#Fastener Inspection Machine

Explore tagged Tumblr posts

Text

Glass Disk Based Optical Sorting Machine For Nuts and Washers in pune | India

With its base of a glass disk, Visimaster's Glass Disk Based Optical Sorting Machine For Nuts and Washers ensures that the manufacturing sector uses the least amount of defective fasteners, nuts,and washers. For that reason, any owner of a manufacturing company who is serious about growing their production line, increasing organizational efficiency, and significantly reducing errors has to have this equipment from Visimaster.

#Glass Disk Based Optical Sorting Machine For Nuts and Washers#Glass Disc Machine for Precision Parts Inspection Pune#Fasteners Inspection Pune#Machine Vision Inspection System#Automatic Vision System For Measurement Pune#Vision System

0 notes

Text

A doll, made of steel, porcelain, brass, hard unrelenting materials that you could hit as hard as you'd like, and even if its porcelain chipped, she would still be more than functional. Its joints and mechanisms redundant, hydraulic systems doubled for reliability, core, synchronized and double calculated for stability. The most reliable system the woman had ever seen. Every joint precision ground. Every bearing press fit into a shock resistant housing. Even it's feet were custom made of hardened stainless steel, each toe and fastener made from a milled block of hardened steel, tamper resistant, naturally. But even as she marveled at the doll, she wondered who'd made such a thing so seemingly delicate in nature, a maid as its dress suggested, so reliable and damage resistant, why ruggedize something made to dust the frames of a house it might never see the outside of?

But that was the confusing part. The machine refused to function, it simply laid there, unmoving, unclicking, dead as if its mainspring had never been wound. Every mechanism she inspected was free of dust, every hydraulically actuated ligament pressurized correctly, it was the most peculiar thing.

But it still acted as if something were wrong. She scratched her head, clearly she were missing something. When it had arrived at her door, it had collapsed on the ground, with a note in its hand begging her to fix the thing. But she ran a leather workshop and the only possible piece of leather she could find was the belt affixing the dolls dress to its waist.

But still, she had once been a mechanic, so she began looking into the doll's problems. Off came the arms, legs, paneling. Still nothing revealed itself. She found its cores, humming magically, seals still intact, both of them synchronized by the most meticulous set of gearing she'd ever laid eyes on. But it was meticulously clean, as if it had never seen a speck of dirt in its life.

Eventually she reassembled the doll, dress and all, before noticing something, a small, well worn ring of parts around the dolls neck. The brass was shiny while the rest had acquired that patena that signified not wear or misuse, but age. Everything bore use, although still it was meticulously cleaned. But not this small stripe of doll around it's neck.

About an inch and a half wide, all the way around, and only in the one spot. She puzzled for a moment, before finally understanding that it wasn't something inside the doll that had broken, but something that it was missing.

She set to work, pulling out her leather working tools and creating a plain black collar. Set with steel hardware and a small brass lock in the back. As she placed the collar on the dollar, it's eyes began to glow again, she sat back, smiled and enjoyed her work for a moment while the doll began to smile.

A sharp rap on the door broke her from the trance of having done good work, and as she opened it a witch stepped in.

"thank you dear, I'm afraid she simply won't work without it, and she went running off to find you before I could stop her. It seems to be in lovely working order now, thank you"

The rudeness of the witch, barging into her workspace without even asking bothered the woman, but the audacity stunned her more than anything.

"How could you let such a thing happen. Arent you supposed to protect such a thing?"

She said this with anger, brows furrowed as clearly this was something a responsible witch would never let happen, she opened her mouth to continue before the witch interrupted her.

"What you see before you is something I have spent longer than you have been alive creating. Every gear, joint, bearing, bone, and set screw has been meticulously created with the precision that would rival anything you've ever done. I use my design as an act of love. I am no leatherworker as my doll knows, and she knows I'd never let something less than perfect grace her body. So she came here, the workshop that held your mother, all those years ago, who created the collar that helped the doll become what she is. She came to the one place in the world she saw as suitable to create what she needed most, the last token of love she could possibly give me, the final gift she could give of the free will she had after her last collar was ripped from her by someone trying to 'set her free from slavery'"

"The gift of her service, and a show of giving me back what others thought was forced from her. It was her choice, to never choose again. And I love her more than I could ever say."

151 notes

·

View notes

Text

A Quiet Morning {Tony Stark x Reader}

Fandom: Marvel

Characters: Tony Stark x Reader

Summary: You wanted coffee and quiet. Tony showed up with a smoking drone and a request for help. So much for a peaceful morning.

The sun filters lazily through the floor-to-ceiling windows of Avengers Tower, casting a golden glow over the sleek, modern kitchen. You’re halfway through your second cup of coffee, perched on a barstool in Tony’s oversized Led Zeppelin t-shirt — stolen, of course — and flipping through a news article you’re not really reading.

For once, it’s quiet. Peaceful. You’re even considering a third cup of coffee, maybe eggs, maybe not. And then —

“Babe.”

Tony’s voice slices into the serenity like a scalpel. Sharp. Immediate. Dangerously casual.

You look up. He’s standing barefoot in the doorway, hair a brilliant mess, coffee mug in one hand and... a small drone clinging to his other arm.

You blink. “Tony. Why is that thing smoking?”

“It’s not smoking,” he says breezily. “It’s… steaming. There’s a difference. One is dangerous. The other is artisanal.”

The drone sparks.

You set your coffee down slowly. “You brought a broken flying toaster into my breakfast.”

“Incorrect. It’s a personal assistant drone that may or may not have accidentally siphoned off the espresso machine’s AI.” He takes a sip of his own coffee as the drone twitches. “Also, I need help.”

“With what? Dismantling your caffeine-fueled Frankenstein?”

Tony walks toward you, the drone flapping uselessly behind him like a bat with vertigo. “Actually, with the arm. It locked on during a test sequence. JARVIS is pretending not to notice. Pepper’s in Tokyo. Bruce said ‘nope’ and left the room. So that leaves you, my capable, compassionate —"

The drone zaps his arm.

“— mildly amused partner,” he mutters.

You sigh and hop off the stool, already inspecting the clamps. “Did you use actual magnetic fasteners?”

“Only the fun kind.”

“That’s not a thing.”

“It is if you believe in it hard enough.”

“Tony.”

“I know.”

You work in silence for a few seconds, your fingers brushing against his warm skin as you try to deactivate the clamps. He’s watching you. You can feel it.

“I was aiming for a morning of cuddles and waffles,” you mutter.

“I was aiming for world peace via hyper-intelligent toast drone. Look at us - both disappointed.”

You glance up at him, one brow raised. “You gonna fix that? Or is it going to keep attacking you every time you say something smug?”

Tony smirks. “Then I’ll never survive the day.”

With a final click, the clamp releases. The drone whirs, drops to the counter, and immediately tries to escape.

Tony slaps a dish towel over it. “Problem solved.”

You stare at him.

“Don’t worry,” he adds. “If it becomes sentient and starts making threats, we’ll just feed it to Thor.”

“Breakfast was peaceful for five whole minutes.”

“Exactly five too many. You were starting to get bored.”

You huff, trying not to smile.

He pulls you into a one-armed hug and kisses your temple. “Admit it - you love the chaos.”

“…Maybe.”

“Don’t worry, babe. I’ll make it up to you.”

“Waffles?”

“Waffles and bacon. Cooked by someone who knows what they’re doing. Definitely not me.”

The drone starts smoking again behind him.

You shake your head. “I’m going back to bed.”

“I’ll bring coffee,” he calls after you. “Assuming the espresso machine doesn’t file for emancipation!”

─── ・ 。゚☆: .☽ . :☆゚. ───

Note: If interested, requests are open!

#my: stories#fandom: marvel#tony stark#tony stark x reader#tony stark x you#tony stark imagine#tony stark fanfiction#marvel#marvel tony stark#marvel reader insert#marvel fanfic#marvel fanfiction

37 notes

·

View notes

Text

Quarry - Chapter 22

Pairing: Din Djarin (The Mandalorian) x f!reader

Summary: Din Djarin is on what he expects to be his last bounty hunt for Greef Karga. After all, Nevarro is swiftly moving away from its previous reputation as a Guild member’s paradise, and Din has more important concerns now, like finding a Jedi to train his mysterious foundling. However, after capturing a wanted starship engineer who would rather go anywhere other than “home,” the Mandalorian is forced to reassess his priorities.

