#Electronic Control Module Repair

Explore tagged Tumblr posts

Text

Electronic Control Module Repair - Sprinters Performance

Electronic Control Module Repair at Sprinters Performance is specialized in fixing damaged components, reprogramming, or replacing faulty parts.

For more kindly visit: https://www.sprintersperformance.com/services

0 notes

Text

Buy ECM| PCM| ECU for your GMC - Clifford Auto Parts

Get top-quality GMC ECM, PCM, and ECU at Clifford Auto Parts. Our extensive selection includes genuine and high-performance engine control modules which are manufactured to optimize your vehicle's performance and reliability. Whether you're looking to replace a faulty ecm or upgrade for better efficiency, we offer reliable solutions for your needs. Shop with confidence and experience exceptional customer service for automotive requirements.

Visit us to know more: https://cliffordautoparts.com/product-category/gmc/

#ecm#pcm#engine control module repair#electronic control module#engine control module replacement#engine control module price#ecu repair service#automotive ecu repair#ecu for sale#pre programmed pcm#pcm powertrain control module#pcm car#pcm car part#automotive pcm

1 note

·

View note

Text

According to the latest security system's evaluation, G53U was behaving strangely. But no more strangely than others after certain stages of augmentation. SecUnit had seen humans start talking to walls or attacking their colleagues. Others would curl up in corners, and only the activation of the controlling implant would force them back to work.

The human brain was fragile—you never knew what would happen when another piece of neural tissue was replaced with state of the art electronics. G53U didn’t attack people. If anything, he avoided them. Rehabilitation, judging by his vitals, was going well, and the security system didn’t care much about his mental state. If things got too bad, the controlling implant would handle it. Over time, cognitive functions would transition to the augments, and everything would stabilize. If not—well, those augments could always be implanted in someone else.

Filing a report to the correctional block was a way to draw attention to an employee’s condition. But G53U hadn’t violated any serious rules. Nothing about his behavior posed a financial threat to the company - yet.

He simply refused to follow the routine. During scheduled rest periods, he wandered the corridors of the residential block or lingered near the coffee machine drinking his usual syrup with a minimal amount of coffee. If forced into his loving pod, he would lie there, hugging himself and breathing like he’d just escaped a chase. It all pointed toward serious issues in future, but for now, SecUnit couldn’t do anything.

Three days later, G53U refused to leave his workstation. That wasn’t technically a violation, and the security system allowed him to stay under observation for an additional shift. Occasionally, humans stayed for overtime in a desperate attempt to chip away at their debts. It never ended well.

"Your behavior does not contribute to survival," SecUnit said, approaching him.

G53U didn’t respond, staring at the table with a gaze full of fear. Was G53U finally afraid of it?

For a while, SecUnit stood over the augmented human, waiting for fear to take over or for G53U to collapse. Eventually, the governor module sent it off on patrol. An hour later, the security system reported that G53U had given up and left his workstation. Appropriate fine was issued.

When SecUnit returned to the ready room after its patrol, it found its cubicle hacked and occupied.

Inside, G53U was asleep.

This was a blatant violation, but SecUnit checked the air circulation and composition inside, then closed the cubicle again.

In the morning, G53U logged his overnight stay as urgent cubicle maintenance and highlighted software and hardware bugs he had corrected. He didn’t seem frightened. SecUnit confirmed all of G53U’s reports. The cubicle now reeked of human and dirty socks.

The next night, G53U came to the ready room with a blanket. SecUnit watched as the fear and despair that had filled him all day evaporated while he spread the blanket out on the floor next to the cubicle. SecUnit concluded that G53U might not be afraid of it after all.

"I can’t sleep there. Alone," G53U snapped in response to another warning from the buffer. "I’m scared, okay? I’m losing it. And you’re the safest thing here. You can throw me out, but if you do, I’ll definitely do something that’ll make you file reports, chase me down, break my arms or legs, or shoot me. You want that?"

All SecUnit could do is to search for another urgent repairs necessity

8 notes

·

View notes

Text

Crimson Dawn Fleet Breakdown: Vessel Classes and Their Capabilities

Crimson Dawn’s naval fleet is a critical component of its military strength, combining advanced technology, strategic versatility, and overwhelming firepower. Each class of vessel within the fleet is designed to fulfill specific roles, ensuring that Crimson Dawn maintains dominance in both defensive and offensive operations.

Cruiser Classes and Capabilities

1. Crimson Reaper

- Role: Command Ship

- Capabilities:

- Enhanced Command and Control Systems: The Crimson Reaper is outfitted with state-of-the-art command and control centers that facilitate seamless coordination of fleet operations, real-time tactical decisions, and comprehensive battlefield management.

- Advanced Sensor Suite for Intelligence Gathering: Equipped with cutting-edge sensors, the Crimson Reaper excels at long-range detection, surveillance, and electronic warfare, providing critical intelligence and situational awareness.

- Heavy Armor for Sustained Engagements: Built with reinforced armor plating and redundant systems, the Crimson Reaper can withstand prolonged assaults, serving as a resilient focal point in major battles.

2. Blood Vanguard

- Role: Heavy Assault Cruiser

- Capabilities:

- Powerful Turbolaser Batteries and Missile Launchers: The Blood Vanguard boasts an array of turbolaser batteries and missile launchers, capable of delivering devastating firepower in sustained barrages that can break enemy formations and defenses.

- Excellent Shield Systems: Outfitted with superior shield generators, the Blood Vanguard is designed to endure significant damage while maintaining offensive operations on the front lines.

- Frontline Engagements: Its combination of firepower and defensive capabilities makes the Blood Vanguard ideal for direct confrontation, spearheading assaults against fortified positions.

3. Scarlet Tempest

- Role: Interdiction Cruiser

- Capabilities:

- Equipped with Gravity Well Generators: The Scarlet Tempest plays a crucial role in controlling the battlefield by generating gravity wells that prevent enemy ships from escaping via hyperspace. This ability is essential for trapping enemy fleets and securing strategic positions.

- Advanced Defensive Systems: The Scarlet Tempest features advanced defensive systems, including reinforced shields and rapid-repair modules, ensuring it can sustain prolonged engagements and fulfill its interdiction role effectively.

- Fighter Launch Bays for Support: With multiple fighter launch bays, the Scarlet Tempest can deploy squadrons of starfighters and bombers to provide additional firepower and cover, supporting both offensive and defensive maneuvers.

