#Engines and Components Products

Explore tagged Tumblr posts

Text

#starlight express#stex#electra the electric engine#electras components#from the '85 london production

105 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

I SHOULD apply to jobs today but I just really don't feel like it. I found one to apply to, but now that I've thought about not moving it's harder to apply places that would require relocation.

Because that one job I was super qualified for apparently was filled before I applied, there is literally nothing in my city that makes me feel any positive emotion. They would all just be to get me out of my current job, which would be good, but I don't want a serious engineering job . I either want to do the academia or continue to design products. I don't want to like design cranes.

#totes bro#i really never wanted to design cranes but i would have done that right out of school#i make commodities now and tbqh would like to continue to make either consumer products or like components#like borderline industrial design if not industrial design#¯\_(ツ)_/¯ and there are some industries that my engineering skills really dont translate to right now#god i also dont want to drive 1 hr to work but i was qualified for that#idk im wondering if it makes sense to just keep my eyes peeled for something in my city that i would enjoy#i will keep applying to academic institutions#idk how picky i can be! eventually i have to just apply to everything#but i dont want to work everywhere:(#wish my city were bigger in times like this

4 notes

·

View notes

Text

Race-Proven Driveline Components for Drag Racing by Strange Engineering

Strange Engineering delivers precision-engineered driveline components designed to handle the intense demands of drag racing and high-powered street applications. Whether it’s U-joints, transmission yokes, driveshafts, or pinion couplers, every part is built for unmatched strength, long-term durability, and proven track performance.

Our Key Driveline Components:

Chrome-Moly Driveshafts

Aluminum Driveshafts

Transmission Yokes

Rear End Yokes

Pinion Couplers

U-Joints

Contact Information:

For more details or to request a sample, visit Strange Engineering’s driveline components or contact Strange Engineering directly:

Phone: 800-646-6718

Visit: https://www.strangeengineering.net/

Address: 8300 N. Austin Ave, Morton Grove, IL

Stay in touch with the latest product developments and company news:

Facebook

Youtube

X

Instagram

#Driveline Components#Racing Driveline Parts#Drag Racing Driveline#Performance Driveshafts#U-Joints and Yokes#Strange Driveline#Drivetrain Parts#High-Performance Driveline#Street & Strip Driveline#Strange Engineering Driveline#Strange Engineering driveline components#high-performance racing driveline parts#custom driveshafts for drag racing#heavy-duty U-joints and yokes#performance drivetrain solutions#driveshaft yokes for race cars#complete drag racing driveline kits#street and strip driveline upgrades#performance rear driveline systems#Strange Engineering drivetrain products

1 note

·

View note

Text

Boost Your Racing Edge with Oval Track Racing Wrap Axles

In the high-stakes world of oval track racing, every component of your vehicle must perform flawlessly under pressure. One essential part that often determines success is the axle. Strange Oval, a leader in performance racing parts, offers specialized Oval Track Racing Wrap Axles that are engineered for strength, flexibility, and reliability.

Unlike standard axles, wrap axles are designed to handle the extreme lateral loads and high torque levels experienced on oval tracks. These axles are built to flex under load—absorbing energy and reducing stress on other drivetrain components. This unique feature enhances traction, improves stability, and delivers a smoother ride through every turn. Whether you race on dirt or asphalt, Oval Track Racing Wrap Axles provide the edge you need to outperform the competition.

Strange Oval uses only high-quality materials and precision engineering to craft these axles, ensuring they meet the demands of serious racers. The ability to customize axle wrap gives drivers control over how their car responds to different track conditions—making setup and tuning more effective.

If you're looking to gain a competitive advantage, upgrading to wrap axles is a smart move. You can easily browse and purchase these high-performance components online through the Strange Oval website. The online store features detailed product descriptions, specs, and support to help you make the right choice for your race car.

Don't let subpar equipment hold you back. Invest in Strange Oval’s Oval Track Racing Wrap Axles today and experience the difference on race day. Visit Strange Oval to shop online and stay ahead of the pack.

Contact Information:

For more details or to request a sample, visit Oval Track Racing Wrap Axles or contact Strange Oval directly:

Phone: 800-653-1099

Choose the Oval Track Racing Wrap Axles for a reliable, efficient, and high-quality products.