Your taste of freedom had been brief but glorious. Now you are a prisoner of the most infamous bounty hunter in the Outer Rim – it’s only a matter of time before he turns you in. There isn’t much you would not do to keep from being sent home, but as you find yourself growing closer to your captor and his strange little companion, you start to wonder whether escape is really what you want.

Set after Chapter 13: The Jedi but before Chapter 14: The Tragedy.

Chapter Tags & Warnings: 18+ MDNI! Reader is Mando's live-in starship engineer, second-person, no use of Y/N, minimal descriptors of reader character, light angst, canon-typical violence and peril, lots and lots of mostly made-up Star Wars technobabble

Series Masterlist | Read on AO3

Note: This chapter features events from season 2 episode "Chapter 16: The Rescue." You will notice borrowed dialogue and synced plot points.

---

Of the seven-person team that Din had assembled to rescue Grogu, you were the only one who had never had the experience of waking for the day only to immediately begin preparing for battle. However, as a pale sunrise bloomed over the horizon of this nowhere planet where you had found Bo-Katan, as the inhabitants of the Firespray all began to roll out of their bunks, you could feel the shift in energy like a tangible thing. The comfort and the softness of sleep, the comradery of your friendships, even the tender intimacy of your shared quarters with Din all dissolved as the ship’s lights flickered on and instead were replaced with an intensity of focus you had never encountered.

It was militant and almost entirely silent, the way each party member prepared themselves, and the lack of easy conversation that had become so normal on the Firespray over the last weeks set you on edge. Blasters were wiped down and loaded, armor was donned, and every belt, pocket, and holster was filled with backup supplies and secondary melee weapons. Everyone took turns in the mess, moving around one another quickly and efficiently like a well-oiled machine. They all seemed to favor light, nourishing breakfasts of nutrient-dense ration bars, canteens of water, and – in Fennec and Cara’s case – strong carafes of caf. You, however, could barely stomach your food, so tied up in knots was your body at the thought of the approaching challenge, but you forced down a few mouthfuls anyway at Din’s insistence.

“Epar, cyar’ika. Eat,” he bid you, hitting you with a hard stare through his visor. “You will need your strength.”

You did not have the same arsenal of supplies as the others, but you did take some time to back up your schematics of Gideon’s light cruiser onto a palm-held holoprojector you borrowed from Boba’s supplies. You also tucked a couple of datasticks into your pockets with some cyphers you recalled from your days of installing and configuring starship security and defense systems. Other than that, all there really was for you to do was to lace up your boots, whip your hair into a tight braid, and wrap your beloved scarf around your head like a headband. You didn’t really need it here, you knew, but at this point, it felt almost foreign to dress without it.

Just before you disembarked to board the Lambda shuttle with the rest of the group, Din took you aside and inspected your blaster while Cara Dune fitted you with a slick black leather utility belt from her own wardrobe. She fastened it snugly around the flare of your hips before slipping a matching leather holster onto the strap.

“Safer than keeping that thing in your pocket,” she quipped with a wry smile, nodding toward the blaster Din was currently polishing and reloading for you. You huffed a laugh and thanked her, but not before she slid three additional tibanna cartridges into your belt loops.

“You really think I’m going to need all this?” you asked warily.

The dark-haired woman shrugged, and you noticed that she had lined her deep brown eyes with kohl this morning, giving a fierce, predatory look to her striking features. “Maybe not, but better to have it than wish you did.” You swallowed thickly, nodding, and she clapped you warmly on the shoulder. “Don’t worry. We’ve got your back.”

“Cyare.”

At the sound of the endearment, you glanced over at Din and found him extending your blaster back to you. You took it with a murmured “thank you” and slipped it into the holster, feeling the cool, steady weight of it against your thigh. It was already more comfortable than having it shoved in your pocket.

“Are you ready?” the bounty hunter rasped.

“As I’ll ever be.”

Inclining his helmet at you solemnly, he pressed his hand into the small of your back and steered you toward the ramp. “Then let’s go.”

---

Mere hours later, in the depths of hyperspace, the boarding party clustered around the helm of the Lambda shuttle as you neared your destination. The recycled air was thick with anticipation, with the knowing that the moment you dropped out of light speed, there would be no more time for preparation. Of course, this was precisely the kind of thing that everyone had been trained for.

Everyone but you.

Shifting on your feet, your palm fell to the grip of your blaster, and you could feel the sweat on your skin slip against its textured surface. Your heart was hammering against your ribcage, your stomach heavy and acidic in your abdomen, and you struggled to keep yourself present – in the moment rather than in your head, lost in your anxieties. At the heart of it all, however, was frustration with yourself. You had fought for this chance, this opportunity to exercise your skills, to contribute, to be kriffing useful for once, and you refused to throw all of that away out of fear. This team needed you; Grogu needed you. You had to get it together.

And so instead of hyperventilating, as you thought you might have done otherwise, you focused on taking deep, steadying breaths and drying your palms against your boilersuit.

“Moff Gideon is mine,” Bo-Katan emphasized from her seat at the helm, hands steady and sure as she manipulated the controls without even hardly looking. “Got it?”

“He’s ex-ISB. He’s got a lot of information.” Cara adjusted her grip on her heavy-repeating blaster rifle, the butt of which sat propped on the toe of her boot. “I need him alive.”

Bo-Katan smiled icily. “I don’t care what happens to him as long as he surrenders to me.”

At that moment, Boba Fett’s low, gravelly voice crackled through the comm system. On one of the readouts on the console in front of you, you could see the vague outline of the Firespray pursuing you through the hyperspace tunnel. “Prepare to exit jump space.”

“Copy that,” the red-head replied. “Get the hell out of there as soon as they clear us to dock. And your shots have to look convincing.”

“Power up those shields, princess. I’ll put on a good show.” You smirked at the sound of his gentle condescension in spite of yourself.

The expression was echoed on Bo-Katan’s sharp-featured face. “Watch out for those deck cannons.”

There was a brief pause, and Boba sounded genuine this time as he responded, “Don’t worry about me. Just be careful in there.”

On the console in front of Koska, you watched as the glowing icon indicating your target coordinates grew ever larger in size.

This was it. It was time.

On instinct alone, you reached out, took hold of Din’s hand, and squeezed, suddenly desperate for something to ground yourself. All broad palms and long, thick fingers, he gripped you back with a ferocity you didn’t expect from his calm, collected exterior. Somehow, knowing that he was just as strung out as you over this eased your fears even more than the touch would have otherwise.

Koska, however, was the picture of composure as she narrated your approach. “Exiting hyperspace in three, two, one…”

The tell-tale, stopped-time sensation of dropping out of hyperspace tugged at your navel, and then –

Bright red blaster cannon fire lit up the forward viewport, Bo-Katan poured on the acceleration, and you took off at the fastest sub-light speed the Lambda shuttle could handle. Dodging Boba’s attacks with expert precision, you noticed that each round only narrowly missed the long, fin-like wings of your hijacked Imperial shuttle. The proximity of a few of them had your heart jumping into your throat, but each time, she managed to evade them.

Up ahead, looming pale and angular and absolutely massive against the inky blackness of space, precisely as you had pictured her, was Moff Gideon’s Imperial light cruiser. And you were headed straight for her.

Bringing her palm down on the comm controls, Bo-Katan hailed the cruiser and shouted into the receiver, affecting a distressed tone, “This is Lambda shuttle 2743, requesting emergency docking!”

Her distress call was met only with silence, and you couldn’t help but glance around at the others’ faces as the subspace connection remained dormant. Would the cruiser really ignore them? They looked like an ally, why would they not –

“Repeat – requesting emergency docking. We are under attack!” Bo-Katan echoed.

This time, a commanding, feminine voice responded. “Copy, Lambda shuttle. Request received.” Another pause, this one much shorter than the last, and then, “Stay clear of launch tube. Deploying fighter squadron.”

