#EMI Filters circuit

Explore tagged Tumblr posts

Text

EMI Filters circuit, 3 phase EMI filter, EMI filter for power supply

BNX02 Series 12.1 x 9.1 mm 0.00043 Ω 10 A 50 V SMT LC Combined EMI Filter

0 notes

Text

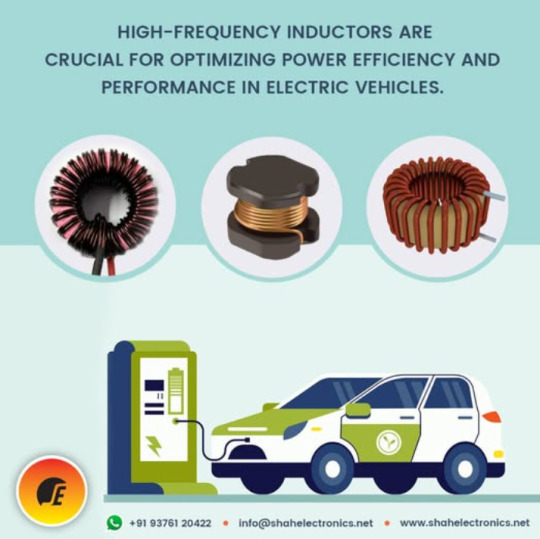

High-Frequency inductors are crucial for optimizing power efficiency and performance in Electric Vehicles. . For more information: Visit: https://www.shahelectronics.net/ Call: +91 7935024960 Email: [email protected]

#currenttransformer#Automotive Circuits#SMPS TRANSFORMER#PULSE TRANSFORMER#COMMON MODE CHOKES#CURRENT TRANSFORMER#EMI LINE FILTER#INDUCTOR COIL#FLYBACK TRANSFORMER#HIGH VOLTAGE TRANSFORMER

0 notes

Text

https://www.futureelectronics.com/p/passives--filters--emi-filters/bnx023-01l-murata-3676152

Filters, EMI Filters, BNX023-01L, Murata

BNX02 Series 9.1 x 12.1 x 3.1 mm 100 V 500 mΩ 15 A SMT Block EMI Filter

#Filters#EMI Filters#BNX023-01L#Murata#EMI filter design#EMI power filter#EMI suppression filter#Emi power filter#rfi EMI filter#dc EMI filter#Power line#EMI noise filter#air filter#Data lines#circuit#USB hubs#EMI thernet

1 note

·

View note

Text

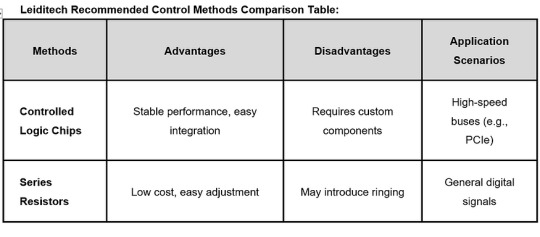

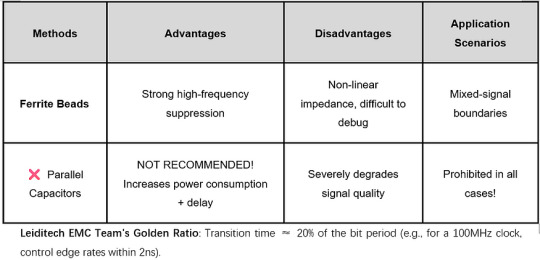

EMC Design Pit Avoidance Guide:

Four no mnemonics

Why does your well-designed product fail EMC testing? The EMC team at Leiditech shares 4 practical EMC design techniques summarized in the “Four No” principles to help you avoid common pitfalls!

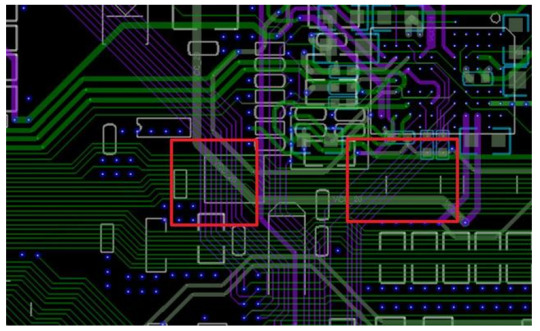

Principle 1: Make Current Take the Shortest Path, Not a Detour

Core Logic: High-frequency currents follow the “path of minimum inductance”. Larger loops → stronger radiation!

Key Insights from Leiditech Lab:

l Signal currents must form closed loops, with return paths closely following the outgoing paths.

l Low-frequency (kHz-level) currents follow the “path of minimum resistance”, with possibly dispersed return paths; high-frequency (MHz-level) currents follow the “path of minimum inductance”, with return paths closely adhering to the main trace.

l Design Tip: Place high-speed signals adjacent to their return planes and reduce the spacing between the signal layer and the ground plane.

Principle 2: Do Not Split the Signal Return Plane

Leiditech EMC engineers’ golden rule: Provide a complete return plane for all signal currents. For low-frequency signals prone to interference or likely to cause board-level interference, use dedicated trace layers to route return currents back to the source rather than splitting the plane. Arbitrary slotting/dividing the ground plane can cause abrupt changes in return paths → surging EMI!

Exceptions:

Independent return traces may be used only for isolating low-frequency sensitive signals (e.g., audio power supplies), provided:

l The independent layer has a separate return path and does not cross high-frequency planes.

l Consult Leiditech EMC experts to avoid case-by-case misapplication.

Warning: A complete plane is the optimal solution in 99% of scenarios!

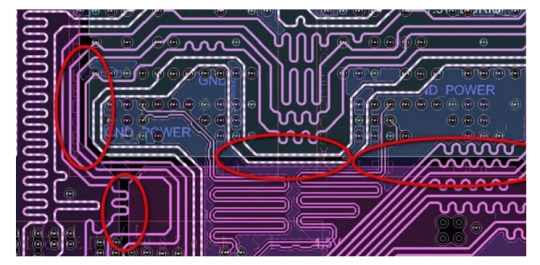

Principle 3: Do Not Route High-Speed Circuits Between Connectors

This is one of the most common issues in PCB designs evaluated by Leiditech Lab. Many simple designs that could easily meet EMC requirements (with no extra cost or effort) end up requiring extensive shielding and filtering due to violating this rule.

Why connector placement matters: At frequencies below several hundred MHz, wavelengths can be meter-scale or longer. While the PCB itself acts as a low-efficiency “antenna” due to its small electrical size, cables or external devices connected to the PCB can become efficient radiators.

When signal currents flow on traces and return through a complete plane, the voltage difference between any two points on the plane is typically proportional to the in-plane current. When all connectors are aligned along one side of the PCB, voltage differences between them are negligible. However, if high-speed circuits are routed between connectors, potential differences of several millivolts or more may arise, driving currents into connected cables and causing excessive radiation emissions.

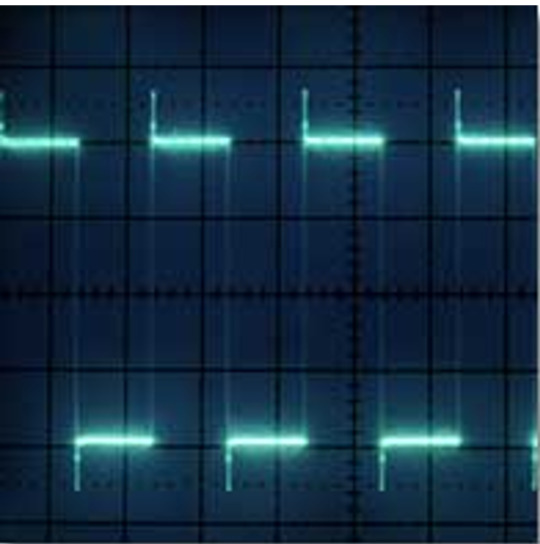

Principle 4: Do Not Blindly Pursue the Fastest Edge; Control Signal Transition Time

Fast edges (1ns) → harmonics up to 2GHz; slow edges (5ns) → harmonics <500MHz.

Leiditech EMC Team’s Golden Ratio: Transition time ≈ 20% of the bit period (e.g., for a 100MHz clock, control edge rates within 2ns).

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out: 📧 [[email protected]] 🌐 Visit us at [en.leiditech.com] #NoMoreBuzzing #DriveInPeace #SmartCarTech #ElectromagneticShield #AutoInnovation #CarSafetyFirst #ShanghaiLeditech #NextGenDriving #HornHarmony #AutoElectronics #EMCProtection #StaticNoMore #SmartDriveSolutions

0 notes

Text

How Do Ferrite Beads Enhance the Performance of Electronic Devices?

