#HVAC simulation

Explore tagged Tumblr posts

Text

Download EVAP-COND 5.0: The Ultimate Heat Exchanger Simulation Tool for HVAC Engineers

In today’s energy-conscious world, optimizing HVAC systems has never been more critical. As a mechanical engineer who has worked extensively with heat exchanger design, I’m excited to share insights about EVAP-COND 5.0, NIST’s powerful simulation package that’s transforming how we design and analyze finned-tube evaporators and condensers. EVAP-COND represents the culmination of decades of…

#carbon dioxide refrigerant#computational intelligence#condenser design#custom refrigerant blends#evaporator modeling#heat exchanger performance#HVAC simulation#inned-tube heat exchangers#ISHED#low-GWP refrigerants#NIST simulation software#non-uniform air distribution#R1234yf#REFPROP#refrigerant circuitry optimization#refrigerant distribution#supercritical refrigerant operation#TableGen2#thermophysical properties#tube-by-tube analysis

0 notes

Text

#quantumcomputing#3d printing#cfd#additive manufacturing#cfd simulation#hvac services#3d printing simulation software#simulation#technology#aerospace engineering#additive manufacturing software#3d sculpting#blender#ai generated#artificial intelligence

0 notes

Text

I love this new hvac technician simulator

15 notes

·

View notes

Text

Subscribing to county job alerts simulation:

You are receiving this email because you joined the XXXX County Talent Community on Suck/My/Balls. You will receive these messages every 7 day(s).

Agent:

LIBRARIAN

Job Matches:

HVAC TECHNICIAN

SOCIAL WORKER (CHILD WELFARE)

SOCIAL WORKER (AGING & ADULT SERVICES)

HVAC TECHNICIAN AGAIN

9 notes

·

View notes

Text

DP2 - Wandering Earth

Week 19:

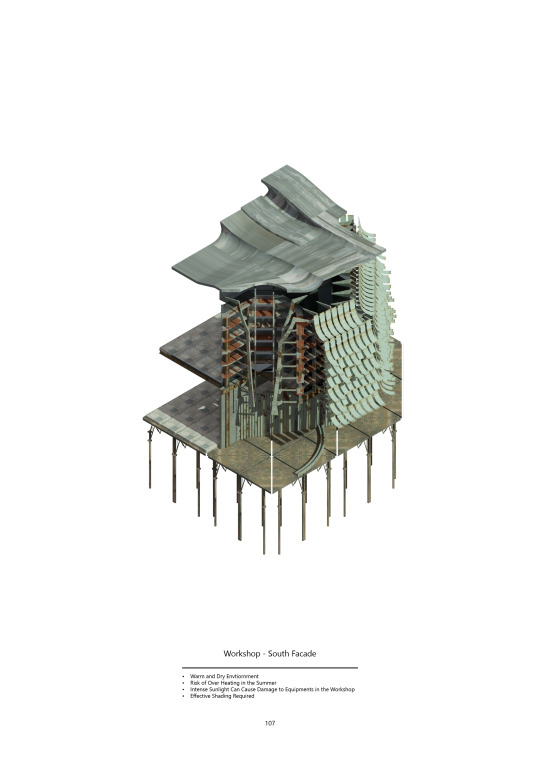

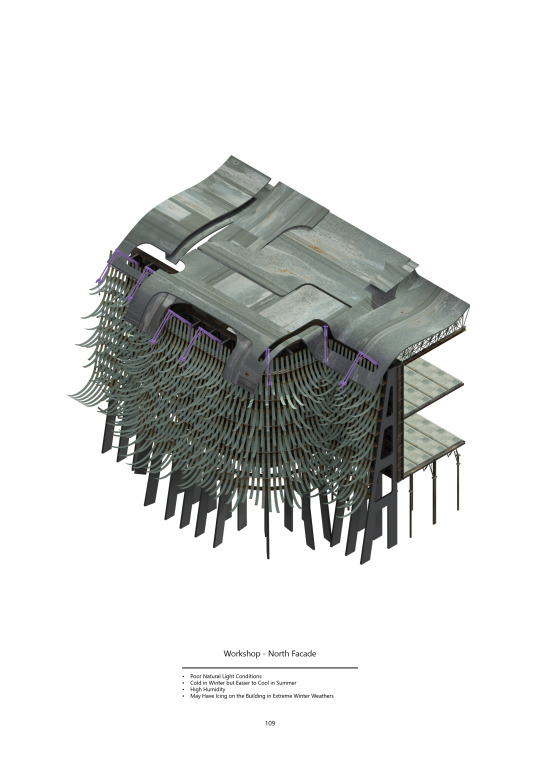

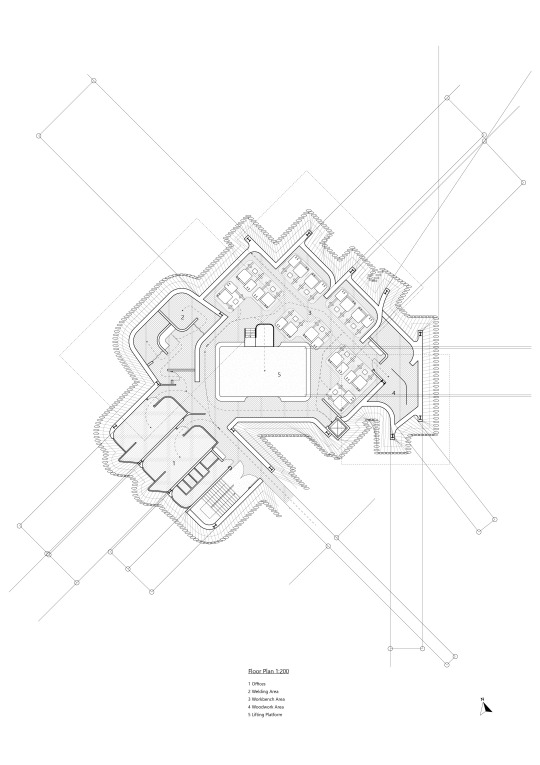

This week I kept focusing on the workshop by first improving on the plan and then choosing three zones from the plan and designed the roof, facade and structural systems specifically to the environmental conditions required by each zone:

The south facing facade receives the highest level of solar radiation and activities including cutting and drilling take place in this zone, which can lead to overheating in the space, especially at summer. Therefore a layered strategy is implemented on the facade with dense and wide rain-fuel/solar panels acting also as shading devices which can result in effective cooling off the space.

The East Facing Facade provides excellent natural light in the morning and has a good view down the hill towards the city, therefore there are voids on the facades to provide opportunities for a balcony area. The facade panels are more curled up to further provide natural lighting and views as there are workbenches behind the east facade.

The North Facade in 2050 will encounter more severed environmental conditions as it receives poor natural light and is normally cold and damp. Therefore the facade panels are less dense to allow more light entering the space and more gaps on the roof to provide lighting. Deicing systems inspired by the aviation industry extends out from the roof to clean the icing that may form on the facade.

The Roof has different levels and grooves to direct the rainwater to drip down onto the facade elements and utilises its potential energy to regenerate energy; but also recycled into the bathroom to be reused. The roof has a curved shape that rises at certain points for lighting purposes.

I should keep working on these three design modules and use line drawings in combination with these renders to reveal the HVAC, structural and water systems of the space. Doing lighting and heating simulations on the interior space to prove the systems function properly

Key ideas mentioned:

Hollow tiles for heating and ventilation systems running through

shape the tiles so it guides the cool down streaming air around the furniture in the room

Pneumatically designed air exhaustion systems for manufacturing area (Reference to Zaha Science Museum)

Shelving systems on the facade to hang and dry the pieces manufactured in the workshop

Light pipes bringing light to the working area that is integrated with the furniture

furniture suspended from the ground with localized heating, water running through the furniture

Ramps connecting the buildings that extend out into the forest and foreshadowing the theme and emotions that the next building is going to bring to the visitors. Buildings get cut through similarly to canyons.

When presenting, show how spatial organization, facade systems and furniture systems are designed differently according to the hot and cold environment and lux levels.

8 notes

·

View notes

Text

I got sucked into playing Oxygen Not Included again and now it’s living rent free in my brain like the boys. Enjoy these extremely specific headcanons on them playing base building/resource management/colony sim games.

Sky - He plays like a normal person. Does his best to make his base thrive but makes all the beginner mistakes. His second attempt is way way better but nothing crazy. Never gets too deep into the mechanics. Only plays for a few hours and eventually stops because someone starts backseat playing.

