#FPCB

Explore tagged Tumblr posts

Text

"Flaming Violet" -Pinewood '25

Pinewood '25

This year’s Pinewood derby entry used a little flexible pcb (fpcb) that we yanked from yet another “flame” light bulb. I used the same bulb once prior for the Starship ornament upon discovering that the manufacturer simply rolls up the board into a cone and uses a second tiny step down circuit to convert 120vac to just a 3.9v circuit- perfect for those tiny batteries we just received for the…

0 notes

Text

Кроме того, существует технология термоэлектрического разделения PCB на основе меди (также известная как технология прямого касания). Это означает, что толщина меди в нужном месте увеличивается с помощью отверстия для покрытия сварочным материалом и гальванической меди, а тепло передается непосредственно от светодиода или других компонентов к медной базе, в то время как сеть цепей независима от тепловой сети.

Как производитель MCPCB, Hitech Circuits производит различные ПХБ на основе меди для своих клиентов.

Для мощных светодиодных ламп (1000 Вт +) и источников питания.

В области светодиодов существует 4 типа платы на основе меди.

0 notes

Text

It is called "4 Layer Flexible Printed Circuit Board",if you just engage in or somehow need this product or custom another new one,welcome contact me to know more details

#4 Layer Flexible Printed Circuit Board#4 Layer FPCB#Flexible Printed Circuit Board#4 Layer Printed Circuit Board#4 Layer Flexible Printed Circuit#4 Layer PCB#FPCB#FPC#PCB

0 notes

Photo

cute i like #beautiful colors

Quick FPC, Rigid-flex PCB prototype and PCB Assembly...

Art by Leah Gardner

74K notes

·

View notes

Text

Flexible PCB | Flexible circuits boards | NFC PCB

Flexible Circuits Boards

Part No.: E0215060979P

Layer count: 2 layer flex PCB

Material: Polymide, 0.15mm,0.5 OZ for all layer

Minimum tack: 8 mil

Minimum space(gap): 5 mil

Minimum hole: 0.25mm

Surface finished: immersion gold

Panel size: 298*28mm/1up

Flexible Circuits Boards, raw material 1 mil Polymide, immersion gold, 3M tape.

#flexible circuit board#flex pcb#NFC PCB#FPCB#flexible printed circuit board

热推

0 热度

1 note

·

View note

Text

Flexible Printed Circuit Boards Market Driven by Consumer Electronics Demand

Flexible Printed Circuit Boards (FPCBs) are thin, bendable interconnect solutions that enable complex circuit designs in compact form factors. These boards consist of a flexible polymer substrate, conductive copper traces, and protective coverlays, offering significant advantages such as reduced weight, enhanced heat dissipation, and higher reliability compared to rigid PCBs. FPCBs are increasingly adopted in smartphones, wearable devices, automotive sensors, medical equipment, and aerospace systems, responding to the industry’s push for miniaturization, flexibility, and rugged performance.

The flexibility of these circuits not only simplifies assembly but also opens up new market opportunities in three-dimensional packaging and foldable gadgets. Continuous advancements in material science and manufacturing processes are driving down production costs while improving signal integrity and durability. Market research suggests that rapid innovation in consumer electronics, coupled with the rising demand for lightweight and high-performance components, is fueling Flexible Printed Circuit Boards Market growth. In addition, stringent space and weight constraints in automotive and aerospace applications further underscore the need for flexible interconnect solutions.

The flexible printed circuit boards market is estimated to be valued at USD 27.02 Bn in 2025 and is expected to reach USD 57.53 Bn by 2032. It is projected to grow at a compound annual growth rate (CAGR) of 11.4% from 2025 to 2032. Key Takeaways

Key players operating in the Flexible Printed Circuit Boards Market are:

-Samsung Electro-Mechanics

-NOK Corporation

-Flex Ltd.

-Jabil Inc.

-Fujikura Ltd.

