#Fiber Laser Cutting Machine for Sale

Text

We are Direct Manufacturer & Supplier Of Fiber Laser Cutting Machines. Order Now . Email Us [email protected]

#Fiber Laser Cutting Machine#Laser Pipe Cutting Machine#Fiber Cutting Machine#Fiber Laser Cutter for Metal#Cnc Fiber Laser Cutting Machine Price#Fiber Optic Laser Cutting Machine#Co2 Fiber Laser#Fiber Laser Equipment#Fiber Laser Cutting Machine for Sale#Cnc Fiber Laser Cutting Machine

2 notes

·

View notes

Text

Where to Find the Best Manufacturers of MIG Welding Machines

The significance of selecting the appropriate welding equipment cannot be emphasized. Among the numerous welding procedures, MIG (Metal Inert Gas) welding has been popular for its adaptability and effectiveness.

Finding the top Mig welding machine Manufacturers is essential for any company investing in this cutting-edge technology. In this blog, we will guide you on where to find top manufacturers while also touching on related equipment like laser cutting machines and fiber laser cutting machines.

1. Research Online

Thoroughly researching MIG welding machine manufacturers online is the first step in locating trustworthy companies. Start with industry-specific websites, forums, and social media platforms where professionals discuss their experiences with various brands. Websites like Weldarc India provide insights not just into MIG welding machines but also into laser welding machine manufacturers, helping you make informed decisions.

2. Industry Exhibitions and Trade Shows

Attending industry exhibitions and trade shows is an excellent way to connect with MIG welding machine manufacturers directly. These gatherings frequently include live demonstrations so you can watch the machines in operation. Not only can you compare different models, but you can also ask manufacturers about their cutting and welding machines, including advanced options like fiber laser cutting machines.

3. Customer Reviews and Testimonials

When evaluating potential manufacturers, always look for customer reviews and testimonials. You can feel more confident in your decision if other firms provide you with positive feedback. Websites that aggregate reviews of welding equipment might be important information. Take note of remarks regarding the functionality, robustness, and after-sales support provided by MIG welding equipment suppliers.

4. Manufacturer’s Reputation and History

When making a purchase, take into account the manufacturer's track record and reputation. Established companies with years of experience in the industry are more likely to offer reliable products and support. Check if the firm specializes in MIG welding machines and study their range, including related equipment like laser welding machines and cutting machines.

5. Technical Support and Warranty

Reliable technical support and warranty options are essential when choosing a MIG welding machine manufacturer. Ask about the available options for after-sale support and service. A manufacturer that stands behind its products will give thorough warranties and be ready to assist you in case of any concerns.

6. Quality and Innovation

Quality is paramount in welding equipment. Look for manufacturers known for using high-grade materials and innovative technology in their MIG welding machines. Businesses that frequently lead the industry in innovation, such as Weldarc India, a well-known manufacturer of fiber laser cutting machines, guarantee that you get cutting-edge technology.

7. Custom Solutions

If your project requires specific features or customization, look for manufacturers that offer tailored solutions. Numerous leading producers of MIG welding equipment are aware of the various demands of their customers and are prepared to modify their offerings accordingly. The correct manufacturer will collaborate with you to determine the optimal solution, regardless of whether you require a regular machine or one that is optimized for laser welding.

In summary

Finding the top MIG welding equipment manufacturers entails rigorous research, attending industry events, and assessing customer comments. By focusing on recognized companies with a reputation for quality and innovation, such as Weldarc India, you can ensure that your investment in welding technology is sound. Recall that the productivity and efficiency of your company will be greatly impacted by your choice of manufacturer, regardless of whether you're shopping for MIG welding machines, laser welding machines, or cutting machines.

#MIGWelding#WeldingMachines#MIGWeldingMachineManufacturers#LaserCutting#FiberLaserCuttingMachine#LaserWelding#CuttingAndWelding#WeldingEquipment#WeldingTechnology#IndustrialWelding#WeldarcIndia#WeldingSolutions#Manufacturing#WeldingIndustry#QualityWelding

0 notes

Text

Some of the top laser engraving machine manufacturers

If you're looking for laser engraving machine manufacturers, here are some of the top laser engraving machine manufacturers that are recognized for their quality and innovation in the industry:

Thunder Laser: Known for high-quality machines with advanced features and excellent customer support. They offer a range of laser engraving machines with user-friendly interfaces.

HiSpeed Laser: A popular brand with a versatile product line that includes cleaning, welding, and engraving machines. They have a global presence with headquarters in China and branches in Brazil and Portugal.

DXTech: Specializes in CO2 and fiber laser devices, offering a variety of laser machines for engraving, cutting, marking, cleaning, and welding. They are recognized for their high-quality machines and advanced laser systems.

Style CNC: Popular for budget-friendly machinery, focusing on fiber and CO2 laser sources. They offer a wide range of CNC and laser machinery, including routers, plasma cutters, and laser engraving machines.

Linxuan Laser: With over 18 years of experience, Linxuan Laser is a top industrial laser marking and engraving machine manufacturer in China. They offer customizable and affordable laser marking and engraving solutions.

Shenzhen Algo Technologies Co.,Ltd: An innovative tech company focusing on commercial laser engraving machines. They have a strong R&D team and production facility, offering solutions tailored to user needs.

Guangdong Guangwei Laser Technology Co., Ltd.: A high-tech enterprise focused on the research, development, production, and sales of laser inner engraving equipment. They offer a one-stop service system for laser inner engraving.

Bomark Machinery Technology Co.,Ltd: A professional CNC machine manufacturer with a range of laser products including marking machines, cutting machines, welding machines, and engraving machines.

Shandong Man Machinery Equipment Co., Ltd.: An integrated enterprise specializing in laser products, including engraving, cutting, and marking machines. Their products are used in various industries and they offer OEM and ODM services.

Hibo Laser: A high-tech enterprise specializing in the application of laser technology, offering customization, sales, and service of laser equipment.