In the world of electronics, reducing noise and ensuring the efficient transmission of signals is crucial. One of the most effective components used for this purpose is ferrite beads. These small yet powerful components are commonly used to filter high-frequency noise in electronic devices, improving their performance and reliability. But how exactly do ferrite beads work, and why are they so essential in modern electronic circuits? Let's explore this in detail.

What Are Ferrite Beads?

Ferrite beads are passive electronic components made from ferrite materials— a mix of iron oxide and other metallic elements. These beads are typically used to suppress electromagnetic interference (EMI) and radio-frequency interference (RFI) in electronic circuits. By absorbing high-frequency signals and converting them into heat, ferrite beads prevent unwanted signals from interfering with the main signals in a circuit.

Ferrite beads are simple in design but highly effective, making them an indispensable tool in the development of stable and high-performing electronic devices.

How Do Ferrite Beads Work?

The operation of ferrite beads is based on the principle of inductance. When an electrical current flows through a circuit, it may produce high-frequency noise or unwanted signals. Ferrite beads act as low-pass filters, blocking high-frequency signals while allowing lower frequencies to pass through without interference.

Here’s how they work:

Inductive Reactance: When the current passes through a ferrite bead, its inductance creates a resistance to high-frequency signals. This resistance increases as the frequency of the signal rises, allowing the bead to filter out higher-frequency noise.

Energy Conversion: The unwanted noise energy is absorbed by the ferrite material and converted into heat, effectively dissipating the interference and ensuring smooth signal transmission.

Types of Ferrite Beads

Ferrite beads come in various shapes and sizes, designed for different applications. The type of ferrite material used can vary depending on the frequency range and the environment in which the bead will be used.

Wire-wound Ferrite Beads: These beads are often used for high-current applications. They are typically placed around a wire to filter noise without affecting the power supply.

Surface-mount Ferrite Beads: These beads are designed to be mounted directly onto the surface of a circuit board. They are smaller and more suitable for modern, compact electronic devices.

Axial Ferrite Beads: Commonly used in power lines, axial ferrite beads are designed to suppress EMI in both directions and are usually placed in-line with cables.

Why Are Ferrite Beads Important?

In today’s increasingly complex electronic environment, interference can be a significant issue. The rise of wireless devices, digital circuits, and high-frequency signals has led to a surge in electromagnetic interference, which can disrupt the normal operation of sensitive components.

Here are some key reasons why ferrite beads are important:

Noise Suppression: Ferrite beads reduce EMI and RFI, which can cause data corruption, malfunctioning circuits, or even complete failure of electronic devices.

Improved Signal Integrity: By filtering out unwanted signals, ferrite beads maintain the integrity of the primary signal, improving the overall performance of the device.

Enhanced Safety: High-frequency noise can sometimes cause circuits to overheat, leading to damage or failure. Ferrite beads help prevent this by absorbing excess energy.

Cost-Effectiveness: Ferrite beads are relatively inexpensive and easy to implement, making them an affordable solution for noise reduction.

Applications of Ferrite Beads

Ferrite beads find their applications across various industries, primarily where EMI and signal integrity are a concern. Some of the key areas where ferrite beads are used include:

Consumer Electronics: From smartphones to laptops, ferrite beads are commonly used in power lines, USB cables, and circuit boards to ensure devices operate smoothly and without interference.

Automotive Electronics: Modern vehicles rely heavily on electronic systems for navigation, communication, and safety features. Ferrite beads help prevent electromagnetic noise from affecting the performance of these systems.

Medical Equipment: Precision is essential in medical devices, and ferrite beads ensure that noise doesn’t compromise the accuracy of medical readings or treatments.

Industrial Machinery: Machines with sensitive electronic components require ferrite beads to filter out noise and prevent malfunctioning in high-power environments.

Communication Systems: Ferrite beads play a critical role in maintaining the quality of signals transmitted in telecommunication networks, radar systems, and satellite communications.

Advantages of Using Ferrite Beads

Ferrite beads provide a range of advantages that make them an essential choice for various applications in electronics:

Compact Size: Ferrite beads are small and lightweight, making them ideal for modern devices where space is limited.

High Efficiency: These components are highly effective in filtering out unwanted high-frequency noise without significantly affecting the overall performance of the circuit.

Ease of Integration: Ferrite beads are easy to integrate into a circuit design, requiring no complex modifications or additional components.

Durability: Ferrite beads are durable and reliable, with a long lifespan, making them suitable for both consumer and industrial applications.

Conclusion

Ferrite beads may appear simple at first glance, but their importance in the realm of electronics cannot be overstated. By efficiently suppressing high-frequency noise, these tiny components help enhance the performance, safety, and reliability of modern devices. Whether you’re working on consumer electronics, automotive systems, or industrial machinery, ferrite beads offer an effective and affordable solution for noise reduction and signal integrity.

By understanding the function and advantages of ferrite beads, you can make informed decisions when designing electronic circuits that meet today’s demanding performance standards.

0 notes

Text

Ferrite Toroid Coils Market: Growth Driven by Corrosion Monitoring Needs

Ferrite Toroid Coils Market Analysis:

The Ferrite Toroid Coils Market was valued at USD 423.6 million in 2024 and is projected to reach USD 625.7 million by 2032, growing at a CAGR of 5.00% during the forecast period (2025-2032).

Ferrite Toroid Coils Market Overview

Ferrite toroid coils, also known as ferrite ring inductors, are magnetic components used in electronic circuits to suppress high-frequency noise and manage electromagnetic interference (EMI). These components are shaped like a doughnut (toroid) and made from ferrite—a ceramic material composed of iron oxide mixed with other metallic elements.

The primary function of these coils is to filter electrical signals, ensuring the stable operation of electronic devices. Due to their enclosed magnetic field and low electromagnetic radiation, they are ideal for use in high-density electronic environments. The core shape minimizes power loss and provides a high inductance per turn, making them highly efficient for various AC and DC applications.

Ferrite toroid coils are essential in power supplies, transformers, EMI filters, and radio frequency circuits. Their versatility, cost-effectiveness, and performance efficiency have made them indispensable across multiple industries such as consumer electronics, automotive, telecom/datacom, and industrial automation.

This report provides a deep insight into the global Ferrite Toroid Coils Market, covering all its essential aspects. This ranges from a macro-overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Ferrite Toroid Coils Market. This report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Ferrite Toroid Coils Market in any manner.

Ferrite Toroid Coils Key Market Trends :

Rising Demand in Automotive Electronics With the shift towards EVs and advanced driver-assistance systems (ADAS), ferrite toroid coils are increasingly used for EMI suppression and efficient energy transfer in automotive electronics.

Growing Adoption in Telecom Infrastructure The 5G rollout and increasing data transmission require reliable components. Ferrite toroid coils support signal integrity and electromagnetic compatibility in telecom/datacom applications.

Miniaturization of Electronic Components The push for smaller, more efficient devices has led to demand for compact ferrite toroid coils under 10 mm, especially in wearable electronics and IoT devices.

Increased Production in Asia-Pacific Countries like China, South Korea, and Japan are leading in coil production due to low-cost manufacturing and rising electronics consumption.

Sustainability and Recycling Initiatives Manufacturers are increasingly focusing on eco-friendly materials and processes in coil production to meet global environmental standards.

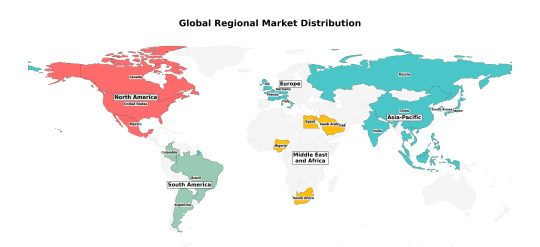

Ferrite Toroid Coils Market Regional Analysis :

North America:Strong demand driven by EVs, 5G infrastructure, and renewable energy, with the U.S. leading the market.

Europe:Growth fueled by automotive electrification, renewable energy, and strong regulatory support, with Germany as a key player.

Asia-Pacific:Dominates the market due to large-scale manufacturing in China and Japan, with growing demand from EVs, 5G, and semiconductors.

South America:Emerging market, driven by renewable energy and EV adoption, with Brazil leading growth.

Middle East & Africa:Gradual growth, mainly due to investments in renewable energy and EV infrastructure, with Saudi Arabia and UAE as key contributors.