These market leaders leverage strong R&D capabilities and strategic partnerships to maintain competitive market share. Samsung Electro-Mechanics invests heavily in advanced material research to deliver high-density interconnect solutions, while NOK Corporation focuses on automotive-grade FPCBs that meet stringent quality standards. Flex Ltd. utilizes its global footprint and contract manufacturing expertise to serve diverse industry segments, driving overall market revenue. Jabil Inc. offers integrated design-to-production services, enhancing supply chain efficiency and reducing time-to-market. Fujikura Ltd. emphasizes continuous innovation in multilayer flexible circuits, targeting next-generation foldable displays and wearable devices. Collectively, these market companies shape market dynamics through collaborative product launches, mergers, and acquisitions, as outlined in leading market reports.

‣ Get More Insights On: Flexible Printed Circuit Boards Market

‣ Get this Report in Japanese Language: フレキシブルプリント基板市場

‣ Get this Report in Korean Language: 유연인쇄회로기판시장

‣ Read More Related Articles- South Korea Emerging as Printed Electronics Leader

0 notes

Text

The advantages of rigid-flex PCB board

1). It can effectively save the space on the circuit board and eliminate the use of connectors

Because the FPCB and rigid pcb board has been combined, the space that originally needed to use the connector can be saved. For some circuit boards with high-density requirements, less connectors will be better. In this way, it also saves the cost of parts using the connectors. In addition, the space between the two boards can be made tighter by eliminating the need for connectors.

2). The signal transmission distance is shortened and the speed is increased, which can effectively improve the reliability

The traditional signal transmission through the connector is “circuit board→connector→flexible pcb board→connector→circuit board”, while the signal transmission of the rigid-flex PCB board is reduced to “rigid circuit board→flexible pcb board→rigid circuit board”, signal transmission distance between different media is shortened, and the problem of signal transmission attenuation between different media is also reduced. Generally, the circuit on the PCB board is made of copper, while the contact terminal of the connector is gold-plated, and the solder pin is fully tin-plated. Moreover, solder paste is required to be soldered on the circuit board, and the signal transmission between different media will inevitably be attenuated. If you switch to a rigid-flex PCB board, these media will become less, and the signal transmission ability can be relatively improved. For some products that require higher signal accuracy, it helps to improve their reliability.

3). Simplify product assembly and save assembly time

The use of a rigid-flex PCB board can reduce the man-hours for SMT parts, because the number of connectors is reduced. It also reduces the man-hours for assembly of the whole equipment, because it eliminates the assembly action of inserting the FPC board into the connector. It also reduces the cost of parts management and inventory, because the required parts is reduced, so the management cost becomes less.

Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

0 notes

Text

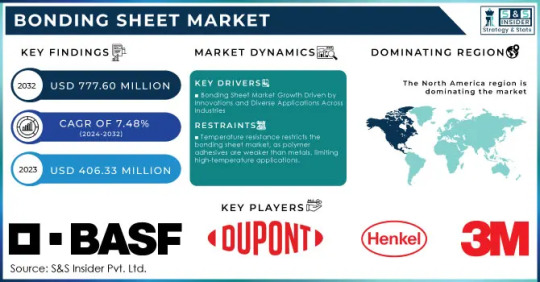

Global Bonding Sheet Market Analysis and Future Prospects

Exploring Growth Trends, Key Players, and Technological Advancements in the Bonding Sheet Industry

The Bonding Sheet Market Size was valued at USD 406.33 Million in 2023 and is expected tot reach at USD 777.60 Million by 2032, and grow at a CAGR of 7.48% over the forecast period 2024-2032.

The global Bonding Sheet Market is driven by rising demand in electronics, automotive, aerospace, and industrial applications. Bonding sheets, widely used for enhancing adhesion between materials, play a crucial role in flexible printed circuit boards (FPCBs), semiconductors, and multilayer constructions. The increasing adoption of miniaturized electronic components and lightweight materials in various industries is expected to further propel market expansion.

