#EPDM

Explore tagged Tumblr posts

Text

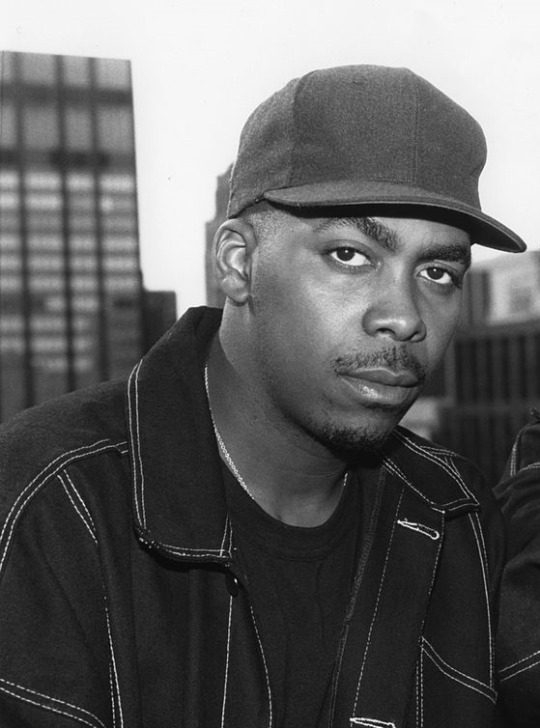

Today in Hip Hop History:

Parrish Smith aka PMD of EPMD was born May 13, 1968

#today in hip hop history#todayinhiphophistory#hiphop#hip-hop#hip hop#music#history#hip hop music#hip hop history#hip hop culture#music history#parrish smith#epdm#pmd#bornday#birthday#mc#emcee#rap#rapper#1968

95 notes

·

View notes

Text

"Soltera" by Shakira is now certified Platinum in Spain for selling 60,000 units in the country. 💋

[via epdm]

7 notes

·

View notes

Text

#construction#roofing company#roofing#home improvement#tennesseeroofers#music city roofers#nashville#nashville roofing company#hendersonville roofing company#gallatin roofing company#gallatin roofing service#nashville roof replacement#hendersonville home roof replacement#contractors#home improvement roofing contractors#roofers near me#commercial roofing#residential roofing#tpo roofing#epdm#roof coating#roof coatings#roofing crews#emergency roofing#24/7 roofing#open 24 hours#sumner county roofing company#davidson county roofing contractors#asphalt shingle roof repair#shingles

2 notes

·

View notes

Text

#EPDM#EPDMRubber#EPDMRubberprices#EPDMRubbermarket#EPDMRubberpricetrend#EPDMRubberpriceforecast#EPDMRubberdemand

2 notes

·

View notes

Text

The Ultimate Guide to Rubber Caps – Materials, Sizes & Features

Rubber caps might seem small, but they play a big role in a wide range of industries. Whether it's sealing off a tube, protecting threads, or masking components during finishing processes, rubber caps are versatile, durable, and essential.

In this ultimate guide, we’ll cover everything you need to know about rubber caps—materials, sizes, types, and key features—so you can find the perfect fit for your application.

🔍 What Are Rubber Caps?

Rubber caps are protective covers used to seal, cover, or protect the ends of pipes, rods, tubing, and other components. They help prevent damage, contamination, or leaks, and are widely used in industries such as:

Automotive

Electronics

Plumbing

Aerospace

Manufacturing

They’re designed to stretch slightly for a snug fit, providing temporary or permanent protection.

🧪 Rubber Cap Materials – Which One Is Right for You?

Rubber caps come in various materials, each suited to different environments and applications:

1. EPDM (Ethylene Propylene Diene Monomer)

Features: Excellent weather, ozone, and UV resistance

Use Case: Outdoor and automotive applications

2. Silicone Rubber

Features: High temperature resistance, flexibility, FDA compliant options available

Use Case: Food-grade, medical, or high-heat environments

3. Nitrile (Buna-N)

Features: Oil and fuel resistant

Use Case: Automotive, fuel systems, and hydraulic applications

4. Neoprene

Features: Chemical, flame, and weather-resistant

Use Case: General-purpose sealing, electrical insulation

5. PVC/Vinyl

Features: Cost-effective, color-coded, flexible

Use Case: Low-stress applications, color marking

Pro Tip: Always check the temperature range and chemical resistance chart before selecting your material.

