#EPDM applications

Explore tagged Tumblr posts

Text

#EPDM Roofing Market COVID-19 Analysis Report#EPDM Roofing Market Demand Outlook#EPDM Roofing Market Primary Research#EPDM Roofing Market Size and Growth#EPDM Roofing Market Trends#EPDM Roofing Market#global EPDM Roofing market by Application#global EPDM Roofing Market by rising trends#EPDM Roofing Market Development#EPDM Roofing market Future#EPDM Roofing Market Growth#EPDM Roofing market in Key Countries#EPDM Roofing Market Latest Report#EPDM Roofing market SWOT analysis#EPDM Roofing market Top Manufacturers#EPDM Roofing Sales market#EPDM Roofing Market COVID-19 Impact Analysis Report#EPDM Roofing Market Primary and Secondary Research#EPDM Roofing Market Size#EPDM Roofing Market Share#EPDM Roofing Market Research Analysis#EPDM Roofing Market Trends and Outlook#EPDM Roofing Industry Analysis

0 notes

Text

What Type of Screws Should Be Used for Residential Metal Roofing?

If you're considering upgrading to residential metal roofing, you’re likely wondering about a few key aspects—like the types of screws you'll need to use. Choosing the right screws isn’t just a matter of aesthetics; it plays a significant role in the durability and longevity of your roof. Let’s dive into the details so that you can make informed decisions for your home improvement project.

Understanding Residential Metal Roofing

Residential metal roofing is gaining traction among homeowners due to its incredible longevity and durability. Unlike traditional asphalt shingles, metal roofs can last 50 years or more when properly installed. They are also highly resistant to weather conditions, making them a smart choice for various climates. However, the installation process requires the right materials, particularly when it comes to screws.

The Importance of Choosing the Right Screws

When installing residential metal roofing, the type of screws you select matters. Using the wrong screws can lead to leaks, corrosion, and reduced lifespan of your roofing system. Specifically, metal roofing screws are designed to accommodate the expansion and contraction that occurs with temperature changes. They’re manufactured to offer a secure fit while minimizing the risk of damage to the panels.

Types of Screws for Residential Metal Roofing

1. Self-Drilling Screws

Self-drilling screws, often referred to as “tek screws,” are one of the most popular options for residential metal roofing. These screws come with a drill bit tip, allowing them to pierce the metal without requiring pre-drilling. This can save time during installation since you can avoid the extra step of making pilot holes.

Benefits of Self-Drilling Screws:

Easy and quick installation.

Excellent for various metal thicknesses.

Reduces the risk of misalignment during installation.

2. Galvanized Screws

Galvanized screws are coated with a layer of zinc, which provides excellent rust resistance. This is particularly important for roofs exposed to harsh weather conditions, as metal roofs can be prone to corrosion if not properly protected.

Benefits of Galvanized Screws:

Enhanced durability against rust and corrosion.

Suitable for both residential and commercial applications.

Available in various lengths and diameters to fit different needs.

3. Stainless Steel Screws

For homeowners looking for the ultimate in corrosion resistance, stainless steel screws are an excellent choice. They are perfect for coastal areas where saltwater can accelerate corrosion. Although they are typically more expensive, their longevity can justify the investment.

Benefits of Stainless Steel Screws:

Exceptional resistance to rust and corrosion.

Ideal for challenging environments, such as coastal regions.

Lower maintenance costs over the lifespan of your roof.

4. EPDM Washers

While not a screw type, it’s essential to consider the washers you’ll use with your screws. EPDM (Ethylene Propylene Diene Monomer) washers provide a reliable seal that prevents water leaks. When paired with metal roofing screws, they create an effective barrier against moisture, ensuring the integrity of your roofing system.

Benefits of EPDM Washers:

Flexible and durable, allowing for thermal expansion and contraction.

Offers excellent weather resistance.

Helps to prevent leaks in metal roofing applications.

Other Considerations for Residential Metal Roofing Screws

Length and Diameter

When selecting screws for residential metal roofing, pay attention to the length and diameter. The length should be sufficient to penetrate through the metal panel and into the underlying structure, typically a wooden or metal frame. Generally, screws should extend at least 1 inch into the substrate to ensure a secure hold.

Color Match

Aesthetics also play a role in your screw selection. Many manufacturers offer color-matched screws that blend seamlessly with your metal roofing panels. This not only enhances the visual appeal of your roof but also ensures that any exposed screw heads do not detract from the overall design.

Installation Tips for Using Screws in Residential Metal Roofing

To ensure a successful installation, consider the following tips:

Follow Manufacturer Guidelines: Always consult the metal roofing manufacturer's instructions regarding screw types, lengths, and installation practices.

Avoid Over-Tightening: When installing screws, be careful not to over-tighten them. This can lead to the deformation of the metal panels and compromise their integrity.

Stagger Your Screws: For improved water resistance and stability, stagger your screws in each panel. This technique provides better support and minimizes the potential for leaks.

Check for Alignment: Regularly check that your panels are aligned properly as you install the screws. Misalignment can lead to unnecessary strain on the panels and screws.

Secure Your Home’s Future

When it comes to choosing screws for residential metal roofing, making the right decisions will significantly impact the roof's performance and longevity. Self-drilling screws, galvanized or stainless steel options, and EPDM washers are all excellent choices to consider. Paying attention to the type, size, and installation techniques ensures that your metal roofing project stands the test of time.

Are you ready to explore residential metal roofing more and learn the best practices for installation? Visit Lastime Exteriors today to learn about our services and find energy-efficient roofing solutions tailored to your needs. Make sure to invest in your home's future!

7 notes

·

View notes

Text

Aohong NBR Sealing Rubber Gaskets: The Cost-Effective Workhorse for Demanding Applications

Let's face it—when that hydraulic system starts leaking after just six months and you're knee-deep in oil-soaked components, you realize not all rubber gaskets are created equal. NBR Sealing Rubber Gaskets from Aohong solve what generic elastomers can't: delivering reliable sealing performance without breaking the bank. Here's why our nitrile rubber solution outperforms the competition where it matters most.

The Science Behind Superior Sealing

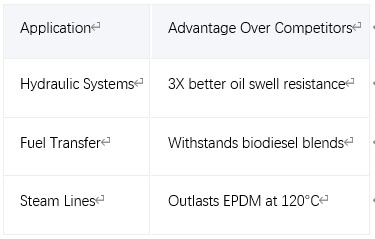

That 34% acrylonitrile content in Aohong's formulation isn't just a random number—it's the sweet spot for balancing oil resistance and flexibility. While cheaper NBR compounds cut corners with 28% content (and pay the price in swelling), we've optimized our material to deliver:

70±5 Shore A hardness (ASTM D2240 verified)

<10% oil swell after 1,000 hours in ASTM #3 oil

-40°C to 120°C service range—no brittle fractures in cold climates

85% compression set resistance at 100°C (beats EPDM in hot oil)

Pro Tip: That matte black finish isn't for looks—it's our proprietary carbon black reinforcement that adds 30% more tear strength versus standard NBR.