Role and Strategic Importance within the Fleet

1. Crimson Reaper: The Command Center

- Strategic Coordination: The Crimson Reaper serves as the nerve center of Crimson Dawn’s fleet, coordinating multi-faceted operations and providing strategic oversight.

- Fleet Command: Its advanced command and control systems ensure that fleet commanders can effectively manage and adapt to dynamic battle conditions, making it an indispensable asset in any large-scale engagement.

2. Blood Vanguard: The Heavy Hitter

- Offensive Powerhouse: As the primary assault vessel, the Blood Vanguard’s firepower can shape the course of battles. Its ability to deliver sustained, powerful attacks makes it a key player in offensive campaigns.

- Frontline Defense: The ship’s robust shield systems and heavy armor allow it to absorb enemy fire, protecting more vulnerable vessels and holding strategic points during engagements.

3. Scarlet Tempest: The Battlefield Controller

- Tactical Advantage: By preventing enemy retreat and maneuvering, the Scarlet Tempest grants Crimson Dawn a significant tactical advantage, enabling the fleet to pin down and destroy opposition forces.

- Support Role: Its ability to deploy fighters and provide defensive cover makes it versatile, enhancing overall fleet cohesion and operational effectiveness.

Integration and Coordination

- Unified Command Structure: Each class of vessel operates under a unified command structure led by high-ranking officers of Crimson Dawn. This unity ensures that strategic goals are met through precise coordination and execution.

- Complementary Roles: The cruisers’ capabilities are designed to complement each other. The Crimson Reaper oversees and strategizes, the Blood Vanguard delivers heavy firepower and holds the line, while the Scarlet Tempest controls and secures the battlefield, preventing escapes and providing critical support.

- Versatility and Adaptability: By integrating these varied capabilities, Crimson Dawn can adapt to a wide range of combat scenarios, from large-scale fleet engagements to targeted strikes and blockade operations.

Conclusion

The fleet of Crimson Dawn, characterized by the Crimson Reaper, Blood Vanguard, and Scarlet Tempest cruisers, represents a formidable blend of command, firepower, and tactical control. Each vessel class is meticulously designed to fulfill its role within the broader strategy, ensuring that Maul’s vision of dominance through strength and versatility is realized on the galactic stage.

By harnessing the strengths of each vessel type and ensuring seamless coordination between them, Crimson Dawn’s fleet stands as a powerful instrument of war, capable of delivering decisive blows to the Republic and any other adversaries that stand in their path.

#star wars#star wars fanfiction#star wars what if#darth maul#savage opress#feral opress#crime syndicate#crimson dawn#dryden vos#heavy cruiser#space ship#check out my fanfic#my fanfiction#Darth Maul: A New Dawn

10 notes

·

View notes

Text

Why are so many cars designed to make it almost impossible to replace the headlight bulbs? Even LEDs do not last forever.

The difficult headlight bulb replacement in modern cars stems from several deliberate design trade-offs – prioritizing other factors over serviceability. Here's why engineers often sacrifice accessibility:

Aerodynamics & Styling Demands:

Low, Sloping Hoods: Aggressive aerodynamic profiles minimize the space under the hood, pushing components (including the headlight assemblies) closer to the radiator, engine, and structural elements.

Seamless Body Lines: Sleek headlight designs with complex contours often require integrated bezels and trim pieces that physically block access points. Removing bumpers or entire assemblies becomes necessary to preserve the desired visual lines.

Thin Headlight Profiles: Modern lights are shallow and wrap tightly around body panels, leaving minimal clearance behind the bulb socket.

Overcrowded Engine Bays:

Packing in Tech: Modern engine compartments are packed with turbochargers, intercoolers, complex intake systems, emission control devices, coolant reservoirs, air ducts, battery boxes, fuseboxes, and wiring harnesses.

Prioritized Placement: Engineers give prime, accessible space to critical components like the air filter, oil dipstick, coolant reservoir, and brake fluid. Headlight bulbs become an afterthought, relegated to the cramped spaces left behind.

Complex Headlight Assemblies (Especially for LEDs):

Sealed Units: Most modern LED headlights are not designed with replaceable "bulbs" like halogens. The LEDs are tiny chips soldered onto circuit boards, integrated with heatsinks, lenses, projectors, and complex electronic drivers.

Thermal Management: LED units require effective heat dissipation, often involving large heatsinks and fans inside the sealed assembly. Making them easily serviceable would compromise the thermal seal and design integrity. They are designed as a single, sealed module.

Alignment & Calibration: Modern adaptive headlights (swiveling cornering beams, auto-leveling) require extremely precise optical alignment and electronic calibration from the factory. Replacing an internal LED chip would likely disrupt this precision far more than swapping a simple halogen bulb. Replacing the whole sealed unit ensures this calibration remains intact (it's locked into the housing).

Moisture Seal: Creating a user-serviceable opening for LED chips without compromising the hermetic seal against moisture (which would rapidly destroy the electronics) is extremely difficult.

Safety and Regulatory Concerns:

Accurate Beam Pattern: Headlights must be perfectly aligned to avoid blinding oncoming traffic. A complex mounting system helps ensure the entire headlight assembly remains stable and doesn't get knocked out of alignment easily. Making bulbs "toolless" might compromise this stability.

Electrical Integrity: Complex connectors and wiring harnesses are designed for reliability over the life of the vehicle, not for frequent disconnection/reconnection by owners. Easier access might increase the risk of moisture ingress or connector damage.

Manufacturing Cost, Efficiency & Profit:

Simplified Assembly Line: Designing for easy post-assembly service adds complexity during manufacturing. Mounting the headlight assembly deep within the front end might be faster/easier on the line than leaving room for hand access later.

Dealer Service Profit: While often overstated as the primary reason, manufacturers know difficult repairs increase the likelihood owners will use dealer service departments, where labor rates are high. Making bulbs easy to swap yourself costs them potential revenue.

Reduced Parts Inventory: Designing around sealed LED modules reduces the number of individual parts needed (bulb types, sockets) and simplifies inventory logistics, even though the module itself is more expensive.

Longevity Focus (Even with LEDs):

Perceived Permanence: While LEDs don't last forever, their projected lifespan (often 10,000-15,000 hours+) significantly exceeds the average ownership period of a vehicle (around 8 years). Manufacturers design knowing that most owners won't need to replace them during their ownership, reducing the incentive to prioritize access.

