#Flexible Packaging & Converting Machinery and Equipment

Explore tagged Tumblr posts

Text

Sheet Fed Paper Bag Machines

In the global push toward sustainable solutions, the paper bag industry has stepped into the spotlight. As consumer demand shifts from plastic to paper, manufacturers have embraced advanced machinery to meet market needs. Among the most transformative technologies is the sheet fed paper bag machine, a system designed to convert flat sheets of paper into eco-friendly bags with efficiency, precision, and speed.Get more news about sheet fed paper bag machine manufacture,you can vist our website!

Unlike roll-fed machines, sheet fed paper bag machines utilize pre-cut sheets rather than continuous paper rolls. This method offers several advantages: it allows for greater material control, better printing alignment, and more customized production runs. Particularly useful for boutique retailers, luxury packaging, and small to medium enterprises, sheet fed systems support flexibility without sacrificing performance.

How It Works

The process begins with loading stacks of printed or unprinted sheets into the feeder section. The machine then guides each individual sheet through a series of mechanical stages: gluing, folding, bottom forming, and gusseting. Advanced models also include inline printing, die-cut handles, and bottom pasting options, resulting in fully formed paper bags ready for distribution.

An important aspect of this equipment is automation. Modern sheet fed machines integrate PLC control systems, touchscreen interfaces, and automatic error detection features. These enhancements reduce manual labor, increase output, and minimize waste—making them ideal for eco-conscious manufacturers.

Benefits to Businesses and the Environment

Environmentally, the switch from plastic to paper bags is only meaningful if production itself is sustainable. Sheet fed paper bag machines typically accommodate recyclable kraft paper and water-based adhesives, minimizing environmental impact. What’s more, manufacturers can use paper made from responsibly managed forests or even recycled stock.

Economically, these machines reduce dependency on long material rolls, simplify logistics, and enable just-in-time production. Businesses can respond swiftly to small orders, seasonal packaging designs, or localized branding—all without committing to excessive inventory or waste.

Industry Applications

This technology finds application in several sectors: food and beverage (think bakery bags or takeout carriers), fashion retail, cosmetics, and even pharmaceuticals. The flexibility to adjust bag sizes, handle types, and printed content makes sheet fed machines suitable for a variety of branding needs.

With e-commerce growth driving demand for attractive and sustainable packaging, many firms are investing in in-house paper bag production. Sheet fed machines offer a compact footprint, making them ideal even for urban factories or decentralized workshops. For global brands seeking green credentials and fast turnarounds, this is a valuable investment.

Future Trends

As artificial intelligence, machine learning, and the Internet of Things (IoT) continue to influence industrial manufacturing, we can expect sheet fed paper bag machines to evolve. Smart sensors for real-time diagnostics, predictive maintenance, and energy-efficient motors will shape the next generation of machines.

Ultimately, as consumers become more environmentally aware and legislative pressure builds against single-use plastics, the role of the sheet fed paper bag machine becomes not just practical—but essential.

0 notes

Text

Paper Cup Blanks vs. Ready-Made Cups: Which Is Better for Your Brand?

When it comes to sourcing disposable cups for your business, one key decision often arises: Should you go for paper cup blanks or ready-made paper cups? Both options serve different purposes and can impact your brand’s visibility, cost efficiency, and customization flexibility. Let’s compare the two to help you choose what works best for your brand.

What Are Paper Cup Blanks?

Paper cup blanks are pre-printed, die-cut sheets of paper that form the body of a paper cup. These blanks are shipped to manufacturers or converters who form the final cup using specialized machinery. They are a popular choice for businesses that want to customize their cups in large volumes or have access to cup-forming facilities.

What Are Ready-Made Paper Cups?

Ready-made paper cups are fully formed, printed, and packaged cups that are ready for immediate use. These are ideal for small to mid-sized businesses looking for quick, hassle-free solutions without the need for additional processing or equipment.

Advantages of Paper Cup Blanks

Cost-Effective in Bulk: Paper cup blanks are often more economical for large-scale orders, especially when you already have forming capabilities or a tie-up with a converter.

Customization Control: You have complete creative control over the design, paper quality, and finish—perfect for businesses focused on strong brand identity.

Flexible Production: Blanks offer flexibility to produce different cup sizes and designs without holding large inventories of finished products.

Advantages of Ready-Made Cups

Convenience: Ready-made cups save time and eliminate the need for any manufacturing setup. Just order and use.

Ideal for Small Orders: For startups, cafes, or food stalls with limited requirements, ready-made cups are more practical and accessible.

Fast Delivery: With minimal lead time, ready-made cups are ideal for urgent needs or seasonal demands.

Which Is Better for Your Brand?

Choose Paper Cup Blanks if you:

Want full control over design and material

Have high-volume needs

Own or partner with a cup-forming facility

Choose Ready-Made Cups if you:

Want a plug-and-play solution

Have lower order volumes

Need a quicker turnaround

Conclusion: Both paper cup blanks and ready-made cups serve unique purposes. Your choice depends on your brand’s size, customization needs, and operational setup. If long-term branding and cost savings matter, cup blanks may be the smarter choice. If convenience and speed are priorities, ready-made cups are the way to go.

#disposable paper cup#paper cup company#paper cup manufacturers#paperblanks#disposable cups#biodegradablebowls#biodegradable#papercupsupplier#paper cups

0 notes

Text

Ensure Optimal Performance with Our AMC Solutions

Introduction to AMC Solutions

Let’s be real—downtime is a killer. Whether you're running a bustling office, a cozy café, or a multi-floor hospital, one system failure can send operations into chaos. That’s where Annual Maintenance Contracts (AMCs) come to the rescue.

Think of AMC as a guardian angel for your infrastructure—always watching, ready to fix problems before you even know they exist.

Why AMC Solutions Are Crucial for Businesses

Minimizing Downtime

Time is money. With AMC, you're not scrambling to find a technician last minute. Regular maintenance checks keep your systems humming and hiccup-free..https://vservit.com/annual-maintenance-contracts/

Enhancing System Lifespan

Neglected machines wear out faster. An AMC ensures all your hardware and equipment are cleaned, updated, and serviced regularly—stretching their lifespan and saving you replacement costs.

Reducing Unexpected Costs

Emergency repairs are often costlier than regular maintenance. AMC helps you budget better by converting unexpected chaos into predictable upkeep.

Types of AMC Solutions We Offer

Every business has different needs. That’s why our AMC services are flexible, modular, and industry-specific.

IT Infrastructure AMC

Your IT setup is the backbone of modern business. We keep it strong and secure.

Servers and Networking Equipment

We monitor and maintain your servers, switches, routers, and firewalls, ensuring peak performance and network stability.

Data Backup Systems

Lost data = lost trust. Our team ensures your backup systems are always functioning, with frequent checks and updates.

HVAC & Electrical AMC

Uncomfortable environments lead to unproductive teams. We handle HVAC units, UPS systems, power backups, and more.

Office Equipment AMC

Those printers and scanners may seem small, but when they fail, chaos ensues.

Printers, Scanners & Copiers

From jammed paper to driver issues, we’ve seen it all—and fixed it all.

Projectors and Conferencing Tools

We help you make an impression, not a technical mess, during client meetings and presentations.

Our Comprehensive AMC Process

We don’t just fix stuff—we optimize, monitor, and support.

Initial Assessment and Audit

We start with a detailed review of your systems, identifying strengths, weaknesses, and immediate risks.

Custom AMC Planning

No one-size-fits-all here. We build a contract tailored to your systems, usage, and business goals.

Scheduled Maintenance Visits

Regular checkups catch the little things before they become big, expensive problems.

Emergency Support Protocol

Got an urgent issue? Our rapid-response team is on standby 24/7.

Benefits of Choosing Our AMC Services

Tailored Service Packages

Whether you're a startup or an enterprise, we craft packages to fit your budget and technical needs.

24/7 Customer Support

Issues don’t clock out at 5 PM—and neither do we. Our support is always available.

