#Electronic Ceramics

Explore tagged Tumblr posts

Text

Advanced Ceramics Market Size, Share Forecast & Geographic Focus 2029

In a world driven by high-performance technologies, traditional materials often fall short. This is where advanced ceramics come into play—bringing superior strength, thermal stability, and corrosion resistance to the table. Once confined to niche scientific applications, these engineered materials are now at the heart of sectors like electronics, automotive, medical, defense, and energy.

The global advanced ceramics market is undergoing a significant transformation. With sustainability, miniaturization, and performance at the forefront of industrial demands, manufacturers and end-users alike are leaning into the unmatched capabilities of advanced ceramics. The market is projected to reach USD 16.27 billion by 2029 from USD 12.16 billion in 2024, at a CAGR of 6.0%, driven by technological advancements and rising applications across various sectors.

What Are Advanced Ceramics?

Advanced ceramics are a class of materials that go beyond traditional clay-based ceramics. Made from highly purified and specially formulated raw materials such as alumina, zirconia, silicon carbide, and titanium dioxide, these ceramics offer superior properties:

High mechanical strength

Excellent wear and corrosion resistance

Exceptional thermal and electrical insulation

Biocompatibility for medical use

Lightweight with high durability

These properties make advanced ceramics indispensable in critical environments where performance is non-negotiable.

Key Market Drivers

1. Electronics & Semiconductors Boom

The electronics industry is one of the most significant consumers of advanced ceramics. Components such as insulators, capacitors, substrates, and sensors rely heavily on the insulating and heat-resistant properties of these materials. As demand for smaller, faster, and more reliable devices grows, ceramic substrates and heat sinks are becoming essential in high-frequency and power electronics.

2. Rising Electric Vehicle (EV) Adoption

The global shift toward electric mobility is a major growth catalyst. Advanced ceramics are used in EV batteries, sensors, braking systems, and thermal management components. Their ability to withstand high temperatures and mechanical stress makes them ideal for the high-performance demands of EVs.

3. Healthcare Advancements

From orthopedic implants and dental prosthetics to surgical instruments, biocompatible ceramics like zirconia and alumina are revolutionizing healthcare. Their inert nature and compatibility with the human body have made them a preferred choice in critical applications. With healthcare technology constantly evolving, the role of advanced ceramics is only set to expand.

4. Energy & Environmental Applications

Advanced ceramics are increasingly used in renewable energy systems, such as solid oxide fuel cells (SOFCs), solar panels, and wind turbines. Their resistance to extreme temperatures and corrosion makes them ideal for energy-efficient and long-lasting solutions. Additionally, they are also used in filtration systems, helping industries reduce environmental impact.

Market Challenges to Watch

While the outlook is promising, there are hurdles to overcome:

High production costs due to complex manufacturing processes

Brittleness in some ceramic compositions under certain mechanical stress

Limited recyclability, making end-of-life management a concern

However, ongoing R&D is paving the way for innovations that can address these challenges, including the development of tougher ceramics and cost-effective fabrication techniques.

Leading Players in the Market

The market is fairly consolidated, with a few key players driving innovation:

Kyocera Corporation – Known for its electronic components and ceramic-based solutions.

3M – Offers ceramics for filtration, electronics, and advanced coatings.

CoorsTek Inc. – A major player in industrial ceramics across multiple applications.

Morgan Advanced Materials – Specializes in engineered ceramics for energy, defense, and healthcare sectors.

CeramTec GmbH – Leading in medical and industrial ceramic components.

Regional Landscape

Asia Pacific holds the lion’s share of the market, led by countries like China, Japan, and South Korea. Rapid industrialization, growing electronics manufacturing, and government investments in healthcare and EV infrastructure are driving growth in this region. North America and Europe follow closely, with a strong focus on innovation and environmental compliance.

Explore the full report – Download the PDF brochure now.

The advanced ceramics market is no longer a quiet niche. It’s becoming a vital backbone for industries requiring materials that outperform metals and polymers. Whether it's for boosting energy efficiency, ensuring medical safety, or enabling next-gen electronics, advanced ceramics are powering the technologies of tomorrow.