Ferrite Toroid Coils Market Segmentation :

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments.

Market Segmentation (by Application)

Consumer Electronic

Automotive

Telecom/Datacom

Others

Market Segmentation (by Type)

Less Than 10 mm

10 mm to 100 mm

More Than 100 mm

Key Company

Fair-Rite

Vacuumschmelze

Wurth Elektronik

Hitachi Metals

Leader Tech

KEMET

Astrodyne

Altech

Laird Performance Materials

Market Drivers

Surge in Consumer Electronics Demand Increasing use of smartphones, laptops, and smart home devices is boosting the demand for ferrite toroid coils for EMI suppression and signal filtering.

Expansion of Electric Vehicle Market The rapid adoption of EVs requires components that can handle high-frequency currents and reduce interference, creating strong demand for toroidal inductors.

Growth in Data Centers and Telecom Rising internet usage and data center expansion are driving the need for coils in power supply units and network hardware.

Market Restraints

Fluctuation in Raw Material Prices Volatility in the prices of ferrite materials and metals affects production costs, leading to pricing challenges for manufacturers.

Availability of Alternatives Alternative inductor technologies such as air-core coils or planar transformers may limit adoption in some low-frequency or cost-sensitive applications.

Design and Size Constraints Despite their efficiency, larger toroid coils can be difficult to integrate into compact or highly miniaturized electronic products.

Market Opportunities

Integration in Renewable Energy Systems Ferrite toroid coils are increasingly being used in solar inverters and wind energy converters to ensure energy efficiency and reduce noise.

Technological Advancements in Coil Design Innovation in coil winding, material composition, and automated manufacturing presents opportunities for performance improvement and cost reduction.

Demand from Emerging Economies Growing electronics production and infrastructure development in countries like India, Vietnam, and Brazil are creating new market opportunities.

Market Challenges

High Competition and Price Pressure The market is fragmented with numerous players, leading to intense price competition and margin pressure.

Strict Regulatory Standards Compliance with international EMI and EMC standards requires continuous product innovation and rigorous testing, increasing R&D costs.

Supply Chain Disruptions Geopolitical tensions and trade restrictions can impact the global supply of raw materials and finished products.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/global-gaas-power-amplifier-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ambient-light-sensor-for-display-system.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/solar-obstruction-light-market-to-reach.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ac-dc-power-supply-converter-market-to.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/boost-charge-pump-ics-market-to-reach.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-motion-detector-sensor-market-to.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/x-ray-inspection-for-security-market-to.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-spatial-filters-market-to-reach.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-e-beam-liner-market-advancements.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-active-quartz-crystal-oscillator.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-ultrasonic-radar-market-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-ammeter-shunt-resistors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-wifi-and-bluetooth-rf-antenna.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-industrial-control-printed.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-scanning-transmission-electron.html

0 notes

Text

RF Filter - RFI EMC Filter

In an era where electronic devices dominate industrial, medical, and commercial applications, maintaining clean and stable power is more critical than ever. Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) can severely disrupt sensitive equipment, leading to malfunctions, data corruption, and even system failures. This is where RFI EMC Filters come into play—providing essential protection by filtering out unwanted noise and ensuring compliance with global Electromagnetic Compatibility (EMC) standards.

At DMC RF, we specialize in manufacturing high-performance EMI/RFI power line filters, including the RFI EMC Filter 5 to 300 AMP (FCL-66, -660 Series), RFI EMC Filters 25 to 200 AMP (DMC FCL-11, -110, -14, -140, -1 Series), and a wide range of RFI EMC Filter Accessories (FCL-55, -66, -660 Series). Our filters are designed to meet the most stringent industry requirements, ensuring optimal performance and reliability.

Understanding EMI, RFI, and EMC Filters

What is EMI and RFI?

EMI (Electromagnetic Interference):��Unwanted disturbances caused by electromagnetic radiation from external sources, affecting electronic circuits.

RFI (Radio Frequency Interference): A subset of EMI, specifically caused by high-frequency signals that disrupt communication and electronic systems.

Why Are EMC Filters Necessary?

Modern electronic devices must comply with EMC regulations (FCC, CISPR, IEC) to ensure they neither emit excessive interference nor are susceptible to external noise. RFI EMC Filters suppress conducted and radiated emissions, protecting both the equipment and surrounding devices from interference.

How Do RFI EMC Filters Work?

These filters use a combination of inductors (chokes), capacitors, and ferrite cores to:

Block high-frequency noise from entering or exiting a device.

Allow clean power to pass through without disruption.

Reduce electromagnetic emissions to meet regulatory standards.

DMC RF’s High-Performance RFI EMC Filters

1. RFI EMC Filter 5 to 300 AMP (FCL-66, -660 Series)

Designed for high-power industrial applications, this series ensures robust noise suppression in demanding environments.

Key Features:

Current Range: 5A to 300A

Voltage Rating: Up to 660V

High Attenuation: Effective noise reduction across a broad frequency spectrum

Rugged Construction: Built to withstand harsh industrial conditions

Compliance: Meets CISPR, EN 55011, and MIL-STD-461 standards

Applications:

✔ Industrial motor drives & servo systems ✔ Medical imaging & diagnostic equipment ✔ Renewable energy inverters & solar power systems ✔ Data centers & telecom infrastructure

2. RFI EMC Filters 25 to 200 AMP (DMC FCL-11, -110, -14, -140, -1 Series)

Ideal for medium-power applications, these filters provide reliable EMI suppression for commercial and industrial equipment.

Key Features:

Current Range: 25A to 200A

High Efficiency: Minimizes conducted and radiated interference

Flexible Mounting Options: Panel or chassis mounting available

Compact Design: Space-saving without compromising performance

Applications:

✔ CNC machines & robotics ✔ Power supplies & UPS systems ✔ HVAC & refrigeration units ✔ Laboratory & test equipment

3. RFI EMC Filter Accessories (FCL-55, -66, -660 Series)

To ensure seamless integration, DMC RF offers a range of compatible accessories, including:

Available Accessories:

Mounting brackets & hardware for secure installation

Shielded enclosures for enhanced EMI protection

Terminal connectors & cable glands

Customizable solutions for specialized applications

Why RFI EMC Filters Are Essential for Your Industry

1. Industrial Automation & Machinery

Prevents interference in PLC systems, servo drives, and robotics.

Ensures smooth operation of CNC machines and conveyor systems.

2. Medical & Healthcare Equipment

Protects sensitive MRI machines, X-ray systems, and patient monitors from noise.

Ensures compliance with medical EMC standards (IEC 60601).

3. Telecommunications & Data Centers

Reduces signal distortion in 5G infrastructure, servers, and networking equipment.

Enhances data integrity and transmission reliability.

4. Renewable Energy Systems

Filters noise from solar inverters, wind turbines, and battery storage systems.

Improves efficiency and lifespan of power electronics.

Choosing the Right RFI EMC Filter

Factors to Consider:

Current & Voltage Ratings – Match the filter to your system’s power requirements.

Attenuation Level – Ensure sufficient noise suppression for your application.

Mounting Style – Panel-mount, chassis-mount, or DIN rail options.

Regulatory Compliance – Check for FCC, CE, CISPR, and UL certifications.

Environmental Conditions – Consider temperature, humidity, and vibration resistance.

Why Choose DMC RF?

✔ Industry-Leading Quality – Rigorously tested for performance & durability. ✔ Wide Range of Options – From 5A to 300A, covering all industrial needs. ✔ Global Compliance – Meets international EMC/EMI standards. ✔ Expert Technical Support – Assistance in selecting the right filter for your application.

In today’s electrically noisy environment, RFI EMC Filters are indispensable for ensuring the reliable operation of sensitive electronic systems. Whether you need a 5A filter for small devices or a 300A industrial-grade solution, DMC RF provides high-performance, compliant, and durable filters tailored to your needs.

By integrating DMC RF’s EMI/RFI power line filters, you can reduce downtime, improve efficiency, and meet global EMC standards with confidence. Contact us now to find the perfect filter solution for your application!

Contact US :

Phone Number : +1(613) 915 5533

Website: https://www.dmcrf.com/emi-rfi-power-line-filters/

1 note

·

View note

Text

The Impact of Electronic Grounding on Noise Reduction and Signal Quality Improvement

In modern electronic systems, achieving stable and clean signal transmission is critical for reliable performance. Traditionally, grounding methods such as the conventional grounding rod or "چاه ارت" (earth pit) have been used to ensure safety and reduce electrical interference. However, advancements in technology have introduced electronic grounding systems as a highly efficient "جایگزین چاه ارت" for improving noise suppression and enhancing signal quality. This article explores how electronic grounding impacts noise reduction and contributes to better signal integrity in various applications.