Stay in touch with the latest product developments and company news:

Facebook

Youtube

X

#Strange Oval Wrap Axles#KERA Axles#Oval Track Racing Axles#Split Diameter Axles#Equal Diameter Axles#Late Model Racing Axles#Modified Racing Axles#Stock Car Axles#Torsional Twist Axles#High-Performance Racing Axles#Durable Racing Components#Precision Machined Axles#Lightweight Racing Axles#Enhanced Traction Axles#Asphalt Racing Axles#Dirt Track Racing Axles#Racing Axle Technology#Strange Engineering Axles#NASCAR Approved Axles#Performance Racing Parts#Oval Racing Product

1 note

·

View note

Text

FORGING STRENGTH FOR MODERN RAILWAYS LOCOMOTIVES

#sheet metal fabrication solutions#heavy fabrication#custom fabrication#industrial fabrication#robotic welding#metal fabrication solutions#customised metal fabrication#metal stamping#Grip Strut Anti-Skid Walkway#locomotive engine components#rail component production

0 notes

Text

What Is Reverse Engineering and When Should You Use It?

In today’s competitive and innovation-driven manufacturing landscape, companies are continually searching for methods to optimize designs, streamline production, and gain deeper insight into existing products. One of the most powerful yet often misunderstood tools that supports these objectives is reverse engineering.

Reverse engineering enables organizations to deconstruct a product or system to understand its components, functions, and design principles. This process is not only used to replicate products but also to analyze their structure, improve upon them, or integrate them into new applications.

This article offers a comprehensive explanation of reverse engineering—what it is, how it works, the technologies involved, its applications across industries, and the scenarios where it proves most valuable.

Defining Reverse Engineering

At its core, reverse engineering is the process of disassembling or analyzing an object to understand how it was designed and manufactured. It involves extracting design information from existing products, often in the absence of technical documentation or original design files.

Unlike traditional engineering, which moves from concept to product, reverse engineering starts with the finished item and works backwards to deduce the original specifications. The insights gained are often used to:

Create 3D models and CAD files

Improve product design

Develop compatible components

Diagnose failures or weaknesses

Reproduce obsolete or legacy parts

Reverse engineering does not necessarily imply copying or duplication. Rather, it is a legitimate and valuable practice in modern product development, maintenance, and innovation.

How Reverse Engineering Works

The reverse engineering process varies depending on the object, industry, and intended outcome, but it generally follows a consistent sequence:

1. Data Acquisition

The first step involves capturing detailed information about the object’s geometry, dimensions, and features. This is typically done using advanced 3D scanning technologies such as:

Laser Scanners: Emit laser beams to detect surface contours.

Structured Light Scanners: Project light patterns and measure distortions to determine surface geometry.

Computed Tomography (CT) Scanners: Capture both internal and external features using X-ray technology.

Coordinate Measuring Machines (CMMs): Use touch probes to precisely measure specific points.

These tools collect millions of data points, forming a comprehensive digital representation of the object known as a point cloud.

2. Data Processing and Mesh Generation

The raw point cloud data is cleaned, aligned, and processed to remove noise and inconsistencies. The next step is to convert the point cloud into a polygonal mesh—a 3D surface composed of interconnected triangles.

This mesh is then optimized to ensure it accurately reflects the physical object’s shape while maintaining a manageable file size for further use.

3. 3D Modeling and CAD Conversion

Once a high-quality mesh is obtained, it is used to reconstruct the object in a computer-aided design (CAD) environment. Engineers develop a fully parametric or feature-based CAD model that replicates the part’s geometry.

At this stage, material specifications, tolerances, and functional features may also be analyzed and documented. The final CAD model can be edited, shared, or integrated into larger assemblies.

4. Analysis and Application

The finished model is then used for various purposes, including design improvements, simulation, tooling development, or manufacturing reproduction. Engineers may also perform stress tests, fit checks, and other simulations using the digital model.

Key Technologies in Reverse Engineering

Advances in digital manufacturing and metrology have significantly expanded the capabilities of reverse engineering. The following technologies are essential:

3D Scanning

High-resolution 3D scanning tools rapidly capture the surface geometry of physical objects, forming the foundation for all subsequent steps. These scanners vary in accuracy, speed, and suitability depending on the object's size, complexity, and material.

CAD Software

CAD platforms such as SolidWorks, Autodesk Inventor, Siemens NX, and others play a crucial role in interpreting scanned data and creating usable design files. These models are often parametric, allowing engineers to modify features and dimensions easily.

Simulation Tools

Finite Element Analysis (FEA) and other simulation tools are used in conjunction with CAD models to evaluate a product’s performance under various conditions. These insights support design optimization and failure analysis.

3D Printing and Prototyping

Rapid prototyping allows teams to test modifications derived from reverse engineering efforts. By printing physical models, engineers can assess fit, function, and ergonomics quickly and affordably.

When Should You Use Reverse Engineering?

