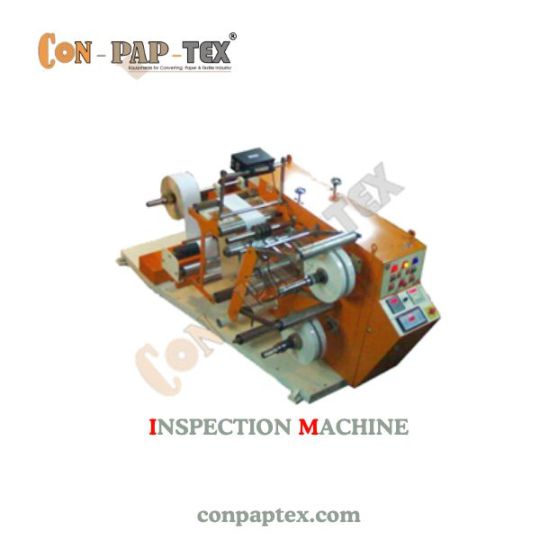

#Inspection Machine

Explore tagged Tumblr posts

Text

inspection machine

#conpaptex#machine#manufacture#industry#inspection machine#export#supplier#service#rewinder machine#inspection machine manufacture

3 notes

·

View notes

Text

Choosing the right NDT inspection machine supplier can make a significant difference in your operations. With its commitment to quality, innovation, and customer satisfaction, Magnatech RMC is the ideal partner for all your NDT needs.

#ndt testing#NDT Inspection Machine#Inspection Machine#business#machine manufacturer#machinery#Magnatech RMC

0 notes

Text

Ampoule Inspection Machine

Glass ampoules that can be injected can be inspected using an automatic ampoule examination machine. The four tracks of the Ampoule Inspection Machine are made of nylon-6 roller chain, and they come with a spinning assembly that includes A.C. drive rejection units and 24V DC wiring. Additionally, the ability to modify speed was made possible with a variable AC frequency drive. All of the machine’s contact parts are composed of authorized engineered polymers and stainless steel, in compliance with cGMP regulations.

0 notes

Text

Top 5 Reasons to Invest in a High-Precision Inspection Machine

In today’s fast-paced manufacturing world, precision and accuracy are critical. An inspection machine is not just an optional tool; it’s essential for ensuring that every product meets the required standards. High-precision inspection machines play a significant role in quality control, helping manufacturers deliver consistently superior products while staying competitive in their respective industries.

The demand for high-quality, defect-free products is growing, making it more important than ever to invest in technology that ensures precision. Whether you're in automotive, aerospace, electronics, or any other manufacturing sector, a high-precision inspection machine can transform the way you do business. Below, we’ll explore the top five reasons why investing in a high-precision inspection machine is a smart move for your company.

Key Takeaways

Investing in a high-precision inspection machine significantly enhances product quality by reducing defects and ensuring consistency.

Inspection machines improve operational efficiency, allowing for faster, more accurate inspections and less downtime.

Over time, an inspection machine can save money by reducing waste, rework, and operational costs.

Companies that adopt high-precision inspection machines gain a competitive edge in their industry by delivering superior products.

The Top 5 Reasons to Invest in a High-Precision Inspection Machine

1. Enhanced Product Quality and Consistency

Quality is everything in today’s manufacturing environment, and a high-precision inspection machine ensures that your products meet exact specifications consistently.

Minimize errors and defects: With accurate measurements and inspections, you can reduce the chance of defective products reaching customers, maintaining your reputation for quality.

Meet precise tolerances: A high-precision inspection machine guarantees that each product is within tight tolerance levels, leading to greater consistency.

Reduce human error: Manual inspection methods are prone to mistakes, but a high-tech inspection machine automates the process, offering more reliable results.

2. Increased Efficiency and Productivity

An inspection machine doesn’t just boost quality; it can also make your production process more efficient.

Automate inspections: By using a high-precision inspection machine, you can automate quality control, speeding up the process and freeing up your workforce for other tasks.

Reduce downtime: With fewer errors and less rework needed, your production lines can run more smoothly, minimizing costly downtime.

Improve throughput: Faster, automated inspections mean you can inspect more products in less time without sacrificing accuracy.

