#DC Solar Cables

Explore tagged Tumblr posts

Text

Best DC solar cable manufacturers in India by Radicon Wire

Radicon Wire is a reputable name among DC solar cable manufacturers in India. With a commitment to quality and innovation, Radicon Wire produces top-notch DC solar cables that meet international standards. Their cutting-edge manufacturing processes ensure reliable and efficient cables for solar power applications. As a trusted player in the industry, Radicon Wire's DC solar cables are designed to withstand diverse weather conditions and deliver optimal performance, making them a preferred choice for solar projects across India. Choose Radicon Wire for your DC solar cable needs and experience the difference in quality and durability.

0 notes

Text

Reliable Solar DC Cable Manufacturer KEI Industries is a reliable manufacturer of solar DC cables. Explore our range of high-quality solar cables designed for efficient and reliable solar power transmission. Choose KEI for your solar cable needs.

0 notes

Text

Fallout's Electrical Grids

Inspired by Any Austin's videos on GTA IV & V (go watch them), I decided to map the path of every electrical pylon in Fallout 3, New Vegas, Fallout 4, and Fallout 76. It was an interesting experience that was sometimes fun and sometimes really dull and boring.

Now, these maps aren't full depictions of the electrical grid - I don't include utility poles for the most part (because there's too many and when I tried it was incredibly boring and dull) or underground cables (because I don't know whether or not they exist). But it does include the electrical pylons, which should give some interesting information about where power is coming from and how it's routed throughout the world.

The Capital Wasteland's Electrical Grid:

The pylons in FO3 are interesting - they're a lot more sporadic in their placement, but they're also pretty fun to follow. Also, almost every line was connected to a substation, which is neat. Fallout 3 also explicitly states that most of the power lines for DC are underground, so it's plausible that some of these lines could just go underground when they end, rather than just stopping.

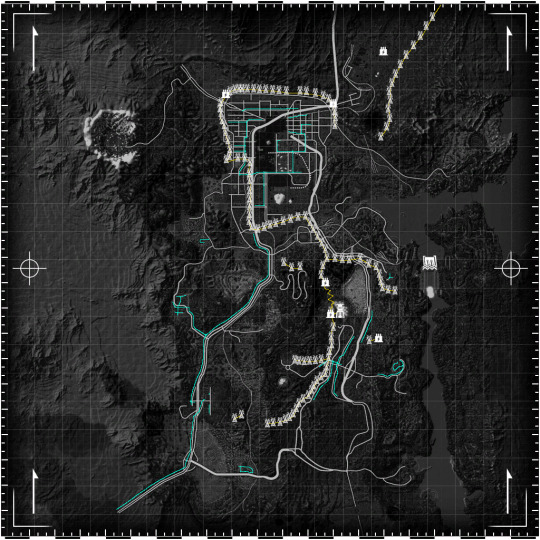

The Mojave Wasteland's Electrical Grid:

New Vegas was honestly a little bit boring to do an electrical survey for. It was mostly just one long line of pylons going across a flat desert, so I found myself very bored while mapping this one. But regardless, it was interesting to see that the pylons form an *almost* complete line, with the exception of a few spots that don't connect.

Also, for New Vegas, I mapped out the utility poles of the world as well, mainly because the pylons didn't give much interesting information. Interestingly, the only utility pole that got anywhere near a substation (where they'd normally hook up to) was a short line nearby the Nevada Winds Solar Farm.

Fun fact, New Vegas also has the only clear indication of underground cables that I was able to find in any of the games. The El Dorado Substation has wires leading directly into the ground facing Helios One, and the substation attached to Helios One's power plant also has lines leading into the ground, facing the El Dorado. It's a neat detail! That's what the squiggly line between Helios One and the El Dorado Substation is meant to portray.

The Commonwealth's Electrical Grid

Fallout 4 was a bit disappointing - there were only 2 pylon lines in the whole Commonwealth, I expected there to be more. The main line at the top starts outside of the map near Sanctuary Hills and goes all the way to an unmarked destroyed power plant nearby County Crossing, where it just kinda... stops.

The other line at the bottom starts at an unmarked substation (which also has a Deathclaw v Behemoth fight) and goes into the Glowing Sea before unceremoniously ending in a single destroyed pylon, with no visible continuation of the line.

I did also start mapping out the utility poles for the Commonwealth like I did for the Mojave, but I got bored because there's a lot more and the Commonwealth is a lot bigger.

Appalachia's Electrical Grid

(You'll have to zoom in to see any detail, since 76's map is very big.)

This one was my favorite electrical grid survey to do, because 76's world is just so damn cool and well made. It's also very cool to see that 76 has the most accurate electrical infrastructure in the entire series! There are 3 pylon lines in Appalachia, each connecting to 3 different power plants across the regions, as well as multiple substations along the routes. Doubly interesting, the utility poles also actually connect to the substations, which is a first!

I was very impressed with the level of detail in 76's world, there's so many little details, like how in the forested regions, the area beneath the pylon wires is actually cleared out, like they are in real life. It was just cool to see the developers actually pay attention to that kind of thing, along with the aforementioned utility poles connecting to the substations.

Conclusion

Now, you may ask, "Why did you do this?" And my answer is, because I thought it'd be neat and I didn't have anything better to do. You might also ask, "What did we learn from this?", to which my answer is basically nothing but hey, at least we reaffirmed that Fallout 76 still has the best world map of the games.

#fallout#fallout 3#fallout new vegas#fallout 4#fallout 76#commonwealth#appalachia#capital wasteland#mojave wasteland#infrastructure#electrical infrastructure#electricity#any austin#detailed#survey#maps#worldbuilding#probably autism#video games

43 notes

·

View notes

Text

The Most Beautiful Christmas Trees on Earth 🧵

L: The Christmas Tree of Gubbio, Italy, entered the Guinness World Records in 1991 as the world's largest.

Covering 130,000 m² with a height of 750m, it requires 800+ lights, 7,500m of cable, and 1,300 hours of work yearly.

Solar panels power its energy-saving LED lights.

R: The Rockefeller Center Christmas Tree, NYC

This iconic tree, usually a Norway spruce 69 to 100 feet (21–30 m) tall, has been a national tradition each year since 1933.

L: Prague Old Town Square, Czech Republic

R: The Polish city of Wroclaw is home to one of the most beautiful Christmas markets and Christmas trees in Europe.

L: Madrid, Spain

R: Vilnius Christmas Tree, Lithuania

L: The Christmas tree from Krakow's Market Square is a true masterpiece of decorative art.

R: Washington, DC, USA

L: Milan, Italy

R: St. Peter's Square, Vatican City

L: Rio de Janeiro, Brazil

This majestic tree is known worldwide for holding the record as the world’s largest floating Christmas tree.

R: Warsaw, Poland

L: Budapest, Hungary

R: Byblos Christmas Tree, Lebanon

L: Moscow, Russia

The main entrance to Gorky Park is decorated with a magnificent Christmas tree.

R: Galeries Lafayette Christmas Tree, Paris, France

L: Strasbourg, France

R: Trafalgar Square, London, UK

L: Florence, Italy

R: Zócalo Christmas Tree, Mexico City

9 notes

·

View notes

Text

Switchgear for Solar and Wind Projects in Bahrain: What You Need to Know

As Bahrain intensifies its commitment to renewable energy, solar and wind power projects are gaining momentum across the Kingdom. The nation’s Vision 2030 emphasizes sustainable growth, and this includes an ambitious target of generating 10% of electricity from renewable sources by 2035. As developers and investors gear up for this energy transition, one component plays a critical role in ensuring system safety, reliability, and efficiency — switchgear.

In this article, we explore why switchgear is crucial in solar and wind power systems, the specific requirements in Bahrain, and how to choose the right solution for your renewable energy project.

What is Switchgear and Why Does it Matter?

Switchgear is a general term covering a wide range of electrical devices used to isolate, protect, and control electrical circuits. It includes circuit breakers, fuses, relays, disconnectors, and load break switches.

