#Custom PCB Design Solutions

Explore tagged Tumblr posts

Text

PCB Designing Company in Gujarat

Innovative PCB solutions in Gujarat! Leading design company, expert in precision layouts for optimal performance. Elevate your electronics with us.Get more info and contact details in India.

#PCB Designing Company#Printed Circuit Board Design Services#PCB Layout Experts#Electronic Design and Manufacturing#Custom PCB Design Solutions#High-Quality PCB Prototyping#Gujarat PCB Fabrication

0 notes

Text

latest Freddie DeBoer seems odd. It's very focused on a sort of consumer-facing understanding of technology for a lot of its runtime. He's not wrong that the changes are smaller than they were in the 1800's but like. That's the low hanging fruit, we all know this, the jump from "not having trains" to "having trains" beats almost any improvement in "trains"

A major change technology has brought to the modern world imo is heavily streamlined manufacturing all across the industrial stack.

If you read like, Bunie Huang's Made in China blog series, in the early 2000's getting a piece of technology made required enormous in-person investment of time and effort working with your manufacturing teams across a pretty broad number of suppliers and industries, you had to get PCB's made, components sourced, moulds designed and set up for injection.

I know people manufacturing small to medium run commercial and industrial electronics, and I did that at my last job. You order machine populated PCB's from your favourite Chinese PCB solutions provider over a web form. If you need ten thousand buttons, you can get that delivered with three emails. Hell, if you want a custom genome to use for some experimental bioreactor, there's multiple competing suppliers who will mail you plasmids that you can customise from online templates and you don't even have to talk to anyone.

And that's just mass manufacturing. If you're making a few thousand of some high end medical equipment, or still in the development phase of design, you can order a titanium laser print to be delivered by the end of the week, or run off a dozen prototypes on your company's fleet of printers using body safe plastics.

Consumer needs don't change much because people are people, we have limited capacity to need things and do things. I've long said that no human can digest more than 50Mbps of media in real time, really. One home cook can only economise their movements so much. A food processor and a pressure cooker can save you some time but the solution to"I want to spend less time cooking at home" will eventually become "don't cook at home, lean on industrial manufacturing of food" and that's fine. There's only so much tech can improve your individual experience before you become the bottleneck.

Faster computers sure, means you can edit video on your phone a little quicker (also hey people ARE editing video on their phone, despite what this blog post says) but it also means Netflix can serve their 4 Petabytes of video library at 400+Gbps from a single server occupying less than 50 liters of space.

It seems disingenuous to act like consumer products feeling stagnant means technology is stagnant.

21 notes

·

View notes

Text

PCB Manufacturing-PCB Assembly-Hitech Circuits

Hitech Circuits is a lеаding PCB Manufacturing & PCB Assembly company with more than 20 years experience in the electronics manufacturing industry. We focus on PCB Design, PCB Layout, Circuit board fabrication, Turnkey PCB assembly, and electronic parts sourcing services.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

We offer a full range of Electronic manufacturing services.

-LED PCB

-Heavy Copper PCB

-Multilayer PCB

-HDI PCB

-Flexible PCB

-Rigid-Flex PCB

-High Speed PCB

-High Frequency PCB

-PCB Reverse Engineering

7 notes

·

View notes

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

2 notes

·

View notes

Text

One-stop PCB assembly service and PCB manufacturing supplier -- Hitechpcba

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

4 notes

·

View notes

Text

Avalon Technologies Limited Is a Top EMS Industries In India

We Provide Services and Solutions Like:

Design

Engineering

NPI

Volume Production

Life Cycle Management

System Integration

PCB Assembly

Cable & Wire Harness

Sheet Metal

Aerospace Metal

Machining

Magnetics

Plastics

Supply Chain & Logistics

2 notes

·

View notes

Text

Wet Scrubber System Manufacturers – Trusted Solutions by Essar Air Systems

Looking for reliable Wet Scrubber System Manufacturers in India? Essar Air Systems stands at the forefront of innovation, offering high-performance air pollution control solutions tailored for diverse industries. With decades of engineering excellence, we specialize in designing and manufacturing robust wet scrubber systems that meet the most stringent environmental standards.

What Is a Wet Scrubber System?

A wet scrubber system is an advanced air pollution control device that removes harmful gases, vapors, and particulates from industrial exhaust streams. It uses a liquid (usually water or a chemical solution) to absorb or neutralize pollutants, making it an ideal choice for industries with high-temperature, corrosive, or dusty emissions.