3. Cost Savings in the Long Run

While the initial investment in a high-precision inspection machine may seem steep, the long-term savings are undeniable.

Reduce rework and waste: By catching defects early, you can avoid costly rework and material waste, saving money in the long run.

Lower operational costs: High-precision inspection machines are designed for efficiency, requiring minimal maintenance and reducing the need for expensive repairs.

Better resource allocation: Automating inspections allows you to allocate labor and resources more efficiently, cutting down on costs associated with manual labor.

4. Competitive Advantage in the Industry

Staying competitive in any manufacturing sector requires adopting the latest technologies, and a high-precision inspection machine is a key component of staying ahead.

Respond to increasing quality demands: As customer expectations rise, so does the need for better quality control. A high-precision inspection machine helps meet these rising standards.

Build a reputation for quality: Consistently delivering defect-free products can help you build a stronger brand, attract new clients, and retain existing ones.

Differentiate yourself from competitors: Companies that invest in the latest inspection technology stand out in the marketplace, gaining a competitive edge.

5. Compliance with Industry Standards and Regulations

In industries like automotive, aerospace, and electronics, meeting regulatory standards is not just desirable—it’s essential. A high-precision inspection machine helps ensure compliance.

Adhere to international standards: Many industries require products to meet strict international standards. An inspection machine helps ensure that every item complies with these regulations.

Avoid penalties: Non-compliance can result in costly fines and damage to your brand’s reputation. With an inspection machine, you can avoid these pitfalls.

Boost customer confidence: Meeting industry standards consistently builds trust with your customers, showing that your products are safe and reliable.

Ensuring compliance with industry standards is easier with a reliable inspection machine, which helps avoid penalties and maintain customer trust.

Conclusion

A high-precision inspection machine is more than just a tool; it’s a smart investment that offers long-term benefits for any manufacturing business. By enhancing product quality, improving efficiency, saving costs, and ensuring compliance, an inspection machine will contribute to the overall success of your operations.

As industries continue to evolve, adopting advanced technologies like inspection machines becomes essential to staying competitive. Whether you're aiming to reduce defects, save on costs, or meet industry standards, investing in a high-precision inspection machine can provide you with the edge you need to succeed.

FAQs

What industries benefit most from high-precision inspection machines?

High-precision inspection machines are essential in industries where accuracy and quality control are critical, such as automotive, aerospace, electronics, medical devices, and precision engineering.

How does a high-precision inspection machine reduce production costs?

An inspection machine reduces production costs by minimizing defects, cutting down on rework, and decreasing material waste. It also increases efficiency by automating the inspection process, reducing the need for manual labor.

Is it difficult to integrate a high-precision inspection machine into existing systems?

Most modern inspection machines are designed to integrate seamlessly into existing manufacturing systems. Many come with software that can be customized to fit your specific production line, making the transition smooth and efficient.

How often should a high-precision inspection machine be calibrated?

It’s essential to calibrate your inspection machine regularly to ensure it continues to deliver accurate results. The frequency depends on usage and the industry’s standards, but it is generally recommended to calibrate the machine at least once a year.

What factors should I consider when choosing a high-precision inspection machine?

Consider factors like accuracy, speed, ease of integration, maintenance requirements, and the specific needs of your industry. You should also ensure that the inspection machine you choose meets relevant industry standards and regulations.

0 notes

Text

The Role of Fabric Inspection Machines in Textile Manufacturing

In the intricate tapestry of textile manufacturing, quality control is the thread that holds everything together, ensuring that the final product not only meets but exceeds the expectations of consumers and industry standards. Central to this process is the fabric inspection machine, a technological marvel that has revolutionized how the industry identifies defects, maintains quality, and ensures customer satisfaction.

The Essence of Fabric Inspection

Before we weave into the specifics of fabric inspection machines, it's crucial to understand the role of fabric inspection in the textile industry. This process involves examining textiles for defects or imperfections that could affect the quality, appearance, or performance of the final product. Traditionally, this was a labor-intensive process requiring skilled inspectors to manually check fabrics, a method prone to human error and inefficiency.