In renewable energy systems, switchgear ensures:

· Safe disconnection of faulty or overloaded circuits

· Protection against overcurrent, short-circuit, and earth faults

· Efficient control and monitoring of power flow

· Coordination with grid and off-grid systems

Renewable Energy Growth in Bahrain

Bahrain’s sunny climate and strong coastal winds make it an ideal location for solar PV and wind power installations. Recent government initiatives — such as the Net Metering Scheme, Tendered Renewable Projects, and Green Building Regulations — are creating opportunities for both utility-scale and distributed renewable energy systems.

However, environmental factors such as high temperatures, humidity, and dust pose challenges for electrical equipment, particularly in outdoor solar and wind sites. This makes the right choice of switchgear even more important.

Key Switchgear Considerations for Solar Projects

In photovoltaic (PV) installations, switchgear must be compatible with DC (direct current) as well as AC (alternating current) systems. Here are specific points to consider:

1. DC Switchgear for PV Arrays

· DC Disconnectors: Isolate individual PV strings for maintenance or emergency shutdowns.

· DC Fuses and Circuit Breakers: Protect cables and components from over currents.

· String Combiner Boxes: Integrate multiple PV strings and incorporate protective devices.

2. AC Switchgear for Inverter Output

· Low-Voltage Circuit Breakers (AC): Used between inverters and transformers or grid connection points.

· Load Break Switches: Offer safe disconnection under load conditions.

· Metering and Monitoring Units: Allow real-time tracking of power output and faults.

3. Environmental Protection

· Use switchgear with IP65-rated enclosures to protect against dust and water ingress.

· UV-resistant materials are vital for long-term durability under the Bahraini sun.

Switchgear in Wind Energy Systems

Wind energy systems involve varying voltage levels and require robust protection due to fluctuating wind speeds and mechanical loading. Key switchgear elements include:

1. Medium Voltage Switchgear

· Used for interconnection between wind turbines and step-up transformers.

· SF6 or Vacuum Circuit Breakers: Provide arc quenching and insulation under high voltage.

2. High-Speed Protection

· Wind turbines are sensitive to voltage dips and transients. Fast-acting relays and breakers prevent equipment damage.

· Reactive power control and grid fault detection are integrated into switchgear assemblies.

3. Compact, Modular Designs

· Space constraints inside turbine towers or nacelles demand compact switchgear solutions with modular layouts.

Bahrain-Specific Compliance and Standards

To ensure your switchgear meets local utility and regulatory requirements, consider the following:

· EWA (Electricity & Water Authority) Requirements: All grid-connected systems must comply with EWA’s interconnection standards, including protection schemes and disconnection devices.

· IEC Standards: Switchgear must comply with relevant IEC 60947 (low-voltage switchgear) and IEC 62271 (high-voltage switchgear) guidelines.

· Thermal Rating and Ambient Temperature: Switchgear should be rated for continuous operation at temperatures up to 50°C, common in Bahraini summers.

Choosing the Right Switchgear Partner

A successful renewable energy project hinges on choosing a reliable switchgear partner. Look for:

· Local experience in Bahraini environmental and regulatory conditions

· Customizable solutions for both rooftop and utility-scale systems

· After-sales support including spares, maintenance, and system upgrades

· Smart switchgear with digital monitoring for preventive maintenance and remote control

Future Trends in Switchgear for Renewables

As solar and wind systems grow more advanced, so does switchgear technology. Key trends include:

· Digital Switchgear: Real-time monitoring, predictive maintenance, and IoT integration

· Arc-Resistant Designs: Enhanced safety for personnel in substations

· Eco-Friendly Alternatives to SF6: Adoption of green gases and air-insulated switchgear

· Hybrid AC/DC Systems: With growing battery storage and hybrid plants, switchgear must handle both current types seamlessly

Conclusion

Whether you’re planning a rooftop PV installation or a wind farm in Bahrain, your switchgear solution must be robust, compliant, and tailored to the region’s unique challenges. By choosing the right switchgear system, you ensure operational efficiency, regulatory compliance, and long-term safety.

If you’re looking for expert advice or need help selecting switchgear for your solar or wind project in Bahrain, our team is here to help. Contact us today for tailored solutions that power your progress sustainably.

#electrical engineers#electrical supplies#switchgear#electrical equipment#911 abc#bahrain25#arcane#artists on tumblr#batman#cats of tumblr

3 notes

·

View notes

Text

youtube

Desk of Ladyada - Sample Sunday and Solar Soft-Start 🔋🔧🪛 https://youtu.be/3Tz-R3F3EYU

Prototypes are in! Tested our USB/Solar/DC to 5V booster—note: loads 200mA need a workaround, but it’s a win for the price. Also tested cables & a spinning motor for holiday vibes! SOIC debugging clips—perfect for 0.3" SOICs on Metro RP2350 boards!

#deskofladyada#sampleprojects#solarpower#hardwaredesign#electronicsengineering#usbbooster#greatsearch#rp2350#norflash#psram#debuggingtools#soicclip#openhardware#adafruit#electronicsprojects#prototyping#techtesting#electronicsmaker#diyengineering#holidaydisplay#Youtube

6 notes

·

View notes

Video

youtube

Qi Technology Wireless Power Bank with Solar Panel Support Double USB-C Charger

Are you tired of constantly running out of battery on your devices while on the go? Well, look no further because the Qi Technology Wireless Power Bank with Solar Panel support is here to save the day! This innovative power bank is designed to keep your devices charged up and ready to go no matter where you are. Let's dive into the features and benefits of this amazing device.

## Cell type: 20000mAh Li-polymer

With a powerful 20000mAh Li-polymer battery, this power bank has enough capacity to charge your devices multiple times before needing to be recharged itself. Say goodbye to constantly searching for an outlet to plug in your devices!

## Wireless Charging Power: 10W/7.5W/5W

The Qi Technology Wireless Power Bank supports wireless charging at different power levels, including 10W, 7.5W, and 5W. This means you can charge your compatible devices wirelessly and quickly without the hassle of cords and cables.

## Input/Output Interface: USB, DC/ DC, Micro-USB

With multiple input and output interfaces, including USB, DC/DC, and Micro-USB, this power bank is compatible with a wide range of devices. Whether you have a mobile phone, tablet, camera, or other electronic devices, you can easily connect them to this power bank for charging.

## Type-C Input / Output: 5V/3A 9V/2A 12V/1.5A

The Qi Technology Wireless Power Bank also features Type-C input and output with various voltage and amperage options. This ensures fast and efficient charging for your devices, so you can get back to using them in no time.

## Applicable Models: Mobile Phone, Tablet PC, Camera, etc.

This power bank is compatible with a wide range of devices, including mobile phones, tablet PCs, cameras, and more. Whether you have an Apple, Android, or other device, you can rest assured that this power bank will keep your devices charged and ready for use.

## Features

- 30000mAh Solar Power bank - Allows charging for 3 devices simultaneously - Qi-Technology Wireless Power Bank with Solar Panel - Full-Speed QI Wireless Charging

In conclusion, the Qi Technology Wireless Power Bank with Solar Panel support is a versatile and reliable charging solution for all your devices. With its high capacity, wireless charging capabilities, solar panel support, and multiple input/output interfaces, this power bank has everything you need to stay powered up on the go. Say goodbye to low battery anxiety and hello to uninterrupted device usage with this top-notch power bank.

#youtube#PowerBank FastCharging StayConnected OnTheGo TechGadgets MustHave PortableCharger TechAccessories StayCharged PowerUp BatteryLife USB-C LEDd

2 notes

·

View notes

Text

AFERIY P010 800W Portable Power Station Review

I have been looking at the AFERIY portable power station and waited until they are on discount. AFERIY P010 800W is one of the highest power output battery in the battery, and I do need this to power my camping kettle, coffee machine, fridge and a mini oven.

I ordered the battery together with a 200W solar panel as I know the sunshine in UK is not the most intense even in summer. I would need a higher power solar panel to take advantage of the free energy from not so optimum daylight.

The battery comes with 28% power and I immediately charged it from the wall socket using the power cable included in the package. It took about an hour to go up to 100% and I am very pleased.