Certified Technicians and Engineers

Our people aren’t just techies—they’re certified pros with years of field experience.

Transparent Reporting

You'll always know what we're doing, when we did it, and what comes next—no surprises, ever.

Industries We Serve

AMC isn’t a one-industry pony. We cater to a diverse range of sectors.

Healthcare

From life-saving equipment to patient databases, we ensure everything works seamlessly.

Education

Smart boards, projectors, computer labs—our AMC keeps learning uninterrupted.

Manufacturing

We maintain machinery systems, energy backups, and production IT for zero downtime.

Retail and Hospitality

Keep checkouts fast and customer comfort optimal—our AMC covers everything from POS systems to air conditioning.

Real-World Success Stories

Case Study: IT AMC for a Growing Startup

A tech startup faced weekly server crashes. After signing up for our AMC, crashes dropped to zero within 3 months, thanks to proactive maintenance and a custom support plan.

Case Study: HVAC AMC for a Hotel Chain

A popular hotel chain had HVAC failures that irritated guests. With our AMC, we implemented quarterly maintenance and remote monitoring. Guest complaints dropped by 85%.

Common Mistakes to Avoid When Choosing AMC Providers

Choosing Based on Price Alone

Cheap doesn’t always mean smart. Sometimes, you get what you pay for—and it's usually less than what you need.

Ignoring SLAs and Support Timelines

Make sure your provider has clear Service Level Agreements. It’s the difference between “we’ll come soon” and “we’ll fix it in 4 hours.”

Not Checking Credentials

Always ask for certifications, testimonials, and references. You wouldn’t trust a random mechanic with your car—don’t do it with your business systems either.

How to Get Started with Our AMC Services

Quick Onboarding Process

We make getting started simple—just fill out a quick form, and we’ll take it from there.

Flexible Contracts & Pricing

Monthly, quarterly, or annually—we have plans to suit your cash flow and operational rhythms.

0 notes

Text

Pepperl Fuchs | Incremental Rotary Encoder 14143613600Y47043

The Pepperl+Fuchs Incremental Rotary Encoder 14143613600Y47043 is a high-performance, reliable device designed to provide precise and accurate rotational measurements in industrial automation systems. As part of Pepperl+Fuchs' renowned series of sensors, this incremental rotary encoder plays a critical role in monitoring and controlling rotational movements in machinery, robotics, and other applications where position feedback is essential.

This particular model is designed with a robust construction, ensuring durability and long-lasting performance even in demanding environments. It uses incremental encoding technology to detect the angular position of a rotating shaft and convert it into an electrical signal that can be easily interpreted by control systems and machinery. The encoder produces a series of pulses, which represent the rotational movement, allowing precise speed and position control.

Key Features:

Incremental Output: The encoder provides incremental signals, typically in quadrature format, which are used to measure both rotational speed and position. This makes it ideal for applications requiring continuous feedback and motion control.

High Precision and Accuracy: Designed to meet high standards of precision, the encoder ensures accurate measurements of rotational movements. It is suitable for applications that demand high resolution and repeatability, such as industrial automation, robotics, and CNC machinery.

Durable and Robust Design: The Pepperl+Fuchs Incremental Rotary Encoder is built to withstand harsh conditions, including vibration, dust, moisture, and temperature fluctuations. Its sturdy housing ensures reliable performance in tough environments.

Versatile Mounting Options: With flexible mounting and connection options, this encoder can be easily integrated into a variety of machines and equipment, making it a versatile choice for OEMs and system integrators.

Wide Range of Applications: This model is ideal for use in applications where rotational position feedback is essential, including in conveyor systems, motors, actuators, pumps, and more. It can also be used in packaging, automotive, and material handling industries.

Easy Installation and Integration: The encoder is designed for quick and easy integration into existing systems, with minimal setup required. Its compatibility with a wide range of control systems makes it a convenient option for a variety of industrial sectors.

Specifications:

Model Number: 14143613600Y47043

Type: Incremental Rotary Encoder

Resolution: Offers high-resolution pulse output for detailed position feedback.

Electrical Interface: Typically available in standard formats like TTL or HTL, ensuring compatibility with various control systems.

Shaft Diameter: Available in different shaft sizes to meet specific mechanical requirements.

Power Supply: The encoder operates on a wide range of supply voltages, ensuring flexibility for various setups.

The Pepperl+Fuchs 14143613600Y47043 Incremental Rotary Encoder is a reliable and cost-effective solution for applications that require precise motion control. Whether in a factory automation system, a robotics project, or an industrial machine, this encoder delivers dependable performance, ensuring smooth operation and optimal productivity. Its high accuracy, robust construction, and easy integration make it a top choice for professionals in industrial and automation fields.