Key Features and Technologies

Modern fabric inspection machines are equipped with a host of features and technologies designed to enhance inspection accuracy and efficiency. Some notable features include:

High-Resolution Imaging: Utilizing high-resolution cameras to capture detailed images of the fabric, allowing for precise defect detection.

Automated Tension Control: Ensuring that fabrics are inspected under consistent tension, which is crucial for accurate defect detection, especially in stretchy materials.

Data Analysis and Reporting: Advanced software tools generate detailed reports on fabric quality, providing valuable insights for quality control and production planning.

The Impact on Textile Manufacturing

The adoption of fabric inspection machine in textile manufacturing has had a profound impact on the industry. These machines have significantly increased the speed and accuracy of fabric inspection, reducing the reliance on manual labor and minimizing human error. This not only improves the overall quality of the textiles produced but also enhances production efficiency, reducing costs and lead times. Furthermore, by automating the inspection process, manufacturers can ensure more consistent quality, bolstering brand reputation and customer satisfaction.

#fabric inspection machine#best fabric inspection machine#fabric inspection#fabric inspection machine in india#fabric inspection machines#inspection machine

0 notes

Text

Meeting Sustainability Goals: A Comprehensive Guide to Choosing the Right Recycling Machines for Your Business

In today’s fast-paced world, where environmental responsibility is more critical than ever, businesses are increasingly recognizing the importance of incorporating eco-friendly practices into their operations. One significant avenue for achieving sustainability goals is through the careful selection of recycling machines. Join us as we explore the keys to choosing the right recycling machines for your business and making a positive impact on the planet.

1. Understanding Your Business Needs:

Before diving into the world of recycling machines, take a step back and analyze your business’s unique needs and processes. Every industry has its own set of challenges and requirements, so it’s essential to identify the types and volumes of materials your business generates. Understanding this aspect will lay the groundwork for selecting recycling machines that align seamlessly with your operational demands.

2. Types of Recycling Machines:

Recycling machines come in various shapes and sizes, each designed to handle specific materials and processes. For instance, Injection moulding machines are excellent for processing plastics. Other machines, such as shredders, compactors, and sorting systems, cater to different materials and stages of the recycling process. Familiarize yourself with the diverse range of recycling machines available to ensure you make informed decisions based on your business’s unique needs.

3. Consider the Lifecycle Impact:

Sustainability is not just about recycling; it’s about creating a closed-loop system that minimizes the environmental impact throughout a product’s entire lifecycle. When selecting recycling machines, consider how they contribute to this holistic approach. Look for machines that not only process materials efficiently but also support the principles of a circular economy, where waste is minimized and resources are conserved.

4. Efficiency and Output Capacity:

While sustainability is at the forefront, it’s crucial to balance environmental concerns with practical business considerations. Assess the efficiency and output capacity of different recycling machines. Look for technologies that not only meet your recycling targets but also integrate seamlessly into your production processes without causing unnecessary delays or disruptions.

5. Technology Integration:

The dawn of Industry 4.0 has brought about exciting advancements in recycling technology. Consider machines that leverage smart technologies, automation, and data analytics to optimize performance. Integration of Internet of Things (IoT) capabilities can enhance the efficiency of recycling processes, providing real-time insights and enabling predictive maintenance to keep your operations running smoothly.

6. Financial Considerations:

Let’s face it – sustainability should not break the bank. Evaluate the financial aspects of investing in recycling machines. Consider the long-term benefits and savings that stem from reduced waste disposal costs, potential revenue from recycled materials, and positive brand image. While the initial investment might seem daunting, the overall return on investment in terms of sustainability and cost-effectiveness can be significant.

7. Training and Support:

Introducing new recycling machines into your business requires a knowledgeable and trained workforce. Look for suppliers that provide comprehensive training programs for your staff. Additionally, consider the level of support offered by the manufacturer – reliable customer service and maintenance support is crucial for ensuring the longevity and optimal performance of your recycling machines.

8. Compatibility with Existing Systems:

Before finalizing your choice of recycling machines, assess their compatibility with your existing production systems. Seamless integration can minimize downtime and streamline the overall workflow. Choosing machines that work in harmony with your current infrastructure ensures a smooth transition into more sustainable practices without disrupting your day-to-day operations.