Electronics vs. Filament: Halogen bulbs fail frequently due to fragile filaments. LED modules are solid-state electronics. While the LEDs themselves are long-lasting, drivers/fans/corrosion can cause the entire module to fail before the individual LEDs burn out. It's simpler/necessary to replace the complex module rather than diagnose and repair individual electronic components embedded within it.

In Summary: Engineers are solving a complex puzzle: maximizing aerodynamics, fitting more technology, meeting strict safety regulations, achieving aggressive styling, managing thermal loads (LEDs), ensuring long-term reliability/sealing, and minimizing manufacturing costs/ease. Prioritizing your ability to quickly replace a bulb is rarely high on that list, especially with LEDs designed as long-life, sealed units for performance and reliability reasons. While frustrating for DIY mechanics, the trade-offs made sense to the designers for the other priorities.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#led light bulbs#led strip lights#car rental#cars#electric cars#classic cars#car#carlos sainz#truck#porsche#sabrina carpenter#suv#lamborghini#bmw#autonomous vehicle headlights#overtake another vehicle#older vehicles#very pretty#vehicle#automatic headlights

2 notes

·

View notes

Text

From Engine to Electronics: Proper Diagnostic Techniques for Resolving Maserati Problems

Maserati, the epitome of Italian luxury and performance, is renowned for its stylish design and high-performance capabilities. However, like any high-end vehicle, Maserati can encounter a range of issues, from engine troubles to electronic malfunctions. Proper diagnostics is crucial in maintaining the health and performance of these sophisticated machines. This article will guide you through the common problems Maserati face and the proper diagnostic techniques to resolve them.

Common Maserati Problems

1. Engine Issues

Maserati engines are marvels of engineering, but they can develop problems over time. Common engine issues include:

Misfires and Rough Idling: This can be caused by faulty spark plugs, ignition coils, or fuel injectors.

Overheating: Often due to a malfunctioning cooling system, such as a failed water pump or a clogged radiator.

Oil Leaks: These can originate from various seals and gaskets, leading to low oil levels and potential engine damage.

2. Transmission Problems

Maserati transmissions are designed for performance but can experience:

Slipping Gears: This could indicate worn-out clutch plates or issues with the transmission fluid.

Delayed Shifts: Often due to problems with the transmission control module or low fluid levels.

3. Electrical and Electronic Failures

Modern Maseratis are equipped with advanced electronics that can sometimes fail, including:

Dashboard Warning Lights: These can indicate issues ranging from simple sensor failures to serious engine problems.

Infotainment System Glitches: Problems with the touch screen, navigation, or audio system are not uncommon.

Diagnostic Techniques

1. OBD-II Scanner

The On-Board Diagnostics II (OBD-II) scanner is an essential tool for diagnosing Maserati problems. It can read error codes from the car's computer, providing insight into various issues.

How to Use: Connect the OBD-II scanner to the port located under the dashboard. Turn on the ignition and follow the scanner’s instructions to retrieve the error codes.

Interpreting Codes: Each code corresponds to a specific problem. For example, P0300 indicates a random/multiple cylinder misfire, while P0128 points to a coolant thermostat issue.

2. Visual Inspection

A thorough visual inspection can reveal obvious issues such as leaks, damaged components, or worn-out parts.

Engine Bay: Check for oil leaks, loose connections, and the condition of belts and hoses.

Undercarriage: Inspect for fluid leaks and damage to the exhaust system.

Electrical Connections: Look for corroded or loose battery terminals and wiring issues.

3. Multimeter Testing

A multimeter is useful for diagnosing electrical issues in a Maserati.

Battery Voltage: Measure the voltage across the battery terminals. A healthy battery should read around 12.6 volts when the car is off and around 14 volts when running.

Sensor Checks: Test various sensors, such as the oxygen sensor or mass airflow sensor, to ensure they are functioning correctly.

4. Compression Test

A compression test helps diagnose internal engine problems such as worn piston rings or valves.

Procedure: Remove the spark plugs and insert a compression gauge into each cylinder. Crank the engine and note the pressure readings. Low or uneven readings indicate internal engine issues.

5. Professional Diagnostic Tools

Maserati dealerships and specialized repair shops use advanced diagnostic tools that can access proprietary systems and provide more detailed information.

SD2/SD3 Diagnostic Systems: These are specialized tools used by Maserati technicians to diagnose and program vehicle systems accurately.

Diagnostic Software: Tools like Xentry or PIWIS can interface with Maserati's electronic systems for comprehensive diagnostics.

Addressing Common Issues

1. Engine Repairs

Misfires and Rough Idling: Replace faulty spark plugs, ignition coils, or fuel injectors. Regular maintenance and using high-quality fuel can prevent these issues.

Overheating: Ensure the cooling system is functioning correctly by checking the water pump, radiator, and thermostat. Flushing the coolant system periodically is also recommended.

Oil Leaks: Identify the source of the leak and replace the necessary seals or gaskets. Regularly check oil levels and change the oil according to the manufacturer's recommendations.

2. Transmission Solutions

Slipping Gears: Inspect and replace worn clutch plates and ensure the transmission fluid is at the correct level. Consider a fluid change if necessary.

Delayed Shifts: Diagnose and repair issues with the transmission control module or solenoids. Regular transmission servicing can prevent many of these problems.

3. Electrical Fixes

Dashboard Warning Lights: Use an OBD-II scanner to identify and address the underlying issue. Reset the warning lights after repairs are completed.

Infotainment System Glitches: Perform software updates and check for any loose connections or faulty components. In some cases, a complete system reset may be required.

Conclusion

Proper diagnostics are essential for maintaining the performance and reliability of your Maserati. By using the right tools and techniques, you can identify and resolve issues promptly, ensuring your luxury car continues to deliver the driving experience it was designed for. Regular maintenance and timely repairs are key to keeping your Maserati in top condition, from the engine to the sophisticated electronics.

#maserati car#maserati car diagnosis#maserati service center#maserati car maintenance#maserati car mechanic

2 notes

·

View notes

Text

Why an Independent BMW Specialist Offers Better Value Than Dealerships

An independent BMW specialist provides an alternative to dealership servicing, offering competitive pricing, deep technical expertise, and personalised service. These independent workshops focus exclusively on BMWs, meaning they are often better equipped to handle complex diagnostics, performance tuning, and long-term maintenance than general garages. For Australian BMW owners seeking reliable, cost-effective servicing, choosing an independent specialist ensures that your car receives expert care without dealership markups.

