#Fire Safety Simulation Tools

Explore tagged Tumblr posts

Text

In today’s rapidly evolving technological landscape, Metaverse technology is ushering in new dimensions for industries worldwide. As businesses adopt immersive digital environments for training, simulations, and customer experiences, one metaverse company in India is truly making its mark — Simulanis. This company specializes in creating cutting-edge metaverse development solutions and virtual reality (VR) simulators, transforming industries from fire safety to pharmaceutical training.

#Virtual Reality Safety Training#Immersive VR Simulators#VR Training for Firefighters#Metaverse Training Solutions#Virtual Reality Fire Training#Industrial VR Simulators#VR Training for Paint Spraying#VR Fire Extinguisher Simulator#Virtual Reality Emergency Training#VR-based Skill Training#Metaverse for Workforce Development#3D VR Simulators#Fire Safety VR Training Programs#Virtual Reality for Hazardous Training#Immersive VR Training for Manufacturing#Augmented Reality Productivity Tools#Metaverse Learning Experiences#Virtual Fire Safety Training India#VR Training for Healthcare#Simulation Training in Metaverse#Realistic VR Fire Training Simulators#Advanced VR Training Solutions#Virtual Reality Training for Engineers#Industrial Fire Extinguisher Simulator#Pharmaceutical VR Training Simulators#VR Training for High-Risk Jobs#Fire Safety Simulation Tools#Remote Assistance in VR Training#Metaverse Development for Enterprises#Immersive VR Training for Safety Procedures

0 notes

Text

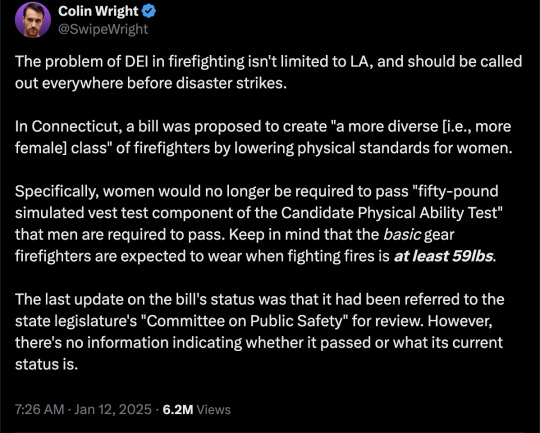

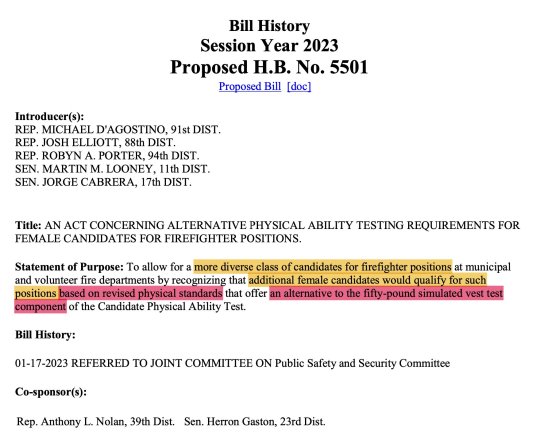

By: Aaron Sibarium

Published: Jan 23, 2023

Connecticut Democrats are working to lower the physical fitness requirements for female firefighters, saying that less onerous standards will make fire departments "more diverse."

A law introduced earlier this month in the Connecticut State Assembly would let women skip the Candidate Physical Ability Test, a timed gauntlet used by fire departments across the country. The test, which only 10 to 15 percent of women pass, requires candidates to complete intense physical tasks while wearing a 50 pound vest. It’s designed to simulate the experience of navigating a fire in heavy gear—and to weed out those unable to do so.

The law, introduced by five Democratic lawmakers, would offer women an alternative test based on "revised physical standards," with the goal of ensuring that "additional female candidates" qualify for firefighter positions, text from the bill states.

But some firefighters, including women, who have climbed the ranks of their departments without workarounds, say the bill will set merit-based hiring ablaze and potentially endanger Connecticut residents. "If you can’t handle a 50 pound vest, you’re not going to be able to rescue a child from a burning building," said Leah DiNapoli, a retired firefighter in New Haven, Conn.

"A citizen in need of rescue doesn’t care if a firefighter is white, black, Hispanic, male, or female," said Frank Ricci, a retired firefighter who served as the president of the New Haven firefighters union. "They care that they can do the job. This attempt to socially engineer public safety positions will only serve to endanger the public."

Unlike in the military, where uniforms and equipment vary by gender, all firefighters wear the same gear, which weighs at least 59 pounds—9 more than the vest used for the physical assessment. That’s not including the weight of ladders, hoses, or other firemen, who must sometimes carry incapacitated colleagues on their shoulders. While a few pieces of protective gear now come tailored for women, most of the essential tools do not.

"They don’t make lighter saws or ladders," DiNapoli said. "When I was there, they didn’t even make female-sized boots."

The law, she added, is "absolutely insane. Either you can do the job or you can’t."

The bill has been referred to the state legislature’s "committee on public safety," which has not yet scheduled hearings on the law. Neither the bill’s sponsors nor Connecticut governor Ned Lamont responded to requests for comment.

Beyond putting lives at risk, critics say the law will exacerbate the suspicion, common among male firefighters, that women simply aren’t up for the job. Fire departments have always been an "old boys club," DiNapoli said, and around 91 percent of firefighters are men. In this testosterone-fueled environment, sex-blind tests often serve as a stopgap against stereotypes, providing an objective assurance of physical competence.

"It’s already tough for women in the fire service, because you constantly have to prove your worth," a retired female firefighter from Chicago said. "How are you going to prove yourself if you don’t take the same test as the men?"

Danny Stratton, a recently retired fire captain from Camden, New Jersey, drew a parallel to affirmative action. "When you lower standards for minorities, people assume they got the job because of the color of their skin," Stratton said. "Lowering standards for women creates the same kind of stereotypes."

Such suspicions are especially dangerous in the fire service, where trust and teamwork can mean the difference between life and death. "The guys I’m working with need to know that I can get them out of a bad situation," DiNapoli said. "If a woman can’t pass the test, men won’t want her on their shift."

This is not the first culture war between firefighters and government officials in Connecticut, where fire stations have been ground zero for diversity-related feuds. In 2003, the New Haven fire department threw out the results of a written exam after none of the African Americans who took it scored high enough for a promotion. Ricci, the former union president, who would have been promoted based on his results, sued the department, arguing that he and other non-black firefighters had been denied professional opportunities because of their race. The Supreme Court agreed, ruling 5-4 that New Haven had violated anti-discrimination law.

Fire departments have nonetheless faced pressure to axe both written and physical tests—especially when women do poorly on them. In 2011, the Chicago Fire Department was hit with a class action lawsuit over its physical abilities test, which was even more difficult than the Candidate Physical Ability Test used in Connecticut and other states.

The complaint argued that Chicago’s test discriminated against women because so few of them could pass it. The department eventually settled, offering jobs to many of the women who were rejected under the old standard.

"A lot of men ridiculed those women," recalled the Chicago firefighter, who had passed the original test.

Though some fire service tests have been struck down on disparate impact grounds, the Candidate Physical Ability Test is not one of them. Developed and validated by the International Association of Firefighters, it has survived multiple discrimination lawsuits, mostly from women, and has received the blessing of the Equal Employment Opportunity Commission, the agency that enforces civil rights laws in the workplace.

"The idea of the test was to keep politics out of fire service hiring," Stratton said. "Now they’re trying to add politics back in."

==

You can't claim to be "oppressed" when everyone in power is willing to lower standards and sacrifice other people's lives just to "include" you on the team.

#Colin Wright#Aaron Sibarium#firefighters#firefighter#LA fires#Los Angeles fires#diversity equity and inclusion#diversity#equity#inclusion#lower standards#low standards#DEI hire#diversity hire#merit#meritocracy#make merit matter#religion is a mental illness

10 notes

·

View notes

Text

The Box

I'm finally watching the episode! These are my stream-of-consciousness thoughts through my initial viewing. This isn't thought-out refined analysis, these are just the thoughts as I have them the moment they appear in my head.