There is a MC4 to XT60 cable for solar panel charging. I bought an solar panel extension cable with MC40 plugs at both end that connects to the integrated power cable that comes out from the solar panel. The other end of the extension cable is connected to the battery’s XT60 cable.

Today I place the solar panel in my garden and connect the cables to the battery input. The AC output is connected to a power extension lead socket bar which powers my 77” OLED TV, FireTV Cube, Echo Sub and a pair of Echo Studio speakers.

On an early June midday today in southeast U.K. , the solar panels fed average 135W power to the battery, while the TV and sound system power output was between 70W - 150W when a Netflix movie was streaming. The battery capacity drops very slowly to 95% in two hours. When I played Spotify on my TV, the capacity climbs back to 100% in an hour.

In a hot and bright summer day, I would expect a higher power generated by the solar panels. I am very pleased with the P010 battery so far. It should be noted that the high voltage and current that the electronics have to handle, careful handling of the battery is necessary particularly during powering up and down of the battery. No power plugs should be inserted or unplugged when the battery is inputting/outputting power.

At 6:00pm the solar panels are still producing > 100W. I do not have any problem with the noise of the cooling fan inside my living room. I have no doubt that the P010 battery will serve me well during my summer campings.

AFERIY P010 Battery

PROS:

800W (1600W surge), lightweight (6.5 kg), PD100W, PD20W, for USB-C and USB-A QC3.0 charging, relatively silent cooling fan.

CONS:

Plastic swinging cover for the power sockets feels flimsy and care should be taken not to break it. Don’t know why it’s designed to open from the bottom and swing up, which is prone to easily broken when accidentally hit upon, rather than swinging open from the top, so that the power cables are always on top to protect the cover.

200W Portable Solar Panel

PROS:

lightweight, contains USB-C and DC sockets for directly charging devices.

CONS:

Cables a bit short. MC4 to Anderson cable in the accessories is out of date technology. No variety of DC adaptor sockets like other brands of solar panels. The integrated supporting legs for the solar panels are a bit short and the tie back from the supports to the panel is too long. This restrains the angle of the panel to max. 40 degrees to the horizontal. Not good to better capture the last light from the setting sun.

#aferiy#aferiy portable power station#portable power station#power station#solar panels#solar energy#power station reviews

3 notes

·

View notes

Text

HVDC Technology Advances Cut Energy Losses to Record Lows

The HVDC Transmission Market is projected to grow at a CAGR of 8% during the forecast period 2024–2031, driven by increasing demand for efficient long-distance power transmission, renewable integration, and grid stability. Unlike AC systems, HVDC enables the transmission of large amounts of electricity with minimal loss and cost over vast distances. It supports the connection of grids with varying frequencies and stabilizes green and three-phase power networks. As global energy systems decarbonize and digitize, HVDC emerges as a critical enabler of future-ready energy infrastructure.

Unlock exclusive insights with our detailed sample report :

Key Market Drivers

1. Renewable Energy Integration

The accelerating deployment of solar and wind energy, particularly in remote or offshore regions, demands highly efficient transmission systems. HVDC’s ability to carry high power loads over vast distances with low energy loss makes it ideal for transmitting renewable energy to consumption centers.

2. Need for Cross-Border Power Connectivity

HVDC systems support cross-border electricity trade and intercontinental power grids, enabling energy exchange between nations with complementary power generation cycles. Projects like Europe's North Sea Wind Power Hub and the U.S.-Canada grid interconnectors highlight this trend.

3. Technological Advancements in Converter Stations

Modern Voltage Source Converters (VSCs) offer improved compactness, efficiency, and grid compatibility, enabling integration with weak AC systems, multi-terminal configurations, and islanded grids.

4. Grid Decentralization and Smart Grid Evolution

With smart grid deployments gaining traction, HVDC is vital for balancing decentralized power sources, enhancing grid resilience, and supporting bidirectional electricity flows across hybrid networks.

5. Urbanization and Electrification Initiatives

Developing economies and urban mega-projects are focusing on energy-efficient infrastructure, where HVDC plays a central role in enabling high-capacity power transfer to cities and industrial zones.

Speak to Our Senior Analyst and Get Customization in the report as per your requirements:

Regional Highlights

United States

The U.S. is witnessing a surge in HVDC development, supported by:

Bipartisan Infrastructure Law investments in grid modernization.

Multi-GW HVDC projects like SOO Green Link, SunZia Transmission, and Champlain Hudson Power Express.

Renewables growth in Texas, Midwest, and the West Coast prompting need for long-distance transmission to Eastern markets.

Strategic role of HVDC in balancing grid instability from variable renewable inputs.

Japan

Japan is actively deploying HVDC systems to:

Bridge eastern and western grids, which operate at different frequencies.

Enhance energy security following nuclear phase-out and growing solar capacity.

Support offshore wind energy evacuation via submarine HVDC cables.

Innovate compact HVDC stations for urban and island environments, led by firms like Hitachi Energy and Mitsubishi Electric.

Industry Segmentation

By Component:

Converter Stations (Line Commutated Converters, Voltage Source Converters)

Transmission Cables (Overhead, Underground, Submarine)

Others (Circuit Breakers, Insulation, Control Systems)

By Project Type:

Point-to-Point Transmission

Back-to-Back HVDC Systems

Multi-Terminal Systems

By Voltage Rating:

Below 500 kV

500 kV–800 kV

Above 800 kV

By Application:

Bulk Power Transmission

Interconnecting Grids

Offshore Wind Integration

Urban Power Distribution

Latest Industry Trends

Ultra-High Voltage DC (UHVDC) Transmission China leads global UHVDC deployment, enabling power flow above ±800 kV, essential for connecting vast renewable energy basins with demand hubs.

Submarine HVDC for Offshore Wind Europe, U.S., and Japan are investing in underwater HVDC lines for efficient transmission from offshore wind farms to mainland grids.

Compact Converter Stations for Dense Cities HVDC converter stations are now smaller and modular, making them ideal for urban environments and reducing land use challenges.

AI and IoT in HVDC Grid Management AI-powered control systems are enhancing real-time diagnostics, predictive maintenance, and fault mitigation in HVDC networks.

Public-Private Partnerships Fuel Global Expansion Collaborations among governments, utilities, and engineering giants are accelerating global HVDC rollouts, particularly in the U.S., Europe, and Asia-Pacific.

Buy the exclusive full report here:

Growth Opportunities

Offshore Renewable Integration: HVDC cables are essential to connect far-shore wind farms and floating solar plants.

Developing Economies: HVDC systems can bridge generation-resource gaps in countries like India, Brazil, and parts of Africa.

Intercontinental Mega-Grids: HVDC will play a pivotal role in pan-continental energy networks, including Asia-Europe-Africa grid proposals.

Flexible HVDC Links: Multi-terminal and hybrid AC/DC grid designs allow for flexible and scalable future energy networks.

HVDC for Hydrogen Hubs: Transmission of clean electricity for green hydrogen production near ports and industrial clusters.

Competitive Landscape

Key players in the HVDC transmission market include:

Hitachi Energy Ltd

Siemens Energy AG

GE Vernova

Nexans S.A.

NR Electric Co., Ltd.

Toshiba Energy Systems

Prysmian Group

NKT A/S

ABB Ltd

LS Cable & System

These firms are heavily invested in:

Next-generation VSC technologies

Flexible DC grid development

Digital twin platforms for HVDC monitoring

Local manufacturing to meet domestic supply chain needs

Stay informed with the latest industry insights-start your subscription now:

Conclusion

The global HVDC transmission market is entering a new era of strategic importance as the world transitions toward sustainable, secure, and smart energy systems. With its high efficiency, scalability, and reliability, HVDC plays a critical role in the future of long-distance power delivery, intercontinental grid connectivity, and renewable energy distribution.

Backed by strong policy support in the United States and Japan, and driven by megaprojects across Asia, Europe, and the Americas, HVDC transmission stands as a cornerstone of decarbonization, energy security, and smart grid evolution.

About us:

DataM Intelligence is a premier provider of market research and consulting services, offering a full spectrum of business intelligence solutions—from foundational research to strategic consulting. We utilize proprietary trends, insights, and developments to equip our clients with fast, informed, and effective decision-making tools.