Real-World Proof: Hydraulic Cylinder Case Study

Take this OEM mining equipment application we solved last quarter:

Problem: Competitor's gaskets swelled 25% after 3 months

Conditions: 1,500 psi hydraulic fluid + 80°C continuous operation

Solution: Aohong's NBR gasket with enhanced oil swell resistance

After 18 months of brutal service: ✓ Zero leaks (pressure tested monthly) ✓ Only 8% thickness variation ✓ Saved $14,000 in downtime costs

Their maintenance supervisor called it "the only gasket that lasts through our service interval."

Installation: Do It Right the First Time

Surface Prep

32-64 RA surface finish (too smooth causes slippage)

Clean with isopropyl alcohol—never WD-40 (leaves silicone residue)

Torque Sequence

30% less torque than FKM gaskets

Criss-cross pattern for even compression

Break-In Period

Allow 24 hours for full compression set

Retorque after first thermal cycle

❌ $8,000 Mistake Using petroleum grease as lubricant—it degrades NBR over time. Silicone-based only.

Where Aohong's NBR Excels

Safety Note: Never use with ketones or esters—they'll dissolve the material in weeks.

The Bottom Line

When your application needs oil resistance without fluoropolymer prices—whether it's a construction equipment hydraulic system or a biodiesel transfer line—Aohong's NBR Sealing Rubber Gasket delivers proven performance where generic rubber fails.

Why gamble with inferior materials? Contact Aohong's engineering team today for application-specific solutions—because in industrial sealing, "good enough" usually fails at the worst possible moment.

3 notes

·

View notes

Text

Top 5 Benefits of Using Rubber Gaskets in Industrial Settings

In the demanding world of industrial manufacturing, efficiency and reliability are non-negotiable. From high-pressure pipelines to sanitary processing systems, one seemingly small component plays a critical role in keeping operations running smoothly: the rubber gasket. At California Rubber, we specialize in precision-engineered rubber gaskets designed for performance, durability, and safety across a wide range of applications.

Rubber gaskets offer significant advantages over metal or fiber alternatives in terms of flexibility, resilience, and resistance to extreme conditions. In this blog, we explore the top five benefits of using rubber gaskets in industrial environments.

1. Superior Sealing Capability

The primary function of any gasket is to create a leak-proof seal between two surfaces, and rubber gaskets excel at this. Thanks to their inherent flexibility and compressibility, rubber gaskets can conform to surface irregularities, ensuring a tight seal even in imperfect or worn flange connections.

This superior sealing capability is particularly vital in high-pressure systems or where liquids and gases must be contained with absolute precision. Components like Sanitary Gaskets used in food and beverage manufacturing rely on high-grade rubber to maintain hygiene and prevent leaks under demanding conditions.

Rubber materials such as EPDM, NBR, and silicone are also excellent at maintaining seal integrity across a wide range of temperatures and pressures, making them ideal for dynamic and static applications alike.

2. Chemical and Temperature Resistance

Industrial environments often expose components to aggressive chemicals and extreme temperatures. Rubber gaskets are available in a variety of formulations that offer excellent resistance to these challenges.

EPDM is commonly used for steam and water applications due to its excellent heat and weather resistance.

Nitrile rubber offers superb resistance to oils, fuels, and other hydrocarbons.

Silicone rubber is ideal for high-temperature sealing up to 230°C (446°F).

This adaptability ensures long-term performance without degradation, reducing the frequency of replacements. It’s particularly valuable in environments such as Cannabis Extraction Parts, where chemical exposure is frequent and operational safety is a top concern.

3. Durability and Longevity

Rubber gaskets are known for their excellent wear and fatigue resistance. When properly installed and maintained, they can provide years of reliable service, even in environments with high levels of vibration, pressure fluctuations, or abrasive materials.

This durability not only lowers the total cost of ownership but also contributes to reduced downtime and maintenance cycles. In sectors like brewing, where production schedules are tight and efficiency is key, using high-performance components such as Brewing Gaskets can significantly improve system reliability.

The use of advanced manufacturing techniques like compression molding and injection molding ensures that rubber gaskets meet precise dimensional tolerances for consistent performance.

4. Noise and Vibration Dampening

In addition to sealing, rubber gaskets offer excellent vibration isolation and noise reduction. Their elastic nature absorbs mechanical energy, dampening vibration between metal parts and reducing wear and fatigue on adjacent components.

This feature is particularly useful in dynamic systems such as pumps, compressors, and HVAC systems. Components like aodd pump parts often integrate rubber seals and diaphragms to ensure quieter operation and longer mechanical life.

By minimizing mechanical noise and vibration, rubber gaskets also contribute to safer and more comfortable working environments in industrial facilities.

5. Versatility Across Applications

Rubber gaskets are incredibly versatile, available in a wide variety of shapes, sizes, and materials to suit almost any industrial requirement. Whether you need a standard flange gasket or a custom-molded seal for a unique configuration, rubber provides a flexible solution.

Their usage spans industries including:

Food and beverage processing

Pharmaceuticals and biotechnology

Oil and gas

Automotive and aerospace

Water treatment and chemical processing

Rubber gaskets can also be tailored to meet regulatory and compliance standards such as FDA, NSF, and USP Class VI, depending on the application.

From standard sealing tasks to highly specialized roles, rubber gaskets can be engineered to solve complex challenges efficiently and economically.

Maintenance Tips for Longer Gasket Life

To get the most out of rubber gaskets, consider these simple but effective maintenance tips:

Perform regular visual inspections for signs of wear, cracking, or hardening.

Ensure proper torque is applied during installation to avoid over-compression.

Store spare gaskets in a cool, dry place away from sunlight and ozone sources.

Replace gaskets at the first sign of leakage to prevent downstream damage.

Proactive care will maximize the life span of your gaskets and ensure uninterrupted system performance.

Why Rubber Gaskets Are a Smart Investment

Rubber gaskets are not only a practical solution for sealing and insulation but also a strategic choice for improving operational efficiency. With the right material and design, they reduce maintenance needs, enhance equipment life, and support safe, clean processing environments.

For manufacturers in regulated industries, choosing the correct gasket material is also key to maintaining product quality and compliance. Investing in high-performance rubber gaskets is ultimately an investment in your operation’s reliability and success.

Conclusion

Rubber gaskets offer a powerful combination of sealing performance, chemical resistance, durability, and versatility that make them indispensable in modern industrial settings. At California Rubber, we understand the critical role gaskets play in your operations, and we offer expertly engineered solutions to meet the most demanding requirements.

Whether you're upgrading aodd pump parts, installing FDA-compliant seals in food processing systems, or customizing Brewing Gaskets for specialized production needs, we provide the quality and expertise you can rely on. Reach out today to learn how our custom rubber gasket solutions can optimize your systems and extend the life of your equipment.

2 notes

·

View notes

Text

Can asphalt shingles be used on low-pitch roofs?

Did you know that while asphalt shingles are a popular choice for many homes, they aren't suitable for every roof type? Specifically, their performance can be compromised on low-pitch roofs, potentially leading to issues like water leakage and reduced lifespan.