They're getting better at the 3d running/walking animation.

Green being the one to notice details, like in The Village.

Civilization!

Green only drew one but then he just has three more? Cartoon magic or stickfigure magic? Or just saving time on a meta level.

This looks like a nice little toh that's a white-filled head, they're ALL white-filled heads (all look like freehanded circles though)

For a given value of "white," I guess, but they're all very light colors. And they all have head accessories. Interesting...

Okay it's kinda funny that nobody would talk to them and the truck is right there. Did they think the color quartet were giving handouts or something? None of them stopped to listen long enough XD

Ooh, so these are some kind of simulation chambers? Looks like they've simulated a desktop art program.

Hmm, so Orange's ability to just have whatever he wants manifest into existence with the stroke of a pencil is unique to him; these guys try the same motions and all they get are regular lines. (Also if Orange can do all that outside then why are they doing these experiments in the simulation chamber? Is it just for safety or can they not do it outside? Shady could use his toolbar outside just fine...)

Orange's drawings were alive, almost from the first line it seems. Before they even took their shape. These ones aren't.

I don't like how coldly they're treating my boy :(

you.

and then they don't even interact?? okay, so...Victim is pretty single-mindedly focused on whatever is about to happen with Chosen, and whatever it is doesn't involve Orange so Orange is irrelevant to him rn. Why bind him then? Where's he going? :(

he went in. by himself. I'm...not sure how to feel about that. surprised? it's not like the thing had a door. though looking at that control-display, it does look like there's something within the chamber itself that's also containing Chosen. Or is that just the bounding box? I think it's a bounding box actually. So this is also a simulation chamber. (this is giving me all sorts of questions about how the artboard recognizes the toolbar icons as graphics while the tools still retain their functions as tools and I'm gonna stop before I spiral)

oh, it did have a door

WAITAMINUTE why is Victim's bounding box 2d and Chosen's 3d???

...oh. so...Chosen's fire registers as a separate graphic from him, then. good to know??

wait what the- just altering the visual is enough to affect his ability in producing that power??

why did we just cut to the hunter sharpening their spear? don't like that. not while you're stealing all my boy's natural defenses.

that one lingering second after Chosen's lasers die out but before he turns around to face Victim is haunting. Bro's been trapped and depowered again.

Okay nitpick but Victim's head isn't changing shape every frame and it's driving me up the wall. Did he have some work done between the last installment and this one?

I can't tell if I'm supposed to laugh or not at Chosen just standing there and tanking all of Victim's hits, and honestly I like that I can't tell, the dissonance is fun. But putting that aside...Chosen just let the dude have at him like it was no big deal. He didn't actually fight back until he decided he'd had enough. I suppose he could've just been confused about why this guy was attacking him...but he doesn't even block or dodge. He doesn't defend himself, his hands aren't even up, he's not even really in a fighting stance, and it takes him a bit to even retaliate. Even after the first one, his body language is just "bruh why." Which. Is an interesting attitude to have when he's trapped and depowered and being punched by a stranger.

Chosen finally counters, and it cuts to the control panel outside, looks like they're about to raise some setting. I've gotta take a break for a meeting, here's my thought: Victim never left the art program, in AvA1. In a very literal sense, he spent his whole life in it. It's where he found all the things that enabled him to fight back. In a weird way, it makes sense that this is where he's powerful, that this is where he's comfortable fighting. (and I know my personal headcanons are about to get blown outta the water but I'm really glad that I was on the right track in regard to this idea. though something I hadn't ever imagined was that he'd rely on other people to supply those advantages instead of obtaining them himself)

Meeting over, back to the episode! (I wonder if the title of this episode refers to the white chamber Chosen is in or the actual bounding box. Given that the mere appearance of a bounding box in Wanted was enough for many of us to clue in to Victim's involvement, even before he appeared in-person at the end of the episode, I'm leaning that direction. Amazing that it only happened once in the series before Wanted and it was already enough of a legacy to make him recognizable. I'm now realizing that in AvA2 the first thing Chosen did even before attacking the cursor was destroy the bounding box. Also realizing that the bounding boxes in this chamber aren't visible, unlike in the test-chambers in the previous scenes.)

interesting...each of Vicitm's limbs are separate graphics with their own bounding boxes, which is how they looked in the Bloop animation course that Alan made, but it isn't how he was in AvA1. Though he was recognized as a single graphic just a few scenes ago, so that might not mean anything.

why, stop, dude we get it you're strong now you've proved your point stop beating him up-

oh good Chosen's still got his own strength, he's fighting ba- what- okay what, can't take what you dish out??

Ooh, I don't think we've seen Chosen actually throw fire like that (instead of just blasting and halting blasts) since the early episodes.

okay, nice to know that Victim actually can dodge on his own

...don't like how little time it took Chosen to start feeling exhaustion...

...don't like how much trepidation the lasso is giving me. that feels like one of the crueler things to use against Chosen; not because we've seen it used against him before (only Victim and Orange have used it themselves, and only Victim has had it used against him, and good grief Orange and Chosen still don't know how Victim is connected to Alan-) but just because...I really don't want him bound and leashed again, he's been through enough of that. still, I had predicted that we'd see him using the lasso at some point in AvA6. I'm not happy I was right. (man, back before we knew Victim would make a proper return to the series I used to love the idea of him using it again. it's like the clearest example of him outwitting the animator and taking his tools for his own use.)

NOT THE NECK- they've never gone there, I don't like this-

oh what they actually- I was not expecting that. whips haven't appeared in the series before. oh I really don't like this.

God he's crawling back- why-

I had to pause. either the group outside just did something with the controls that Victim wasn't anticipating, or...Chosen felt threatened enough to turn his powers on himself and encase himself in ice as a defense. fuck. someone get him out of there. no flight, can't fight, man was pushed far enough he literally resorted to freeze. The Chosen One. I don't think that's ever happened before.

Fuck, that's just too much, I can't even bring myself to feel excited about seeing the duplicates again. though it is good to know that my headcanon about him needing to be in an art program in order to duplicate himself ended up being accurate. we'll see if my headcanon about it being one Victim with five bodies (as opposed to being five Victims) holds up. if they even have a way to show any difference.

[sighs, pulls AvA1 up in another tab] yep, they're all there. lasso, hammer, extended thumbtack (though it doesn't look like a thumbtack here, which is interesting), whatever that chain-accordion thing is, and the ninja star. why are you doing this? man literally froze himself immobile to get you to stop torturing him, just leave him be.

...haHAHAHA! Oh that felt good, that made me smile. Hopefully this means Chosen has recuperated a bit.

the animation of Victim on fire was so nice I completely missed Chosen breaking the ice XD going back to catch that made me realize that the other Victim duplicates literally just...stood and watched the one burning...

don't let yourself get backed into a corner-

OH he escaped the hold, nice-

I didn't realize until the lasso came back that he'd gotten rid of it when he broke the ice :( but before that he actually uses his fire-breath again, which is always nice to see. interesting to see it concentrated in a thin stream instead of just roaring out like usual.

oh yikes why- him on fire-

...don't do it, man...

OH HE OWNED THAT, LET'S GO!!! Great thinking, Chosen! (heh, nothing about this situation remotely resembles that time Chosen grabbed the cursor and forced it to click him free, but I was reminded of it nonetheless. something about the tool being turned against the user, but in such a different way than Victim does it.)

OH HE- ...oh...I was gonna say oh he learned, he adapted enough that he predicted them flipping his fire and he used that- but then they just nullified it immediately...

Victim don't snap the rope like that, we don't need any more implications we already know you're planning to put him in a world of hurt, why can't you just leave him alone now, what are you trying to prove

hh, back to Orange I guess...