Reverse engineering is applicable in a wide range of situations across multiple industries. It is especially useful when dealing with legacy components, product innovation, or systems integration. Below are the most common scenarios that justify the use of reverse engineering.

1. Recreating Obsolete or Legacy Parts

One of the primary uses of reverse engineering is to reproduce discontinued components for machines, vehicles, or systems that are no longer supported by the original manufacturer. With no access to original drawings or tooling, reverse engineering provides a reliable way to maintain critical assets and extend their lifecycle.

This is particularly valuable in aerospace, defense, rail, and heavy industries, where replacing entire systems is impractical or cost-prohibitive.

2. Product Improvement and Optimization

Reverse engineering enables manufacturers to analyze existing products and identify opportunities for improvement. Engineers can assess design weaknesses, material inefficiencies, or manufacturing complexities and apply innovative solutions to enhance performance, durability, or cost-effectiveness.

The process often leads to

Lighter and stronger designs

Reduced manufacturing steps

Better ergonomics or aesthetics

Improved energy efficiency

3. Competitive Analysis

Organisations often use reverse engineering to examine competitor products and gain insights into their features, performance, and manufacturing techniques. This helps in benchmarking, identifying intellectual property challenges, and driving innovation.

While care must be taken to respect legal and ethical boundaries, competitive reverse engineering is a legitimate practice used for market intelligence and strategic planning.

4. Integrating New Components with Existing Systems

In cases where new parts or systems need to work seamlessly with older components, reverse engineering ensures dimensional compatibility and functionality. By modeling the existing hardware accurately, engineers can design new components that align perfectly without trial and error.

This use is common in:

Automotive retrofits

Industrial equipment upgrades

Electronic system integration

5. Quality Control and Inspection

Reverse engineering is sometimes used as a validation tool in quality assurance. By scanning and modeling a manufactured part, teams can compare it to the original design and detect any deviations or defects.

This process enhances dimensional verification, especially for complex geometries that are difficult to measure with traditional tools.

6. Digital Archiving

Preserving the design data of critical components through reverse engineering creates a digital archive for future reference. This is important in museums, aerospace restoration, and asset management, ensuring that data is never lost even if physical components degrade or disappear.

Industries Benefiting from Reverse Engineering

The versatility of reverse engineering means it is widely applicable across a variety of sectors:

Aerospace

Airplane components, many of which have long service lifecycles, often require replacement or refurbishment after the original manufacturing data is lost. Reverse engineering ensures structural integrity and regulatory compliance.

Automotive

Classic cars, custom vehicles, and prototype parts benefit greatly from reverse engineering. It enables part reproduction, modification, and even digital recreation of entire vehicle systems.

Medical Devices

Medical implants, prosthetics, and surgical instruments are reverse-engineered to improve functionality, ensure anatomical fit, or replicate discontinued designs.

Consumer Electronics

Electronics companies often disassemble products to understand PCB layouts, circuitry, and design logic. This enables repair, customization, or the development of compatible accessories.

Industrial Manufacturing

Reverse engineering supports tooling design, process improvement, and machine maintenance. It is also used to digitize old parts or machinery for integration into modern workflows.

The Role of Reverse Engineering in Innovation

Beyond its practical applications, reverse engineering fosters innovation by bridging the gap between legacy knowledge and modern capabilities. It encourages experimentation, cross-functional learning, and iterative improvement.

By understanding the details of how a product works, engineers can:

Identify underutilized features

Explore alternative materials

Develop more efficient manufacturing methods

Combine legacy and modern technologies

This approach is particularly important for companies striving to remain competitive in rapidly evolving markets. It allows them to leapfrog development stages, reduce R&D costs, and bring products to market faster.

Ethical and Legal Considerations

While reverse engineering is a powerful tool, it must be practiced within ethical and legal boundaries. It is important to respect patents, copyrights, trade secrets, and intellectual property (IP) rights.

Organizations using reverse engineering must ensure their efforts do not infringe on protected designs. In many jurisdictions, reverse engineering for interoperability or repair purposes is legal, but copying patented elements without permission is not.

Working with professional providers of reverse engineering services in Australia ensures that all procedures are carried out in compliance with local laws and international IP standards.

Choosing the Right Reverse Engineering Partner

The effectiveness of reverse engineering relies heavily on the skill, experience, and tools used. Partnering with specialists who understand materials science, digital modeling, and manufacturing processes ensures accurate, high-quality results.

Providers offering reverse engineering services in Australia are equipped with advanced scanning systems, robust CAD platforms, and cross-industry expertise. They help clients navigate complex engineering challenges, from legacy part digitization to modern product development, while maintaining confidentiality and regulatory compliance.

