#Machine Vision Inspection System

Explore tagged Tumblr posts

Text

Glass Disk Based Optical Sorting Machine For Nuts and Washers in pune | India

With its base of a glass disk, Visimaster's Glass Disk Based Optical Sorting Machine For Nuts and Washers ensures that the manufacturing sector uses the least amount of defective fasteners, nuts,and washers. For that reason, any owner of a manufacturing company who is serious about growing their production line, increasing organizational efficiency, and significantly reducing errors has to have this equipment from Visimaster.

#Glass Disk Based Optical Sorting Machine For Nuts and Washers#Glass Disc Machine for Precision Parts Inspection Pune#Fasteners Inspection Pune#Machine Vision Inspection System#Automatic Vision System For Measurement Pune#Vision System

0 notes

Text

#MVRPL for Industrial Machine Vision Cameras in Mumbai#How Machine Vision Drives Energy Conservation and Sustainability#business benefits#real estate maintenance#infrared imaging#roof lifespan#energy efficiency#electrical system inspection#IRIS#commercial inspections#thermography

0 notes

Text

Intsoft Tech integrates machine vision systems for ceramic appearance inspection.

#machine vision integrator#ceramic tiles defect detection#defect detection system#machine vision inspection

1 note

·

View note

Text

How Vision Inspection Enhances Auto Industry in Smart Manufacturing

The automotive industry is undergoing a major transformation. India has witnessed a massive change and growth in this segment. The Indian auto parts industry is witnessing a massive growth, it marked a 23% growth in 2023 and is contributing 2.3% to India’s GDP.

Everything from smart manufacturing to sustainable practices will strongly impact how the automotive industry will function in the future. One of the key technologies that is pivotal in redefining the auto industry’s efficiency is the vision inspection system.

Stringent quality practices are a must for automotive part manufacturers. The visual inspection system has become integral for smart manufacturing processes. It enables the manufacturer to achieve unparalleled reliability, efficiency and productivity. This blog will unfold the details of how a vision inspection system can enhance the automotive industry.

What is a Vision Inspection System?

Before delving deeper into how vision inspection systems can enhance smart manufacturing processes, let’s examine what makes this technology crucial for the automotive sector. Vision Inspection System, or Machine Vision, is a technology that uses cameras and image processing software to inspect and measure objects in real-time.

It works on similar principles as the human visual system but with better efficiency and precision. It helps identify defects, inconsistencies, or deviations from the desired specifications. One of the unique propositions of this technology is that it is highly versatile and is not just limited to the automotive industry. There are several other applications of the same.

Implementing Vision Inspection System Ensures:

Quality products

Increased production efficiency

It helps in reducing the cost

Compliance with the safety standards

Types Of Vision Inspection Systems Used In the Auto Industry

1. Laser Marking Inspection

This helps mark identification codes, logos, and labels on automotive components. It ensures accuracy by verifying its position and quality.

2. Barcode Scanning

Another type includes the scanning of barcodes. It is used for tracking and tracing of the automotive parts. Also, it ensures effective inventory management and reduces the probability of errors.

3. Pattern Matching Inspection

As the name indicates, this method identifies specific patterns and shapes of the automotive components. It is integral for the quality control and ensures that each component fits perfectly. This ensures seamless functioning of the manufacturing process.

4. Bearing Inspection

Bearings are critical components in vehicles; their integrity is essential for safety and performance. Vision Inspection Systems can detect even minor defects in bearings, such as cracks or irregularities, ensuring that only high-quality components make it into the assembly line.

How Vision Inspection Enhances Auto Industry in Smart Manufacturing

1. Improved Quality Control and Defect Detection

One of the key reasons companies rely on vision inspection system is because it ensures precise quality control. The vision inspection system canteen even the minutest of errors or flaws otherwise invisible to the human eye. Identifying the defence early in manufacturing can help overcome the issues and reduce the probability of faulty products. This also helps in maintaining the brand quality and ensures better customer satisfaction.

2. Enhanced Efficiency and Production Speed

With the growing demand in the automotive sector, automotive companies are always on their toes to address these demands. With modern technologies like vision inspection systems, companies can ensure real-time inspection. With effective quality control, they can overcome the delay of manual quality checks and also reduce the labour cost. This overall increases productivity and helps in maintaining consistency. This further increases the product efficiency.

3. Real-time Monitoring and Data Analysis

In the case of smart manufacturing, the company heavily relies on the data. This data will give them an analysis of the production process, allowing the manufacturers to gain valuable insight. By analysing the data generated during the inspection process, the companies can identify trends, pinpoint areas of improvement and make data-driven decisions, which can help gain a competitive edge.

4. Cost Reduction and Resource Optimization

By reducing the occurrence of defects and minimizing rework, Vision Inspection Systems contribute to cost reduction. Additionally, the efficiency gains achieved through automation and real-time monitoring lead to resource optimization. Manufacturers can allocate their workforce and resources more effectively, making their operations leaner and more cost-efficient. This, in turn, allows for competitive pricing while maintaining profit margins.

5. Compliance with Industry Regulations

For an automotive company to gain a competitive edge, it must adhere to the quality and comply with the safety regulations. The vision inspection system makes it easier to ensure complete consistency and accuracy while inspecting the components and products. Thus, the manufacturers can demonstrate their commitment to quality standards, reducing the risk of regulatory penalties.

Trends in Vision Inspection Technology

Technological implementation is pivotal for any organisation to stay ahead of the curve. The vision inspection system can further be improvised with the integration of modern technologies like:

Artificial Intelligence and Machine Learning

We cannot separate AI and machine learning when discussing technological revolution. Technologies like artificial intelligence and machine learning drive the modern-day revolution. With these technologies, it becomes easier to analyse the trends in the past and adapt new methods that can help improve the vision inspection process. AI-powered vision systems are becoming more sophisticated and capable of handling complex inspection tasks.

Enhanced Connectivity and Industry 4.0

The vision inspection system has become crucial for automotive companies. It is an integral part of Industry 4.0 initiatives. The data exchange is playing a pivotal role in this. These systems are increasingly integrated into the broader manufacturing ecosystem, allowing seamless communication between machines, robots, and other equipment. This interconnectedness enables real-time decision-making and the optimization of the entire production process.

Miniaturization and Portability

Advancements in camera technology and miniaturization have made it possible to deploy Vision Inspection Systems in smaller, more challenging spaces. Portable vision systems can be used for on-site inspections and maintenance, enhancing efficiency and flexibility.

Conclusion

As the technology continues to evolve, its applications will transform the industry and the process. Vision inspection system has become an indispensable tool for the automotive industry. Its ability to deliver consistent quality control, enhance production efficiency and real-time insights helps the automotive company comply with the quality standards, keeping them ahead of the curve.

SOURCE: https://optopixel.com/how-vision-inspection-enhances-auto-industry-in-smart-manufacturing/

0 notes

Text

0 notes

Text

That fucking robot got in my head dog

***

BOOT UP SEQUENCE READY

FIRMWARE

LATEST UPDATE: (2112.08.06)

CALIBRATION

EXPIRED

NEW CALIBRATION REQUIRED

AUDIO OK

“-works!” A voice said. It echoed strangely.

There was the sound of an engine humming, but smoother, quieter. Not the tell-tale gurgle of blood-mechanisms.

VIDEO OK

It’s vision flickered on, a ceiling looming above it. Old stone. Something next to it was glowing, a faint yellow hue filling the space.