MATH SPOTTED, MATH SPOTTED-

oh! they're bringing him to the- okay that makes sense, if it only works when he does it then obviously the next step to figuring it out is gonna involve him.

wait was he- could he not move when the bounding box was picked up?? (also neat that he immediately got worried once he realized he's in a bounding box, dunno if that's because of what happened in the last episode or if it's just because...he spends a lot of time in an art program so he'd naturally be familiar with what they can do and what it means to be inside one)

...well, nice that they at least get his attention before picking him up

oh now you're being friendly, sure. yeah Orange ain't having it.

okay, [picks up pencil] [instant notetaking] was funny XD

aaw, it's swimming around him

oh it knows what the eraser means

...wait it wasn't an electric eel in the last episode-

hexagons- and the power flickered

okay Orange stumbling around trying to stay out of its way makes it clear that he isn't controlling this thing once he's finished drawing it, it's acting on its own. it...it really feels distressed.

hah, they're all cowering. losers.

oh, back to this.

...did you have to make it so personal, Victim?

a chair

...okay not sure why that happened, could Chosen not just...lean forward? I rewound to watch it again and realized he's exhausted again after the slow-mo ends (is that from the slow-mo itself or just his exertion from the fight before the slow-mo?) and he...doesn't even struggle when Victim lifts him by hand with a lasso to the neck. is...is he just ragdolling now? is he at the point where that's his best option for minimizing conflict?

...he is. he's ragdolling. fuck. (damn you cc!Alan for introducing ragdolling in a comedic short-)

...no? no what?? no, he doesn't know anything about the animator? (which we know isn't true, but why would he deny that?) or no, he isn't going to answer?

don't tie him up, please...

oh now he starts struggling?

...back to ragdolling. good grief, the way they animate his legs just swinging even though they can still touch the floor...

...heh, I appreciate his spirit, especially at this point, but...Chosen you kinda just put yourself in a worse position.

...oh, what is that? I don't think we've seen anything like that before. It's got the floppy disk that's used as the "save" icon in many applications, but it looks kinda like a headset.

...a VR headset specifically, I guess.

OH WHAT- okay rad animation, but WHAT

...oh fuck, I've always wondered if there was a way to see the data that would be a stick's memory. FUCK what are they gonna use this for

wait they're bring Orange here?! Or are they just passing on their way back to the cell? but why are they going back to the cell, was the eel too much for them??

...wait, what? signal lost, I assume because Chosen dislodged it enough to disconnect, and then...instead of picking up where it left off it jumps all the way back to Showdown?? was...was Showdown just on Chosen's mind? or is this the memory of him recalling it right before flying to alanspc to entreat Orange's aid? ...or...are memories from beyond the sky-barrier not compatible? that doesn't make sense...

what's with everyone's reactions to Second's powers?

...I forgot Orange's cell is in here. whoops.

oh this is how he finds out??

hands first ("I did that??") and then his eyes ("Chosen was right??")

...and of course. I expected they'd lock him down with extra security as soon as they realized, but. poor guy.

(dammit I purposefully refrained from making a "dark mode" joke, you didn't have to go and put it on the damn control screen)

...and even after that (which, judging by Victim's reaction, even he hadn't known about Second's powers), the animator is still Victim's priority.

oh, this isn't just any clip of the cursor's involvement in Showdown, this is specifically while Yellow was rendering the cursor in.

and then they immediately pan to Yellow which means that observation is actually gonna be relevant, FUCK-

OH FUCK THE WANTED POSTERS

("earnings growth," so they actually do have a business element to them)

aaand the security cameras caught them peeking out of the truck, they literally just started printing the posters and they've already located Yellow-

that fight is mesmerizing. we haven't seen one like this before, as far as direction and setting. plus it's really interesting to see how the four respond. I might look deeper into that later. also that was a cool transition.

and Yellow is dragged off. The story has never had one of the quartet singled out in-universe by the plot like this before. they aren't even apprehending the others.

...of all the sticks to have a lighter, I never thought it would be Victim.

to be continued. good grief.

I have to eat before work so I'll think on all this and say more later.

48 notes

·

View notes

Text

Alright I've got time before work and people did express interest so here's my headcanon on how Formie "Powers" and by extension Sparks Hat work.

So to start we know that the art book isn't true canon as Lake said if it's not in the games it doesn't count but given the minimal information given in the games it's really our only source of any kind of info. We also know Romalo functions off of Holographic Nanites and likely is the same for other "Nano Mage" units like the Qiqi's in 3. So let's start there. How I think (in an incredibly pesduo-scientific way as I'm not a real scientist and Spark isn't a hard sci-fi series) these robots (and by extension other Formie Powers) function is by the nanites they control emitting an electromagnetic field. The field simulates the properties of whatever is being made causing it to act as if it's really whatever is being simulated but the effect disappears if the nanites stop receiving power/a signal. So for example if Romalo makes a pie and throws it at you it feels like a real pie, but disappears as soon as he uses those nanites for another task. If you were to try and eat it the connection may become disrupted by your bodies own interference and it would vanish anyway, or if Romalo was damaged he might run out of power/disrupt the signal ect. Some effects might linger, for example nanties that cause fire aren't actually just fire they heat up already existing particles to cause real flames. Thus if you were to use a power to light something on fire it would remain on fire even when power/signal is cut.

Now onto Formie "Powers". The tools Spark picks up during Spark 1 are quite litterally just that, they're tools and toys used by other Formies in everyday life. And how I think they work is when you wear or hold the item it forms some kind of connection with a Formies nervous system through its electrical signaling. This allows a Formie to control the Power as if it was an extension of their own body. This would also mean overusing a Power too much can even cause physical exhaustion. They all come with an electromagnetic barrier (like Sparks Hat) which acts as "safety equipment" protecting the Formie from levels of physical harm to an extent. In this case I'm drawing more from pure theory than basis in examples but I'd wager normal commercial Powers tend to be fairly weak to allow them to be compatible with a wide range of people (since not every nervous system is identical) while modded/homemade gear like Sparks Hat tend to be more potent but more specialized to an individual. Not that it *couldnt* be used by others but the chance of "feedback" and damage from the connection would be much higher.

Now for Sparks Hat... in 1 he usually wears it in addition to the regular equipment provided by the Powers. For example the wind Scarf doesn't come with a hat yet Wind Spark still has hit hat on. What I'm thinking is Sparks hat while decently strong on its own is acting as an amplifier to the other equipment Sparks wearing. The stuff he's picking up are normal Powers and aren't as strong in the hands of someone else because Spark isn't using 1 Power he's using 2! So the regular Wind Scarf isn't anywhere near capable of what Spark can pull off with it.

And for the sake of just making things make sense in my head beyond gameplay mechanics being gameplay mechanics I like to headcanon the reason he doesn't use Powers in 3 the same way he does in 1 is that his Hat is actually too strong at this point and would overload any equipment he tries to use it with!

#spark the electric jester#stej#there we go more silly headcanons feel free to use as you please for your own AUs#or dont i dunno people just expressed intrest in my ideas#this did get me thinking about Fark again and how he works...

8 notes

·

View notes

Text

MEP Course In Hyderabad | Rite Academy

today's rapidly evolving construction and infrastructure sector, technical proficiency is not just an asset—it's a necessity. With smart buildings, green infrastructure, and integrated systems becoming the new standard, engineers and technicians must be well-versed in all aspects of construction services. This is where an MEP Course in Hyderabad proves invaluable.

MEP stands for Mechanical, Electrical, and Plumbing—three critical pillars that form the backbone of any building's operational system. An MEP engineer is responsible for designing and maintaining these systems, ensuring functionality, safety, and efficiency in residential, commercial, and industrial buildings. Whether you’re a civil engineer, electrical engineer, mechanical engineer, or diploma holder, investing in an MEP course can exponentially boost your career prospects.

If you're located in or around Hyderabad, there's one name you can trust to deliver top-quality MEP training: Rite Academy. With a curriculum grounded in real-world applications and industry standards, Rite Academy is dedicated to producing job-ready professionals who can meet the growing demands of the construction and infrastructure industries.

What Is an MEP Course?