What Sets Independent BMW Specialists Apart?

Specialist workshops offer several advantages over traditional dealerships:

Dealership-Level Diagnostics: Many independent specialists use factory-level scanners and software to interpret BMW-specific fault codes.

Lower Labour Rates: Without dealership overheads, independent workshops often charge less while delivering comparable or superior service.

In-Depth Model Knowledge: Technicians are often passionate BMW owners themselves, bringing hands-on experience beyond technical manuals.

Flexibility in Parts Sourcing : May use genuine BMW parts or high-quality alternatives that meet or exceed factory specifications.

Personalised Customer Interaction : Smaller workshops typically offer direct communication with technicians, improving transparency and trust.

These differences make independent specialists appealing to many BMW owners.

What Types of Repairs and Services Do Specialists Handle?

An independent BMW specialist covers a broad range of mechanical and electronic needs:

General Servicing and Oil Changes : Performing scheduled maintenance using approved fluids and filters.

Transmission and Differential Repairs : Addressing gearbox issues, clutch replacements, and differential wear in rear-wheel and all-wheel-drive models.

Electrical Fault Diagnostics : Troubleshooting complex electrical issues including wiring harness failures, sensor malfunctions, and module reprogramming.

Suspension and Steering Component Replacement : From control arms to subframe mounts, specialists address wear items that affect ride quality and handling.

Air Conditioning and Climate Control Servicing : Refilling refrigerant, replacing compressors, and fixing heater core issues.

These services ensure that even older models remain roadworthy and comfortable.

How Do Independent Specialists Approach Diagnostics?

Diagnosing modern BMWs requires advanced equipment and experience:

Factory-Level Scan Tools : Many specialists use ISTA or similar software to access real-time data and coding adjustments.

Interpretation of Error Codes : Unlike generic code readers, BMW specialists understand the context behind each fault message.

CAN Bus and Module Communication : Experts diagnose issues within interconnected systems that general mechanics may struggle to interpret.

Software Updates and Recalls : Some independent shops apply official software patches and firmware upgrades when needed.

Component Testing and Swaps : When a part fails intermittently, specialists often test components rather than replace outright.

This methodical approach reduces guesswork and unnecessary part replacements.

What Should You Expect in Terms of Cost and Turnaround Time?

Costs at an independent BMW specialist vary but often compare favourably to dealership pricing:

Labour Rate Differences : Independent shops typically charge lower hourly rates, making complex jobs more affordable.

Parts Pricing Options : Some specialists source parts directly from Europe, while others use local distributors for faster turnaround.

Transparent Billing Practices : Reputable specialists itemise costs, ensuring clarity on parts, diagnostics, and repair work.

Repair Duration Variability : Minor services may take a few hours, while major repairs could take several days depending on parts availability.

Value for Money : Despite being independent, many offer higher service quality than dealerships due to focused expertise and smaller client loads.

These factors contribute to a more satisfying and cost-efficient ownership experience.

How to Select the Right Independent Specialist

Finding a reputable independent BMW specialist involves several steps:

Community Recommendations: Enthusiast forums and local BMW clubs often list trusted service providers.

Review Online Feedback: Reading past customer experiences gives insight into reliability, communication, and work quality.

Verify Technical Qualifications: Ensure the workshop employs licensed technicians with experience in modern BMW platforms.

Check for Proper Tools and Equipment: The best specialists invest in the latest scanning and diagnostic tools.

Visit the Workshop in Person: Seeing the environment and meeting the team builds confidence in the service provider.

A well-researched choice leads to better outcomes and long-term vehicle satisfaction.

Final Thoughts

An independent BMW specialist offers a compelling alternative to franchised dealerships, particularly for those seeking expert diagnostics, cost-effective repairs, and tailored service. With the right specialist, owners can enjoy the full potential of their BMW without paying inflated dealership prices. As the market for independent workshops grows, so does the opportunity for Australian BMW drivers to access high-quality, model-specific care that supports both daily commutes and weekend driving pleasure.

0 notes

Text

youtube

India’s Leading ECM Repair and Training Center – Hi-Tech Khanna

Hi-Tech Khanna is India’s top destination for ECM repair training and advanced diagnostic education. Recognized as one of India’s best ECM training centers, we offer hands-on learning and in-depth technical knowledge to help you become a skilled ECM technician. Our ECM repair courses in India, including both offline and online ECM repair courses, are designed for beginners and professionals seeking to upgrade their skills in automotive electronics.

Our facility is equipped with advanced tools and real ECM units for practical training. From diesel and petrol ECM modules to advanced vehicle control systems, our instructors provide real-time problem-solving techniques and job-ready skills.

Hi-Tech Khanna also offers professional ECM repair services in India, ensuring quality service with expert precision. Whether you're aiming for a career or looking to expand your workshop services, Hi-Tech Khanna delivers results you can rely on.

#HiTechKhanna#ECMRepairIndia#ECMTrainingIndia#ECMRepairCourse#OnlineECMCourse#BestECMTraining#AutomobileElectronics#CarECMRepair#DieselECMTraining#AutoDiagnosticTraining#ECMSpecialist#VehicleECMRepair#ECMTrainingCenter#AutomotiveTrainingIndia#HiTechECM#Youtube

0 notes

Text

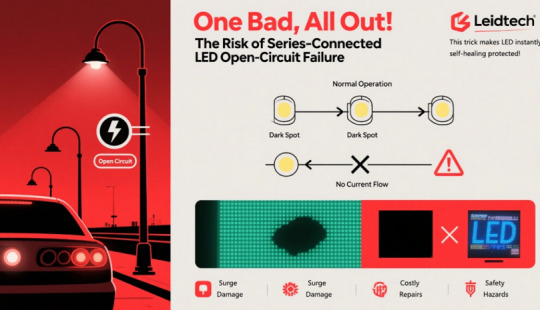

ED Light Fails? This “Invisible Self-Healing” Solution is Trusted by 90% of Engineers!

How Deadly is LED Open-Circuit Failure?

Imagine: Outdoor streetlights suddenly go dark in segments, car taillights lose a bead, or mall LED screens develop dark spots — all often caused by a single open-circuited LED bead.

Series-connected LEDs fear “one fails, all fail!” Thermal shock, ESD, or lightning strikes can blackout entire lighting systems, causing costly repairs.

