#Film Rewinder Machine Manufacturer

Text

Roll Slitting Machine Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The Roll Slitting Machine Global Market Report 2024 by The Business Research Company provides market overview across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa, encompassing 27 major global industries. The report presents a comprehensive analysis over a ten-year historic period (2010-2021) and extends its insights into a ten-year forecast period (2023-2033).

Learn More On The Roll Slitting Machine Market:

https://www.thebusinessresearchcompany.com/report/roll-slitting-machine-global-market-report

According to The Business Research Company’s Roll Slitting Machine Global Market Report 2024, The roll slitting machine market size is expected to see strong growth in the next few years. It will grow to $2.95 billion in 2028 at a compound annual growth rate (CAGR) of 5.1%. The growth in the forecast period can be attributed to expansion of the renewable energy sector, expansion of the printing and converting industry, growth in flexible packaging, and increased use of flexible packaging materials, development of e-commerce. Major trends in the forecast period include development of advanced automation and control systems, precision cutting technologies, development of energy-efficient and waste-reducing slitting technologies, customization and versatility, and digital control systems.

The growing e-commerce industry is expected to propel the growth of the roll-slitting machine market going forward. The e-commerce industry encompasses online platforms where goods and services are bought and sold electronically, facilitating transactions between businesses, consumers, and suppliers worldwide. The growth is supported by increased internet penetration, the convenience of online shopping, broader product availability, and evolving consumer preferences towards digital transactions. Roll slitting machines are required in the e-commerce industry for efficiently processing and packaging various materials, like packaging films and labels used in shipping and product packaging. For instance, in October 2021, according to a report published by the International Trade Administration, a US-based agency, it is anticipated that e-commerce for consumer goods will constitute approximately 22% of global retail sales in 2024, with a projected average annual growth rate exceeding 1%. Additionally, global retail e-commerce sales are expected to maintain a steady increase of 8% annually through 2024. Therefore, the growing e-commerce industry is driving the growth of the roll-slitting machine market.

Get A Free Sample Of The Report (Includes Graphs And Tables):

https://www.thebusinessresearchcompany.com/sample.aspx?id=17250&type=smp

The roll slitting machine market covered in this report is segmented –

1) By Type: Roll Or Log Slitters, Slitter Rewinders

2) By Material: Paper, Polymers, Foil, Other Materials

3) By Slitter Blade: Large Circular Blade, Fixed Band Blade

4) By Distribution Channel: Direct Sales (Original Equipment Manufacturer (OEM)), Indirect Sales

5) By Industry: Paper And Pulp, Textile, Packaging, Other Industries

Major companies operating in the roll slitting machine market are developing technologically advanced products, such as high-performance rewinder slitters, to better serve customers with advanced features. A high-performance rewinder slitter is a precision machine designed to efficiently slit and rewind various materials, such as paper, film, and foil, with exceptional speed and accuracy. It is often used in industrial manufacturing processes. For instance, in February 2022, Vemax, a Brazil-based machinery company, launched the Vemax VRXS STDH Rewinder Slitter. The distinctive feature of Vemax's high-performance equipment lies in its differential axles, tailored for heavy-duty operations with paper, plastic, or self-adhesive films, serving flexible packaging, labeling, and tag industries globally. These machines integrate an advanced control system, enabling direct communication via an internal network with the machine's PLC and all electronic components. This technology facilitates remote and online programming adjustments and repairs, emphasizing innovation, safety, and quality in flexible packaging machinery.

The roll slitting machine market report table of contents includes:

1. Executive Summary

2. Roll Slitting Machine Market Characteristics

3. Roll Slitting Machine Market Trends And Strategies

4. Roll Slitting Machine Market - Macro Economic Scenario

5. Global Roll Slitting Machine Market Size and Growth

.............