Conclusion

Reverse engineering is a powerful, multi-purpose process that enables organizations to derive valuable design and manufacturing data from existing physical products. Whether used for reproduction, enhancement, integration, or analysis, it offers significant advantages across the product lifecycle.

By turning physical objects into digital intelligence, reverse engineering allows industries to move forward while learning from the past. It supports innovation, sustainability, and precision in a world where adaptability and speed are crucial to success.

As industries increasingly adopt digital technologies and advanced manufacturing techniques, reverse engineering will play an even more integral role—especially when executed by trusted professionals who offer comprehensive reverse engineering services in Australia and beyond.

#reverse engineering#product development#3D scanning#CAD modeling#engineering services#component analysis#design replication

1 note

·

View note

Text

Get the Best in Agriculture: Reliable Rotavator Components from Ludhiana

Agriculture is the backbone of our economy, and ensuring its success starts with reliable equipment. When it comes to sourcing durable, efficient, and high-quality rotavator components, SBJ Nirmal Products in Ludhiana stands out as a trusted name in the industry. In this blog, we’ll delve into what makes SBJ Nirmal Products the go-to choice for farmers worldwide.

Introduction to SBJ Nirmal Products and Its Mission

At SBJ Nirmal Products, our mission is simple yet impactful: to empower farmers with top-notch agricultural components that enhance productivity and minimize equipment downtime. With decades of expertise in manufacturing rotavator parts, we’re committed to quality, innovation, and customer satisfaction.

Why Choose Ludhiana for Agricultural Components?

Ludhiana, often referred to as the "Manchester of India," is a hub for industrial excellence. Its well-established infrastructure, skilled workforce, and commitment to quality make it the perfect base for manufacturing agricultural components.

A Hub of Quality Manufacturing: Ludhiana's factories are renowned for precision engineering and consistent quality.

Global Reach from a Local Base: From Ludhiana, SBJ Nirmal Products serves customers not only in India but also in Bangladesh, Nepal, Sri Lanka, and beyond.

The Importance of Reliable Rotavator Components

Reliable components are crucial for maximizing efficiency in agriculture. Here’s why:

Enhancing Agricultural Productivity: Quality rotavator parts ensure smooth soil preparation, leading to better crop yields.

Reducing Equipment Downtime: Durable components reduce the frequency of repairs, saving time and money.

SBJ Nirmal Products: A Legacy of Excellence

With over 4,500 rotavator parts in our portfolio, SBJ Nirmal Products has built a legacy of trust and excellence.

Trusted by Farmers Worldwide: Our components are designed to meet the diverse needs of farmers across the globe.

Key Features of Our Rotavator Components

At SBJ Nirmal Products, every component is crafted with precision and attention to detail. Here are some standout features of our rotavator parts:

Durability and Longevity: Built to withstand tough agricultural conditions, our components last longer, offering unmatched value.

Precision Engineering: Our parts are manufactured to exact specifications, ensuring perfect compatibility with a wide range of rotavator models.

Cost-Effectiveness: We provide high-quality products at competitive prices, making advanced agricultural technology accessible to all.

A Deep Dive into Popular Rotavator Components

Our extensive range of rotavator parts includes some of the most sought-after components in the market:

Crown Pinions: Designed for optimal torque and smooth operation, these are essential for high-performance rotavators.

Stub Axles: Known for their robustness, our stub axles ensure stability and reliability during field operations.

Rotavator Blades: Crafted from high-grade materials, these blades deliver efficient soil cutting and mixing, enhancing field preparation.

SBJ Nirmal’s Commitment to Quality and Innovation

Quality and innovation are the cornerstones of our manufacturing process. Here’s how we ensure excellence:

ISO-Certified Manufacturing Processes: Our production facilities adhere to the highest international standards.

Use of Advanced Technologies: From CAD design to CNC machining, we leverage cutting-edge technology to deliver superior products.

Sustainable Practices in Component Manufacturing

We are dedicated to sustainable manufacturing practices that benefit both the environment and the community:

Eco-Friendly Materials: Our components are made using materials that are sustainable and recyclable.

Minimizing Waste and Maximizing Efficiency: Advanced manufacturing techniques help us reduce waste and optimize resource use.

Testimonials: Farmers Speak About SBJ Nirmal Products

Our commitment to quality and service has earned us glowing reviews from farmers worldwide:

Real-Life Stories of Success: Many farmers have shared how our rotavator parts have transformed their operations.

Positive Feedback from Around the Globe: From India to Nepal, our customers praise the durability and efficiency of our products.