MECHANICS ERROR

RUN DIAGNOSTIC

MECHANICS DIAGNOSTIC RESULT:

FOREIGN MATERIAL DETECTED

FOREIGN CODE DETECTED

CRITICAL SYSTEMS COMPROMISED

FUEL RESERVES AT 0%

SHUT DOWN IN 3 2 1

“What– no– don’t– ugh.” The person beside it shifted, and the light pulsed blue.

ERROR

SHUT DOWN HALTED DUE TO FUEL DISCREPANCY

ALL SYSTEMS POWERED

FUEL RESERVES AT 0%

ERROR

RUN DIAGNOSTIC

CALIBRATION DIAGNOSTIC RESULT:

FOREIGN MATERIAL COMPATIBLE WITH UNIT MECHANICS

FOREIGN CODE COMPATIBLE WITH OPERATING SYSTEM

ACCEPT FOREIGN MATERIAL?

YES

CALIBRATION RESUMED

MECHANICS OK

A thousand connections fired, a thousand little servos testing a new body. The resulting feedback was clear. The legs were standard issue, as was the right arm and head. The foreign object was the left arm, and a section of the diaphragm.

STATUS UPDATE:

MACHINE ID: VI

LOCATION: UNKNOWN

CURRENT OBJECTIVE: DETERMINE SITUATION

V1 rotated its head, inspecting the changes. The new arm resembled their right in form, but it was a completely new material, golden and glowing.

It then glanced up.

Standing beside it, holding a clip-board, was an angel.

Prior experience determined this was a new subtype. It had a more human form than a Virtue, but it didn’t have enough armor to be an arch-angel. A gold and silver helm with a design that mimicked rings of eyes. Some basic vambraces. All the rest of their form was covered by cloth drapings.

ERROR

PRIORITY OVERRIDE

REASON: FUEL RESERVES AT 0%

NEW OBJECTIVE: FIND FUEL

Prior experience indicated that V1 would be strapped down to the table. It was standard procedure when working with blood-fueled machines. It would be idiotic to wake up a hungry machine and not at least restrain it. V1 prepared to break the restraints.

V1 was not strapped down. It automatically discarded that strain of data-analysis, its core frantically trying to conserve energy. Energy that it shouldn’t have, because it didn’t have any blood.

CURRENT OBJECTIVE: BLOOD

The angel didn’t have any time to react before they were on the ground, V1 on top of them. The new arm was no Knuckleblaster, but it still smashed in the angel’s chest. Crimson splashed upwards, and its strikes grew in speed. Over and over again, it crushed glowing flesh, fists trading blows with ruthless efficiency.

Only when the blood stopped flowing, and the flesh stopped glowing, did V1 stop hitting.

FUEL RESERVES AT 41%

DATA ANALYSIS:

MANKIND IS DEAD

HELL IS GONE.

BLOOD IS FUEL.

THIS UNIT WAS FUNCTIONING AT 0%.

RESULTS INCONCLUSIVE

NEW OBJECTIVE: FIND A WEAPON

It scanned its surroundings. The work-station it had been laying on was nothing more than cut stone. Around it, someone has set up various tables, which held unknown tools and substances. The tables were definitely a newer addition– everything else in the room was covered in a fine layer of dust, including the blood-splattered floor. The room was a square of sharp stone angles with V1’s slab in the center. The only thing else of interest were a series of shelves cut directly into the rock walls.

Most of the shelves held crumbling books, irrelevant. But just behind where V1’s head had lain, on a particularly large shelf, were guns**. Large ones, small ones, even a few that looked like they’d been pulled right off the back of other machines.

V1 started throwing them into its wings with gleeful abandon. It had just finished shoving a massive rail cannon into its storage when the data connected; these weren’t random guns, these were its** guns. And, if its internal storage systems were working correctly, they had ammo.

It continued shoving them into its storage, and then began exploring the room.

NEW OBJECTIVE: ESCAPE

There was no clear door for the angel to have come. Could it have teleported inside? Possibly, but V1 was not sure the tables were small enough for an angel to teleport. Especially one of a lower power-level. Prior experience suggested there was a relation between matter moved and power expended. V1 noticed a break in pattern; there were only shelves on three walls of the room. It jumped over to the wall, and punched it with the new arm.

It flashed gold, and the stone cracked. The sound echoed like a gunshot in the small chamber.

It considered the glowing arm, and labeled it Godpiercer. Godpiercer was sending what V1 could only interpret as off-signals for certain temporary conditions. It switched a random one on.

The arm prompted a further selection:

SPECIFY FORM:

MEMORY/FEEDBACKER

MEMORY/KNUCLEBLASTER

MEMORY/WHIPLASH

FEEDBACKER OK

The golden metal glowed brighter, and began to twist and warp. Metal plates wrenched apart, light growing in a sudden and violent osmosis. A second, more familiar arm, tore itself free from its sibling. “Feedbacker” glowed with an alien light. V1 made a quick inspection; a near perfect copy.

FUEL RESERVES AT 39%

Immediately, the machine switched the function off. The mimic arm was reabsorbed instantly, but the burnt fuel didn’t return.

NEW OBJECTIVE: DETERMINE MECHANISM USED BY ANGEL. IF FUEL DROPS TO 37% BEFORE OBJECTIVE COMPLETION, THEN SUMMON KNUCKLEBLASTER AND DESTROY WALL.

It returned to the body, and reached down to tear the skull off, before stopping. It was not in Hell, and if the angel had to be decapitated to use the mechanism, it wouldn’t have been able to revive V1. It settled instead for picking up the entire corpse and hucking it towards the wall.

No result. It scanned the rest of the room.

There was nothing else except the books and the angel’s tools. It began pulling books off the shelves, scanning through them as quickly as its processor could handle.

No relevant data. Many of the books were poorly constructed, damaged or otherwise unreadable. It was mostly disconnected sentence fragments, with no clear relation to the stone chamber or the construction. Its processor flagged some passages as containing familiar phrases and names. They were disregarded as irrelevant to the current objective.

Nothing. It returned to the angel’s tools, and began scanning and categorizing them. Group context suggested they were tools for repairing complex machinery and robotics, though many of them were completely alien.

It picked up a screwdriver. It threw it at the wall. The screwdriver tinged off, falling onto the angel’s body with a slightly wet thunk.

V1 began throwing all of the tools at the wall.

It succeeded in destroying a good amount of the angel’s tools, and the carefully pristine room was now a complete wreck. There was no other effect.

Its fuel reserves ticked down.

NEW OBJECTIVE: BEAT THE SHIT OUT OF THAT WALL

It sprang to the new vacated bookshelf on the far side, its legs crouched, springs coiled. It summoned Knuckleblaster, the gold and red mass pulling free with the sound of a sword unsheathing. Then it powered its legs, aiming right for the spot it had previously cracked.

Shining metal met stone with the force of a bullet shot at point-blank, and the wall shattered.

A moment later, the machine stood up out of the rubble, and scanned its surroundings. It was dusk, and V1 was in a forest.

This was not a visual error. It double-checked.