Rubber Cap Sizes & How to Measure

Choosing the right size is crucial for a secure fit. Here’s what you need to consider:

✅ Inside Diameter (ID)

The internal opening of the cap should be slightly smaller than the component to ensure a snug fit.

✅ Length or Height

Longer caps provide more coverage but may be harder to apply or remove.

✅ Wall Thickness

Thicker walls provide more durability and protection but may reduce flexibility.

👉 Available Sizes:

Rubber caps are available in standard sizes ranging from 1mm to over 100mm, and custom sizes can be made for specific applications.

Types & Features of Rubber Caps

1. Tapered Rubber Caps

Conical shape

Fits a range of diameters

Ideal for masking and sealing

2. Round End Caps

Domed end

Good for sealing pipes or tubes

3. Pull-Tab Rubber Caps

Includes a tab for easy removal

Used in manufacturing or finishing processes

4. Threaded Rubber Caps

Internal threads match component threads

Secure fit for threaded rods or bolts

5. High-Temperature Masking Caps

Used during powder coating, anodizing, or plating

Can withstand heat up to 600°F (315°C)

✅ Key Benefits of Rubber Caps

Protection: Guards against dust, dirt, and physical damage

Sealing: Prevents leaks and contamination

Color Coding: Easy identification

Reusability: Many caps are reusable for multiple cycles

Custom Branding: Some manufacturers offer custom colors or logos

🛒 Where to Buy Rubber Caps?

Rubber caps are available from industrial suppliers, hardware stores, and custom manufacturers. When choosing a supplier, consider:

Material variety

Size options

Customization services

Compliance (FDA, RoHS, REACH)

Bulk pricing

Final Thoughts

Rubber caps are more than just simple stoppers—they’re essential components in protecting and sealing valuable equipment. Whether you need a high-temp silicone cap or a simple vinyl cover, understanding the materials, sizes, and features will ensure you choose the right solution.

Looking for high-quality rubber caps for your next project? Make sure to select a trusted supplier that offers the material specs, sizing, and durability your application requires.

#industrialsolutions#industrialrubber#rubbercomponents#RubberCaps#IndustrialProtection#SealingSolutions#MachineryCare#SiliconeCaps#EPDM#RubberProducts#ManufacturingSolutions#ProtectiveCaps#HeavyMachinery

0 notes

Text

Best EPDM Rubber Flooring in UAE

We are the leading EPDM flooring supplier in UAE. Our EPDM flooring service available in Dubai, Abu Dhabi & all over UAE. We offer you a better quality of EPDM flooring for both commercial and home purposes. They are used at home, at school, and in professional GYMs.

For More Info. Visit Us: https://rubberflooringuae.com/ Email Us: [email protected] Call Us: +971 545911811

#EPDM#EPDMFlooring#EPDMRubberFlooring#EPDMFlooringSupplier#EPDMFlooringShop#EPDMFlooringOnline#EPDMFlooringDubai#EPDMFlooringUAE#EPDMFlooringAbudhabi#RubberFlooringUAE

0 notes

Text

Today in Hip Hop History:

Parrish Smith aka PMD of EPMD was born May 13, 1968

#today in hip hop history#todayinhiphophistory#hiphop#hip-hop#hip hop#music#history#hip hop music#hip hop history#hip hop culture#music history#parrish smith#epdm#pmd#bornday#birthday#mc#emcee#rap#rapper#1968

61 notes

·

View notes

Text

"Copa Vacía" by Shakira feat. Manuel Turizo has been certified 2X PLATINUM in Spain (120,000 units).