9. Environmental Certifications and Compliance:

Ensure that the recycling machines you’re considering adhere to environmental standards and certifications. Look for equipment that meets regulatory requirements and has received certifications such as ISO 14001 for environmental management. Choosing compliant machines not only demonstrates your commitment to sustainability but also protects your business from potential legal and reputational risks.

10. Flexibility and Adaptability:

In a rapidly evolving business landscape, adaptability is key. Select recycling machines that offer flexibility in handling a variety of materials and can adapt to changes in your recycling needs. This flexibility ensures that your investment remains viable over the long term, accommodating shifts in market demands or alterations in the types of materials your business uses.

11. Waste Monitoring and Reporting:

Real-time monitoring and reporting capabilities can provide valuable insights into your recycling processes. Consider recycling machines equipped with sensors and reporting tools that track key metrics such as material volumes processed, recycling rates, and energy consumption. This data not only helps in optimizing operations but also facilitates transparent reporting on your sustainability achievements to stakeholders and customers.

12. End-of-Life Considerations:

Just as you’re concerned about the end-of-life of the materials you recycle, consider the end-of-life of the recycling machines themselves. Look for manufacturers that prioritize recyclability and responsible disposal of their equipment. Understanding the environmental impact of retiring machines is crucial for maintaining a truly sustainable approach throughout the entire lifecycle of your recycling infrastructure.

13. Collaboration with Suppliers and Partners:

Building a sustainable business involves collaboration not only within your organization but also with suppliers and partners. Choose recycling machine suppliers who share your commitment to sustainability. Establishing partnerships with environmentally conscious suppliers ensures a holistic approach to sustainability, from the raw materials used in your products to the machines employed in the recycling process.

14. Community Engagement:

A sustainable business is often deeply connected to its community. Consider how your choice of recycling machines can contribute to community engagement. Perhaps there are opportunities to collaborate with local recycling initiatives, or the use of certain machines can support employment in the community. Engaging with local stakeholders fosters a positive relationship and demonstrates your commitment to being a responsible corporate citizen.

Conclusion:

As you navigate the landscape of recycling machines, it’s evident that sustainability goes beyond mere waste reduction. It encompasses compatibility, certifications, adaptability, and even community engagement. With each decision, you’re contributing to a more resilient, eco-friendly, and socially responsible future. Your commitment to sustainability is not just a choice; it’s a journey that leaves a lasting impact on the world around you.

#injection moulding#blow moulding machine alphamac#injection moulding machines#moulding machine#blow moulding machines#inspection machine

0 notes

Text

locker theme requests for @octopanko and @cassiopeia-mori ty for these cool suggestions :3

#the design of the door of the arcade one is inspired by the ddr floor buttons#i originally also tried to make a version that was more purpley but it didn't fit with the color palette of the arcade machine decoration#upon closer inspection i notice that the top sticker on the inner door of the arcade one should be moved up a smidge but it's too late...#the lovecore one ended up v cutesy but i think i made a comm a long time ago that was also lovecore but more romantic#if i find it i might also post that one on here#teehee#splatoon locker#splatoon 3#request

50 notes

·

View notes

Text

I feel like we don't talk enough about the weird ways Viktor's future in Zaun is foreshadowed. When you mix every instance together it creates this weird mixture of heartbreak and terror.

For example, in the flashback when Viktor first meets Singed the entrance Viktor came through has a relief that looks like a shrouded figure. Personally, it reminds me of Huck post-timeskip.

In post timeskip Zaun there's a greenhouse called "The Herald's Palace" based on the sign that's framed with blue swirls similar to Jinx's tattoos, and it's being guarded by men wearing masks similar to the Machine Herald. The guards are even given long clubs reminiscent to the Herald's staff.

When Viktor visits Singed to share his research, when he looks into the container holding Rio, Viktor’s reflection in the fluid and glass makes him appear in better health compared to now. (Chemtech, the answer to filters in a pre-instagram world)

In the same scene, the silhouette of Rio's body vaguely resembles the outline of the Machine Herald's mask that appeared in the tarot card scene. The stand that frames the shot even resembles the Machine Herald's staff.