Bo-Katan shot a significant look at Koska, and the dark-haired woman clenched her jaw and nodded once. You realized they must have come to the same conclusion – the plan would need to remain the same even in the face of this new hurdle. In order to board the ship where it was most vulnerable, the Lambda shuttle would be facing down the TIE fighter squadron head-on – at the mouth of the launch tube.

Just as this thought occurred to you, a single silver TIE fighter streaked from the opening of the launch tube, rocketing out into space through the narrow walls of the aperture. Through the viewport, you watched as the fighter drew closer, closer, closer still. Bo-Katan held her course, however, continuing to dodge Boba’s cannon fire while never once wavering in her aim. For a moment, you thought the fighter might not adjust course in time, but then, at the last second, it veered hard to starboard and only barely missed clipping wings with the shuttle.

You swore you could feel a collective breath of relief being released across the room, but the feeling was short-lived as another TIE fighter appeared at the mouth of the launch tube.

If the first of the squadron had cut it close, this one was downright reckless. Blasting at top speeds through the narrow mouth of the tunnel, you were certain you could see the black reflective surface of the pilot’s helmet through his own transparisteel viewport before he finally dropped into a steep dive and ducked beneath the Lambda shuttle.

And still, Bo-Katan and Koska held steady. The aperture of the launch bay glowed bright blue in the distance, visible through the long, thin tunnel right at the nose of the light cruiser. Another fighter was being brought out – you could see it clearly now; another was about to launch, and the shuttle was nearly at the tunnel’s mouth.

You were coming in too hot. If Gideon’s crew launched that fighter, you would meet in midair, trapped in the restrictive space of the launch tunnel with nowhere to go, and no dodging or maneuvering – no matter how expertly done – would be enough to stop a collision.

The crew on the light cruiser seemed to have noticed the same. Bursting through the comm lines with urgency, the communications officer barked, “Request denied! Please clear launch tube until fighters deploy!”

Bo-Katan grit her teeth and responded, a bit of real anxiety beginning to creep into her façade. “Negative! Negative! We are under attack!”

You braced yourself against the nearest bulkhead as the shuttle dodged another volley of rounds from the Firespray, and in that moment, bright green blaster cannon fire joined the red. The two TIE fighters had joined the fray. Your pilots were left then to dodge both assailants and somehow still thread the needle into the mouth of the launch tube.

Gripping Din’s hand in yours even harder, you swallowed the ball of fear that had begun to build in your throat.

You had talented pilots at the helm of your ship – experienced fighters, cunning warriors both with nerves of steel, you told yourself. You had to trust their timing, their skills. Otherwise, you would be a harried mess before you even had the chance to step foot out of the shuttle and begin the mission in truth.

“Clear launch tube immediately!” the comm link commanded, and although she knew they could not see her, Bo-Katan shook her head, red bob dancing along her jaw.

It was miraculous, truly, what the would-be Mandalorian ruler was able to accomplish over the next few seconds. The sequence of events began to blur together, dissolving into one long, chaotic moment, but the next thing you knew, the entrance to the launch loomed directly in front of the viewport. You felt the ship shift with the mechanical vibration of the shuttle’s wings lifting into their vertical position, narrowing the ship dramatically, and just as they locked into place, you breached the mouth of the tube with mere inches to spare on either side.

But you were still coming in too hot, too fast. The short distance between the mouth of the tube and the ship’s shield-guarded launch portal was quickly disappearing, and there was no way the bulky wings of the Lambda shuttle were going to make it into that tiny opening unscathed.

“Hang on!” Fennec warned, seeing the same thing you did. Din dropped your hand and wrapped his arm around your waist, pulling you into his side as though preparing to shield you against the inevitable collision. You hid your face in the crook of his shoulder, unable to watch, as the aperture swallowed the shuttle whole.

The impact was immediate and brutal, clipping the edge of the portside wing and sending you, Din, and Cara all flying across the cabin and slamming into the unforgiving deck plating. Din cushioned your fall somewhat, though you couldn’t say the beskar was a much more comfortable place to land. The shuttle trembled violently around you, and bright sparks flew as both wing joints dragged along the inside of the launch tube. The belly of the ship bounced once, then twice, the vibration ringing through your teeth, and finally – after what felt like an eternity but in reality was a mere handful of seconds – you skidded to a stop at the end of the launch tube.

The moment the shuttle stopped rumbling beneath your bodies, Din and Cara were on their feet, and you scrambled to follow. This was the moment – time to execute the next phase of the plan. And time for you to leave the bounty hunter’s side and pray that you would reunite on the bridge unharmed.

Gripping the side of your face in one hand and drawing his blaster with the other, Din yanked you to him and pressed his forehead to yours one last time.

“K’oyacyi, cyare. Come back safe.”

“You, too,” you whispered, breath fogging his visor. “Go get him. Bring him home.”

“We’ve got her, Mando,” Cara assured him as she raised her blaster rifle, pushing her dark, disheveled hair out of her face. “C’mon. Time to go.”

You nodded once, drew your own blaster from your holster, and stepped back as Fennec shouldered her way to the rear of the cabin. With sharp, determined eyes, she did a quick inventory of the room, ensuring that all members of the boarding party were prepared to disembark.

When her gaze landed on you, she said, “Remember the plan, girl. Keep to the center of the formation, wait for clear windows to shoot, and for kriff’s sake, don’t try to be a hero.”

Releasing a huff of laugh, you agreed with a glib “yes, ma’am,” and then Bo-Katan’s sharp voice rang out behind you, the sound modulated by the sudden addition of her helmet vocoder.

“Drop the ramp – let’s go.”

As the ramp began to descend, dense, white coolant steam billowed from the shuttle’s undercarriage, obscuring your view of the bay ahead. In the distance, you could hear a Storm Trooper shouting, “Clear the launch tube! What are you doing? Get that thing out of here – ”

Whatever he was meant to say next, he never got the opportunity. With steady precision, Koska raised her blaster pistol and shot twice through the fog, and instead of more protests, all you heard was a pained “argh” and the sound of two armored bodies hitting the deck.

Then chaos erupted.

Shoulder to shoulder, Fennec and Koska led the charge down the ramp while Bo-Katan and Cara brought up the rear. You stayed tucked between them, blaster drawn, head down, the marshal’s broad form shielding you from the bright red bolts of light that filled the air. In the distance, you could see more than a dozen Imperials charging at the shuttle – some in full Storm Trooper white, others in officer gray, all with blasters drawn, raining fire on your boarding party.

But the women who surrounded you moved as a unit – like one that had been fighting arm-in-arm for years rather than days. It was tactical, the way they divided the oncoming hoard of combatants, and in perfect synchronicity, they cut through the launch bay like a hot knife through butter. The sound of it was overwhelming – the overlapping shrieks of volley after volley of blaster rounds, the whip of a grappling line from one of the Mandalorians’ vambraces, the flare of heat from a jetpack, the echo of heavy boots sprinting across durasteel deck plating. You kept your head on a swivel, your own blaster at the ready, but by the time your party had made it to the far side of the launch bay – leaving a trail of Imperial bodies in your wake – you found that you hadn’t even needed to fire it.

They had eliminated everyone in their path with such deadly precision, your presence had been entirely superfluous.

However, you hardly had the opportunity to feel self-conscious about that fact. Just as you had predicted, just as Mayfeld had warned you as you sat huddled over datapads and schematics in the depths of hyperspace, the moment the ship’s internal sensors detected blaster energy signatures, the launch bay doors slid shut. Emerging from the depths of the bulkheads on either side, two blast doors slammed closed over them, and a series of forbidding red lights flared to life around the metallic doorframe. The control panel to the right of the door also glowed red, and you felt the faintest surge of satisfaction at the sight.

The first security checkpoint had been activated. No one would be leaving the launch bay without passing a genetic scan and a chain code verification. You had been right.

“You’re up,” Fennec beckoned as the group approached the foreboding door, and you nodded silently.

This was what you were here for. This was something you could do.