Why Choose Essar Air Systems for Wet Scrubber Solutions?

At Essar Air Systems, we combine deep technical expertise with a commitment to sustainability and innovation. Here’s why we are among the most trusted wet scrubber system manufacturers in India:

✔ Custom-Engineered Systems

Every industry has unique needs. We design custom wet scrubber systems to suit your specific emission profile, whether it's chemical, pharmaceutical, food processing, steel, or power generation.

✔ Superior Build Quality

Our systems are built using high-grade materials resistant to corrosion, abrasion, and high temperatures—ensuring long service life and low maintenance costs.

✔ High Removal Efficiency

Essar's wet scrubbers offer over 99% efficiency in removing particulate matter, acid gases (like SO₂ and HCl), and odors, helping clients meet environmental regulations with confidence.

✔ Expert Technical Support

From design to commissioning and after-sales service, our expert team ensures seamless support and performance optimization throughout the product lifecycle.

Applications of Our Wet Scrubber Systems

Essar Air Systems provides wet scrubbers for a wide range of industrial applications:

Chemical Manufacturing

Steel and Metallurgy

Pharmaceuticals

Food and Beverage

Pulp and Paper

Fertilizer Plants

Waste Incineration Units

Whether you're dealing with acid mist, volatile organic compounds (VOCs), or dust-laden gases, our wet scrubber systems deliver clean air performance you can trust.

Types of Wet Scrubbers We Manufacture

We offer various types of wet scrubber systems to suit different industrial processes:

Venturi Scrubbers �� Ideal for high-efficiency particulate removal

Packed Bed Scrubbers – Best for gas absorption and chemical neutralization

Spray Tower Scrubbers – Simple and effective for odor and gas removal

Cyclonic Scrubbers – Combines centrifugal force and water scrubbing

Each system is engineered with precision and tested for efficiency and durability before delivery.

Sustainability & Compliance

At Essar Air Systems, we prioritize environmental sustainability. Our wet scrubbers not only reduce emissions but also help companies comply with CPCB/PCB air quality standards, thus avoiding penalties and enhancing environmental credentials.

Partner With One of India’s Leading Wet Scrubber Manufacturers

With a strong reputation built over years of service, Essar Air Systems continues to lead the way in air pollution control solutions. Our commitment to quality, customization, and client satisfaction makes us a preferred partner across India and beyond.

Get in Touch

Ready to upgrade your emission control system? Contact Essar Air Systems, your trusted wet scrubber system manufacturer, for a customized, efficient, and eco-friendly solution.

0 notes

Text

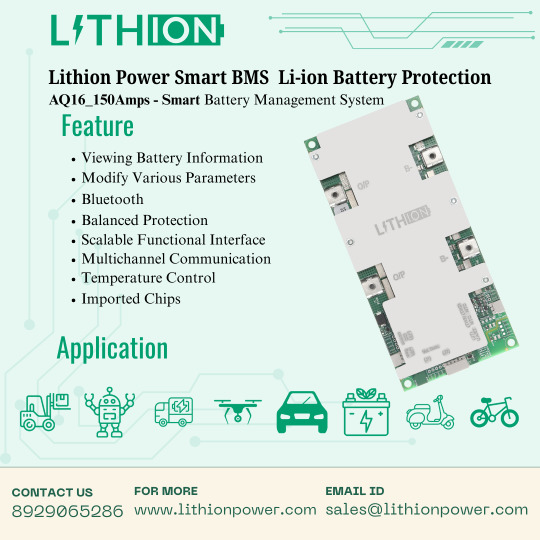

AQ16 150A Smart Battery Management System – Advanced Protection & Monitoring

As the demand for powerful lithium battery packs rises—driven by electric vehicles, solar storage, and industrial backup systems—reliable battery management becomes critical. Enter the AQ16 150A Smart Battery Management System (BMS): a high-current, intelligent protection board built to handle demanding applications with precision and safety. Whether you're designing a high-capacity Li-ion or LiFePO₄ battery bank, this BMS delivers performance you can trust.

⚡ What Makes a BMS “Smart”?