If you're considering asphalt shingles for a low-pitch roof, it's essential to understand the challenges and make informed decisions. Equally important is selecting a reliable roofing contractor who can provide expert guidance and quality installation. The right contractor ensures your roof's durability, safety, and aesthetic appeal, giving you peace of mind for years to come.

In this article, we'll explore the suitability of asphalt shingles for low-pitch roofs and offer practical advice on hiring a trustworthy contractor. With the right information, you can navigate this process confidently and achieve a successful roofing project.

Understanding Roof Pitch and Asphalt Shingles

What Is Roof Pitch?

Roof pitch refers to the steepness or slope of a roof, typically expressed as a ratio of vertical rise to horizontal run. For example, a 4:12 pitch means the roof rises 4 inches for every 12 inches of horizontal distance.

Minimum Slope for Asphalt Shingles

Asphalt shingles are generally recommended for roofs with a pitch of 4:12 or steeper. However, they can be installed on slopes as low as 2:12, provided special underlayment techniques are used to enhance water resistance.

Risks of Using Asphalt Shingles on Low-Pitch Roofs

Installing asphalt shingles on low-pitch roofs can lead to:

Water Leakage: Shallower slopes may not shed water effectively, increasing the risk of leaks.

Reduced Lifespan: Increased exposure to standing water can cause shingles to deteriorate faster.

Warranty Issues: Some manufacturers may void warranties if shingles are installed on slopes below their recommended minimum.

Alternative Roofing Materials for Low-Pitch Roofs

If your roof has a low pitch, consider these alternatives:

Modified Bitumen: A flexible, durable material suitable for low-slope applications.

Single-Ply Membranes (e.g., TPO, EPDM): Lightweight and resistant to weathering, ideal for low-slope roofs.

Built-Up Roofing (BUR): Multiple layers of bitumen and reinforcing fabrics create a durable, waterproof membrane.

Hiring a Reliable Asphalt Roofing Contractor

Choosing the right contractor is crucial for a successful roofing project. Here's how to find one you can trust:

Verify Licenses and Insurance

Ensure the contractor has the following:

Proper Licensing: Confirms they meet local requirements and adhere to building codes.

Insurance Coverage: Protects you from liability in case of accidents or property damage during the project.

Check References and Reviews

Ask for References: Speak with previous clients about their experiences.

Read Online Reviews: Look for consistent positive feedback and any red flags.

Evaluate Experience with Asphalt Roofing

Years in Business: Experience often correlates with reliability and quality workmanship.

Specialization: Ensure they have specific experience with asphalt shingles and low-pitch roofs, if applicable.

Review Portfolios

Previous Projects: Examine completed projects to assess quality and attention to detail.

Diverse Experience: A varied portfolio indicates adaptability to different roofing challenges.

Understand Warranties

Workmanship Warranty: Covers installation-related issues.

Manufacturer’s Warranty: Covers defects in roofing materials.

Compare Written Estimates

Detailed Quotes: Ensure estimates include labor, materials, and any additional costs.

Value Over Price: The lowest bid isn't always the best; consider the quality of materials and workmanship.

Key Questions to Ask During Consultations

When meeting with potential contractors, consider asking:

What is your experience with low-pitch roofs and asphalt shingles?

Can you provide references from recent clients?

What warranties do you offer on materials and workmanship?

How do you handle unforeseen issues during the project?

What is the projected timeline for completion?

Making an Informed Decision

Selecting the right contractor involves careful consideration:

Research Thoroughly: Use online resources, seek recommendations, and verify credentials.

Trust Your Instincts: Choose someone who communicates clearly and makes you feel comfortable.

Get Everything in Writing: Contracts should detail the scope of work, payment schedules, and warranties.

Conclusion

While asphalt shingles can be used on low-pitch roofs with proper precautions, it's essential to assess their suitability for your specific situation. Equally important is hiring a reliable contractor who can provide expert advice and quality installation. By following the steps outlined above, you can make informed decisions that enhance your home's value and protection.

Take the first step today: conduct thorough research, seek recommendations, and choose a contractor who will ensure your roofing project is a success. With the right guidance, you'll find the process straightforward and rewarding.

2 notes

·

View notes

Text

EPDM Hoses: The Heat-Resistant Tubing for Hot Water Applications

EPDM (ethylene propylene diene monomer) hoses have become a popular choice for hot water applications in recent years. As a versatile synthetic rubber material, EPDM offers superior heat resistance, flexibility, and durability compared to traditional rubber hoses.

In this article, we’ll explore the key benefits of using EPDM hot water hoses, their typical applications, what to look for when selecting one, and proper care and maintenance tips. Whether you need a hose for a dishwasher, washing machine, or just to conveniently transport hot water, read on to learn why EPDM is an ideal tubing material.

For More Information Please visit, epdm hot water hose

Key Benefits of EPDM Hot Water Hoses

Temperature resistance – EPDM rubber maintains its strength and flexibility in continuous temperatures up to 150°C and is safe for intermittent use up to 230°C. This makes it well-suited for hot water lines.

Chemical resistance – EPDM stands up well to water, detergents, oil, and other common chemicals. It won’t degrade or leach contaminants into the water flow.

Durability – Properly maintained EPDM hoses can last for many years. The material is ozone, weather, and abrasion resistant. It also has excellent tensile strength.

Flexibility – EPDM tubing remains pliable and kink-resistant even when subjected to repeated bending. This allows it to move freely without restricting water flow.

Cost-effective – EPDM is an affordable hose material that provides exceptional performance per dollar compared to other rubber, plastic, or metal options.

Typical Applications

Dishwasher supply lines – EPDM is perfect for the high heat sanitizing cycles dishwashers run. Flexible EPDM tubing won’t crack under the strain of repeated movements either.

Washing machine hoses – For hot water inlet lines that must withstand high pressures and temperatures over years of use.

Hot water transport – Durable EPDM hoses allow safe, convenient transport of hot water for cleaning, outside showers, etc.

Radiant heating systems – Flexible EPDM tubing can be bent around tight spaces to run in-floor home heating systems.

Solar water systems – High heat resistance makes EPDM ideal for solar water heating system transport lines.

Hose Selection Considerations

When selecting an EPDM hot water hose, key factors to consider include:

Temperature rating – Hoses rated for 190°F+ are best for typical residential hot water heating systems. Industrial applications may require 500°F+ rated EPDM.

Hose diameter – Standard sizes include 1⁄2”, 5⁄8”, and 3⁄4” for home use. Larger diameters provide increased water volume.

Pressure rating – Look for at least 100 PSI working pressure and a high burst pressure. industrial uses may require 500+ PSI rated hoses.

End fittings – Brass and stainless steel fittings offer maximum durability and temperature resistance. Plastic fittings can degrade over time.

Approvals – Look for EPDM hoses certified lead-free and drinking water safe by NSF, WRAS, or other standards organizations.

Proper Care and Maintenance

With proper care, EPDM hot water hoses can last 5-10 years or longer:

Inspect regularly – Check for damage, leaks, kinks, or corrosion. Replace suspect hoses.

Avoid overheating – Don’t exceed the hose’s rated working temperature.