1 note

·

View note

Text

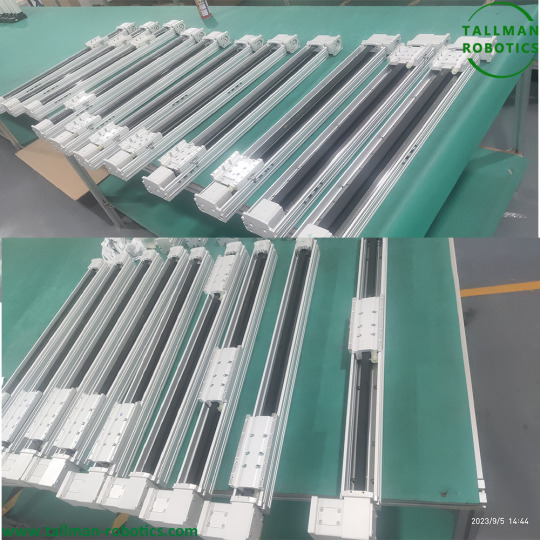

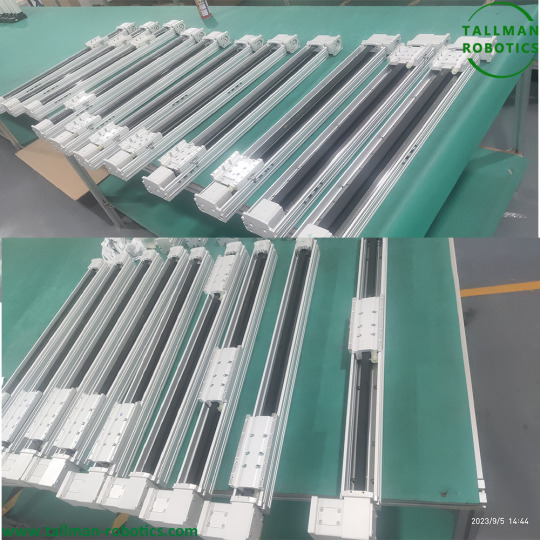

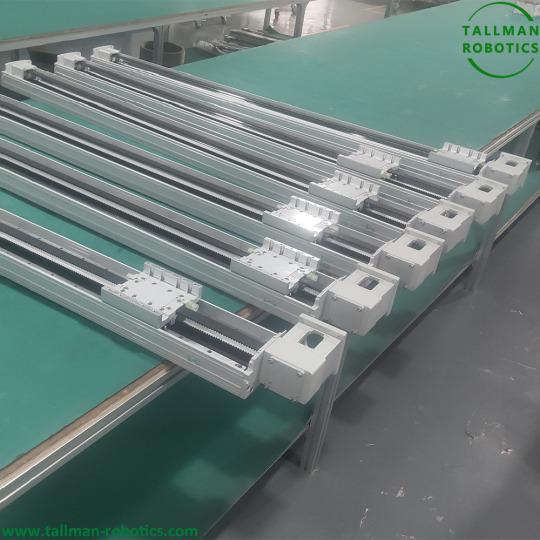

Stroke Adjustable Linear Module

Stroke adjustable linear modules are mechanical devices used in automation and machinery to provide linear motion. The term "stroke adjustable" refers to the ability to change or adjust the length of the linear movement (stroke) that the module can perform. This adjustability is crucial in applications where the required travel distance may vary or need to be precisely set for different tasks. Key Features of Stroke Adjustable Linear Modules: 1. Adjustable Stroke Length: The primary feature is the ability to adjust the stroke length, which can be done manually or automatically depending on the design. This allows for flexibility in positioning and movement. 2. Linear Motion: These modules convert rotary motion (from a motor) into linear motion, typically using a lead screw, ball screw, or belt drive mechanism. 3. Precision and Accuracy: They are designed to provide precise and accurate linear movement, which is essential in applications like CNC machines, 3D printers, and robotic arms. 4. Load Capacity: They can be designed to handle various load capacities, from light-duty applications to heavy-duty industrial tasks. 5. Mounting Options: These modules often come with multiple mounting options, making them versatile for different installation requirements. 6. Integration with Control Systems: They can be integrated with various control systems, including PLCs (Programmable Logic Controllers) and CNC systems, for automated control of the stroke length and position. Technical Parameters Items TMSA60 TMSA70 TMSA80 TMSA80F TMSA100 TMSA120 TMSA175 TMSA210 Slide width(mm) 8/10/20/25 20/25/30 10/12/15/20/25/30 10/12/15 24/30 15/20/25/30/40 45/60/100/120 45/60/100/120 Minimum distribution distance(mm) 8.5mm 20mm 10mm 10mm 24mm 15mm 10mm 45mm Slide quantity(pcs) >2 >2 >2 >2 >2 >2 >2 >2 Repeatability accuracy(mm) ±0.02 mm ±0.02 mm ±0.02 mm ±0.02 mm ±0.02 mm ±0.02 mm ±0.02 mm ±0.02 mm Positioning accuracy(mm) ±0.05 mm ±0.05 mm ±0.05 mm ±0.05 mm ±0.05 mm ±0.05 mm ±0.05 mm ±0.05 mm Distribution distance accuracy(mm) ±0.1 mm ±0.1 mm ±0.1 mm ±0.1 mm ±0.1 mm ±0.1 mm ±0.1 mm ±0.1 mm Input torque(N.m) Above 0.3 Above 1.3 Above 1.3 Above 1.3 Above 1.3 Above 1.3 Above 3.2 Above 3.2 Driving solution 42 stepper motor/ 100W servo motor 57 Stepper Motor/ 200W/400W Servo Motor 57 Stepper Motor, 200W/400W Servo Motor 57 Stepper Motor, 200W/400W Servo Motor 57 stepper motor 200W/400W servo motor +gear reducer 86 stepper motor 200W/400W/750W servo motor +gear reducer 86 stepper motor 750W servo motor +gear reducer 86 stepper motor 750W servo motor +gear reducer Maximum Sliding frequency 120 cpm 120 cpm 120 cpm 120 cpm 120 cpm 120 cpm 120 cpm 120 cpm

Applications of Stroke Adjustable Linear Modules: Automation Systems: Used in automated assembly lines, packaging machines, and material handling systems. Robotics: Integral components in robotic arms and other robotic systems where precise linear movement is required. CNC Machinery: Employed in CNC routers, mills, and lathes for precise tool positioning. Medical Devices: Utilized in medical imaging systems, surgical robots, and diagnostic equipment. 3D Printing: Essential in 3D printers for controlling the movement of the print head or build platform. Types of Stroke Adjustable Linear Modules: 1. Motorized Linear Modules: Equipped with a motor (stepper, servo, or DC motor) for automated control of the stroke length. 2. Manual Linear Modules: Adjusted manually, often used in applications where the stroke length does not need to change frequently. 3. Belt-Driven Linear Modules: Use a belt and pulley system for smooth and high-speed linear motion. 4. Screw-Driven Linear Modules: Utilize a lead screw or ball screw for precise and high-force linear motion. Advantages of Stroke Adjustable Linear Modules: Flexibility: The ability to adjust the stroke length makes these modules highly versatile. Precision: Provides accurate and repeatable linear motion. Ease of Integration: Can be easily integrated into existing systems and controlled via various means. Durability: Designed to withstand rigorous use in industrial environments. In summary, stroke adjustable linear modules are essential components in many automated systems, offering the flexibility of adjustable stroke lengths along with precise and reliable linear motion. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#AdjustableStrokeLinearActuator#AdjustableStrokeLinearActuators#Automotivelinearactuator#ElectricAdjustableStrokeIndustrialLinearActuator#LinearActuatorwithadjustablelimitswitches#linearactuatorwithadjustablestroke

0 notes

Text

Kanpur’s Naveen Print and Pack installs Bobst Novafold folder gluer

Naveen Print and Pack, a prominent carton and corrugated packaging company in Kanpur, has witnessed remarkable growth since its inception. Founded in 1980 by Yogesh Dixit, the company initially started as a small commercial printing unit.

Over the years, it has transformed into a major player in the packaging sector, thanks to its advanced technology and commitment to quality. The company recently commissioned a new Bobst Novacut folder gluer with a 4/6 corner attachment to spur its converting section.

The company’s journey toward packaging began in the early 1990s when it purchased its first offset printing machine in 1993. This investment marked the start of Naveen Print and Pack’s venture into the packaging business. By 2004, Prashant Dixit, the next generation of leadership, took over and the company started modernizing its operations. Under his leadership, the company made significant upgrades, such as acquiring Heidelberg presses, which enhanced its production capabilities.

In 2014, Naveen Print and Pack expanded its offerings by entering the corrugated packaging market, creating a sister concern, Pack Safe, which focuses on outer packaging. This expansion helped the company diversify its products and strengthened its position.

Looking for more space and an improved manufacturing setup, Naveen Print and Pack found a new location along the Kanpur-Lucknow highway in 2016. The company’s new plant, spanning 5,000 square meters (about 59,000 square feet), allowed it to expand its operations significantly. By 2017-18, the company completed the first phase of construction and shifted its operations to the new facility.

In 2021, the company made a major investment in a six-color Heidelberg UV press. This new equipment played a key role in enhancing the company’s ability to meet growing demand while maintaining the highest standards of packaging quality.

Bobst folder gluer- an enabler in efficiency

One of the most transformative investments for Naveen Print and Pack has been the acquisition of the Bobst Novafold folder gluer. This machine has drastically improved production efficiency. Before the installation of the Bobst machine, the company used a semi-automatic machine that produced 5,000-7,000 cartons per hour. Now, with the Bobst Novafold folder gluer, production has surged to 12,000-15,000 cartons per hour.

The machine’s ability to deliver consistent, high-quality output has significantly reduced bottlenecks and improved production timelines. “The Bobst Novafold folder gluer has been a game-changer,” says Prashant Dixit. “It has not only increased our productivity but ensured we can meet the most demanding client specifications. We first purchased a pre-owned Bobst die cutter in 2009. It is still performing great. So, we were well aware of Bobst performance.”

Dixit further emphasises the importance of investing in top-tier machinery. "In this industry, you cannot compete without the right equipment," he explains. "The key to staying ahead is constant investment in technology."

In addition to a well-equipped converting department, the press section of the company has multiple Heidelberg presses of various configurations.

Serving a diverse range of industries

Naveen Print and Pack serves a broad spectrum of industries, including agarbatti manufacturers, pharmaceuticals, chemicals, and hosiery. The company’s ability to cater to various sectors reflects its flexibility and commitment to meeting diverse client needs. Though Kanpur has not seen the same pace of industrial growth as other regions, Dixit remains optimistic about the future, citing improvements in infrastructure and law and order that will foster growth in Uttar Pradesh’s packaging sector.

Looking ahead- expansion plans for 2025

Naveen Print and Pack is far from done with its growth plans. The company is currently expanding its manufacturing capacity with the construction of an additional 10,000 square feet of space. Dixit is confident that the infrastructure improvements in the region, coupled with a more business-friendly environment, will lead to increased demand for packaging products. "As more industries, especially in the pharmaceutical and FMCG sectors, set up manufacturing plants, there will be a corresponding demand for packaging," he says.