HGLASER: A pioneer and leader in laser industrial application in China, providing laser equipment and intelligent manufacturing solutions. They offer a wide range of laser machines for various industries.

These laser engraving machine manufacturers are known for their precision, innovation, and customer service. When choosing a laser engraving machine, consider factors such as the machine's capabilities, the material you intend to engrave, and the level of support provided by the manufacturer.

0 notes

Text

Fiber Laser Cutting Machine in Thane

In today’s fast-paced manufacturing environment, precision, speed, and efficiency are paramount. Whether you're a small-scale business or a large industrial operation, having the right equipment can significantly impact your productivity and bottom line. If you're in Thane and looking for top-notch fiber laser cutting machines, look no further than GK Laser Enterprises.

Why Choose Fiber Laser Cutting Machines?

Fiber laser cutting machines are a revolutionary technology in the field of metal processing. These machines use a fiber laser to cut through a variety of materials with high precision. The laser beam is focused on a small spot, which allows for cutting with extreme accuracy, making it ideal for applications requiring intricate designs and fine details.

Here’s why fiber laser cutting machines are the preferred choice for many industries:

High Precision and Accuracy: One of the most significant advantages of fiber laser cutting machines is their precision. They can cut complex shapes and patterns with minimal deviation, ensuring that each piece meets the exact specifications.

Speed and Efficiency: Fiber lasers are known for their high cutting speeds, which can greatly reduce production time. This speed does not compromise the quality of the cut, making it possible to produce more in less time.

Low Maintenance: Fiber laser cutting machines require less maintenance compared to other cutting technologies. This is because they have fewer moving parts and use fiber optics to deliver the laser beam, which reduces wear and tear.

Versatility: Fiber laser cutting machines are versatile and can cut a wide range of materials, including metals like steel, aluminum, brass, and copper. This versatility makes them suitable for various industries, from automotive to electronics.

Energy Efficiency: These machines are more energy-efficient than traditional cutting methods, which can lead to significant cost savings in the long run. Their lower energy consumption also makes them an environmentally friendly option.

GK Laser Enterprises - Your Trusted Partner in Thane

At GK Laser Enterprises, we understand the needs of businesses in Thane and beyond. Our fiber laser cutting machine in Thane are designed to deliver exceptional performance, reliability, and value. Here’s why GK Laser Enterprises is the best choice for your fiber laser cutting needs:

Advanced Technology: We offer the latest in fiber laser cutting technology. Our machines are equipped with advanced features that ensure precise cuts, high efficiency, and long-lasting performance.

Customization: We understand that every business has unique needs. That's why we offer customized solutions to meet your specific requirements. Whether you need a machine for high-volume production or specialized cutting tasks, we can tailor our products to suit your needs.

Expert Support: Our team of experts is always available to provide support and guidance. From helping you choose the right machine to providing after-sales service, we're here to ensure you get the most out of your investment.

Competitive Pricing: At GK Laser Enterprises, we believe in offering high-quality products at competitive prices. We work closely with our clients to provide cost-effective solutions without compromising on quality.

Training and Installation: We don't just sell machines; we also ensure that you know how to use them effectively. Our comprehensive training programs cover everything from basic operation to advanced techniques, ensuring that your team can operate the machine with confidence. Additionally, our skilled technicians handle the installation process, ensuring your machine is set up correctly and ready for immediate use.

Applications of Fiber Laser Cutting Machines

Fiber laser cutting machines from GK Laser Enterprises can be used in various applications, including:

Automotive Industry: For cutting parts and components with high precision.

Electronics Industry: For cutting thin sheets of metal used in electronic devices.

Jewelry Making: For creating intricate designs on metal.

Construction: For cutting structural materials and metal frameworks.

Conclusion

Investing in a fiber laser cutting machine from GK Laser Enterprises in Thane is a smart decision for businesses looking to enhance their production capabilities. With our advanced technology, customized solutions, and dedicated support, we ensure that you get the best value for your money.

Contact us at GK Laser Enterprises today to learn more about our fiber laser cutting machines and how they can benefit your business.

0 notes

Text

Exploring Laser Cutting Machine Manufacturers and Prices in Hyderabad

Hyderabad, a city renowned for its technological innovation and manufacturing prowess, has become a significant hub for laser cutting machine manufacturers. Whether you're a small business looking to expand your production capabilities or an industrial giant in need of precision cutting tools, Hyderabad offers a variety of options tailored to meet your needs. This blog will delve into the landscape of laser cutting machine manufacturers in Hyderabad and explore the factors influencing laser cutting machine prices in the region.

The Rise of Laser Cutting in Hyderabad

As industries in Hyderabad continue to grow, the demand for advanced manufacturing technologies like laser cutting machines has surged. These machines are integral to sectors such as automotive, aerospace, electronics, and metal fabrication due to their precision, efficiency, and ability to handle complex designs. The rise in demand has encouraged numerous manufacturers to establish a presence in Hyderabad, making the city a key player in the laser cutting market.

Leading Laser Cutting Machine Manufacturers in Hyderabad

Hyderabad hosts several reputable laser cutting machine manufacturers, each offering a range of products tailored to different industrial needs. Here are some of the leading manufacturers:

SLTL Group: Known for its innovative laser solutions, SLTL Group is a prominent name in Hyderabad's manufacturing landscape. They offer a wide range of laser cutting machines, including fiber laser cutting machines, CO2 laser cutters, and hybrid models, all designed to deliver precision and efficiency.

Prakash Laser: Another significant player, Prakash Laser, offers advanced laser cutting machines that cater to various industries. Their machines are known for their durability, precision, and ease of use, making them a popular choice among Hyderabad's industrial sector.

Perfect Laser: Perfect Laser has made a name for itself by providing high-quality laser cutting machines that offer excellent performance at competitive prices. Their machines are designed for versatility, handling everything from thin metals to thicker materials with ease.