How to Purchase from SBJ Nirmal Products

We make it easy for farmers and dealers to access our products:

Online Ordering Options: Our website offers a seamless ordering experience, complete with detailed product descriptions and specifications.

Dealer Networks in India and Beyond: Our extensive network ensures prompt delivery and reliable after-sales support.

Conclusion: Elevate Your Farming Efficiency with SBJ Nirmal Products

When it comes to reliable, high-quality rotavator components, SBJ Nirmal Products in Ludhiana is a name you can trust. With a legacy of excellence, a commitment to innovation, and a focus on sustainability, we are dedicated to empowering farmers worldwide. Choose SBJ Nirmal Products and experience the difference in agricultural efficiency and productivity.

#rotavator components#reliable agricultural parts#SBJ Nirmal Products#rotavator parts manufacturer#Ludhiana agricultural parts#high-quality rotavator components#durable rotavator parts#precision engineering in agriculture#cost-effective rotavator parts#crown pinions#stub axles#rotavator blades#sustainable manufacturing#ISO-certified rotavator parts#global rotavator parts supplier#rotavator parts in India#buy rotavator components online#agricultural productivity#farming efficiency#trusted rotavator parts

0 notes

Text

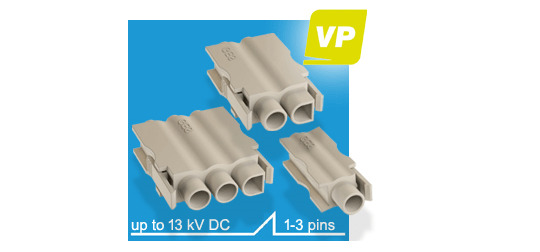

High Voltage Connectors | HV Passive Components | High Voltage Products, GmbH

Check out HV Products' wide range of HV connectors, available in various configurations and designs. Our products are trusted by customers worldwide for their reliability and precision engineering, making them ideal for sensitive industrial and scientific applications.

Contact Us Today!

#High Voltage Connectors#High Voltage Products#HV connectors#HV Passive Components#precision engineering#scientific applications

0 notes

Text

Shalin Design Provides CAD Design and Drafting Services for Mechanical Industries

Shalin Designs has established itself as a trusted provider of CAD design and drafting services for the mechanical industry. Specializing in both 2D and 3D CAD services for mechanical engineering, the firm supports manufacturers and mechanical engineers in streamlining design processes and enhancing product development.

Meeting Industry-Specific CAD Design Needs

Mechanical industries often rely on precise, well-structured designs, whether it's for mechanical product CAD design services or mechanical CAD drafting services for components and machinery. Shalin Designs understands these unique demands and delivers solutions tailored to meet exact specifications.

Our expertise extends across a wide spectrum of services:

Mechanical CAD Modeling Services: Create highly accurate models for parts, assemblies, and systems.

CAD Drafting for Mechanical Components: Convert ideas into detailed drawings that streamline the manufacturing process.

Mechanical Product CAD Drafting Services: Develop technical drawings and schematics for production.

Custom CAD Design for Mechanical Engineers: Support engineers with specialized, custom designs that meet industry standards.

Our clients frequently seek 3D CAD modeling for mechanical parts, particularly in industries where complex geometries and precision are paramount.

Why Shalin Designs Excels in CAD Drafting and Design

Unlike other providers, Shalin Designs places a focus on efficient project turnaround without compromising accuracy. Our use of cutting-edge CAD software and our team of experienced drafters and engineers ensures you receive detailed designs, ready for manufacturing. With CAD drafting for industrial machinery and mechanical products, we offer innovative solutions for both simple and complex projects.

Moreover, outsourcing CAD design services to us can help mechanical industries overcome resource challenges. Our clients from the USA, UK, Canada, and Australia frequently benefit from outsourcing as it cuts down costs and speeds up time-to-market.

The Benefits of CAD Design for the Mechanical Industry

Mechanical engineers rely on CAD design not only for accuracy but for visualization. Tools like 2D and 3D CAD services empower engineers to model their parts and components from every angle before committing to physical prototypes. This minimizes error and leads to more efficient production.

Furthermore, with mechanical CAD design solutions offered by Shalin Designs, firms can easily adapt designs for manufacturing processes. For instance, our mechanical part CAD design and drafting enables manufacturers to execute the production of components with confidence that the designs are correct.

How Our Services Support Manufacturers

One of the most critical aspects of mechanical design is ensuring compatibility between all parts. Shalin Designs offers CAD drafting for mechanical components that are easy to modify or scale for various production runs. This makes us an invaluable partner for companies dealing with production at different volumes.