Source: Listas Ventas España

#shakira#shakira mebarak#manuel turizo#celebs#celebrities#copa vacia#2x platinum#spain#lista ventas espana#epdm#news

11 notes

·

View notes

Text

Trusted EPDM Rubber Sheet Suppliers for Industrial Needs

Searching for trustworthy of EPDM Rubber Sheet Suppliers? Premium EPDM rubber sheets from Duratuf Products are well-known for their outstanding resistance to ozone, weather, and chemicals. Our EPDM sheets are ideal for a range of industrial applications because they offer superior performance and durability. Examine our selection right now and get in touch with reliable vendors who offer global delivery.

#EPDM Rubber#EPDM Rubber Sheet Suppliers#Rubber Sheet Suppliers#EPDM Rubber Sheet#EPDM#EPDMSuppliers

0 notes

Text

EPDM Membran Kaplama ve Isı Yalıtımı

EPDM membran kaplama, modern inşaat ve yalıtım projelerinde sıklıkla tercih edilen bir malzemedir. Uzun ömürlülüğü, dayanıklılığı ve yüksek performansı ile dikkat çeken EPDM membran kaplama, birçok avantaj sunmaktadır. Bu yazıda, EPDM membran kaplamanın özellikleri, avantajları ve uygulama alanlarına dair detayları inceleyeceğiz.

EPDM Membran Nedir?

EPDM membran, sentetik kauçuk bazlı bir malzemedir. Genellikle düz çatı uygulamalarında, su yalıtımı ihtiyacını karşılamak üzere kullanılır. EPDM membran kaplama, çeşitli iklim koşullarına dayanıklıdır ve UV ışınlarına, ozona ve hava koşullarına karşı direnç gösterir.

EPDM Membran Kaplamanın Avantajları

1. Uzun Ömürlü Yapı

EPDM membran kaplama, 20 yıl veya daha uzun bir hizmet ömrü sunabilen son derece dayanıklı bir malzemedir. Bu, bir kez uygulandığında uzun yıllar boyunca bakım gerektirmeden kullanılabileceği anlamına gelir, böylece toplam maliyetleri düşürür.

2. Su Yalıtımı

EPDM membran, tamamen su geçirmezdir ve su sızdırmazlığı sağlar. Çatılarda, teraslarda ve diğer düz yüzeylerde mükemmel bir su yalıtım çözümü sunar. Bu özellik, su hasarını ve nem sorunlarını önlemeye yardımcı olur.

3. Kolay Uygulama

EPDM membran kaplama, hafif ve esnek bir yapıda olduğu için uygulama süreci oldukça kolaydır. Roll olarak satılan EPDM membran, hızlı bir şekilde uygulanabilir ve iş gücü maliyetlerini azaltır.

4. Çevre Dostu Seçenek

EPDM membran, geri dönüştürülebilir bir malzemedir ve çevreye duyarlı bir yalıtım seçeneği sunar. Doğal kaynakları en aza indirerek açık hava koşullarına dayanıklılığı sayesinde çevresel etkiyi de azaltır.

5. Isı Yalıtımı

EPDM membran kaplama, ısıya karşı dirençlidir ve gelişmiş ısı yalıtım özellikleri sunar. Bu özellik, enerji verimliliğini artırarak ısı kaybını en aza indirir ve enerji tasarrufu sağlar.

Uygulama Alanları

EPDM membran kaplama, çeşitli alanlarda kullanılabilir. Başlıca uygulama alanları şunlardır:

Düz Çatılar: EPDM membran, düz çatılar için ideal bir su yalıtım çözümüdür.

Teraslar: Teras alanlarında etkili bir su geçirmezlik sağlar.

Konteynerler: Su yalıtımı ve koruma amaçlı konteyner kaplama uygulamalarında kullanılır.

Endüstriyel Tesisler: Depo alanları ve diğer endüstriyel yapılar için dayanıklı bir kaplama seçeneğidir.