#Advanced Ceramics#High Performance Materials#Ceramic Components#EV Materials#Electronic Ceramics#Medical Ceramics#Sustainable Manufacturing

0 notes

Text

Self-sensing cantilever design enhances microelectromechanical system performance in challenging environments

Microelectromechanical systems (MEMS) are tiny devices that integrate various components, such as miniature sensors, electronics and actuators, onto a single chip. These small devices have proved highly promising for precisely detecting biological signals, acceleration, force and other measurements. Most of the MEMS developed to date are made of silicon and silicon nitride. While some of these devices have achieved promising results, their material composition and design limit their sensitivity and versatility, for instance limiting their use in wet environments. In a recent Nature Electronics paper, researchers at Ecole Polytechnique Fédérale de Lausanne (EPFL) introduced an innovative cantilever design for MEMS based on a polymer, a semiconductor and ceramic. Cantilevers are tiny flexible beams that can adapt their shape in response to external forces or molecular interactions, thus potentially serving as sensors or actuators.

Read more.

16 notes

·

View notes

Text

ANDY STOTT // CERAMICS [CERAMICS 12” SGL, 2005]

13 notes

·

View notes

Text

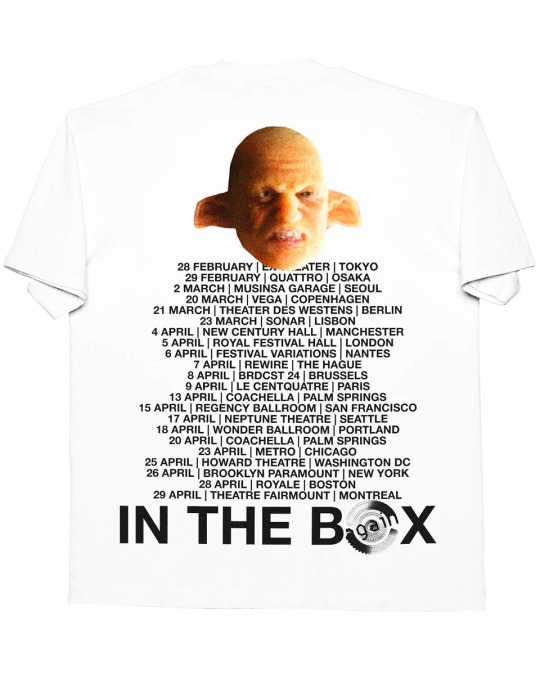

Oneohtrix Point Never x Online Ceramics

9 notes

·

View notes

Audio

Clark’s Ceramics Is The Bomb

#clark#ceramics is the bomb#warp records#music#electronic#idm#techno#acid techno#breakbeat#electronica#ambient#leftfield#experimental#dance#bandcamp

2 notes

·

View notes

Text

Ceramic-PCB-fabrication-and-Electronics-assembly, Hitech Circuits from China

Hitech focuses on one-stop electronic manufacturing services (EMS), covering ceramic printed circuit board manufacturing and electronic assembly, surface mount technology assembly, through-hole soldering, etc. All its products are widely used in various electronic devices.

Technical Parameters

Product type: ALN Ceramic PCB

Material: Aluminum Nitride Ceramic 180W/m.K

Layer/Thickness: 1L/1.5mm

Copper thickness: 1 OZ

Surface treatment: Hard gold

Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

0 notes

Text

Tension Measurement

Zhengtaifeng Co., Ltd offers reliable tension measurement tools to optimize your manufacturing process. Our equipment delivers precise, real-time data, ensuring consistent tension control for superior product quality in wire and cable operations.