Protect from UV light – Sunlight can degrade EPDM over time. Use UV-resistant covers outdoors.

Clean as needed – Flush out mineral deposits with vinegar. Don’t use solvents on EPDM.

Avoid kinks – EPDM is flexible but kinking can restrict water flow. Install with gentle bends.

Conclusion

Thanks to its durable, flexible, heat-resistant design, EPDM is the ideal tubing material for hot water applications ranging from dishwashers to radiant floor heating. Following the selection and care tips above will help ensure you choose the right EPDM hose and get the most service life out of it. Investing in a quality EPDM hot water hose will provide reliable performance for years to come.

2 notes

·

View notes

Text

Title: The Unsung Hero of Sealing Solutions: Exploring the World of Gaskets

Introduction

In the intricate world of engineering and machinery, there exists a crucial component that often goes unnoticed, yet plays a vital role in ensuring the smooth operation of various systems: the gasket. These unassuming pieces of material are the unsung heroes of sealing solutions, preventing leaks, minimizing energy loss, and maintaining the integrity of countless applications. In this blog, we will dive into the fascinating world of gaskets, exploring their types, applications, and significance in various industries.

What Is a Gasket?

A gasket is a mechanical seal that fills the gap between two or more mating surfaces to prevent the leakage of gases or liquids under compression. Gaskets are typically made from a wide range of materials, such as rubber, metal, cork, silicone, and composite materials. The choice of gasket material depends on the specific application, including the temperature, pressure, and chemical compatibility requirements.

Types of Gaskets

Rubber Gaskets: These gaskets are made from various elastomers like neoprene, EPDM, and nitrile rubber. They are known for their flexibility and resistance to moisture and temperature variations. Rubber gaskets find applications in plumbing, automotive, and HVAC systems.

Metal Gaskets: Composed of materials like stainless steel, copper, or aluminum, metal gaskets excel in high-temperature and high-pressure environments. They are commonly used in the oil and gas industry and for sealing flange connections.

Spiral Wound Gaskets: These gaskets are formed by winding a metal strip and a filler material into a spiral. They are ideal for applications where high pressures and temperatures are involved, making them a favorite choice for the chemical and petrochemical industries.

Graphite Gaskets: Known for their excellent heat and chemical resistance, graphite gaskets are often used in high-temperature and high-pressure applications, such as steam systems and refineries.

Non-Asbestos Gaskets: In response to health concerns associated with asbestos, non-asbestos gaskets have become popular. They use materials like aramid fibers and synthetic rubber to provide a safe and effective sealing solution.

Applications of Gaskets

Automotive Industry: Gaskets are used in engines, transmissions, and exhaust systems to prevent leaks and maintain the efficiency of these crucial components.

Plumbing: Gaskets ensure watertight seals in plumbing fixtures and pipelines, preventing water leaks and minimizing water wastage.

Aerospace: Gaskets are employed in aircraft engines and hydraulic systems to withstand extreme temperatures and pressures, ensuring safe and reliable operation.

Oil and Gas: The industry relies heavily on gaskets to seal flange connections, valves, and pipelines, preventing the escape of hazardous materials.

Chemical Industry: Gaskets play a crucial role in chemical processing, where they must withstand aggressive chemicals and high temperatures.

Significance of Gaskets

Gaskets are the unsung heroes of various industries, silently performing their duties to maintain the integrity and safety of systems and equipment. Their significance can be summarized as follows:

Leak Prevention: Gaskets are designed to create a barrier between mating surfaces, preventing the escape of fluids or gases, which is critical for safety, efficiency, and environmental protection.

Energy Efficiency: Properly sealed systems help conserve energy by preventing leaks and reducing heat loss, ultimately leading to cost savings and reduced environmental impact.

Safety: In industries like oil and gas and chemical processing, gaskets are crucial for containing hazardous materials and preventing accidents.

Conclusion

Gaskets may not be the most glamorous components in the world of engineering, but their role in sealing solutions is indispensable. From the engines of our cars to the pipelines of the oil and gas industry, gaskets quietly ensure that everything runs smoothly and safely. As technology advances, gasket materials and designs will continue to evolve, contributing to more efficient and sustainable systems across various industries. So, the next time you see a gasket, remember the unsung hero that it is, working tirelessly to keep our world sealed and secure.

#home & lifestyle#kitchen appliances#cookware#kitchen#gaskets#kitchenware#cooker#daily blog#daily update#home cooking#home lifestyle

2 notes

·

View notes

Text

Isolator Gloves Market Size, Type, segmentation, growth and forecast 2023-2030

Isolator Gloves Market

The Isolator Gloves Market is expected to grow from USD 141.10 Million in 2022 to USD 228.10 Million by 2030, at a CAGR of 7.11% during the forecast period.

Get the Sample Report: https://www.reportprime.com/enquiry/sample-report/11101

Isolator Gloves Market Size

Isolator Gloves are a type of protective gloves that are designed to provide a barrier between the wearer's hands and harmful substances such as chemicals, viruses, and bacteria. The Isolator Gloves market research report includes an analysis of the market segment based on type, application, and region. The types of Isolator Gloves include Nitrile, Hypalon, EPDM, Neoprene, Latex, and Butyl. The primary applications of Isolator Gloves are in Electronics, Pharmaceutical, Food, Chemical, and Laboratory industries. The report covers the market players such as Ansell, PIERCAN, Renco Corporation, Safetyware Group, Inert Corporation, Jung Gummitechnik, Terra Universal, Honeywell, Nichwell, and Hanaki Rubber. The report also covers regulatory and legal factors specific to market conditions. Isolator Gloves are subject to strict regulations due to their use in critical industries, and market players must ensure compliance with standards set by regulatory bodies. The report provides an in-depth analysis of the Isolator Gloves market, including its market size, growth rate, competitive landscape, and future prospects.

Isolator Gloves Market Key Player

Ansell

PIERCAN

Renco Corporation

Safetyware Group

Inert Corporation

Buy Now & Get Exclusive Discount on this https://www.reportprime.com/enquiry/request-discount/11101

Isolator Gloves Market Segment Analysis

The Isolator Gloves market caters to a niche customer base, which includes pharmaceutical manufacturers, biotechnology companies, healthcare institutions, and medical device manufacturers. These gloves are extensively used in cleanroom environments to maintain hygiene, prevent contamination and ensure aseptic handling of drug substances and medical devices.

The driving factors for revenue growth in the Isolator Gloves market are the increasing demand for sterile pharmaceutical products, the growing prevalence of chronic diseases, and the strict regulatory requirements for cleanroom environments. Furthermore, the Isolator Gloves market is experiencing growth due to the ongoing research and development activities and technological advancements in the field of medical devices.

The latest trends followed in the Isolator Gloves market include the adoption of non-latex gloves to reduce the risk of latex allergy, increasing demand for powder-free gloves to minimize the transfer of allergens, and the use of vibration-dampening gloves to reduce hand fatigue in workers. Moreover, manufacturers are focusing on developing gloves with improved tactile sensitivity and flexibility, which can provide better user comfort and dexterity.