Wild - Chaos. His base is somehow drowning, on fire, in the middle of a drought and freezing. All at once. Literally nothing is working and his little guys are all dying to death. His second attempt is not any better. Nor is his third. He’s not good at micromanaging and constantly tries to build things that are way too big and wayyyy too resource heavy and it ends up killing him. He was super into building a really cool hot tub/massage room and neglected to make sure his guys have oxygen. But he’s having fun so it’s all good

Champion - Is on top of everything. Reads the entire in-game encyclopedia before he even starts the game so he knows everything he needs to. His base is very spartan but at least nothings on fire. Enjoys the challenge of planning ahead and creative problem solving.

Twilight - Gets way too invested in the little creatures. Creates a whole big ranch and makes the place really, really nice for his pets. His people are vegan and he lets his base starve to death because he can’t bring himself to eat his animals. But also mourns the loss of every one of his people. It’s a heartbreaking game for Twilight. He prefers games when he can pet the animals, not eat them.

Warriors - Base building isn’t his preferred genre but he gives it a try anyway. Aesthetics before anything is his playstyle. His base works well enough but he does surrender some efficiency to make it pretty. Dresses up all his little guys and gives them snazzy clothes. But he loses interest pretty fast and goes to bother Sky.

Hyrule - His base is a mess of hallways and ladders. No real central area because he just want to expand and see what’s out there. Is a real explorer. He ends up accidentally opening up his base to the cold vacuum of space and kills everyone.

Legend - Hates that he’s constantly running out of resources. If it’s not air then it’s water, and if it’s not water it’s food, and if it’s not food it’s space, and if it’s not space it’s fucking air again! He curses up a storm every time something goes wrong. Which is all the time.

Four - Spreadsheets. Lots and lots of spreadsheets. Sixty hours in and his base is ten miles long with a ridiculously convoluted yet effective HVAC system that abuses every game mechanic to be self sustaining. Runs on things like giving his base contaminated food to give them food poisoning to make them vomit so he can refine that vomit back into clean water to offset the moisture entropy. A monster of efficiency. Four loves building games where there are calculable data sets and realistic physics. Can and will play this game forever is no one stops him.

Wind - He streams it and names his colony members after viewers. Uses console commands to do crazy things like spawn in 100 colonists and summons meteor showers to spice things up. He’s pretty decent and he actually learns to to use the convoluted automation mechanics. Also mods. Lots and lots of mods.

Time - His base dies immediately. This old man never got more advanced than Pong and so when he is confronted with a game in which the density and weight of different gasses is important he can’t handle it. He accidentally digs down and his whole colony suffocates on carbon dioxide within 5 minutes. He puts the game down and never plays again.

Dark - Only plays for a bit before he stops. Even though it’s just simulation he doesn’t enjoy the strange sense of claustrophobia it gives him. He’ll happily watch Twi play it though.

Shadow - He logs into Fours game and disconnects one (1) wire somewhere in the base.

#I’m sorry for being a big nerd but#I’m actually not#😎#when two obsessions collide#you get a nearly incomprehensible post ✌️#townhouse au#hsh au#st0rmyverse

7 notes

·

View notes

Text

Why Is MEP Acoustic Service Important for Building Design in the UAE?

Sound control in buildings is much more than luxury in an environment such as the UAE, it is a must. Extremely poor sound control can hinder comfort, productivity, and compliance in a wide array of building types, from high-rise towers to industrial plants. Acoustic MEP services enable clients to have the best sound quality and noise reduction necessary for MEP systems. Clients searching for the best acoustic MEP company in UAE should realize that knowledge of the applicable building codes and regional performance expectations are critical when looking for an acoustic MEP partner.

About Our Company

SkyTech LLC is a leading provider of engineering consultancy in the UAE, and focusing on MEP acoustic solutions for any residential, commercial, or industrial infrastructure. Our commitment to innovative solutions with client satisfaction at the forefront, allows our acoustic specialists to support ensuring compliance with noise conditions and comfort with any environment needing specification for acoustics, or enables clarity and comfort for any environment in providing acoustics.