Understanding Laser Cutting Machine Prices in Hyderabad

When considering the purchase of a laser cutting machine in Hyderabad, it's essential to understand the factors that influence pricing. The cost of a laser cutting machine can vary widely depending on several key factors:

Type of Laser Cutting Machine: The type of laser cutting machine—fiber, CO2, or hybrid—plays a significant role in determining the price. Fiber laser machines tend to be more expensive due to their efficiency and ability to cut through thicker materials.

Power and Speed: Higher-powered machines that offer faster cutting speeds generally come at a premium. However, investing in a more powerful machine can lead to long-term savings by reducing production time.

Brand and Features: Established brands with a reputation for quality often charge higher prices. Additionally, machines equipped with advanced features like automation, multi-axis cutting, or specialized software can increase the overall cost.

After-Sales Service and Support: Manufacturers that offer comprehensive after-sales service, including installation, training, and maintenance, may charge more. However, this added support can be invaluable in ensuring the longevity and performance of the machine.

Import vs. Local Manufacturing: Machines imported from international manufacturers might be more expensive due to customs duties and shipping costs. On the other hand, locally manufactured machines could offer better value for money while maintaining high standards of quality.

Finding the Right Laser Cutting Machine in Hyderabad

When searching for a laser cutting machine in Hyderabad, it's crucial to balance your budget with your specific needs. Start by identifying the materials you'll be working with, the production volume, and any special requirements like intricate design work or high-speed cutting. From there, explore the offerings of various manufacturers, comparing features, pricing, and customer reviews.

Consider reaching out to manufacturers directly to request a quote and discuss your needs in detail. Many companies offer demos or trials, allowing you to test the machine's capabilities before making a purchase. Additionally, don't overlook the importance of after-sales support, as a reliable service provider can make a significant difference in your overall experience.

Conclusion

Hyderabad's robust manufacturing sector offers a wealth of options for those in the market for a laser cutting machine. By understanding the factors that influence pricing and researching the top manufacturers, you can make an informed decision that meets your production needs and budget. Whether you're looking for a high-powered machine for industrial applications or a more affordable option for smaller projects, Hyderabad has a laser cutting solution for you.

0 notes

Text

How to Choose the Best Fiber Laser Cutting Machine Manufacturer

In the fast-paced world of metal fabrication, it is very important to choose the right metallurgical machine to ensure the highest quality. accuracy, efficiency, and longevity of the machine. As a company like Weldarc India, a renowned manufacturer of fiber laser cutting and concrete machines, we understand the importance of decision-making when choosing a supplier. Here is a comprehensive guide to help you choose the best fiber laser cutting machine manufacturer.

Know your needs

Before entering the selection process, it is important to be clear about your needs. Consider the following:

1. Material types and thickness

Different fiber laser cutting machines are designed to handle different types and thicknesses. Make sure the manufacturer offers machines that can cut the type of metal you're working with, whether it's stainless steel, aluminum, copper, or metal.

2. Output volume

Set requirements for output volume. High production environments require machines with higher cutting speeds and more power to meet demand.

3. Precision and Quality

If your project requires precision and a high-quality finish, look for manufacturers known for their advanced laser technology and ability to cut accurately.

Research Manufacturers Once you've identified your needs, you can begin researching potential manufacturers. Below, you will find some important information:

4. Reputation and experience

Choose a builder who has a good reputation and experience in the industry. Established companies like Weldarc India have a proven track record and a deep understanding of technology and market requirements.

5. Customer reviews and testimonials

Read customer reviews and testimonials to understand the manufacturer's credibility, product quality, and customer service. Positive feedback from other users is a strong indicator of a reliable manufacturer.

6. Certifications and standards

Ensure that the manufacturer complies with relevant industry standards and certifications. Adherence to standards such as ISO ensures that machines meet quality and safety requirements.

Evaluation of product range

A diverse product range reflects a manufacturer's ability to meet different needs. Evaluate their applications based on:

7. Machine specifications

Look at the technical specifications of the machines, such as power output, cutting speed, accuracy, and computer compatibility. Make sure that the requirements are as per your needs.

8. Technology and innovation

Manufacturers that invest in research and development are more likely to deliver technology. Look for features like automatic loading and unloading systems, advanced software integration, and efficient cooling systems. 9. Customization Options Some projects require custom solutions. Choose a manufacturer that offers customization options to adapt the device to your specific needs.

Assessing Support and Service

After-sales support and service are essential to maintaining the performance and longevity of your equipment. Consider the following:

10. Technical Support

Reliable technical support guarantees that problems are quickly resolved. Check if the manufacturer offers comprehensive technical support, including remote assistance and on-site service.

11. Training programs

Proper training will enable your team to operate the machine efficiently and safely. Choose manufacturers that offer comprehensive training programs for your employees. 12. Maintenance and availability of spare parts

Regular maintenance is important for the life of the machine. Make sure the manufacturer offers maintenance services and spare parts are available to minimize downtime.

Compare prices

While price is not the only deciding factor, it is important to get value for your investment. Compare prices from different manufacturers, remember:

13. Initial price vs. Long-term value

Consider the initial purchase price versus the long-term value of the unit. The higher initial cost can be offset by the unit's durability, efficiency, and lower operating costs over time.

14. QUESTIONS AND WARRANTIES

A comprehensive warranty provides peace of mind and protection against possible errors. Check the warranty terms provided by the manufacturer.

Making the Final Decision

After researching and comparing, narrow down your options and make an informed decision. Here are some final steps:

15. Visit the manufacturer

If possible, visit the manufacturer's facility to see the machines in action and assess quality closely. This also provides an opportunity to meet the group and discuss your interests.

16. Request a Show

Request a showing of the cars you want. This way you can see what they are doing and make sure they meet your expectations.

17. Review Contracts and Agreements

Carefully review all contracts and agreements before purchasing. Make sure all terms are explained, including delivery times, prices, and after-sales support.