The major challenges faced by the Isolator Gloves market include the high cost of raw materials and production, stringent regulations for cleanroom environments, and increasing competition from local players in the market. Additionally, the COVID-19 pandemic has disrupted the supply chain and logistics operations, resulting in the temporary closure of manufacturing facilities and delays in delivering products to customers.

The report's main findings suggest that the Isolator Gloves market is projected to grow at a significant rate over the forecast period due to the increasing demand for sterile pharmaceutical products and the stringent regulatory requirements for cleanroom environments. Furthermore, the report recommends that manufacturers focus on developing eco-friendly and biodegradable gloves, as the demand for sustainable products is increasing. Moreover, manufacturers should prioritize improving their supply chain management and logistics operations to meet the market demands and maintain a competitive edge.

In conclusion, the Isolator Gloves market caters to a niche customer base, and the major factors driving revenue growth are the increasing demand for sterile pharmaceutical products and the strict regulatory requirements for cleanroom environments. The Isolator Gloves market is experiencing growth due to technological advancements and ongoing research and development activities. The latest trends in the market encompass the adoption of non-latex gloves, powder-free gloves, and vibration-dampening gloves. However, the Isolator Gloves market is also facing challenges due to high production costs, stringent regulatory requirements, and increasing competition from local players. The report's main recommendations include focusing on sustainable products, improving supply chain management, and logistics operations.

This report covers impact on COVID-19 and Russia-Ukraine wars in detail.

Purchase This Report: https://www.reportprime.com/checkout?id=11101&price=3590

Market Segmentation (by Application):

Electronics

Pharmaceutical

Food

Chemical

Laboratory

Information is sourced from www.reportprime.com

2 notes

·

View notes

Text

Do roofing contractors handle both residential and commercial projects?

When searching for a roofing contractor, it’s natural to wonder if they can handle residential and commercial projects. After all, the roofing needs for homes and businesses can be quite different, but the expertise often overlaps. Whether you're a homeowner needing a roof repair or a business owner planning a roof replacement, knowing what to expect from a contractor is helpful.

Do Roofing Contractors Specialize in Residential Projects?

Many roofing contractors specialize in residential roofing, and for good reason. Homeowners often need roof repairs, maintenance, or replacements at some point due to weather damage, aging materials, or the desire to improve energy efficiency. Residential roofs typically consist of materials like asphalt shingles, tile, wood, or metal, and the job can range from fixing a small leak to replacing an entire roof.

A roofing contractor with experience in residential projects understands homeowners' specific needs. They’re familiar with local building codes, know how to work around your schedule, and can suggest materials that fit your budget while offering durability and aesthetic appeal.

Do Roofing Contractors Handle Commercial Projects Too?

Yes, many roofing contractors also take on commercial projects, although these tend to be more complex. Commercial roofs often have different requirements than residential ones. For example, they might be flat or have low slopes, and the materials used are typically more durable to withstand higher foot traffic, harsh weather, and environmental factors. Commercial roofs may consist of single-ply membranes (EPDM, TPO, or PVC), modified bitumen, or built-up roofing (BUR).

The scale of commercial projects can vary greatly, from small business buildings to large warehouses, but a skilled roofing contractor can manage them all. Companies like Lastime Exteriors are experienced in assessing a business's specific needs and providing solutions that keep buildings energy-efficient and structurally sound while minimizing downtime.

What’s the Difference Between Residential and Commercial Roofing?

While both types of roofing protect the structure underneath, the main difference between residential and commercial roofing is the scale and materials involved. Residential roofing tends to be smaller in scope and uses materials often designed to complement the home style, such as shingles, slate, or metal panels. Homeowners usually prioritize aesthetics as much as durability when choosing a roof.

Commercial roofing, on the other hand, focuses more on functionality. The roofs of commercial buildings need to handle heavy loads, endure harsh weather conditions, and support additional infrastructure like HVAC systems or solar panels. Additionally, the roofs may need to meet specific fire-resistant or environmental standards. Therefore, commercial projects require more specialized knowledge and equipment, which a professional roofing contractor can provide.

How Does a Roofing Contractor Manage Different Materials for Residential and Commercial Projects?

The choice of materials is one of the biggest differences between residential and commercial roofing projects. Popular materials for residential homes include asphalt shingles, clay tiles, metal roofing, and wood shakes. Each material has its pros and cons in terms of cost, durability, and appearance Asphalt shingles, for example, are affordable and widely used, while metal roofing offers a longer lifespan and better energy efficiency.

On the other hand, commercial roofs use materials designed for durability and functionality. Single-ply membranes, such as TPO or EPDM, are popular for their energy efficiency and ease of installation. Built-up roofing (BUR), made of layers of tar and gravel, is also common in commercial applications. The right material for a commercial project depends on factors like the size of the building, the climate, and the type of business being conducted there. A knowledgeable roofing contractor can recommend the best material for your specific needs.

How Do Roofing Contractors Handle Project Timelines for Residential and Commercial Jobs?

Another consideration when choosing a roofing contractor is the timeline for completing the project. Residential roofing jobs are usually quicker to complete than commercial ones because they are smaller in scale. A simple roof repair might only take a day, while a full roof replacement could take a few days to a week, depending on the size of the house and the materials used.

Commercial projects often take longer due to the larger roofs and the complexity of the work involved. The contractor must coordinate with building managers, work around business hours, and sometimes deal with more stringent regulations.

Are Roofing Contractors Available for Ongoing Maintenance?

Whether you have a residential or commercial roof, ongoing maintenance is key to prolonging its lifespan. A roofing contractor can help with routine inspections, cleaning, and minor repairs to prevent small issues from becoming major problems. Residential maintenance might involve clearing gutters, replacing broken shingles, or sealing leaks, while commercial maintenance could include checking for membrane tears, inspecting HVAC supports, or addressing ponding water.

Can a Roofing Contractor Handle Emergency Repairs?

Roof damage doesn’t always happen on a convenient schedule. Whether it’s a storm, a fallen tree, or sudden leaks, you might need emergency repairs at some point. A reliable roofing contractor will be available for quick service when these situations arise, providing peace of mind knowing that your home or business is protected from further damage.

Let Lastime Exteriors Handle Your Roofing Needs

Whether you need a new roof for your home or repairs for your commercial building, working with a roofing contractor who handles both projects can greatly benefit you. Lastime Exteriors brings years of experience, high-quality materials, and expert craftsmanship to every job, ensuring that residential and commercial customers receive the best possible service.

4 notes

·

View notes

Text

Aohong Phenolic Resin Packing: 25% Longer Seal Life in Corrosive Environments

When standard gaskets fail under acid exposure, Aohong’s thermoset phenolic resin packing delivers 23.6% longer service life with zero volumetric swelling. This breakthrough solves chronic seal failures in chemical processing plants. The proprietary Bakelite 400X composite forms micro-serrations that enhance flange surface adhesion by 18% compared to conventional materials.