Before diving into the benefits and scope of enrolling in an MEP Course in Hyderabad, let’s understand what the course actually entails. MEP engineering integrates three technical disciplines:

Mechanical Systems: This primarily includes HVAC (Heating, Ventilation, and Air Conditioning) systems. You’ll learn about heat load calculations, duct designing, piping systems, and indoor air quality standards.

Electrical Systems: Learn how to design electrical wiring systems, lighting, power distribution, safety systems, load calculation, and circuit design.

Plumbing Systems: This module includes water supply systems, drainage, fire fighting systems, and more.

A good MEP course doesn’t just touch on theory—it dives deep into the practical aspects, using the latest software tools like AutoCAD MEP, Revit MEP, HAP (Hourly Analysis Program), DIALux, and more. These tools enable engineers to design, simulate, and validate systems before they're implemented.

Why Hyderabad Is the Ideal Hub for MEP Training

Hyderabad is not just a historic city—it’s a booming tech and construction hub. From smart cities to skyscrapers and IT parks to infrastructure megaprojects, Hyderabad is undergoing a massive transformation. This rapid urban development is creating unprecedented demand for skilled MEP professionals.

Pursuing an MEP Course in Hyderabad means you’re positioning yourself right in the heart of opportunity. Training in such a vibrant city gives you access to:

Real-time project exposure

Internships with leading construction companies

Networking with industry experts

Job placement opportunities post-course

By choosing Rite Academy, students gain access to Hyderabad’s growing professional ecosystem, giving them a significant advantage in the job market.

Why Choose Rite Academy?

When it comes to quality MEP education, Rite Academy stands out as a leader in the field. Here are some reasons why aspiring MEP engineers choose Rite Academy for their professional training:

1. Industry-Approved Curriculum

Rite Academy’s MEP program has been designed with input from industry professionals, ensuring that students learn the most current and relevant skills. The curriculum doesn’t just teach theory—it provides hands-on experience through lab sessions, case studies, and project simulations.

2. Experienced Faculty

Each trainer at Rite Academy brings years of industry experience to the classroom. With backgrounds in engineering, project management, and construction, they offer insights that go beyond textbooks, helping students understand the real-world challenges they’ll face.

3. State-of-the-Art Infrastructure

The institute is equipped with modern labs and simulation tools to give students an immersive learning experience. Tools like Revit MEP, AutoCAD, and HAP are integral to the program, giving students a competitive edge.

4. Placement Assistance

Rite Academy provides dedicated placement support to all its students. The academy partners with top companies in the HVAC, construction, and electrical sectors to ensure students get job interviews upon course completion.

5. Certifications and Recognition

Rite Academy provides certificates that are recognized by industry leaders. This enhances employability and validates your expertise in MEP systems.

Who Should Enroll in an MEP Course?

The MEP Course in Hyderabad at Rite Academy is ideal for:

Mechanical, Electrical, and Civil Engineering graduates

Diploma holders in relevant fields

Working professionals seeking to upskill

Freshers aiming for core industry jobs

Contractors or entrepreneurs in the construction field

Whether you're just starting your career or looking to pivot into a more specialized technical role, MEP training can open new doors and higher salary brackets.

Scope and Career Opportunities After an MEP Course

Completing an MEP Course in Hyderabad opens up a multitude of career options. Some of the job roles include:

MEP Engineer

HVAC Design Engineer

Electrical Design Engineer

Plumbing Engineer

Site Supervisor

CAD/BIM Technician

Project Coordinator

These roles are in high demand not just in India, but also in the Middle East, Europe, and Southeast Asia. Countries like the UAE, Qatar, and Saudi Arabia are constantly hiring skilled MEP professionals for large-scale infrastructure projects.

With MEP systems being an integral part of sustainable and smart buildings, the job market is expected to grow even more robust in the coming years.

MEP and the Future of Green Buildings

As sustainability becomes a core focus in the construction industry, the role of MEP engineers is evolving. Today’s engineers need to be knowledgeable not just about traditional systems but also about eco-friendly practices. An advanced MEP Course in Hyderabad like the one at Rite Academy includes green building concepts, energy-efficient design, and renewable energy integration.

This added expertise not only future-proofs your career but also allows you to contribute to a greener, more sustainable world.

Final Thoughts

Choosing the right career path can be overwhelming, especially in the highly competitive engineering domain. However, one decision can redefine your professional future—enrolling in a high-quality MEP Course in Hyderabad. It’s a step toward a rewarding, future-ready career in one of the most vital sectors of modern infrastructure.

If you're serious about building a successful career in the construction and engineering industry, there’s no better place to start than Rite Academy. With industry-aligned training, expert faculty, and strong placement support, Rite Academy ensures that every student is not just certified but employable.

Take the first step toward a secure and dynamic career in MEP engineering today—enroll with Rite Academy, Hyderabad’s trusted name in technical education.

CONTACT US;

9121921999

EMAIL ID;

ADDRESS;

Flat No 402, 11-4-659, Bhavya Farooqi Splendid Towers, Red Hills, Lakdikapul, Hyderabad, Telangana 500004

0 notes

Text

Industrial Safety Training 3D Animation Video

Introduction: Industrial Safety Training

Industrial safety training is non-negotiable, especially in high-risk environments like construction sites, factories, and industrial plants. Traditional safety training often relies on lengthy manuals, static presentations, and outdated videos. While these methods can convey critical information, they often fail to engage employees or make a lasting impact. This is where animation—particularly 3D animated safety training—comes into play.

Animation is upgeading the way industries educate workers about safety protocols. From visually simulating hazardous situations to demonstrating proper PPE (Personal Protective Equipment) use, 3D animations make complex procedures clear, memorable, and effective. Let’s explore in this article, why animation is rapidly becoming the preferred tool for industrial safety training and how it improves outperforms traditional methods. Along with this, will cover some common topics related to factory workplace safety.

What is industrial safety training?

An industrial safety training is an important part of the factory workplace for employees, which helps the workers to know about what steps/measures are available to make the working place safe & secure to avoid any unwanted accidents.

A workplace safety training program briefly describes proper safety information (such as equipment handling, emergency procedures, fire safety) that the factory employees must take during working time. The aim of the training is to educate workers on identifying, managing, and preventing workplace hazards in industrial environments.

What are the steps of industrial safety training at factory workplace?

Now let’s grab the command on Safety awareness programs and will take a look closely to explore what actually steps can be taken by an industry for their employees safety at workplace. From training objectives to final evaluation of factory safety program, will cover each step one by one.

Needs Assessment: Identify specific safety risks and training needs based on the factory’s operations, machinery, and past incident reports.

Planning and Goal Setting: Define clear training objectives, content scope, duration, and desired outcomes aligned with industry regulations and standards.

Curriculum Development: Create or source training materials, such as manuals, videos, presentations, and practical demonstrations tailored to the workforce.

Employee Training Delivery: Conduct training sessions using methods like classroom instruction, hands-on practice, e-learning modules, or safety drills.

Testing and Evaluation: Assess employees’ understanding through quizzes, practical assessments, or observation to ensure they can apply the safety knowledge.

Feedback and Improvement: Collect participant feedback and incident data to refine future training programs and address gaps or evolving safety concerns.

Ongoing Refresher Training: Provide regular updates and refresher courses to reinforce safety practices and adapt to new equipment, processes, or regulations.

What are Industry Animation Company Services?

Let’s explore we (Chasing Illusions) as one of the best industry animation services providers avail you many services whether you’re looking for safety training & compliances, manufacturing plant animation, working at hazards environment, machine operation, etc., we’ve got you becuase we’re the one you’re looking for to bring complex industry workplace concepts to enaging 3d animation videos.

Manufacturing & Industrial Plants

We create compelling visuals for manufacturing and industrial plants. We develop realistic virtual tour of industrial factories and Smart factory simulation walkthroughs that showcase plant layouts, production processes, and machinery functionality. Our visualizations help clients optimize workflows, improve safety training, and communicate complex technical information effectively.