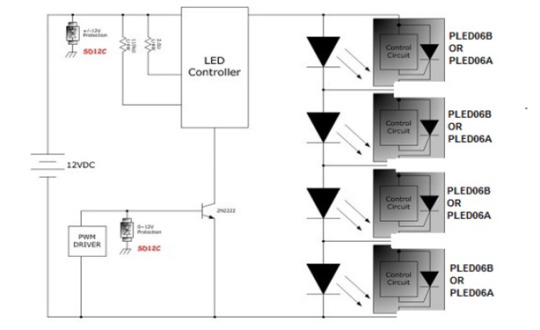

Leiditech LED Shunt Solution: Invisible Self-Healing for LED Failures

(Diagram: PLED06B control circuit with bypass logic for open-circuit LEDs)

As an EMC innovation leader, Leiditech’s LED Shunt open-circuit protection device revolutionizes traditional protection. Take the flagship PLED06CB as an example:

✅ Dual Protection Mechanism

▶ Anti-blackout: Bypasses each failed bead in series-connected LED strings, keeps the rest lit

▶ Lightning and Surge Resistance: Easily withstands 24A surges, ensuring LED beads are not instantly “blown up” by high voltage.

✅ Intelligent Response & Auto-Reset

▶ Normal State: High impedance (leakage <10μA), zero impact on brightness

▶ Fault State: <1ns ultra-fast conduction when voltage hits breakdown threshold (e.g., 6V), bypassing faulty beads

▶ Auto-Recovery: Automatically resets to high impedance after the fault is cleared (e.g., bead replacement or system reboot)

Full-Scenario Applications

1. Outdoor & Industrial Lighting (Streetlights, tunnels, billboards):

- Meets CQC3158–2024 (China energy efficiency standard) energy efficiency, survives lightning surges, ensures single-fault resilience

2. Automotive Electronics (Headlights, taillights, turn signals):

- Complies with ISO 16750–3 vibration/thermal standards

- Combined with automotive TVS (SM8S33CA) and ESD (SMC24) for full-power protection

3. Smart Home & Commercial Lighting (LED strips, panel lights):

- Eliminates dark spots from single-bead failure

- PWM (Pulse Width Modulation) dimming compatible — protection remains active during dimming

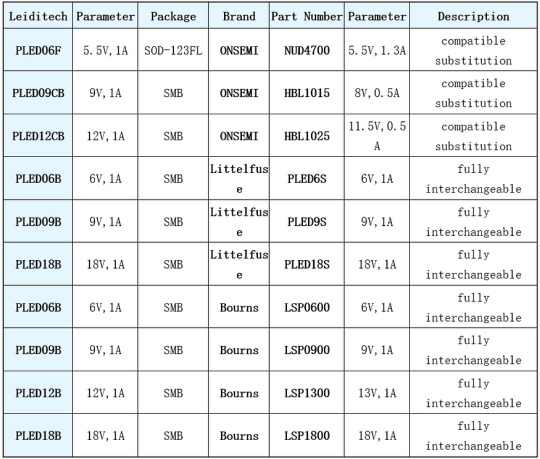

Leiditech’s PLED Series LED shunts can perfectly replace those of other brands.

3-Step Selection Guide

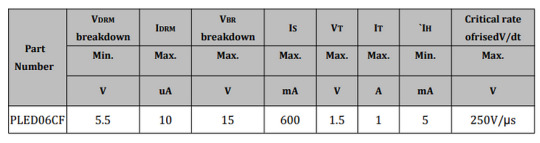

Core Parameter Matching

- Breakdown Voltage (VBR): ≥1.5x LED operating voltage (e.g., 5.5V VBR for 3.3V LEDs)

- Holding Current (IH): ≥5mA (ensures sustained conduction)

- On-State Current (IT): 1A max (high-power tolerance)

- Package: SOD-123FL (compact) / SMB (high-power)

2. Design Tips

- Layout: Place LED Shunt close to LED terminals to minimize parasitic inductance

- Thermal Management: Calculate conduction power (P=Vf×I), ensure adequate heat dissipation

3. Certifications

- UL, VDE, IEC 62031 compliant

- Accelerates CQC3158–2024 energy efficiency compliance

Leiditech: Beyond Components — Total Technical Support

From “single-fault blackout” to “invisible bypass,” LED Shunt ensures:

- Outdoor Lighting: 10+ year lifespan via surge protection

- Automotive: Zero-fault safety compliance

- Smart Home: Seamless user experience

Unique Services:

- Free EMC lab testing (ESD, surge, EFT)

- Customizable parameters for high-voltage/high-frequency scenarios

- “Zero-fault” combo solutions (PTC+TVS+ESD) for multi-risk protection

Leiditech — Leading EMC Solutions Provider

- Specializing in ESD, TVS, TSS, GDT, MOV, MOSFET, inductors.

- Custom R&D team ensures tailored protection for your application.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com] #LEDProtection #SelfHealingTech #Leiditech #NoMoreBlackouts #SmartLighting #AutoLighting #IndustrialLED #InvisibleFix #ZeroDowntime #PLEDSeries #SurgeProtection #ESDShield #NextGenLighting #EngineerTrusted #TechWithoutFailure

0 notes

Text

Upgrade your Chrysler pcm with Clifford Auto Parts. We offer high-quality, ready-to-install Chrysler pcm modules. It ensures immediate compatibility and optimal performance. Whether you need a Chrysler ecu programming or repair, we provide reliable solutions to keep your Chrysler running smoothly.

Visit us to know more: https://cliffordautoparts.com/product-category/chrysler/

#electronic control module#engine control module replacement#engine control module price#ecu repair service#automotive ecu repair#ecu for sale#ecu for car#pcm module#pcm rebuilders#pre programmed pcm#pcm powertrain control module

0 notes

Text

Expert German Auto Repair in Simi Valley

German vehicles are known for their precision, performance, and luxury. Whether you drive a BMW, Audi, Mercedes-Benz, Volkswagen, or Porsche, maintaining your vehicle requires expert care. If you're searching for German auto repair in Simi Valley, you're in the right place. Specialized technicians in your area are equipped to keep your German car running like new.

Why Choose a German Auto Repair Specialist?

German engineering is unique. These vehicles use advanced technology, intricate systems, and strict manufacturing standards. That’s why a general mechanic may not have the tools or training to repair German cars effectively. Here's why you need a German auto repair expert:

Certified technicians trained to handle complex German systems.