Speaking of the tarot card, in Viktor's "the Magician" card, the figure is holding an object that could be the hexcore. What's more interesting is that within that hexcore-like object is Jinx's champion teaser tag, it was just turned sideways to resemble the math symbol fish, ∝, though sideways it still makes Jinx's "X". On top of that both tarot cards are initialed with a "VJ", like Viktor and Jinx.

This is just a quick rundown because there's a bunch of the cosmic Void imagery that gets crossed with the human biology that will take longer to get into. It's just interesting how Viktor's story, which initially stood alone in Zaun and was largely influenced by Piltover is now becoming more entagled into the stories of Zaun's more influential champions, Singed and Jinx.

#arcane#viktor arcane#machine herald#i feel like people take lol's canon too literally and expect the machine herald to show up bcuz arcane is lol#it prevents you from really inspecting the material#the more i learn about viktor in lol the more difference i see between him and the original version#singed arcane#jinx arcane#arcane meta

112 notes

·

View notes

Text

maybe we’re meant to lose the ones we love / but i’ll fight for you till then

#calron#my favorite album of all time ngl#also upon further inspection i realize i should’ve swapped aaron and calls places#<- if we’re going w the chemical boy and mechanical bride theory#selfish machines#magisterium#the magisterium#callum hunt#aaron stewart#pierce the veil

33 notes

·

View notes

Text

In the sunrise.

#bikelife#motorcycle#motorbike#motorsports#futurism#technology#motor city machine guns#future#futuristic#industrial#robotics#industry inspection#my art#digital art#illustration#graphic design#creative design#design#creative#planets#graphic art#cybernetics#cyberpunk art#cyberpunk#artwork#moto#poster art#machine

5 notes

·

View notes

Text

everyone please appreciate these blood splatters outside of my workplace yesterday <3

#a woman fell at the crosswalk and hit her head and stood there getting bandaged up <3#she was ok she went to the mercy next door but I was quite alarmed at the puddle (she didn’t hit her head that jagged rock don’t worry)#this has been the craziest week. boss steals a car. woman cracks her head on sidewalk. we get a health inspection. and new ice machine.#ALL IN ONE DAY#I work in a coffee shop!!!!#a day in the life of steeve

4 notes

·

View notes

Text

there's something that feels so shitty about how, when youtubers sell their own products, they never, ever shout out, acknowledge or appreciate the factory workers who made it possible. youtubers with their own make up stores, nail polish stores, clothes, even something like a jigsaw puzzle. you might even get footage from the factory, yknow, how novel. but the faces of the people making your product are always obscured. in one video, the youtuber thanked the design team of the production company who worked directly with them, which is good, but then, they never even mentioned how it was produced. because it was made by a person making it.

#jamie.txt#it just. yeah man. proletariat. factory worker and factory owner#we're fully invisible. even TO the factory owner#we've had many inspections this year in my factory but even as they look you in the face they only see a machine for making.

9 notes

·

View notes

Text

How to Maintain Your Inspection Machine for Optimal Performance: 5 Tips

Maintaining your inspection machine is crucial for ensuring its optimal performance and longevity. Inspection machines are vital in various industries, from manufacturing to pharmaceuticals, where precision and reliability are paramount. Regular maintenance not only extends the lifespan of your equipment but also ensures accuracy, reduces downtime, and minimizes repair costs. In this article, we will explore five essential tips to help you maintain your inspection machine effectively.

Key Takeaways

Regular maintenance increases the lifespan of your inspection machine.

Proper cleaning, calibration, part replacement, software updates, and lubrication are essential.

Neglecting maintenance can lead to frequent breakdowns, higher costs, and compromised inspection quality.

Understanding the Importance of Regular Maintenance

Benefits of Regular Maintenance

Increased Machine Lifespan: Routine maintenance helps your inspection machine last longer by preventing wear and tear.

Improved Accuracy and Performance: Keeping your machine in top condition ensures it operates accurately and efficiently.

Reduced Downtime and Repair Costs: Regular checks and fixes help avoid major breakdowns, saving time and money.

Consequences of Neglecting Maintenance

Frequent Breakdowns: Lack of maintenance leads to more frequent machine failures.

Higher Operational Costs: Repairing a broken machine is often more expensive than regular maintenance.