Key Players

Leading companies shaping the bonding sheet market include:

3M Company

Henkel AG & Co. KGaA

DuPont de Nemours, Inc.

BASF SE

Fujikura Ltd.

Nitto Denko Corporation

Shin-Etsu Polymer Co. Ltd.

Avery Dennison Corporation

Tesa SE

Sika AG

Future Scope

With ongoing advancements in material science and the rapid growth of 5G technology, the bonding sheet market is set to witness increased demand in high-frequency applications. The automotive sector's shift towards electric vehicles (EVs) and the aerospace industry's need for lightweight, high-strength materials also present promising growth opportunities. Additionally, innovations in eco-friendly and biodegradable bonding sheets will cater to sustainability concerns.

Emerging Trends in the Bonding Sheet Market

The industry is experiencing notable trends such as:

Integration of advanced adhesives: Enhanced thermal and electrical conductivity to meet high-performance requirements.

Miniaturization of electronic devices: Increasing use of bonding sheets in flexible and rigid-flex PCBs.

Growing demand in automotive electronics: Adoption in EV battery systems and smart vehicle components.

Eco-friendly materials: Development of sustainable bonding solutions to reduce environmental impact.

Advancements in 5G and semiconductor technologies: Rising applications in next-gen communication devices and high-speed computing.

Key Points

The bonding sheet market is expected to grow at a CAGR of X% from 2024 to 2030.

Demand is rising in automotive, aerospace, and consumer electronics industries.

Asia-Pacific dominates the market, with North America and Europe also seeing significant adoption.

Sustainable and high-performance bonding solutions are becoming a key industry focus.

Ongoing R&D efforts are leading to enhanced thermal resistance and improved durability.

Conclusion

As industries continue to innovate and prioritize efficiency, the Bonding Sheet Market remains integral to modern technology and manufacturing. With increasing applications in electronics, automotive, and aerospace, coupled with sustainability-driven advancements, the market is poised for sustained growth in the coming years. Industry players focusing on R&D, eco-friendly solutions, and high-performance materials will gain a competitive edge in this evolving landscape.

Read Full Report: https://www.snsinsider.com/reports/bonding-sheet-market-2554

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Bonding Sheet Market#Bonding Sheet Market Size#Bonding Sheet Market Share#Bonding Sheet Market Report#Bonding Sheet Market Forecast

0 notes

Text

#Flexible Printed Circuit Board#Flexible Printed Circuit#Flexible Printed Circuit India#Flexible Printed Circuit Manufacture#electronics manufacturing companies#electronic manufacturers company#Electronics Manufacturing India#Electronics Manufacturing Services#Electronics Manufacturing Service India

0 notes

Text

Polyimide Varnish Market Investment Trends and Market Expansion to 2033

Introduction

Polyimide varnish is a high-performance polymer coating extensively used in various industries, including electronics, aerospace, automotive, and medical sectors. The demand for polyimide varnish has witnessed significant growth in recent years, driven by its exceptional thermal stability, chemical resistance, and electrical insulation properties. As industries continue to innovate and develop more advanced applications, the polyimide varnish market is poised for sustained growth. This article delves into the key market trends, growth factors, challenges, and future opportunities in the polyimide varnish industry.

Market Overview

Polyimide varnish is primarily utilized as a protective coating, offering resistance to extreme temperatures, mechanical stress, and harsh environmental conditions. It is commonly applied in flexible printed circuit boards (FPCBs), wire enamels, insulating coatings, and electronic components. The growing demand for miniaturized and highly durable electronic components has further propelled the market's expansion.

Download a Free Sample Report:-https://tinyurl.com/bddcwh6j

Key Market Segments

The polyimide varnish market can be segmented based on various factors such as type, application, and region.