Service Overview

MEP noise and vibration assessment

Acoustic design for HVAC, generators, pumps, and plumbing systems

Soundproofing and insulation recommendations

Noise control strategies for LEED and Estidama requirements

Acoustic simulation and 3D modeling

Site inspection and noise measurement reports

Key Features / Benefits

Expertise in local and international acoustic standards

Compliance with UAE regulations and green building codes

Custom design integration with existing MEP systems

Reduction of airborne and structure-borne noise

Improved occupant comfort and building efficiency

Enhanced property value through better sound environments

Process / How It Works

Consultation & Site Assessment

Noise Impact Analysis using simulation tools

Customized Acoustic Design Plan

Integration with MEP Layout

Implementation Support and Post-Construction Testing

Industries Served / Applications

High-rise residential and commercial towers

Hospitals and healthcare facilities

Hotels and resorts

Educational institutions

Industrial and manufacturing plants

Shopping malls and entertainment centers

Looking to eliminate unwanted noise from your building systems? Partner with the best MEP acoustic company in UAE today. Contact us for a consultation or to learn how we can enhance your project’s acoustic performance. Take a look at our Structural Design Service.

0 notes

Text

Carbon Audits & Zero-Carbon Offsetting: What UK Commercial Landlords Need to Know in 2025

Introduction

As the UK continues marching towards its 2050 net-zero emissions target, commercial landlords have more pressure on them to meet carbon reduction standards. While 2025 sees more stringent enforcement of the Minimum Energy Efficiency Standards (MEES) and SECR regulations, knowledge of the nitty-gritty of carbon auditing and zero-carbon offsetting is now more important than ever before. From GHG reporting to actionable EPC upgrades, things are moving quickly and visionary landlords are now paying for tools to get ahead.

Learning About Carbon Audits in the Commercial Arena

Carbon audits measure the environmental footprint of a building, calculating Scope 1, 2, and increasingly Scope 3 emissions. This is the baseline UK commercial landlords require to develop a carbon-reduction strategy. Considering all forms of HVAC energy consumption right through to lighting installation, a comprehensive audit identifies the highest-carbon hotspots of activity. These findings are the basis upon which to make future plans, enhance energy performance, and achieve MEES compliance in commercial Properties.

CCA Environmental, a UK consulting company, aids enterprises through the provision of in-depth energy surveys created with Dynamic Simulation Modelling EPC UK software, which supports accurate emissions prediction and scenario analysis. This is particularly helpful for landlords controlling intricate buildings that need precise Level 5 EPCs.

Carbon Audits & MEES Regulations: A Strategic Intersection

A Strategic Intersection MEES regulations for non-domestic properties now mandate minimum EPC ratings, which are increased to C by 2027 and B by 2030. Carbon audits, along with MEES-conformant EPC Plus reports, assist landlords in reaching these levels at an affordable cost. An EPC Plus report exceeds typical EPCs with affordable, building-specific recommendations for upgrading.

While the majority of property owners look for a "Level 5 EPC assessor near me," they ought to consult professionals who understand the relationship between carbon performance and legal energy objectives. CCA Environmental's Commercial EPC Level 5 specialists offer advice not only for compliance but also for sustained environmental performance and value creation.

The Role of Zero-Carbon Offsetting in EPC Upgrades

With best practice, even it is not possible to eliminate all carbon on-site. Where it is not the case, zero-carbon offsetting has its supplementary role. Verified offset schemes can be used by landlords to assist commercial buildings in achieving MEES requirements where physical improvement will be uncostable or insufficient by itself.

These offsets are especially well-fitted to historic or old buildings where intrusive improvements cannot be made. CCA Environmental advises landlords on assessing offsetting solutions under MEES exemptions and EPC upgrades—ensuring solutions are legal and effective.

Smart Metering & Energy Management Integration

As smart metering becomes a reality, commercial property advantages and benefits lie ahead. They increase real-time tracking, providing better forecasting and analysis of energy consumption. Leasing more precise data through smart technology allows landlords to input and calibrate more precise data into energy performance models—better carbon estimates and EPC ratings.

With smart data, CCA Environmental optimizes its EPC consultancy for MEES regulation. That translates into more precise reporting, more customized upgrade strategies, and less guesswork—a big win in the quest to comply with UK minimum energy efficiency standards EPC requirements.