Conclusion

Choosing fiber laser cutting machine manufacturers is an important decision related to production efficiency and product quality. By knowing your needs, researching the manufacturers, evaluating their products, and evaluating their support services, you can make the right choice. Companies like Weldarc India, with their vast experience and commitment to quality, are a good choice to ensure you get a reliable and high-performance fiber laser cutting machine. Investing in the right manufacturer will not only enhance your operational capabilities but also ensure long-term success in the competitive metal industry.

#welding#weldarc india#industrial welding solutions#welding technology#fiberlasercuttingmachines#fiber laser cutting machine manufacturers#fiber laser cutting machines#welding products#weldarcindiapvtltd#faridabad

0 notes

Text

Best CNC Laser Cutting Machine in India

Identifying the best CNC laser cutting machine in India involves more than just looking at specifications; it requires an understanding of the market dynamics, application needs, and technological advancements that define modern manufacturing. Among the top contenders, the MSB CNC Fiber Laser Cutting Machine stands out due to its exceptional precision and versatility. Designed for various materials such as metal, wood, and acrylic, this machine utilizes advanced fiber laser technology that not only enhances cutting speed but also reduces operational costs. Its user-friendly interface allows operators, even those with minimal training, to engage with the sophisticated software that controls the cutting process, ensuring accuracy and repeatability.

The robust build quality is matched by the safety features integrated into the design, such as automatic shut-off in case of malfunction, making it suitable for both small workshops and large-scale industrial applications. Furthermore, with the relevance of sustainability in manufacturing today, the MSB machine operates with lower energy consumption compared to traditional cutting machines, aligning with eco-friendly practices that many businesses are now adopting.

The support and after-sales service offered by manufacturers are equally crucial in solidifying customer trust. Companies that provide training, maintenance packages, and readily available spare parts often receive positive feedback from users looking to maximize uptime and machine longevity. When evaluating the best CNC laser cutting machines, it is essential to consider not just the initial investment but also the total cost of ownership, including maintenance, consumables, and the potential for technology upgrades.

Another key player in the Indian market is the HSG LASER cutting machine, known for its exceptional cutting quality and high-speed operation. This machine excels in industries where precision is paramount, such as automotive and aerospace, and features an intelligent control system that optimizes cutting paths and reduces waste material, ultimately increasing productivity. Customers have praised its reliability and performance, especially for intricate designs that require meticulous attention to detail.

Price is often a decisive factor; hence it is essential for prospective buyers to evaluate machines within their budget while also considering the potential return on investment based on their production needs. Entry-level models are available for smaller operations, while high-end machines cater to large manufacturing setups demanding high throughput and versatility.

Recent advancements in technology also mean that businesses can explore additional functionalities, such as 3D laser cutting and engraving capabilities, which can further enhance their service offerings and market competitiveness. Vendors that offer customization options for their CNC laser cutting machines are often seen as more appealing, as they allow businesses to tailor features according to specific operational requirements.

In conclusion, while the MSB CNC Fiber Laser Cutting Machine and HSG LASER stand out for their performance and customer support, selecting the best CNC laser cutting machine in India ultimately depends on the unique needs of the buyer. Focus on assessing machine specifications, total ownership costs, supplier service quality, and technological advancements in laser cutting is critical in making an informed decision. The right choice not only optimizes workflow efficiency but also positions a business for long-term growth in a competitive landscape, making the investment in a quality CNC laser cutting machine a strategic move rather than just a financial expenditure.

Email :- [email protected]

For More Info Visit Us At :- https://sawantgroup.co.in/

Mobile No :- +91 98810 66175

#best cnc bending services india#best mig welding machine#best spot welding services in pune#pre-treatment for surface preparation in pune#cnc bending#best tube#best ss fabrication services in india#cnc punching services in pune#machinery#cnc punching

0 notes

Text

New Fibre Laser Cutting Machines For Sale

Purchasing something expensive like fiber laser cutting machines is a big move. If in this scenario you get a good sale on the same then what can be better than that? Yes, World Machinery is an established organisation in the manufacturing industry that put New Fibre Laser Cutting Machines For Sale. If you wanna get acknowledged for the same instinctively, you can subscribe to our newsletter through the official website of World Machinery. What are you looking for? Subscribe to our Newsletter and get the new Fibre laser Cutting Machines at exciting prices.

0 notes

Text

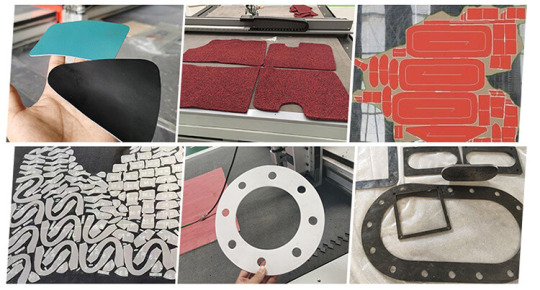

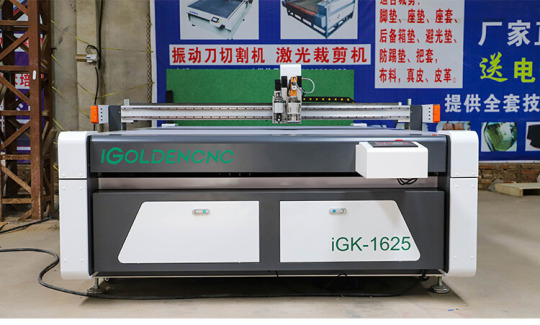

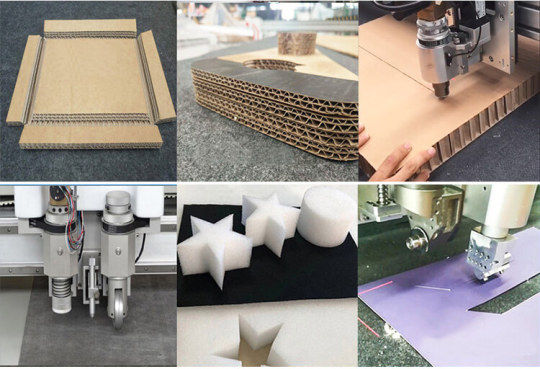

CNC Knife Cutter Machine for PE and EVA Foams

CNC knife cutter machines are widely used in industries such as packaging, textile, automotive, aerospace, and signage. They offer precise and efficient cutting capabilities, enabling the production of intricate shapes and patterns with minimal material waste.