32. Global Roll Slitting Machine Market Competitive Benchmarking

33. Global Roll Slitting Machine Market Competitive Dashboard

34. Key Mergers And Acquisitions In The Roll Slitting Machine Market

35. Roll Slitting Machine Market Future Outlook and Potential Analysis

36. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Pelican Rotoflex with gravure press and turret slitter — hall 10/C03

Pelican Rotoflex, a leading manufacturer of converting machinery, will be present at drupa 2024 with its Solomark 6450 rotogravure press and the latest Acrostar turret slitter. While the rotogravure press will just be showcased at the two printing units, there will be a live demonstration of the Acrostar turret slitter.

Sanat Gandhi, senior technical executive, Pelican Rotoflex, said, “Due to certain restrictions on the usage of inks and solvents at the drupa 2024 exhibiting hall, we will not be able to present any live demonstration of Solomark 6450. Visitors, however, can witness a live demonstration of our recently launched turret slitter.”

Led by ELS technology, the Solomark 6450 rotogravure press operates at a speed of up to 450 m/min and offers excellent web processing capabilities for various films, including thinner, and more sustainable substrates. The machine is equipped with a unique semi-floation dryer with 3D and 2D hole technology for quick drying and a high-efficiency ventilation module that ensures minimal solvent residue on the substrate.

With a changeover of rewinder within 30 seconds regardless of the number of rewinds, the Acrostar turret slitter is characterized by closed-loop tension control on the rewinder with load cell feedback, which ensures consistent high-quality finished rolls. Its innovative shaft support design extends the life of the differential shaft, even under rotational loads, thus enhancing durability and reliability.

Pelican Rotoflex will be present at drupa 2024, in hall 10/C03

0 notes

Text

An Overview of Stretch Film Manufacturing Machines: Types and Functions

Stretch Film Manufacturing Machines are specialized pieces of equipment used to produce stretch film, which is commonly used for packaging and securing products during transportation and storage. These machines play a crucial role in ensuring the durability, elasticity, and quality of the stretch film. Here's an overview of the types of stretch film manufacturing machines and their functions:

1. Blown Film Extrusion Machines:

Description: These machines use the blown film extrusion process to produce stretch film. The process involves melting polymer granules and extruding them through an annular slit die, followed by blowing to expand the film into a tube and cooling it to form the film.

Function: Blown film extrusion machines provide films with higher puncture resistance and more strength compared to other types. They allow for better control over film thickness and quality.

2. Cast Film Extrusion Machines:

Description: In contrast to blown film machines, cast film extrusion machines use a flat die to extrude the molten polymer. The extruded film is then cooled on chilled rollers.

Function: These machines produce films that are clearer and have better cling properties than blown films. Cast film machines generally have higher production rates and produce films with more consistent thickness.

3. Co-extrusion Film Machines:

Description: Co-extrusion machines combine multiple layers of material into a single stretch film product. These machines can have two or more extruders to process different types of polymers or the same polymer with different properties.

Function: The primary function is to produce multilayer stretch films, where each layer can impart different characteristics such as strength, cling, puncture resistance, or barrier properties.

4. Pre-stretch Film Machines:

Description: These machines are designed to stretch the film mechanically before it is wound onto rolls. The pre-stretching process improves the film's yield and can significantly reduce material costs.

Function: They elongate the film by using rollers rotating at different speeds. The resulting film is thinner but has increased strength and is more economical due to reduced material usage.

5. Rewinding Machines:

Description: After the film is extruded and wound onto large rolls, rewinding machines are used to convert these large rolls into smaller, more manageable rolls for commercial distribution.

Function: These machines rewind the film from the larger rolls to smaller ones, often adding a secondary layer of packaging. They can also be used to inspect the film for defects and ensure quality control.

6. Recycling Machines:

Description: In an effort to promote sustainability, some stretch film manufacturing setups include recycling machines that process production waste or used stretch film.

Function: These machines clean, melt, and pelletize the waste film, turning it back into a usable form for manufacturing, thus reducing waste and promoting circular economy practices.

Choosing the Right Machine:

The choice of machine depends on the desired film properties, production volume, and specific application requirements. For example, high-clarity film requirements might favor cast film machines, while high-strength films might be better produced with blown film machines.