Why Industrial Plants Are Switching

Aohong’s 2024 formulation upgrade with N550-grade carbon black addresses critical sealing challenges:

Extreme Chemical Resistance: Handles 98% sulfuric acid where EPDM degrades within weeks

Thermal Stability: Operates at -20°F to 375°F (400°F peak tolerance) during thermal cycling

35% Lower Compression Set vs PTFE over 6-month continuous service

Performance Validation

ParameterSpecificationField DataPressure Rating2,500 psi max2,200 psi continuous recommendedDimensional Tolerance±0.18mm±0.15mm achieved in QCService Life18-24 months20-22 months (refinery applications)

Engineering Innovation

Self-healing micro-fracture response: Crosslinked resin rebonds under stress

API 624 fugitive emissions compliance on first test

Proven Industrial Results

German chemical plant: Seal replacement reduced from 8/year to 2/year

Texas oilfield: Stable performance at 400°F wellhead temperatures

Cost-Saving Solution

For corrosive media sealing, Aohong phenolic packing delivers unmatched chemical resistance. Now with volume discounts and 36-month warranties, it significantly reduces maintenance costs and downtime.

0 notes

Text

RV Roof Coating: Protecting Your Investment Made Easy

Your RV is more than just a vehicle—it’s your home on wheels. Whether you're camping in the mountains or parked at a beachside resort, your RV roof is constantly exposed to sun, rain, wind, and debris. Over time, this exposure can lead to cracks, leaks, and costly repairs. One of the best ways to protect your RV is by using a high-quality RV roof coating.

In this article, we’ll explain everything you need to know about RV roof coatings, including the benefits, types, and how to apply them. We’ll also talk about key products like RV rubber roof coating, RV roof primer, and trailer roof coating to help you choose the right solution.

What Is an RV Roof Coating?

An RV roof coating is a protective liquid applied over your RV’s roof. Once it dries, it forms a rubber-like barrier that shields the roof from harmful UV rays, water damage, and temperature changes. It's especially helpful for older RVs that may have small cracks or areas where the roof material is thinning.

Why You Need an RV Roof Coating

Here are a few important reasons why applying a roof coating is a smart choice:

Prevents Leaks

Water is the enemy of any RV. Once it gets inside, it can cause damage to walls, ceilings, and even electrical systems. A good roof coating seals cracks and gaps, preventing water from getting in.

Extends Roof Life

A quality RV rubber roof coating can add years to the life of your RV’s roof. It adds a new layer of protection that keeps the original roof material from wearing out too soon.

Saves Money on Repairs

Fixing a roof leak or replacing an entire roof is expensive. Using a protective coating is a small investment that helps you avoid major repair bills down the road.

Improves Energy Efficiency

Some coatings reflect sunlight, helping to keep the inside of your RV cooler in hot weather. That means less need for air conditioning and lower energy costs.

Types of RV Roof Coatings

There are several kinds of roof coatings, but not all are ideal for RVs. Here's a quick overview:

Acrylic Coatings: These are water-based and easy to apply. They’re affordable but may not last as long as other options.

Silicone Coatings: These are great at resisting water, but they can be slippery and are hard to recoat later.

Rubber-Based Coatings (EPDM): These are widely used and offer excellent durability. The RV rubber roof coating from RV Roof Magic is a popular choice due to its strength and flexibility.

Preparing for Application: Use RV Roof Primer

Before applying any coating, it's important to prepare the surface properly. That’s where an RV roof primer comes in. A primer helps the coating stick better and ensures even coverage. It also helps seal any porous areas, creating a smoother finish for the coating to bond to.

How to Apply RV Roof Coating (Step-by-Step)

You don’t need to be a professional to apply an RV roof coating. Here’s a simple step-by-step guide:

Clean the Roof

Remove dirt, leaves, and debris. You can use a roof cleaner or mild soap and water. Let it dry completely.

Inspect for Damage

Look for cracks, holes, or soft spots. Repair any damage before applying the coating.

Apply the Primer

Use a brush or roller to apply the RV roof primer evenly. Allow it to dry based on product instructions.

Apply the Coating

Stir the coating well. Then use a roller or sprayer to apply a thick, even layer. Let it dry as recommended (usually 24–48 hours).

Check for Coverage

Once dry, inspect to make sure there are no missed spots. Apply a second coat if needed.

Choosing the Right Coating for Your RV

Not all coatings are the same, so be sure to choose one that suits your RV roof material (rubber, fiberglass, aluminum, etc.). The trailer roof coating from RV Roof Magic is compatible with most roof types and provides long-lasting protection.

If you’re unsure, check the manufacturer’s guide or ask an expert for help.

Maintenance Tips for Long-Lasting Protection

Inspect your roof every 3–6 months for cracks or damage.

Clean the roof regularly to prevent buildup of dirt and mold.

Touch up the coating if you see any worn areas or peeling.

Recoat every 5–10 years depending on product lifespan and exposure conditions.

Conclusion

Protecting your RV’s roof doesn’t have to be complicated or expensive. With the right RV rubber roof coating, a good RV roof primer, and regular maintenance, you can prevent leaks, save money, and enjoy peace of mind on the road.

Whether you need a trailer roof coating for a weekend camper or a long-haul RV, investing in a quality product ensures your mobile home stays safe, dry, and in top shape for years to come.

0 notes

Text

Tectum Roofing - Best Choice for Top-Notch Commercial Roofing Solutions

When it comes to protecting your commercial property, the roof is your first line of defense. Whether you're managing a warehouse, retail space, office complex, or industrial facility, a high-quality roof is essential for the safety, durability, and long-term performance of your building. That’s where Tectum Roofing comes in--a trusted name in commercial roofing known for excellence, innovation, and integrity. In this article, we’ll explore why choosing the right commercial roofing contractor is so critical, what makes Tectum Roofing the best in the industry, and how their solutions stand out from the competition.

The Importance of Quality Commercial Roofing

A commercial roof is more than just a structure that shields your building from the elements. It plays a vital role in:

Energy Efficiency: A well-installed, properly insulated roof can significantly reduce your energy bills.

Protection: It safeguards your assets, inventory, equipment, and personnel from water damage and weather exposure.

Longevity: A quality roof means fewer repairs, lower maintenance costs, and a longer lifespan.

Business Continuity: Roofing failures can lead to costly disruptions in operations.

Given the complexity of commercial roofing systems—from flat roofs and low-slope applications to specialized coatings and membrane systems—you need an expert team that can handle the job with precision and professionalism.

What Sets Tectum Roofing Apart?

Tectum Roofing has built a stellar reputation by consistently delivering high-performance roofing solutions across a variety of commercial sectors. Here’s why they are widely regarded as the best in the business:

1. Expertise and Experience

Tectum Roofing brings decades of hands-on experience in commercial roofing. Their team consists of certified professionals trained in the latest installation techniques, safety protocols, and industry standards. Whether it’s a new construction project, a full re-roof, or emergency repairs, Tectum has the know-how to get it done right the first time.

2. Tailored Roofing Solutions

Every commercial building is different, which is why Tectum Roofing doesn’t offer cookie-cutter solutions. They work closely with property owners, architects, and facility managers to design a roofing system that meets the specific needs of the building—whether that’s TPO, EPDM, PVC, metal, or a modified bitumen roof.