Slipping to the front of the group, you took notice of how the other members closed ranks around you, placing their own bodies between you and any potential threats. The room around you was silent, almost eerily so, and you knew that none other than your team had been left alive. But still, they protected you.

For now, however, you shoved all of the warm feelings that realization elicited to the side and instead dug one of your arsenal of datasticks out of your pocket. You gripped it between your teeth to free up your hands, and then, digging the tips of your fingers into the frame of the control panel, you wrenched it open, exposing the inner workings of the terminal. The wires and switches and flashing lights before you might have looked anonymous and random to others, but to your eyes, it was a puzzle waiting to be solved.

Plugging the datastick into the open port, you went to work.

Slice into the internal security system. Access the secondary protocols. Isolate the launch bay terminals, cut them off from the rest of the system. Identify the unique override sequence. You frowned, drawing your lower lip between your teeth in concentration. The press of bodies around you shifted restlessly as the seconds ticked by. You resisted the urge to reassure them – you were close, you were almost there, just one more redirect and –

“That’s it,” you breathed, removing the datastick, replacing the control panel cover. With quick fingers, you entered a series of commands into the panel, and suddenly, all of the lights surrounding the blast doors flickered blue. With a loud, mechanical thunk, every layer of the barrier retracted back into the bulkheads, and the path ahead looked back at you, clear and open.

Behind you, Cara released a breath of relief, and Bo-Katan swept an impassive stare from the bottoms of your boots to the top of your head, as though appraising you. “Well done,” she said, brusque but earnest. “Now fall back.”

You tucked your datastick back into your pocket and withdrew your blaster from your holster as you retreated back into formation. Koska took point once again as the party charged down the open corridor, and you encountered no enemies along its length. After a handful of minutes, you came upon a path that branched perpendicularly to the left, and Koska held up her fist for you all to slow to a stop. Blaster drawn, she peeked around the corner and scanned the area quickly. “All clear.”

Bo-Katan rounded the corner ahead of her, taking in the new corridor for herself. “A little too clear,” she agreed. Beckoning the group forward, she proceeded cautiously, and as you advanced, you realized that you had come upon an open-air catwalk connecting two sections of the ship. Above and below the narrow strip of decking that stretched out before you was nothing but open, vacuous space, and if you dared to glance down, you could see the infinite blackness twinkling back at you from beyond the life support system’s ray shields. Swallowing the wave of anxiety that washed over you at the sight, you kept your eyes on the back of Bo-Katan’s helmet instead.

“Keep your eyes open,” she cautioned as you began to traverse the catwalk. You were back to the center of the formation, as planned, allowing the others to keep themselves between you and the unfamiliar surroundings, but your blaster remained firmly gripped in your hand anyway, ready to defend yourself should you need to.

You made it about halfway across the catwalk unmolested. Just as you were beginning to think that this leg of your journey might prove to be blessedly simple, four Storm Troopers emerged from the open door ahead.

As if they had planned such a synchronous maneuver in advance (which, to be fair, they probably had), both Koska and Bo-Katan fired up their jetpacks and dove off opposite edges of the catwalk, leaving you, Cara, and Fennec to face the oncoming assailants alone. The marshal was quick to dig her fingers into the back of your boilersuit and tug you bodily behind her, but that didn’t stop you from raising your pistol. On instinct alone, you thrust the muzzle of your blaster into the space between the other two women’s bodies, and your fire joined theirs in gunning down the troopers. You couldn’t be certain whether any of your rounds landed, but by the time all of them had either crumpled to the floor or fallen off the edge of the catwalk, the unlucky Storm Troopers had only managed to get off a single round. No one from the boarding party had been harmed.

“Freeze! Drop your weapons!”

A sharp, modulated voice rang out behind you, and your stomach dropped, all of the bravado you had felt mere moments ago slipping away as quickly as it had come. Turning slowly, you found six more Storm Troopers equipped with sleek black blaster rifles spilling onto the catwalk.

“Dank farrik,” you swore under your breath, icy, paralyzing fear gripping your spine for the first time since leaving the shuttle. There had to be too many of them. You didn’t have the element of surprise like you had with the others; these troopers already had their weapons trained on you, and on this narrow walkway, there was nowhere to hide.

Should you surrender, you wondered? Drop your pistol to the floor, put your hands in the air? The idea had your stomach rolling. No, you couldn’t give up, not now –

The distinctive rumble of jetpacks reverberated off of the nearby bulkheads, and a rush of relief so powerful it nearly had your knees buckling washed over you as both Koska and Bo-Katan shot out from their hiding places under the catwalk. From several feet in the air, they rained blast fire down on the unsuspecting troopers, red light and white sparks flying with each impact, and in a handful of seconds, all six of your would-be captors had collapsed into white plastoid heaps on the deck.

You sent the two Mandalorians grateful smiles as they landed smoothly back on the surface of the walkway, and then you were off again, proceeding with haste through the open archway ahead.

---

The deeper into Moff Gideon’s cruiser the boarding party penetrated, the more confident you became. The adrenaline racing through your veins felt less unsettling, rattling on your nerves; instead it seemed to focus you, blocking out all other concerns and fears and narrowing your field of vision to just the mission at hand. Keep your head down. Shoot when you have to. Override every barrier, disable every checkpoint in your path. Trust your comrades to keep you safe, but watch their backs, as well. It reminded you a bit of the Razor Crest’s pursuit of Kevok Teklolq, the way you found yourself able to sink into this role, to concentrate only the task in front of you to the exclusion of all else.

As you made your way across a densely-packed cargo bay, surrounded on all sides by Fennec and Cara’s blaster fire and crumpling white-armored bodies, you felt as focused and in-control as you did behind the helm of a starship. So when one of those anonymous plastoid helmets rounded the corner in front of you, blaster at the ready, you didn’t hesitate, and at this close of a range, even you couldn’t miss.

You shot once. Twice.

The soldier let out a pained grunt and toppled to the floor, and if bile rose in the back of your throat at the sound, you were too focused on reaching the next checkpoint to notice.

Unfortunately, that next check point appeared to be at the far end of an endless series of corridors, and each one seemed to be filled with more Imperial forces than the last. The closer you drew to the bridge, the tighter the defenses. Keeping tight to your formation, the five of you cleared each hall as you entered it, the occasional round bouncing off of Bo-Katan and Koska’s armor as you advanced. It wasn’t until you reached the last turn that the endless wave of combatants became too much to bear.

“Split up!” Cara barked, breaking away from the group. Her massive blaster rifle propped firmly under her arm, she placed herself in front of the rest of you, strong shoulders broad and centered as she took on the oncoming troopers like a force of nature. You tucked yourself behind a support beam, pressing yourself against the bulkhead to steady your aim and did your best to back her up, but next to her oversized rounds, the ones coming from your little pistol seemed to almost inconsequential.

However, as Cara reached the end of the corridor, you heard a distinctive whirring, seizing sound coming from her rifle, and you watched as she quickly found her own support beam to take shelter behind as she cried, “My gun’s jammed!”

Fennec was quick to jump to her aid, yelling, “I got you!” The assassin was nimble, light on her feet, dodging shot after shot as she cut down the corridor toward where Cara had hidden. She was good, great even as more and more Storm Troopers fell at her feet, but it wasn’t enough. The two Mandalorians were occupied with forces approaching from behind, and while the marshal wrestled with her uncooperative weapon, Fennec was outgunned.

A sickening bolt of fear broke through your concentration as you watched yet another trooper round the corner into the corridor, raise his blaster, and take aim directly at the Rebel dropper at his feet.

“Cara!”

Again, you didn’t think, didn’t hesitate. You shot off three rounds, two of which arced wide, but the third one kept true and collided with the trooper’s chest. He staggered back with the force of the impact, a hollow “ugh!” ringing out through his helmet, and then Cara Dune was on her feet once more. Having given up on repairing her blaster rifle, she deftly spun the thing around and wielded the stock like a bludgeon. Lifting the gun high, she shattered the trooper’s helmet in a deadly blow, and white shards of plastoid sprayed through the air as the man collapsed, motionless on the ground.

The marshal shot a wild grin over her shoulder at you, pride gleaming in her dark eyes. “Thanks,” she huffed breathlessly.