By understanding the different types of Stretch Film Manufacturing Machines and their functions, manufacturers can select the most appropriate equipment to meet their production needs and produce high-quality stretch film for various packaging applications.

0 notes

Text

Ocean International - Excellent Plastic Manufacturing Machinery

Established in 2012, Ocean International stands tall as a premier manufacturer, exporter, and supplier of top-tier machinery including Slitting, Rewinding, Extruder, Plastic, Packaging, and Printing Machinery.

Crafting Machinery Excellence

Under the expert guidance of our accomplished mentors with extensive industry experience, we have solidified our position as a reputable organization. Our forte lies in manufacturing, supplying, and exporting an array of machinery, tailored to meet client specifications.

At Ocean International, we stand as pioneers in the realm of plastic machinery production. Fueled by an unwavering dedication to excellence and client contentment, we specialize in offering an expansive array of top-tier industrial equipment. Our offerings span a broad range of cutting-edge machinery, meticulously crafted to enhance operations in various sectors. Whether it's our meticulously designed Extrusion Machines meeting varied film production demands or our avant-garde Slitting & Rewinding Machinery ensuring flawless production flow, we provide a holistic range of solutions.

Know more about Plastic Recycling Machinery visit - https://oceaninternational.co/plastic-recycling-machine/

#BiodegradableBagMakingMachine#PlasticRecyclingMachine#ExtrusionMachine#PaperCoatingMachine#TwoLayerBlownFilmMachine#RotogravutePrintingMachine#AdhesiveCoatingLaminationMachine#BoppTapeCoatingMachine#TarpaulingMakingMachine#SyntheticStringSutliMakingMachine#StretchFilmMakingMachine#MulchFilmMakingMachine#MultilayerBlownFilmMachine#ExtrusionCoatingLaminationMachine#AirBubbleFilmMakingMachine#PpPetBoxStrappingMachine#PetBottleWashingLine#CantileverSlitterRewinderMachine#SlittingandRewindingMachinery#AdhesiveLaminationCoatingPlant#MonolayerBlownFilmMachine#AdhesiveCoatingMachine#FlexographicPrintingMachine#PrintingMachinery#BottomSealBagMachine#BagMakingMachinery

1 note

·

View note

Video

undefined

tumblr

Customized Roll to Roll CCD Guide Hole Punching Machine manufacturers From China | VILITY

We are a manufacturer of good reputation in SHENZHEN CHINA and Our main products are as follow: 1/ Screen printing machine CCD Visual alignment systems, High speed(150 impressions per minute) 2/ Guide hole punching machine and Hole Drilling machine ( Most famous factory in China ) . 3/ Die-cutting machine. ( High Precision and Fully Automatic ) . 4/ High Precision Laminator, film tearing machine. 5/ Oven Dryer, LED UV Dryer, ( High capacity and best price). 6/ Screen printing accessories. Feeding unit, multi-layer rack, rewinder and so on. 7/ Screen, screen frame customization.

0 notes

Text

Top Benefits Of An Air Shaft In Manufacturing

The manufacturing industry-centric air shaft is employed for fitting into the core that wounds a variety of materials, including paper, cards, and plastic films. It readily expands on fitting into a core, leading to flawless operation during the manufacturing cycle.

Plenty of industrial converting machines employ the product. A slitting machine, widely known as a slitter rewinder has an air shaft in its core. It is basically designed to cut or slit large rolls of different types of material into smaller rollers. How does its engineering work? In this regard, you can connect with a reputed air shaft manufacturer.

An air shaft is also recognized by many other names in the industry circles, including air expandable shaft and air expanding shaft.

Salient Features of the Air Shaft

A premium quality air shaft displays the following salient features during application:

Competent to adjust to different speed variations

Proficient to adjust to different core widths

Demonstrates high speed, when repositioning of the product doesn’t happen

Efficient gripping

Efficient core centering

Manages uneven cores

For detailed information, collaborate with a prominent air shaft manufacturer in Ahmedabad.