By Type:

Solvent-based Polyimide Varnish

Water-based Polyimide Varnish

By Application:

Electronics (Flexible Printed Circuits, Insulating Coatings, Semiconductors)

Aerospace & Defense (Wire Coatings, Protective Layers)

Automotive (Sensor Protection, Heat-resistant Coatings)

Medical (Bio-compatible Coatings)

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Market Drivers

Several factors are driving the demand for polyimide varnish across different industries:

1. Rising Demand in Electronics Industry

The electronics sector is the largest consumer of polyimide varnish, particularly for its use in flexible printed circuits and insulating coatings. With the increasing adoption of consumer electronics, wearable devices, and miniaturized components, the need for durable and heat-resistant coatings has surged.

2. Growth in Aerospace and Automotive Sectors

In aerospace and automotive applications, polyimide varnish provides excellent insulation and protection against high temperatures. The expansion of the electric vehicle (EV) industry, where polyimide coatings play a crucial role in battery insulation and electronic component protection, is further driving market growth.

3. Technological Advancements

Continuous research and development in polymer technology have led to improved formulations of polyimide varnish with enhanced performance characteristics. Innovations in nanotechnology and high-performance coatings are also contributing to market expansion.

4. Expanding Industrial Applications

Apart from traditional sectors, polyimide varnish is gaining traction in medical applications, including bio-compatible coatings for medical devices and implants. The growing healthcare industry is expected to open new growth avenues for manufacturers.

Market Challenges

Despite its strong growth potential, the polyimide varnish market faces several challenges:

1. High Production Costs

Polyimide varnish is relatively expensive to produce due to the high cost of raw materials and complex manufacturing processes. This factor can limit its adoption in cost-sensitive applications.

2. Environmental and Regulatory Concerns

The use of solvent-based polyimide varnish raises environmental concerns due to volatile organic compound (VOC) emissions. Regulatory bodies are imposing stringent restrictions on VOC emissions, prompting manufacturers to shift toward eco-friendly alternatives.

3. Fluctuations in Raw Material Prices

The prices of raw materials used in polyimide varnish production, such as polyamic acid and solvents, can fluctuate due to supply chain disruptions and geopolitical factors. These fluctuations impact the profitability of manufacturers and end-users.

Regional Insights

1. North America

The North American polyimide varnish market is driven by strong demand from the aerospace, electronics, and automotive industries. The presence of leading technology companies and ongoing R&D efforts contribute to market growth.

2. Europe

Europe is a significant market for polyimide varnish, with increasing applications in automotive electronics and renewable energy sectors. The region’s stringent environmental regulations are encouraging the development of sustainable and low-VOC coatings.

3. Asia-Pacific

Asia-Pacific dominates the global polyimide varnish market, driven by the rapid expansion of the electronics and semiconductor industries in countries like China, Japan, and South Korea. The growing automotive and aerospace sectors further boost demand in this region.

4. Latin America and Middle East & Africa

These regions are witnessing gradual growth in the polyimide varnish market, primarily due to rising industrialization and increasing investments in infrastructure and technology-driven applications.

Future Outlook

The polyimide varnish market is expected to witness sustained growth over the next decade. Key trends shaping the future of the market include:

1. Shift Toward Eco-friendly Solutions

Manufacturers are focusing on developing water-based and low-VOC polyimide varnishes to comply with environmental regulations and meet sustainability goals.

2. Expansion in Electric Vehicles

The rising adoption of electric vehicles is anticipated to fuel the demand for polyimide varnish in battery insulation, motor windings, and electronic components.

3. Integration of Advanced Materials

The use of nanotechnology and advanced polymer composites in polyimide varnish formulations will enhance their performance, leading to new applications and increased adoption.

4. Strategic Partnerships and Mergers

Companies are investing in collaborations, mergers, and acquisitions to strengthen their market presence and expand their product portfolios.