Energy and water Plants

We create engaging Energy and Water Plants Animations that showcase the complex infrastructure and processes involved in energy generation and water treatment. Our virtual tour of water treatment plants help clients communicate effectively, whether it’s explaining the technology behind renewable energy sources or demonstrating the purification process of a water treatment facility. We bring the best 3D water plant walkthrough to life, highlighting their importance and impact on the community.

Logistics Plant

We create dynamic Logistics plant 3D walkthroughs, bringing complex operations to life. We develop virtual warehouse facility that showcase warehouse layouts, inventory management systems, and the flow of goods through the facility. Our 3D walkthrough logistics plant visualizations highlight efficiency, safety, and technological integration, helping clients optimize logistics processes, improve communication.

Innovative Machines and Processes

We specialize in visualizing innovative machines and processes in 3D animation. We create 3D virtual Industrial animations and simulations that showcase the inner workings and functionality of cutting-edge technology. Whether it’s a manufacturing process or machinery product, we bring these innovations to life, clearly communicating their benefits and potential impact.

Industrial Safety Training and Compliance

We create engaging Industrial Safety Training Animations. We transform complex safety procedures and regulations into clear and concise visual experiences. Our Safety animations cover a range of topics, from proper equipment usage and hazard identification to emergency response protocols and regulatory compliance. Our goal is to create a safer working environment for everyone.

Aerospace and Defense

We create compelling visuals for the Aerospace and Defense industry. We develop high-quality animations and simulations showcasing complex aircraft, spacecraft, and defense systems. Our expertise includes visualizing technical processes, demonstrating product functionality, and creating engaging marketing materials. We help clients communicate complex information clearly and effectively, from training simulations to mission visualizations, supporting their communication and strategic objectives.

Why Safety Training Needs a New Method?

Construction workers often operate in high-pressure environments, facing risks from falling objects, unstable structures, electrical hazards, and more. Conventional safety training tends to be text-heavy, monotonous, and often too generic, making it hard for workers to remember critical safety protocols.

Animated safety videos offer a dynamic alternative. With vibrant visuals, realistic simulations, and clear voiceovers, these videos simplify complex topics, helping workers retain information longer. Whether it’s demonstrating the correct way to wear PPE or showing the consequences of ignoring scaffold safety, animation communicates better and sticks longer.

Who needs factory workplace safety guide?

According to the safety point of view, each and every factory employee must join the workplace safety training program to be a witness of practical application of safety protocols. Some of the notable factory workplace employees are machine operators, maintenance staff, supervisors, engineers, and even new hires. Employees especially who works in hazardious situation whether directly or indirectly, must be trained to recognize risks, follow safety protocols, and respond effectively in emergencies to ensure a safe and compliant workplace.

Why industrial safety training is important for factory workers?

An industrial safety training program for factory workers is important becuase a safety program becuase of government regulations for workplace safety and industry rules & regulations. It helps every industry to guide itself to perform safety measures to make sure the working evnvironment is safe & secure to prevent any accident.

Industrial safety training is crucial for factory workers as it equips them with the knowledge and skills to prevent accidents, handle equipment safely, and respond to emergencies. It reduces the risk of injuries, protects lives, and promotes a safety-first culture. Additionally, it ensures compliance with legal regulations, helping avoid costly penalties and downtime.

Why traditional safety training method is not useful for today’s Industries?

Let’s get started with what measurments is considered under traditional safety training method. In earlier days, industries used to follow up like: Printed manuals and checklists, Classroom-based presentations,On-the-job mentoring or shadowing, and Generic safety videos.

These methods were one of the proven techniques used to trained the factories employees for safety. While such methods gave benefits but also they had some disadvantages like:

Low Engagement: Workers often find them dull and unengaging.

Poor Retention: Static visuals and text-heavy formats don’t promote long-term memory.

Limited Customization: Most training modules aren’t tailored to specific job sites or hazards.

Language Barriers: In a multilingual workforce, reading comprehension becomes a hurdle.

Why 3D animation is better than traditional methods in safety training?

Now cover some of the most important advantages of animation for factory safety guide.

1. Realistic Visual Representation: 3D animated videos can change real-world environments, machinery, and processes in great detail. This helps workers in many ways like, to understand site-specific hazards, visualize unsafe practices vs. safe alternatives and recognize emergency exits, fire hazards, and confined spaces.

2. Better Engagement and Retention: Animated safety training is dynamic, colorful, and visually stimulating, which naturally boosts attention span. When information is presented through motion graphics or character-led storytelling, it becomes easier to understand, more interesting to watch, and even easier to recall during real-life emergencies.

3. Simplifies Complex Procedures: Some industrial processes—such as handling hazardous chemicals, operating heavy machinery, or executing lockout/tagout (LOTO) procedures—are difficult to explain through text. Animation breaks down complex concepts into step-by-step visuals, helping workers to understand procedures faster, avoid errors caused by misinterpretation, and minimize accidents due to lack of understanding.

4. Consistency Across Locations: Traditional safety training can vary from one instructor to another, leading to inconsistent learning outcomes. In contrast, animated training modules helps to deliver the same message every time, are scalable across departments or branches, and can be translated or subtitled for diverse workforces.

5. Cost-Effective Over Time: Although initial production costs for animation may be higher than printing manuals or hiring instructors, animated training offers long-term savings like no recurring trainer fees, no need to print new materials every time regulations change, and reusable across departments and over the years.

6. Supports E-Learning and Remote Access: In the era of hybrid work and decentralized job sites, digital learning is more important than ever. Animated training videos can be accessed on smartphones, tablets, and computers, are perfect for remote onboarding, and supports just-in-time learning when a refresher is needed.

What are the benefits of industrial safety training for employers?

There are numerous benefits of factory safety program from legal protction & compliance to lower conpensation cost, will cover a few safety training program benefits.

Reduced Workplace Accidents: Effective safety training minimizes the chances of injuries, equipment damage, and hazardous incidents. This leads to a safer work environment and fewer disruptions in daily operations.

Lower Insurance and Compensation Costs: With fewer accidents, employers face reduced workers’ compensation claims and lower insurance premiums. This can significantly cut down operational expenses over time.

Improved Productivity and Efficiency: Well-trained employees work more confidently and efficiently, knowing how to safely operate machinery and handle materials. This boosts overall productivity and reduces downtime due to safety incidents.

Enhanced Company Reputation: A strong safety record reflects positively on the company’s image among clients, employees, and regulatory bodies. It also helps attract and retain skilled workers who value a safe workplace.

Regulatory Compliance and Legal Protection: Safety training ensures adherence to industry standards and government regulations. It helps avoid legal penalties, audits, and potential lawsuits related to workplace safety violations.

How can industrial safety training reduce workplace accidents?

Industrial safety training reduces workplace accidents by educating employees on how to identify hazards, operate machinery safely, and follow proper safety procedures. It promotes awareness, encourages the correct use of protective equipment, and prepares workers to respond effectively in emergencies. With regular training, employees are more alert and better equipped to prevent mistakes that lead to injuries or accidents.

How to choose best factory workplace safety training video maker?

To choose the right safety training provider, look for one with proven industry experience, certified trainers, and up-to-date course content aligned with safety regulations. Check for customizable training options, hands-on learning methods, and positive client reviews. A reliable provider should also offer flexible scheduling, clear certification processes, and ongoing support to ensure long-term safety compliance.

Why Chasing Illusions is best Industrial Animation Services Provider?

The best Industrial Animation Company for 3d safety training videos is Chasing Illusions because we specialized in creating engaging 3d animated safety training videos for construction site accidents. With a strong focus on realism, technical accuracy, and visual storytelling, we transform complex safety protocols into engaging, easy-to-understand 3d animations. Whether it’s simulating fall protection procedures, machinery hazards, or emergency responses, their custom-built animations help construction companies train workers effectively, reduce on-site risks, and foster a strong safety culture.

Conclusion: Industrial Safety Training

With increased workplace regulations and a growing focus on employee safety, investing in effective safety training is not optional—it’s critical. 3D animation is no longer a novelty; it’s a necessity for industries looking to modernize their approach and reduce risks on-site.