Sonuç

EPDM membran kaplama, dayanıklılığı, su yalıtım özellikleri ve enerji verimliliği ile inşaat sektöründe tercih edilen bir malzemedir. Uzun ömürlü yapısı, kolay uygulanabilirliği ve çevre dostu özellikleri ile birçok projede başarılı sonuçlar elde edilmesini sağlar. EPDM membran kaplama, hem ticari hem de bireysel projelerde güvenilir bir yalıtım çözümü sunarak, inşaat alanında önemli bir yer edinmiştir.

0 notes

Text

EPDM Excellence: Choose Organix Building System for Superior Solutions

Discover unparalleled quality with Organix Building System LLC – your top choice for EPDM in Dubai. Our advanced solutions redefine excellence, ensuring durability and performance. Elevate your projects with the best EPDM, exclusively from Organix Building System LLC.

Know More: https://www.organixbs.com/epdmmembrane.php

0 notes

Text

Guess Who’s Back? The Pack is!

Hey Valerie Echter and all Packers’ fans! Remember that sneak peek on September 17th? We showed you inside the blender and the sack with 70% forest green and 30% yellow EPDM mix. Well, now, here's the big reveal—the mold peel! Doesn’t it just scream Lambeau Field vibes? #sportsflooring #homegymflooring

🔗 Catch the action here! 🔗

#SportsFlooring#HomeGymFlooring#EPDM#RubberFlooring#LambeauField#Packers#FitnessFlooring#WorkoutSpace#GymDesign#InteriorDesign#FlooringDesign#USRubber

1 note

·

View note

Text

Revolutionizing the Rubber Realm: A Deep Dive into the Thriving EPDM Market Landscape

In the ever-evolving landscape of the global market, the Ethylene Propylene Diene Monomer (EPDM) industry is poised for significant growth. According to the latest report, the EPDM Market is estimated to be USD 3.6 billion in 2022 and is projected to reach USD 4.8 billion by 2027, reflecting a noteworthy Compound Annual Growth Rate (CAGR) of 5.9% during the forecast period from 2022 to 2027.

EPDM Market Overview

EPDM, a versatile synthetic rubber, finds its applications across diverse sectors, including Automotive, Building & Construction, Plastic Modification, Tires & Tubes, Wires & Cables, and Lubricant Additives. Automotive, in particular, emerges as the major driver of the EPDM market, contributing significantly to its growth. As the automotive sector experiences a robust recovery in the Asia-Pacific (APAC) region, the demand for EPDM is expected to surge.

Key Insights and Opportunities

The automotive application holds the largest share in the EPDM market, with China playing a pivotal role. The country's focus on developing new energy vehicles (NEVs), encompassing Fuel Cell Electric Vehicles (FCVs), Plug-in Hybrid Electric Vehicles (PHEVs), and Battery Electric Vehicles (BEVs), is a key catalyst for the increased usage of EPDM in the automotive industry. According to the China Association of Automobile Manufacturers (CAAM), the total production of cars in 2021 witnessed a 3% year-on-year increase.

Additionally, the growing demand for electric and hybrid vehicles presents new opportunities in the EPDM market. The development of eco-friendly technologies for EPDM production aligns with the global shift towards sustainable practices in the automotive sector.

Manufacturing Processes and Market Dynamics

EPDM can be manufactured through various processes, and the Solution Polymerization Process currently dominates the market. This process is highly versatile, allowing for the production of a wide range of polymers. Polymerization and catalyst technologies play a crucial role in tailoring EPDM to meet specific application and processing needs.

Regional Market Dynamics

The Asia-Pacific region emerged as the frontrunner in the global EPDM market in 2021, with China being a key player in both production and consumption. The region's dominance is attributed to the concentration of EPDM producers and the flourishing automotive and construction sectors. New construction projects and sustained growth in the automotive industry are propelling the EPDM market in Asia Pacific.

Industry Players and Strategies

Leading players in the EPDM market include ARLANXEO, DOW Inc., Exxon Mobil Corporation, JSR Corporation (Kumho Polychem Co. Ltd.), PetroChina Company Limited, Versalis S.p. A., SK Global Chemical Co., Ltd., Sumitomo Chemical Co., Ltd., and Mitsui Chemicals, Inc. These industry giants are actively shaping the market through strategic initiatives, ensuring competitiveness and sustainability.