Conclusion

The polyimide varnish market is on a strong growth trajectory, driven by advancements in electronics, aerospace, automotive, and medical industries. While challenges such as high production costs and environmental concerns exist, ongoing innovations and the shift toward sustainable solutions present new opportunities for growth. With increasing applications across various industries and regions, the polyimide varnish market is expected to remain dynamic and lucrative in the coming years.Read Full Report:-https://www.uniprismmarketresearch.com/verticals/chemicals-materials/polyimide-varnish.html

0 notes

Text

Revolutionizing Display Technology: The Role of Flexible Substrates in Foldable Devices

A new market report reveals that the global flexible substrate market, valued at over US$2.6 Bn in 2021, is poised for extraordinary growth—projected to exceed US$28.7 Bn by the end of 2031, expanding at a robust CAGR of 18.9% from 2022 to 2031.

Market Overview and Key Insights:

Flexible substrates play a critical role in modern electronics, providing both structural support and signal transmission in devices ranging from flexible displays to photovoltaic cells. Materials such as ultrathin glass, metal foils, and plastic films particularly polyethylene terephthalate (PET), polyethylene naphthalate (PEN), and polyimides (PIs) offer the unique combination of flexibility, durability, and optical clarity required by today’s optoelectronic applications. These substrates not only support the rapid evolution of display devices but also enable innovations in foldable smartphones, flexible printed circuit boards (FPCBs), touch panels, and thin solar cells.

Top Market Trends and Growth Drivers:

The accelerating adoption of consumer electronics has been a major catalyst for market expansion. Driven by digitization, the rising demand for elegant and robust designs has led to a surge in foldable smartphone shipments. According to industry insights, foldable device shipments jumped 232% in 2021 to reach 7.5 million units, are projected to increase by 112% in 2022 to 15.9 million units, and are expected to hit 51 million units by 2026. Furthermore, the flexibility offered by these substrates is increasingly recognized as a cost-effective and durable alternative to traditional materials. Advances in semiconductor technology—which serves as the foundation for modern electronics are directly boosting the use of flexible substrates across consumer electronics, automotive, aerospace, biotechnology, telecommunications, military, and renewable energy sectors.

Innovations in Renewable Energy and Next-Generation Electronics:

Flexible substrates are making significant inroads into renewable energy solutions, particularly in the production of lightweight, thin-film solar panels. These panels, which integrate easily into a variety of surfaces from mobile devices to building facades offer improved efficiency and lower manufacturing costs. This technology not only supports the growing demand for clean energy but also enhances the durability and lifespan of solar cells through innovative manufacturing processes such as roll-to-roll processing. Looking forward, next-generation flexible electronics promise to expand market opportunities further by enabling applications in flexible lighting, wearable health monitors, implantable medical devices, and energy-harvesting sensors for robotics and unmanned aerial systems.

Companies Profiled:

Ube Industries, Ltd.

DuPont

3M Company

Panasonic Corporation

Schott

Fuentek Kolon, LLC.

Dow

Jiangsu SuCushi Technology Co.

Nippon Electric Glass Co., Ltd.

DuPont Teijin Films

BenQ Materials Corporation

Sheldahl Corporation

Polyonics, Inc.

Market Segmentation

By Material

Polymers

Polyimides

Polyethylene Naphthalate (PEN)

Polyethylene Terephthalate (PET)

Others (Molecules, Oligomers, etc.)

Silicon

Glass

Metal Oxides

CNT (Carbon Nanotubes)

Application

Sensors

PCBs

Displays

Photovoltaic

Batteries

Light Emitting Diode (LED)

Others

End-use Industry

Consumer Electronics

Automotive

Healthcare

IT and Telecom

Energy and Utilities

Aerospace and Defense

Others

Regions Covered

North America

Europe

Asia Pacific

Middle East & Africa

South America

Future Outlook and Scope:

The future of the flexible substrate market is marked by continued innovation and diversification. As semiconductor advances continue to drive the development of flexible electronics, the market is expected to witness an influx of new applications that will further cement its role as a cornerstone of modern technology. The evolution of flexible substrates is set to redefine product design and manufacturing across multiple industries, paving the way for a more connected and energy-efficient global landscape.