0 notes

Text

Pneumatic Actuators Manufacturers & Suppliers in India

Automation is crucial in improving the manufacturing processes, accuracy, and efficiency in the industrial market. One of these vital components in the processes of industrial automation is the pneumatic actuator. Pneumatic actuators are mechanisms that actuate valves and other devices by converting compressed air into motion to perform work. Such actuators find application in many industries, which include, but are not limited to, manufacturing and packaging, robotics, and even the automotive industry. With the growing need for automation, the demand for quality pneumatic actuators and Auto Drain Valve Angle Valves, PU Tubes and Coil, Pneumatic Nailor and Parallel Grippers, and many more from the regions of Delhi, Gurugram, and North India has skyrocketed.

This detailed blog aims to describe the classification of pneumatic actuators, their essential elements, and trustworthy producers and distributors of pneumatic actuators in India. They will address their significance, their uses, and where the best such products are located.

Understanding Pneumatic Actuators

Pneumatic actuators are kinds of mechanical devices controlled by compressed air. These devices literally change the energy created by compressed air into either linear or rotary motion that is capable of performing work. They are also used to drive machines or open and close valves, gates, and other mechanical devices. This is a practical device that is widely used due to its straightforward application and speed, as well as its low cost.

There are two main types of pneumatic actuators:

Linear actuators: As the name suggests, these actuators produce linear or straight line motion. Applications of these actuators include valve operation, material positioning, and even robotics.

Rotary actuators: In contrast, rotary actuators are operated in a circular or rotational type of motion and are used in robotic arms, conveyor belts, and mechanical devices that demand complex motion.

Many industries, such as manufacturing, automotive, pharmaceuticals, packaging, or food processing, rely heavily on pneumatic actuators. The ability to control large systems with compressed air is beneficial in many industries and is preferred in numerous settings where effective, precise, reliable, and affordable operations are needed.

Key Components for Pneumatic Systems

Though pneumatic actuators are necessary in automation systems, there are many other components that are required to allow the proper functioning of any pneumatic system. Some of the commonly used accessories with pneumatic actuators are:

1. Auto Drain Valve Angle Valves

An Auto Drain Valve An angle valve is a type of equipment that helps in eliminating the condensed moisture in a pneumatic system automatically. While using compressed air in the systems, moisture buildup occurs due to temperature changes or humidity. This moisture, if not regulated, can lead to rust, sediment, and ultimately the degradation of pneumatic machinery’s efficiency.

The Auto Drain Valve Angle Valve is particularly made to maintain the quality of the compressed air by ensuring that it’s free of dissolvable materials. This leads to enhanced operational efficiency and increased durability of the pneumatic components. There are several different kinds of these valves, which make them more appropriate for a wide range of industrial applications in the Delhi, Gurugram, and North India regions.

2. PU Tubes and Coil

In pneumatic systems, PU tubes and coils are indispensable components, as these are used for interconnecting elements such as actuators, valves, and other pneumatic devices with compressed air. PU material has high flexibility, abrasion resistance, and high pressure resistance, which allows these tubes to be used in almost any environment.

There are different sizes, colours, and lengths of PU tubes in the market, which makes it easier for manufacturers and suppliers in Delhi, Gurugram, and other parts of North India to provide tailor-made solutions. Be it industrial, automotive, or automation requirements, PU tubes and coils provide cost-effective solutions ensuring proper distribution of air through the entire system.

3. Pneumatic Nailor

The Pneumatic Nailor is a tool that uses compressed air to drive nails into materials. It is commonly used in industries such as construction, packaging, and woodworking for high-speed fastening applications. These tools are preferred because they provide precision and speed while reducing manual labor.

Manufacturers and suppliers in Delhi, Gurugram, and North India offer a variety of Pneumatic Nailors designed to meet different fastening needs. Whether for light-duty or heavy-duty applications, a Pneumatic Nailor can ensure fast and secure fastening, improving productivity in the workplace.

4. Parallel Gripper

A parallel gripper is a darn near necessity in some robotic systems in particular industries that require precise handling of their parts. It is a device that makes it easier for a robot to pick, move, and place things with great accuracy. The Parallel Gripper works by applying equal and opposite forces to two jaws that are set up parallel to one another, which makes it possible to grab objects correctly without letting them slip or break.

In industrial automation, parallel grippers are also used in pick-and-place operations, assembly lines, and other operations where accuracy is required. There are parallel grippers enhanced and offered by manufacturers and suppliers in Delhi, Gurugram, and North India that fit certain weight and size metrics, which allows for broader robotic use.

Pneumatic Actuators and Their Applications

Pneumatic actuators and the components mentioned above have a very vast area of application in different industries. Let us discuss some of the specific uses of pneumatic actuators:

Automation Systems: Pneumatic actuators are an essential component in industrial automation when precise and repetitive linear motion is needed. In automated manufacturing and assembly lines as well as sorting and packing, pneumatic actuators are employed.

Valve Control: Most valves present in water treatment plants, chemical plants, and oil refineries are operated with the help of pneumatic actuators.

Robotics: Pneumatic actuators are commonly incorporated into robotic arms, thus allowing these structures to operate accurately during assembly, packaging, and material handling tasks.

Packaging: In the field of packages, pneumatic actuators work in controlling any operations performed by machines that are meant for sealing, filling, or labeling.

Automotive Industry: In the production of vehicles, a pneumatic actuator enables lifting, pressing, clamping, etc. and finds application in assembly lines.

Finding Reliable Pneumatic Actuators Manufacturers & Suppliers in India

When searching for a reputable manufacturer or supplier of pneumatic actuators, auto drain valve, angle valves, PU tubes and coils, parallel grippers, or pneumatic nailors, one must be careful about the choice. Delhi, Gurugram, and North India manufacturers or suppliers of the same are there to provide the necessary long-lasting and effective equipment.

When choosing a supplier, look for factors such as:

Experience in the pneumatic industry.

A wide range of products to suit different applications.

Customization options for specific needs.

Quality assurance and certifications.

A strong reputation in the industry, backed by customer reviews.

Conclusion: The Importance of Pneumatic Actuators in Industrial Automation

With the expansion of industries in Delhi, Gurugram, and North India, it is necessary to have reliable, efficient, and durable pneumatic systems. Pneumatic actuators and their components, such as Auto Drain Valve, Angle Valves, PU Tubes & Coil, Pneumatic Nailors, Parallel Grippers, etc., help to enhance industrial automation and decrease the operational costs.

By cooperating with the most reputable pneumatic actuator manufacturers and suppliers in India, firms can be sure that they have the appropriate components for the automation work, thus improving productivity, efficiency, and safety. These products have reliable solutions for all pneumatic system requirements, whether in the manufacturing, robotics, or packaging industries.

Contact today local manufacturers and suppliers to get the variety and the specific pneumatic solution for your industrial applications.

#pneumatic valves types#pneumatic valves#types of pneumatic valves#mercury pneumatics dealers#vs enterprises#mercury pneumatic dealers in delhi#Pneumatic Dealers

0 notes

Text

SINAMICS V90: Future-Proofing Your Automation System

Automation systems are central to achieving heightened efficiency, precision, and scalability across various sectors. However, as important as these systems are, they face significant challenges—complex installation processes, integration issues with existing technologies, and a constant need for upgrades to handle evolving industrial demands.

A good example of this technological breakthrough is the Siemens SINAMICS V90 servo drive system, which provides a reliable solution suited to modern industrial requirements. This article explores how the SINAMICS V90 not only enhances current operational capabilities but also ensures businesses are equipped for future challenges, setting a new standard in automation excellence.

What is SINAMICS V90?

The SINAMICS V90 is a highly optimized servo drive system designed to meet the versatile demands of motion control applications. This system, comprising the Siemens V90 servo drive and the SIMOTICS S-1FL6 servo motor, is engineered for a wide range of applications, making it a cost-effective solution that enhances the competitive edge of businesses by reducing time-to-market.