Compromised Inspection Quality: An unmaintained machine may produce inaccurate results, affecting the quality of inspections.

Tip 1: Establish a Regular Cleaning Schedule

Cleaning Procedures

Daily Cleaning: Wipe down surfaces and remove any debris.

Weekly Cleaning: Clean more thoroughly, focusing on areas prone to buildup.

Monthly Cleaning: Perform deep cleaning, including hard-to-reach parts.

Recommended Cleaning Products and Tools

Cleaning Agents: Use non-abrasive, manufacturer-recommended cleaning agents.

Tools: Soft brushes, microfiber cloths, and compressed air can help clean your machine effectively.

Safety Precautions During Cleaning

Protective Gear: Wear gloves and safety goggles to protect yourself from cleaning agents.

Proper Handling: Follow the manufacturer’s instructions to avoid damaging sensitive components.

Tip 2: Perform Routine Calibration

Importance of Calibration

Ensuring Accuracy and Reliability: Regular calibration maintains the machine's precision, crucial for reliable inspections.

How to Calibrate Your Machine

Step-by-Step Calibration Process: Follow the manufacturer’s guide or a professional service to ensure proper calibration.

Frequency of Calibration

Manufacturer's Recommendations: Typically, machines should be calibrated annually or as specified by the manufacturer.

Tip 3: Inspect and Replace Worn Parts

Identifying Worn Parts

Signs of Wear and Tear: Look for visible damage, unusual noises, or decreased performance.

How to Replace Parts

Step-by-Step Replacement Guide: Consult the machine's manual or seek professional assistance for replacing parts.

Recommended Replacement Schedule

Usage and Manufacturer Guidelines: Replace parts based on how often the machine is used and the manufacturer’s suggestions.

Tip 4: Keep Software and Firmware Updated

Importance of Software Updates

Enhancements and Bug Fixes: Updates improve functionality and fix any existing issues.

How to Update Software and Firmware

Step-by-Step Update Process: Follow the manufacturer’s instructions or use their support services to update software.

Scheduling Regular Updates

Setting Reminders and Automating Updates: Regularly check for updates and automate the process if possible.

Tip 5: Maintain Proper Lubrication

Importance of Lubrication

Reducing Friction and Wear: Lubrication minimizes friction, preventing wear and tear on moving parts.

Types of Lubricants to Use

Recommended Lubricants: Use lubricants specified by the manufacturer for optimal performance.

Lubrication Schedule

Frequency of Lubrication: Lubricate parts as per the manufacturer's guidelines, typically after a certain number of operating hours.

Conclusion

Maintaining your inspection machine is essential for ensuring its longevity and optimal performance. By following these five tips—establishing a regular cleaning schedule, performing routine calibration, inspecting and replacing worn parts, keeping software updated, and maintaining proper lubrication—you can keep your inspection machine running smoothly and efficiently. Regular maintenance not only enhances the machine’s accuracy and reliability but also saves you time and money in the long run. Start implementing these tips today to maximize the performance of your inspection machine.

FAQs

Q: How often should I clean my inspection machine?

A: Daily, weekly, and monthly cleaning tasks are recommended to ensure thorough maintenance.

Q: Why is calibration important for inspection machines?

A: Calibration ensures that the machine operates accurately and reliably, which is crucial for precise inspections.

Q: How do I know when to replace parts in my inspection machine?

A: Look for signs of wear and tear, such as visible damage or decreased performance, and follow the manufacturer’s recommended replacement schedule.

Q: What should I do if my machine's software is outdated?

A: Follow the manufacturer’s instructions to update the software and firmware, ensuring your machine runs with the latest improvements and bug fixes.

Q: How often should I lubricate my inspection machine?

A: Lubricate parts according to the manufacturer’s guidelines, typically after a specified number of operating hours, to maintain optimal performance.

Regular maintenance of your inspection machine is a small investment that pays off significantly in terms of efficiency, reliability, and longevity. Keep your machine in top shape with these simple yet effective tips!

0 notes

Text

The vending machine dialogue for each of the snacks is so funny and cute and they're siblings your honor.

Transcripts under the cut:

Hotdog $7

Edgeworth: "When you're in hot water, you might need a hot dog." ... Hmm... It looks like the slogan was decided through a public contest. And the winner was... Prosecutor Winston Payne... ?