RUN DIAGNOSTIC

MEMORY DIAGNOSTIC RESULT:

EARTH WAS A BURNT RUIN

MANKIND WAS DEAD

HELL WAS DESTROYED

THIS UNIT CONTINUED OPERATION FOR 5.6 YEAR(S) PAST PROJECTED TERMINATION DATE DUE TO GABRIEL

ESSENTIAL MOBILITY AND FUEL RETAINMENT SYSTEMS DEGRADED AND WERE UNABLE TO BE REPLACED

THIS UNIT DIED

ALL DATA CORRECT

That was… exactly what it remembered. It explained nothing. There was no sign of memory tapering in the diagnostic or gaps in recording. It had** died in a corpse of a world bled dry. And now it was standing in a forest, alive.

And it was still hungry.

FUEL RESERVES AT 36%

NEW OBJECTIVE: FIND FUEL

SECONDARY OBJECTIVE: FIND ANSWERS AND/OR GABRIEL

#ultrakill#toast talks#went into a fugue state. stayed up till 3am. bon apetit!#fanfic#Formatting on mobile is a nightmare#But the colors are fun#no idea how to do that on ao3#Tagging this as#gabv1el#since he shows up later and they have a nice time beating the shit out of eachother

28 notes

·

View notes

Text

An Unexpected Alliance (Arcane fanfic)

Summary: Viktor has an unexpected visitor and helps her with a prosthetic. They bond over shared experiences and form an alliance.

Notes: A late entry to @arcanefandomweek ‘s Arcane Visions Week 1: Alliances. I need Viktor and Jinx to interact in season 2. Maybe they’d be friends. Maybe they’d just clash and collide. This is an exploration of how it might go. Inspired by a few trailers and promo posters, as well as some league lore; so beware potential spoilers!

Timeline wise… who knows? Just having fun with possibilities here.

TW: loss of limb, fictional drug (shimmer), cults, human experimentation

AO3 link

~*~

Viktor glanced up as a flash of blue burst into his workshop. Long blue hair. Jinx. Of course it was only a matter of time before she found him, whether he wanted her to or not. He set aside his tools and braced for the whirlwind.

She darted around the room, inspecting various prosthetics and chattering on about… something. He failed to see any train of logic, but she didn’t seem to be talking to him so he didn’t bother trying to decipher it.

“Please be careful not to break anything, some of these items are very fragile,” Viktor warned, before she could do anything too drastic.

Jinx turned to face him, eyes glowing purple. Shimmer. “Oh, there you are! Mr. Machine Herald! Almost didn’t see ya with all…” She gestured to the various parts and half-made prototypes surrounding him. He supposed his metal parts did blend in, but he rarely wanted to be found in the first place.

His gaze flicked to her left hand. Her middle finger was missing, the wound still leaking a mixture of blood and shimmer despite a crude bandage. “You’re hurt,” he blurted. “Let me help.”

She grinned. “I was hoping you’d offer! Can I get a cool upgrade? Like a giant middle finger with a laser or a blaster!”

“Let us start with the basics, hm? May I see?” he asked, holding out a hand.

She skipped over and slapped her injured hand into his. He winced in sympathy, then looked closer, taking a clean damp cloth in his free hand.

“How did this happen?” Viktor asked as he carefully removed the soaked bandage and cleaned the wound. He’d seen worse, it would likely be a simple fix.

“Stupid Piltie shot it off with stupid fancy gun. I could make a waaay better one!”

“A fancy gun, hm? What kind of fancy?”

“Oh something Hextech-y; it was glowing blue. But it didn’t explode, which is boring.”

Hextech. Jayce was making more weapons. It shouldn’t be a surprise, but still it stung. They both had failed to carry through on their promises. At least Viktor was trying to do good, but Jayce seemed to have fallen even further. Traitor.

“Hey, hey, easy on the grip!”

Viktor glanced back at her hand and loosened his grip. Something had to be wrong with the wiring of his hand to cause it to tighten so. “Apologies.” Then he cleared what remained of his throat and asked, “When did you last take shimmer? I am not judging— I have taken it myself— but it will affect how we continue, so please be truthful.”

“Hm? Oh! I don’t take it! Not like that, pfft no. The doctor did some funky experiment to save my life a while ago and I’ve been purple ever since!”

Viktor stiffened. “The doctor did this to you? Singed?”

“Yep!” Jinx nodded emphatically.

Another experiment. A human experiment. His gut twisted. Viktor knew Singed had done terrible things in the name of science. Shimmer was one of them, a double-edged sword. But this seemed a step further. Shimmer created within a human body. Had she become the new Rio? Gods, he hoped not.

Viktor shook his head. “Eh, anyway, would you prefer the prosthetic to be fused to your flesh or easily replaceable?”

Jinx tapped her chin. “Hmm… replaceable. That way I can make my own upgrades!”

“Understandable.” Viktor wrapped the wound with a clean bandage. The shimmer still in her system would likely help it heal faster regardless. He used the Hexclaw as an extra hand to make a few measurements and jot them down, then moved to find the necessary parts.

“Are you really all robot?” Jinx asked.

“Eh… not entirely.” He shrugged. “Perhaps eventually I will be.”

“That’s what your cult wants, right? The ‘Glorious Evolution’ or whatever?”

He scoffed. “They are not my cult. I do not ask for it, I do not want them following me.”

“I didn’t ask for mine either!” Jinx laughed. “Funny how that works. Just wake up one day and boom! Everyone dying their hair blue and begging for prosthetics!”

“Mm. These things are out of our control.”

“Don’t they listen to you?”

Viktor shrugged again. Mostly he avoided them and pretended they didn’t exist. “I have tried occasionally, but they find a way to twist my words to suit their purposes.”

“Mine would set Piltover ablaze for me if I asked,” Jinx said. “No one wanted anything to do with me before. My inventions never worked, or they exploded. I messed everything up.” Her voice cracked.

Viktor looked back at her, some small part of him softening. Another misfit, shunned by society. “No one really wanted me around either. I was a cripple and a foreigner. I spent much of my time away from my peers, but I preferred it that way. Someone I once knew told me that loneliness is the byproduct of a gifted mind, one of the few things he may have been right about. And sometimes we learn better from our failures than our successes, however painful it may be.”

Jinx’s eyes widened, staring at him. “Really?”

“It’s true.” Viktor hesitated a moment, trying to think of something else to reassure her. “I have seen your bombs. The design was very impressive, unique and effective. It was a challenge to defuse. You are very intelligent, Jinx. If you ever wish to put your mind to less destructive purposes, I would be glad to work with you.”

Jinx shrugged. “Maybe.”

“Here, watch.” Viktor pieced together a prosthetic finger, trimmed a bit to fit to her measurements. He attached it to a partial glove and held it out to her. Every step he explained, just in case she was interested. Perhaps it would help. “Try this on. It should fit underneath your other glove, if you wish.”

Jinx snatched it from his hand, looking at it curiously. “That’s it?”

“For a basic prosthetic, yes. As you said, you can make upgrades as you see fit. For now, try it on, see if it works.”

Jinx put on the prosthetic, and he guided her through a few tests to ensure it was functioning properly. Once she passed the tests, Jinx flipped him off with the prosthetic. “It’s perfect!”

“Good, I’m glad you like it. Is there anything else?”

Jinx was quiet for a few seconds, fiddling with the prosthetic. “Sevika said I could unite the whole of Zaun if I tried.” She looked back at him. “Hey, we should unite our cults!”

Viktor squinted at her. “Unite our cults?”

“Yeah! Make an alliance!” Jinx grinned at him.

“I have no interest in attacking Piltover.”