When creating mechanical CAD drawings for manufacturing, precision is everything. Our designs offer clarity and precision, whether for large-scale industrial machinery or smaller mechanical parts. Clients often outsource CAD drafting to ensure they receive high-quality, production-ready designs at competitive rates.

Learn more about the How Mechanical CAD Drafting Services Enhance Manufacturing

Outsourcing CAD Design for Mechanical Engineering: A Strategic Choice

Outsourcing your mechanical CAD design needs can provide numerous advantages. Shalin Designs has worked with multiple industries and clients around the globe, offering mechanical CAD modeling services and CAD drafting for industrial machinery at scale. Our extensive experience allows us to handle projects with varying degrees of complexity, ensuring efficient and cost-effective results.

Companies looking to scale their operations or reduce internal workloads often turn to us for mechanical design and drafting outsourcing. By leveraging our expertise, your team can focus on core activities while we take care of the design process. Top 10 Benefits of Outsourcing Mechanical CAD Design Services.

Tools and Technology at Shalin Designs

We utilize the latest CAD software, ensuring precision and flexibility in all designs. Our mechanical CAD services extend to 2D drawings for documentation and 3D models that help visualize complex assemblies. This dual approach allows our clients to transition seamlessly from design to production.

Client Success Story: Helping a Mechanical Firm Streamline its Design Process

One of our clients, a mid-sized mechanical manufacturing firm, approached us to design CAD models for a new line of machinery. Their in-house team struggled with the complexity of the project and deadlines were approaching fast. Shalin Designs stepped in, providing mechanical product CAD drafting services and 3D CAD modeling for mechanical parts that helped them meet their launch date.

Not only did we deliver detailed designs, but our input allowed them to catch a critical error in one of the assembly layouts, saving them substantial costs during manufacturing. This example illustrates the importance of working with experienced CAD design professionals who understand the intricacies of mechanical components.

Conclusion

Shalin Designs is your trusted partner for mechanical CAD design and drafting services. Whether you're in need of custom CAD design for mechanical engineers, or seeking to outsource your CAD drafting for the mechanical industry, we have the expertise and resources to meet your needs.

Contact us today to learn how our services can help your business achieve more efficient design workflows, reduce production errors, and improve overall project outcomes.

#CAD Design for Mechanical Industry#Mechanical CAD Drafting Services#3D CAD Modeling for Mechanical Parts#Mechanical Engineering CAD Services#CAD Drafting for Mechanical Components#Mechanical Design and Drafting Outsourcing#CAD Design for Manufacturing Industry#Mechanical CAD Design Solutions#2D and 3D CAD Services for Mechanical Engineering#Mechanical Product CAD Design Services#Mechanical CAD Modeling Services#Outsource CAD Drafting for Mechanical Industry#CAD Drafting for Industrial Machinery#Mechanical Part CAD Design and Drafting#Custom CAD Design for Mechanical Engineers#Mechanical Product CAD Drafting Services#Mechanical CAD Drawings for Manufacturing#Shalin Designs

0 notes

Text

Diving System Component Design engineer

Sea Engineering | Design Eng - Expert Diving System Component Design Engineers. We specialize in innovative, reliable, and high-quality components for diving systems. Enhance your underwater projects with our experienced design engineers. Contact us today for bespoke solutions!

For more Details:

Visit our Website:

Phone: 9024691230

Email: [email protected]

Address: 50 Forest Rd Dartmouth, NS B3A 2M5, Nova Scotia, Canada

1 note

·

View note

Text

MBL Audio

#The Art of Sonic Reproduction:#MBL Audio has long been revered for its unique approach to audio reproduction. Inspired by the vision of its founder#Wolfgang Meletzky#MBL Audio combines state-of-the-art technology with a passion for artistic expression. Their audio systems are designed to provide an unpar#Extraordinary Design and Craftsmanship:#One of the standout qualities of MBL Audio is its extraordinary design and craftsmanship. Each MBL Audio system is a work of art#meticulously crafted with attention to detail and precision. The distinctive Radialstrahler omnidirectional loudspeakers#renowned for their unconventional shape#are a hallmark of MBL Audio's commitment to creating an immersive soundstage. From the polished aluminum cabinets to the finest materials u#MBL Audio products exude a sense of luxury and refinement.#MBL Audio pushes the boundaries of audio engineering with its innovative technology. The Radialstrahler drivers#deliver unparalleled dispersion and an enveloping soundstage. MBL's proprietary technologies#further enhance the clarity#precision#and coherency of the audio reproduction. These advancements result in a sound that is remarkably detailed#MBL Audio offers a comprehensive range of audio systems and components#MBL Audio offers a diverse selection of amplifiers#UnitedHomeAudio.com serves as an esteemed platform for MBL Audio#allowing enthusiasts to explore and acquire their exceptional audio systems and components. The partnership between MBL Audio and UnitedHom