A traditional BMS protects battery cells from overcharging, over-discharging, short circuits, and thermal issues. But a smart BMS takes it a step further—it offers:

Real-time monitoring

Bluetooth/RS485 communication

Mobile app support

Configurable settings for voltage, current, and temperature thresholds

Data logging and error reporting

The AQ16 150A includes all this and more, making it one of the most advanced options for 16S battery packs.

🔧 Key Features of the AQ16 150A Smart BMS

🔋 Supports 16S Battery Packs

Designed for 16 cells in series, this BMS is compatible with both Lithium-ion and LiFePO₄ chemistries—commonly used in 48V battery configurations.

💪 150A Continuous Discharge

With a current handling capacity of up to 150 amps, the AQ16 is ideal for high-power applications like:

Electric cars, bikes, and scooters

Inverters and solar energy systems

Off-grid and backup battery banks

Industrial automation systems

📶 Bluetooth & UART/RS485 Communication

Monitor the health of your battery system remotely through a smartphone app or integrated display (depending on configuration). Real-time data includes:

Cell voltages

Pack voltage

Charge/discharge current

State of charge (SOC)

Temperature readings

Active protections or warnings

🧠 Intelligent Protection Suite

The BMS is equipped with advanced safety protocols, including:

Overcharge and under-voltage protection

Overcurrent and short-circuit protection

High and low-temperature cut-off

Passive cell balancing to maintain voltage consistency across all cells

🔌 Configurable Parameters

Users can adjust voltage thresholds, current limits, and balance activation settings via the app or software, allowing full control over how the BMS behaves under specific conditions.

🛠 Installation & Use Cases

Installing the AQ16 150A is straightforward, especially with support for plug-and-play communication modules. It's best suited for:

🛻 Electric Vehicles (EVs) – Capable of handling fast acceleration currents

☀️ Solar Storage Systems – Ensures safety and longevity in high-capacity packs

🔋 Energy Backup Units – Reliable performance for critical applications

🛠 DIY Powerwalls and Custom Battery Packs – Ideal for makers and pros alike

✅ Why Choose AQ16 150A?

When you're dealing with high current and sensitive lithium cells, you can't afford poor-quality components. The AQ16 series is designed with:

Industrial-grade MOSFETs

Multi-layer PCBs for better heat dissipation

Secure firmware with update support

Compatibility with major battery monitoring apps

In short, this BMS offers industrial-grade protection with consumer-level ease of use.

🔚 Final Thoughts

The AQ16 150A Smart Battery Management System is a powerhouse solution for anyone building or managing large lithium battery packs. With robust protection, smart monitoring, and flexible communication options, it ensures your battery system runs safely and efficiently—even under high load.

If you’re serious about safety and performance in your battery-powered project, this BMS deserves a place at the core of your system.

#bms#battery management system#lithion#lithium battery#lithion power#batterymanagementsystem#electricvehicle#ev#lithionpower

0 notes

Text

Exact Solution Electronics: Your Trusted Partner for Precision Electronic Components

In today’s fast-paced technological landscape, finding the exact electronic components you need can be a challenge. Whether you're an engineer, a tech enthusiast, or a business sourcing high-quality parts, Exact Solution Electronics delivers unmatched precision, reliability, and performance. Our commitment to providing the exact solutions for every electronic need has made us a leader in the industry.

This comprehensive guide explores why Exact Solution Electronics stands out, the range of products and services we offer, and how we ensure you always get the exact match for your requirements.

Why Precision Matters in Electronics

Electronics is a field where even the smallest deviation can lead to significant performance issues. A resistor with the wrong tolerance, a capacitor with incorrect capacitance, or a microchip that doesn’t meet specifications can cause system failures. That’s why Exact Solution Electronics focuses on delivering the exact components every time.

Key Benefits of Choosing Exact Solution Electronics

Unmatched Accuracy – We source and supply components that meet stringent industry standards, ensuring you get the exact specifications required.

Extensive Inventory – From common resistors and capacitors to rare integrated circuits, our catalog covers a vast range of electronic parts.

Technical Expertise – Our team of engineers and specialists provides expert guidance to help you find the exact solution for your project.

Global Reliability – Whether you're a local business or an international enterprise, we ensure timely delivery and consistent quality.