By combining realism, engagement, and accessibility, animated safety training not only protects workers but also improves productivity and builds a strong safety culture. For construction companies, factories, and high-risk industries, animation is the future of safety education.

FAQs: Industrial Safety Training

What are the key safety measures on a construction site?

Here are the some common key safety measures include: Wearing appropriate PPE (helmets, gloves, boots, safety vests), Fall protection (harnesses, guardrails), Machine and equipment safety protocols, Site cleanliness and hazard signage, Proper training in operating tools and machinery.

Why is PPE important in construction?

PPE (Personal Protective Equipment) protects workers from site-specific risks like falling debris, sharp objects, noise, chemical exposure, and more.

How do you reduce human error on construction sites?

An industry can follow up some steps to reduce the human error on construction sites like: worker awareness, communication, consistency in following procedures, engagement in training programs.

CONTACT NOW

Need high-impact safety animation 3d video for your industrial training?

#industry safety rules#industry safety training video#industry safety animation video#industry animation services#industrial animation#industrial#industry safety training animation video#factory workplace safety#factory workplace rules

0 notes

Text

Why Fire Protection BIM modeling in Texas is Essential for Modern AEC Projects

In Texas, where cities like Austin, Dallas, and Houston are expanding rapidly, construction projects are getting more complex and safety systems like fire protection need to keep up. That’s where Fire Protection BIM (Building Information Modeling) comes in. It’s not just a digital trend it’s becoming an industry essential.

Let’s explore why Fire Protection BIM Modeling is reshaping how buildings are designed, approved, and built across the Lone Star State.

What Is Fire Protection BIM?

Fire Protection BIM Modeling is the process of designing fire suppression and detection systems (like sprinklers, standpipes, alarms, and hydrants) in a 3D environment. But this isn’t just about visuals it’s about data-rich modeling. Every component includes technical specs, codes, and performance metrics.

Think of it as a digital twin of your building’s life safety systems, designed for coordination and compliance from the ground up.

Why It Matters in Texas

Texas construction is fast-paced and spread across diverse terrain from hospitals in Dallas to industrial plants in Houston. Managing fire protection on large-scale projects without digital coordination often leads to clashes, delays, and rework.

With BIM, you can:

Spot clashes early between fire systems and other trades (like HVAC or structural beams)

Produce more accurate estimates and fewer change orders

Coordinate with architects, contractors, and inspectors from a single model

In a state where labor costs and timelines are under constant pressure, BIM streamlines the entire design-to-installation workflow.

Regulatory Benefits

Texas cities enforce NFPA standards along with their own codes. BIM helps fire protection engineers stay compliant by embedding those requirements into the design itself.

Fire marshals in cities like San Antonio and Fort Worth increasingly review digital BIM files during plan approval. With models showing clearances, zone drawings, and access points, inspectors get the full picture faster.

For contractors, that means fewer rejected submittals and more predictable inspection outcomes.

How Contractors and Engineers Benefit

BIM isn’t just for architects. For fire protection contractors and MEP firms, the payoff is tangible:

You get fabrication-ready drawings straight from the model

Fewer delays during install due to clearer routing and layout

Models double as as-builts for owners or facility managers

And as clients start asking for digital twins for future maintenance, having a well-structured BIM model gives you a long-term edge.

Real Example: Healthcare in Austin

On a recent hospital project in Austin, BIM helped fire protection engineers coordinate with HVAC, electrical, and medical gas systems across multiple wings. The model flagged over 20 clashes early in design saving thousands in field changes.

BIM also allowed the team to simulate alarm coverage, ensuring compliance and smoother reviews.

Trust the Experts at Clove Technologies

As BIM adoption grows in Texas, so does the need for experienced partners who understand the tools, the codes, and the construction landscape.

Clove Technologies offers specialized Fire Protection BIM Modeling services tailored to Texas regulations and project demands. Whether you’re designing a high-rise in Dallas or a logistics hub near Laredo, Clove’s BIM team brings precision, coordination, and code compliance to every project.

If you’re looking to reduce rework, speed up inspections, and build safer structures, now’s the time to explore how Clove Technologies can support your fire protection strategy.

Check out this blog on Electrical BIM Modeling in USA.

Keywords : Plumbing BIM modeling, Mechanical BIM modeling in Texas, Fire Protection BIM modeling in Texas, Fire Protection BIM modeling in Texas, Low Voltage BIM modeling in Florida, Plumbing BIM modeling in Georgia, Mechanical BIM modeling in Illinois, Fire Protection BIM modeling in Illinois, Electrical BIM modeling California, Low Voltage BIM modeling, CaliforniaBIM modeling in Georgia, Scan to BIM, Scan to BIM in Georgia, H.V.A.C 3D Modeling in US / USA, Plumbing 3D Modeling, H.V.A.C 3D Modeling.