Franziska: Hmph. What a pathetic slogan. No presence at all! Now if it was up to me it would read... "If you leave matters in a Von Karma's hands, everyone in court will be found guilty dogs!"

Edgeworth: ... Objection!

Franziska: Overruled!

Orange Juice $9

Edgeworth: "When it's looking bad, blind your opposition with some OJ!" Are they promoting violence?

Franziska: Don't worry. My whip will make sure anybody following this advice won't be for long.

Edgeworth: (Compared to the sting of a whip, the sting of orange juice may not be so bad.. )

Beef Jerky $9

Edgeworth: "Don't be a jerk in court like these beef jerks!" I see...

Franziska: Objection! Miles Edgeworth! Wouldn't you agree that it's a very clever pun?

Edgeworth: Do you really think they put that much effort into the product name?

Franziska: *with lots of shaking and flashing* Even a foolish fool could understand the foolish thinking of the fool who made it up! *without the shaking and flashes* You're acting so foolishly that I got so thoroughly mad, and am now utterly famished!

Edgeworth: ... If you wanted a pack of these, all you had to do was act like a normal person.

Milk $7

Edgeworth: "Defendant's Fresh Milk!" ... What exactly is that supposed to mean?

Franziska: I bet it means that the milk is freshly milked by various defendants on trial right now.

Edgeworth: No, I think it might mean that this was milked right here from the various defendants.

Franziska: Miles Edgeworth... You can't possibly be serious!

Edgeworth: ... Of course not.

Ham Sandwich $8

Edgeworth: "Don't let the prosecution and the defense make a ham sandwich out of you!" ...?

Franziska: It sounds like it's directed at that ham of a Judge.

Edgeworth: Well, it certainly isn't directed at me. I can out-maneuver him any day.

Swiss Rolls $6

Franziska: "Stay neutral as the Swiss do until the end of these!" ... The end of what?

Edgeworth: Well, I assume it means the end of the trial. I suppose this means that one should eat these during a recess...?

Franziska: You can't eat during a trial so I suppose the only time you can eat them is now, huh!

Edgeworth: I wouldn't mind if you wanted to eat one niw. They come in packs of two, after all.

Franziska: Hmph. We're in the middle of an investigation! Besides, I don't have $6 on me!

Edgeworth: If you want, we can pool our money and buy a pack together.

Franziska: If I have to split it with you, then I don't want it!

#POV: You're on forensics inspecting the hallway while two pretentious kids read a vending machine in the middle of a murder investigation#miles edgeworth#franziska von karma#aai1#game posting

47 notes

·

View notes

Text

Understanding Plastics Machinery: Common Types and Functions

Plastic machinery plays a pivotal role in our daily lives, as it is responsible for transforming raw plastic materials into a myriad of products we use regularly. From the packaging of our groceries to the components in our electronics, plastics processing machinery is the driving force behind it all. In this blog, we will explore the functions of plastic machinery and delve into the most common types used in the plastics industry.

Understanding the Role of Plastic Machinery

Plastic machinery, also known as plastics processing machinery, comprises a diverse range of equipment specifically designed for molding, shaping, and processing plastic materials. These machines are vital for the production of a wide array of products, offering versatility and efficiency. Let's delve into what these machines do and the key roles they play:

Injection Molding Machines:

What They Do: Injection molding machines are workhorses of the plastics industry. They operate by injecting molten plastic material into a mold, where it cools and solidifies, forming the desired product. This process is known for its precision and is suitable for manufacturing a broad range of products.

Common Applications: Injection molding machines are used to create items like plastic containers, automotive parts, medical devices, toys, and consumer goods.

Extrusion Machines:

What They Do: Extrusion machinery is primarily used for producing plastic products with a consistent cross-section. It involves melting plastic granules and forcing the material through a shaped die to create products such as pipes, tubes, and profiles.

Common Applications: Extrusion machines are used in the production of plastic pipes, films, sheeting, and various profiles for construction and automotive components.

Blow Molding Machines:

What They Do: Blow molding machines are essential for creating hollow plastic products, such as bottles, containers, and automotive fuel tanks. This process involves melting plastic and blowing it into a mold, giving it the desired shape as it cools.