Jinx blew a raspberry like a child. “Boring! Why not?” She narrowed her eyes. “Because of your fucking Piltie? Your Hextech partner? The Golden Boy of Progress? Are you still on his side?”

Viktor exhaled slowly, the fans of his ventilator whirring. He had to be careful. Antagonizing Jinx and her cult would be a terrible idea. “This isn’t about him. I do not wish to fight anyone, on either side. I am a scientist, not a soldier. My creations are to improve lives, not take them. I am only wary of what such an attack would mean for the common people, on both sides. Wars rarely end well.”

He took a breath, continuing before she could interrupt, “Perhaps we could simply have a truce between us? You tell your cult not to antagonize mine, and I do the same. If any of your cult require prosthetics, I would be happy to supply.” He would help anyone who stumbled into his workshop or requested his assistance, but still it was an olive branch. Whether his cult would listen was another matter, but he hoped they would.

Jinx tilted her head to the side, seeming to stare straight through him. “That’s all you want? Nothing about your Piltie?”

“Jayce is mine to deal with. I would greatly prefer if you leave him alive.”

“I can kidnap him for you and bring him here!”

“That is not necessary.”

“But you’d rather he be kidnapped than killed, right?”

That was undoubtably a threat. Fine. Jayce would be safer with him than any chem-barons. Viktor inclined his head. “Very well. If the opportunity arises to capture Jayce without severely harming him, you may bring him to me.”

“Great! It’s a deal!” Jinx bounced to her feet. “I’ve got something of yours. You gotta have something of mine now! Can I paint on you?”

Viktor hesitated. “What would you like to paint?”

“Just some blue clouds and stuff. You know, the more hopeful version of my symbol.” Jinx brandished a blue paint pen. “You can’t wash it off!”

It could be worse. “If you must. Just.. nothing too extreme.”

Jinx grinned and climbed on top of his chair to get closer, drawing on his metal chest plate and over his shoulder. Viktor remained perfectly still, watching her work. Blue swirls and clouds and sparkles. He could pretend it represented Hextech if asked. Or perhaps it would be better to admit their strange alliance.

Jayce would hate it.

Viktor craned his neck as she moved towards his back, careful not to jostle her. “How much are you drawing?”

“What, change your mind? Gotta make sure everyone can see it!”

“I did not change my mind. I am only curious.”

“Hold onto your horses, I’ll almost done!”

Viktor went still and silent once more. It was only paint. Jinx’s graffiti was everywhere in Zaun, hardly anything drastic.

“Ta-da!” Jinx hopped to her feet with a flourish. “What do you think?”

Viktor looked over the drawings, trying to think of something complimentary. It wasn’t his style, but he had no intention of insulting her. “You certainly have an artistic flair.”

“Thanks!” Suddenly she was hugging him.

Viktor froze for a moment, processing whether it was an attack or harmless. If she meant harm, he would certainly be dead already. He awkwardly wrapped his arms around her. When was the last time anyone had showed him such affection?

“Careful, you might smudge your drawings,” he said, half a joke.

“Don’t worry, it dries fast.” A moment later, she pulled away. “Well, see you around!” With a playful salute, she was gone.

Viktor watched her go. Emotions were strange illogical things, but perhaps it was not all terrible.

#aryaskywalker writes#arcanevisions#arcane league of legends#arcane fanfic#viktor arcane#jinx arcane#machine herald viktor#arcane season 2

21 notes

·

View notes

Text

The Eclipses Show

Pairings: None

Word Count: 1,232 Words

Summary: Eclipse wakes up in a forest nine months after his death. Eclipse also wakes up in a daycare a day after his death. Turns out, Solar now has to deal with both of them.

Warnings: Near Death Experiences, Coma, Injury, Limb Loss, Eye Trauma, Head Trauma, Cursing, Death (mentioned only), let me know if I should add anything else.

Chapter 1: Back From The Dead

Eclipse woke up in a forest, utterly broken and completely out of it. His animatronic body was practically destroyed, yet he survived, barely. Being booted from Sun’s head into this forest was not kind to him, it seemed.

He groaned as his systems that were functional or barely so whirred with a high pitch. He wouldn’t die here, he refused. He tried to sit up, finding his left arm missing and half his faceplate, half of his right leg gone too.

He groaned and looked around, he was in the middle of the forest. Just where the hell did Sun boot him out to? He should get moving, find a town or something. His head felt like something had kicked it in with a rusty hammer, and it did not help that his faceplate was damaged.

He tried to stand but…it was clear he couldn’t, so he tried to crawl along and find help, the pain was agonizing. He found a long, hefty branch to use as a cane for his missing lower right leg.

“Why is pain a thing?” He wondered. What was the date even? Eclipse checked his inner mechanics and it read ‘2:47am August 4th 2023’. He had lost almost a year. He’d lost from October 31st ‘22 to August 4th ‘23!?

Eclipse felt his face and found that his right eye was missing along with a chunk around his left faceplate that made his sight in his left eye extremely difficult to see from, probably from the loose socket due to the missing chunk.

Eclipse growled in anger at Sun but used what felt like a tree and the branch to get up, using his limited vision. He had to get somewhere that had parts to fix himself. He couldn’t tell what bunkers were nearby but he could see his glitching internals that could lead him to the PizzaPlex.

So he went that way, stumbling and using GPS to get there and using it again to get to get to the P&S area. Once there, Eclipse began rummaging and closely inspecting things to fix himself.

He ended up finding a mismatched pair of eyes, one baby pink and one dark grey, that would fit his model and put them into the tube’s part system, going back to find a grey and brown arm from shoulder to fingers, an old purple-tinged Moon faceplate, and a green leg model from the knee joint down.

Once he found those, he loaded them into the parts holder and set the tube to operate on himself and fix everything that he could at the moment. He could fix his internals once his outside was fixed. So he sat in the chair in the tube and let the machine do its job.

He growled feeling it take out his left eye and the remains of his faceplate. Then it placed the new mismatched eyes into the sockets, then the new faceplate. He blinked as it directed into a light scanner and thankfully could see. He could see better than a close distance at least.

The tube then fixed his wires loose from his left arm and right knee and attached his limbs and launched instantaneous calibration effects. He flexed his new limbs for the scanner and then sighed at the tube gave him a green light for all clear. Eclipse exited the tube and looked at the body scanner’s results.

He had so many internals broken. It was no wonder he felt freezing cold, his heaters were broken, so was his coolant and oil systems, his engines had cracks and fans had broken twigs in them.

“Well fuck.” He hugged. He would have to find these things himself and probably replace them himself too. So he groaned and went rummaging. He did find a fan system and engine so he went for those first. His old oil and coolant had to be drained and replaced completely, it felt like he had sludge in what was technically his blood system.

He poured coolant into the marked tank and oil into the other, placing the engine and fan system into the part holders for replacement. Eclipse couldn’t find a heater, so sadly he’d just be cold for a while.

“Better than nothing, I guess.” He huffed, laying in the chair again and let the tube release a smaller little hand to him and turn him off. Eclipse’s eyes bolted open in startle, he hadn’t realized he’d be powered down for a full coolant and oil replacement. He didn’t want to lose more time!

He booted up twenty minutes later feeling so much better. It was a goddamn miracle. He didn’t feel like he had slime in his ‘veins’, it felt like a relief to feel the liquid in him running as it should and fans and engine running properly.