Download PDF Report :

Navigating the Future

As the EPDM market continues to evolve, keeping an eye on ethylene propylene diene monomer prices, EPDM market trends, and the EPDM price trend for 2023 will be critical. Stakeholders should remain vigilant about the dynamic market forces, ensuring they are well-positioned to capitalize on emerging opportunities and navigate challenges.

The EPDM market's growth trajectory is marked by resilience and adaptability, making it a key player in the global rubber market. Stay tuned for more updates on the EPDM market, where innovation meets opportunity in this dynamic industry landscape.

0 notes

Text

Buy #1 Durable EPDM Flooring Dubai

We offer premium quality EPDM flooring Dubai with expert installation services all over the UAE. Buy our EPDM flooring at an affordable price.

We are the best EPDM flooring services provider in Dubai, UAE. Our synthetic rubber floors and tiles are unmatched in quality and durability.

For More Info.

Visit Us: https://rubberflooringuae.com/ Email Us: [email protected] Call Us: +971 545911811

0 notes

Text

#zengerler#okul#zepoxy#epdm#business#economy#prefabrik home#prefabricated#prefabricated buildings#prefabricated modular health clinics#prefabrication#zemi̇n#epoxy#entrepreneur#fitness

1 note

·

View note

Text

EPDM Roofing Systems - Everything You Need to Know

Avoid installing the wrong roofing system on your commercial building. Knowing the benefits of an EPDM roofing system and how one protects your structure will help you determine which commercial roofing system is best for your needs.

newimageroofingatlanta.com gathered essential information on EPDM roofing systems, their compelling benefits, and how they are manufactured.

What is EPDM?

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber material commonly used in multiple applications, including roofing systems. This material is renowned for its excellent durability, weather resistance, and versatility. EPDM roofing membranes are widely used in the construction industry to install flat or low-slope roofs on industrial, commercial, and residential buildings. Consider the following benefits of EPDM roofing:

Exceptional Durability – One of the primary reasons for selecting an EPDM roofing system is its exceptional durability. EPDM is a synthetic rubber membrane that can withstand a range of environmental stressors, including:

Exposure to UV rays

Extreme temperatures

Inclement weather conditions

EPDM roofs have a proven track record of longevity. They can last anywhere from 20 to 30 years or more with proper maintenance, making them a durable, reliable, and cost-effective roofing solution.

Superior Weather Resistance – EPDM roofing systems are renowned for their ability to withstand a range of severe weather conditions. They are highly resistant to damage from rain, snow, hail, and ice. EPDM membranes are designed to expand and contract with temperature fluctuations, ensuring they remain intact and effective over time. This weather resistance provides unparalleled peace of mind to property owners, knowing that their roofs can stand up to the elements.

Energy Efficiency – EPDM roofs are excellent at reflecting sunlight and heat away from the structure, contributing to significant energy savings. EPDM roofing’s reflective nature helps reduce the cooling load on the building during hot summer months, leading to lower energy bills. EPDM roofing materials are often completely recyclable, further promoting environmental sustainability and reducing your carbon footprint (associated with cooling systems).

Low Maintenance Requirements – Maintaining an EPDM roofing system is straightforward, and its low maintenance requirements are another significant advantage. Routine inspections and occasional cleaning are typically all that’s required to keep your EPDM roof in excellent condition. EPDM’s resistance to mold and algae growth helps maintain its pristine appearance and structural integrity, reducing the need for frequent repairs or replacements.

Cost-Effective Installation – EPDM roofing systems are known for their cost-effective installation. They are lightweight and can be installed quickly, which leads to reduced labor costs. Additionally, EPDM membranes come in large rolls, allowing for seamless installation with minimal seams or joints, reducing the risk of leaks over time. This efficiency in installation can save property owners substantial time and money.