You weren’t certain how you felt about that sentiment just now, knowing that you were being thanked for helping her to take a life, even if it had been to save hers. But you could unpack that another time, you decided. Now, your expertise was needed at the doors to the lift that loomed ahead – the lift that would take you to the cruiser’s bridge deck. You were nearly there.

You didn’t wait to be prompted. While the others polished off the remaining troopers, you darted over to the lift, outlined as all the other checkpoints had been in bright red lights. You got to work immediately – peeling back the control panel cover, plugging in one of your datasticks, everything just as you had done for the previous checkpoints. However, as you felt the rest of the boarding party fall into formation behind you, you noticed that each time you thought you had disabled a set of protocols successfully, the effects seem to only last for a moment or two. The layers of security would fall away, and then they would surge back into place, as if you hadn’t just spent long, precious seconds systematically taking them apart.

“Fuck.” The curse came out breathless, and you could feel sweat gathering on the back of your neck and across your forehead as the realization shot down your spine like a livewire. “They’re changing it.”

“What is it?” Bo-Katan asked sharply, her modulated voice sounding just over your shoulder.

“The ship’s crew is countering. The security algorithm has started to vary – they’re trying to stop us from reaching the bridge.”

“Can you compensate?”

You weighed your answer only briefly before nodding. “Yes.”

The new cypher was complex, more nuanced and layered than the first, as though designed to test the limits of your knowledge and see how far you could push them. As you keyed through the terminal, you dug through your memories, your experiences with programs like this one. You pictured your father’s starship database, the endless stores of information, wishing you could remember even half of what you had studied at his side. You had always been more of a hardware girl, anyway; more than anything, you wished you had your plasma torch just so you could see how the security team on the bridge would respond to you simply cutting through the doors they erected in your path.

“Not to rush you, engineer, but if we need to find an alternate way to the bridge, we need to know now.”

“Shh,” you whispered, keeping your eyes on the open terminal before you. You were so close. You could feel it, you just needed to focus, you just needed –

There.

Your hands flew to reassemble the control panel, dropping your datastick back into your pocket once more. One quick command sequence, the foreboding red lights flickered blue, and the lift doors slid open without prompting.

All of the breath left your lungs in one loud exhale, and then you were all piling into the lift car. You input the bridge level number before anyone could ask, and as the car began to rise, you collapsed back against the durasteel wall in relief.

That had been too close for your comfort.

The near-complete silence in the narrow walls of the lift was jarring after the sounds of battle. You could hear the pounding of your heart for the first time since you had left the shuttle, and your own breath sounded too loud in your ears. In the quiet, Bo-Katan turned to you and demanded, “Did you shush me back there?”

Stars, had you? You supposed you had. Perhaps not the wisest choice – to be so disrespectful to the future Mand’alor. It hadn’t been consciously done, but still…

Thankfully, you were saved from needing to answer for this slight by Marshal Dune banging the butt of her blaster rifle on the floor and cursing loudly. “Dank farrik!” She fussed with the action, opening and closing it multiple times, blaster parts clanking against one another in a way no one in the lift could have ignored. “Son of a mudscuffer!”

“Are you sure you don’t need any help?” Bo-Katan asked wryly.

With gritted teeth, Cara slammed the stock of her gun down once more, this time with enough force that you could feel the vibration of it through the floor. A distinctive whirring sound emanated from the depths of the rifle, and you breathed a sigh of relief as she said, “I think that did it.”

Just then, the lift arrived at the bridge level, and the marshal swung her oversized weapon around toward the opening lift door. “Excuse me,” she muttered under her breath, and then she was leading the charge, teeth bared, pouring a never-ending stream of glowing yellow blaster fire down the enemy-filled hallway.

“Hostiles! Stop!”

The command from one of the Storm Troopers ahead did not deter you. The four of you followed in the marshal’s wake, unleashing every ounce of aggression you had left, and just as before, the dense press of armored bodies fell in the face of your party’s sheer force. However, as you gained ground toward the bridge, which shone in the distance, you watched as one final security checkpoint – one you hadn’t planned for – flared to life around its entrance. Warning lights glared red in the frame, two layers of blast doors slammed shut at the end of the corridor, and you swore you could feel the leaden finality of them reverberate through your bones.

Somewhere off to your right, Fennec shouted your name through the deafening roar of blaster fire.

“Go! Get that door open!” she shouted, her low, warm voice hoarse and strained. “I’ll cover you!”

Wordlessly, you nodded, and then you were off like a shot, sprinting down the remaining distance between you and the door with single-minded focus. You did not allow yourself to look as troopers fell around you at the end of Fennec’s rifle, did not allow yourself to hesitate as you jumped over their bodies, as you ducked their flying blaster bolts. You trusted the assassin. Your teammate, your friend. She would keep you safe as you ran. She had to.

You nearly skidded to a stop by the time you made it to the bridge’s entrance. Bracing yourself with your palms against the durasteel, you curled your shoulders inward and tried to make yourself as small a target as possible as you got to work. There was no four-fighter squadron shielding your back this time. You would need to be fast.

As you sliced into the system, you found even more modifications to the algorithms than you had seen on the lift. Brows pulled low, lip between your teeth, you took deep, steadying breaths as you worked. You kept the peril of your situation at arm’s length, knowing that if you allowed yourself to experience it, to really hear the fight going on around you, you would freeze. Instead, you kept your eyes on the terminal, and you ripped the protocol to shreds.

You were putting the control panel cover back on when you heard it – Cara’s voice, then Fennec’s, then even Bo-Katan’s cutting through the chaos. Your name, repeated over and over. “Get down! Get down!”

You hit the deck on your knees, legs collapsing beneath you.

And three blaster bolts collided with the durasteel blast doors right where your head had been.

You felt as though your stomach had fallen clean out of your body as you stared up at the glowing hot dents in the metal, all clustered together right where you had been standing. Sweat poured down your face, fatigue settling in your bones. Stars, that had nearly been the end of you. Your mind flew to Din and then to Grogu, thankful down to your core that you hadn’t seen the last of them.

So overwhelmed were you that you barely noticed Cara coming up behind you until she hauled you to your feet.

“You’re all right, sweetheart, shake it off,” she encouraged, brushing imaginary dust from your shoulders. “We took care of that guy, don’t worry. Let’s get in this room, huh?”

You nodded gratefully. With the other woman’s arm still tucked protectively around your shoulders, you entered the final command sequence, and the security system disarmed.

The party made quick work of the few Imperials left on the bridge when the doors opened. Fanning out across the room, it took only a handful of quick, efficient shots to have the entire bridge crew on the ground.

Koska charged straight for the security station, withdrawing an abandoned code cylinder from the console. “Weapons systems disarmed,” she said. “Secondary security protocols also disabled. Everyone should be able to move freely now.”

Thank the Maker. All that was left now was to wait for Din to rendezvous with you all, and with any luck, he would have Grogu in tow. Your relief was all-consuming, and you found yourself sinking into one of the officers’ chairs with a sigh.

However, there was one member of your party who did not seem especially pleased with the results of your efforts. After taking a full tour around the perimeter of the bridge, Bo-Katan Kryze came to stand in front of the viewport, confusion and fury pouring from her in palpable waves even through her impassive helmet.

Shoving both of her blaster pistols into her holsters with force, she hissed, “Where’s Gideon?”

You glanced around at the bodies that littered the floor, seeing a handful of troopers, a couple of officers in gray... But no one in command black.

Moff Gideon wasn’t here.

---

Mando'a Translations:

epar - eat k’oyacyi - Cheers! Hang in there! Come back safely. Literally, "stay alive"

#din djarin#din djarin x reader#din djarin x f!reader#din djarin x you#the mandalorian#din djarin fanfiction#the mandalorian fanfiction#pedro pascal#pedro pascal characters#pedro pascal character fanfiction

46 notes

·

View notes

Text

Top Tips for Fast and Safe Panel Assembly

Panel assembly is a critical process in the electrical industry that directly impacts safety, performance, and efficiency. Whether you’re building distribution panels, control boards, or switchgear systems, the goal is to assemble panels quickly without compromising safety or quality. In this post, we’ll explore proven tips to help electricians, technicians, and panel builders streamline their workflow while ensuring compliance with safety standards.