Factory-grade diagnostics that read specific fault codes.

Access to OEM parts that match original specifications.

Knowledge of service intervals tailored to German vehicles.

Common German Auto Services in Simi Valley

Top-rated German auto repair shops in Simi Valley offer a full range of services for all major German brands. Here’s a breakdown of common services you can expect:

1. Engine Diagnostics and Repair

German engines are powerful but require exact diagnostics. Expert shops use factory-level scanners to identify issues fast.

2. Transmission Service

Brands like BMW, Mercedes, and Audi often use specialized transmissions. A certified shop will provide the right fluids, programming, and repair methods.

3. Brake Repair and Replacement

German vehicles often feature advanced ABS systems and performance brakes. Proper maintenance is key for safety and control.

4. Suspension and Steering Repair

German cars are known for their smooth ride and tight handling. If your suspension feels off, it may be time for shock, strut, or bushing replacement.

5. Oil Changes and Maintenance

Regular maintenance extends the life of your German car. Reputable Simi Valley shops use synthetic oil and follow manufacturer-recommended intervals.

6. Electrical System Repairs

From sensors to control modules, German vehicles rely on electronics. Skilled shops can diagnose and fix electrical issues quickly and accurately.

German Brands We Service in Simi Valley

Many repair shops in Simi Valley specialize in all major German automakers:

BMW: Engine tuning, cooling systems, oil leaks, VANOS repairs

Mercedes-Benz: Airmatic suspension, transmission services, Service A/B

Audi: Turbocharger diagnostics, Quattro systems, timing chain repairs

Volkswagen (VW): DSG transmission service, coolant system repairs

Porsche: Brake upgrades, engine rebuilds, performance tuning

Mini Cooper: Clutch replacement, oil filter housing, valve cover gaskets

Why Simi Valley Drivers Trust German Auto Repair Shops

Choosing a local Simi Valley German auto repair shop has several benefits:

Personalized Customer Service

Independent shops often offer more attention and care than large dealerships. You speak directly to the technician working on your car.

Competitive Pricing

German auto repair doesn’t have to cost a fortune. Local shops offer dealer-quality service without the inflated pricing.

OEM Parts and Warranties

Top-rated shops use OEM or OE-equivalent parts, often with warranty coverage for peace of mind.

Transparent Communication

From digital inspections to detailed invoices, honest shops keep you informed every step of the way.

Signs You Need German Auto Repair

Don’t wait for a breakdown. Watch for these warning signs in your German vehicle:

Check engine light stays on

Burning smells or fluid leaks

Transmission hesitation or hard shifting

Unusual noises while braking or accelerating

Uneven tire wear or vibration

Poor fuel economy or reduced performance

How to Choose the Right German Auto Repair in Simi Valley

Not all repair shops are created equal. Use this checklist to find the best one for your vehicle:

Certified and trained in German automotive systems

Equipped with dealer-level diagnostic tools

Experience with your specific car brand and model

Transparent estimates and honest recommendations

Positive online reviews and strong local reputation

FAQs About German Auto Repair in Simi Valley

How often should I service my German car?

Most German vehicles require service every 7,500 to 10,000 miles, depending on the model and type of oil used.

Are independent German repair shops as good as dealerships?

Yes. Many use the same tools and training as dealers but offer lower prices and more personalized service.

Can I maintain my warranty if I don’t go to the dealership?

Yes. As long as the shop uses approved parts and keeps detailed records, your warranty remains valid.

What makes German auto repair more expensive?

German cars often use high-performance parts and require specialized knowledge, which can raise repair costs.

Do German repair shops in Simi Valley offer warranties?

Most reputable shops offer warranties on both parts and labor typically ranging from 12 months to 3 years.

Conclusion

If you own a German vehicle, you know the value of quality and performance. Trusting a German auto repair specialist in Simi Valley ensures your car gets the expert attention it needs. From diagnostics to routine maintenance, local professionals offer top-tier service without the dealership price tag. Your vehicle deserves the best—choose a German auto repair shop that matches its excellence.

0 notes

Text

Agriculture Equipment Manufacturing Company: Premier Solutions Today!

Boosting Farm Efficiency with Premium Equipment

In today’s fast-paced agricultural landscape, farmers need machinery that keeps pace with demanding workloads. Partnering with a specialized agriculture equipment manufacturing company ensures access to durable, reliable, and innovative solutions. From robust tillage implements to high-capacity harvesters, the right machinery can transform planting cycles, reduce downtime, and ultimately increase yields. By relying on experts who understand farm challenges, producers can focus on core operations while enjoying peace of mind that their equipment will perform when it matters most.

Commitment to Quality and Innovation

Choosing an experienced provider often translates to receiving machines built with meticulous attention to detail. Leading agricultural machinery fabrication manufacturers invest heavily in research and development, staying at the forefront of metalwork techniques, component integration, and automation. Whether it’s precision-engineered frames that resist corrosion or electronic control modules that optimize fuel consumption, thoughtful design delivers tangible benefits. Farmers gain machinery that not only meets industry standards but also introduces forward-thinking features—giving them a competitive edge in a market where efficiency and sustainability are paramount.

Customized Solutions for Every Farm

No two farms are identical, and a one-size-fits-all approach rarely suffices. That’s why many producers turn to a trusted agriculture equipment manufacturing company capable of tailoring solutions to specific crop types, acreage, and soil conditions. Whether the need is for customized attachments, adjustable frame heights, or reinforced gearboxes to handle rocky terrain, bespoke fabrication solves critical pain points. Collaborative engineering sessions allow farmers to communicate precise requirements—ensuring that final products integrate seamlessly into existing workflows, fit within budget constraints, and deliver a rapid return on investment.

Excellence in Fabrication and Assembly

Fabrication is both an art and a science. Top-tier agricultural machinery fabrication manufacturers maintain rigorous quality-control measures at every production stage. Skilled welders, machinists, and assemblers work in synchrony to produce equipment that adheres to tight tolerances. From laser cutting of high-strength steel plates to robotic welding for consistently uniform joints, advanced processes reduce waste and minimize the risk of field breakdowns. Assembling complex hydraulic systems and testing performance under real-world loads further ensures that each piece of machinery operates flawlessly from day one.