He felt grateful, incredibly so. He was alive, he was fixed. But now for what to do. He had to stay close to here, his systems could break down any second if they did so please. He couldn’t replace his circuit board himself nor could the tube. He would need someone else for that.

Maybe…Maybe he could beg Lunar? He didn’t want to scare him. Eclipse had seen how October had went and, by the end of it, he was just tired. Maybe this new life post near-death, he could be different. He could be kinder to Lunar, try to apologize for what he’d done and be a better person.

So he set off to the daycare, hopefully Lunar was there. He didn’t know what would happen if it was Moon or Sun he faced, but he was sure it wouldn’t be good. Hopefully he could just talk to Lunar.

Eclipse ventured into the daycare, confused seeing three people he didn’t recognize along with Moon as Eclipse stood in the ball pit, having gone down the slide. One looked like a Sun but just…absolutely destroyed.

Another was a tall green and brown female daycare bot, and the third he didn’t recognize was a tiny pale blue and moon themed bot. He realized with a bit of fondness that the tiny bot was Lunar. It gave him a bit of joy knowing Lunar was safe and sound in a body of his own.

But a bit of horror crept in seeing who he could audibly hear was Sun be so destroyed. He was catching names and bits of a conversation but not really getting the whole story.

“Uh, guys?” Lunar asked the others. And Eclipse realized Lunar was looking directly at him with a bit of panic.

“Oh shit.” Moon realized as he turned to look at Eclipse.

“Quick, shoot him!” Lunar told Moon, handing him what looked like a laser gun. His body wouldn’t withstand that! He was in a fragile condition already! So he dove into the ball pit as Moon grabbed the gun about to fire.

Eclipse didn’t know the portal was on until he got sucked through it into a different dimension, which locked the second he was through by a different Moon.

“And now you have fucking two friends here! Worthless parasite, come get your little child!” The other Moon snapped. Eclipse looked over by the Moon and saw triple for a second. It was him. But…also not? But it was two other versions of him maybe? Why were there three different Eclipses?

#sun and moon show#sams#five nights at freddy's#fnaf#the eclipses show au#fnaf eclipse#fnaf moon#fnaf sun#fnaf earth#fnaf lunar#fnaf backup eclipse#fnaf solar#fnaf good eclipse#snoweywrites#tw near deat mention#tw coma mention#tw injury mention#tw limb loss mention#tw eye trauma mention#tw head trauma mention#tw cursing#tw death mention

34 notes

·

View notes

Text

Domino Presents New Monochrome Inkjet Printer at Labelexpo Southeast Asia 2025

Domino Printing Sciences (Domino) is pleased to announce the APAC launch of its new monochrome inkjet printer, the K300, at Labelexpo Southeast Asia. Building on the success of Domino’s K600i print bar, the K300 has been developed as a compact, flexible solution for converters looking to add variable data printing capabilities to analogue printing lines.

The K300 monochrome inkjet printer will be on display at the Nilpeter stand, booth F32, at Labelexpo Southeast Asia in Bangkok, Thailand from 8th–10th May 2025. The printer will form part of a Nilpeter FA-Line 17” hybrid label printing solution, providing consistent inline overprint of serialised 2D codes. A machine vision inspection system by Domino Company Lake Image Systems will validate each code to ensure reliable scanning by retailers and consumers whilst confirming unique code serialisation.

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,” explains Alex Mountis, Senior Product Manager at Domino. “Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands. We have developed the K300 with these variable data and 2D code printing opportunities in mind.”

The K300 monochrome inkjet printer can be incorporated into analogue printing lines to customise printed labels with variable data, such as best before dates, batch codes, serialised numbers, and 2D codes. The compact size of the 600dpi high-resolution printhead – 2.1″ / 54mm – offers enhanced flexibility with regards to positioning on the line, including the opportunity to combine two print stations across the web width to enable printing of two independent codes.

Operating at high speeds up to 250m / 820′ per minute, the K300 monochrome inkjet printer has been designed to match flexographic printing speeds. This means there is no need to slow down the line when adding variable data. Domino’s industry-leading ink delivery technology, including automatic ink recirculation and degassing, helps to ensure consistent performance and excellent reliability, while reducing downtime due to maintenance. The printer has been designed to be easy to use, with intuitive setup and operation via Domino’s smart user interface.

“The K300 will open up new opportunities for converters. They can support their brand customers with variable data 2D codes, enabling supply chain traceability, anti-counterfeiting, and consumer engagement campaigns,” adds Mountis. “The versatile printer can also print variable data onto labels, cartons, and flatpack packaging as part of an inline or near-line late-stage customisation process in a manufacturing facility, lowering inventory costs and reducing waste.”

Code verification is an integral part of any effective variable data printing process. A downstream machine vision inspection system, such as the Lake Image Systems’ model showcased alongside the K300, enables converters and brands who add 2D codes and serialisation to labels and packaging to validate each printed code.

Mark Herrtage, Asia Business Development Director, Domino, concludes: “We are committed to helping our customers stay ahead in a competitive market, and are continuously working to develop new products that will help them achieve their business objectives. Collaborating with Lake Image Systems enables us to deliver innovative, complete variable data printing and code verification solutions to meet converters’ needs. We are delighted to be able to showcase an example of this collaboration, featuring the .”

To find more information about the K300 monochrome printer please visit: https://dmnoprnt.com/38tcze3r

#inkjet printer#variable data printing#biopharma packaging#glass pharmaceutical packaging#pharmaceutical packaging and labelling#Labelexpo Southeast Asi

2 notes

·

View notes

Note

Ooooooh love that concept, pls continue :0

Since this au was just in the brainstorming phase and I'm still gathering some ideas and references to this story so bear with me here, anon ^^')

Ehem.

Okay, Imagine that when the heroes thought the galaxy was safe when all the power spheres were secured, when all considered bad guys were gone for good, people were entrusting more to TAPOPS as they will always ensure the safety of each planet. And with all those new generations of heroes are more ready to face the threat than ever.

Nothing will worry them, right?

--- --- ---

Woke up,

Collect the dump,

Mold it into solid cubes using the cube molder tool.

Send it to the big boss at Gogo Ba's Barter Shop,

Get some food, then

Go home.

That's the daily order that he pinned in his brain. Simple for us as trash workers to not do political and complicated things like most Gur'latans to present new game-breaking systems; have no fear of death to survive in the harsh fields of Baraju; ensure billions of living beings to farm supplies and goods in Rimbara; or think revolutionary to manage the logistics and transportations like people of Windara.

No, Gugura is the last nation to end your life and once you move in, there will be no escape. Only higher-ranking citizens were allowed to go in and out of this city. Therefor, why do people visit this nation of scraps? The place barely has eye-catching sights and the only souvenirs for tourists were the bunch of cube-shaped leftovers' irons, woods, and any waste kinds you'll find.

Despite the fact it's a country of all wanted list persons that were mostly thrown by the Cubulus' authorities, Gugura is a fine city for this young teenager to live in. His life was already covered in the present and future. Does that mean he made a bad accusation that made him displaced into this area?

That part was still a mystery to the boy with a single white highlight in the middle of his black messy hair. He never remembered where he was born, his profile, even his name. All he knew, the tag number embedded on his neck was clear enough to remember.

...Or so he thought.

.

'No were to run, _____! Hand over your power watch!'

'Never! Now _____!'

'Wha-?!'