1. Plan Thoroughly Before Assembly

Efficiency starts with preparation. Before you begin, study the layout drawings and electrical schematics carefully. Make a checklist of all the required components — circuit breakers, relays, terminal blocks, wire ducts, and enclosures.

· Pre-arrange tools and materials

· Verify component compatibility with design

· Identify high-priority tasks and dependencies

A well-organized plan saves time and avoids costly errors during installation.

2. Use Modular and Pre-Fabricated Components

Using modular devices like DIN-rail mountable circuit breakers or pre-assembled terminal blocks can reduce build time significantly.

Benefits:

· Faster mounting and wiring

· Easier upgrades and replacements

· Reduced wiring complexity

Where possible, opt for plug-and-play components or pre-terminated wiring kits.

3. Maintain a Clean and Organized Work Area

A tidy workstation boosts productivity and prevents mistakes. Use labeled bins, trays, and tool organizers to keep everything accessible.

· Segregate power, control, and signal cables

· Keep fasteners and tools sorted by size/type

· Remove scrap materials and wire offcuts regularly

A clean work area also improves safety and reduces trip hazards.

4. Label Components and Wiring Clearly

Proper labeling speeds up installation and future maintenance. Use heat-resistant wire markers or automated labeling machines for consistency.

Label:

· All wires at both ends

· Control devices (relays, contactors, timers)

· Terminal blocks and busbars

Clear identification is essential for testing, fault isolation, and panel certification.

5. Use the Right Torque Tools

Over- or under-tightened terminals can cause failures or fire risks. Always use torque screwdrivers or wrenches calibrated to the manufacturer’s specifications.

· Ensure solid mechanical and electrical contact

· Reduce the risk of arcing or overheating

· Document torque settings for quality records

Following torque guidelines is a best practice for long-term reliability.

6. Apply Effective Cable Management

Good cable routing isn’t just about aesthetics — it enhances performance and safety.

· Use wire ducts, cable ties, and strain reliefs

· Maintain minimum bend radii, especially for data cables

· Separate AC power and control wiring to avoid interference

Neatly routed cables simplify inspections and future modifications.

7. Conduct Final Visual and Electrical Inspection

Before energizing the panel:

· Inspect all terminations and mounting

· Check for exposed conductors or loose parts

· Test insulation resistance and continuity

· Verify grounding and bonding paths

A comprehensive inspection reduces commissioning delays and ensures compliance with safety standards.

8. Document As-Built Changes

If any field modifications were made during assembly, update the panel drawings and documentation to reflect those changes.

Include:

· Wiring diagrams

· Component serial numbers

· Torque test records

· Electrical test results

Accurate documentation is essential for maintenance, certification, and future upgrades.

9. Train Your Assembly Team

Skilled workers build faster and safer panels. Provide regular training on:

· Electrical safety and lockout/tagout

· Schematic interpretation

· Safe use of hand and power tools

· Latest panel-building standards (e.g., IEC, UL, NEC)

An informed and competent team minimizes rework and enhances build quality.

Final Thoughts

Fast panel assembly doesn’t mean cutting corners. By following structured processes, using the right tools, and prioritizing safety, you can consistently deliver high-quality panels — on time and within budget.

Looking for top-tier switchgear accessories and panel-building solutions? Contact us today to explore how we can support your projects with reliable, efficient, and cost-effective products.

5 notes

·

View notes

Text

@lovelylostminds

It wasn't uncommon. Being 'lent' out like a- well, like a weapon. Which he was. So if he could feel surprise, he supposed he wouldn't feel it now. The Asset, the only designation he'd ever been given, stood stock still with his hands at his sides; eyes forward while listening to his orders with rapt attention.

"Misson understood." He said emotionlessly, not flinching when his handlers began their routine inspection of his arm after leading him to the chair. This is when his mind becomes fuzzy, The Asset knew that much. The chair was associated with fear and fear was associated with pain but pain was associated with compliance. So with the slightest pause, he was pushed into the chair and buckled in, resigned to his fate.

It seemed he had a new mission. And for once, he did not have a handler that would be overseeing every action he took, not that he would take any that were not sanctioned by HYDRA of course, but as far as he could remember… it was uncommon. Eyes focused blankly in front of him, this time without a mouth guard, the scientists began to do maintenance on his arm, willing his ears to drown out the sounds of metal against metal, the same way he drowned out his screams of pain, biting down on his tongue until all he could taste was iron.

When he was finally done, it seemed that they had arrived, given by the rough touch-down landing and violent shove he was given. "Awake. You have your mission parameters. You will not make us look bad, Asset. While you are their property for now, know who you truly belong to." His handler hissed into his ear even as one of the other men slapped the muzzle onto his mouth, the spikes being driven into his lip as it was fastened around his head too tightly. Just a reminder, he figured out a long time ago.

Upon walking down the ramp, his knives and weapons all concealed to his liking, The Asset's eyes roamed the terrain as he was given his final warning, to which he only replied with a jerked nod before he was approached by four guards, one to flank every side of him. Too bad they didn't realize that even that wouldn't stop him if they were to cross him.

After what seemed like hours and most likely was, he was finally led into the facility, cold steel-blue eyes regarding and disregarding everything and everyone in his path, all being stored in a mental catalog of his own, internal notes being filed away with every new bit of information. But one thing still wasn't clear to The Asset.

What was he truly doing here? He understood that this man, the man who led the organization- Trask, this puny man, was after something of his, something that HYDRA could provide yet only he could deliver.

Walking by cell after cell, he knew well enough to keep his eyes straight forward, but for some miraculous reason, he remembered a time much like this only… involving the Russians. A little girl. Red hair. Betrayal. Shaking his head minutely, he turned his cold gaze to the cell that was the most guarded by mechanisms, not people, which gave him cause to wonder. Who could that small woman that was curled up in the corner be?

He knew, after all, just how cruel humans were, but when they combined their sadism with machines? The possibilities were endlessly painful. So lost in thought, he didn't realize that his lax expression was still being captured by the scantily clad woman and only when his cold eyes met by a defeated and scared set of the most entrancing eyes he had ever seen, looking into what seemed like a tsunami of emotions, all clearly trying to be hidden behind a resolve but one that he was trained to see right through. It wasn't until he heard someone clearing their throat that he jerked his eyes back towards the man who had been talking, clearly irritated that HYDRA's best Asset had already been distracted, but when he set his eyes on the scientist, the other man paled, and The Asset simply nodded his understanding.

Led to a room, an actual room- with a bed and a blanket, he was told what he was to do there. He was there to get these people- no, that wasn't the word. These enhanced oddities that were found scattered throughout humanity, therefore making them abominations, were to be put up to par. They were to be sussed out over the next three months by The Asset, and it was to be seen if any of these… things, he thought with little malice, were worthy of joining HYDRA's cause.

Still silent even after he was given a meal, still standing until he was sure that he would not be bothered for that evening again did he reach behind his head to unbuckle the multitude of straps and locks that held his muzzle in place before painfully pulling it off abruptly, the wound it had made earlier already healed only to be ripped open again, not that he noticed.

His day would start early, that much he knew. Might as well eat while he could, sleep while he could, rest while he could. This might not be as simple of a mission as he thought it to be was the last thought that ran through his mind as he took the pillow and blanket over to the corner of the room, dropping himself to the concrete floor and rested his head on what was truly a pitiful excuse of a pillow with an even worse blanket covering his body.

But to him? It was the most luxurious thing he had gotten the chance to use, to his knowledge at least. Oh, how he hated the cold. No, he hated his maintenance, his restrictions… he loathed the cold. One could even say the cold… was a fear of his, not that anyone would ever know that, of course.

So, with that in mind, he fell asleep… Only to be woken up abruptly the moment it was 4 am by the sound of guards hassling the cell occupants, taunts of food, or jeers of abuse being thrown around, causing him to frown. Taking a moment to orient himself, he regrettably withdrew from the blanket, folded it, and placed everything as it was so that he could step to the door, the muzzle now back in place as he reached for the door, almost not expecting it to open but nonetheless it still did. He was a guest, after all. He had free reign of this facility to an extent.