About Us Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. The firm scrutinizes factors shaping the dynamics of demand in various markets. The insights and perspectives on the markets evaluate opportunities in various segments. The opportunities in the segments based on source, application, demographics, sales channel, and end-use are analysed, which will determine growth in the markets over the next decade. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers, made possible by experienced teams of Analysts, Researchers, and Consultants. The proprietary data sources and various tools & techniques we use always reflect the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in all of its business reports.

Contact:

Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA – Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected] Follow Us: LinkedIn| Twitter| Blog | YouTube

0 notes

Text

Flexible Printed Circuit Board Market Report 2024-2033 | By Types, Applications, Regions And Players

The flexible printed circuit board global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Flexible Printed Circuit Board Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The flexible printed circuit board market size has grown rapidly in recent years. It will grow from $23.63 billion in 2023 to $26.20 billion in 2024 at a compound annual growth rate (CAGR) of 10.9%. The growth in the historic period can be attributed to miniaturization of electronic devices driving demand for compact circuitry, consumer electronics boom increasing demand for flexible PCBS, medical device innovation utilizing flexible and space-efficient circuitry, military and aerospace applications for lightweight and durable PCBS, and demand from industrial automation for flexible PCBS.

The flexible printed circuit board market size is expected to see rapid growth in the next few years. It will grow to $38.81 billion in 2028 at a compound annual growth rate (CAGR) of 10.3%. The growth in the forecast period can be attributed to the emergence of foldable devices driving market growth, electric vehicles (EVS) market growth and increased adoption of flexible PCBS, healthcare wearables demand for flexible PCBS in medical devices, smart packaging solutions utilizing flexible PCBS for electronic components, and rise of artificial intelligence (ai) applications across industries driving demand. Major trends in the forecast period include increasing adoption of internet of things (IoT) devices, rise of foldable and flexible display technologies, emphasis on miniaturization in electronic devices, surge in automotive electronics integration, and advancements in materials and manufacturing technologies.

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/flexible-printed-circuit-board-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers - The increasing adoption of electric vehicles is expected to propel the growth of the flexible printed circuit board market going forward. An electric vehicle (EV) is a vehicle that uses one or more electric motors for propulsion. Flexible printed circuit boards (FPCBs) in electric vehicles are used to efficiently connect and manage electronic components in limited spaces, enhancing reliability and performance. For instance, in April 2023, according to the International Energy Agency, a France-based intergovernmental organization, electric cars accounted for 21% of sales in 2022, an increase from 18% in 2021 and 10% in 2020. Therefore, the increasing adoption of electric vehicles is driving the growth of the flexible printed circuit board market.

Market Trends - Major companies operating in the flexible printed circuit board market are focused on developing new products, such as ultra-slim semiconductor bases, to increase their profitability in the market. Ultra-slim semiconductor bases in flexible printed circuit boards enable enhanced flexibility, miniaturization, and improved electrical performance in various electronic devices. For instance, in February 2023, LG Innotek Co. Ltd., a South Korea-based electric component manufacturer, launched the 2-metal chip on film (COF). This advanced COF, featuring over 4,000 dual-sided circuits and 24-micrometer microvias, enables faster signal transmission and supports higher-resolution screens. Its flexibility and thinness allow for more compact designs in electronic devices.

The flexible printed circuit board market covered in this report is segmented –

1) By Type: Single-Sided FPCBs, Double-Sided FPCBs, Multilayer FPCBs, Rigid-Flex FPCBs, Other Types 2) By Laminate: FR-4Polyamide, Composite Epoxy Material Grade-1, Paper, Other Laminates 3) By End User: Industrial Electronics, Aerospace And Defense, Information Technology And Telecom, Automotive, Consumer Electronics, Other End Users

Get an inside scoop of the flexible printed circuit board market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=13849&type=smp