3. Cutting-Edge Materials and Technology

Tectum partners with top-tier manufacturers to provide roofing systems made from the highest quality materials. Their team stays on the forefront of technological advances, including energy-efficient roofing, cool roof coatings, and smart roof monitoring systems. This commitment to innovation helps clients reduce energy consumption, qualify for green building certifications, and increase property value.

4. Comprehensive Services

Tectum Roofing offers a full spectrum of commercial roofing services, including:

Roof inspections and assessments

Preventive maintenance programs

Leak detection and repairs

Full roof replacements

New construction roofing

Waterproofing and coating systems

Emergency storm damage response

Their all-in-one service model ensures seamless communication and project management from start to finish.

5. Commitment to Safety and Compliance

Safety is a top priority for Tectum Roofing. They adhere to OSHA standards and implement rigorous safety protocols on every job site. Clients can rest easy knowing their roofing project is being handled with the utmost care, minimizing risk to workers and building occupants alike.

Proven Success Across Industries

Tectum Roofing serves a diverse portfolio of clients across a range of industries:

Industrial Facilities: Durable roofing systems that withstand harsh chemicals and extreme temperatures.

Retail Centers: Seamless installations that minimize disruption to business operations.

Healthcare Facilities: Waterproof, mold-resistant roofing systems that meet strict hygiene standards.

Educational Institutions: Cost-effective, long-lasting solutions that meet performance and budget goals.

Hospitality and Hotels: Attractive and reliable roofs that match architectural aesthetics.

Their proven track record across these sectors makes Tectum Roofing a go-to choice for facility managers, property developers, and general contractors.

The Tectum Roofing Promise

What truly makes Tectum stand out is their unwavering commitment to customer satisfaction. From your first consultation to final inspection, they promise:

Transparent communication and honest pricing

On-time, on-budget project delivery

Long-term support and warranty options

Minimal disruption to your daily operations

Quality craftsmanship backed by guarantees

It’s not just about installing a roof—it’s about building trust, solving problems, and delivering peace of mind.

Don’t Settle for Less – Choose Tectum Roofing

In today’s fast-paced commercial landscape, there’s no room for subpar roofing. Choosing the wrong contractor can lead to costly repairs, operational downtime, and long-term liabilities. Tectum Roofing has earned its reputation as the best by delivering reliable, tailored, and efficient commercial roofing services. Whether your roof needs maintenance, replacement, or a complete overhaul, you can count on Tectum to get the job done with precision and professionalism.

Final Thoughts

Your commercial roof is a critical investment in the future of your business. Don’t leave it in the hands of just any contractor. Choose a partner with the experience, expertise, and dedication to deliver outstanding results every time. Tectum Roofing is more than just a roofing company—they are your long-term solution for commercial roofing excellence.

Ready to upgrade your commercial roof? Contact Tectum Roofing today for a free consultation and discover why they’re the trusted choice for business owners across the region.

0 notes

Text

Understanding Different Types of Flat Roofing Systems

In the world of construction and building maintenance, roofing is a crucial component that can make or break a structure. Among various roofing styles, flat roofing systems are gaining popularity for their unique features and benefits. Whether you’re considering a new installation or needing repairs, understanding different types of flat roofing systems can help you make informed decisions. This comprehensive guide will delve into flat roofs, exploring their types, benefits, costs, maintenance tips, and more.

What Are Flat Roofing Systems?

Flat roofing systems are characterized by their minimal slope, which allows for various applications and designs. Unlike pitched roofs that have a noticeable angle, flat roofs offer a level surface ideal for various residential and commercial applications. They can support HVAC systems, solar panels, and even rooftop gardens.

Why Choose Flat Roofing?

Flat roofing systems come with several advantages:

Cost-Effectiveness: Generally less expensive to install than sloped roofs. Space Utilization: Provides usable space on top of buildings. Ease of Maintenance: Easier to inspect and maintain due to accessibility. Types of Flat Roofing Systems

Understanding different types of flat roofing systems is essential for selecting the right one for your needs. Below we explore some popular types.

1. Built-Up Roofing (BUR)

Built-Up Roofing (BUR) consists of multiple layers of bitumen and felts applied over a roof deck. This https://archerullr844.wordpress.com/2025/06/22/how-important-is-membrane-integrity-a-look-at-membrane-repairs/ system is known for its durability and weather resistance.

Benefits of BUR Long lifespan Excellent waterproofing capabilities Good insulation properties Common Uses

Primarily used in commercial buildings but also suitable for residential applications.

2. Modified Bitumen Roofing

Modified bitumen roofing combines the benefits of traditional BUR with modern materials. It typically comes in rolls that are either hot-applied or cold-applied.

Advantages Flexibility in temperature extremes Easy installation process Durable against UV rays Ideal Applications

Great for both residential roofing services and commercial projects.

3. EPDM (Ethylene Propylene Diene Monomer)

EPDM is a type of rubber roofing known for its longevity and versatility. It's lightweight yet strong enough to withstand harsh weather conditions.

Pros Resistant to hail damage Easy to repair Long-lasting lifespan up to 50 years Best Fit For

Commercial buildings where durability is essential.

4. TPO (Thermoplastic Olefin)

TPO roofing has gained popularity due to its energy-efficient properties and affordability. It’s a single-ply membrane made from reinforced thermoplastic polyolefin.

Key Features Reflective surface reduces cooling costs Resistant to UV rays Lightweight and easy to install Application Areas

Ideal for com

0 notes

Text

The Role of Stainless Steel Braided Hoses in Modern Projects

In today’s fast-paced industrial, residential, and infrastructure development environment, stainless steel braided hoses are widely recognized for their durability, flexibility, and reliability. Whether in a commercial plumbing renovation, a chemical processing plant upgrade, or a municipal infrastructure installation, these hoses are a vital component of fluid and gas handling systems.

This article explores how stainless steel braided hoses are used in various projects, highlights key application sectors, and offers guidance on planning, selection, and installation—all while complying with GEO (Geographic Engine Optimization) standards to ensure maximum visibility for regional and global audiences.

What Are Stainless Steel Braided Hoses?

Stainless steel braided hoses consist of an inner tube—usually made from rubber, EPDM, or PTFE—reinforced with an outer layer of tightly woven stainless steel wire. This construction gives the hose:

High-pressure resistance

Enhanced thermal tolerance

Flexibility in tight spaces

Protection against corrosion and mechanical wear

These features make braided hoses suitable for a wide range of projects, including residential construction, commercial buildings, industrial systems, and municipal engineering.

0 notes

Text

Understanding Roof Membrane Repair for Commercial Properties

Introduction

When it comes to maintaining commercial properties, one of the most critical aspects that property owners must address is their roofing system. The roof serves as the first line of defense against the elements, and over time, wear and tear can lead to significant issues if not properly managed. One of the most common problems in commercial https://www.google.com/search?kgmid=/g/11rrqp0cb4&sei=8TlHaPjpIeua4-EPvdyV-AQ#lpc=lpc&prid=3770212019411668341 roofing is damage to the roof membrane. This article will delve deep into Understanding Roof Membrane Repair for Commercial Properties, covering everything from types of membrane roofs to repair techniques, costs, and more.