Manufacturing Industries Drawing Benefits from the Air Shaft

Manufacturing industries galore are drawing benefits from mechanical product, including:

Packaging

Steel

Paper

As far as dimension of the air shaft is concerned, it is available in different dimensions. In case, you are searching for a custom-designed air shaft, you can collaborate with a reputed air shaft manufacturer.

Applications

An airshaft is a mechanical device designed for handling winding reels in the processing of web-fed materials.

0 notes

Text

INDUSTRIAL ADHESIVE TAPE

As one of the professional industrial tape manufacturers in China, Egret supplies many types of industrial adhesive tape. Particularly, applied to refrigerator, air conditioning, ducting work, building, insulation industries. Not to mention our advantage of coating abilities, we also have capabilities to slit, cut, rewind, die cutting and other converting services. Important to realize, our strong adhesive tape is aluminum foil tape, PE tape, po film, PET tape, MOPP/TPP tape, PVC non-adhesive tape.

Choose Egret as Your Industrial Adhesive Tape Supplier

Choose Egret as Your Industrial Adhesive Tape Supplier. Egret mfg offers many kinds of adhesive tapes, including Aluminum foil tape, PE white tape, PET blue tape, Masking paper tape, Cloth tape, PVC air conditioner tape, Vinyl electrical tape, Double-sided tissue tape, TPP/MOPP tape, Foam tape (VHB,PE,PU, EPDM, NBR, PVC,EVA,etc), BOPP packing tape, Kraft paper tape, PE protective film, PVC duct tape, etc. We mix and produce our own formula adhesive to save cost & improve adhesion.

Moreover, Egret has 10 adhesive coating lines. Likewise, 15 slitting machines with huge capacity. Additionally, our products certified with UL, ROHS, REACH, BS, CE, etc.

Furthermore, we’re Top 1 seller for aluminum foil tape in refrigerator industry in China. Especially, Egret is a golden supplier of Samsung, Toshiba, Haier, Midea, Arcelik, Hisense, etc

Features Of Industrial Adhesive Tape

What are the benefits & features of Egret adhesive tape?

Egret adhesive tape can replace of the bolts and nuts, to make it clean looking.

High adhesion and excellent tack

Good aging resistance for both indoor & outdoor use

Joints/seams sealing against moisture and vapor barrier

Easy hand tear for workers to use on-site

Excellent heat & light reflecting of aluminum foil backing

Combination of baking material ensures high flexibility and conformability

Extremely easy for hand-tear, easy-used by workers

Neat and invisible looking to be excellent alternative to metal fasteners, welding

0 notes

Text

How Many Types Of Winding Machines Are There?

Textile engineers should possess a comprehensive understanding of the various types of winding machines utilized in the textile industry for converting yarn from bobbins, hanks, etc. into appropriate packaging. This article outlines the classification of these winding machines. Winding machines play a crucial role in the textile and paper industries, where large spools of material are commonly used. These machines enable the efficient wrapping of a variety of materials such as fabric, paper, string, cord, yarn, wire, tape, rope, twine, thread, and wire onto an industrial-sized spool as required. In essence, winding machines facilitate the initial spooling of vast quantities of materials. Are you looking for a textile machinery manufacturer in Gujarat that offers various types of winding machines? If yes, don’t wait and connect with Weavetech today.

How Does Winding Machine Work?

Winding machines typically consist of a rotating spindle or shaft that holds the core or spool onto which the material is wound. The material to be wound is usually fed through a guide mechanism that ensures uniform distribution across the spool. The spindle or shaft rotates, pulling the material onto the spool in a precise and controlled manner, with tension and speed being closely monitored to ensure quality winding. Depending on the type of winding machine, the spool may rotate, the material may be fed at a variable speed, or both. Some machines also have features such as automatic stop mechanisms or sensors to detect and alert the operator to any problems during the winding process. Overall, the winding machine operates with precision and consistency to ensure that the material is wound onto the spool in a uniform and efficient manner.

Types of Winding Machine?