Our research repository comprises more than 6,300 detailed reports covering over 40 industries, serving the evolving research demands of 200+ companies in 50+ countries. Whether through syndicated studies or customized research, our robust methodologies ensure precise, actionable intelligence tailored to your business landscape.

Contact US:

Company Name: DataM Intelligence

Contact Person: Sai Kiran

Email: [email protected]

Phone: +1 877 441 4866

Website: https://www.datamintelligence.com

#HVDC transmission market#HVDC transmission market size#HVDC transmission market growth#HVDC transmission market share#HVDC transmission market analysis

0 notes

Text

From Design to Execution: AmperSolar’s Commercial Solar Engineering Process Explained

As the world transitions toward cleaner energy, solar power stands out as one of the most efficient and scalable options. Behind every successful solar project, especially on a commercial or utility scale, lies a robust engineering process—one that transforms initial concepts into fully operational solar energy systems.

AmperSolar is at the forefront of this transition. Known for its expertise in Utility Scale Solar Farm Engineering, Commercial Solar Engineering, and Rooftop Solar Engineering, AmperSolar brings a streamlined, professional approach to every project it takes on.

In this blog, we’ll take you through the complete engineering process that AmperSolar follows—from design and analysis to execution and commissioning. Whether you’re planning a rooftop system for your business or a large-scale solar farm, understanding this process can help you appreciate the depth of work that goes into turning solar potential into real-world power.

Step 1: Initial Consultation and Feasibility Assessment

Every project begins with a conversation. AmperSolar starts by understanding the client’s goals, energy needs, site conditions, and long-term sustainability plans. Whether it’s a commercial facility or a multi-megawatt utility-scale farm, gathering detailed input early ensures a more tailored solution later.

Next comes the feasibility assessment. This includes:

Evaluating the site’s solar potential using satellite imagery and physical surveys.

Checking structural viability for rooftop solar engineering projects.

Reviewing existing electrical infrastructure.

Analyzing financial incentives and return on investment.

The goal here is to determine if the site and conditions are suitable for a solar installation, and what kind of system would deliver the best results.

Step 2: Power System Study for Solar Sites

Once feasibility is confirmed, AmperSolar conducts a comprehensive Power System Study for Solar Sites. This step is crucial, especially for grid-connected commercial and utility-scale projects. The study includes:

Load analysis and energy usage patterns.

Grid compatibility and interconnection requirements.

Voltage levels, fault current calculations, and short circuit analysis.

Protection coordination studies.

By carefully analyzing the power system, AmperSolar ensures the proposed solar solution integrates seamlessly with the local grid while meeting all safety, reliability, and performance standards.

This is particularly important in Nationwide Engineering for Utility-Scale projects, where regulations and infrastructure conditions vary from state to state.

Step 3: Engineering Design and Planning

Now the project enters the detailed design phase. AmperSolar’s in-house team of engineers and technical experts prepares a full-scale plan that includes electrical, structural, mechanical, and civil aspects of the installation.

Key components of this phase include:

1. System Layout and Sizing

Optimizing the number of solar panels based on site area and sun exposure.

Designing for maximum efficiency and minimal shading.

Selecting inverters, mounting systems, and cabling.

2. Electrical System Design

Creating single-line diagrams (SLDs).

Planning AC/DC wiring routes.

Designing grounding, bonding, and protective systems.

3. Structural Engineering

Assessing roof or ground structure load capacity.

Customizing racking systems for Rooftop Solar Engineering or ground mounts.

Wind load and seismic calculations.

4. Compliance and Permitting

Ensuring designs meet all NEC codes and local authority requirements.

Preparing documentation for building and electrical permits.

Facilitating environmental and utility approvals.

AmperSolar’s attention to detail in this phase sets the foundation for a smooth installation and a high-performance system.

Step 4: Procurement and Logistics

With designs finalized and permits underway, the next step is sourcing the components and organizing project logistics. AmperSolar works with top-tier manufacturers to procure high-efficiency solar panels, inverters, racking systems, and balance-of-system components.

During procurement, they:

Ensure all components meet project specifications and engineering standards.

Schedule delivery to align with the installation timeline.

Manage storage and staging for larger Utility Scale Solar Farm Engineering projects.

This phase also includes planning for manpower, equipment rentals, and any subcontracted services. Keeping everything aligned minimizes delays and cost overruns during the build.

Step 5: Construction and Installation

This is where the project starts to take physical shape. The construction process is carefully managed to ensure speed, safety, and precision.

For Commercial Solar Engineering projects, AmperSolar typically:

Installs racking and mounting structures on roofs or ground areas.

Places and connects solar panels with precision.

Integrates inverters, combiner boxes, and other electrical components.

Routes and terminates wiring according to code.

Tests mechanical connections and system grounding.

For Utility-Scale Solar Farm Engineering, the scale is much larger and may include:

Civil grading and site preparation.

Trenching for underground cabling.

Large-scale racking installation using specialized machinery.

Medium voltage equipment installation and grid-tie infrastructure.

Coordination with utility companies for interconnection.

Throughout the installation, safety protocols are strictly followed, and progress is tracked using detailed project management tools.

Step 6: Testing and Commissioning

Once the physical system is in place, AmperSolar carries out a thorough commissioning process to ensure everything operates as intended.

This involves:

Performance testing of each system component.

Verifying inverter start-up and communication systems.

Testing voltage and current levels under load.

Simulating fault conditions and validating protection systems.

Monitoring output compared to projected models.

AmperSolar also handles final inspections with building authorities and utility companies, ensuring full code compliance and operational readiness.

Only after everything passes the final checks is the system activated and connected to the grid or facility power system.

Step 7: Monitoring and Ongoing Support

The job doesn’t end once the solar system goes live. AmperSolar provides post-installation support, including:

Setting up real-time performance monitoring platforms.

Troubleshooting assistance and technical support.

Maintenance schedules and performance optimization.

Warranty management and system documentation.

Ongoing monitoring is critical to identify and correct any drops in performance early, especially in Nationwide Engineering for Utility-Scale systems where uptime translates directly into revenue.

Tailored Solutions for Every Solar Project

Whether it’s a 500 kW commercial rooftop or a 50 MW solar farm, AmperSolar applies the same rigorous, expert-driven approach. Their specialization in Expert Utility & Commercial Solar Engineering allows them to customize every solution while keeping timelines, budgets, and client expectations in check.

Here's how different project types benefit from AmperSolar's engineering expertise:

Rooftop Solar Engineering

Ideal for commercial buildings, warehouses, and retail centers.

Efficient use of unused roof space.

Reduces energy costs while improving sustainability credentials.

Commercial Solar Engineering

Ground or roof-mounted systems for mid-to-large businesses.

Scalable designs tailored to the facility's energy usage.

Integration with backup systems or energy storage as needed.

Utility Scale Solar Farm Engineering

Massive energy output for grid contribution.

Advanced interconnection planning and grid compliance.

High efficiency through layout optimization and precision engineering.

Nationwide Presence with Localized Expertise

What makes AmperSolar unique is its ability to provide Nationwide Engineering for Utility-Scale and commercial projects, while still understanding the nuances of local regulations, climate conditions, and utility requirements.

From California’s dense permitting environment to Texas’ open solar policies, AmperSolar adapts its engineering process to meet the needs of every state. Their ability to scale without compromising quality makes them a reliable partner for solar developers, business owners, and institutions across the U.S.

Conclusion: Engineering Solar Success with AmperSolar

Solar engineering isn’t just about installing panels—it’s about designing systems that are safe, efficient, and built to last. From feasibility studies and Power System Study for Solar Sites to installation and ongoing support, AmperSolar’s step-by-step approach ensures high performance at every stage.

Their dedication to Expert Utility & Commercial Solar Engineering and experience in Rooftop Solar Engineering and Utility Scale Solar Farm Engineering makes them a trusted name in the renewable energy industry.

By combining deep technical knowledge with a client-first approach, AmperSolar helps businesses and developers across the country harness the full potential of solar energy—efficiently, effectively, and responsibly.