SECR, CRREM & Long-Term Portfolio Strategy

Commercial property owners also have to consider SECR (Streamlined Energy and Carbon Reporting) and CRREM (Carbon Risk Real Estate Monitor) regulations. Both are geared towards future-proofing and transparency based on fact-based carbon reduction strategies.

CCA Environmental assists customers in aligning carbon audit numbers with CRREM pathways so that properties continue at the levels of emission intensity. It prevents penalty and market underestimation as sustainability is becoming a leading asset class in commercial property.

Conclusion: Act Proactively

Zero-carbon offsetting and carbon audits are not just jargon terms; they are rapidly becoming standard weapons in the UK commercial landlord's toolkit. As 2025 approaches, the time for action is now. Whether you are in charge of one property or a national portfolio, effective carbon management can deliver significant cost and regulatory savings.

CCA Environmental is leading the charge with its specialist carbon audit services, analysis of EPC Plus reports, and tailored MEES consultancy. For those who are keen to combine environmental responsibility with business sustainability, the next step is then to collaborate with an experienced consultancy.

To future-proof your buildings and satisfy MEES requirements non-domestic properties need to adhere to, contact CCA Environmental now. Learn how strategically positioned carbon audits, smart metering, and zero-carbon offsetting will optimize the performance and compliance of your portfolio.

#carbon audit#carbon footprint consultants#carbon reduction plan#carbon offsetting schemes#carbon audit net zero strategy#MEES#EPC Plus Report#Commercial EPC's

0 notes

Text

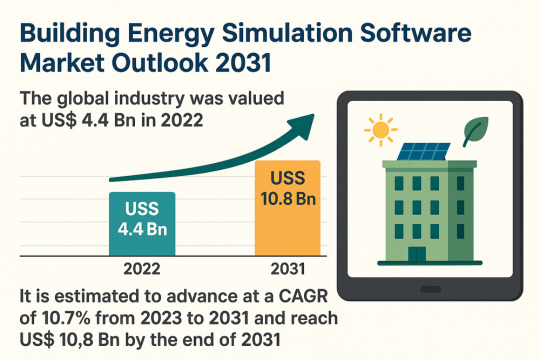

Sustainable Design Powers Building Energy Simulation Software Market Boom

The global building energy simulation software market is poised for significant growth, expanding from US$ 4.4 billion in 2022 to an estimated US$ 10.8 billion by 2031, at an impressive CAGR of 10.7%. This growth trajectory reflects the increasing demand for energy-efficient and sustainable building solutions driven by stricter environmental regulations, integration of smart technologies, and the adoption of AI and ML in building simulation tools.

Market Overview

Building energy simulation software enables stakeholders including architects, engineers, and energy consultants to model, simulate, and optimize the energy performance of buildings. These tools help reduce carbon emissions, lower operating costs, and ensure compliance with stringent energy codes and standards. They also support performance analysis for HVAC systems, lighting, plug loads, and water usage in residential, commercial, and institutional buildings.

The industry is experiencing strong momentum with the growing emphasis on green building certifications, retrofitting of existing infrastructure, and the integration of Internet of Things (IoT) technologies into construction and facilities management processes.

Market Drivers & Trends

The growth of the building energy simulation software market is primarily driven by:

Government regulations aimed at reducing building emissions

Increased adoption of smart building technologies and IoT

Rising demand for energy-efficient retrofitting of older structures

Technological advancements enabling real-time modeling and faster simulations

Financial incentives and tax benefits for energy-efficient construction

The increasing urgency to comply with frameworks such as the EU’s Energy Performance of Buildings Directive (EPBD), New York City’s Local Law 97 (LL97), and other national standards like Germany’s Buildings Energy Act and the Dubai Green Building Regulations, continues to create substantial demand for these tools.

Latest Market Trends

One of the most notable trends is the integration of Artificial Intelligence (AI) and Machine Learning (ML) into simulation software. These technologies improve modeling accuracy, reduce simulation time, and provide advanced predictive analytics. AI algorithms can automatically generate energy models based on design inputs, simulate future energy demand, and suggest optimal solutions for minimizing consumption and enhancing occupant comfort.

Another key trend is the availability of cloud-based platforms that enable collaboration and access to real-time simulation data, making energy modeling more accessible and scalable for small- to mid-sized firms.