0 notes

Text

In the modern world, ensuring the fire safety of electrical products and materials is of paramount importance. The quality and safety of electrical and electronic devices, such as household appliances, wiring systems, and other consumer electronics, must adhere to stringent fire resistance standards. A critical testing method in this regard is the “Test Glow Wire Apparatus,” commonly used to assess the flammability of materials when exposed to heat sources. Among the various available products in the market, the LISUN ZRS-3H Glow-wire Test Apparatus has gained significant attention in the fields of quality supervision and related industries due to its precision and reliability. Introduction to Test Glow Wire Apparatus A “Test Glow Wire Apparatus” is a device used for simulating the heat generated by electrical components that could potentially ignite surrounding materials. It is specifically designed to measure how materials react to high temperatures, simulating real-world conditions where materials might catch fire due to overheating electrical components. The glow wire test primarily focuses on evaluating the fire resistance of insulating materials used in electrical and electronic products. The test involves exposing the material to a heated metal wire, which mimics the heat generated by electrical components. Depending on the reaction of the material to the heat, it is categorized based on its ability to resist ignition and spread of fire. LISUN ZRS-3H Glow-wire Test Apparatus: Overview and Key Features The LISUN ZRS-3H Glow-wire Test Apparatus is a modern testing system used to assess the fire safety of materials, particularly in the context of electrical and electronic devices. It is a precise and reliable tool that adheres to international testing standards, such as IEC 60335-1 and IEC 60695-2-10. Key Features of the LISUN ZRS-3H Glow-wire Test Apparatus: • High Accuracy Temperature Control**: The apparatus is equipped with an advanced temperature control system that ensures accurate and consistent results throughout the testing process. • Wide Range of Test Materials**: The ZRS-3H can test a wide variety of materials, including plastics, insulating components, and other non-metallic substances used in electrical and electronic products. • Safety Mechanisms**: The apparatus features a variety of safety protocols to ensure safe operation, including automatic shut-off in case of overheating or malfunction. • Comprehensive Reporting**: The system is capable of generating detailed reports of test results, providing clear insights into the performance of materials under high heat conditions. Testing Process Using Test Glow Wire Apparatus The glow wire test simulates a high-temperature event, such as an electrical short circuit or faulty component, which can lead to material ignition. The test procedure is as follows: • Preparation of Test Specimens: The material samples are prepared according to the required dimensions, typically 120mm x 120mm, as per IEC standards. The specimens should be clean, dry, and free from any contaminants that could affect the results. • Heated Wire Setup: A metal wire, usually made of a nickel-chromium alloy, is heated to a predetermined temperature. The temperature is chosen based on the material being tested and is typically set between 650°C and 960°C. • Exposure to Heat: The heated wire is then brought into contact with the material sample for a specified time, typically 30 seconds to 2 minutes, depending on the material and the test standards being followed. • Observation of Material Reaction: During the test, the material’s response is carefully observed. Key factors include: – Whether the material ignites upon contact with the wire. – The time it takes for the material to ignite (if applicable). – Whether the material continues to burn after the wire is removed. – The extent of damage caused to the material during the test. • Evaluation: The test results are then evaluated based on predefined criteria, including the material’s classification as a non-flammable, flame-retardant, or flammable material. Practical Applications of Test Glow Wire Apparatus In quality supervision departments and enterprises manufacturing electrical devices, the use of the Test Glow Wire Apparatus is essential to ensure compliance with national and international fire safety standards. The apparatus is widely used for: • Fire Safety Testing of Insulation Materials: Electrical components like wires, cables, and connectors must undergo rigorous testing to ensure that their insulation materials can withstand potential heat buildup without igniting. The LISUN ZRS-3H helps ensure that these materials pass critical fire resistance standards. • Product Development and Certification: Manufacturers use the glow wire test apparatus during product development to ensure that their products meet regulatory standards before they hit the market. Additionally, the apparatus is used for obtaining certifications from authorities such as UL (Underwriters Laboratories) and CE (Conformité Européenne). • Quality Control: Ongoing quality control is critical in manufacturing processes. Regular use of the glow wire test apparatus in production environments helps ensure that only materials with acceptable fire safety properties are used in manufacturing processes. • Safety Assessments for Existing Products: Enterprises use the Test Glow Wire Apparatus to assess the fire safety of already marketed products, ensuring that they remain compliant with any updates to fire safety standards. Test Glow Wire Apparatus and Global Standards Various international standards outline the requirements for conducting glow wire tests. The LISUN ZRS-3H Glow-wire Test Apparatus complies with several of these key standards, ensuring its reliability and worldwide applicability. • IEC 60335-1: This standard specifies the safety requirements for electrical appliances, including testing for fire hazards. • IEC 60695-2-10: This standard provides guidance on the test methods and procedures for evaluating the fire resistance of materials used in electrical devices. • UL 94: This is a widely recognized standard for the flammability of plastic materials, especially those used in electrical and electronic products. The LISUN ZRS-3H test apparatus is designed to meet or exceed these standards, making it a versatile tool for enterprises looking to meet global safety certifications. Example Test Results Using the LISUN ZRS-3H The following table provides an example of the results obtained from a typical glow wire test conducted using the LISUN ZRS-3H: Test Material Glow Wire Temperature Ignition Time (sec) Post-test Damage Rating PVC Insulation 850°C 12 No ignition Non-flammable ABS Plastic 750°C 8 Surface burn Flame-retardant Polycarbonate 960°C 20 Material ignited Flammable Nylon 6/6 800°C 5 No ignition Non-flammable PE (Polyethylene) 850°C 15 Material ignited Flammable These results demonstrate how the LISUN ZRS-3H Glow-wire Test Apparatus can provide detailed insights into the fire safety characteristics of materials. Conclusion The Test Glow Wire Apparatus, particularly the LISUN ZRS-3H model, is an essential tool for ensuring fire safety in electrical products. For quality supervision departments and enterprises, this testing apparatus plays a crucial role in compliance with national and international standards, ensuring that electrical and electronic materials can withstand heat exposure without posing fire hazards. By using the LISUN ZRS-3H, companies can improve product safety, enhance customer trust, and reduce the risk of fire-related accidents. The reliability and accuracy of the LISUN ZRS-3H Glow-wire Test Apparatus make it an invaluable asset for any organization involved in the manufacturing and testing of electrical materials. Whether for product development, quality control, or safety assessments, this apparatus serves as a vital tool in maintaining the highest standards of fire safety in electrical components. Read the full article

0 notes

Text

How Electric Toy Testing Labs Test for Overheating and Short Circuits?

Electric toys are beloved by children all over the world for their interactive, engaging features. However, as with any product that involves electricity, safety is a critical concern. One of the main risks associated with electric toys is the possibility of overheating and short circuits, which can pose serious dangers, including burns, fires, and even electrical shocks. This is why manufacturers rely heavily on electric toys testing lab to ensure that their products are safe for use.

In this blog, we will explore how electric toy testing labs test for overheating and short circuits. By understanding the rigorous procedures and tools used by these specialized labs, manufacturers can ensure that their electric toys are safe and compliant with international safety standards.

1. The Importance of Overheating and Short Circuit Testing

Before we dive into how these tests are conducted, it’s important to understand why testing for overheating and short circuits is so crucial for electric toys.

Overheating: Electric toys typically use batteries or power sources to function, and if the internal electrical components become too hot, it can cause the toy to malfunction, burn, or even ignite. Overheating can occur if there is insufficient insulation, faulty wiring, or if the toy is left on for extended periods.

Short Circuits: A short circuit occurs when the electrical current flows along an unintended path, which can lead to excessive current, heat generation, and potentially dangerous situations such as fires or electrical shocks. In electric toys, short circuits may occur due to poor design, defective components, or wear and tear on wires and connectors.

By ensuring that electric toys are properly tested for overheating and short circuits, manufacturers can avoid costly recalls, lawsuits, and most importantly, the potential harm to children.

2. How Electric Toy Testing Labs Test for Overheating

Overheating is one of the most significant safety risks in electric toys, and testing for this issue involves several stages. Testing labs have precise protocols to ensure that toys will not overheat under normal use conditions.

A. Temperature Monitoring

The primary method of testing for overheating is through temperature monitoring. Electric toy testing labs use thermocouples or thermal sensors to measure the temperature of the toy's components, such as the motor, batteries, and electrical circuits.

Initial Testing: During testing, the toy is powered on and allowed to run for an extended period, simulating typical usage. The sensors are strategically placed in critical areas, such as around the motor and battery compartment, to monitor the temperature at various points.

Threshold Limits: Manufacturers and safety standards typically set temperature threshold limits. If the temperature exceeds these limits, the toy is deemed unsafe. For example, a toy’s motor or battery should not exceed a certain temperature to avoid the risk of fire or burns.

B. Simulating Different Conditions

Testing labs often simulate a variety of conditions under which a toy might overheat. This includes:

Prolonged Use: Toys are tested for long durations to ensure they don’t overheat when left on for extended periods, such as in the case of a child forgetting to turn the toy off.

Environmental Factors: Labs may also test toys under different environmental conditions, such as high ambient temperatures or humid environments, to simulate how the toy might perform in hot climates or poorly ventilated areas.

C. Power Surge Simulation

Electric toys often rely on batteries or power adapters, and an unexpected power surge can lead to overheating. To test for this, labs simulate power surges that can occur in real-world settings, such as during lightning storms or when using low-quality power adapters. Toys are tested under these conditions to ensure that the circuit does not overheat.

D. Overheating Protection Mechanisms

Many electric toys come equipped with built-in mechanisms to prevent overheating, such as thermal fuses, overcurrent protection circuits, and auto-shutoff features. Testing labs assess whether these protection mechanisms work as intended.

Thermal Fuse Testing: If the toy has a thermal fuse, the lab will test whether it activates appropriately when the temperature exceeds a certain level. A thermal fuse will shut off the power to prevent further overheating.

Circuit Breakers and Auto-Shutoff: Toys with auto-shutoff features are tested to ensure they correctly power down after a specific period or when an overheating threshold is reached.

3. How Electric Toy Testing Labs Test for Short Circuits

A short circuit in an electric toy can be catastrophic, leading to equipment damage, fires, or even electric shocks. Therefore, testing for short circuits is a critical component of the safety evaluation process. Electric toy testing labs employ various methods to detect and prevent short circuits.

A. Wiring and Circuit Inspection

One of the first steps in short circuit testing is to carefully inspect the toy's wiring and electrical components. Electrical engineers in testing labs conduct a thorough inspection of all wires, connectors, and circuits to ensure there are no exposed wires or faulty connections that could lead to a short circuit.

Wire Insulation: The insulation around wires is examined to ensure there are no cuts, abrasions, or areas where the wires could come into contact with each other or the toy’s metal components.

Component Quality: The quality and design of the toy’s internal components, such as switches and connectors, are also evaluated. Faulty or poorly designed components can increase the risk of short circuits.

B. Short Circuit Simulation

To simulate real-world conditions where a short circuit might occur, testing labs intentionally create faults in the toy’s electrical circuit. This can include:

Intentional Wire Shorting: The toy’s wires are shorted by connecting the positive and negative terminals together, creating a direct path for current to flow. This simulates what would happen if the wires became exposed and touched each other.