Common Applications: The beverage and packaging industries widely use blow molding machinery to produce containers and bottles.

Thermoforming Machines:

What They Do: Thermoforming machinery is used to shape plastic sheets into specific forms by heating the material and molding it with a die. This technique is popular for creating disposable packaging and trays.

Common Applications: Thermoforming is used to produce food containers, blister packs, and other disposable packaging.

Rotational Molding Machines:

What They Do: Rotational molding, or rotomolding, is employed for creating large, hollow plastic products. The process involves rotating a mold while heating and cooling the plastic material inside, resulting in uniform thickness.

Common Applications: Rotational molding is utilised for products like playground equipment, storage tanks, and large containers.

Co-extrusion Machines:

What They Do: Co-extrusion machines allow for the combination of multiple plastic materials during the extrusion process. This enables the creation of products with different layers, each with distinct properties.

Common Applications: Co-extrusion is commonly used in food packaging with barrier layers, multilayer films for electronics, and multi-color profiles.

Plastic Welding Machines:

What They Do: Plastic welding machines are used to join plastic components by melting their surfaces and fusing them together. This is especially useful for repairing plastic parts or joining them in various industries.

Common Applications: Plastic welding is applied in the automotive industry, construction, and the repair of plastic products.

Mould Temperature Controllers:

What They Do: Mold temperature controllers are not directly involved in shaping plastic products but play a crucial role in maintaining precise mold temperatures during processes like injection molding. Consistent mold temperature ensures product quality and reduces cycle times.

Common Applications: Mold temperature controllers are essential in injection molding and other processes where maintaining consistent mold temperature is critical.

Plastic Recycling Machinery:

What They Do: Plastic recycling machinery is vital in the efforts to reduce plastic waste and promote the circular economy. These machines are designed to recycle used plastics into new products and involve processes like shredding, melting, and pelletizing.

Common Applications: Plastic recycling machinery is crucial in reducing plastic waste and promoting sustainability by creating new products from recycled materials.

Auxiliary Equipment:

What They Do: Beyond the core processing machines, various auxiliary equipment supports the plastics processing industry. This includes material handling equipment, granulators, conveyors, and quality control devices.

Common Applications: Auxiliary equipment is used to streamline the production process, reduce waste, and ensure product quality by supporting the main machinery.

Selecting the Right Machinery

Choosing the appropriate plastics processing machinery is a critical decision that affects the efficiency and cost-effectiveness of production. Several factors should be considered when selecting machinery:

Type of Plastic Material: Different plastics require specific processing techniques and machinery. The machinery used for polyethylene may not be suitable for processing polycarbonate.

Product Specifications: The desired product's size, shape, and complexity will influence the choice of machinery. Some machines are better suited for small, intricate parts, while others are ideal for large, hollow structures.

Production Volume: The volume of products to be manufactured is a key factor. Some machines are designed for high-volume production, while others are more suitable for lower quantities.

Budget Constraints: Budgetary considerations play a significant role in machinery selection. The cost of the machine, maintenance, and energy consumption all impact the overall cost of production.

Conclusion

Plastic machinery is the backbone of the plastic industry, responsible for transforming raw plastic materials into the products that have become an integral part of our daily lives. Understanding the different types of plastics processing machinery and their applications is crucial for manufacturers, engineers, and anyone involved in the plastic industry. The plastics industry's commitment to innovation extends to packaging, where the integration of the world's fastest Automatic Bagging Machines has significantly improved the speed and precision of product packaging.

By staying informed about the latest advancements and best practices, the industry can continue to meet the evolving needs of a changing world while promoting sustainability and innovation.

#blow moulding machine alphamac#inspection machine#injection moulding#recycling machine#moulding machine#blow moulding machines#plastics processing machinery#injection moulding machines

0 notes

Text

2024/07/23 CNC CMM from GD Prototyping inspection

#design#autos#business#cnc machining#precision machining#prototype machining#prototyping#prototype#cnc cmm#cmm#coordinate measuring machine market#inspection#testing#rapid prototyping#machining parts#precision#cnc part

2 notes

·

View notes