Our Product Range: Finding the exact Match for Your Needs

At Exact Solution Electronics, we understand that every project has unique demands. Our product lineup is designed to cater to diverse industries, including:

1. Industrial Electronics

Manufacturing and automation require durable, high-performance components. We supply:

Precision sensors for accurate measurements

Robust circuit boards designed for harsh environments

Power management systems that ensure efficiency

2. Consumer Electronics

From smart home devices to wearable tech, our components power the gadgets of tomorrow. We offer:

High-efficiency microcontrollers

Advanced display modules

Energy-saving power circuits

3. Automotive Electronics

Modern vehicles rely on sophisticated electronics. Our solutions include:

Engine control modules (ECMs)

Advanced driver-assistance systems (ADAS) components

Reliable wiring harnesses

4. Telecommunications & Networking

With the rise of 5G and IoT, connectivity demands precision. We provide:

High-frequency RF components

Signal processing chips

Low-latency networking hardware

How Exact Solution Electronics Ensures Quality

Rigorous Testing & Certification

Every component undergoes strict quality checks to ensure it meets the exact industry standards. We partner with certified manufacturers and conduct:

Electrical performance testing

Environmental stress testing

Longevity and durability assessments

Custom Solutions for Unique Requirements

Sometimes, off-the-shelf parts aren’t enough. Our engineering team can:

Modify existing components to fit specialized needs

Develop custom PCB designs

Source rare or obsolete parts through our global network

Fast & Reliable Sourcing

Finding the exact part shouldn’t take weeks. Our streamlined supply chain ensures:

Quick order processing

Real-time inventory updates

Worldwide shipping options

The Future of Electronics with Exact Solution Electronics

Technology evolves rapidly, and so do the demands for precision components. Exact Solution Electronics stays ahead by:

Embracing Emerging Technologies

AI & Machine Learning Components – Supporting next-gen automation

Green Energy Solutions – Efficient power modules for sustainable tech

Quantum Computing Hardware – Preparing for the next revolution in computing

Commitment to Innovation & Sustainability

We continuously invest in:

Eco-friendly manufacturing processes

Recycling programs for electronic waste

Energy-efficient product designs

Why Businesses Trust Exact Solution Electronics

Case Study: A Leading Automotive Manufacturer

A global car manufacturer needed a custom engine control module that could withstand extreme temperatures. Our team:

Designed a specialized PCB with enhanced thermal resistance

Conducted rigorous stress testing

Delivered a solution that improved vehicle performance by 20%

Customer Testimonials

"Exact Solution Electronics provided the exact components we needed, with zero defects. Their technical support was exceptional." – Lead Engineer, Tech Innovations Inc.

"We’ve been sourcing from them for years. Their reliability is unmatched." – Procurement Manager, Global Electronics Corp.

How to Get Started with Exact Solution Electronics

Step 1: Define Your Requirements

List the exact specifications (voltage, current, tolerance, etc.)

Determine quantity and lead time

Step 2: Browse or Consult Our Experts

Search our online catalog for standard parts

Contact our support team for custom solutions

Step 3: Place Your Order with Confidence

Fast checkout & secure payment

Real-time order tracking

Conclusion: Your exact Electronics Partner

When precision matters, Exact Solution Electronics is the name you can trust. From standard components to custom-engineered solutions, we ensure you get the exact quality, performance, and reliability you need.

Explore our catalog today and experience the difference!

0 notes

Text

Aimtron: Your Reliable Partner for PCB Assembly Manufacturing Services in Illinois

In the fast-paced world of electronics manufacturing, having a trusted partner for PCB assembly services can make all the difference. That’s where Aimtron Corporation stands out. Located in the heart of Illinois, Aimtron has established itself as a leader in providing end-to-end PCB assembly and electronics manufacturing services to clients across a wide range of industries—from aerospace and defense to healthcare, industrial automation, and consumer electronics.

Why Choose Aimtron?

1. Comprehensive PCB Assembly Services

Aimtron offers a full spectrum of PCB assembly services including:

Surface Mount Technology (SMT)

Through-Hole Assembly

Turnkey PCB Assembly

BGA and Micro-BGA Assembly

Prototyping to Full-Scale Production

Whether you need a quick-turn prototype or high-volume production, Aimtron has the technology and expertise to deliver consistent quality.

2. State-of-the-Art Manufacturing Facility

At Aimtron’s Illinois facility, quality is more than a promise—it’s a standard. Equipped with cutting-edge SMT lines, automated optical inspection (AOI), X-ray inspection for BGAs, and in-circuit testing, Aimtron ensures every board meets the highest quality benchmarks.