Precision Winding Machines: These machines are used for winding fine wires, threads, and fibers onto spools, bobbins, or cones with high precision and accuracy. These machines are commonly used in the textile industry for manufacturing yarn, thread, and other fibers. Gujarat is a hub for textile machinery manufacturers in India, and there are several well-known manufacturers of precision winding machines in the state and Weavetech is one amongst them.

Drum Winding Machines: These machines are used for winding heavy wires, cables, and ropes onto large drums or spools. They are commonly used in the wire and cable industry. Drum winding machines are equipped with sensors and controls that monitor the tension, speed, and other parameters to ensure consistent winding quality. Textile machinery manufacturers in India produce a wide range of drum winding machines to meet the needs of various applications. These manufacturers design their machines to be durable, reliable, and efficient, with high levels of automation to minimize operator involvement.

Coil Winding Machines: These machines are used for winding coils of wire onto magnetic cores, such as those used in transformers and inductors. These machines are designed to handle a variety of wire sizes and types, including copper, aluminum, and other specialty wires. Coil winding machines can produce coils of different shapes and sizes, including rectangular, cylindrical, and toroidal shapes.

Toroidal Winding Machines: These machines are used for winding wire onto toroidal cores, which are donut-shaped magnetic cores used in transformers, inductors, and other electrical components. Toroidal winding machines use advanced technology to ensure precise winding of the wire onto the core. They are equipped with sensors and controls that monitor tension, speed, and other parameters to ensure consistent winding quality. These machines can handle high-speed winding, producing large quantities of toroidal cores with consistent winding quality.

Rewinding Machines: These machines are used for rewinding rolls of paper, film, and other materials into new rolls with different sizes and lengths. Several textile machinery manufacturers in Gujarat specialize in winding machines, including Weavetech. We offer a range of winding machines, from manual to fully automated models, to meet the needs of different applications.

Bobbin Winding Machines: These machines are used for winding yarn, thread, and other fibers onto small bobbins or spools, typically used in the textile industry. They are equipped with sensors and controls that monitor tension, speed, and other parameters to ensure consistent winding quality. Some advanced bobbin winding machines also have the capability to detect and correct for any winding errors, ensuring a high level of winding accuracy.

Cheese Winding Machines: These machines are used for winding yarn or thread onto large cones or cheese-shaped spools, typically used in the textile industry. Cheese winding machines are used in the textile industry for winding yarn onto cylindrical tubes called cheese. These machines are designed to handle a variety of yarn types and sizes, including natural and synthetic fibers, and can produce cheese of different diameters and lengths.

If you are looking for reliable and high-quality textile machinery solutions in Gujarat, look no further than Weavetech. As a leading textile machinery manufacturer in Gujarat, Weavetech offers a wide range of machines that cater to the needs of textile manufacturers across various sectors. Contact Weavetech today to learn more about their textile machinery solutions and how they can help you improve your textile production operations in Gujarat.

Original Source: https://www.weavetech.com/blog-detail/32/how-many-types-of-winding-machines-are-there/

0 notes

Link

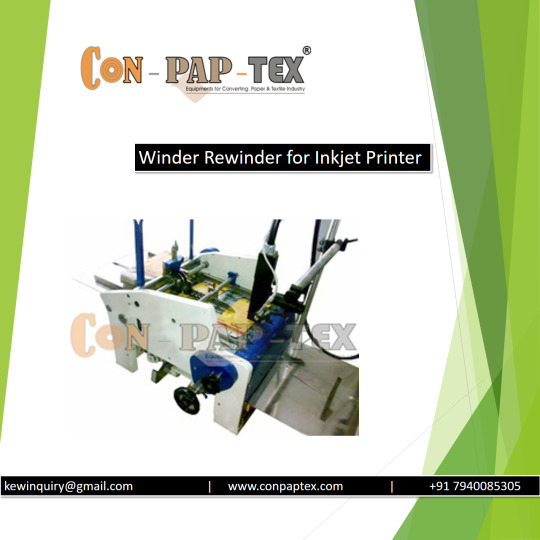

#Winder Rewinder for Inkjet Printer Manufacturer#Winder Rewinder for Inkjet Printer#Winder Rewinder for Inkjet#Winder Rewinder#Winder Rewinder Machine