Understanding Electronic Grounding

Electronic grounding refers to the practice of establishing a common electrical reference point within a system using advanced techniques and materials designed to minimize impedance and electrical noise. Unlike traditional grounding methods that rely solely on physical earth connections, electronic grounding integrates additional components such as capacitors, resistors, and filters to provide more precise control over the electrical environment.

Suggested Reading: Advantages and Disadvantages of Using Electronic Grounding

Noise in Electronic Systems

Electrical noise is any unwanted disturbance that interferes with the desired signal. Noise sources can be internal, such as switching power supplies, or external, like electromagnetic interference (EMI) from nearby devices. Excessive noise degrades signal quality, leading to data errors, reduced performance, and sometimes hardware damage.

Role of Electronic Grounding in Noise Reduction

Lowering Ground Impedance

Electronic grounding reduces the impedance of the grounding path, allowing unwanted currents and interference signals to dissipate more effectively. This lowers the potential difference across components and minimizes noise coupling.

Improved Shielding and Filtering

Incorporating electronic components such as filters and capacitors in the grounding network helps absorb high-frequency noise and prevents it from affecting sensitive parts of the circuit.

Enhanced Isolation

Electronic grounding techniques can isolate different sections of a system, reducing ground loops that are common sources of interference.

Enhancement of Signal Quality

By providing a stable reference potential and minimizing noise, electronic grounding directly improves the quality of signals. This is especially important in sensitive applications like audio processing, communication systems, and precision measurement instruments. Improved signal integrity results in clearer audio, more accurate data transmission, and reliable device operation.

Applications

Telecommunications: Reducing noise in signal lines to ensure clear and uninterrupted communication.

Medical Devices: Protecting sensitive diagnostic equipment from interference.

Industrial Automation: Enhancing the accuracy and reliability of sensors and controllers.

Consumer Electronics: Improving audio and video quality in home entertainment systems.

Conclusion

Electronic grounding serves as a modern and effective "جایگزین چاه ارت" that addresses the limitations of traditional grounding methods. By significantly reducing electrical noise and stabilizing signal references, it plays a vital role in enhancing the overall performance and reliability of electronic systems. As technology evolves, adopting advanced grounding solutions becomes essential for meeting the growing demands of high-quality signal processing and noise immunity.

0 notes

Text

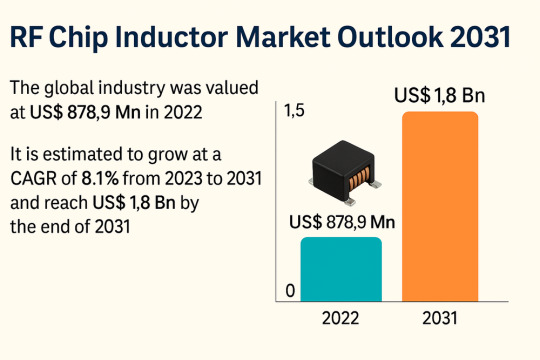

Robust Growth Forecast for Global RF Chip Inductor Market Through 2031

The global RF chip inductor market, valued at US$ 878.9 Mn in 2022, is projected to reach US$ 1.8 Bn by 2031, expanding at a CAGR of 8.1% from 2023 to 2031. Driven by rapid advancements in wireless communication, miniaturization of electronic devices, and increased integration of RF components in automobiles, the market is poised for robust growth throughout the forecast period.

Market Overview: RF chip inductors are integral components in wireless systems, designed for use in compact electronic circuits to manage radio frequency (RF) signals. These inductors are commonly integrated into System-on-Chip (SoC) and Integrated Circuit (IC) applications across smartphones, laptops, automotive electronics, and Internet of Things (IoT) devices.

Ceramic and ferrite types dominate the RF chip inductor market, with ceramic variants gaining significant traction due to their high-Q factors and low losses.

Market Drivers & Trends

1. Proliferation of Wireless Devices The surge in global demand for smartphones, tablets, smartwatches, and wireless earphones has led to a parallel rise in demand for RF chip inductors. These components are essential for wireless signal tuning and filtering, enabling efficient data transmission.

2. Automotive Electronics Boom Modern vehicles are evolving into connected hubs with built-in infotainment, GPS, keyless entry, and telematics systems. RF chip inductors are critical to these systems, especially in enabling secure and efficient data communication. India’s vehicle exports exceeding 5.6 million units in 2022 underscore the automotive sector's expanding role.

3. Government Investments Strategic investments in telecommunications infrastructure, like India's US$ 611.1 Mn for BharatNet, bolster the deployment of RF components, accelerating market growth.

Latest Market Trends

Miniaturization and Material Innovation Key industry players are focused on innovating smaller form factor inductors that can perform at higher frequencies. Advanced material research is helping improve signal integrity and reduce power consumption.

Rise of Wearables and IoT RF chip inductors are becoming central to the performance of wearable technologies, enabling seamless Bluetooth and Wi-Fi connectivity.

Increased Demand for Ceramic Inductors Ceramic chip inductors, which held a 54.3% share in 2022, offer superior performance, particularly in high-frequency environments. This segment is expected to grow at 8.4% CAGR during the forecast period.

Key Players and Industry Leaders

The global RF chip inductor industry is moderately consolidated with major players driving technological advancements through R&D and strategic partnerships. Leading companies include:

Murata Manufacturing Co., Ltd.

Coilcraft Inc.

KYOCERA AVX Components Corporation

Vishay Intertechnology, Inc.

Johanson Technology Incorporated

Würth Elektronik GmbH & Co. KG

Viking Tech Corporation

These companies are investing in ceramic and multilayer inductor technologies, launching ultra-miniature and high-performance products.

Access important conclusions and data points from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85752

Recent Developments

Gowanda Electronics (Feb 2022) launched the SMP0603 ceramic chip inductors, targeting power and RF applications in automotive and industrial systems.

KYOCERA AVX (Mar 2021) introduced the LCCI series multilayer ceramic chip inductors, designed for compact mobile and wireless systems including RFID, WLAN, and EMI suppression in high-frequency circuits.

Market Opportunities

Emerging Markets Rapid urbanization and rising digital connectivity in developing countries, particularly in Asia Pacific and Latin America, present significant growth potential.

5G Rollout The global deployment of 5G networks will further increase the demand for high-performance RF chip inductors, especially those that can handle ultra-high frequencies.

Electric and Autonomous Vehicles The transition toward autonomous and electric vehicles is expected to significantly boost demand for compact and robust RF components, opening lucrative avenues for market expansion.

Future Outlook

The RF chip inductor market is projected to continue its upward trajectory due to:

Expansion in consumer electronics production

Innovation in inductor materials and manufacturing

Strategic alliances and mergers among major players

Growing application in healthcare and industrial IoT

By 2031, the market is expected to nearly double in size, creating opportunities across the value chain, from component design and production to system integration.

Market Segmentation

By Type

Ceramic

Ferrite

By Structure Type

Film

Wire Wound

Multilayer

Air Core

By Inductance Range

Up to 100 nH

100–200 nH

200–400 nH

400–800 nH

800 nH–3.3 µH

Above 3.3 µH

By Application

Infotainment Systems

Smartphones

Portable Electronics

Broadband

Computer Peripherals

RFIDs

RF Transceivers

Others (Medical Imaging, PCS Modules)

By End-use Industry

Automotive & Transportation

Aerospace & Defense

Consumer Electronics

IT & Telecommunications

Industrial

Others (Healthcare, Energy, etc.)

Regional Insights

Asia Pacific leads the global RF chip inductor market, holding 40.8% market share in 2022. It is projected to maintain dominance due to:

High concentration of consumer electronics manufacturers

Growth in automotive production and export

Expansion of 5G infrastructure, especially in China, Japan, and South Korea

North America accounted for 27.6% market share in 2022 and is likely to experience steady growth due to advanced R&D capabilities and adoption of high-frequency RF applications in aerospace and defense.

Europe is also a promising region, especially with increasing focus on electric mobility and connected car infrastructure.

Why Buy This Report?

Comprehensive Market Coverage: Includes quantitative and qualitative analysis from 2017 to 2031.

In-depth Segmentation: Extensive breakdown by type, application, structure, and region.

Company Profiles: Detailed insights into major players and their strategic developments.