3. Engineering Excellence

Aimtron doesn’t just assemble PCBs; it partners with clients from concept to production. Their team of skilled engineers provides:

Design for Manufacturability (DFM)

Design for Testability (DFT)

Component sourcing and BOM optimization

Technical support and value engineering

This collaborative approach reduces lead times, lowers costs, and enhances product reliability.

4. Commitment to Quality and Compliance

Aimtron is ISO 9001 and ISO 13485 certified, ITAR registered, and RoHS compliant, ensuring adherence to global quality and regulatory standards. Their robust quality management system supports continuous improvement and customer satisfaction.

5. Customer-Centric Approach

Aimtron believes in building long-term partnerships. Their customer-first philosophy translates into responsive communication, transparent pricing, and a flexible manufacturing model that adapts to changing project needs.

Serving Illinois and Beyond

While Aimtron proudly operates from Illinois, its reputation for reliability and precision extends far beyond state lines. Clients across the U.S. and internationally trust Aimtron for mission-critical electronics manufacturing solutions delivered on time and within budget.

Industries Served

Medical Devices

Aerospace & Defense

Automotive

Industrial Control

Consumer Electronics

IoT & Smart Devices

Let’s Build the Future Together

At Aimtron, innovation meets execution. With a perfect blend of technology, talent, and tenacity, Aimtron is not just a PCB assembly vendor—it’s your strategic partner in bringing great ideas to life.

Looking for a dependable PCB assembly manufacturer in Illinois? Partner with Aimtron and experience quality, reliability, and excellence every step of the way.

#ElectronicsManufacturing#PCBAssemblyServices#DesignforTestability#DesignforManufacturability#PCBassemblymanufacturerinIllinois#SurfaceMountTechnology#Through-HoleAssembly

0 notes

Text

Explore the High-Performance KIA SIP KIA6299H – A Reliable Audio Power Amplifier

When it comes to dependable audio amplification solutions, the KIA SIP KIA6299H stands out as a trusted choice among professionals and electronics enthusiasts alike. Offered in a convenient lot of 2 on Nikkoe.com, this integrated circuit is designed to deliver strong and clear audio signals, making it ideal for a variety of sound-related applications.

What is the KIA SIP KIA6299H?

The KIA6299H is a Single In-line Package (SIP) audio power amplifier developed by KEC. SIP modules like the KIA SIP are known for their compact form factor and efficient pin layout, making them easy to install on PCBs with limited space. The KIA6299H is specifically designed for use in stereo audio amplification, offering high output power with minimal external components.

This IC supports dual-channel output and is commonly used in stereo systems, radios, televisions, and small audio systems. With its built-in thermal shutdown and overvoltage protection, the KIA SIP provides enhanced durability and long-term reliability in electronic circuits.

Key Features of the KIA SIP KIA6299H

Dual Channel Audio Output – Supports stereo output with clear, powerful sound.

Compact SIP Design – The single in-line package allows for easy PCB integration.

Built-in Protections – Includes overvoltage, short circuit, and thermal shutdown features.

High Efficiency – Delivers high output with low distortion and minimal heat generation.

Low Component Requirement – Simplifies circuit design and assembly.

Why Choose the KIA SIP from Nikkoe.com?

When sourcing electronic components, quality and authenticity matter. Nikkoe.com offers a genuine KIA SIP KIA6299H IC in a lot of 2, ensuring you get not only a great price but also reliable performance. Whether you're repairing existing audio systems or designing new ones, this IC provides the trusted performance that engineers have relied on for years.

Additionally, Nikkoe.com offers fast shipping, competitive pricing, and excellent customer service. Buying from a reputable supplier reduces the risk of counterfeit components and ensures your project meets both functional and safety standards.

Applications of the KIA6299H SIP

Thanks to its robust design and efficient performance, the KIA SIP is used in:

Home stereo systems

Portable audio equipment

Television audio output stages

DIY audio amplifier projects

Educational electronics kits

Final Thoughts

If you’re looking for a compact, durable, and efficient audio amplifier IC, the KIA SIP KIA6299H is a top-tier choice. With features that support high-quality audio performance and protection mechanisms for longevity, this IC is perfect for any audio project.

Order your KIA SIP today from Nikkoe.com and experience quality electronics backed by expert service.