Key Players and Industry Leaders

Major players in the global market include:

Autodesk, Inc.

4M S.A.

Integrated Environmental Solutions Ltd (IES)

DesignBuilder Software Ltd

Trimble Inc.

EQUA Simulation AB

Trane Technologies plc

StruSoft AB

BuildSimHub, Inc.

Environmental Design Solutions Ltd

Maalka Inc.

BRE Group

These companies are heavily investing in R&D to improve simulation speed, user interfaces, and integration with Building Information Modeling (BIM) tools, thus enhancing market competitiveness.

Access important conclusions and data points from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=77350

Recent Developments

Autodesk Inc., in November 2022, launched rapid operational energy analysis tools in Autodesk Spacemaker, allowing real-time visual feedback during early design phases—enabling energy-efficient decisions from the outset.

In February 2023, Glodon Company Limited, via its subsidiary MagiCAD Group, acquired a majority stake in EQUA Simulation AB. This strategic acquisition is expected to accelerate simulation technology development and expand global market reach.

These developments reflect the industry’s move toward comprehensive, real-time, and AI-integrated platforms.

Market Opportunities

Several untapped opportunities lie ahead for market players:

Emerging markets in Asia Pacific, the Middle East, and South America are expected to experience robust demand for simulation tools amid urbanization and green building initiatives.

AI-enabled automation can open new possibilities in design optimization and energy forecasting.

Partnerships with government bodies and educational institutions may drive innovation and training in simulation technologies.

Smart city projects and rising interest in Net-Zero Energy Buildings (NZEBs) present a fertile ground for software deployment.

Future Outlook

The future of the building energy simulation software market looks promising, with robust growth expected across all regions. The emphasis on data-driven architecture, zero-emission goals, and sustainable urban development will continue to influence market dynamics.

With continued advances in ML algorithms, simulation engines, and 3D visualization capabilities, energy simulation tools will become indispensable for building design, renovation, and facility management. Furthermore, integration with digital twins and BIM platforms will enhance their strategic role in urban planning and smart infrastructure development.

Market Segmentation

By Component:

Software / Platform

Services

Professional

Consulting & Integration

Support & Maintenance

Managed

By Deployment:

Cloud

On-premise

By End-user:

Residential

Commercial

Others

By Region:

North America

Europe

Asia Pacific

Middle East & Africa

South America

Regional Insights

North America leads the market due to a well-established ecosystem of universities, research labs (like NREL), and government-funded sustainability programs. The U.S., in particular, is witnessing widespread adoption of simulation software driven by regulations such as LL97 in New York.

Europe remains at the forefront of green construction regulations and energy performance mandates, making it a lucrative market for simulation software providers.

Asia Pacific is expected to record the fastest CAGR during the forecast period. Rapid urbanization, combined with rising environmental consciousness and increasing investments in green buildings across China, India, and Southeast Asia, is fueling demand in the region.

Why Buy This Report?

This comprehensive report offers:

In-depth analysis of market trends, drivers, and opportunities

Detailed segmentation and regional analysis

Competitive landscape with profiles of major players

Insights into government regulations and their impact on market dynamics

Forecasts up to 2031 with historic data and growth projections

Updates on key market developments and strategic movements

AI and ML integration trends reshaping the simulation software ecosystem

Whether you are a software developer, a building consultant, a policymaker, or an investor, this report offers invaluable insights into the future of energy-efficient construction technologies.

Explore Latest Research Reports by Transparency Market Research: Data Center Rack Market: https://www.transparencymarketresearch.com/data-center-rack-market.html

Virtual Reality in Gaming Market: https://www.transparencymarketresearch.com/virtual-reality-gaming-market.html

Retail Analytics Market: https://www.transparencymarketresearch.com/retail-analytics-market.html

3D Reconstruction Technology Market: https://www.transparencymarketresearch.com/3d-reconstruction-technology-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

B.Tech in Mechanical Engineering: A Timeless Branch with Limitless Possibilities

Mechanical Engineering is often referred to as the “evergreen branch” of engineering—and for good reason. It is one of the oldest and broadest disciplines, involving the design, development, manufacturing, and maintenance of mechanical systems. If you're someone who enjoys understanding how machines work and are passionate about innovation, then B.Tech in Mechanical Engineering could be the perfect course for you.