0 notes

Text

From Design to Execution: AmperSolar’s Commercial Solar Engineering Process Explained

As the world transitions toward cleaner energy, solar power stands out as one of the most efficient and scalable options. Behind every successful solar project, especially on a commercial or utility scale, lies a robust engineering process—one that transforms initial concepts into fully operational solar energy systems.

AmperSolar is at the forefront of this transition. Known for its expertise in Utility Scale Solar Farm Engineering, Commercial Solar Engineering, and Rooftop Solar Engineering, AmperSolar brings a streamlined, professional approach to every project it takes on.

In this blog, we’ll take you through the complete engineering process that AmperSolar follows—from design and analysis to execution and commissioning. Whether you’re planning a rooftop system for your business or a large-scale solar farm, understanding this process can help you appreciate the depth of work that goes into turning solar potential into real-world power.

Step 1: Initial Consultation and Feasibility Assessment

Every project begins with a conversation. AmperSolar starts by understanding the client’s goals, energy needs, site conditions, and long-term sustainability plans. Whether it’s a commercial facility or a multi-megawatt utility-scale farm, gathering detailed input early ensures a more tailored solution later.

Next comes the feasibility assessment. This includes:

Evaluating the site’s solar potential using satellite imagery and physical surveys.

Checking structural viability for rooftop solar engineering projects.

Reviewing existing electrical infrastructure.

Analyzing financial incentives and return on investment.

The goal here is to determine if the site and conditions are suitable for a solar installation, and what kind of system would deliver the best results.

Step 2: Power System Study for Solar Sites

Once feasibility is confirmed, AmperSolar conducts a comprehensive Power System Study for Solar Sites. This step is crucial, especially for grid-connected commercial and utility-scale projects. The study includes:

Load analysis and energy usage patterns.

Grid compatibility and interconnection requirements.

Voltage levels, fault current calculations, and short circuit analysis.

Protection coordination studies.

By carefully analyzing the power system, AmperSolar ensures the proposed solar solution integrates seamlessly with the local grid while meeting all safety, reliability, and performance standards.

This is particularly important in Nationwide Engineering for Utility-Scale projects, where regulations and infrastructure conditions vary from state to state.

Step 3: Engineering Design and Planning

Now the project enters the detailed design phase. AmperSolar’s in-house team of engineers and technical experts prepares a full-scale plan that includes electrical, structural, mechanical, and civil aspects of the installation.

Key components of this phase include:

1. System Layout and Sizing

Optimizing the number of solar panels based on site area and sun exposure.

Designing for maximum efficiency and minimal shading.

Selecting inverters, mounting systems, and cabling.

2. Electrical System Design

Creating single-line diagrams (SLDs).

Planning AC/DC wiring routes.

Designing grounding, bonding, and protective systems.

3. Structural Engineering

Assessing roof or ground structure load capacity.

Customizing racking systems for Rooftop Solar Engineering or ground mounts.

Wind load and seismic calculations.

4. Compliance and Permitting

Ensuring designs meet all NEC codes and local authority requirements.

Preparing documentation for building and electrical permits.

Facilitating environmental and utility approvals.

AmperSolar’s attention to detail in this phase sets the foundation for a smooth installation and a high-performance system.

Step 4: Procurement and Logistics

With designs finalized and permits underway, the next step is sourcing the components and organizing project logistics. AmperSolar works with top-tier manufacturers to procure high-efficiency solar panels, inverters, racking systems, and balance-of-system components.

During procurement, they:

Ensure all components meet project specifications and engineering standards.

Schedule delivery to align with the installation timeline.

Manage storage and staging for larger Utility Scale Solar Farm Engineering projects.

This phase also includes planning for manpower, equipment rentals, and any subcontracted services. Keeping everything aligned minimizes delays and cost overruns during the build.

Step 5: Construction and Installation

This is where the project starts to take physical shape. The construction process is carefully managed to ensure speed, safety, and precision.

For Commercial Solar Engineering projects, AmperSolar typically:

Installs racking and mounting structures on roofs or ground areas.

Places and connects solar panels with precision.

Integrates inverters, combiner boxes, and other electrical components.

Routes and terminates wiring according to code.

Tests mechanical connections and system grounding.

For Utility-Scale Solar Farm Engineering, the scale is much larger and may include:

Civil grading and site preparation.

Trenching for underground cabling.

Large-scale racking installation using specialized machinery.

Medium voltage equipment installation and grid-tie infrastructure.

Coordination with utility companies for interconnection.

Throughout the installation, safety protocols are strictly followed, and progress is tracked using detailed project management tools.

Step 6: Testing and Commissioning

Once the physical system is in place, AmperSolar carries out a thorough commissioning process to ensure everything operates as intended.

This involves:

Performance testing of each system component.

Verifying inverter start-up and communication systems.

Testing voltage and current levels under load.

Simulating fault conditions and validating protection systems.

Monitoring output compared to projected models.

AmperSolar also handles final inspections with building authorities and utility companies, ensuring full code compliance and operational readiness.

Only after everything passes the final checks is the system activated and connected to the grid or facility power system.

Step 7: Monitoring and Ongoing Support

The job doesn’t end once the solar system goes live. AmperSolar provides post-installation support, including:

Setting up real-time performance monitoring platforms.

Troubleshooting assistance and technical support.

Maintenance schedules and performance optimization.

Warranty management and system documentation.

Ongoing monitoring is critical to identify and correct any drops in performance early, especially in Nationwide Engineering for Utility-Scale systems where uptime translates directly into revenue.

Tailored Solutions for Every Solar Project

Whether it’s a 500 kW commercial rooftop or a 50 MW solar farm, AmperSolar applies the same rigorous, expert-driven approach. Their specialization in Expert Utility & Commercial Solar Engineering allows them to customize every solution while keeping timelines, budgets, and client expectations in check.

Here's how different project types benefit from AmperSolar's engineering expertise:

Rooftop Solar Engineering

Ideal for commercial buildings, warehouses, and retail centers.

Efficient use of unused roof space.

Reduces energy costs while improving sustainability credentials.

Commercial Solar Engineering

Ground or roof-mounted systems for mid-to-large businesses.

Scalable designs tailored to the facility's energy usage.

Integration with backup systems or energy storage as needed.

Utility Scale Solar Farm Engineering

Massive energy output for grid contribution.

Advanced interconnection planning and grid compliance.

High efficiency through layout optimization and precision engineering.

Nationwide Presence with Localized Expertise

What makes AmperSolar unique is its ability to provide Nationwide Engineering for Utility-Scale and commercial projects, while still understanding the nuances of local regulations, climate conditions, and utility requirements.

From California’s dense permitting environment to Texas’ open solar policies, AmperSolar adapts its engineering process to meet the needs of every state. Their ability to scale without compromising quality makes them a reliable partner for solar developers, business owners, and institutions across the U.S.

Conclusion: Engineering Solar Success with AmperSolar

Solar engineering isn’t just about installing panels—it’s about designing systems that are safe, efficient, and built to last. From feasibility studies and Power System Study for Solar Sites to installation and ongoing support, AmperSolar’s step-by-step approach ensures high performance at every stage.

Their dedication to Expert Utility & Commercial Solar Engineering and experience in Rooftop Solar Engineering and Utility Scale Solar Farm Engineering makes them a trusted name in the renewable energy industry.

By combining deep technical knowledge with a client-first approach, AmperSolar helps businesses and developers across the country harness the full potential of solar energy—efficiently, effectively, and responsibly.

0 notes

Text

DC Fast Charger Engineering Explained: Speed Meets Precision with AmperEVcharging

As electric vehicles (EVs) continue to rise in popularity, the demand for faster, smarter, and more efficient charging infrastructure is growing. One of the most essential components of this landscape is DC fast charger engineering. At AmperEVcharging, we specialize in creating tailored solutions that blend speed with precision, ensuring that EV owners spend less time charging and more time driving.

In this blog, we’ll break down what DC fast charger engineering involves, how it ties into broader EV charging station engineering, and why solid infrastructure design and permitting play such a crucial role in the process. Whether you're a property owner, developer, or business looking to adopt EV charging solutions, this guide will help you understand the essentials.