It was only hours later after he had met with almost every man, woman, and… a child that was captured here, a set of painful tasks already in mind for each and every one of them, that he was led to the last and smallest cell. There was nothing in it save for something misshapen and yellow and a blanket. Along with the woman, of course.

"We saved the worst for last, sir. Or… best for last. It depends on how you look at it." The guard sneered as they entered the woman's teeny cell, large enough that it seemed endless going upwards, creating a never-ending vacuum that looked endless, cold, and evil, but small enough in every other way that it was evident this wasn't a cell. This was a cage.

After a brief introduction to this prisoner, with no mention of her abilities, much to his confusion, he was left alone with her. That's where The Asset found himself at the current moment. Standing over a fragile, wisp of a woman who was obviously terrified by the way she was shaking and not meeting his eyes- his legs apart somewhat with his arms crossed, the silver of his left arm glinting in the florescent lighting as he silently observed her, wanting to see what her first move would be; because after the first 45 minutes… it should have been very clear that he was not going to fold first.

Still standing, robotic and unmoving, he simply arched a brow as the time hit an hour and a half of silence, his hardened gaze finally catching hers, causing his breath to catch in his chest the moment they did for some reason. What the fuck was wrong with his chest, and why did his fingers twitch as if in a natural reflex to reach out and see if her skin was soft or as porcelain as it appeared to be.

He was malfunctioning; that had to be it, and he should have informed HYDRA's liaison but all he could think of was the fact that it was so fucking cold and all he could logically think of was illogical; that he was being sent back to the cryo. So he kept his mouth shut at the broken parts of his being and simply pushed his malfunctions to the back of the mind.

He was growing tired of this game but he was not built to tire.

She would have to give in for him to begin her assessment.

She needed to deserve this punishment.

She should be blessed with the honor.

#You asked for this. I only made it 1000x worse with plans of angst.#lovelylostminds#No grave can hold my body down I'll crawl home to her My babe would never fret none about what my hands and my body done; Charlotte & Yasha

4 notes

·

View notes

Text

Safety First: Navigating Heavy Equipment with Confidence

Heavy equipment serves as the backbone of various industries, including construction, mining, agriculture, and forestry. These powerful machines enable the efficient completion of complex tasks, but their operation requires an unwavering commitment to safety. Due to their sheer size and power, heavy equipment demands strict adherence to safety protocols. In this comprehensive blog, we'll explore crucial safety tips for using heavy equipment, covering everything from training and certification to emergency procedures.

Training and Certification Operating heavy equipment requires a solid foundation of training and certification. Proper training equips operators with a deep understanding of the machinery's features, controls, and safety guidelines. Certified operators are better prepared to make informed decisions, handle unexpected situations, and reduce the risk of accidents.

Read and Understand Manuals Every piece of heavy equipment comes with an operator's manual provided by the manufacturer. These manuals contain valuable information on machine operation, maintenance requirements, and safety precautions. Familiarize yourself with the manual thoroughly before operating the equipment to ensure safe and proper usage.

Pre-Operational Checks Performing pre-operational checks is essential to prevent accidents caused by mechanical failures. Regularly inspect the equipment for signs of damage, leaks, or wear. Check fluid levels, tire pressure (if applicable), and ensure that all safety features, such as lights and alarms, are functioning correctly.

Safety Gear and Personal Protective Equipment (PPE) Operators should always wear the appropriate personal protective equipment (PPE) while operating heavy equipment. This may include hard hats, high-visibility clothing, gloves, ear protection, and safety glasses. PPE is designed to minimize the risk of injury in case of accidents or unforeseen events.

Seat Belts and Enclosed Cabs If the heavy equipment is equipped with an enclosed cab, operators must always wear seat belts while operating. Seat belts provide an extra layer of protection in the event of sudden movements or accidents.

Maintain a Safe Distance Operators and other workers must maintain a safe distance from operating heavy equipment. Establish clear work zones and restricted areas to prevent unauthorized access and minimize the risk of accidents.

Communication Protocols Effective communication is vital in a work environment involving heavy equipment. Ground personnel and operators should establish clear communication methods, such as hand signals, radios, or signaling devices, to convey instructions and warnings.

Avoid Overloading Exceeding load capacities can compromise the stability of the equipment and increase the risk of tipping over. Adhere to manufacturer guidelines regarding load limits to prevent accidents.

Mind Your Surroundings Always be aware of your surroundings while operating heavy equipment. Watch out for obstacles, pedestrians, and other vehicles, particularly in busy job sites. Use mirrors, cameras, and other aids to enhance visibility.

Emergency Procedures All operators should be well-versed in emergency procedures. Understand how to shut down the equipment quickly in case of a problem and know the steps to take in the event of an emergency.

Proper Parking and Shutdown When parking heavy equipment, ensure that it is on a level surface and all safety devices are engaged. Lower attachments to the ground, engage the parking brake, and turn off the engine before leaving the equipment.

Secure Loads Properly When lifting or carrying loads, make sure they are securely fastened using appropriate attachments. Unsecured loads can shift, causing an imbalance and potentially leading to accidents.

Adapt to Weather Conditions Weather conditions can significantly impact heavy equipment operation. Rain, snow, and wind can create slippery surfaces and reduce visibility. Adjust your driving behavior and exercise extra caution during adverse weather.

Scheduled Maintenance Scheduled maintenance is essential for keeping heavy equipment in optimal condition. Regular inspections, fluid checks, and servicing help prevent unexpected breakdowns that can lead to accidents.

Clean and Organized Work Area A clean and organized work area is essential for safety. Remove tripping hazards, debris, and obstacles that could impede the safe operation of heavy equipment.

Avoid Distractions Operating heavy equipment requires full concentration. Avoid distractions such as phone calls, texting, or engaging in conversations that divert your attention from the task at hand.

Tire Safety Inspect tires for wear and damage regularly. Proper tire maintenance ensures stability and prevents blowouts that can lead to accidents.

Beware of Power Lines Exercise caution when operating heavy equipment near power lines. Maintain a safe distance to prevent accidental contact, which can result in electrocution.

Immediate Reporting If you notice any mechanical issues or abnormalities during operation, stop using the equipment and report the problem to supervisors or maintenance personnel immediately.

Continuous Training and Improvement Safety protocols and technology are constantly evolving. Stay updated with the latest safety practices and techniques through ongoing training, seminars, and workshops.

Conclusion Operating heavy equipment is a task that demands precision, knowledge, and an unwavering commitment to safety. These comprehensive safety tips can help operators minimize risks, prevent accidents, and ensure the well-being of everyone involved. From proper training and certification to thorough pre-operational checks and effective communication, each step plays a crucial role in maintaining a safe work environment. Safety is a shared responsibility, and everyone on the job site must work together to prioritize it. By embracing a culture of safety and adhering to these guidelines, operators can confidently operate heavy equipment while mitigating potential hazards and contributing to the success of projects in various industries. Readmore...

3 notes

·

View notes

Text

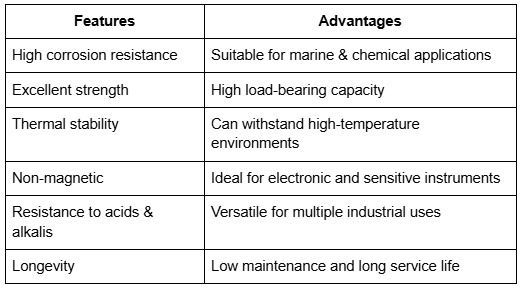

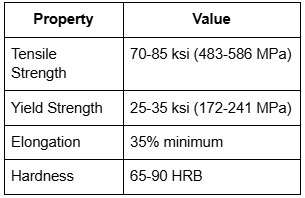

A Complete Guide to Fasteners and Trusted Fasteners Suppliers in India

Akbar Ali Fasteners, a leading manufacturer of fasteners in India, delivers high-quality fastening solutions trusted across industries. Fasteners are the unseen heroes of modern construction, machinery, and engineering. From towering skyscrapers to everyday home appliances, fasteners play a crucial role in holding things together with strength and reliability. As demand grows for durable and high-performance fastening solutions, the role of Fasteners Manufacturers and Fasteners Suppliers in India becomes increasingly important.