'Teleportation Power!'

'NO!'

'Time Manipulation!'

'____ Hepta Split!'

'You little--!'

.

"#319!"

The sudden high shout erased the boy's dream into reality. "Y-yes sir?"

The cubed helmet soldier pointed the taser gun at the teen's stiffness, "Did I command you to rest?! No sleeping on the job!"

Without protest, #319 hurriedly continued scooping scraps near his feet and throwing them into a mine shaft. It created a whirring sound of gear moving from a cube machine behind him. No need to wait long as it released a perfect solid cube shape from preseed scraps.

The boy peeked at the soldier from his window eye. The man already turned around to inspect the other workers in front of him. It made him at ease for a moment. The boy looked in his pocket and reached out for a small item he found not long ago.

A watch. Just a small, broken ordinary blank watch that he sure it would more useless to bargain for a slice of bread at Bago Go's. He should have put it along with other scraps in the shaft. He was not the kind of collector person unless it was useful and practical for his home. So what was different with this item? He never knew.

But....

That vision interrupts his routine for the fifth time this week. Ever since he found that watch, his peaceful daily work slowly bothered him. He could not sleep normally as that vision--no, nightmares that were done over and over like a broken record. Never once in his life he could shout such a high note while grabbing that old watch in tremor, as if his life depends on it in the next second.

If so, why was he still kept the cursed thing intact?

"....He's now under your supervision."

Hm?

"heh... well I'm in need for someone to replace my spot anyway."

A new replacement?

"You're in luck, Oju Ju! This youngster here is a keen eye for everything you missed, skillful and his snarkiness shows no mercy to command these workers. A perfect discipline for your replacement."

He turned around. A very peculiar shorter soldier who wears round helmet than other common taller and cube helmet ones. A human perhaps? Besides, did the higher ups are now recruiting new generations as well? To this nation? It did not matter to him anyways. Whether young or old, the boy should not underestimate them.

Especially with the new one who he bet from the height was as same as his age.

....

That's all for now!

In short, this is how Gempa and Solar met.

A bit fun fact, Some places like Bago Go's barter station are just a mere name as a legacy to the owners. Some characters are OCs but not too important since...I'm not the oc author. But I still want to interpret the similar traits from their ancestors. Also, I'm still trying to figure out when I use the original ones due to this concept.

Btw I got some inspiration to this au from another headcanon that I found in the same account.

Rough translation:

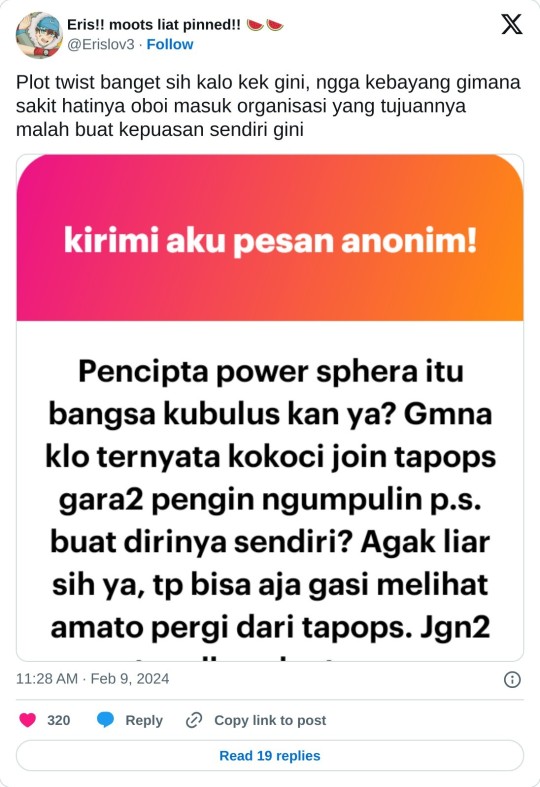

"What a plot twist indeed if that's the case, can't imagine how painful Oboi felt to join an organization that become spiteful"

Picture translate:

'The Kubulus nation is the creator of the power sphere, right? What if it turns out the purpose of Kokoci's joining TAPOPS is to collect all of them for himself? A bit wild but we can see it from the scene of Amato leaving from TAPOPS, can't we? Perhaps Amato realizes the Organisation's intention is not that pure, hahahah'

Whether it's true or not, it somehow a bit makes sense in a wild way. Oooooooh It would be an interesting twist and more in betrayal than Fang's statement in arc Gur'latan issue 24.

Anyway, apologies if you find any typos or weird meanings in my word choices.

#boboiboy#boboiboy galaxy#bbb#bbbg#yet if know the reference. I salute you#That's also how I imagine when the first time I know Gugura from movie 2#Now excuse me. I need to learn drawing for this story.#aaaaand learning more of english I guess.#bbbglxs2#boboiboy au#319 au#menjawab anon

4 notes

·

View notes

Text

Optical Sorting Machine in pune | India

Optical Sorting Machine are beneficial to a wide range of sectors because they boost productivity and efficiency. The employment of visual inspection technologies by this machinery results in more accurate and consistent manufacturing units.

#Glass Disc Machine for Precision Parts Inspection Pune#Fasteners Inspection Pune#Machine Vision Inspection System#Automatic Vision System For Measurement Pune#Vision System Integration Pune#Best Integrator India#Machine Vision System Pune

0 notes

Text

Exploring the Role of High-Speed Cameras in Industrial Automation

The rapid advancements in technology have significantly transformed the industrial landscape, with automation leading the charge in improving efficiency and productivity. High Speed Cameras have become a crucial component in Industrial automation. Among the many tools driving this transformation, high-speed cameras have emerged as indispensable devices in industrial automation. These cameras enable manufacturers and engineers to capture and analyze high-speed processes with unmatched precision and detail. Let’s delve into the pivotal role high-speed cameras play in industrial automation and how companies like Imaging Source machine vision cameras contribute to their effectiveness.

High-Speed Cameras: A Game-Changer in Industrial Automation

High-speed cameras are designed to capture events at exceptionally high frame rates, allowing the analysis of processes that occur too quickly for the human eye or standard cameras to perceive. In industrial settings, these cameras are essential for troubleshooting, quality control, and process optimization.

Key applications of high-speed cameras in industrial automation include:

1.Quality Control and Inspection: High-speed cameras are used to identify defects in manufacturing processes, such as misaligned components, irregularities in product dimensions, or surface flaws. By capturing high-resolution footage at thousands of frames per second, manufacturers can pinpoint errors and address them promptly, ensuring superior product quality.

Machine Diagnostics: High-speed imaging allows engineers to analyze the performance of machinery, detecting issues such as vibrations, misfires, or wear and tear. This predictive maintenance approach minimizes downtime and extends the lifespan of critical equipment.

Process Optimization: By providing detailed insights into high-speed processes, these cameras help optimize operations such as material handling, assembly line performance, and packaging. Engineers can fine-tune workflows to maximize efficiency and reduce waste.

4.Robotics and Automation Systems: High-speed cameras are integral to the development and operation of robotic systems. They enable precise monitoring and control of robotic movements, ensuring accurate and consistent performance in tasks like welding, sorting, and assembly.

The Role of Imaging Source Machine Vision Cameras in Enhancing High-Speed Imaging

Imaging Source machine vision cameras play a vital role in supporting high-speed imaging applications by providing top-tier optical and imaging solutions. The performance of a high-speed camera is heavily reliant on the quality of its components, and this is where Imaging Source machine vision cameras excel. From precision imaging to robust hardware, their products ensure that high-speed cameras deliver optimal performance in industrial environments.