Affordable cnc oscillating knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

CNC Knife Cutter Machine

A CNC knife cutter machine, also known as a CNC cutting machine or a CNC oscillating knife cutter, is a computer-controlled cutting system specifically designed for precision cutting of various materials. It utilizes a vibrating or oscillating knife, which moves rapidly up and down to cut through the material.

Affordable cnc oscillating knife machine have two types: ① CNC Router machine add oscillating knife cutting knife head (Knife together with spindle independent work, compatible with cnc router cotrol system, and running perfectly, Solve the processing needs of soft materials); ② Professional oscillating knife cutting machine ( Professional and efficient ). Accordding to functions: can be divided into oscillating knife cutting , round knife cutting, pneumatic knife cutting. you need to accordding to different material shapes cutting, choose different knives.

CNC can provide all kinds CNC Knife Cutter Machine for sale:

CCD camera series: automatic edge finding, automatic scanning, automatic imaging system.

CNC knife cutter machine table size:

CNC oscillating knife cutting machine for sale have model: 6090, 1390, 1410, 1610, 1325, 1530, 2030, and working table size 600*900mm, 900*1300mm, 1000*1400mm, 1000*1600mm, 1300*2500mm, 1500*3000mm, 2000*3000mm etc, maybe some regions describe cnc knife cutter machine table size with feet: 3*4, 3*5, 4*8, 5*10 etc. We also accept custom table sizes,to meet customer needs.

CNC Knife Cutter Machine Processing advantages

With the continuous development of numerical control technology, more and more customers choose to use smart cutting equipment instead of workers. It uses advanced oscillating knife cutting technology to select different tools according to material thickness and hardness. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

There are 6 advantages to using the CNC Knife Cutter Machine to cut the foam:

1. More flexible; EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials; automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting; can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized; AMOR EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Different types of tools can be configured; customers can configure different processing tools according to the processing materials – round knife, pneumatic knife, punching knife, vibrating knife, and other cutter heads to configure freely to cut other materials except for foam;

6. Achieve higher cutting efficiency; AMOR EVA foam cutting machine adopts Japanese Mitsubishi servo motor with cutting speed of up to 2000mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

CNC Knife cutter machine application

Affordable cnc Digital knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

Oscillating Knife Details

Cutting Capabilities

CNC knife cutter machine are versatile and can cut a wide range of materials, including but not limited to:

Soft materials: Foam, rubber, gaskets, textiles, carpets, felt, leather, etc.

Rigid materials: Cardboard, corrugated board, honeycomb board, thin plastics, composite materials, etc.

Other materials: Vinyl, paper, cork, magnetic sheets, adhesive-backed materials, and more.

The oscillating knife’s high-frequency motion allows for clean and precise cuts, even in intricate designs or complex patterns.

Additional Tool Option

In addition to the oscillating knife, CNC knife cutter machines can often accommodate other cutting tools or attachments, expanding their capabilities. Some common additional tools include:

Creasing wheels: Used for creating creases or scoring lines in materials like cardboard or paper, enabling easier folding or bending.

Perforation wheels: Used to create perforated lines for tear-off sections in materials like paper or cardboard.

Routing attachments: Used for cutting harder materials like acrylic or wood, where an oscillating knife may not be suitable.

The ability to interchange tools allows for more versatility in the types of materials and applications that can be handled by the machine.

High Precision and Repeatability

CNC knife cutter machines offer excellent precision and repeatability in cutting. The computer-controlled nature of the machine ensures accurate cutting paths, resulting in consistent and high-quality finished products. This is especially beneficial for industries that require precise fitting, such as packaging or automotive interior components.

Design Flexibility

With the help of specialized software, CNC knife cutter machines can process various design file formats, allowing for flexibility in design creation. Designs can be imported from computer-aided design (CAD) software or created directly within the cutting software. This flexibility enables customization, prototyping, and small-batch production with ease.

Production Efficiency

CNC knife cutter machines streamline the cutting process, reducing manual labor and increasing production efficiency. Once the cutting program is set up, the machine can autonomously execute the cutting tasks, optimizing material usage and minimizing waste. This automation also allows for faster turnaround times, enabling manufacturers to meet tight deadlines and handle larger production volumes.

Integration with Workflow

CNC knife cutter machine can be integrated into a larger production workflow, connecting with other equipment or systems. This integration facilitates seamless material handling, automated nesting (arranging shapes to minimize material waste), and data exchange, enhancing overall productivity and efficiency.

0 notes

Text

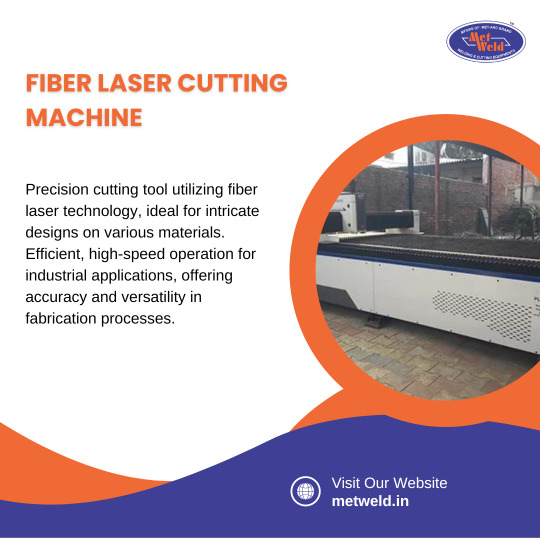

High-Quality Fiber Laser Cutting Machines

In the realm of manufacturing precision and efficiency, high-quality Fiber Laser Cutting Machines stand out as the pinnacle of modern engineering. These cutting-edge machines offer unparalleled precision, speed, and versatility, making them indispensable in various industries. As a leading manufacturer of Fiber Laser Cutting Machines, we take pride in delivering cutting-edge solutions that redefine the standards of excellence. Our machines are meticulously crafted using state-of-the-art technology and superior quality materials, ensuring optimal performance and longevity.