Performance: With features like a 1 MHz pulse train setpoint and 20-bit encoder resolution, the system achieves high positioning accuracy, essential for precision-driven processes. The drive and motor offer a 300% overload capacity, which, along with fast acceleration and braking capabilities, significantly boosts productivity.

Design: The robust design of the Siemens V90 includes PCB coating and high-quality bearings, enhancing the system's reliability even in harsh environmental conditions. Integrated safety functions like STO (Safe Torque Off) provide additional security, preventing unexpected motor movement and ensuring the safety of both machinery and operators.

Ease of Use: Commissioning the SINAMICS V90 is straightforward, thanks to the SINAMICS V-Assistant, a standalone graphic configuration software that simplifies setting parameters, jogging, troubleshooting, and monitoring. This user-friendly approach ensures quick setup and minimal downtime.

SINAMICS V90 Servo Drive Capabilities

The V90 servo drive system, designed for optimal performance and easy operation, includes a range of features tailored for efficient automation. Below is a table highlighting key attributes and capabilities of the system:

Feature

Description

Power Range

0.05 to 7.0 kW, accommodating both single and three-phase networks.

Motor Compatibility

Specifically paired with SIMOTICS S-1FL6 servo motors for enhanced performance.

Communication Interfaces

Multiple options including PTI, PROFINET, USS, or Modbus RTU for versatile integration.

Drive Sizes

Available in eight converter frame sizes and seven motor shaft heights to suit various applications.

Cooling

Designed to operate without external cooling; heat dissipation through the motor surface.

Installation

Features quick-release connectors for fast and straightforward installation.

Overload Capability

Capable of handling a threefold overload, ensuring robust operation under demanding conditions.

Commissioning

Plug-and-play setup with minimal configuration needed for quick commissioning.

Control Compatibility

Integrates seamlessly with Siemens SIMATIC PLC control systems for streamlined automation.

Application Across Industries

The Siemens V90 is suitable for diverse applications such as pick & place, labeling, horizontal packaging, and printing. Its ability to manage both simple and complex motion control tasks makes it a preferred choice for industries looking for a reliable and efficient automation solution.

Coupled with the SIMOTICS S-1FL6 servo motor, the V90 servo drive system showcases its flexibility and efficiency across a broad spectrum of industries.

Manufacturing and Production Control In the manufacturing sector, the Siemens V90 drive system is frequently utilized for precise position and speed control, essential for assembly lines and automated production processes. The integration with SIMATIC S7-1200 and S7-1500 PLCs via PROFINET enhances its functionality, allowing for seamless communication and synchronization of complex manufacturing operations.

Packaging and Assembly: For industries focused on packaging and assembly, the SINAMICS V90 motor provides reliable solutions for conveyor systems and automated assembly lines. The drive's ability to perform with high dynamic responses ensures that operations are not only fast but also accurate, which is crucial for maintaining throughput and reducing downtime.

Robotics and CNC Machines: The adaptability of the V90 extends to robotics and computer numerical control (CNC) machining. Here, the drive system excels in applications requiring complex motion sequences and high precision, such as in robotic arm positioning and CNC machining centers.

Material Handling: The v90 also finds its application in material handling systems, where smooth and controlled motion is necessary. Its robust design supports the demands of applications like cranes and lifting equipment, providing the necessary control to handle materials safely and efficiently.

Textile and Woodworking: These industries require precise control for processes like weaving, cutting, and engraving. The V90's ability to handle complex motion sequences makes it a valuable asset, improving productivity and product quality.

Benefits of the SINAMICS V90

The SINAMICS V90 servo drive system, integral to Siemens' SINAMICS product line, delivers notable advantages across a range of industrial applications. Here are some key benefits detailed through real-world use cases and statistical data:

Energy Efficiency and Cost Savings: The Siemens v90 motor is designed to optimize energy use, particularly in applications like pumps, fans, and compressors. By transitioning from mechanical control systems to variable-speed drives, the V90 significantly reduces power consumption, especially under partial load conditions. This shift can result in up to 70% savings on energy costs, making a substantial economic impact for businesses focused on sustainability and efficiency.

Scalability and Flexibility: With a broad spectrum of power ratings (0.05 to 7.0 kW) and the ability to operate across single and three-phase networks, the Siemens V90 offers remarkable scalability. This flexibility is further enhanced by its compatibility with various communication interfaces such as PTI, PROFINET, USS, and Modbus RTU, allowing seamless integration into existing automation systems.

Operational Efficiency: The SINAMICS V90 system is known for its quick commissioning features and high reliability, which significantly reduce downtime and maintenance costs. The drive system is not only easy to install but also ensures continuous, trouble-free operation across diverse environmental conditions.

Diverse Industrial Applications: From manufacturing and robotics to packaging and material handling, the Siemens V90 motor proves its versatility. For example, in manufacturing, it facilitates precise control over machinery, enhancing product quality and production rates. In material handling, it provides the necessary control to manage operations smoothly and safely.

Integration in Automation Systems: As part of Siemens' Totally Integrated Automation (TIA) philosophy, the v90 drive system works cohesively within a larger automation framework. This integration capability allows for centralized control and management of various drive tasks, streamlining operations and reducing complexity.

Conclusion: Your Next Steps with Naksh Technology

Naksh Technology Solutions LLP is committed to driving innovation and efficiency in automation through the SINAMICS V90 and its comprehensive suite of automation solutions. As industries evolve, partnering with a leader like Naksh ensures that your automation systems are not only up to date but also future-proof. For more information or to schedule a consultation, explore our website and discover how we can make a significant impact on your operational success.

0 notes

Text

Understanding Pneumatic Linear Actuators: A Comprehensive Guide

Pneumatic linear actuators have become essential components in various industries, enabling efficient and precise movement through the use of compressed air. These devices transform energy into linear motion, playing a crucial role in automation, manufacturing, robotics, and more. This comprehensive guide explores the principles, components, advantages, applications, and future trends of pneumatic linear actuators.

What Are Pneumatic Linear Actuators?

A pneumatic linear actuator is a mechanical device that converts compressed air energy into linear motion. When air is introduced into a cylinder, it pushes a piston, creating movement in a straight line. This simple yet effective mechanism allows for a wide range of applications in settings where quick and reliable movement is needed.

Key Components

Piston: The heart of the actuator, it moves within the cylinder when compressed air is applied.

Cylinder: The housing that contains the piston, designed to withstand high pressure.

Air Supply System: Comprises valves, filters, and regulators to manage the flow of compressed air, ensuring consistent performance.

Mounting Hardware: Allows for flexible installation in various machinery or equipment.

How It Works

When compressed air enters the cylinder, it forces the piston to move. The speed and distance of the piston’s movement can be controlled by adjusting the air pressure and the design of the actuator. This makes pneumatic actuators highly versatile, capable of performing a variety of tasks with precision.

Advantages of Pneumatic Linear Actuators

1. Speed and Responsiveness

Pneumatic actuators are known for their fast response times. This quick movement is crucial in environments where speed is essential, such as manufacturing lines and robotics.

2. Simplicity and Cost-Effectiveness

The straightforward design of pneumatic systems means fewer components and less complexity compared to electric or hydraulic systems. This simplicity leads to lower initial costs and reduced maintenance needs.

3. Durability

Pneumatic actuators are built to withstand harsh conditions. Their robust construction allows them to operate effectively in environments with dust, moisture, and extreme temperatures.

4. Safety and Environmental Considerations

Using compressed air minimizes the risk of electrical hazards, making pneumatic systems safer. Additionally, pneumatic actuators do not require hydraulic fluids, reducing environmental risks.

Applications of Pneumatic Linear Actuators

Pneumatic linear actuators are utilized across a wide range of industries, thanks to their versatility:

1. Manufacturing

In manufacturing, these actuators are used for assembly, packaging, and material handling. Their speed and precision help streamline production processes.