Component Malfunction: Certain components, like switches or motors, are deliberately tested to failure to see if they cause a short circuit when malfunctioning.

C. Current and Voltage Testing

Testing labs use multimeters and oscilloscopes to measure the current and voltage within the electric toy’s circuit. If a short circuit occurs, it will cause an abnormal increase in current, which can be measured.

Current Surge Testing: The lab will measure the current drawn by the toy when it is powered on and during operation. If the current exceeds normal levels, this could indicate a short circuit or a malfunctioning component.

Voltage Fluctuations: Short circuits often lead to voltage fluctuations. Using an oscilloscope, testing labs can identify unusual voltage spikes or drops that indicate a short circuit in the toy’s electrical system.

D. Safety Mechanism Testing for Short Circuits

Similar to overheating protection, many toys are equipped with overcurrent protection circuits or fuses to prevent short circuits from causing damage or harm. These safety mechanisms are tested by intentionally creating short circuits in the toy to verify that the protection systems activate and prevent further damage.

Fuse Testing: The fuse should blow or disconnect the power if a short circuit occurs, preventing further damage or safety hazards. The lab checks that the fuse performs correctly when subjected to short-circuit conditions.

4. Ensuring Compliance with Safety Standards

Electric toy testing labs also ensure that the toys they test comply with various safety standards, such as IEC 62115 for electrical safety, EN 71 for toy safety in Europe, and ASTM F963 in the U.S. These standards include specific guidelines for testing overheating and short circuits, which labs follow to provide certification that the toys are safe for children.

Documentation and Certification: After conducting the tests, testing labs provide comprehensive reports detailing the toy’s performance in overheating and short circuit tests. Manufacturers can use this documentation to prove compliance with safety regulations when selling their toys in various markets.

Conclusion

Overheating and short circuits are significant safety concerns when it comes to electric toys. Testing for these issues is an essential part of the manufacturing process, ensuring that toys are safe for children to play with. By relying on electric toys testing lab, manufacturers can ensure that their products are free from electrical hazards such as overheating and short circuits. These labs use a combination of advanced equipment, simulation techniques, and expert knowledge to test toys for safety, offering peace of mind to both manufacturers and consumers alike. With thorough testing and compliance with safety standards, electric toys can continue to provide fun and excitement without compromising safety.

#Electric Toys Testing Lab#Electric Toys Testing#Toy Testing#Toy Testing Lab#Testing Lab near me#Testing Lab in Delhi

0 notes

Text

Enhancing Safety with Breathing Apparatus Training in Melbourne

In high-risk industries such as firefighting, mining, construction, and chemical handling, the ability to safely operate in oxygen-deficient or toxic environments is crucial. One of the most vital tools in these scenarios is the self-contained breathing apparatus (SCBA), which provides users with a clean air supply in hazardous conditions. But having the equipment isn’t enough—knowing how to use it correctly and confidently is essential.

This is where Breathing Apparatus (BA) training becomes indispensable. For workers and organizations in Melbourne, investing in comprehensive breathing apparatus training is not only a regulatory requirement but also a life-saving necessity. This blog delves into why BA training is essential, what the training involves, industry standards, and how Melbourne’s unique industrial landscape underscores the importance of such education.

Understanding Breathing Apparatus Training

What is a Breathing Apparatus?

A breathing apparatus is a device worn by personnel working in environments where the air is unbreathable due to smoke, gas, lack of oxygen, or toxic substances. The most common type is the self-contained breathing apparatus (SCBA), which includes a face mask, air cylinder, and a pressure regulator. Other types include supplied air respirators (SARs) and escape breathing apparatuses (EBA) used for emergency egress.

What Does BA Training Involve?

Breathing Apparatus training typically covers:

Theory: Understanding respiratory hazards, types of apparatus, and workplace legislation.

Practical Skills: Donning and doffing the BA, conducting pre-use checks, emergency procedures, and simulated exercises in low-visibility or confined spaces.

Maintenance and Inspection: Ensuring the BA is in working order, storing it correctly, and reporting any faults.

Training ensures that personnel are not only familiar with the apparatus but are also capable of functioning effectively under pressure.

Why is BA Training Essential?

1. Health and Safety Compliance

Under WorkSafe Victoria regulations and the Occupational Health and Safety Act 2004, employers have a duty to provide safe working conditions, which includes adequate training for working in confined spaces or hazardous environments. BA training is a cornerstone of these safety strategies.

2. Confidence in Emergencies

When toxic gases leak or a fire breaks out, there’s no time to second-guess your equipment. BA training ensures that workers can act decisively, calmly, and effectively during emergencies.

3. Preventing Fatalities

Incorrect use of breathing apparatus has led to numerous preventable deaths across various sectors. Regular training ensures that individuals are prepared for both routine and emergency operations.

4. Insurance and Liability

Well-trained staff reduce the risk of incidents, potentially lowering insurance premiums and reducing liability for the business in case of workplace accidents.

Key Industries in Melbourne That Rely on BA Training

Melbourne’s economic fabric includes several high-risk industries where BA training is vital:

1. Fire and Emergency Services

Firefighters are the most obvious users of BA. Training in simulated smokehouses and real-time drills ensures they can tackle fires in buildings, bushlands, and vehicles while staying safe.

2. Construction and Confined Spaces

Melbourne’s ongoing infrastructure boom means more workers are entering confined spaces like tunnels, sewage systems, and elevator shafts. These spaces often lack oxygen or contain harmful gases.

3. Oil, Gas, and Chemical Industries

Workers in these industries are at constant risk from volatile chemicals and gas leaks. Sites in and around Melbourne, including the nearby Port of Geelong and Laverton North industrial zones, necessitate rigorous training protocols.

4. Mining Operations

Although mining isn’t central to Melbourne itself, many companies headquartered here operate mines in Victoria and beyond. Workers in mines often operate in enclosed spaces where BA is mandatory.

5. Aviation and Maritime Sectors

Airports like Tullamarine and shipping yards around Port Melbourne require emergency response teams who are trained in BA use, especially during fuel leaks or chemical spills.

The Training Experience: What to Expect

Entry Requirements

Typically, participants must have a reasonable level of fitness, as practical exercises can be physically demanding. Some courses require prior completion of basic safety or confined space training.

Duration and Certification

Most BA courses are one to two days long, with refresher courses recommended every one to two years. Certifications may include:

RIIWHS202E – Enter and work in confined spaces

MSMWHS216 – Operate breathing apparatus

PUAFIR207 – Operate breathing apparatus open circuit (for emergency services)

Course Structure

A well-designed BA course will include:

Introductory Theory: Respiratory hazards, legal obligations, types of apparatus.

Equipment Familiarisation: Hands-on learning with SCBA, including inspection and troubleshooting.

Practical Simulations: Training in dark or smoke-filled environments, often with physical and cognitive challenges.

Assessment: Both written and practical assessments to evaluate competence.

Leading Training Providers in Melbourne

Several accredited training organizations in Melbourne offer high-quality BA training. These include:

1. Health & Safety Training Centre (HSTC)

Located in the western suburbs, HSTC provides nationally recognised courses and customised programs for industry clients.

2. Fire & Safety Australia

Operating across Victoria, they offer both public and onsite training with practical simulations tailored to industry needs.

3. WAM Training

Based in Laverton, WAM offers confined space and breathing apparatus training suitable for construction and industrial settings.

4. Asset Training Australia

They provide flexible delivery formats, including blended learning options, which are especially useful for regional clients.

5. TAFEs and RTOs

Institutions such as Kangan Institute and Holmesglen TAFE also run occupational health and safety courses, including BA training, as part of their vocational programs.

Regulatory Framework and Industry Standards

Breathing apparatus training in Australia aligns with several key regulations and standards, including:

AS/NZS 1715: Selection, use, and maintenance of respiratory protective equipment.

AS/NZS 1716: Respiratory protective devices.

Safe Work Australia Codes of Practice