Industry Analysis: Includes Porter’s Five Forces, value chain analysis, and market attractiveness.

Actionable Insights: Identify key opportunities, regional hotspots, and emerging applications.

Explore Latest Research Reports by Transparency Market Research: Semiconductor Etching Equipment Market: https://www.transparencymarketresearch.com/semiconductor-etching-equipment-market.html

Linear Motor Market: https://www.transparencymarketresearch.com/linear-motor-market.html

Wafer Handling Robots Market: https://www.transparencymarketresearch.com/wafer-handling-robots-market.html

Time of Flight Sensor Market: https://www.transparencymarketresearch.com/time-of-flight-sensor-market.html

0 notes

Text

Industrial UPS for Offset & Digital Printing

Eprompt Enterprise stands out as a pioneer in supplying effective and dependable printing solutions in the fast-paced world of digital printing. One critical factor in their success is their use of superior uninterruptible power supply (UPS) technology. In this blog article, we'll look at the characteristics and benefits of Eprompt Enterprise's UPS systems, emphasizing how they help digital printing processes.

High-Frequency and Double-Conversion Online Technology :

By utilizing high-frequency and double-conversion online technology, Eprompt Enterprise incorporates the most recent innovations in UPS technology. This provides a smooth transition from utility to battery power, ensuring a steady and dependable power source for digital printing equipment. Eprompt Enterprise's UPS systems give uninterrupted, high-quality prints to their clients by avoiding power outages and fluctuations.

Completely Digitized Microprocessor Control :

Eprompt Enterprise's UPS systems have completely digitized microprocessor control, which allows for exact monitoring and control of power settings. This sophisticated control system provides peak performance, efficiency, and dependability. The computer continually monitors input and output voltages, battery state, and other vital factors, enabling fast reaction and modification to ensure stable power output.

Broad Input Voltage Variety :

Eprompt Enterprise's UPS systems are built to work with a broad variety of input voltages. They can manage variable input voltages while still delivering a stable and controlled output voltage even in areas with unreliable power networks. This adaptability provides constant performance while also protecting digital printing equipment from harm caused by voltage fluctuations.

Highly Efficient and High Input Power Factor :

In every digital printing process, efficiency is critical. UPS systems from Eprompt Enterprise have excellent efficiency levels of up to 91%, saving energy usage and operational expenses. The UPS systems optimize power utilization with a high input power factor of 0.99, resulting in greater productivity and less environmental impact.

LCD Display and Smart Monitoring :

The LCDs on Eprompt Enterprise's UPS systems give real-time information on essential parameters like as input/output voltages, battery status, load levels, and system diagnostics. This enables operators to efficiently monitor and troubleshoot the UPS system. The UPS systems also feature clever RS232 connections, allowing for simple interaction with monitoring software and optional SNMP cards for remote monitoring and administration.

Robust Protection and Reliability :

Eprompt Enterprise's UPS systems provide full protection against short circuits, overloads, and voltage surges, protecting digital printing equipment from harm. IGBT technology, which is employed in both the inverter and rectifier stages, guarantees exceptional reliability and long-term performance. Additionally, the UPS systems have EMI/RFI noise filters, which reduce electrical noise interference that might compromise print quality.

Eprompt Enterprise's advanced UPS technology is critical in enabling digital printing processes. Eprompt Enterprise ensures uninterrupted power supply, optimal performance, and reliable operation of their digital printing equipment with features such as high-frequency and double conversion online technology, fully digitized microprocessor control, wide input voltage range, high efficiency, LCD, and robust protection mechanisms. Eprompt Enterprise is a trusted partner for organizations seeking efficient and high-quality printing solutions in today's competitive digital printing market by employing innovative UPS technology.

0 notes

Text

DAEJOO : A Trusted Name in Marine & Industrial Automation Explore the Full Range at Aeliya Marine

In the constantly changing world of ocean and industrial automation, few names have withstood the test of time, providing precision, reliability, and confidence. One of them is DAEJOO, known around the globe for its cutting-edge engineering and high-reliability parts. Be it a business vessel traveling open seas or an assembly line that cannot pay the luxury of a second of downtime, DAEJOO’s automation components guarantee performance sans compromise.

At Aeliya Marine Tech, we are pleased to showcase a handpicked range of original DAEJOO products designed to satisfy marine engineers as well as industrial specialists. Ranging from hard-to-find PCBs to reliable relay units and control modules, our DAEJOO product portfolio is extensive, quality-approved, and ready to ship across the globe.

About DAEJOO Engineering Excellence You Can Rely On

DAEJOO Industrial Co., Ltd., based in South Korea, is a renowned producer of marine-grade electrical and automation components. With an emphasis on high-performance circuit design, interface reliability, and system safety, DAEJOO has emerged as the go-to option for shipyards, offshore platforms, naval maintenance teams, and industrial control engineers globally.

The mission of the company has ever been simple: to produce parts that endure, even in extreme environments. Those are products resistant to high humidity, saltwater corrosion, voltage spikes, and temperature extremes conditions prevalent both in marine and heavy industrial applications.

Discover the DAEJOO Product Categories at Aeliya Marine

Let’s start with some of the fundamental product categories found on our website under the DAEJOO banner:

1. Control Modules

DAEJOO’s control modules are the workhorse of a wide range of shipboard and industrial automation applications. With sturdy build quality and reliable interfacing logic, the modules provide the seamless execution of commands and control signals on any automation network.

Standard features :

High insulation resistance

DIN-rail mounting with compact dimensions

LED indication of diagnostic status

Fail-safe options

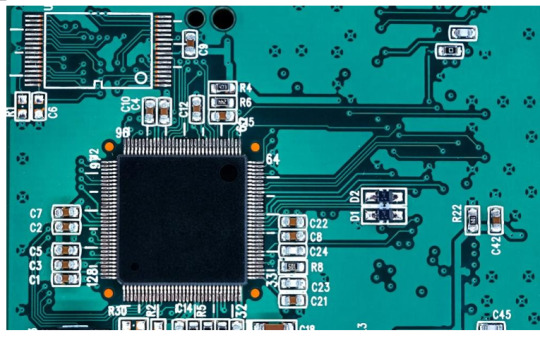

2. Interface Boards & PCBs

DAEJOO Printed Circuit Boards (PCBs) are designed to provide precise signal control and voltage regulation. They find application in main control panels, sensor systems, navigation controls, and motor interface units.

Regardless of whether you’re replacing a defective board or modernizing an old system, these PCBs provide :

Consistent copper trace paths

Built-in EMI protection

Components with surface-mount or through-hole

Clear part labeling and revision control

3. Relays & Timer Units

DAEJOO relays are ideal for timed switching, fault detection, and manual override systems applications. Their small sizes and conventional pin configurations simplify integration.

Benefits are:

Low power coil operation

Long mechanical and electrical life

High surge withstand capacity

ISO and IEC compliance

4. Power Supply Units & I/O Modules

In both factory and marine systems, power stability and input/output control are essential. DAEJOO’s power supply units provide stable voltage output with protective features such as overcurrent and thermal shutdown.

At the same time, their I/O modules provide :

Modular expansion

Easy plug-and-play connections

Flexible voltage and signal support (DC/AC)

Noise-filtering for reliable communication

Why Purchase DAEJOO from Aeliya Marine Tech?

At Aeliya Marine, we’re not merely product resellers we’re technical allies. Our mission is to assist engineers and purchasing teams in discovering genuine, tried, and deployable components, particularly when time and dependability are most critical.

Here’s why our customers worldwide have confidence in us:

1. Authenticated Genuine Parts

We buy directly from trusted networks so that each DAEJOO component is genuine and performance-verified. No fakes, no inferior substitutes only the original.

2. Complete Specifications & Images

We offer detailed specs, model codes, datasheets (where necessary), and hi-res images so you can be sure of what you’re getting.

3. Fast Dispatch & Global Shipping

Want it ASAP? We facilitate quick and trusted shipping to world ports and cities. Our logistics division in Mumbai is capable of processing express overseas orders.

4. Competitive Prices & Bulk Rate Discounts

Competitive prices and discounts for multi-unit purchases make Aeliya Marine the intelligent choice for business and solo technicians.

5. Professional Customer Support

We are here to assist you with selecting the proper part, confirming compatibility, and monitoring your order. Need some help with installation or wiring schematics? No worries.