2. Robotics

Pneumatic actuators provide motion for robotic arms and grippers, allowing for rapid and precise manipulation of objects in various tasks.

3. Food and Beverage

In the food industry, pneumatic actuators are essential for packaging, bottling, and sorting, ensuring hygiene and efficiency in operations.

4. Medical Devices

They play a critical role in medical equipment, enabling precise movements in surgical instruments and diagnostic tools.

5. Aerospace

Pneumatic actuators are used in various aerospace applications, such as landing gear and control surfaces, where reliability and rapid response are vital.

Maintenance and Best Practices

To ensure optimal performance and longevity of pneumatic linear actuators, regular maintenance is essential. Here are some best practices:

Regular Inspections: Check for leaks, wear, and proper alignment. Early detection can prevent larger issues.

Air Quality Management: Use filters to ensure clean, dry air is supplied to the system, minimizing contamination.

Lubrication: Regularly lubricate moving parts to reduce friction and wear.

Pressure Monitoring: Keep an eye on the air pressure to ensure it remains within the recommended range for optimal operation.

Future Trends

As technology continues to advance, the future of pneumatic linear actuators looks promising. Emerging trends include:

Integration with IoT: Smart technology integration will allow for real-time monitoring and control, enhancing automation capabilities.

Advanced Materials: New materials can improve performance, reduce weight, and enhance durability.

Increased Customization: As industries demand more specialized solutions, manufacturers are likely to offer customizable options for pneumatic actuators.

Conclusion

Pneumatic linear actuators are vital to modern automation and control, offering speed, efficiency, and reliability across various applications. Understanding their components, advantages, and applications can help industries leverage this technology effectively. As innovations continue to shape the landscape of pneumatic systems, these actuators will remain at the forefront of automation, driving productivity and enhancing operational efficiency in diverse sectors. By harnessing the power of compressed air, pneumatic linear actuators are set to play an increasingly significant role in the future of industrial automation.

Contact Us

21225 FM 529 Rd

Houston, TX 77433

Cypress Area

Phone: +1-713-934-0171

Fax: +1-713-934-9099

0 notes

Text

Roll Slitting Machine Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The Roll Slitting Machine Global Market Report 2024 by The Business Research Company provides market overview across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa, encompassing 27 major global industries. The report presents a comprehensive analysis over a ten-year historic period (2010-2021) and extends its insights into a ten-year forecast period (2023-2033).

Learn More On The Roll Slitting Machine Market: https://www.thebusinessresearchcompany.com/report/roll-slitting-machine-global-market-report

According to The Business Research Company’s Roll Slitting Machine Global Market Report 2024, The roll slitting machine market size is expected to see strong growth in the next few years. It will grow to $2.95 billion in 2028 at a compound annual growth rate (CAGR) of 5.1%. The growth in the forecast period can be attributed to expansion of the renewable energy sector, expansion of the printing and converting industry, growth in flexible packaging, and increased use of flexible packaging materials, development of e-commerce. Major trends in the forecast period include development of advanced automation and control systems, precision cutting technologies, development of energy-efficient and waste-reducing slitting technologies, customization and versatility, and digital control systems.

The growing e-commerce industry is expected to propel the growth of the roll-slitting machine market going forward. The e-commerce industry encompasses online platforms where goods and services are bought and sold electronically, facilitating transactions between businesses, consumers, and suppliers worldwide. The growth is supported by increased internet penetration, the convenience of online shopping, broader product availability, and evolving consumer preferences towards digital transactions. Roll slitting machines are required in the e-commerce industry for efficiently processing and packaging various materials, like packaging films and labels used in shipping and product packaging. For instance, in October 2021, according to a report published by the International Trade Administration, a US-based agency, it is anticipated that e-commerce for consumer goods will constitute approximately 22% of global retail sales in 2024, with a projected average annual growth rate exceeding 1%. Additionally, global retail e-commerce sales are expected to maintain a steady increase of 8% annually through 2024. Therefore, the growing e-commerce industry is driving the growth of the roll-slitting machine market.

Get A Free Sample Of The Report (Includes Graphs And Tables): https://www.thebusinessresearchcompany.com/sample.aspx?id=17250&type=smp

The roll slitting machine market covered in this report is segmented –

1) By Type: Roll Or Log Slitters, Slitter Rewinders 2) By Material: Paper, Polymers, Foil, Other Materials 3) By Slitter Blade: Large Circular Blade, Fixed Band Blade 4) By Distribution Channel: Direct Sales (Original Equipment Manufacturer (OEM)), Indirect Sales 5) By Industry: Paper And Pulp, Textile, Packaging, Other Industries

Major companies operating in the roll slitting machine market are developing technologically advanced products, such as high-performance rewinder slitters, to better serve customers with advanced features. A high-performance rewinder slitter is a precision machine designed to efficiently slit and rewind various materials, such as paper, film, and foil, with exceptional speed and accuracy. It is often used in industrial manufacturing processes. For instance, in February 2022, Vemax, a Brazil-based machinery company, launched the Vemax VRXS STDH Rewinder Slitter. The distinctive feature of Vemax's high-performance equipment lies in its differential axles, tailored for heavy-duty operations with paper, plastic, or self-adhesive films, serving flexible packaging, labeling, and tag industries globally. These machines integrate an advanced control system, enabling direct communication via an internal network with the machine's PLC and all electronic components. This technology facilitates remote and online programming adjustments and repairs, emphasizing innovation, safety, and quality in flexible packaging machinery.

The roll slitting machine market report table of contents includes:

1. Executive Summary

2. Roll Slitting Machine Market Characteristics

3. Roll Slitting Machine Market Trends And Strategies

4. Roll Slitting Machine Market - Macro Economic Scenario

5. Global Roll Slitting Machine Market Size and Growth .............

32. Global Roll Slitting Machine Market Competitive Benchmarking

33. Global Roll Slitting Machine Market Competitive Dashboard

34. Key Mergers And Acquisitions In The Roll Slitting Machine Market

35. Roll Slitting Machine Market Future Outlook and Potential Analysis

36. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Rafia Film Scrap Plastic Recycling Machinery in Algeria

R Mech Machines LLP is an Exporter of Rafia Film Scrap Plastic Recycling Machinery in Algeria. Our manufacturing unit is in Ahmedabad, Gujarat, India. R Mech Machines LLP Offers Plastic Scrap Turbo Washing Machines, Plastic Scrap Grinder Machines, Plastic Scrap Shredder Machines, Blade Sharpening Machines, Screw Press Squeezer Machines, and Friction Washer Machines. We specialize in high-performance raffia film scrap plastic recycling machinery designed to optimize plastic waste processing. Our advanced equipment features robust shredders, precision granulators, and efficient extruders that handle raffia film and other plastic scraps with ease. Built with durable components and cutting-edge technology, our machines ensure superior efficiency and minimal maintenance. Ideal for industries aiming to recycle and repurpose plastic waste, our solutions convert scrap into valuable, reusable pellets, promoting sustainability and reducing environmental impact. Application: Plastic Film Recycling Packaging Waste Management Plastic Waste Processing Rafia Film Recovery Flexible Packaging Recycling Waste-to-Resource Solutions R Mech Machines LLP is an Exporter of Rafia Film Scrap Plastic Recycling Machinery in Algeria and including locations like Algiers, Oran, Constantine, Annaba, Blida, Batna, Djelfa, Setif, Sidi Bel Abbes, Biskra, Tlemcen, El Oued, Skikda, Tiaret, Bejaïa, Tizi Ouzou, Bordj Bou Arreridj, Bechar, Bouira, Tebessa, Chlef, Ain Oussera, Mostaganem, El Eulma, Hassi Messaoud. For any questions or further information, please contact us. View Product: Click here Read the full article

0 notes

Text

SMD provides a wide variety of Servo Gearbox

High Precision Servo Gearbox: SMD’s Diverse Solutions for Industrial Applications

In the realm of industrial automation, accuracy is crucial. Servo gearboxes are vital components that ensure accurate, reliable motion control across various applications. SMD Gearbox, a leader in the field, offers a broad selection of high-precision servo gearbox reducers designed to meet the specific needs of various industries.