As a Fiber Laser Cutting Machines manufacturer, we understand the critical importance of reliability and precision in every component. From the robust frame to the advanced laser technology, each aspect is engineered to deliver consistent, high-quality results. Our commitment to innovation drives us to continually refine and enhance our machines, staying ahead of industry trends and meeting the evolving needs of our customers.

When it comes to Fiber Laser Cutting Machines, precision is paramount. Our machines are meticulously calibrated and tested to ensure the highest level of accuracy, allowing for intricate cuts with minimal material wastage. Whether you're working with thin sheets or thick plates, our machines deliver unparalleled precision, efficiency, and reliability, empowering you to achieve exceptional results with every cut.

As a Fiber Laser Cutting Machines manufacturer, we prioritize customer satisfaction above all else. From initial consultation to after-sales support, we strive to provide comprehensive solutions tailored to meet your specific requirements. With our commitment to quality, innovation, and customer service, we are your trusted partner in the pursuit of excellence in fiber laser cutting technology.

#fiberlasercuttingmachine#fiberlaesrcuttingmachinemanufacturers#industrialproducts#industrialequipment#metweld#cncmachines#manufacturers

0 notes

Text

How to Choose India's Top Manufacturers of Robotic Welding Machines

The modern industrial environment demands automation, efficiency, and precision more than ever. Robotic welding robots, which offer unmatched accuracy and speed in welding processes, have completely changed the manufacturing industry. Selecting the best robotic welding machine manufacturers in India is essential for companies trying to stay competitive. The most important things to take into account when choosing the ideal manufacturer for your requirements are covered in this article.

Recognizing the Value of Robotic Welding

Modern production relies heavily on robotic welding equipment, especially in industries like heavy machinery, aerospace, and automotive. By automating tedious operations, these devices improve worker safety, provide uniform weld quality, and cut down on material waste. The number of firms providing robotic welding solutions is growing along with the demand for these products. But not every manufacturer offers the same caliber of innovation, service, and quality.

Important Things to Think About When Selecting a Manufacturer

1. Credibility and Background

A manufacturer's experience and reputation are important determinants of its dependability. Reputable manufacturers with a track record of success are more likely to offer dependable after-sales support and top-notch equipment. Examine case studies, testimonials, and reviews from customers to determine the manufacturer's reputation in the market.

For example, Weldarc India has established a strong name in the Indian market thanks to its state-of-the-art fiber laser cutting machines. With years of experience and a wide range of products, companies like these frequently have the know-how to customize robotic welding systems to meet the demands of particular industries.

2. Innovation in Technology

With ongoing developments in automation, artificial intelligence, and precision welding methods, the field of robotic welding is expanding quickly. Research and development (R&D)-focused manufacturers are more likely to present creative solutions that can boost your manufacturing efficiency.

Seek out suppliers of robotic welding equipment with the newest technology available, such as real-time monitoring, adaptive control systems, and smooth connection with other automation systems. This technical advantage may completely alter the way that businesses compete in the marketplace.

3. Customization Abilities

When it comes to welding operations, every business has different needs. A one-size-fits-all strategy might not work. Prominent producers provide customization choices so that robotic welding robots can be customized to meet certain requirements. Modifiable features like software integration, specific welding heads, and machine size adjustments guarantee that the machine will work flawlessly as part of your production line.

Weldarc India, for instance, demonstrates their capacity to meet a variety of industrial needs by not only manufacturing fiber laser cutting machines but also providing a range of welding goods. It is important to have this flexibility when choosing a manufacturer.

4. After-Sale Assistance and Maintenance

Investing heavily in a robotic welding system requires constant support to keep it operating properly. Take into account the post-purchase services offered by the manufacturer, such as installation, training, upkeep, and repair. Reducing downtime and sustaining productivity can be greatly aided by having a readily available supply of spare parts and a customer support team that responds quickly.

It is better to engage with manufacturers who have a significant presence in India, such as those who provide extensive service networks. This local presence guarantees that you won't have to wait a long time to receive the assistance you require.

5. Economy of Cost

Even if it plays a big role, cost shouldn't be the only thing taken into account. Sometimes the best value isn't necessarily found in the cheapest alternative. Rather, concentrate on the machine's total cost-effectiveness, taking into account aspects like durability, energy efficiency, and the possibility of long-term savings through lower maintenance and higher output.

Examine the total cost of ownership for various manufacturers, accounting for the machine's anticipated lifespan, running expenses, and original investment. If a somewhat greater initial cost results in cheaper operating costs and a longer equipment life, then it might be justified.

6. Adherence to Industry Standards

Robotic welding equipment has to abide by strict industry norms and guidelines, especially when it comes to quality and safety. Verify that the manufacturer satisfies all applicable regulatory standards, including ISO certifications. This compliance protects the safety of your operations in addition to the machine's quality.

Long-term investment protection is ensured by manufacturers who adhere to the most recent industry standards and are more likely to produce machines that satisfy present and future regulatory needs.

Know more: Fiber Laser Cutting Machine manufacturer

The Function of Manufacturers of Fiber Laser Cutting Equipment in Robotic Welding

In modern manufacturing, robotic welding is frequently combined with fiber laser cutting technologies. Prominent producers such as Weldarc India provide a complete solution for your production demands by offering both robotic welding systems and fiber laser cutting machines. Higher precision and efficiency may be achieved by combining these technologies, thus it's critical to take into account suppliers who have experience in both fields.

In summary

Selecting the best robotic welding machine manufacturer in India necessitates carefully weighing several criteria, including reputation, cost-effectiveness, industry standards compliance, technical innovation, customization possibilities, and after-sales support. Manufacturers with experience in cutting and welding technologies, such as Weldarc India, provide a dependable choice for companies wishing to improve their manufacturing capacities.