What is DC Fast Charger Engineering?

DC fast charger engineering refers to the specialized design and development of Direct Current (DC) charging systems that provide rapid power delivery to electric vehicles. Unlike AC chargers that convert electricity within the vehicle, DC chargers handle the conversion externally, sending high-voltage DC electricity straight to the battery. This allows for much faster charging—perfect for high-traffic locations or time-sensitive applications.

DC fast chargers typically range from 50 kW to over 350 kW, and the engineering behind them requires thoughtful planning, robust hardware design, and seamless integration into the existing power grid.

At AmperEVcharging, our engineering team focuses on building systems that prioritize safety, efficiency, and scalability, all while ensuring compatibility with a wide range of EV models.

The Role of EV Charging Station Engineering

Before a DC fast charger can be installed, there’s a larger picture to consider—EV charging station engineering. This encompasses everything from site evaluation and power availability to layout planning and utility coordination.

Key components include:

Electrical load analysis: How much power is available on-site and how much will the charging station need?

Cable routing and trenching plans: Ensuring the physical infrastructure supports safe and efficient installation.

Charger placement and accessibility: Stations need to be ADA-compliant and driver-friendly.

Safety systems and signage: From ground fault protection to fire safety and visibility.

AmperEVcharging works closely with clients to assess these needs early in the process. We provide full engineering design packages that guide your project from concept to completion.

Infrastructure Design: Building a Strong Foundation

Successful EV charging infrastructure design is not just about selecting a charger and plugging it in. It requires a strong foundation built on planning, coordination, and compliance. Without a well-thought-out design, projects can face costly delays or even fail to meet code requirements.

Key aspects of EV infrastructure design include:

Power capacity assessment: Can the location handle the load of multiple fast chargers?

Transformer and panel sizing: Upgrading electrical systems where needed.

Conduit and wiring specs: Ensuring materials meet local and national electrical codes.

Integration with solar or battery storage (optional): For clients interested in energy efficiency and cost savings.

At AmperEVcharging, we simplify this complex process. Our team creates custom infrastructure designs that align with your site's unique power capabilities and business goals.

Level 2 vs. DC Fast Charging: Understanding the Difference

While DC fast chargers are ideal for rapid charging, Level 2 EV charger design also plays a vital role in the charging ecosystem. Level 2 chargers provide AC power, usually offering 10-60 miles of range per hour of charging, depending on the vehicle and charger specs.

Level 2 chargers are perfect for workplaces, residential communities, and locations where vehicles are parked for several hours. They're more affordable to install and operate, making them a great entry point for businesses and property owners.

That said, DC fast chargers are essential for:

Highway corridors

Fleet depots

Urban centers

Busy commercial locations

Choosing between Level 2 and DC fast charging—or using both—is a decision best made during the engineering and planning phase, something AmperEVcharging helps clients evaluate based on traffic patterns, usage needs, and energy capacity.

Permit Drawings: The Blueprint Behind Success

Before installation can begin, one crucial step is the creation of EV charging permit drawings. These are detailed documents that illustrate the electrical layout, charger specifications, conduit paths, panel upgrades, safety elements, and more.

Permit drawings are essential for getting approval from the Authority Having Jurisdiction (AHJ) and local utility providers. They must be accurate, code-compliant, and professionally prepared.

At AmperEVcharging, our engineers prepare comprehensive drawing sets tailored to your local codes. These often include:

Site plans

Electrical single-line diagrams

Load calculations

Trenching and conduit layouts

ADA accessibility design

Having accurate permit drawings in place helps avoid delays and speeds up approvals, giving you a clear roadmap for installation.

AHJ Permitting: Navigating Regulatory Compliance

One of the most important—and often misunderstood—steps in deploying EV charging stations is AHJ permitting for EV stations. The AHJ is the local building department or regulatory agency responsible for reviewing and approving your plans before construction begins.

The permitting process can involve:

Reviewing electrical and civil plans

Ensuring code compliance with NEC and local amendments

Fire safety and zoning reviews

Accessibility standards verification

Since each jurisdiction may have different requirements, working with a partner like AmperEVcharging ensures your project adheres to all applicable regulations. Our team coordinates directly with AHJs to expedite the review process and address any revisions quickly.

Utility Approval: The Final Green Light

Before flipping the switch on a new charging station, you’ll also need utility approval for EV chargers. Utilities want to ensure their grid can handle the additional demand and that your installation won't negatively impact surrounding infrastructure.

This step can involve:

Load studies and impact assessments

Transformer upgrades

Meter panel installation or changes

Demand response program eligibility

AmperEVcharging facilitates this process by working directly with utility companies on your behalf. We handle technical documentation, coordinate inspections, and ensure your installation meets utility requirements for connection and billing.

Why Precision Matters in DC Fast Charger Engineering

Engineering a DC fast charger isn’t just about speed—it’s about precision. When poorly designed, fast chargers can strain power systems, degrade vehicle batteries, and lead to safety hazards. With careful planning, however, they become reliable, efficient, and scalable assets.

At AmperEVcharging, precision is part of our core process:

Site-specific engineering ensures safety and efficiency.

Load balancing avoids unnecessary upgrades.

Smart integration supports future scalability.

Real-time monitoring ensures performance and uptime.

Whether you’re designing one station or a city-wide network, our team ensures your charging solution is engineered for the long haul.

Why Choose AmperEVcharging?

We’re not just a charging equipment provider—we’re an end-to-end solutions partner. With years of experience in EV charging station engineering, our team at AmperEVcharging offers:

Turnkey design and engineering

Customized site layouts

Permit drawing creation

AHJ and utility coordination

Support for both Level 2 and DC fast chargers

Future-ready infrastructure designs

Every project we take on is backed by technical know-how, regulatory expertise, and a commitment to helping clients bring their EV charging visions to life.

Final Thoughts

As EV adoption continues to accelerate, reliable and fast charging infrastructure is no longer optional—it’s essential. With DC fast charger engineering, you unlock the potential to serve more drivers, reduce wait times, and future-proof your property for tomorrow’s mobility needs.

From EV charging infrastructure design to permit drawings, AHJ permitting, and utility approvals, AmperEVcharging guides you through every step. We believe that when speed meets precision, great things happen—and our engineering solutions reflect that philosophy.

If you're ready to bring high-performance EV charging to your site, connect with AmperEVcharging today. Let's build the future—one charge at a time.

0 notes

Text

DC Fast Charger Engineering Explained: Speed Meets Precision with AmperEVcharging

As electric vehicles (EVs) continue to rise in popularity, the demand for faster, smarter, and more efficient charging infrastructure is growing. One of the most essential components of this landscape is DC fast charger engineering. At AmperEVcharging, we specialize in creating tailored solutions that blend speed with precision, ensuring that EV owners spend less time charging and more time driving.

In this blog, we’ll break down what DC fast charger engineering involves, how it ties into broader EV charging station engineering, and why solid infrastructure design and permitting play such a crucial role in the process. Whether you're a property owner, developer, or business looking to adopt EV charging solutions, this guide will help you understand the essentials.

What is DC Fast Charger Engineering?

DC fast charger engineering refers to the specialized design and development of Direct Current (DC) charging systems that provide rapid power delivery to electric vehicles. Unlike AC chargers that convert electricity within the vehicle, DC chargers handle the conversion externally, sending high-voltage DC electricity straight to the battery. This allows for much faster charging—perfect for high-traffic locations or time-sensitive applications.

DC fast chargers typically range from 50 kW to over 350 kW, and the engineering behind them requires thoughtful planning, robust hardware design, and seamless integration into the existing power grid.

At AmperEVcharging, our engineering team focuses on building systems that prioritize safety, efficiency, and scalability, all while ensuring compatibility with a wide range of EV models.

The Role of EV Charging Station Engineering

Before a DC fast charger can be installed, there’s a larger picture to consider—EV charging station engineering. This encompasses everything from site evaluation and power availability to layout planning and utility coordination.

Key components include:

Electrical load analysis: How much power is available on-site and how much will the charging station need?

