to source materials from international suppliers. Trade disputes or sanctions may further complicate the global supply chain, leading to price instability. On the other hand, trade agreements and favorable import-export policies can reduce costs and create more competitive pricing in the market. These factors can have a ripple effect on NBR prices, especially in countries that rely on imports for a significant portion of their NBR supply.

In addition to raw material costs, supply chain disruptions, and demand fluctuations, the exchange rate also plays a role in determining NBR prices. As NBR is traded globally, fluctuations in currency values can impact the cost of raw materials and finished products. For example, a strong US dollar may make NBR more expensive for buyers in other countries, while a weak dollar could make imports more affordable. Currency exchange rate fluctuations can add an additional layer of complexity to the pricing dynamics in the global NBR market.

Looking forward, the NBR market is expected to experience steady growth, driven by increased demand from industries such as automotive, healthcare, and manufacturing. However, challenges such as raw material price volatility, environmental regulations, and supply chain disruptions will continue to influence NBR pricing. Companies in the NBR industry must stay vigilant and adopt strategies to mitigate these risks, such as hedging against raw material price fluctuations or diversifying their supply sources. As the global economy recovers and technological advancements continue to shape the industry, the NBR market is likely to see new innovations and pricing models that could affect its future trajectory.

In conclusion, the Nitrile Butadiene Rubber market is highly sensitive to a range of factors, including raw material prices, supply chain dynamics, demand from key industries, environmental regulations, and trade policies. The volatility of crude oil prices, fluctuations in supply and demand, and changes in production capacity are some of the key drivers of NBR price fluctuations. As the market continues to evolve, businesses and stakeholders must monitor these factors closely to navigate price changes and ensure a steady supply of NBR for their applications. By staying informed about market trends and adjusting to emerging challenges, companies can better manage the costs associated with NBR and maintain a competitive edge in the marketplace.

Get Real time Prices for Nitrile Butadiene Rubber (NBR): https://www.chemanalyst.com/Pricing-data/nitrile-butadiene-rubber-71

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#NBR Price#NBR Prices#NBR Pricing#Nitrile Butadiene Rubber#Nitrile Butadiene Rubber Price#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Polymerized Styrene-Butadiene Rubber (SBR) Market Size, Demand & Supply, Regional and Competitive Analysis 2025–2032

Definition

Polymerized Styrene-Butadiene Rubber (SBR) is a synthetic rubber derived from the copolymerization of styrene and butadiene. Known for its excellent abrasion resistance, aging stability, and cost-effectiveness, SBR is widely used in the manufacture of tires, footwear, adhesives, and various rubber goods. It is a key material in the automotive and construction sectors due to its durability and flexibility.

There are different grades of SBR, including emulsion SBR (E-SBR) and solution SBR (S-SBR), with the latter offering enhanced performance characteristics such as better rolling resistance and wet grip in tires. The increasing focus on high-performance, fuel-efficient tires has significantly boosted the demand for SBR globally.

Market Size

📥 Download Sample Report PDF

As of 2024, the global Polymerized SBR market is valued at USD 4.68 billion and is projected to reach USD 6.31 billion by 2032, growing at a CAGR of 3.85% during the forecast period. The rising demand from the automotive industry, especially in tire manufacturing, continues to be a primary growth driver.

Growth Projections and Trends

The global SBR market is expected to witness consistent growth due to the rising demand for synthetic rubber in automotive tires, which account for the largest share of SBR consumption. Furthermore, the transition toward green and sustainable tires in Europe and Asia is promoting the use of solution SBR.

Key trends include:

Growth in electric vehicle (EV) production.

Increasing preference for high-performance tires.

Rising industrialization in Asia-Pacific.

Technological advancements in polymer modification for enhanced performance.

Market Dynamics (Drivers, Restraints, Opportunities, Challenges)

Drivers

Rising Automotive Production: Automotive manufacturing, especially in Asia-Pacific, continues to be a key driver, as SBR is essential in tire manufacturing.

Cost-Effectiveness: Compared to natural rubber and other synthetic types, SBR offers a more economical solution with acceptable performance.