#Ceramic products#Winding nozzle#Hysteresis Brakes#Winding machine china#Wire and Cable products#Tension Measurement#Electronic Tensioner#Magnetic tensioner#Servo tensioner#Mechanical tensioner

0 notes

Text

okay i decided to order the refurbed laptop. my plan is to make sure it runs acceptably (i'm guessing it's probably a "user turned it on once or twice and disliked the screen" situation tbh), see if the touch display it has is any worse than my current display, and then decide if i want to replace the display myself or not lol

#nadia rambles#if it's worse than my current display i'll definitely replace it. if it's the same i will probably have to think about it...#i'd LIKE to upgrade to 100% srgb and those displays are only $200 ish instead of $500 but if it's acceptable enough... we'll see#2025 is my year of buying refurbished normally expensive electronics for a third the price lmao#w/ intent for some amount of longevity and flexibility instead of relying on cheaper less durable tech#coincidentally we also switched to almost entirely ceramic plates and bowls recently in an attempt to lessen our plastic use#partly for health reasons since obv that plastic is already made and being presumably tossed out but...

1 note

·

View note

Text

Understanding Capacitors: Their Key Types, Applications, and Impact on Electric Performance

In the realm of modern electronics, the optimal performance of systems and devices regularly hinges on the proper integration and interplay of various board-level components that perform unique roles. Among the many electrical elements that serve as building blocks of design, items known as capacitors stand out as some of the most critical forms of passive components despite their relatively simple function. This blog will provide a comprehensive overview of capacitors for your knowledge, examining their fundamental design, common types, notable applications, and key considerations for ongoing use.

What Are Capacitors and How Do They Affect Electric Performance?

At their core, capacitors are two-terminal electronic components used to temporarily store electrical energy in an electric field. Structurally, they consist of two conductive plates that are separated by a dielectric material, which determines the component’s ability to store a charge. When connected to a power source, a capacitor will accumulate electrons on one plate while depleting those on the other, leading to a voltage difference across the two. The stored charge can then be used as a transient source when power is removed, or be harnessed for other various purposes.

The impact of capacitors on electric performance is quite multifaceted, as they are widely relied on for functions like energy storage, voltage regulation, signal smoothing, noise filtering, and coupling or decoupling AC/DC signals. Generally speaking, the exact capabilities and design of capacitors will vary based on the application they are to serve, with a range of options being available.

Key Capacitor Types and Their Applications

Capacitors are available in many variations, with some of the most widely used types including:

● Ceramic Capacitors: These are among the most common capacitors for many systems and devices, recognized for their compact size, cost-effectiveness, and stability over a wide temperature range. They are particularly ideal for high-frequency applications across consumer, telecommunication, and automotive settings, where they are used for decoupling and filtering.

● Electrolytic Capacitors: Known for their high capacitance values, electrolytic variations are polarized capacitors used in power supply circuits for bulk energy storage and smoothing purposes. They are also essential in devices requiring large, steady power outputs, with examples including audio amplifiers and industrial power converters.

● Tantalum Capacitors: These capacitors offer stable performance and reliability, particularly benefiting compact circuits. Their high volumetric efficiency also makes them suitable for applications like mobile phones and embedded systems, where space is more often constrained.

● Film Capacitors: Valued for their long-term stability and low inductance, film capacitors are prevalent in motor drives, inverters, and audio equipment, where performance consistency is of the highest concern.

● Supercapacitors (Ultracapacitors): Designed for exceptionally high energy storage, these capacitors bridge the gap between conventional capacitors and rechargeable batteries. This has allowed them to find popularity within renewable energy systems, hybrid vehicles, and memory backup systems.

Selecting the appropriate capacitor type for one’s specific operations is crucial, as mismatched parts or options that do not meet performance requirements can cause reduced efficiency, damage, or even device failure.

Important Maintenance and Replacement Considerations

While capacitors are designed for reliability, they are still subject to wear and aging like other electronics, especially when facing prolonged use within high-stress environments that involve heat, voltage fluctuations, or continuous charging/discharging cycles. Understanding the operational lifespan and degradation signs of capacitors is thus critical for upholding system integrity.

Common Signs of Capacitors Issues

Common signs of capacitor failure or damage will generally include bulging, leakage, reduced capacitance, or system instability. While some of these issues may be noticeable right away, it is important to conduct regular inspections to ensure that there are no underlying conditions that may be less noticeable. Preventative maintenance will always save one time and money, with manufacturer recommendations being the most advisable to follow to best extend the service life of parts.