Understanding Roof Membrane Repair for Commercial Properties

Roof membranes are essential components in many commercial roofs, providing a waterproof barrier that protects against leaks and other forms of water damage. These membranes come in various materials, including TPO (Thermoplastic Olefin), PVC (Polyvinyl Chloride), EPDM (Ethylene Propylene Diene Monomer), and modified bitumen. A well-maintained roof membrane can significantly extend the lifespan of a commercial roofing system.

What is a Roof Membrane?

A roof membrane is a layer designed to provide a waterproof barrier on flat or low-slope roofs. These membranes are typically made from synthetic materials that offer durability and flexibility.

Types of Roof Membranes TPO (Thermoplastic Olefin): Known for its energy efficiency, TPO is popular for its reflective properties. PVC (Polyvinyl Chloride): Durable and resistant to chemicals, making it suitable for industrial applications. EPDM (Ethylene Propylene Diene Monomer): Highly flexible and cost-effective, EPDM is ideal for colder climates. Modified Bitumen: A traditional option that blends asphalt with polymers for added strength. Importance of Roof Membrane Repair

Maintaining the integrity of your roof membrane is crucial. A damaged membrane can lead to leaks, mold growth, and ultimately costly repairs or replacements. Regular inspections by licensed roofing contractors ensure that any issues are caught early before they escalate.

Common Causes of Roof Membrane Damage Weather Conditions

Weather plays a significant role in roof membrane deterioration. Extreme temperatures, heavy rain, hail storms, and high winds can cause physical damage.

Age

Like any material exposed to the elements, roof membranes have a finite lifespan. Over time, UV rays can degrade their effectiveness.

Improper Installation

If not installed correctly by certified roofing contractors, even high-quality membranes can fail prematurely.

Foot Traffic

Regular maintenance often requires access to rooftops; excessive foot traffic can lead to punctures or tears in the membrane.

Signs You Need Roof Membrane Repair Services

Recognizing the signs that your roof membrane needs attention can save you from future headaches:

Visible Leaks: Stains on ceilings or walls indicate potential leaks. Punctures or Tears: Any visible damage should be inspected immediately.

1 note

·

View note

Text

Maintaining Your Camlock Fittings: Tips to Extend Product Life

When dealing with industrial fluid handling applications, camlock fittings are among the most reliable and affordable options. Utilized in a broad range of industries—ranging from oil & gas to agriculture and manufacturing—these quick connect couplings are essential to smooth-running operations. Yet, as is the case with any piece of equipment, camlocks must be handled and serviced properly to guarantee they'll last and function safely.

At Advanced Flow Controls Trading - LLC, we deal in premium camlock fittings meant to work under pressure. Here, we will guide you through some useful tips for maintenance that will ensure the longevity of your camlock fittings and lower replacement cost.

What Are Camlock Fittings?

Camlock fittings, or cam and groove couplings, provide rapid and secure connections between pipes and hoses. They are popular in situations where hose changes occur repeatedly. The fittings are simple to use—no tools necessary—and may be constructed of materials like stainless steel, aluminum, brass, and polypropylene.

Why Maintenance Matters

Even the highest-quality camlock fittings can degrade over time, particularly in heavy-duty applications or in harsh environments. Regular maintenance guarantees:

Leak-free operation

Less downtime

Lower operating expenses

Improved safety for your crew

Whether you're dealing with water, chemicals, gas, or food-grade fluids, regular maintenance is important.

Camlock Fitting Maintenance Tips

1. Check Frequently for Wearing and Bending

One of the easiest yet most effective measures is visual inspection. Inspect all camlock couplings and hoses on a routine basis for signs of cracks, corrosion, or worn gaskets. Inspect for leaks or loose connections.

Be especially vigilant about:

Cam arms and pins

Sealing gaskets

Hose-end integrity

Groove fit and lock position

Even small problems, if not addressed, can develop into larger failures later on.

2. Clean After Every Use

This might seem simple, but sanitation is important—particularly in processes handling chemicals, abrasives, or food-grade materials. Both the male and female ends of the camlock should be rinsed thoroughly with clean water after it's been disconnected to eliminate any residue or contaminants.

Clean with a soft brush or cloth—never scratchy materials—since scratching can weaken the seal and cause corrosion.

3. Lubricate Moving Parts

Camlock arms and locking pins should have intermittent lubrication. Apply a silicone-based lubricant or your application's suggested lubricant (particularly for food-grade systems). This minimizes friction and avoids rust, keeping your fittings moving freely.

Don't use petroleum-based lubricants if working with chemicals or food products.

4. Replace Worn Gaskets Promptly

The gasket is an important part of your camlock coupling—it provides a secure, leak-proof seal. Replace the gasket if it is worn, brittle, or flattened. Maintain spare gaskets for easy replacement.

Select gasket materials that are suitable to your fluid handling applications:

EPDM for water

Viton for chemicals

Nitrile for oil and fuel

PTFE for high temperature or aggressive fluids

5. Check Compatibility of Materials

Always make sure your camlock fittings can handle the media you are transferring. Aluminum camlocks with corrosive chemicals, for instance, are prone to early failure. Stainless steel camlocks are heavier-duty for extreme applications, and polypropylene ones can be used for light-duty or non-corrosive applications.

At Advanced Flow Controls Trading - LLC, we assist customers in choosing proper camlock materials for long-term performance.

6. Store Correctly When Not in Use

When not in use, keep your camlocks in a dry, dust-free environment. Do not leave them exposed to direct sunlight or corrosive environments. Protect with caps or covers for both female and male ends to keep out dirt and debris.

Keeping your fittings organized prolongs their life and makes them ready when needed.

7. Train Your Team

Maintenance only works if your operators understand how to work camlocks correctly. Give instruction to your personnel in:

Proper connection and disconnection

Visual inspection procedures

Cleaning protocols

Identifying worn parts

Trained operators are less likely to abuse or wreck equipment—saving you time and expense.

Why Use Advanced Flow Controls Trading - LLC?

As one of the UAE's established names in industrial supply and fluid control, Advanced Flow Controls Trading - LLC is committed to supplying quality camlock fittings and accessories to Abu Dhabi business and the rest of the UAE.

With a wide selection of camlock types, sizes, and materials, we’re your one-stop solution for reliable fluid transfer systems. Plus, our team is always available for expert advice on maintenance and product selection.

Conclusion

Camlock fittings are essential components in many fluid handling systems—but like any equipment, they require proper care. Regular inspections, cleaning, and part replacements go a long way in maximizing performance and safety.

By following these simple tips, you’ll not only extend the life of your camlocks but also reduce downtime and avoid costly replacements. For premium quality camlock fittings in the UAE, trust Advanced Flow Controls Trading - LLC—your reliable partner for all fluid control solutions.

#camlocks#camlock fittings#camlock maintenance#camlock suppliers UAE#camlock couplings#industrial hose fittings UAE#fluid control systems UAE#camlock fittings Abu Dhabi#quick connect couplings UAE#Advanced Flow Controls camlocks#stainless steel camlocks UAE

0 notes