What Are Fasteners?

Fasteners are mechanical components used to join two or more objects together securely. They include bolts, nuts, screws, washers, rivets, and studs. Fasteners come in various materials such as stainless steel, carbon steel, alloy steel, brass, and more. Their usage spans across industries like automotive, aerospace, construction, marine, and electronics.

Why Choose Reliable Fasteners Manufacturers?

Choosing the right Fasteners Manufacturers ensures that the product meets performance and safety standards. In India, a wide network of manufacturers offers fasteners that comply with global quality norms such as ASTM, DIN, ISO, and BS. These manufacturers use high-grade raw materials, advanced forging and machining processes, and strict quality control procedures to produce fasteners that are durable, corrosion-resistant, and able to withstand extreme temperatures and pressures.

The growing infrastructure sector in India has led to a boom in the demand for fasteners. This has made the country a hub for quality fastener suppliers offering competitive prices and reliable delivery timelines. Whether you need fasteners for construction, petrochemical, or general engineering use, trusted Fasteners Suppliers in India are capable of meeting diverse needs.

Benefits of Buying from Top Fasteners Suppliers in India

Wide Range of Products:

Top Fasteners Suppliers in India provide a comprehensive range of products including hex bolts, socket head cap screws, carriage bolts, heavy hex nuts, spring washers, and more.

Customization: Many fastener manufacturers offer customized solutions based on drawings or samples provided by clients.

Cost-Efficiency: India’s competitive manufacturing environment allows Fasteners Suppliers to offer products at lower costs without compromising quality.

Global Reach: Fasteners Manufacturers in India cater not only to domestic clients but also export to markets in Europe, the Middle East, Africa, and the USA.

Applications of Fasteners

Fasteners are used in almost every industry imaginable. In the automotive sector, they are crucial for assembling engines and body parts. In the construction sector, fasteners hold together steel frameworks and reinforce structures. In electronics, tiny screws and nuts are used for assembling devices. Regardless of the application, Fasteners must be strong, reliable, and corrosion-resistant to ensure the safety and functionality of the final product.

Quality Standards Followed by Fastener Supplier

A reputed Fasteners Supplier in India adheres to strict quality assurance processes. They conduct material testing, tensile testing, hardness testing, and dimensional inspections to ensure each batch of fasteners meets the required standards. Certifications such as ISO 9001:2015, PED, and CE mark are common among the leading players in the industry.

Final Thoughts

When it comes to securing the integrity of any structure or machine, using high-quality Fasteners is not an option—it’s a necessity. Fastener suppliers in India have earned a reputation for delivering world-class products that meet the highest quality standards. Whether you're looking for standard or customized fasteners, sourcing from trusted Fasteners Suppliers ensures strength, durability, and cost-efficiency.

As the industry continues to grow, India remains a leading destination for Fasteners, backed by innovation, quality, and a commitment to excellence. Choose wisely—choose Fasteners Manufacturers in India for all your fastening needs.

0 notes

Text

Key strategies to enhance the durability and reliability of double roller press granulators

In modern organic and compound fertilizer production, double roller press granulators have become indispensable core equipment. Ensuring the long-term reliable operation of these high-value machines not only significantly reduces production costs but also guarantees consistent product quality.

1. Quality Material Selection

The durability of double roller press granulators depends first on the material quality of their core components. The roll skins, as the parts in direct contact with materials, should be made of high-hardness, wear-resistant alloys. Bearing material is equally critical—high-quality bearings maintain stable operation under heavy loads, reducing damage caused by overheating.

2. Maintenance and Care

Daily maintenance should focus on inspecting and cleaning the roll surfaces, removing buildup promptly to prevent uneven wear. Weekly checks should prioritize the drive system, lubrication, and loose fasteners. Monthly thorough maintenance requires a full inspection of roll clearance, bearing condition, and hydraulic system pressure, along with necessary part replacements.

3. Optimized Operating Parameters

Adjusting the granulator’s operating parameters based on material properties is vital. Excessively high roller speeds increase vibration and wear, while overly slow speeds reduce output. Keeping material moisture content within the ideal range (typically 15–20%) significantly reduces corrosion and wear on the rolls.

4. Timely Part Replacement

Replace roll skins once wear exceeds 5% of the original diameter. Inspect the pressure belt comprehensively every six months. Bearings should be preventively replaced every 1–2 years, depending on usage intensity.

By applying these strategies together, the service life and reliability of double roller press granulators can be greatly improved—maximizing return on investment.

0 notes

Text

Optical Sorting Machine in pune | India

Optical Sorting Machine are beneficial to a wide range of sectors because they boost productivity and efficiency. The employment of visual inspection technologies by this machinery results in more accurate and consistent manufacturing units.

#Glass Disc Machine for Precision Parts Inspection Pune#Fasteners Inspection Pune#Machine Vision Inspection System#Automatic Vision System For Measurement Pune#Vision System Integration Pune#Best Integrator India#Machine Vision System Pune

0 notes

Text

Optimizing Performance: A Troubleshooting Guide for Automatic Wire Coiling and Twist Tie Machines

Automatic wire coiling and twist tie machines are indispensable in many manufacturing processes, yet they can encounter various operational challenges. Understanding the root causes of these issues and implementing effective solutions is paramount for maintaining productivity and ensuring consistent output. This guide delves into common machine malfunctions and provides practical strategies for addressing an all-too-frequent problem: inconsistent twist tie length.

Identifying Common Machine Malfunctions

The smooth operation of automatic wire coiling and twist tie machines can be disrupted by several factors. Proactive identification of these issues is the first step toward effective troubleshooting.

Mechanical Wear and Tear: Over time, the constant motion and friction within these machines lead to the degradation of critical mechanical components. Parts such as bearings, gears, and drive belts are particularly susceptible to wear. This deterioration can manifest as diminished power transmission, increased vibration, or a noticeable decline in operational precision, directly impacting the quality of the twist ties.

Electrical System Anomalies: The electrical backbone of these machines is crucial for their functionality. Malfunctions can range from simple issues like poor contact in power connections to more complex problems such as a failing motor or a faulty circuit board. These electrical glitches can prevent the machine from starting, cause intermittent operation, or lead to unpredictable performance, all of which compromise efficiency.

Sensor-Related Issues: Modern automatic machines rely heavily on sensors to monitor various parameters, including wire position, feeding speed, and twist tie formation. If these sensors become misaligned, dirty, or outright defective, they can transmit inaccurate data to the control system. This erroneous information can lead to imprecise control over the wire, resulting in defects like incorrect twist tie length or even complete operational halts.

Software and Firmware Glitches: The sophistication of today's machines means they are often controlled by complex software programs. Bugs, compatibility conflicts, or corrupted firmware can prevent the machine from executing its pre-programmed instructions correctly. This can lead to erratic behavior, an inability to process specific commands, or a complete deviation from expected operational sequences, undermining the machine's reliability.

Resolving Inconsistent Twist Tie Length

When your machine begins producing twist ties of varying lengths, a methodical approach to troubleshooting is essential. The following steps can help you restore consistency:

Thorough Mechanical Inspection: Begin by meticulously examining all mechanical parts involved in the coiling and twist tie process. Pay close attention to the coiling wheels, wire guides, and especially the twist tie blades. Look for any signs of physical damage, such as bends, nicks, or excessive wear. Ensure all components are securely fastened and properly aligned. Any worn or damaged parts should be replaced immediately with manufacturer-approved spares to prevent further issues.

Optimizing Wire Tension: The tension applied to the wire as it feeds into the machine is a critical factor influencing twist tie length. Excessive tension can stretch the wire, leading to shorter ties, while insufficient tension can cause slack and result in longer, inconsistent ties. Consult your machine's user manual for recommended tension settings or seek advice from a qualified technician to achieve the optimal balance for your specific wire type and application.