0 notes

Link

#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder Machine

0 notes

Link

We offer Different types of high-quality spare parts Doctor Rewinder Machine Manufacturer, heavy duty Doctoring Film Strip Winding Rewinding Machine, Doctoring Film Strip Winding Rewinding, Film Rewinder Machine, Doctoring Rewinding Machine, Doctoring Rewinder Machine, Winding Rewinding, Slitter Rewinder Machine, Coil Winding, Inspection Doctoring Slitting. We specializing manufacturing Doctoring Film Strip Winding Rewinding Machine. Specially built for film strip winding with 100% correction doctoring winding.

#Doctoring Film Strip Winding Rewinding Machine#Doctoring Film Strip Winding Rewinding#Film Strip Winding Rewinding#Film Rewinder Machine#Film Rewinder Machine Manufacturer#Doctoring Rewinding Machine#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Winding Rewinding Machines#Doctoring Rewindings

0 notes

Link

We have been manufacturing various types of Doctoring Rewinding Machine for separate industries and for different request per client’s requirement. Custom and proper Application for Doctoring Rewinding Machine, 28 separate type of Doctoring Rewinding Machine Manufacturer, exporter, supplier. Doctoring Rewinding Machine with Slitting System like, Standard Doctoring Rewinding Machine, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding with Slitting System, Table Top Doctoring Rewinding etc.

#Doctoring Rewinding Machine#Doctoring Machine#Doctoring Rewinding Machine with Slitting System#Doctoring Rewinding Machine Manufacturers#Inspection Machine#Doctoring Rewinding Machine Price#Heavy Duty Doctoring Rewinding Machine#Film Winder Rewinder Machine#Winding Rewinding Machine#Slitting Rewinding Machines

7 notes

·

View notes

Link

Krishna Engineering Works is biggest manufacturer of film ribbon slitter rewinder machine at best price range. Our Film Ribbon Slitter Rewinder Machine required for its accurate slitting and rewinding premium qualities with meeting International Standard. It ensures perfect slitting of material with consistent, flawless results and constant line speed. For more information visit our website krishnaengineeringworks.com or contact us at [email protected]

#Slitter rewinder machine#Film slitter rewinder machine#film ribbon slitter rewinder machine#Slitter rewinder machine manufacturer#Slitter rewinder at best price

4 notes

·

View notes

Link

Krishna Engineering Works is biggest manufacturer, exporter & supplier of over wrap film slitter rewinder machine at best price. We are manufacturing slitting machine for different types like Poly Films, Overwraps films are transparent non heat sealable, corona treated both side, for overwrap. For more information visit our website krishnaengineeringworks.com or have any types inquiry direct contact us at [email protected]

#Over wrap film slitter rewinder machine#slitter rewinder machine manufacturer#slitting machine at best price#all types of slitter rewinder

2 notes

·

View notes

Link

KEW ENGG MFG PVT LTD is biggest manufacturer, exporter & supplier of Deep Freeze Film Slitter Rewinder Machine at best price. We are manufacturing, exporting & supplying all types of slitter rewinder for deep freeze film including EVA, LDPE, MDPE & HDPE. For more information about products and inquiry please visit our official website “kew.net.in” or contact us at [email protected]

#Paper slitter rewinder machine#slitter rewinder machine#slitter rewinder machine manufacturer#deep freeze film slitter rewinder machine at best price#slitter rewinder manufacturers

5 notes

·

View notes

Link

KEW ENGG MFG PVT LTD is manufacturer, exporter & supplier of Heat sealable polyester film slitter rewinder machine. We are at leading position in manufacturing & exporting high quality slitter rewinder machine. It has a modular design and several automation options with high-quality equipment. For more information visit our website kew.net.in

#Slitter Rewinder Machine#Slitter Manufacturer#Slitter Rewinder Machine at best price#Sealable Polyster Film Slitter Rewinder Machine

1 note

·

View note