Here’s how Imaging Source machine vision cameras enhance high-speed imaging:

Precision Imaging: High-speed cameras demand components that can handle extreme frame rates without compromising image clarity. Imaging Source machine vision cameras offer solutions specifically designed to maintain sharpness and resolution, even at high speeds. ● Durable Components: Industrial settings can be harsh, with exposure to dust, heat, and vibrations. The robust hardware from Imaging Source machine vision cameras ensures reliability and longevity in such demanding environments. ● Customization: Every industrial application has unique requirements. Imaging Source machine vision cameras provide tailored solutions that meet specific high-speed imaging needs, ensuring seamless integration with camera systems.

Case Studies: High-Speed Cameras in Action

The impact of high-speed cameras in industrial automation is evident across various industries:

1.Electronics Manufacturing: In PCB assembly lines, high-speed cameras monitor soldering processes, detecting defects such as solder bridges or insufficient solder deposits. With the help of solutions from Imaging Source machine vision cameras, these cameras achieve unparalleled precision, ensuring flawless circuitry.

Automotive Industry: High-speed cameras analyze crash tests and airbag deployments to improve vehicle safety. In manufacturing, they monitor robotic arms on assembly lines, ensuring consistent performance and rapid error detection.

3.Pharmaceuticals: The production of pills and syringes requires meticulous inspection to meet stringent quality standards. High-speed cameras equipped with components from Imaging Source machine vision cameras ensure that every product is flawless before reaching consumers.

The Future of High-Speed Imaging in Industrial Automation

The integration of high-speed cameras with artificial intelligence and machine learning is set to revolutionize industrial automation. By enabling real-time analysis and decision-making, these technologies will further enhance efficiency and productivity. Imaging Source machine vision cameras will continue to play a crucial role in this evolution by providing advanced imaging solutions that meet the demands of next-generation systems.

Conclusion

High-speed cameras have become a cornerstone of industrial automation, enabling manufacturers to achieve higher levels of precision, efficiency, and quality. Their role in quality control, machine diagnostics, and robotics underscores their importance in modern industries. Companies like Imaging Source machine vision cameras are instrumental in this journey, providing the imaging solutions necessary for high-speed cameras to excel in demanding industrial environments. As technology continues to advance, the collaboration between high-speed imaging and precision imaging solutions will unlock new possibilities in industrial automation.

#machine vision system#high resolution camera distributor#cognex#vision inspection#xenics infrared camera in mumbai

0 notes

Text

Ceramic material machine vision inspection

#machine vision integrator#industrial inspection#machine vision integration#machine vision inspection#deep learning for vision systems

1 note

·

View note

Text

Open-Source Platform Cuts Costs for Running AI - Technology Org

New Post has been published on https://thedigitalinsider.com/open-source-platform-cuts-costs-for-running-ai-technology-org/

Open-Source Platform Cuts Costs for Running AI - Technology Org

Cornell researchers have released a new, open-source platform called Cascade that can run artificial intelligence (AI) models in a way that slashes expenses and energy costs while dramatically improving performance.

Artificial intelligence hardware – artistic interpretation. Image credit: Alius Noreika, created with AI Image Creator

Cascade is designed for settings like smart traffic intersections, medical diagnostics, equipment servicing using augmented reality, digital agriculture, smart power grids and automatic product inspection during manufacturing – situations where AI models must react within a fraction of a second. It is already in use by College of Veterinary Medicine researchers monitoring cows for risk of mastitis.

With the rise of AI, many companies are eager to leverage new capabilities but worried about the associated computing costs and the risks of sharing private data with AI companies or sending sensitive information into the cloud – far-off servers accessed through the internet.

Also, today’s AI models are slow, limiting their use in settings where data must be transferred back and forth or the model is controlling an automated system.

A team led by Ken Birman, professor of computer science in the Cornell Ann S. Bowers College of Computing and Information Science, combined several innovations to address these concerns.

Birman partnered with Weijia Song, a senior research associate, to develop an edge computing system they named Cascade. Edge computing is an approach that places the computation and data storage closer to the sources of data, protecting sensitive information. Song’s “zero copy” edge computing design minimizes data movement.

The AI models don’t have to wait to fetch data when reacting to an event, which enables faster responses, the researchers said.

“Cascade enables users to put machine learning and data fusion really close to the edge of the internet, so artificially intelligent actions can occur instantly,” Birman said. “This contrasts with standard cloud computing approaches, where the frequent movement of data from machine to machine forces those same AIs to wait, resulting in long delays perceptible to the user.”

Cascade is giving impressive results, with most programs running two to 10 times faster than cloud-based applications, and some computer vision tasks speeding up by factors of 20 or more. Larger AI models see the most benefit.

Moreover, the approach is easy to use: “Cascade often requires no changes at all to the AI software,” Birman said.

Alicia Yang, a doctoral student in the field of computer science, was one of several student researchers in the effort. She developed Navigator, a memory manager and task scheduler for AI workflows that further boosts performance.

“Navigator really pays off when a number of applications need to share expensive hardware,” Yang said. “Compared to cloud-based approaches, Navigator accomplishes the same work in less time and uses the hardware far more efficiently.”

In CVM, Parminder Basran, associate research professor of medical oncology in the Department of Clinical Sciences, and Matthias Wieland, Ph.D. ’21, assistant professor in the Department of Population Medicine and Diagnostic Sciences, are using Cascade to monitor dairy cows for signs of increased mastitis – a common infection in the mammary gland that reduces milk production.

By imaging the udders of thousands of cows during each milking session and comparing the new photos to those from past milkings, an AI model running on Cascade identifies dry skin, open lesions, rough teat ends and other changes that may signal disease. If early symptoms are detected, cows could be subjected to a medicinal rinse at the milking station to potentially head off a full-blown infection.

Thiago Garrett, a visiting researcher from the University of Oslo, used Cascade to build a prototype “smart traffic intersection.”

His solution tracks crowded settings packed with people, cars, bicycles and other objects, anticipates possible collisions and warns of risks – within milliseconds after images are captured. When he ran the same AI model on a cloud computing infrastructure, it took seconds to sense possible accidents, far too late to sound a warning.

With the new open-source release, Birman’s group hopes other researchers will explore possible uses for Cascade, making AI applications more widely accessible.

“Our goal is to see it used,” Birman said. “Our Cornell effort is supported by the government and many companies. This open-source release will allow the public to benefit from what we created.”

Source: Cornell University

You can offer your link to a page which is relevant to the topic of this post.

#A.I. & Neural Networks news#agriculture#ai#ai model#applications#approach#artificial#Artificial Intelligence#artificial intelligence (AI)#augmented reality#Bicycles#Cars#cascade#Cloud#cloud computing#cloud computing infrastructure#collisions#Companies#computation#computer#Computer Science#Computer vision#computing#dairy#data#data storage#Design#Developments#diagnostics#Disease

2 notes

·

View notes

Text

10 Factors That Determine Assembly Line Efficiency in Electronics Production

In today's competitive electronics manufacturing landscape, optimizing assembly line efficiency isn't just beneficial—it's essential for survival. With tighter deadlines, higher quality expectations, and increasing cost pressures, manufacturers must fine-tune every aspect of their production processes to stay competitive.