Regional Insights - Asia Pacific was the largest region in the flexible printed circuit board market in 2023. North America is expected to be the fastest-growing region in the forecast period. The regions covered in the flexible printed circuit board market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - 3M Company, Jabil Inc., Flex Ltd., Nitto Denko Corporation, Samsung Electro-Mechanics Co. Ltd., Zhen Ding Technology Holding Limited, Fujikura Ltd., NOK Corporation (Nippon Mektron Ltd.), Molex LLC, TTM Technologies Inc., Tripod Technology Corporation, Austria Technologie & Systemtechnik Aktiengesellschaft, FLEXium Interconnect Inc., Multi-Fineline Electronix Inc., Cicor Group, Interflex Co. Ltd., ICHIA Technologies Inc., NewFlex Technology Co. Ltd., IEC Electronics Corp., Eltek Ltd., Career Technology Mfg. Co. Ltd., Sumitomo Electric Industries Ltd., Multek Corporation, Daeduck GDS Co. Ltd., Flexcom Inc.

Table of Contents 1. Executive Summary 2. Flexible Printed Circuit Board Market Report Structure 3. Flexible Printed Circuit Board Market Trends And Strategies 4. Flexible Printed Circuit Board Market – Macro Economic Scenario 5. Flexible Printed Circuit Board Market Size And Growth ….. 27. Flexible Printed Circuit Board Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Darüber hinaus gibt es thermoelektrische Trenntechnik (auch Direktberührungstechnologie genannt) für Leiterplatten auf Kupferbasis. Es bedeutet, durch Lötmaskenöffnung und Galvanisierung von Kupfer die Kupferdicke der erforderlichen Positionen zu erhöhen, leitet die Wärme direkt von den LEDs oder anderen Komponenten zur Kupferbasis, während das Schaltungsnetzwerk unabhängig vom thermischen Netzwerk ist.

Als MCPCB-Hersteller stellte Hitech Circuits verschiedene Kupfer-Basis-PCB für Kunden her,

Das für High Power LED Feuerzeug mit 1000W+ und Netzteil verwendet wurde.

Im LED-Bereich gibt es vier Arten von kupferbasierten Leiterplatten.

0 notes

Text

FPC Strengths

Interconnection, miniaturization, lightweight: FPC can bend and 3D bend as needed, using R-FPCB can reduce the noise and reliability of the terminal, thereby simplifying the connection and saving connectors and terminals, and reducing the weight of the product.

#pcb#flex pcb#rigid-flex pcb#flex circuit pcb#flexible pcb board#flexible circuit board#fpcway#fpcway.com#www.fpcway.com#today on tumblr

0 notes

Text

Flexible Leiterplatten, auch als Flexschaltungen bekannt, werden manchmal als eine Leiterplatte (PCB) angesehen, die sich biegen kann, obwohl es in Wirklichkeit erhebliche Unterschiede zwischen Leiterplatten und Flexschaltungen gibt, wenn es um Design, Fertigung und Funktionalität geht. Ein häufiger Fehler, den Designer machen, ist, eine flexible Schaltung nach den gleichen Regeln wie eine Leiterplatte zu entwerfen. Flex PCB erfordern ein einzigartiges Setup und haben ihre eigenen Designregeln, die das Hitechpcb-Team als "flexizing" bezeichnet hat und in den letzten Jahren hart daran gearbeitet hat, sie zu perfektionieren.

Flexible Leiterplatte, die auch Flex PCB, flexible Leiterplatte oder Flexschaltung genannt wird, besteht aus PI-Basismaterial, Klebeschicht, Kupferschicht, Deckschicht und manchmal mit Versteifungen. Flexible Leiterplatten werden jetzt weit verbreitet verwendet, um traditionelle FR4 Leiterplatten in verschiedenen verschiedenen Anwendungen aufgrund der Vorteile von Flex PCB speziell zu ersetzen. Obwohl teurer als eine normale starre Leiterplatte, könnte das richtige Design in der richtigen Anwendung Gewicht und Zeit bei der Montage sparen, gepaart mit der Zuverlässigkeit, die flexible Leiterplatte zu einer lohnenden Überlegung macht.

0 notes