You can be sure that the manufacturer you choose will not only satisfy your present requirements but also foster your future expansion and creativity in the cutthroat manufacturing market by concentrating on these important factors.

#Robotic Welding Machine Manufacturers India#Fiber Laser Cutting Machine manufacturer#welding products manufacturer in India#Welding Machine manufacturer in India#robotic welding systems#welding automation#industrial welding machines#laser welding machines#automated welding solutions#welding technology in India

0 notes

Text

An introduction to the concept of laser engraving machine manufacturers

Laser engraving machines are sophisticated tools used for a variety of applications, from industrial manufacturing to personal crafting projects. Here's an introduction to the concept of laser engraving machine manufacturers:

Laser Engraving Machine Manufacturers: An Overview

Laser engraving machine manufacturers are companies that specialize in the design, development, and production of laser engraving equipment. These machines use focused laser beams to engrave or etch designs onto various materials, including wood, metal, plastic, glass, and more. The precision and versatility of laser engraving machines make them invaluable in a wide range of industries, such as:

Craftsmanship and Art: For intricate designs on small items.

Industrial Production: For mass production of engraved parts or products.

Personalization: For customizing items with names, logos, or unique designs.

Key Features of Laser Engraving Machines

Manufacturers typically offer a range of laser engraving machines with different capabilities, including:

Laser Power: The power of the laser beam, measured in watts, determines the machine's cutting and engraving depth.

Work Area: The size of the surface area that can be worked on at one time.

Precision: The level of detail the machine can achieve, often measured in microns.

Speed: The rate at which the machine can complete an engraving task.

Software Compatibility: The ability to work with various design and control software.

Notable Manufacturers

Some of the notable laser engraving machine manufacturers include:

Ortur Lasers: Known for affordable and high-quality laser engravers, such as the Ortur Laser Master series.

HGLaser: A pioneer in laser industry applications, offering a range of laser equipment.

Universal Laser Systems (ULS): Specializes in CO2 and fiber laser systems for various applications.

Epilog Laser: Offers a wide range of laser engraving and cutting machines for both business and personal use.

Gravograph: Provides laser engraving solutions for various materials and industries.

Choosing a Manufacturer

When selecting laser engraving machine manufacturers, consider the following factors:

Reputation: The manufacturer's standing in the industry and customer reviews.

Product Range: The variety of machines and capabilities offered.

Support and Service: The availability of technical support, warranty, and after-sales service.

Customization: The ability to customize machines to specific needs or industry standards.

Pricing: The cost of the machine in relation to its features and capabilities.

Manufacturers often provide detailed specifications, user manuals, and software to help customers get the most out of their laser engraving machines. Investing in a machine from a reputable manufacturer ensures quality, reliability, and longevity in your laser engraving projects.

0 notes

Text

Double Table Fiber Laser Cutting Machine Market Size, Share, Growth Analysis, Trends and Forecast 2031

The global "Double Table Fiber Laser Cutting Machine Market Market" report indicates a consistent and robust growth trend in recent times, projecting a positive trajectory expected to persist until 2031. A significant trend observed in the Double Table Fiber Laser Cutting Machine Market market is the rising consumer inclination towards environmentally sustainable and eco-friendly products. Furthermore, a notable advancement in this market is the increasing incorporation of technology to elevate both product quality and efficiency. Cutting-edge technologies like artificial intelligence, machine learning, and block chain are actively employed to develop innovative products that outperform traditional options in terms of effectiveness and efficiency. The Double Table Fiber Laser Cutting Machine Market Market Research Report for 2024 highlights emerging trends, growth opportunities, and potential scenarios envisioned up to the year 2031.

By delving into the latest trends, the report keeps businesses abreast of the dynamic market environment, helping them identify emerging opportunities and navigate potential challenges. The meticulous analysis covers various aspects, offering valuable insights into the historical performance of the market and presenting the current (CAGR) status.

Get a Sample Copy of the Report at: https://www.proficientmarketinsights.com/enquiry/request-sample-pdf/1823

Who are the biggest Double Table Fiber Laser Cutting Machine Market manufacturers worldwide?

Han's Laser (China)

Amada (Japan)

LVD (Belgium)

Penta-Chutian (China)

HG Laser (China)

The Double Table Fiber Laser Cutting Machine Market Market is described briefly as follows:

The global Double Table Fiber Laser Cutting Market size was USD 1027.8 million in 2024 and the market is projected to touch USD 1686.1 million by 2031, exhibiting a CAGR of 8.60 % during the forecast period.

SWOT Analysis of Double Table Fiber Laser Cutting Machine Market Market:

A SWOT analysis involves evaluating the strengths, weaknesses, opportunities, and threats of a particular market or business. In the case of the keyword market, we'll be looking at the factors that can impact the industry's performance.

Pestle Analysis of Double Table Fiber Laser Cutting Machine Market Market:

To better comprehend the market environment, a five-force analysis is performed, which takes into account the bargaining power of the customer, the supplier, the threat of substitutes, the threat of new entrants, and the threat of competition.

Get a Sample Copy of Double Table Fiber Laser Cutting Machine Market Market Report

What are the Types in Double Table Fiber Laser Cutting Machine Market Market?

Open Type Fiber Laser Cutting Machine

Closed Type Fiber Laser Cutting Machine

What are Applications in Double Table Fiber Laser Cutting Machine Market Market?

General Machinery Processing

Automotive Industry

Home Appliance

Aerospace and Marine

Others

Inquire or Share Your Questions If Any before the Purchasing This Report:https://www.proficientmarketinsights.com/enquiry/queries/1823

Geographical Segmentation:

Geographically, this report is segmented into several key regions, with sales, revenue, market share, and Double Table Fiber Laser Cutting Machine Market market growth rate in these regions, from 2017 to 2028, covering

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia, and Vietnam)

South America (Brazil etc.)