What is a Servo Gearbox?

A servo gearbox is a specialized mechanism designed to decrease the speed while boosting the torque of servo motors. These gearboxes play a crucial role in converting the high-speed, low-torque output of a servo motor into the low-speed, high-torque output required by many industrial applications. This transformation allows for precise control over the motion and positioning of machinery, making servo gearboxes indispensable in fields such as robotics, automation, and manufacturing.

SMD’s Range of Servo Gearbox Solutions

SMD Gearbox offers a wide range of servo gearbox reducers specifically designed to cater to the needs of various industries. Whether you need compact gearboxes for tight spaces, robust models for heavy-duty applications, or versatile units that can be easily integrated into various systems, SMD has a solution.

1. Inline Planetary Gearboxes

Inline planetary gearboxes are known for their compact design and high efficiency. These gearboxes are perfect for tight spaces, as they align the input and output shafts efficiently. SMD’s inline planetary gearboxes offer excellent torque transmission with minimal backlash, ensuring smooth and precise motion control. They are widely used in robotic arms, CNC machines, and other automated systems where accuracy is crucial.

2. Right Angle Gearboxes

Right-angle gearboxes are designed to transmit power between intersecting shafts, usually at a 90-degree angle. This makes them perfect for applications where space constraints require a change in the direction of motion. SMD’s right-angle gearboxes are available in various configurations, including models with hollow shafts for easy integration with other components. These gearboxes are commonly used in conveyor systems, packaging machines, and other industrial equipment.

3. Hollow Rotary Gearboxes

Hollow rotary gearboxes combine the functionality of a gearbox with the precision of a rotary table. They feature a large, central hole that allows cables, shafts, or other components to pass through, making them ideal for applications requiring organized wiring or complex assembly configurations. SMD’s hollow rotary gearboxes are perfect for indexing tables, pick-and-place robots, and other applications where precision and compactness are key.

4. Harmonic Gearboxes

Harmonic gearboxes, also known as strain wave gearboxes, are renowned for their high precision and zero backlash. These gearboxes use a unique mechanism involving a flexible spline and a wave generator to achieve high gear reduction ratios with exceptional accuracy. SMD’s harmonic gearboxes are especially suited for applications in the robotics industry, where precise positioning and repeatability are essential. They are commonly used in multi-axis robotic joints, medical devices, and aerospace systems.

5. Cycloidal Gearboxes

Cycloidal gearboxes are known for their ability to handle high shock loads and offer smooth, reliable operation. These gearboxes use a cycloidal motion principle, which provides high torque transmission and minimal wear. SMD’s cycloidal gearboxes are ideal for applications requiring high load capacity and durability, such as in heavy machinery, wind turbines, and industrial robots.

Why Choose SMD Gearbox?

SMD Gearbox stands out in the industry due to its commitment to quality, innovation, and customer satisfaction. Here’s why SMD is a trusted partner for your servo gearbox needs:

Precision Engineering: Every SMD gearbox is designed with meticulous attention to detail, ensuring high performance and reliability.

Diverse Offerings: SMD’s wide range of gearboxes caters to various industrial applications, from robotics to manufacturing.

Customization: SMD offers tailored solutions to meet specific customer requirements, providing flexibility and adaptability in design.

Support and Service: With a strong technical team and comprehensive after-sales support, SMD ensures that customers receive the best service and solutions for their needs.

Conclusion

In today’s fast-paced industrial environment, the demand for precise, reliable, and efficient motion control systems is higher than ever. SMD Gearbox delivers on all fronts with its extensive range of high-precision servo gearboxes. Whether you’re in robotics, automation, or any other sector requiring exacting performance, SMD has the right gearbox solution for you. Choose SMD for unparalleled quality and innovation in servo gearbox technology.

#smdgearbox#gearboxmanufacturer#supplier#gearbox#automation#manufacturingindustry#harmonicgearbox#planetarygearbox#linearmotion#hollowrotaryreducer

0 notes

Text

"Driving Productivity: How Servo Drives Optimize Production"

Servo drives are the unsung heroes of industrial automation, powering precision motion control systems in a wide array of applications, from robotics and CNC machines to packaging equipment and semiconductor manufacturing. These sophisticated electronic devices convert electrical signals into precise mechanical movements, allowing for unparalleled accuracy, speed, and flexibility in machinery operation. With their ability to precisely control torque, velocity, and position, servo drives play a crucial role in optimizing production processes, improving product quality, and increasing productivity. As industries embrace Industry 4.0 and the Internet of Things (IoT), servo drives are evolving to become smarter and more interconnected, enabling real-time monitoring, diagnostics, and predictive maintenance. This proactive approach minimizes downtime, reduces maintenance costs, and enhances overall equipment effectiveness. Moreover, advancements in servo drive technology, such as regenerative braking and energy-efficient designs, contribute to sustainability efforts by reducing energy consumption and environmental impact. As automation continues to revolutionize manufacturing and beyond, servo drives remain at the forefront, empowering innovation and driving efficiency in the modern industrial landscape.

#ServoDrive #IndustrialAutomation #PrecisionControl #MotionControl #SmartManufacturing #IoT #Industry40 #EnergyEfficiency #PredictiveMaintenance #ManufacturingInnovation #SmartTechnology #EfficientProduction #IndustrialRobotics #AutomationSolutions #ProductivityBoost

0 notes

Text

BEI 924-01063-001 Industrial Encoder H25: Optimize Operations with High-Quality Precision

The Bei 924-01063-001 Industrial Encoder H25 is a robust and versatile device designed to provide accurate feedback in industrial automation systems. As an encoder, its primary function is to convert mechanical motion into electrical signals, enabling precise control and monitoring of machinery and equipment.

In the world of industrial automation, precision and reliability are paramount. And when it comes to precise motion control and feedback systems, the Bei 924-01063-001 Industrial Encoder H25 stands out as a trusted solution. In this guide, we'll delve into what makes this encoder special, its key features, applications, and why it's a crucial component in various industries.

Features of the Bei 924-01063-001 Industrial Encoder H25

High Precision: The H25 encoder boasts exceptional accuracy, allowing it to detect even the slightest movements with precision. This level of accuracy is essential for tasks requiring tight tolerances and fine control.

Durable Construction: Built to withstand harsh industrial environments, the H25 encoder features a rugged construction that ensures reliable performance even in demanding conditions. Its robust design protects it from dust, moisture, vibration, and temperature variations, ensuring longevity and reliability.

Versatile Compatibility: The H25 encoder is compatible with a wide range of industrial equipment and control systems, making it a versatile solution for various applications. Whether used in manufacturing, robotics, or motion control systems, the H25 encoder seamlessly integrates into existing setups, providing accurate feedback and control.

Incremental and Absolute Modes: The H25 encoder supports both incremental and absolute encoding modes, offering flexibility in how motion is tracked and monitored. Incremental encoding provides real-time feedback on movement, while absolute encoding offers precise position information, allowing for accurate positioning and motion control.

Easy Installation and Setup: Installing and configuring the H25 encoder is straightforward, thanks to its user-friendly design and intuitive setup process. With minimal effort, users can quickly integrate the encoder into their systems and start benefiting from its precise feedback capabilities.

Applications of the Bei 924-01063-001 Industrial Encoder H25

Manufacturing: In manufacturing environments, the H25 encoder plays a vital role in controlling conveyor systems, robotic arms, CNC machines, and other equipment requiring precise motion control. Its high precision and durability make it well-suited for tasks such as positioning, speed control, and synchronization.

Robotics: In robotic applications, the H25 encoder provides accurate feedback on joint positions, enabling robots to perform precise movements and tasks with efficiency and reliability. Whether used in industrial robots, automated guided vehicles (AGVs), or collaborative robots (cobots), the H25 encoder ensures optimal performance and safety.