Hot DAEJOO Products Available on Our Site

Below are some of our top customers’ favorites from our new DAEJOO range :

DAEJOO Interface Card DJ-2310 Series : Applied in ship automation consoles

DAEJOO DJR-105 Relay Unit : Suitable for motor protection and emergency override

DAEJOO Terminal Block DJT Series : Corrosion-proof and compact

DAEJOO Control Unit DJK-218 : Multi-channel logic control of automation systems

All of these products come with technical descriptions and pictures to assist you in identifying them properly.

Applications of DAEJOO Products

DAEJOO components are engineered to withstand the demanding requirements of various industries, including:

Marine Applications :

Engine Room Automation

Navigation Control Panels

Bridge Monitoring Systems

Alarm & Safety Circuits

Industrial Applications :

PLC-Based Automation

Machine Tool Controls

Conveyor System Integration

Power Distribution Panels

The versatility of DAEJOO components ensures that they are the first choice for engineers in various fields.

The Aeliya Marine Advantage : More Than Just a Vendor

When you buy from Aeliya Marine Tech, you’re buying from an organization that shares your sense of urgency and technical sophistication. We deal with professionals from shipyards, offshore facilities, steelworks, cement factories, and automakers who rely on us for:

Rare to find obsolete spares

System-compatible substitutes

Thoroughly inspected used & refurbished parts

Open service, from inquiry through delivery

We also assist customers in locating similar or compatible models when the original DAEJOO product is not available preventing downtime and saving money.

Wrapping Up : Reliable Technology for Demanding Systems

With DAEJOO’s established reliability and Aeliya Marine’s rapid response service, you can flow your maintenance, repair, or system upgrade project with total peace of mind. Whether you are upgrading your control room, renovating an ageing PCB, or refining a relay-based system, our DAEJOO series is designed to assist you to deliver results.

Ready to explore?

Click Here To View The Complete Daejoo products Collection

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter#deajoo

0 notes

Text

What Are EMI Filters and Why Are They Crucial in Electronic Devices?

EMI filters, or electromagnetic interference filters, are essential components used in electronic circuits to block unwanted electromagnetic noise. These filters help prevent interference from affecting the performance of devices such as computers, medical equipment, and communication systems. By suppressing high-frequency noise signals, EMI filters ensure smoother operation and increased reliability. Whether you’re dealing with industrial applications or consumer electronics, understanding EMI filters can help you design better, more compliant systems. They not only protect the equipment but also reduce emissions, ensuring adherence to global EMC regulations. Choosing the right EMI filter based on voltage, current, and frequency is vital to achieve optimal noise suppression. Learn how EMI filters safeguard your devices and ensure uninterrupted functionality.

0 notes

Text

Electronic Ballasts Manufacturer in Ahmedabad

An electronic ballast is a device that regulates the current and voltage supplied to gas-discharge lamps, such as fluorescent and high-intensity discharge (HID) lamps, ensuring efficient and stable operation. Unlike traditional magnetic ballasts, electronic ballasts convert incoming alternating current (AC) into direct current (DC) and then into high-frequency AC, typically ranging from 20 to 60 kHz. This high-frequency operation enhances the luminous efficiency of lamps by approximately 10% and reduces total energy consumption by about 20%, contributing to significant energy savings. The internal structure of an electronic ballast comprises several key components: an EMI filter to suppress electromagnetic interference, a rectifier to convert AC to DC, a DC filter to smooth the current, an inverter to generate high-frequency AC, and often a control circuit to manage the overall operation. This design not only ensures efficient power conversion but also minimizes flickering and audible noise, providing a more comfortable lighting environment. One of the notable advantages of electronic ballasts is their ability to provide a flicker-free start and steady light output, which reduces visual fatigue and enhances visual comfort. They also offer reliable lamp ignition, even under varying voltage conditions, and can extend lamp life by delivering consistent power and reducing stress on lamp components. Furthermore, electronic ballasts are lighter and more compact than their magnetic counterparts, facilitating easier installation and integration into various lighting fixtures.

For More Details Click Here: https://www.indiantradebird.com/product/electronic-ballasts

0 notes

Text

What causes LED headlights to flicker for a half minute and then work perfectly?

LED headlights that flash for about 30 seconds before functioning normally may be caused by several potential problems. Here are the most likely causes and their explanations:

Common causes and solutions for LED headlights that briefly flash and then resume normal operation are as follows:

1. Unstable voltage

Alternator failure: When the alternator cannot provide stable power, it will cause the LED headlights to flicker due to voltage fluctuations (manifested by abnormal values on the vehicle voltage meter). If the output of the driver exceeds the rated specifications of the LED chip (for example, providing 300mA for an LED rated for 250mA), the excessive current will make the light output unstable until thermal or electrical equilibrium is reached. It is recommended to go to a car repair shop to check the charging system.

Battery aging: When the battery is low or at the end of its life, the voltage drop at the moment of startup may cause the LED to flash briefly.

2. Circuit connection problems

Poor contact: Loose plugs, oxidized wiring, or improper wiring during modification (such as reverse polarity) can cause intermittent power outages.

Wiring harness aging: Aging or damage to the vehicle wiring may cause abnormal resistance. It is recommended to check the wiring harness insulation and connectors.

3. Abnormal cooling system

Insufficient cooling space: Some LED headlights require more than 2 inches of cooling space. If the fan is blocked or dusty, it may cause the overheat protection to trigger a temporary shutdown. Overheat protection is activated, and poor heat dissipation of the driver or headlight housing will trigger the thermal protection circuit. The driver may cycle on/off until the temperature stabilizes, causing temporary flickering.

Defective cooling design: Insufficient heat sink or fan efficiency of inferior lamps, and the temperature rises suddenly after long-term use, causing abnormalities.

4. Product compatibility and quality

Driver failure: LED drivers convert AC power to DC power. If the performance of internal components such as filter capacitors deteriorates, they may not be able to smooth the voltage ripple initially, causing flickering until the capacitor is fully charged. Over time, as the capacitor resumes function, this delay will shorten.

Adaptability issues: If the lamp is not compatible with the original car H4/H7 interface (such as not using an adapter), it may cause power supply abnormalities.

5. Other factors

Electromagnetic interference: Electromagnetic interference (EMI), near high-power electronic devices (such as inverters, motors or radio transmitters) can cause voltage spikes or noise in the LED circuit, causing flickering until the interference source is removed or the driver compensates.

Environmental humidity: Products that do not meet the IP68 waterproof rating may experience internal short circuits in humid environments.

Troubleshooting suggestions:

Prioritize the detection of vehicle charging system voltage (normal range 13.5-14.5V);

Check whether the lamp is installed properly, reseat the connector and clean the contacts;

Replace with a well-known brand and compatible LED headlight (such as SNGL with anti-flicker design), and replace the driver with a high-quality, compatible device. Look for brands with strong thermal management and EMI shielding.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#headlight bulb#headlamp#headlight#car light#carparts#cars

0 notes

Text

Ferrite Core Choke Market Opportunities in Oil & Gas and Chemical Industries

MARKET INSIGHTS

The global Ferrite Core Choke Market was valued at US$ 674 million in 2024 and is projected to reach US$ 987 million by 2032, at a CAGR of 4.9% during the forecast period 2025-2032. The U.S. market accounted for 32% of global revenue in 2024, while China’s market is expected to grow at a faster 7.2% CAGR through 2032.

Ferrite core chokes are passive electronic components designed to suppress electromagnetic interference (EMI) and filter high-frequency noise in electronic circuits. These devices utilize ferrite materials – ceramic compounds of iron oxide with nickel, zinc or manganese oxides – which exhibit high magnetic permeability and electrical resistivity. Common types include surface-mount (SMD), through-hole, and toroidal chokes, with applications ranging from power supplies to automotive electronics.

Market growth is driven by increasing demand for EMI suppression in consumer electronics and electric vehicles, where ferrite chokes help meet stringent electromagnetic compatibility (EMC) regulations. The automotive grade segment, representing 28% of 2024 sales, is seeing particular growth due to rising EV adoption. Leading manufacturers like TDK and Murata continue to innovate with compact, high-temperature resistant designs, though supply chain disruptions for rare earth materials remain a challenge.

MARKET DYNAMICS

MARKET DRIVERS

Expanding Telecommunications Infrastructure to Accelerate Ferrite Core Choke Demand

The global telecommunications sector is undergoing massive expansion with 5G rollouts and datacenter proliferation, driving substantial demand for ferrite core chokes. These components are critical for electromagnetic interference (EMI) suppression in high-frequency circuits – a function becoming increasingly vital as 5G base stations multiply globally. Current projections indicate over 4 million 5G base stations will be deployed worldwide by 2030, each requiring multiple ferrite core components for signal integrity. Furthermore, hyperscale datacenters are adopting these chokes at a compound annual growth rate exceeding 15% to manage power quality in their server farms. This dual demand from telecom infrastructure and cloud computing is propelling the market forward at an unprecedented pace.