Replacement Tips

Despite best efforts, there will come a time in which capacitors will simply need to be replaced. When searching for suitable replacements, it is vital to match key specifications like voltage rating, capacitance value, polarity, and temperature tolerance to the original item. Substituting a part with improper ratings may compromise safety and system functionality, among other issues. Additionally, sourcing replacements from reputable distributors is important to avoid counterfeit components that may not meet performance or safety standards.

The Importance of Partnering with a Trusted Source for Capacitor Procurement

With capacitors playing a central role in nearly all electronic systems, sourcing reliable, high-performance components for any new assembly or repair is a priority for engineers and procurement professionals alike. To meet this demand, ASAP Semiconductor offers access to an extensive inventory of capacitors and other board-level components through its purchasing platform, AFR Enterprises.

Through this website, customers can explore a diverse catalog of capacitor types from manufacturers like CSC Capacitor and other industry leaders. Each product listing is carefully vetted for quality and traceability, with everything being subject to rigorous quality assurance practices as necessary prior to shipment to ensure compliance with industry standards. Whether one is sourcing replacements for a repair or seeking top-quality components for a demanding project, AFR Enterprises offers a dependable procurement experience backed by industry expertise and timely delivery. See if ASAP Semiconductor is the right option for you when you explore AFR Enterprises’s selection of capacitors and get in touch with staff.

#capacitors#electronic components#energy storage#voltage regulation#ceramic capacitors#electrolytic capacitors#tantalum capacitors#film capacitors#CSC Capacitor#AFR Enterprises

0 notes

Text

Sintered salt (NaCl)

Processing The salt has been compacted (20MPa) and sintered for four hours at 785 degrees C Applications A sintered preform of salt can be used as a preform in the investment casting of open celled metal foams. The preform can then be washed out. Sample preparation The sample has been sputter-coated with gold Technique Scanning electron microscopy (SEM) Length bar 140 μm Further information The interconnectivity of pores in the reticulated aluminium foam was found to be strongly dependent on the degree of sintering of the salt. The sintering occurs by a non-densifying mechanism but the necks grow progressively wider with time. Four hours provides sufficient interconnectivity for the salt to be readily washed-out. Contributor J A Curran Organisation Department of Materials Science and Metallurgy, University of Cambridge

Source.

#Materials Science#Science#Ceramics#Salt#Magnified view#Scanning electron microscopy#Foams#Sintering#University of Cambridge#DoITPoMS

26 notes

·

View notes

Text

Alumina (AL2O3)Ceramic PCB

Layer Count: 1 layer

Unit Size: 55mm *130mm

Board Thickness:2.0mm

Surface Finish:gold plating

Solder Mask: White

0 notes

Text

Ceramic Capacitor, Murata capacitors, Consumer electronics, Data processing

1812 47 nF 1 kV ±10% Tolerance X7R SMT Multilayer Ceramic Capacitor

0 notes

Text

Lithium Ceramic (LCB) Electronic Battery Market Size, Competitive Landscape and Regional Analysis, Forecast to 2031

According to our (Global Info Research) latest study, the global Lithium Ceramic (LCB) Electronic Battery market size was valued at US$ 467 million in 2024 and is forecast to a readjusted size of USD 801 million by 2031 with a CAGR of 8.7% during review period. Lithium Ceramic (LCB) Electronic Battery is a next-generation energy storage technology that integrates ceramic materials to enhance the battery's safety, performance, and longevity. The ceramic materials, typically used as solid electrolytes or protective coatings, play a crucial role in improving safety by preventing thermal runaway and minimizing flammability. They also enhance stability by offering excellent chemical and thermal resistance, ensuring the battery maintains high performance over many cycles. Additionally, ceramics improve ionic conductivity, which boosts the battery's efficiency, and provide mechanical strength to prevent issues like dendrite growth that could lead to short circuits. This report is a detailed and comprehensive analysis for global Lithium Ceramic (LCB) Electronic Battery market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2025, are provided. This report is a detailed and comprehensive analysis for global Lithium Ceramic (LCB) Electronic Battery market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2025, are provided. Market segment by Type: Sheet Type、Laminate Type、Module Type、Others Market segment by Application:Automotive、Consumer Electronics、Industrial and Energy Storage、Others Major players covered: ProLogium Technology、Evonik、NGK INSULATORS、TDK、QuantumScape、Samsung SDI、Toyota、Ion Storage System、Ilika、Natrion