Motion Control Systems: Motion control systems rely on encoders like the H25 to accurately track and control the movement of motors, actuators, and other components. From servo drives to linear motion systems, the H25 encoder enhances the performance and accuracy of motion control applications across various industries.

Packaging and Material Handling: In packaging and material handling applications, the H25 encoder facilitates precise control of conveyors, sorting systems, and packaging machines. Its high precision and reliability ensure smooth operation and efficient handling of goods, contributing to increased productivity and throughput.

Renewable Energy: The H25 encoder finds applications in renewable energy systems such as wind turbines and solar trackers, where it helps optimize the performance and efficiency of power generation equipment. By accurately tracking the position and movement of turbine blades or solar panels, the H25 encoder ensures maximum energy capture and output.

Benefits of Using the Bei 924-01063-001 Industrial Encoder H25

Improved Precision: With its high accuracy and resolution, the H25 encoder enables finer control and positioning accuracy, resulting in improved product quality and consistency.

Enhanced Reliability: The rugged construction and robust design of the H25 encoder ensure reliable performance in challenging industrial environments, minimizing downtime and maintenance costs.

Versatile Performance: From precise motion control to position feedback, the H25 encoder offers versatile performance across a wide range of applications, making it a valuable asset in diverse industrial settings.

Easy Integration: With its compatibility with standard interfaces and protocols, the H25 encoder can be seamlessly integrated into existing systems without the need for extensive modifications or programming.

Cost-Effective Solution: Despite its advanced features and capabilities, the H25 encoder provides excellent value for money, offering reliable performance and longevity at a competitive price point.

Why Choose the Bei 924-01063-001 Industrial Encoder H25?

Reliability: Built to withstand harsh industrial environments, the H25 encoder offers reliable performance even in the most demanding conditions.

Accuracy: With its high-resolution sensing technology, it provides precise position feedback, ensuring accurate motion control and positioning.

Versatility: The H25 encoder's multiple output options and wide operating temperature range make it suitable for a wide range of industrial applications.

Ease of Integration: Its simple installation and standard electrical connections make it easy to integrate into existing systems, minimizing downtime and installation costs.

BEI 924-01063-001 Industrial Encoder H25 is a powerhouse of performance and reliability, making it the encoder of choice for industrial automation applications. With its advanced features, rugged construction, and versatile design, it provides unparalleled precision and durability in the most demanding environments. Whether you're in manufacturing, material handling, automotive, renewable energy, or packaging, the H25 encoder is sure to exceed your expectations and deliver superior results.

0 notes

Text

Flexure Print N Pack to commission new blown film extrusion line in 2024-25

Ahmedabad-based flexible packaging converter Flexure Print N Pack is set to expand its capabilities with significant new investments. The company plans to commission a multilayer blown film extrusion line within the financial year 2024-25, aiming to strengthen its vertical integration. Flexure Print N Pack is also gearing up to install converting machinery for both monolayer and multilayer packaging in the next few months, according to Jainam Shah, managing partner at Flexure Print N Pack.

“We are also exploring collaborations with industry suppliers to add value to our wide-web flexographic printed products through offline processes,” Shah said in an exclusive interview with Packaging South Asia.

Current capabilities and machinery

Flexure at present operates four flexographic printing presses, including one central impression press and three stack-type configured presses. The facility is equipped with an advanced photopolymer plate mounting machine along with anilox sleeves and photopolymer plate cleaning machines to ensure quality and durability. In the lamination department, the company utilizes both solvent-free and solvent-based lamination machines.

The slitting department boasts drum-type and cantilever differential slitting machines. For conversion, Flexure Print N Pack runs a variety of machines, including bottom seal bag-making machines, side seal bag-making machines, slit-seal plus gusset machines, and multiple pouch-making machines.

A milestone year in 2024

Reflecting on 2024, Shah described the year as "busy, challenging, and eventful," marked by significant achievements. Flexure Print N Pack reached a notable milestone by successfully printing 208 LPI print resolution jobs on its flexographic press. The company also conducted trials with hybrid screening, water-based inks, and extended color gamut, which are set to transition into full-scale production in the coming months.

Established in 2001, the Asian Packaging Excellence Awards recognize outstanding achievements, innovation, and contributions to packaging production across the Asia region, celebrating the pinnacle of excellence in the Asian packaging industry.

“These awards underscore our commitment to excellence in packaging production,” Shah said.

Production capacity and solutions

Flexure Print N Pack currently converts between 175 and 200 metric tonnes of material per month. The company’s product portfolio spans a range of exclusive flexographic-printed solutions, including LDPE, CPP, TQPP, BOPP, PET, coated paper, and compostable films as substrates. These materials are supplied in monolayer and multilayer roll forms, as well as in converted pouch formats.

Flexure Print N Pack specializes in manufacturing a variety of packaging solutions, including bakery bags, shopping bags, hygiene application pouches, vacuum pouches, zipper pouches, quad seal pouches, and stand-up pouches, among others.

A vision for the future

With its new investments and a focus on innovation, Flexure Print N Pack is poised to strengthen its position in the flexible packaging industry, Shah said. The addition of the blown film line and enhanced converting capabilities will enable the company to meet evolving market demands and reinforce its reputation for quality and innovation.

0 notes

Text

Linear Motion Actuators Are Under Assembly

Linear Motion Actuators are devices that convert rotational motion into linear motion. They are commonly used in various applications where linear movement is required, such as robotics, automation systems, industrial machinery, and automotive systems. Linear motion actuators provide controlled and precise linear displacement, allowing them to perform tasks like pushing, pulling, lifting, or positioning objects.

Linear Motion Electric Actuators are versatile and widely used in various applications where precise control, automation, and compactness are important. Some common applications of electric actuators include: 1. Robotics: Electric actuators play a fundamental role in robotic systems, enabling precise and controlled movement of robot arms, grippers, and joints. They provide the necessary motion control for tasks such as pick and place, assembly, welding, and inspection in industrial and collaborative robot applications. 2. Automation Systems: Electric actuators are extensively used in automation systems across industries, including packaging, material handling, and assembly lines. They provide linear motion for tasks like conveyor belt control, part positioning, sorting, and machine loading and unloading. 3. Medical Equipment: Electric actuators find applications in medical devices and equipment, such as hospital beds, patient lifts, surgical tables, and adjustable medical chairs. They allow for smooth and precise adjustment of the equipment's position, ensuring patient comfort and facilitating healthcare professionals' work. 4. Automotive Systems: Electric actuators are used in various automotive applications, including power windows, seat adjustments, trunk lifts, and electric steering systems. They provide controlled and reliable motion for convenience, comfort, and safety features in vehicles. 5. HVAC Systems: Electric actuators are employed in heating, ventilation, and air conditioning (HVAC) systems for controlling dampers, valves, and airflow. They enable precise adjustment of temperature, airflow direction, and ventilation, improving energy efficiency and comfort in buildings. 6. Aerospace and Defense: Electric actuators are used in aerospace and defense applications, such as aircraft wing flaps, landing gear, throttle control, and missile guidance systems. They offer precise and rapid motion control in critical aerospace and defense operations. 7. Home Automation: Electric actuators are utilized in home automation systems for tasks like opening and closing curtains, blinds, windows, and doors. They provide convenient and automated control over these household functions. 8. Entertainment and Motion Simulators: Electric actuators are employed in entertainment industry applications, including motion simulators, virtual reality systems, and amusement park rides. They create realistic and immersive experiences by providing motion and vibration effects. Linear Motion Actuators offer advantages like precise control, compact size, quiet operation, energy efficiency, and easy integration with control systems. They are well-suited for applications that require accurate positioning, automation, and control flexibility. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#1AxisGantry#LinearCarriagesAndSlides#LinearSlidingGuide#MultiAxisLinearActuator#SingleAxisGuideArm#SingleAxisLinearActuator#SingleAxislinearmotion#SingleAxisStages

0 notes