Middle East and Africa (Egypt and GCC Countries)

Some of the key questions answered in this report:

Who are the worldwide key Players of the Double Table Fiber Laser Cutting Machine Market Industry?

How the opposition goes in what was in store connected with Double Table Fiber Laser Cutting Machine Market?

Which is the most driving country in the Double Table Fiber Laser Cutting Machine Market industry?

What are the Double Table Fiber Laser Cutting Machine Market market valuable open doors and dangers looked by the manufactures in the worldwide Double Table Fiber Laser Cutting Machine Market Industry?

Which application/end-client or item type might look for gradual development possibilities? What is the portion of the overall industry of each kind and application?

What centered approach and imperatives are holding the Double Table Fiber Laser Cutting Machine Market market?

What are the various deals, promoting, and dissemination diverts in the worldwide business?

What are the key market patterns influencing the development of the Double Table Fiber Laser Cutting Machine Market market?

Financial effect on the Double Table Fiber Laser Cutting Machine Market business and improvement pattern of the Double Table Fiber Laser Cutting Machine Market business?

Purchase this Report (Price 3200 USD for A Single-User License) at:https://www.proficientmarketinsights.com/purchase/1823

TOC of Global Double Table Fiber Laser Cutting Machine Market Market Research Report 2023

1 Double Table Fiber Laser Cutting Machine Market Market Overview

2 Market Competition by Manufacturers

3 Double Table Fiber Laser Cutting Machine Market Production by Region

4 Double Table Fiber Laser Cutting Machine Market Consumption by Region

5 Segment by Type

6 Segment by Application

7 Key Companies Profiled

8 Industry Chain and Sales Channels Analysis

9 Double Table Fiber Laser Cutting Machine Market Market Dynamics

10 Research Finding and Conclusion

11 Methodology and Data Source

0 notes

Video

youtube

Hot sale 4 in1 3KW handheld fiber laser welding cleaning cutting machin...

0 notes

Text

Crafting a Unique Experience: The Journey of Shandong Yunlian Technology Co., Ltd.

In the fast-paced world of technology, Shandong Yunlian Technology Co., Ltd. has emerged as a pioneer, crafting unique and innovative solutions in the laser machinery industry. Since its establishment, the company has been on a journey of constant growth and innovation, transforming the landscape of laser technology.

At the heart of Shandong Yunlian Technology lies its commitment to research and development. The company's team of dedicated professionals is constantly pushing the boundaries of laser technology, developing cutting-edge machines that are not just efficient but also reliable and long-lasting. This focus on innovation has enabled the company to create a diverse range of products that cater to the needs of factories worldwide.

One of the key products in Shandong Yunlian Technology's portfolio is its fiber laser welding machines. These machines are designed to provide precision welding at high speeds, ensuring consistent results and increased production efficiency. The company's laser cleaning machines, on the other hand, offer a safe and effective way to remove surface contaminants, restoring the original finish of materials.

In addition to its product line, Shandong Yunlian Technology also prides itself on its commitment to quality. The company holds certifications such as CE, FDA, and ISO9001, which are testament to its dedication to meeting the highest standards of quality and safety. This commitment extends to its after-sales service as well, ensuring that customers receive prompt and professional support whenever they need it.

The journey of Shandong Yunlian Technology has not been without challenges, but the company has always emerged stronger and more resilient. Its success can be attributed to its unwavering commitment to innovation, quality, and customer satisfaction. As the company continues to grow and expand, it remains focused on its mission: to create laser machinery that transforms factories and industries, driving them towards a brighter future.

Looking ahead, Shandong Yunlian Technology plans to continue its journey of innovation and growth. The company is exploring new technologies and applications that will further enhance the capabilities of its machines, making them even more efficient and user-friendly. With its commitment to excellence and dedication to its customers, Shandong Yunlian Technology is poised to lead the laser machinery industry into an exciting new era.

0 notes

Text

best cnc laser cutting machine in india

As of my last update in January 2022, the "best" CNC laser cutting machine can vary based on specific requirements such as cutting precision, speed, material compatibility, and budget. However, several brands are known for producing high-quality CNC laser cutting machines in India. Here are a few reputable options:

Trumpf: Trumpf is a globally recognized manufacturer of CNC laser cutting machines known for their precision, reliability, and cutting-edge technology. They offer a range of machines suitable for various applications and industries.

Bystronic: Bystronic is another leading manufacturer of CNC laser cutting machines, offering innovative solutions for sheet metal processing. Their machines are known for their high performance, energy efficiency, and advanced features.

Amada: Amada is renowned for producing a wide range of CNC laser cutting machines designed to meet the needs of diverse industries. Their machines are known for their exceptional quality, accuracy, and durability.

Prima Power: Prima Power offers a comprehensive range of CNC laser cutting machines, including fiber lasers and CO2 lasers, catering to different cutting requirements. Their machines are known for their speed, flexibility, and cost-effectiveness.

Mazak: Mazak is a trusted name in the manufacturing industry, offering CNC laser cutting machines that deliver precision cutting and superior performance. Their machines are known for their reliability, innovation, and user-friendly interface.

When considering the best CNC laser cutting machine for your needs, it's essential to evaluate factors such as cutting capacity, laser power, machine size, software compatibility, service and support, and overall value for money. Additionally, reaching out to dealers or representatives of these brands, such as Sawant Group in Pune, can provide valuable insights and assistance in selecting the right machine for your specific requirements. Always ensure to inquire about warranty, after-sales service, and training options to make an informed decision.

We provide :-

best cnc laser cutting machine in india

CNC punching services in pune

best MIG Welding Machine

Pre-Treatment for Surface Preparation in pune

best CNC bending services india

best SS fabrication services in india

best spot welding services in pune

best tube, pipe, and angle cutting services in Pune

best automotive manufacturers in pune

best manufacturing and assembly services

We Provide

For more info,:-https://sawantgroup.co.in/[email protected]

0 notes