0 notes

Text

How Custom Electronic Product Design & Development Services Revolutionize Consumer Electronics Projects

The Growing Demand for Customized Consumer Electronics

Why Off-the-Shelf Solutions Fall Short in Modern Markets

The consumer electronics sector is advancing swiftly. Users now crave more tailored and robust devices. Off-the-shelf options frequently disappoint in meeting these desires. They often lack personalization, brand uniqueness, and flexibility for new advancements. Many companies find it tough to carve out a distinct presence in a crowded market. This happens because standard parts create uniformity across items. Moreover, pre-made electronics might not address specific operational needs. As a result, this leads to weaker user satisfaction and stifled creativity.

How Custom Electronic Design Addresses Unique Consumer Needs

Custom electronic design and product development allow firms to craft gadgets suited to precise market wants. This applies to specialized fields like wearable health tools or smart home systems. A bespoke method ensures devices blend cutting-edge innovations while fulfilling visual and practical demands. With features like IoT linkage, AI-powered controls, and refined downsizing, electronic product design projects are molding the future of consumer electronics. By teaming up with a consumer electronic design company, businesses tap into expert design services for electronic products. This keeps them ahead of emerging trends.

The Role of Electronic Design and Product Development in Innovation

From Concept to Reality: Key Stages of Custom Product Development

The path from an idea to a market-ready gadget involves several steps. It starts with brainstorming and possibility checks. Here, engineers evaluate technical needs and market potential. Once the concept gains approval, designers shift to circuit planning and model-building. Prototyping enables testing of electronic parts and spotting design issues early. After passing tests, the item moves to production. At this stage, injection molding electronics methods ensure top-notch output. Finally, growth factors are tackled to smooth out mass creation and supply flow.

Integrating Plastic Injection Molding for Enhanced Product Performance

Plastic injection molding for electronics is vital for item strength, appeal, and affordability. Many consumer electronics plastic parts, like phone shells and smart gadget cases, depend on exact molding. Using an electronic components mold ensures circuit boards and delicate hardware stay safe from outside harm. Additionally, advanced substances like fire-resistant plastics boost safety. This is especially true in high-heat uses. Injection molding electronics techniques offer budget-friendly answers for both limited and vast production runs.

Optimizing Consumer Electronics with Advanced Electronic Design

PCB Design and Miniaturization for Portable Electronics

Today’s consumer electronics value mobility and power savings. Small PCB layouts, with layered circuits and tiny controllers, are crucial for items like smartwatches, fitness bands, and wireless earphones. Electronic product design and manufacturing aim to cut energy use without hurting performance. Engineers use clever arrangement tactics to ensure smooth connections, low disruption, and better heat release. This results in more dependable and efficient portable electronics product design and development.

Material Selection: Balancing Aesthetics and Functionality

Picking the right substances is key in consumer electronics product development and design. Tough plastics like ABS, polycarbonate (PC), and medical-grade silicone lead to comfortable and sturdy items. ABS brings durability and cost savings, while PC offers clarity and heat resistance. This makes PC perfect for gadgets with LED screens. Medical-grade silicone suits wearables needing skin-friendly and bendable materials. A carefully planned material choice lifts both user enjoyment and rule compliance.

Plastic Injection Molding: A Game-Changer for Consumer Electronics

High-Precision Molds for Complex Electronic Components

The accuracy needed in electronic product development and design calls for highly precise molds. Advanced mold-making tech ensures parts hit tolerances as fine as 0.01mm. Such precision is critical for tiny electronics, where fit and alignment affect gadget performance. Plastic molding for electronics allows mass creation of intricate pieces without losing uniformity. Consumer electronics plastic parts made via injection molding electronics processes serve fields from healthcare tools to IoT uses.

Cleanroom Manufacturing for Medical and High-Standard Electronics

For medical wearables and top-tier electronics, cleanroom production is essential. Electronic components mold creation in controlled spaces ensures parts stay free of dirt and are finely crafted. Many consumer electronics design and manufacturers follow ISO 13485 rules. This ensures compliance with medical and safety norms. From UV cleaners to diagnostic gear, injection molding electronics processes uphold strict cleanliness and dependability standards.

Overcoming Challenges in Electronic Product Development

Ensuring Scalability Without Compromising Quality

Scaling production while keeping quality high is a big hurdle in electronic product development. Quick prototyping, mold refinement, and automated assembly lines boost manufacturing speed. Consumer electronic design companies use DFM (Design for Manufacturability) plans to cut production costs while maintaining excellent results. Plus, electronics plastic injection molding solutions help keep consistency across large batches.