Cable routing and trenching plans: Ensuring the physical infrastructure supports safe and efficient installation.

Charger placement and accessibility: Stations need to be ADA-compliant and driver-friendly.

Safety systems and signage: From ground fault protection to fire safety and visibility.

AmperEVcharging works closely with clients to assess these needs early in the process. We provide full engineering design packages that guide your project from concept to completion.

Infrastructure Design: Building a Strong Foundation

Successful EV charging infrastructure design is not just about selecting a charger and plugging it in. It requires a strong foundation built on planning, coordination, and compliance. Without a well-thought-out design, projects can face costly delays or even fail to meet code requirements.

Key aspects of EV infrastructure design include:

Power capacity assessment: Can the location handle the load of multiple fast chargers?

Transformer and panel sizing: Upgrading electrical systems where needed.

Conduit and wiring specs: Ensuring materials meet local and national electrical codes.

Integration with solar or battery storage (optional): For clients interested in energy efficiency and cost savings.

At AmperEVcharging, we simplify this complex process. Our team creates custom infrastructure designs that align with your site's unique power capabilities and business goals.

Level 2 vs. DC Fast Charging: Understanding the Difference

While DC fast chargers are ideal for rapid charging, Level 2 EV charger design also plays a vital role in the charging ecosystem. Level 2 chargers provide AC power, usually offering 10-60 miles of range per hour of charging, depending on the vehicle and charger specs.

Level 2 chargers are perfect for workplaces, residential communities, and locations where vehicles are parked for several hours. They're more affordable to install and operate, making them a great entry point for businesses and property owners.

That said, DC fast chargers are essential for:

Highway corridors

Fleet depots

Urban centers

Busy commercial locations

Choosing between Level 2 and DC fast charging—or using both—is a decision best made during the engineering and planning phase, something AmperEVcharging helps clients evaluate based on traffic patterns, usage needs, and energy capacity.

Permit Drawings: The Blueprint Behind Success

Before installation can begin, one crucial step is the creation of EV charging permit drawings. These are detailed documents that illustrate the electrical layout, charger specifications, conduit paths, panel upgrades, safety elements, and more.

Permit drawings are essential for getting approval from the Authority Having Jurisdiction (AHJ) and local utility providers. They must be accurate, code-compliant, and professionally prepared.

At AmperEVcharging, our engineers prepare comprehensive drawing sets tailored to your local codes. These often include:

Site plans

Electrical single-line diagrams

Load calculations

Trenching and conduit layouts

ADA accessibility design

Having accurate permit drawings in place helps avoid delays and speeds up approvals, giving you a clear roadmap for installation.

AHJ Permitting: Navigating Regulatory Compliance

One of the most important—and often misunderstood—steps in deploying EV charging stations is AHJ permitting for EV stations. The AHJ is the local building department or regulatory agency responsible for reviewing and approving your plans before construction begins.

The permitting process can involve:

Reviewing electrical and civil plans

Ensuring code compliance with NEC and local amendments

Fire safety and zoning reviews

Accessibility standards verification

Since each jurisdiction may have different requirements, working with a partner like AmperEVcharging ensures your project adheres to all applicable regulations. Our team coordinates directly with AHJs to expedite the review process and address any revisions quickly.

Utility Approval: The Final Green Light

Before flipping the switch on a new charging station, you’ll also need utility approval for EV chargers. Utilities want to ensure their grid can handle the additional demand and that your installation won't negatively impact surrounding infrastructure.

This step can involve:

Load studies and impact assessments

Transformer upgrades

Meter panel installation or changes

Demand response program eligibility

AmperEVcharging facilitates this process by working directly with utility companies on your behalf. We handle technical documentation, coordinate inspections, and ensure your installation meets utility requirements for connection and billing.

Why Precision Matters in DC Fast Charger Engineering

Engineering a DC fast charger isn’t just about speed—it’s about precision. When poorly designed, fast chargers can strain power systems, degrade vehicle batteries, and lead to safety hazards. With careful planning, however, they become reliable, efficient, and scalable assets.

At AmperEVcharging, precision is part of our core process:

Site-specific engineering ensures safety and efficiency.

Load balancing avoids unnecessary upgrades.

Smart integration supports future scalability.

Real-time monitoring ensures performance and uptime.

Whether you’re designing one station or a city-wide network, our team ensures your charging solution is engineered for the long haul.

Why Choose AmperEVcharging?

We’re not just a charging equipment provider—we’re an end-to-end solutions partner. With years of experience in EV charging station engineering, our team at AmperEVcharging offers:

Turnkey design and engineering

Customized site layouts

Permit drawing creation

AHJ and utility coordination

Support for both Level 2 and DC fast chargers

Future-ready infrastructure designs

Every project we take on is backed by technical know-how, regulatory expertise, and a commitment to helping clients bring their EV charging visions to life.

Final Thoughts

As EV adoption continues to accelerate, reliable and fast charging infrastructure is no longer optional—it’s essential. With DC fast charger engineering, you unlock the potential to serve more drivers, reduce wait times, and future-proof your property for tomorrow’s mobility needs.

From EV charging infrastructure design to permit drawings, AHJ permitting, and utility approvals, AmperEVcharging guides you through every step. We believe that when speed meets precision, great things happen—and our engineering solutions reflect that philosophy.

If you're ready to bring high-performance EV charging to your site, connect with AmperEVcharging today. Let's build the future—one charge at a time.

#ev charging station engineering#ev charging permit drawings#ev charging infrastructure design#level 2 ev charger design#dc fast charger engineering

0 notes

Text

Best Solar BOS Kit for Reliable Solar Panel Installation - Samptel Energy

Samptel Energy offers the Best Solar BOS Kit with all essential components like DCDB, ACDB, SPD, MCB, MC4 connectors, and solar cables. Ideal for reliable rooftop and commercial solar panel installations across India.

With years of industry experience and a deep understanding of solar infrastructure, Samptel Energy proudly delivers India’s most trusted and complete Solar BOS Kit — a tailor-made Balance of System solution crafted for smooth, safe, and reliable solar panel installations.

Our kits are built to serve the growing needs of solar EPC companies, residential installers, and industrial projects by offering premium-quality components under one roof. Whether it’s a 3kW rooftop system or a large-scale solar plant, our BOS Kits ensure seamless performance, long-term safety, and hassle-free integration.

✅ Why Choose Samptel Energy’s Solar BOS Kit?

Complete system: DCDB, ACDB, SPD, MCBs, MC4 connectors, solar DC cables & grounding accessories

High-quality, certified materials

Pre-tested and pre-wired options for faster installation

Designed for both residential & commercial solar projects

Every component of our BOS Kit undergoes rigorous quality checks and adheres to strict engineering standards. We prioritize performance, safety, and reliability — because we understand that a solar system is only as strong as its weakest connection.

Today, solar professionals across India trust Samptel Energy’s BOS Kits for their dependable performance, low maintenance requirements, and ease of installation.

💡 Looking for a complete Solar BOS Kit? Power your solar project with Samptel Energy’s trusted solution — Safe, Fast, and Built to Last.

📲 Call: +91 99980 50519 📧 Email: [email protected] 🌐 Visit: https://www.samptelenergy.com/products/solar-bos-kit-solar-balance-of-system-kit/

1 note

·

View note

Text

Tech Talk 101: Solar Glossary for Beginners - GB Solar

Solar energy is, to be sure, a whole new language to learn, filled with wires and watts and lots of wonderful things! Be it solar panels atop your roof or trying to make sense of your energy bills, understanding solar jargon could make or break the deal for you. You needn’t be an engineer or a person who is an expert in solar backgrounds to do it, so fear not. Let us break it down in layman’s terms for the benefit of your solar-gleaming knowledge!

The Basics: Back to Science Class!

Let’s warm up with some simple concepts you may vaguely remember from school:

Current (I): Imagine electricity as a river, and current is how fast the water (electrons) flows. There are two types—Alternating Current (AC) and Direct Current (DC). The SI Unit of current is Ampere (A)

Alternating Current (AC): This is what powers your home. It flows back and forth, changing direction—like waves lapping on a shore.