Electric Vehicle Revolution Creating New Application Frontiers

The automotive industry’s shift toward electrification represents a significant growth vector for ferrite core chokes. Modern electric vehicles incorporate between 50-100 ferrite components per vehicle for functions ranging from onboard charging to battery management systems. With electric vehicle production volumes projected to surpass 40 million units annually by 2030, the automotive segment is emerging as one of the fastest-growing application areas. Leading manufacturers are developing specialized automotive-grade ferrite chokes that meet stringent AEC-Q200 qualifications for temperature stability and vibration resistance. The parallel growth of charging infrastructure, which requires similar EMI suppression components, further amplifies this market opportunity.

MARKET RESTRAINTS

Raw Material Volatility Impacting Manufacturing Economics

Ferrite core choke production faces persistent challenges from raw material price fluctuations. The primary composition of nickel-zinc and manganese-zinc ferrites makes the market sensitive to nickel price swings, which have varied by over 40% in recent years. This volatility creates unpredictable manufacturing costs that strain profit margins, particularly for smaller producers. Additionally, rare earth element supply chain disruptions have periodically caused shortages of critical dopants like yttrium and lanthanum that enhance ferrite performance. These material constraints force manufacturers to either absorb cost increases or risk losing business to alternative EMI suppression technologies.

Miniaturization Trend Composing Technical Hurdles

The industry-wide push toward smaller electronic devices is testing the physical limits of ferrite core technology. While ferrite compositions can be optimized for higher frequency operation, core losses increase exponentially as dimensions shrink below critical thresholds. This creates an engineering dilemma – consumers demand increasingly compact devices, but physics dictates certain minimum sizes for effective EMI suppression at target frequencies. Many manufacturers report development cycles stretching 20-30% longer when designing chokes for space-constrained applications like wearable tech or ultra-thin notebooks. This technical barrier is particularly acute in the consumer electronics segment where product lifecycles continue to accelerate.

MARKET OPPORTUNITIES

Renewable Energy Integration Opening New Growth Channels

The global transition toward renewable energy systems presents compelling opportunities for ferrite core choke manufacturers. Solar inverters and wind turbine converters require specialized EMI filters to meet stringent electromagnetic compatibility standards. Each megawatt-scale solar installation typically incorporates between 50-200 ferrite components for harmonic filtering. With solar capacity additions projected to exceed 300 GW annually by 2025, this represents a substantial greenfield opportunity. Concurrently, vehicle-to-grid (V2G) systems emerging in smart grid applications will require new choke designs capable of bidirectional power flow management.

Advanced Material Formulations Enabling Market Expansion

Materials science breakthroughs in ferrite compositions are unlocking previously inaccessible application areas. Novel nickel-zinc ferrites now demonstrate stable performance up to 2GHz with core losses reduced by 40-60% compared to conventional formulations. This performance leap is enabling adoption in cutting-edge sectors like aerospace electronics and medical imaging equipment. Several manufacturers have recently introduced chokes with integrated heat dissipation features, solving long-standing thermal management challenges in power-dense applications. These material innovations allow ferrite technology to maintain relevance against emerging alternatives like nanocrystalline and thin-film solutions.

MARKET CHALLENGES

Intensifying Competition from Alternative Technologies

Ferrite core chokes face growing competition from emerging EMI suppression solutions. Thin-film inductors based on MEMS fabrication techniques offer superior miniaturization capabilities for portable electronics. Meanwhile, nanocrystalline cores achieve higher saturation flux densities that appeal to power electronics designers. These alternatives typically command 20-30% price premiums today, but their cost structures follow semiconductor-like learning curves. Many major OEMs are allocating R&D budgets to assess these technologies, particularly for next-generation products where space constraints or efficiency requirements exceed ferrite capabilities. This competitive pressure forces ferrite manufacturers to continuously enhance performance while maintaining cost advantages.

Supply Chain Complexities Causing Production Bottlenecks

The fragmented nature of ferrite core manufacturing creates vulnerabilities in the component supply chain. Core production, wire winding, and final assembly often occur across multiple specialized facilities spanning different regions. This distributed model proved problematic during recent global logistics disruptions, with average lead times ballooning from 8-10 weeks to over 20 weeks for some choke types. The situation is particularly challenging for automotive customers operating just-in-time manufacturing systems. Some tier-one suppliers report maintaining 30-50% higher inventory buffers to mitigate these risks, increasing working capital requirements across the value chain.

FERRITE CORE CHOKE MARKET TRENDS

Growing Demand for Miniaturized Electronic Components to Drive Market Growth

The ferrite core choke market is experiencing steady growth due to increasing demand for compact, high-performance electronic components across industries. With consumer electronics accounting for over 35% of total market demand, manufacturers are focusing on developing smaller yet more efficient ferrite-based inductors that can handle higher frequencies without saturation. The ongoing miniaturization trend in mobile devices, wearables, and IoT applications has led to optimized ferrite material compositions with improved permeability and lower core losses at frequencies exceeding 100 MHz. Furthermore, advancements in multilayer ceramic capacitor (MLCC) technology are creating complementary demand for matching choke components.

Other Trends

Automotive Electrification Spurs Application Growth

The automotive sector represents one of the fastest-growing segments for ferrite core chokes, with electric vehicle production increasing by 54% annually in key markets. Modern EVs require sophisticated EMI suppression in charging systems, battery management, and power conversion circuits where ferrite chokes provide critical noise filtering. Automakers increasingly specify high-temperature grade ferrites capable of stable operation under 150°C thermal conditions. This has led to material innovations like nickel-zinc (NiZn) ferrites gaining traction alongside traditional manganese-zinc (MnZn) compositions for specialized automotive applications.

Telecommunications Infrastructure Expansion Creates New Opportunities

Rollouts of 5G networks and fiber-optic infrastructure are generating substantial demand for broadband ferrite components. Telecom-grade chokes must maintain performance across wider frequency bands while resisting interference from adjacent components. Base station deployments increased by 28% year-over-year in major markets, creating steady demand for power line chokes and common mode filters. Manufacturers are responding with specialized ferrite formulations optimized for high-frequency operation above 1 GHz while maintaining compact form factors needed for dense equipment racks.

Supply Chain Diversification Becomes Strategic Priority

Recent geopolitical tensions and material shortages have prompted manufacturers to reevaluate supply chain strategies for ferrite core production. While China currently supplies approximately 60% of global ferrite powder, companies are establishing alternative sourcing relationships and regional production facilities. Several leading choke manufacturers have announced capacity expansions in Southeast Asia and North America, with projected increases of 15-20% in localized raw material processing capabilities by 2026. This geographic diversification aims to mitigate risks while maintaining quality standards through stringent process controls.

COMPETITIVE LANDSCAPE

Key Industry Players

Strategic Product Innovation Drives Competition in the Ferrite Core Choke Market

The global ferrite core choke market exhibits a moderately consolidated structure, with established electronics component manufacturers competing alongside specialized magnetic solution providers. TDK Corporation emerges as the market leader, commanding approximately 18% revenue share in 2024. Their dominance stems from extensive R&D capabilities and a vertically integrated supply chain that spans across Asia, Europe, and North America.

Competitors Murata Manufacturing and Yageo Corporation collectively hold roughly 25% market share, leveraging their strong foothold in consumer electronics and telecommunications sectors. These Japanese and Taiwanese firms benefit from precision manufacturing capabilities and strategic partnerships with OEMs in high-growth application areas.

Market dynamics show increasing competition in automotive-grade ferrite chokes, where players like Triad Magnetics and Coilcraft, Inc. are gaining traction. The shift toward electric vehicles and advanced driver-assistance systems (ADAS) has prompted these suppliers to expand their high-temperature resistant choke offerings, with several product launches anticipated through 2025.

North American manufacturers such as Magnetic Component Engineering, Inc. are adopting hybrid strategies – combining customized solutions for industrial applications with cost-competitive standard products. Meanwhile, emerging players in Southeast Asia are disrupting the market with competitively priced general-grade chokes, particularly for mid-range consumer electronics.

List of Key Ferrite Core Choke Manufacturers

TDK Corporation (Japan)

Murata Manufacturing Co., Ltd. (Japan)

Yageo Corporation (Taiwan)

Triad Magnetics (U.S.)