Why Investing in Proven Manufacturing Pays Off

Cutting corners on equipment may yield short-term savings, but long-term costs often skyrocket due to frequent repairs, energy inefficiencies, and unpredictable downtimes. By partnering with a reputable agricultural machinery fabrication manufacturers partner, farmers receive not only durable products but also comprehensive support services. Preventive maintenance plans, quick-response repair teams, and readily available spare parts reduce unplanned stoppages. Moreover, well-engineered machines often retain higher resale values—providing an additional financial incentive when equipment cycles reach the end of their service life.

Conclusion: Equip Your Farm for the Future

Embracing innovation in agriculture starts with selecting machinery that embodies quality, reliability, and adaptability. An experienced agriculture equipment manufacturing company offers more than just metal and motors—it delivers solutions designed to streamline operations, reduce costs, and boost overall productivity. Backed by proven expertise and state-of-the-art fabrication practices, farms can confidently navigate evolving market demands, deliver bountiful harvests, and secure long-term success.

0 notes

Text

Restoring Clarity and Control: The Importance of Digital Dashboard Repair by Cartronix

Modern vehicles rely heavily on digital systems, and the dashboard is one of the most vital interfaces between you and your car. From displaying speed and fuel levels to providing crucial alerts and performance indicators, the digital dashboard plays a central role in your driving experience. When it begins to malfunction—whether it’s flickering screens, inaccurate readings, or complete failure—it can compromise both safety and performance. That’s where digital dashboard repair becomes essential, and Cartronix is the trusted name drivers turn to for reliable service.

Why Dashboard Failures Should Never Be Ignored

A failing dashboard is more than just an inconvenience. It can prevent you from seeing critical warnings, lead to missed maintenance alerts, and cause confusion over your vehicle’s condition. Problems like a blank screen, faulty backlighting, or erratic gauge behavior may start small, but they can quickly become serious if left unchecked. Accurate information from your dashboard is essential for making informed decisions behind the wheel, so timely repair is crucial to avoid long-term complications or potential safety risks.

Expert Diagnostics and Repair from Cartronix

Cartronix has built a strong reputation for precision and reliability in digital dashboard repair. With advanced diagnostic tools and skilled technicians, the team at Cartronix can identify the root of any issue quickly and effectively. Whether the problem lies in the instrument cluster, internal circuitry, or display modules, their experts are equipped to handle the full spectrum of dashboard repairs across a wide range of makes and models.

Rather than replacing the entire dashboard, which can be expensive, Cartronix focuses on repairing and restoring existing components. This cost-effective approach not only saves you money but also helps preserve your vehicle’s original parts and calibration. Their technicians work meticulously to ensure that all repairs meet or exceed manufacturer standards, so you can drive with full confidence in your dashboard’s accuracy and performance.

A Trusted Name in Automotive Electronics

Cartronix is known throughout the industry for its expertise in automotive electronics, and digital dashboard repair is one of the company’s core services. With years of experience and a commitment to quality, Cartronix serves customers across the UK who rely on their fast turnaround times, transparent pricing, and exceptional customer care.

From private vehicle owners to garages and dealerships, clients trust Cartronix for professional repairs that last. Every dashboard repair is backed by rigorous testing and quality assurance to ensure optimal function before returning it to the vehicle.

Restore Your Dashboard, Restore Your Confidence

When your dashboard fails, you don’t have to settle for high-cost replacements or live with uncertainty behind the wheel. With Cartronix, you can restore your dashboard to full functionality with expert care and efficient service. If you’re experiencing issues with display lights, faulty readings, or unresponsive screens, don’t wait for the problem to worsen. Trust Cartronix for professional digital dashboard repair that gets you back on the road safely and confidently.

#lcd pixel repair for cars#Display Fixing Specialists#digital dashboard and LCD pixel repair#digital dashboard repair#Instrument Cluster Repair Specialists#Car Instrument Cluster Repair Specialists#lcd Pixel Repair uk#instrument cluster removal and refitting service#cluster repair service#car cluster repair

0 notes

Text

Why do some car manufacturers make it extremely difficult to change a headlight bulb, sometimes requiring a trip to the dealership?

Why Some Car Manufacturers Make Headlight Bulb Replacement Difficult Replacing headlight bulbs in modern vehicles can feel like navigating an engineering maze, often requiring specialized tools or dealership intervention. This complexity stems from design priorities, regulatory compliance, and advanced technology integration. Below are the key reasons and their implications:

Advanced Lighting Systems

Modern vehicles increasingly use adaptive headlights (e.g., auto-leveling, cornering beams) and integrated LED arrays or laser modules instead of traditional bulbs. These systems are tightly controlled by onboard computers and sensors. For example: Adaptive Headlights: Adjust brightness and direction based on steering input or road conditions. Even minor misalignment can disrupt the entire system, requiring recalibration with proprietary software.

Integrated LED/Laser Modules: Often soldered into sealed assemblies rather than using replaceable bulbs. Replacing them may necessitate swapping the entire headlight unit.

Engineering and Aesthetic Trade-offs

Manufacturers prioritize sleek, aerodynamic designs and compact packaging, which often result in tightly packed engine bays and headlight housings: Space Constraints: Headlights may be fused with grilles, fenders, or bumper components. Accessing the bulb might require removing the wheel well liner, battery, or air filter housing.

Proprietary Fasteners: Custom clips or screws demand specialized tools, discouraging DIY repairs.

Regulatory Compliance and Safety Standards

Strict homologation rules (e.g., SAE, ECE) mandate precise beam patterns, brightness, and alignment. To ensure compliance: Tamper-Proof Designs: Manufacturers discourage aftermarket modifications by sealing systems or using non-standard components. Non-OEM parts risk failing inspections or causing glare hazards.

Self-Leveling Requirements: Adaptive headlights must maintain proper alignment with the road, which can only be reset via dealership diagnostics.

Profit and Service Model

Dealerships and certified repair shops benefit from locked-in servicing: Software Dependencies: Adaptive systems require proprietary diagnostic tools (e.g., OEM scanners) to reset error codes or recalibrate sensors.

Warranty Control: Manufacturers may void warranties if non-certified technicians attempt repairs, steering owners to dealerships.

Safety and Durability Considerations

Sealed Assemblies: Protect sensitive electronics from moisture and dust, ensuring longevity and UV resistance.

Electrical Complexity: Modern bulbs (e.g., HID, LED) require precise voltage regulation. Incorrect handling can damage the vehicle’s electrical system or reduce bulb lifespan.