Navigating Regulatory Compliance in Global Markets

Meeting global rules is vital for consumer electronics hitting worldwide markets. Items must earn marks like CE, FCC, and RoHS to ensure safety and eco-friendliness. Consumer electronics design and manufacturers team up with rule-making groups. They ensure materials, electrical safety, and signal compatibility meet global benchmarks. Clear records and strict testing steps ensure smooth market access.

Case Studies: Transformative Outcomes of Custom Design

Wearable Health Devices: Merging Electronics with Ergonomic Design

A top healthcare firm worked with a consumer electronic design company to build a wearable ECG tracker. By adding custom sensors and medical-grade plastics, the device gained top comfort, precision, and rule compliance. This effort showed how custom electronic product design can transform patient care with user-friendly innovation.

Smart Home Gadgets: Seamless Integration of Electronics and Injection-Molded Housings

A smart home brand turned to electronic design and product development services for a voice-activated device. Using plastic injection molding for electronics, they created a heat-proof, fire-safe casing. The end result blended toughness and utility perfectly. It set new standards in smart home creativity.

Partnering with the Right Consumer Electronics Design Company

Key Criteria for Selecting a Design and Manufacturing Partner

Choosing the best partner in electronic product design and manufacturing is critical for project wins. A solid firm should offer full-cycle development, from prototyping to part sourcing and assembly. Skills in injection molding electronics and strong supply links ensure speed and savings. Open communication and sticking to global compliance rules further improve the process.

Silkbridge: Your Partner in Custom Electronic Design and Assembly

Silkbridge Electronic Technology is a top consumer electronics design company excelling in full product creation. With know-how in plastic injection molding for electronics and advanced PCB design, Silkbridge delivers high-quality, scalable answers. Their ISO 13485-certified cleanrooms and precise mold-making skills ensure top production levels for wearables, IoT gadgets, and smart electronics. As a trusted name in electronic product design and development, Silkbridge helps brands turn fresh ideas into market-ready hits efficiently.

FAQs About Custom Electronic Product Development

How does custom electronic product design reduce time-to-market for consumer gadgets?

By speeding up prototyping, using fast PCB creation, and refining design for manufacturability, custom electronic product design cuts production timelines and delays.

What role does plastic injection molding play in cost-effective electronics manufacturing?

Plastic injection molding allows mass creation of tough, precise electronic casings at lower costs. It ensures uniformity and design flexibility.

Can custom design services accommodate small-batch production for niche markets?

Yes, adaptable manufacturing and quick prototyping enable efficient small-batch runs for specialized consumer electronics.

How are medical-grade plastics integrated into wearable electronics?

Medical-grade plastics ensure skin safety, toughness, and health rule compliance. They’re ideal for smart medical gadgets.

What certifications should a consumer electronics design company hold for global sales?

Key marks include CE, FCC, ISO 9001, and ISO 13485 for quality, safety, and rule compliance across markets.

How do you ensure quality control in electronic assembly and molding processes?

Thorough testing, automated checks, and sticking to industry norms maintain precision and reliability in production.

Ready to lift your next consumer electronics project? Contact Silkbridge today for a free consultation at [email protected] or reach out via WhatsApp: https://wa.me/8618122838771. Let’s bring your electronic innovations to life!

0 notes

Text

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

4 notes

·

View notes

Text

High-Performance Thermally Conductive Adhesives – First Seal India

As electronics and industrial systems grow more compact and powerful, efficient heat dissipation becomes critical. One essential solution in thermal management is the use of thermally conductive adhesives. First Seal India stands out as a trusted supplier in India, delivering high-performance thermal adhesive solutions that offer both strong mechanical bonding and superior heat transfer capabilities.

What Are Thermally Conductive Adhesives?

Thermally conductive adhesives are specially formulated compounds designed to bond components while facilitating the transfer of heat away from sensitive electronics or mechanical parts. They are commonly used in LED lighting, power electronics, automotive systems, and heat sinks.

Why Choose First Seal India?

At First Seal India, we understand the balance between thermal conductivity, structural strength, and electrical insulation. Our thermally conductive adhesives are manufactured to meet the needs of cutting-edge industries requiring precise heat management and long-term reliability.