Direct Current (DC): DC is straight to the point—electricity flows in one constant direction, just like the energy from batteries or solar panels

Voltage (V): Think of this as the “pressure” pushing electricity through a wire. More voltage means more power pushing electrons from one point to another. The SI unit of Voltage is Volt (V).

Power (W): This is how fast energy is used or generated. The SI Unit for Power (W) is Watt.

1 kilowatt (kW) = 1,000 watts

1 megawatt (MW) = 1,000 kW

1 gigawatt (GW) = 1,000 MW

Kilowatt-Hour (kWh): This is the “unit” seen on your electricity bill. A 1 kilowatt appliance used for one hour is one kWh consumed. Monitor your household appliances, and very soon, you will find out how much solar power you might need!

Utility Grid: The giant web that sends power from big power plants to your home or office. It’s what you’re currently plugged into.

Solar Panel Speak: Your Intro to Solar Modules

Now let’s zoom in on the stars of solar power—the panels and their partners:

Solar Panel: Photovoltaic panels are made up of photovoltaic (PV) cells, which are converters of sunlight into electricity, typically by using silicon. Connect a whole bunch of them together and you’ll get a solar array.

Solar Inverter: Solar panels do produce DC power, but home electricity runs on AC. So in between comes the inverter that operates conversions of the two, hence rendering solar power usable.

Balance of System (BoS): Everything in your solar setup except the panel—like cables, mounting frames, batteries, and wiring. The unsung heroes!

Panel Efficiency: This tells you how good your panel is at converting sunlight into electricity. The higher, the better. GB Solar offers 20–23% efficiency—top-tier stuff!

Bifacial Panels: Unlike traditional panels that work from one side, bifacial ones capture sunlight from both the front and back. More sun, more power!

Monocrystalline Panels: Sleek and black, these are made from a single crystal of pure silicon. They’re efficient and premium, but also a bit pricier.

Polycrystalline Panels: Blueish and made from multiple silicon crystals, these are more budget-friendly but slightly less efficient.

Solar Tech Innovations: PERC vs. TOPCon

PERC (Passivated Emitter and Rear Cell):

Imagine your solar cell is a bucket catching sunlight. PERC adds a reflective layer to the bucket’s base, so nothing escapes—more light captured, more energy made.

TOPCon (Tunnel Oxide Passivated Contact):

Now imagine an ultra-bucket that reflects, catches, and transfers light faster with minimal loss. TOPCon cells are energy efficiency champions, especially in hotter climates.

Solar System Types: Know Your Setup

Grid-Tied (On-Grid) Systems: Stay connected to the grid while using solar energy. If you produce extra, you can send it back and earn credit!

Off-Grid Systems: No grid? No problem. These standalone systems use batteries to store energy for night-time or cloudy-day use.

Hybrid Systems: Best of both worlds—connected to the grid and equipped with battery backup for added reliability.

Rooftop Solar: Popular among residential and small commercial spaces. Easy to install, easy to maintain—just keep it clean!

Ground-Mounted Solar: Perfect for high-capacity projects. The panels are installed on sturdy ground structures, ideal for farms and industrial plants.

Solar Policies & Financial Terms (aka Money Talk)

Here’s where solar meets your wallet. These terms are worth knowing:

Net Metering: Produced more power than you used? Send it to the grid and get credited for it!

Gross Metering: All your solar power goes to the grid, and you receive a fixed rate for every unit.

Feed-in Tariff (FiT): A guaranteed price you get paid for the solar energy you export to the grid.

Time-of-Day (ToD) Tariff: Electricity costs shift depending on demand—cheaper at night, costlier in the evening.

Renewable Purchase Obligation (RPO): Big consumers are legally required to source a portion of their energy from renewables.

Open Access Solar: Large businesses can buy solar power directly from producers, bypassing the local utility.

Electricity Duty Exemptions: Incentives like zero duty charges make solar even more affordable.

Power Purchase Agreement (PPA): A contract to sell solar power at agreed rates—usually signed between producers and DISCOMs.

Accelerated Depreciation: A big reason solar is great for industries—you get tax benefits by writing off the project cost quickly.

Capital Subsidy: Government support to reduce initial solar setup costs—makes the transition more budget-friendly.

Renewable Energy Certificates (RECs): Certificates that prove you’ve generated green energy. They can be traded or used to meet RPOs.

Green Bonds: Investors fund green projects like solar plants through bonds. Good for your karma and your portfolio!

Solar Investment Tax Credit (ITC): A tax benefit allowing you to deduct a portion of your solar investment from your income tax.

Bankable Solar Projects:A project that’s profitable, stable, and attractive to investors.

Levelized Cost of Energy (LCOE): The average cost of electricity from your solar system over its lifespan—a great metric to understand ROI.

Ready to Go Solar?

What is now making you feel a little better with the solar lingo? Rather, learn your solar ABCs and make wiser green choices whether it is to go totally off-grid or just reduce electricity bills.

Have you no idea how to begin? Relax. Ask our experts for advice free of charge.

Contact Us – Turning your roof into a power station!

Blog Source -- Tech Talk 101: Solar Glossary for Beginners - GB Solar

#top solar panel manufacturer in gujarat#solar parks#solar panel manufacturer in gujarat#solar panel manufacturers gujarat#solar epc companies#solar epc solutions#solar energy

0 notes

Text

Solar Maintenance Services

Maintaining your solar panel system optimizes performance and extends its lifespan. It also helps keep your warranty valid.

Inspections check for corrosion, loose connections, and other issues that could cause problems down the road. They also identify any shading from trees, bushes, or new buildings.

Finding a good provider starts with evaluating their experience and client satisfaction. Look for a licensed and certified crew.

Clean the Panels

The best way to get the most out of your solar energy system is to keep it clean. This means removing any dirt or debris that can hinder sunlight absorption and reduce electricity production. Ideally, this should be done twice per year. However, more frequent cleaning may be needed if you live in an area with high levels of dust or pollen or if you haven’t had rain in a while.

Professional solar cleaners typically use a hose with soapy water to safely clean your solar panels. They avoid using very cold water as this can cause thermal shock and damage your solar panel. They also avoid abrasive sponges that could scratch the surface.

They can also check underneath your panels for any signs of animals nesting under them (in which case they’ll spring for solar critter guards), and can take advantage of your monitoring system to verify that the solar panels are still generating at peak performance.

Inspect the Inverter

The inverter is responsible for converting DC power from your panels into AC power that can be used in your home. It is crucial to ensure the inverter has proper ventilation to avoid overheating that can lead to smoke damage or a potential fire hazard.

During your solar maintenance services inspection, a technician will look at the inverter to make sure it’s functioning properly and is displaying the correct information. Any inconsistencies or anomalies in the data should be addressed as soon as possible.

If your inverter is displaying an error code, check the manufacturer’s guidelines for troubleshooting tips. A persistent error code could indicate that the inverter needs to be replaced, or that there are more serious problems causing it to shut down. If this is the case, an O&M package can help cover costs like inverter repairs. A plan like this can also provide protections similar to those that you’d get with a warranty on a car or home.

Inspect the Wiring

The solar wiring configurations and electrical connections need to be checked to prevent damage, safety issues, and to maintain optimum performance. Loose connections can lead to loss of energy production and can be a fire hazard. Electrical faults can be caused by voltage drops, corrosion, improper initial installation, or other environmental factors.

Regular inspections can detect these problems and address them promptly. It is also important to keep a diagram of your solar panel system for reference, as it will show how components are connected and the direction of current flow.

If your monitoring system shows a significant drop in energy output or warning lights appear on the inverter, contact a professional immediately. These are signs of serious problems that require immediate attention to ensure safety and warranty compliance. A qualified technician can perform a thorough visual inspection, test the inverter, and inspect the panels, cables, and mounting materials for physical damage or corrosion. They can also help you plan for future repairs and insurance claims.

Monitor the Output

Many solar energy systems have in-home or online monitoring apps to help you track daily, weekly, and annual production. By logging in to the platform and comparing performance to expected output, you can spot problems early and have them addressed.