The overall report focuses on primary sections such as – market segments, market outlook, competitive landscape, and company profiles. The segments provide details in terms of various perspectives such as end-use industry, product or service type, and any other relevant segmentation as per the market’s current scenario which includes various aspects to perform further marketing activity. The market outlook section gives a detailed analysis of market evolution, growth drivers, restraints, opportunities, and challenges, Porter’s 5 Force’s Framework, macroeconomic analysis, value chain analysis and pricing analysis that directly shape the market at present and over the forecasted period. The drivers and restraints cover the internal factors of the market whereas opportunities and challenges are the external factors that are affecting the market. The market outlook section also gives an indication of the trends influencing new business development and investment opportunities.

The Primary Objectives in This Report determine the size of the total market opportunity of global and key countries,assess the growth potential for Lithium Ceramic (LCB) Electronic Battery and competitive factors affecting the marketplace,forecast future growth in each product and end-use market. Also,this report profiles key players in the global Lithium Ceramic (LCB) Electronic Battery market based on the following parameters - company overview, sales quantity, revenue, price, gross margin, product portfolio, geographical presence, and key developments.

Lithium Ceramic (LCB) Electronic Battery market is split by Type and by Application. For the period 2020-2031, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets.

Market segment by region, regional analysis covers North America (United States, Canada, and Mexico),Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe),Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia),South America (Brazil, Argentina, Colombia, and Rest of South America),Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa).

The report provides insights regarding the lucrative opportunities in the Lithium Ceramic (LCB) Electronic Battery Market at the country level. The report also includes a precise cost, segments, trends, region, and commercial development of the major key players globally for the projected period.

The Lithium Ceramic (LCB) Electronic Battery Market report comprehensively examines market structure and competitive dynamics. Researching the Lithium Ceramic (LCB) Electronic Battery market entails a structured approach beginning with clearly defined objectives and a comprehensive literature review to understand the current landscape. Methodologies involve a mix of primary research through interviews, surveys, and secondary research from industry reports and databases. Sampling strategies ensure representation, while data analysis utilizes statistical and analytical techniques to identify trends, market sizing, and competitive landscapes. Key areas of focus include trend analysis, risk assessment, and forecasting. Findings are synthesized into a detailed report, validated through peer review or expert consultation, and disseminated to stakeholders, with ongoing monitoring to stay abreast of developments.

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

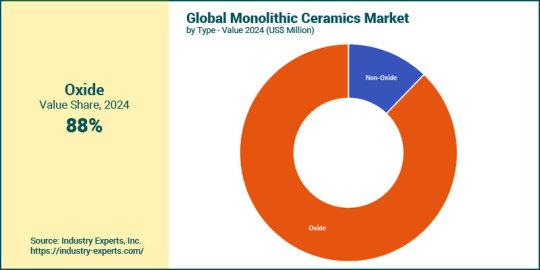

Photo

(via Global Monolithic Ceramics Market Size, Outlook 2024-2030)

#monolithic ceramics market overview#global monolithic ceramics industry#monolithic ceramics applications#monolithic ceramics in automotive industry#monolithic ceramics in electronics#monolithic ceramics in defense sector#monolithic ceramics market trends

0 notes

Text

https://www.futureelectronics.com/p/passives--capacitors--ceramic-capacitors--multilayer-ceramic-capacitors/grm31cc80g227me11l-murata-9093933

Types of Capacitors, Data processing, Capacitors Ceramic, electrolytic capacitor

Multilayer Ceramic Capacitors MLCC - SMD/SMT 1206 220uF 4.0volts *Derate Voltage

#Murata#GRM31CC80G227ME11L#Multilayer Ceramic Capacitors#Data processing#Capacitors Ceramic#electrolytic capacitor#RF Capacitors#MLCCs#High voltage#Consumer electronics#Ceramic Capacitors#Microwave Capacitor#multilayer ceramic chip

1 note

·

View note