Key Product Features:

High Thermal Conductivity: Efficient heat dissipation (typically 1.0 – 6.0 W/mK)

Excellent Bond Strength: Long-lasting adhesion to metals, ceramics, and plastics

Dielectric Properties: Safe for use around sensitive electronic circuits

Chemical and Moisture Resistance: Performs in harsh environmental conditions

Customization Options: Available in one-part or two-part formulations (epoxy, silicone)

Applications:

Our thermally conductive adhesives are used in:

Heat sinks and power modules

Battery packs and EV components

LED assemblies and PCB bonding

Consumer electronics and telecom equipment

Industrial automation and HVAC units

Trusted by Engineers, Preferred by Industries

Backed by years of expertise in sealing, bonding, and adhesive technologies, First Seal India provides solutions that combine performance, durability, and application ease. We also offer technical support and formulation customization based on your industry requirements.

Explore our full range of adhesive and thermal management products at: 👉 https://firstsealindia.com/

0 notes

Text

ASC: The Ultimate Destination for High-Performance Digital PCB and PCB Digital Solutions

In the digital age, the backbone of every advanced electronic device is a reliable and efficient digital PCB. At American Standard Circuits (ASC), we specialize in delivering world-class PCB digital solutions that cater to the needs of innovators across a spectrum of industries. From aerospace and automotive to medical, telecommunications, and green energy, ASC’s commitment to quality, speed, and technical expertise makes us the preferred partner for digital PCB manufacturing and design.

Unmatched Expertise in Digital PCB Manufacturing

ASC’s reputation as a leader in digital PCB manufacturing is built on decades of experience, state-of-the-art facilities, and a relentless pursuit of innovation. We offer a comprehensive range of PCB digital services, from the simplest single-sided boards to intricate multilayer and HDI (high-density interconnect) designs. Our advanced capabilities allow us to support even the most complex digital PCB requirements, ensuring your products are equipped for maximum performance and reliability.

Our digital PCB manufacturing capabilities include:

Multilayer and HDI digital PCB fabrication: Up to 40+ layers for sophisticated electronic systems.

Controlled impedance and high-speed signal management: Critical for data-intensive and high-frequency digital applications.

Blind, buried, and microvias: Enabling compact, space-saving PCB digital layouts.

Conductive and non-conductive via filling: Supporting advanced circuit design and reliability.

Edge plating, castellations, and custom finishes: For specialized connectivity and enhanced durability.

Lead-free and RoHS-compliant processes: Meeting global environmental and safety standards.

We partner with top-tier material suppliers such as Isola, Nelco, Panasonic, Shengyi, and Taconic, ensuring every digital PCB we produce meets the highest industry standards.

Rapid Turnaround and Certified Quality

At ASC, we understand that speed is essential in bringing your innovations to market. That’s why we offer quick-turn digital PCB services, with some projects completed in as little as 24 hours. Our robust quality assurance program is backed by Class III and MIL certifications, making us a trusted supplier for mission-critical applications where failure is not an option.

Every PCB digital solution undergoes rigorous inspection and testing, guaranteeing reliability, performance, and consistency. Our commitment to quality means you can trust ASC to deliver digital PCBs that exceed your expectations.

End-to-End Support and Engineering Excellence

From initial concept to final delivery, ASC’s team of digital PCB experts is dedicated to your success. We provide comprehensive engineering support, including design-for-manufacturability (DFM) reviews, material selection guidance, and rapid prototyping. Our responsive customer service ensures that most technical questions are answered immediately, helping you avoid costly delays and keep your project on track.

Serving a Wide Range of Industries

ASC’s digital PCB and PCB digital solutions are integral to the success of companies in:

Aerospace & Defense: Certified, rugged digital PCBs for high-reliability environments.

Automotive: Advanced PCB digital systems for next-generation vehicles.

Medical: Precision digital PCBs for diagnostic, imaging, and monitoring equipment.

Telecommunications: High-frequency, high-speed digital PCB solutions for modern networks.

Industrial & Green Energy: Durable and efficient digital PCBs for automation and sustainable energy systems.

Choose ASC for Your Digital PCB Needs

When you choose ASC, you’re partnering with a leader in digital PCB and PCB digital innovation. Our advanced manufacturing capabilities, certified processes, and experienced team ensure your digital PCB projects are completed on time, within budget, and to your exact specifications.

0 notes