Magnetic Component Engineering, Inc. (U.S.)

Coilcraft, Inc. (U.S.)

C.A. Spalding Co. (U.S.)

Magnetic Circuit Elements Inc. (U.S.)

Able Coil & Electronics Co., Inc. (U.S.)

Manutech, Inc. (U.S.)

Segment Analysis:

By Type

General Grade Segment Holds Significant Market Share Due to Widespread Electronics Applications

The market is segmented based on type into:

General Grade

Automotive Grade

Others

By Application

Consumer Electronics Segment Dominates with Increasing Demand for Power Management Solutions

The market is segmented based on application into:

Consumer Electronics

Automotive

Telecom/Datacom

Others

By End User

Original Equipment Manufacturers (OEMs) Lead Market Adoption for Integrated Circuit Designs

The market is segmented based on end user into:

Original Equipment Manufacturers (OEMs)

Aftermarket

System Integrators

By Core Material

Nickel-Zinc Ferrite Cores Gain Traction for High-Frequency Applications

The market is segmented based on core material into:

Manganese-Zinc Ferrite

Nickel-Zinc Ferrite

Others

Regional Analysis: Ferrite Core Choke Market

North America The North American ferrite core choke market demonstrates steady growth, largely driven by robust demand from the telecommunications and automotive sectors. The U.S. remains the largest contributor, supported by 5G infrastructure deployment and rising EV adoption, both of which require high-performance EMI suppression components like ferrite chokes. Recent investments in semiconductor manufacturing under the CHIPS Act ($52.7 billion allocated) are expected to further boost demand for electronic components, reinforcing market expansion. However, supply chain disruptions and reliance on imported raw materials remain key challenges for manufacturers in the region.

Europe Europe maintains a strong position in the ferrite core choke market due to stringent EMC compliance standards, particularly in Germany and France where industrial automation and automotive sectors dominate. The EU’s push for energy-efficient electronics under eco-design regulations has spurred innovation in high-temperature-resistant ferrite materials. Sustainability initiatives have also led to increased R&D in recyclable chokes. However, market growth faces constraints from rising energy costs and competition from Asian manufacturers offering cost-competitive alternatives. Tier-1 suppliers like TDK and Murata continue to lead through technological differentiation.

Asia-Pacific Accounting for over 45% of global consumption, the Asia-Pacific region dominates the ferrite core choke market, with China, Japan, and South Korea as production hubs. Massive electronics manufacturing output—particularly consumer devices and telecom equipment—fuels ongoing demand. China’s local component sourcing mandates have stimulated domestic ferrite choke production, though quality inconsistencies persist in mid-tier suppliers. Meanwhile, India emerges as a high-growth market due to expanding smartphone penetration and EV infrastructure development. Price sensitivity remains a key market characteristic, favoring general-grade chokes over premium automotive-grade variants.

South America The South American market shows moderate but uneven growth, with Brazil leading regional demand primarily for consumer electronics applications. Economic volatility limits widespread adoption of advanced ferrite core solutions, keeping the market reliant on imported standard-grade chokes. Infrastructure gaps in testing and certification hinder local manufacturing development. However, gradual modernization of industrial facilities and telecom networks in Argentina and Colombia presents niche opportunities for suppliers specializing in cost-optimized solutions tailored to emerging market needs.

Middle East & Africa This region represents an emerging market with growth concentrated in GCC countries and South Africa, where telecom tower deployments and datacenter construction drive choke demand. The lack of local production facilities results in complete import dependency, creating logistical challenges. While adoption rates lag behind global averages, increasing digitalization projects—such as Saudi Arabia’s NEOM smart city initiative—suggest long-term potential. Market development is constrained by limited technical expertise in high-frequency applications and preference for lower-cost alternatives to ferrite-based solutions.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Ferrite Core Choke markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Ferrite Core Choke market was valued at USD million in 2024 and is projected to reach USD million by 2032.

Segmentation Analysis: Detailed breakdown by product type (General Grade, Automotive Grade, Others), application (Consumer Electronics, Automotive, Telecom/Datacom), and end-user industry to identify high-growth segments and investment opportunities.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. The U.S. market size is estimated at USD million in 2024, while China is projected to reach USD million by 2032.

Competitive Landscape: Profiles of leading market participants including TDK, Murata, Yageo, Triad Magnetics, and Coilcraft, Inc., covering their product offerings, R&D focus, and recent developments.

Technology Trends & Innovation: Assessment of emerging materials, miniaturization trends, and evolving industry standards in ferrite core technology.

Market Drivers & Restraints: Evaluation of factors driving market growth such as increasing demand for EMI suppression in electronics, along with challenges like raw material price volatility.

Stakeholder Analysis: Insights for component suppliers, OEMs, system integrators, and investors regarding strategic opportunities in the evolving ferrite components ecosystem.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/global-gaas-power-amplifier-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ambient-light-sensor-for-display-system.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/solar-obstruction-light-market-to-reach.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ac-dc-power-supply-converter-market-to.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/boost-charge-pump-ics-market-to-reach.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-motion-detector-sensor-market-to.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/x-ray-inspection-for-security-market-to.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-spatial-filters-market-to-reach.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-e-beam-liner-market-advancements.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-active-quartz-crystal-oscillator.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-ultrasonic-radar-market-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-ammeter-shunt-resistors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-wifi-and-bluetooth-rf-antenna.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-industrial-control-printed.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-scanning-transmission-electron.html

0 notes

Text

Insulation Safety Breakthrough for Medical-Grade Rocker Switches: IEC 60601-1 Leakage Current Control and Lifecycle Reliability Design

Introduction

In medical devices, rocker switches serve as critical interfaces for life-support equipment (e.g., ventilators, dialysis machines) and diagnostic tools (e.g., ultrasound systems, endoscopes). Their electrical safety directly impacts patient and clinician lives. The IEC 60601-1 standard mandates stringent requirements for leakage current, insulation strength, and mechanical durability, with leakage current control and insulation design as core compliance challenges. This article dissects medical-grade rocker switch design through material selection, structural optimization, and process validation, supported by failure analyses and innovations tailored to medical environments (e.g., frequent sterilization, high humidity).

1. IEC 60601-1 Leakage Current Limits and Risk Scenarios

1.1 Leakage Current Categories and Thresholds

Earth Leakage Current: ≤0.5mA (normal), ≤1mA (single fault).

Enclosure Leakage Current: ≤0.1mA (normal), ≤0.01mA (patient-contact parts).

Patient Leakage Current: ≤0.01mA DC / 0.1mA AC (CF-type devices).

1.2 High-Risk Scenarios and Failure Modes

Sterilization Corrosion: Ethanol/hydrogen peroxide infiltration swells insulation (PA66吸水率: 1.8%→3.5%), dropping insulation resistance from 10^12Ω to 10^8Ω.

High Humidity: Operating room humidity ≥70% reduces creepage distances, causing flashover.

Mechanical Fatigue: 200+ daily actuations degrade seals (IP67→IP54).

2. Insulation Design Essentials for Medical Rocker Switches

2.1 Material Selection: Dielectric Strength vs. Chemical Resistance

Base Materials:Housing: PPS (CTI≥600V) outperforms PC/ABS in chemical resistance.Insulation Barriers: Ceramic-filled epoxy (FR-4) withstands 5x longer arc exposure.

Contact Materials:AgSnO₂: 70% slower oxidation than pure silver in humidity.Gold Plating (≥0.5μm): Prevents sulfidation-induced leakage fluctuations.

2.2 Structural Design: Creepage and Clearance Control

Primary-Secondary Isolation:Basic Insulation: ≥3.0mm between contacts and metal housing (250V).Supplementary Insulation: Polyimide films (0.2mm, 4kV withstand) shield PCBs.

Leakage Prevention:"Labyrinth" seals + medical silicone gaskets (50±5 Shore A) extend liquid paths to 12mm.Case Study: A ventilator switch reduced disinfectant ingress from 0.1mL to 0.01mL via dual O-rings and drainage channels.

2.3 Process Validation: Lifecycle Testing

Dielectric Strength Test: 1.5kV AC applied for 1 minute (IEC requires 1kV), leakage ≤0.5mA.

Damp Heat Test: 40°C/93% RH for 168 hours; insulation resistance ≥100MΩ.

Mechanical Endurance: 100,000 cycles; seal compression ≤15% (ISO 815).

3. Extended Design: Medical-Specific Innovations

3.1 EMI Shielding and Filtering