Performance Enhancement in Tires: S-SBR provides enhanced grip, fuel efficiency, and safety, making it increasingly popular in premium tire segments.

Restraints

Fluctuation in Raw Material Prices: The volatility of crude oil prices significantly impacts the cost structure of SBR.

Environmental Concerns: Traditional production processes for SBR emit pollutants, prompting scrutiny and stricter environmental regulations.

Opportunities

Sustainable and Green Tire Technologies: The growing demand for eco-friendly products creates new markets for advanced SBR formulations.

Expansion in Emerging Markets: Industrial growth and rising consumer demand in Latin America, Southeast Asia, and the Middle East present expansion opportunities.

Challenges

Competition from Natural Rubber and Alternatives: Natural rubber and thermoplastic elastomers pose substitution threats in some applications.

Stringent Regulatory Frameworks: Increasing environmental and safety standards require continuous innovation and investment in cleaner production technologies.

Regional Analysis

North America

The SBR market in North America is driven by demand in the automotive replacement tire sector and by ongoing construction activity. The U.S. dominates the regional market due to its mature automobile and industrial sectors.

Europe

Europe is focusing on high-performance, low-emission tires. Stringent environmental regulations are prompting a shift from E-SBR to S-SBR. Germany, France, and Italy are key consumers.

Asia-Pacific

Asia-Pacific is the largest and fastest-growing market for SBR, with China, India, and Japan being the main contributors. This region benefits from large-scale automotive manufacturing and favorable industrial policies.

Latin America

Countries like Brazil and Mexico are experiencing growth in vehicle production and infrastructure, supporting the demand for SBR in tires and industrial applications.

Middle East & Africa

Growth is modest but steady in this region, driven by expanding construction activities and increasing investments in industrial development.

Competitor Analysis

Key players in the global Polymerized SBR market include:

Lanxess AG – A leading supplier of synthetic rubbers, including SBR for high-performance applications.

Trinseo – Specializes in emulsion and solution SBR for tire and technical rubber goods.

JSR Corporation – A pioneer in solution polymerization technologies used in green tire production.

Sinopec – A major producer in China, serving domestic and global markets.

Goodyear Chemical – Offers a wide range of SBR grades tailored for automotive and industrial use.

These companies focus on product innovation, capacity expansion, and strategic partnerships to strengthen their market presence and respond to environmental concerns.

Market Segmentation

By Type

Emulsion SBR (E-SBR)

Solution SBR (S-SBR)

By Application

Tires

Footwear

Adhesives & Sealants

Industrial Rubber Goods

Others

By Geography

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

FAQs

1. What is the current market size of the Polymerized SBR market? The global market size is estimated at USD 4.68 billion in 2024 and is projected to reach USD 6.31 billion by 2032.

2. Which companies are the major players in the Polymerized SBR market? Major players include Lanxess AG, Trinseo, JSR Corporation, Sinopec, and Goodyear Chemical.

3. What are the key factors driving the growth of the SBR market? Growth is driven by rising automotive production, increasing demand for high-performance tires, and cost-effectiveness of SBR.

4. Which region is expected to lead the SBR market? Asia-Pacific dominates the market due to large-scale automotive and industrial activities.

5. What are the emerging trends in the SBR market? Key trends include the shift toward green tires, adoption of solution SBR, and sustainability in rubber production.

📘 Get The Complete Report & TOC: https://www.24chemicalresearch.com/reports/292628/global-polymerized-styrenebutadiene-rubber-market-2025-2032-66

📥 Download a Free Sample Report PDF: https://www.24chemicalresearch.com/download-sample/292628/global-polymerized-styrenebutadiene-rubber-market-2025-2032-66

CONTACT US: 203A, City Vista, Fountain Road, Kharadi, Pune, India - 411014 International: +1(332) 2424 294 Asia: +91 9169162030

Follow Us On LinkedIn: https://www.linkedin.com/company/24chemicalresearch/

About 24Chemical Research: Founded in 2015, 24ChemicalResearch has become a trusted source for detailed and insightful chemical industry market reports. Our data-driven insights help global clients, including over 30 Fortune 500 companies, achieve measurable business growth.

0 notes