Eco-Friendly Alternative – EPDM roofing systems are an eco-friendly roofing option. EPDM membranes are typically composed of recyclable materials and can be fully repurposed at the end of their useful life. This sustainable aspect aligns with the growing demand for environmentally responsible construction practices.

Note: EPDM roofs also contribute to energy efficiency, reducing the carbon footprint of the building and helping property owners reduce their environmental impact.

Versatility and Adaptability – EPDM roofing systems are incredibly versatile and adaptable to multiple architectural styles and roof designs. They can be installed on flat roofs, low-slope roofs, or even steep-slope roofs. EPDM roofing materials are available in different thicknesses and can be fully adhered, mechanically fastened, or ballasted, depending on your project’s specific needs. This versatility makes EPDM a suitable choice for both new construction and roof replacement projects.

See if an EPDM roofing system is appropriate for your structure by requesting a free roof inspection.

How is EPDM Manufactured?

To fully understand how EPDM offers so many incredible benefits, here’s an overview of how EPDM roofing membranes are manufactured:

Raw Materials – EPDM is made from a combination of several raw materials, including:

Ethylene

Propylene

Diene monomers

These materials are derived from petrochemical sources. The specific formulations and additives may vary depending on the manufacturer and the intended application.

Polymerization – The manufacturing process begins with the polymerization of the raw materials. This process chemically bonds the ethylene, propylene, and diene monomers to create the EPDM polymer. The polymerization is typically done using catalysts and heat.

Vulcanization – After the EPDM polymer is formed, it needs to be vulcanized to achieve its desired physical properties. Vulcanization is a polymer cross-linking process that increases strength, durability, and heat resistance. This is typically achieved by adding sulfur and using heat or chemical accelerators.

Processing – The vulcanized EPDM rubber is processed into the desired form, which is often in large sheets or rolls. During this stage, multiple additives may be mixed in to enhance specific properties, like UV resistance, flexibility, and/or flame resistance.

Sheet Formation – The EPDM rubber is then processed into sheets or rolls at a desired thickness. These sheets are typically available in various widths and lengths to suit different roofing applications.

Curing – The EPDM sheets may go through a curing process to ensure that they are fully set and ready for use. This process typically involves applying heat to further improve their physical properties.

Reinforcement – Some EPDM roofing membranes may have reinforcement layers incorporated into them. These reinforcement layers, often made of polyester or fiberglass, are embedded within the EPDM sheets (creating a composite) to provide additional strength and stability.

Final Quality Control – Before the EPDM roofing material is packaged and shipped to customers, it undergoes multiple rigorous quality control checks to ensure that it meets industry standards and specifications. This includes checking for defects, thickness consistency, and quality.

Once the EPDM roofing material is manufactured and quality-controlled, it is ready for distribution and installation on roofs. EPDM roofing systems are known for their ease of installation, as the sheets can be adhered to the roof substrate using various methods, like adhesive, ballast, or mechanical fasteners.

Visit and subscribe to this commercial and residential roofing contractor’s YouTube channel for short informational videos on multiple roofing topics.

EPDM Roofing Systems

In this article, you discovered what EPDM is, its multiple benefits, and how it is manufactured for roofing systems.

Understanding what EPDM is, its valuable benefits, and its extreme versatility will contribute to making informed decisions when installing or replacing your roofing system.

Failure to educate yourself about different roofing systems can lead to an inadequate or problematic roof being installed on your structure with costly consequences.

Sources: energystar.gov/products/building_products/roof_products/other_types_roofing_that_can_save_energy gccds.msstate.edu/research/altconstruction/roof/roof.pdf vtechworks.lib.vt.edu/bitstream/handle/10919/109460/polymers-14-01308.pdf?sequence=1&isAllowed=y mulehide.com/en-us/News-Events/Blog/why-choose-epdm

New Image Roofing Atlanta

2020 Howell Mill Rd NW Suite 232 Atlanta, GA 30318 (404) 680-0041

To see the original version of this article, visit https://www.newimageroofingatlanta.com/epdm-roofing-systems-everything-you-need-to-know/

1 note

·

View note