Key Takeaways Factor Impact on DIY Replacement Advanced Tech Requires calibration tools and software Regulatory Compliance Tamper-resistant designs Aesthetic Design Tight packaging limits access Service Incentives Encourages dealership dependency

Advice for Owners: Consult Manuals: Some models allow bulb access via hidden panels.

Invest in Professional Help: For adaptive or laser systems, dealerships ensure compliance and safety.

Avoid Aftermarket Modifications: Non-homologated parts risk fines or accidents.

While frustrating, these design choices reflect a balance between innovation, safety, and market dynamics. For complex systems, dealerships remain the safest (if pricier) option.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#headlight bulbs#headlight bulb#car culture#cars#classic cars#race cars#cartoon#car#suv#porsche#truck#carlos sainz#supercar#automobile#car light#headlight restoration#headlamps#headlamp#headlight#aftermarket new lamp

2 notes

·

View notes

Text

Exploring the Legacy of the Electronic Industries Alliance (EIA)

In the modern industrial age, compatibility is not a choice — it’s a necessity. Whether you’re replacing a marine vessel’s navigation system or keeping an industrial control panel up and running, having components that comply with tested, widely supported standards makes for smooth sailing.

Part of the most significant drivers of such standards has been the Electronic Industries Alliance (EIA).

Even though the EIA officially shut down in 2011, its work continues to be realized through standards that are still being used up to this day. Here at Aeliya Marine, we proudly provide a wide selection of parts that meet or refer to these long-standing standards so our customers always have access to tried and tested, compatible, and dependable parts.

In this blog, we’ll explain why EIA standards matter, the benefits of choosing EIA-compliant parts, and why sourcing them from Aeliya Marine is the smart choice for engineers, procurement teams, and maintenance professionals worldwide.

The Enduring Value of EIA Standards

Established in 1924, the EIA grew with the electronics market for almost nine decades. Its standards — on connectors, communication protocols, resistors, cables, and more — set the foundation of modern electronics.

Now, although the organization no longer exists, its standards remain well entrenched in:

Industrial automation systems

Marine electronics

Oil & gas instrumentation

Power & energy equipment

Factory automation

Telecommunications infrastructure

If your application has long equipment lifecycles or needs to stay cross-vendor compatible, chances are EIA-compliant parts are essential to your success.

Why EIA Standards Are Important to Today’s Buyers

Following are the reasons why engineers and procurement professionals continue to look for EIA-compliant parts:

Proven Compatibility

EIA standards guarantee that components from various manufacturers will be compatible with one another — even across various generations of equipment.

Long-Term Availability

Most EIA standards remain used in existing designs, so replacements and compatible parts are readily available for older systems.

International Acceptance

EIA standards are accepted worldwide, simplifying procurement for worldwide projects and guaranteeing compliance with regulatory specifications.

Easy Integration

By selecting parts that comply with standardized EIA standards, you minimize integration issues particularly critical in multi-vendor settings.

Advantages of Selecting EIA-Compliant Products

Let’s examine the business benefits more closely:

Greater system reliability

EIA standards were created to provide strong performance — essential in marine, industrial, and offshore environments where failure can’t be tolerated.

Reduced maintenance expenditures

Standardized components ensure quicker, easier, and less expensive maintenance and repair.

Less downtime

Compliant, standards-based components minimize the likelihood of system mismatching and integration issues.

Future-proofing

Even with advancing technology, EIA-compliant interfaces (e.g., RS‑232 or RS‑485) continue to be popular and supported.

Cross-vendor flexibility

Selection of EIA-compliant parts permits you to procure from several reliable vendors, minimizing supply chain risk.

Why Select Aeliya Marine for EIA-Standard Parts?

At Aeliya Marine, we know that when you procure industrial and marine parts, you’re not merely purchasing components — you’re investing in the reliability of your systems over the long term.

Here’s why thousands of customers worldwide make us their number-one source for EIA-compliant and EIA-referenced components:

Massive Inventory

Our Electronic Industries Alliance vendor page contains a broad range of:

Connectors & terminals

Communication modules (RS‑232, RS‑485)

Industrial automation components

Marine-grade electronics

Monitoring & control devices

We stock components from hundreds of reliable manufacturers that produce to EIA specs making it easy to locate everything you need in one place.

Rapid & Dependable Shipping

We know the urgency of industrial and maritime procurement. That’s why we provide rapid, dependable international shipping, so your components show up when you need them not in weeks.

Quality Control

Our staff thoroughly inspects and tests our components. Whether purchasing new or surplus components, you can expect consistent quality and confirmed compliance with industry standards.

Expert Assistance

Not certain which section is suitable for your system’s needs? Our knowledgeable staff is available to assist you select the best component saving you time and preventing expensive errors.

Competitive Pricing

We provide great value assisting you in managing costs while keeping the high standards of quality and reliability.

Trusted Global Supplier

With happy customers in Europe, Asia, the Middle East, and the Americas, Aeliya Marine is a reputable brand in the international industrial and marine parts supply chain.

Why Purchasing from a Reliable EIA Supplier is Important

Where you purchase EIA-compliant components really does make a difference.

Purchasing from unknown sources brings risk:

Components can be counterfeit or inferior

Compatibility problems lead to expensive integration failure

Warranty and support are not available

At Aeliya Marine, we deal with only reputable suppliers and have complete traceability of our stock so you can rest easy.

Keep Your Systems Humming with EIA-Standards and Aeliya Marine

The Electronic Industries Alliance might not be around as an organization anymore but its legacy lives on in the standards that make today’s industrial and marine systems function.

At Aeliya Marine, we are honored to continue this tradition. Our thoughtfully edited lists of EIA-compliant and EIA-referenced components provide engineers, buyers, and maintenance personnel a reliable source for maintaining mission-critical systems at peak performance.

By using Aeliya Marine, you benefit from:

Huge inventory of standards parts

Expert assistance and rapid support

Global shipping that you can count on

Quality that you can believe in

Great value for your money

Whether it’s keeping an offshore platform running, upgrading a factory, or servicing marine electronics, Aeliya Marine is your performance partner.

Visit our Electronic Industries Alliance vendor page today and learn how EIA standards and Aeliya Marine can fuel your success.

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter

0 notes

Text

How to Fix Chassis Control System Error in Your Infiniti Q50: Ultimate Troubleshooting Guide