1 note

·

View note

Text

Frigidaire 5304524332 Oven Control Electronic | HnKParts

#5304524332#Frigidaire#Oven#ControlElectronic#HnKParts#KitchenAppliance#HomeAppliance#Manufacturer Name:FRIGIDAIRE#Product Number:5304524332#OEM Part Number:5304524332#The Frigidaire 5304524332 Oven Control Electronic#available at HnKParts#is a crucial component for Frigidaire ovens. Engineered for precise temperature control and functionality#this electronic module ensures optimal cooking performance. Trust this genuine Frigidaire part for reliable operation and accurate cooking#700 Nicholas BLVD Suite 105 Elk Grove Village IL 60007#https://www.hnkparts.com/5304524332-frigidaire-control-electronic

1 note

·

View note

Text

Tri Component Products Corporation takes pride in crafting clutch plates that redefine performance standards in automotive engineering. Our clutch plates, meticulously engineered with precision, serve as the backbone of seamless power transfer in vehicles. Here's why Tri Component stands out:

Precision Engineering: Our clutch plates are crafted with precision engineering techniques, ensuring optimal fit, durability, and performance.

Quality Materials: We use high-quality friction materials and metal alloys, guaranteeing reliability and longevity even in the most demanding driving conditions.

Custom Solutions: Tri Component offers custom clutch plate solutions tailored to specific vehicle models and performance requirements, ensuring a perfect match every time.

Environmental Responsibility: We prioritize eco-friendly manufacturing processes and materials, reflecting our commitment to sustainability.

Experience the difference with Tri Component's clutch plates – unlocking unparalleled performance and driving satisfaction on every journey. Trust Tri Component for clutch plates that exceed expectations and elevate automotive excellence!

0 notes

Text

Stub Axle Suitable for Sonalika: A Game-Changer for Heavy-Duty Farming Equipment

In the modern agricultural world, efficiency and durability are critical for farming machinery. Farmers rely heavily on equipment like rotavators to handle demanding tasks, and Sonalika rotavators have become a top choice for their performance in heavy-duty farming. To ensure these rotavators perform at their best, components like the stub axle play a pivotal role. SBJ Nirmal Products, a leading name in agricultural machinery parts, delivers high-quality stub axles suitable for Sonalika, empowering farmers with reliable solutions.

Introduction to Stub Axles

A stub axle is a vital component in farming machinery, responsible for supporting the wheel assembly and enabling smooth rotation. Its role is critical in ensuring mobility and balance, especially in heavy-duty farming equipment. Without a durable and reliable stub axle, machinery performance can be severely impacted, leading to downtime and costly repairs.

Importance of Heavy-Duty Stub Axles in Agriculture

Heavy-duty farming tasks place immense pressure on machinery parts, and stub axles must endure extreme loads and rough terrains.

Durability Matters: In agricultural fields, where machinery often operates on uneven and harsh surfaces, weak components can wear out quickly.

Efficiency and Reliability: A robust stub axle ensures that rotavators can perform tasks efficiently, minimizing downtime and boosting productivity.

For farmers using Sonalika rotavators, choosing a reliable stub axle like the one from SBJ Nirmal Products can make a significant difference.

SBJ Nirmal Products: Delivering High-Quality Stub Axles

When it comes to precision-engineered components, SBJ Nirmal Products stands as a trusted name in Ludhiana and beyond. With years of expertise in manufacturing rotavator parts and rotavator components, SBJ focuses on:

High-quality materials

Precision engineering

Stringent quality control processes

This dedication ensures that every stub axle suitable for Sonalika meets the highest standards of durability and performance.

Features of Stub Axle Suitable for Sonalika

SBJ Nirmal Products designs stub axles that stand out in the market due to their superior features:

High-Grade Material: Manufactured from premium-grade steel, SBJ stub axles offer unmatched strength and resistance to wear and tear.

Corrosion Resistance: SBJ uses advanced coating technologies to protect stub axles from rust, ensuring a longer lifespan.

Perfect Compatibility: SBJ stub axles are engineered specifically for Sonalika rotavators, ensuring a perfect fit and seamless operation.

Load-Bearing Capacity: Designed to handle heavy loads without bending or breaking, even under tough farming conditions.

These features make SBJ’s stub axle a reliable solution for farmers relying on Sonalika rotavators.