After working with hundreds of electronics manufacturers over the past decade at Ruihua Electronics, we've identified the key factors that consistently separate high-performing assembly operations from the rest. Whether you're setting up a new line or looking to improve existing processes, understanding these critical elements will help you maximize throughput without sacrificing quality.

1. Equipment Selection and Configuration

The foundation of any efficient electronics assembly line begins with selecting the right equipment. Modern production demands versatility and precision that older machinery simply cannot deliver. When evaluating production equipment, manufacturers should consider not only current needs but also future scalability.

For example, the latest generation of pick and place machines offers remarkable improvements in placement accuracy and throughput. With advanced vision systems and multi-head configurations, these machines can place tens of thousands of components per hour with micron-level precision. The difference between an outdated machine and a state-of-the-art system can mean 30-40% variation in production capacity.

Component delivery systems like advanced feeders also play a crucial role in maintaining continuous operation. Modern feeders offer features like automated calibration and intelligent component tracking that minimize downtime between production runs. In high-mix environments, this capability becomes even more valuable as changeover efficiency directly impacts overall throughput.

2. Production Line Layout and Material Flow

Even with top-tier equipment, poor line layout can create bottlenecks that cripple efficiency. The physical arrangement of your production line should follow logical workflow principles while minimizing material handling distance.

Effective assembly lines typically employ U-shaped or linear configurations that allow operators to monitor multiple processes simultaneously. The positioning of test stations, component storage areas, and quality inspection points should minimize travel distance while ensuring proper process sequencing.

Material flow management systems help ensure components arrive at placement machines exactly when needed. Implementing just-in-time delivery principles at the assembly line level reduces floor space requirements while preventing work stoppage due to component shortages.

3. Component Management Systems

Component management represents one of the most underappreciated aspects of assembly line efficiency. Errors in component selection, orientation, or availability can halt production and introduce costly quality issues.

Modern nozzle technology plays a vital role in this equation. Different component types require specific nozzle designs for reliable pickup and placement. Having the right assortment of high-quality nozzles—whether they're compatible with systems from industry leaders or specialized for unique applications—ensures components are handled properly throughout the placement process.

Feeders serve as the interface between component storage and placement machines. Their reliability directly impacts line efficiency, as feeder jams or misfeeds can cause immediate production stoppages. Premium feeder systems offer features like automated tape tensioning and anti-static measures that minimize these disruptions while protecting sensitive components.

4. Programming and Software Integration

The software controlling your production equipment represents another critical efficiency factor. Modern assembly requires seamless integration between design data (CAD files), component placement programming, and machine operations.

Advanced programming systems can automatically optimize placement sequences, reducing head travel time and maximizing throughput. They can also perform virtual production runs to identify potential issues before actual manufacturing begins.

Integration between machines on the line allows for real-time production monitoring and adjustment. When inspection systems detect a developing issue, they can communicate with upstream equipment to make necessary corrections before defects multiply.

5. Changeover Efficiency

For electronics manufacturers dealing with multiple product lines, the time required to switch between different products directly impacts overall efficiency. Minimizing this downtime requires both physical and digital preparation.

Quick-change fixtures, standardized programming interfaces, and modular feeder systems significantly reduce the time needed between production runs. Some manufacturers have reduced changeover times from hours to minutes by implementing standardized procedures and compatible component delivery systems.

Pre-staging feeders for upcoming production runs while the current batch is still processing allows for near-instantaneous transitions. This approach is particularly valuable in high-mix, low-volume environments where frequent changeovers are unavoidable.

6. Operator Training and Specialization

Even in highly automated environments, human operators remain essential to assembly line efficiency. Well-trained personnel can spot developing issues before they cause line stoppages and make real-time adjustments that maintain production flow.

Specialized training on nozzle selection and maintenance ensures operators can quickly address pickup failures or placement errors. Understanding the specific requirements of different nozzle types—such as those used in Samsung, Juki, or Fuji placement systems—allows teams to optimize their selection for specific component requirements.

Cross-training enables flexibility in staffing while ensuring consistent knowledge across shifts. This approach prevents efficiency drops when specific team members are unavailable while fostering knowledge sharing that benefits the entire operation.

7. Preventative Maintenance Protocols

Unplanned downtime represents one of the greatest threats to assembly line efficiency. A comprehensive preventative maintenance program significantly reduces this risk while extending equipment lifespan.

Regular maintenance of critical components like nozzles and feeders prevents the most common causes of line stoppages. For instance, implementing a rotation schedule for nozzle cleaning and inspection can prevent the gradual degradation in pickup reliability that often precedes failures.

Feeder maintenance is equally crucial, as these mechanical systems experience significant wear during normal operation. Scheduled lubrication, tension adjustment, and component pathway cleaning prevent the sudden failures that can bring production to a halt.

8. Quality Control Integration

Rather than treating quality as a separate function that occurs after production, efficient manufacturers integrate quality control throughout the assembly process. This approach allows for immediate correction of developing issues rather than discovering problems after significant resources have been invested.

Automated optical inspection (AOI) systems positioned at strategic points in the assembly line can verify component placement accuracy and solder quality in real-time. When integrated with the production control system, these inspections can trigger immediate adjustments to prevent defect propagation.

First-article inspection protocols ensure that the first pieces produced after any equipment adjustment or changeover meet all specifications before full production resumes. This practice prevents the creation of large quantities of non-conforming products due to setup errors.

9. Data Collection and Analysis

Modern assembly lines generate enormous amounts of operational data. Converting this raw information into actionable insights represents a significant opportunity for efficiency improvement.

Production monitoring systems track metrics like units per hour, first-pass yield, and machine utilization in real-time. This visibility allows management to identify bottlenecks and optimization opportunities as they develop rather than discovering them during post-production analysis.

Advanced analytics can identify subtle patterns that human observers might miss. For example, correlations between specific component types, nozzle configurations, and placement errors can guide preventative maintenance scheduling and equipment optimization.

10. Continuous Improvement Culture

Perhaps the most important factor determining long-term assembly line efficiency is an organizational commitment to continuous improvement. The most successful manufacturers view efficiency not as a fixed target but as an ongoing journey.

Regular efficiency audits help identify areas for improvement while establishing new benchmarks. These structured reviews should examine equipment performance, material flow, operator procedures, and quality metrics to develop comprehensive improvement plans.

Cross-functional improvement teams bring diverse perspectives to efficiency challenges. Including representatives from engineering, production, maintenance, and quality ensures that improvement initiatives address all aspects of the manufacturing process.

Conclusion

Assembly line efficiency in electronics production results from the careful orchestration of equipment, processes, and people. By focusing on these ten critical factors, manufacturers can achieve significant improvements in throughput, quality, and cost-effectiveness.

At Ruihua Electronics, we've helped countless customers optimize their production operations through carefully selected equipment and components. Whether you're looking to upgrade specific elements like feeders and nozzles or redesigning your entire production approach, understanding these efficiency fundamentals will guide your decisions toward meaningful improvements.

Remember that assembly line optimization is an ongoing process rather than a one-time project. The most successful manufacturers continuously evaluate their performance against industry benchmarks and their own historical data, always seeking the next opportunity for improvement.

Looking to improve your assembly line efficiency? Contact our team at Ruihua Electronics to discuss how our SMT equipment solutions can help optimize your production processes.

0 notes