Benefits of Using SBJ Stub Axle for Sonalika

Choosing the right components for farming machinery directly impacts productivity and profitability. Here’s how SBJ stub axles benefit farmers:

Enhanced Performance: A reliable stub axle ensures smooth wheel rotation and balance, improving rotavator efficiency.

Increased Operational Efficiency: With reduced breakdowns and minimal downtime, farmers can complete tasks faster.

Cost Savings: SBJ stub axles are built to last, reducing maintenance costs and frequent replacements.

Higher Productivity: A durable component allows Sonalika rotavators to handle heavier loads without compromise.

By using SBJ stub axles, farmers get peace of mind knowing their machinery will perform consistently.

How SBJ Stub Axles Outperform Competitors

What sets SBJ Nirmal Products apart from other manufacturers is their focus on quality and precision. Each stub axle undergoes:

Advanced Manufacturing: SBJ employs cutting-edge technology to ensure each axle meets exact specifications.

Quality Testing: Rigorous testing processes guarantee durability, strength, and performance under real-world conditions.

Feedback Integration: SBJ continuously improves its products based on feedback from farmers and industry experts.

This commitment to excellence ensures that SBJ stub axles outperform cheaper alternatives that often fail under pressure.

SBJ Stub Axle: Tested for Reliability

Reliability is a non-negotiable factor for farming machinery. SBJ stub axles undergo extensive quality checks, including:

Load Testing: To ensure they can bear extreme loads without deformation.

Durability Tests: Simulating real farming conditions to test resistance to wear and tear.

Precision Checks: Guaranteeing compatibility and smooth installation with Sonalika rotavators.

Farmers using SBJ products consistently report fewer breakdowns and longer machinery life.

Real-Life Applications of SBJ Stub Axle in Farming

Farmers across Punjab and neighboring states rely on SBJ stub axles for heavy-duty farming tasks. Some common applications include:

Soil Preparation: Ensuring rotavators perform efficiently during plowing and tilling.

Load Transportation: Helping rotavators carry heavy agricultural produce without mechanical strain.

Rough Terrain Operations: Providing stability and durability on uneven fields.

With SBJ stub axles, farmers can tackle challenging tasks without worrying about equipment failure.

Cost-Effectiveness of SBJ Stub Axle for Sonalika

While high-quality components often come at a premium, SBJ Nirmal Products ensures affordability without compromising quality. SBJ stub axles offer:

Long-Term Value: Reduced need for frequent replacements saves money over time.

Competitive Pricing: Affordable rates make SBJ products accessible to farmers across different economic backgrounds.

Lower Maintenance Costs: Durable materials reduce wear and tear, cutting down on repair expenses.

For farmers looking to maximize their return on investment, SBJ stub axles provide a cost-effective solution.

How to Identify a High-Quality Stub Axle

To ensure you’re investing in a reliable stub axle, look for these key characteristics:

Material Quality: High-grade steel with corrosion resistance.

Load-Bearing Strength: Tested for heavy loads and tough conditions.

Manufacturer’s Reputation: Choose trusted names like SBJ Nirmal Products.

Precision Engineering: Proper dimensions and smooth compatibility with your machinery.

SBJ’s stub axles tick all these boxes, making them a preferred choice for Sonalika rotavators.

Conclusion: The Future of Heavy-Duty Farming with SBJ Stub Axles

In the demanding world of agriculture, farmers need components they can trust. SBJ Nirmal Products has proven to be a game-changer by delivering stub axles suitable for Sonalika rotavators that combine durability, precision, and affordability. By empowering farmers with reliable solutions, SBJ plays a crucial role in enhancing productivity and ensuring the success of heavy-duty farming operations.

For farmers seeking quality that lasts, SBJ Nirmal Products is the ultimate partner in agricultural success.

#Stub axle for Sonalika#Sonalika tractor parts#heavy-duty farming equipment#durable stub axle#SBJ Nirmal Products#reliable tractor parts#precision-engineered stub axle#Sonalika spare parts#farming machinery components#high-quality stub axle#agricultural equipment parts#tractor axle replacement#heavy-duty tractor solutions#stub axle manufacturer#SBJ Nirmal Ludhiana.

0 notes

Text

“Like a master conductor leading an orchestra, Avalon Technologies harmonizes design, engineering, and production to create the symphony of electronics manufacturing.”

#electronic manufacturing services#EMS#electronic assembly#PCB manufacturing#electronics design services#electronic component manufacturing#OEM services#electronics production#custom electronics#PCB assembly#electronic engineering services#EMS provider#electronic product manufacturing#turnkey manufacturing services#electronics supply chain.

0 notes