In the age of automation, robotics, and sustainable energy, mechanical engineers are playing a critical role in shaping the future. From automobiles and aerospace to energy systems and manufacturing, the scope is vast and continuously evolving.

What is B.Tech in Mechanical Engineering?

B.Tech in Mechanical Engineering is a four-year undergraduate program that provides students with a strong foundation in physics, mathematics, material science, thermodynamics, mechanics, and design principles. It blends theoretical knowledge with practical skills through laboratory work, industry projects, internships, and workshops.

Students learn to use advanced software like AutoCAD, SolidWorks, ANSYS, and MATLAB to design and analyze mechanical systems. In addition to core mechanical subjects, modern programs also include electives like robotics, artificial intelligence in manufacturing, and green energy technologies.

Why Choose Mechanical Engineering?

Mechanical engineering is ideal for students who are creative, analytical, and have a keen interest in building and improving machines or mechanical systems. Here are a few key reasons why this branch remains a top choice:

Versatile Career Options: Mechanical engineers can work in industries like automotive, aerospace, energy, HVAC, robotics, and even healthcare.

Global Demand: It is a globally recognized field with high employment potential both in India and abroad.

Gateway to Innovation: Mechanical engineers often lead innovation in product development, sustainable technologies, and automation.

Strong Earning Potential: With the right skills and experience, professionals can enjoy a lucrative career.

Career Opportunities After B.Tech in Mechanical Engineering

Graduates from B.Tech in Mechanical Engineering programs have a wide array of career paths available:

Design Engineer

Production Engineer

Quality Control Engineer

Maintenance Engineer

HVAC Engineer

CAD/CAE Analyst

Research & Development Engineer

Project Manager

Those interested in higher studies can pursue M.Tech, MBA, or specialized certifications in areas like mechatronics, 3D printing, or AI in manufacturing.

Choose the Right College: IILM College Greater Noida

For students seeking a high-quality engineering education, IILM College of Engineering and Technology, Greater Noida, stands out as a top choice. Recognized for its excellence in technical education, IILM offers a comprehensive B.Tech in Mechanical Engineering program that combines academic rigor with hands-on learning.

Here’s why IILM Greater Noida is considered a leading Mechanical Engineering College in Greater Noida:

Experienced Faculty: Learn from industry experts and PhD holders.

State-of-the-art Labs: Equipped with modern tools and simulation software.

Industry Exposure: Internships, live projects, and industrial visits.

Career Support: Strong placement cell with ties to top companies in manufacturing, automotive, and design sectors.

Skill Development: Emphasis on soft skills, leadership, and entrepreneurship.

1 note

·

View note

Text

Design Procedures for Heating-Only Systems: An 8-Step Methodology

Designing effective heating-only HVAC systems requires a methodical approach that ensures adequate capacity while avoiding oversizing. The following 8-step procedure provides a comprehensive framework for designing these systems, focusing on peak heating loads to determine appropriate equipment sizing. Design Procedures for Cooling-Only Systems: An 8-Step Methodology Design Procedures for…

#air system operation#airflow sizing#coil load determination#design heating conditions#design procedure#Energy efficiency#equipment sizing#HVAC heating systems#instantaneous heat loss#peak load calculation#right-sizing#space heat losses#supplemental heating#supply air temperatures#system airflow requirements#system simulation#system-based design#terminal reheat coils#Thermal comfort#ventilation air#zone loads

0 notes

Text

Additive manufacturing is the technique of creating three-dimensional products from CAD models by layering on the material using digital data.

Additive Manufacturing, previously known as rapid prototyping, and currently popular as 3D printing

Read the Full article on our website: https://www.paanduvapplications.com/what-is-additive-manufacturing

#additivemanufacturing#metal 3d printing service#LPBF#cfd#CFD simulation#simulation#hvac services#AM Procoess

0 notes

Text

Facility Management Market Future Trends Indicate Smart Solutions, Sustainability, and Integrated Service Models Ahead

The facility management market is entering a new era marked by rapid innovation, evolving client expectations, and increasing demand for sustainable operations. As the industry continues to evolve, future trends are shaping a transformative path focused on smarter, greener, and more integrated solutions. From the adoption of advanced technologies to strategic outsourcing and sustainability practices, facility management is no longer a behind-the-scenes function but a strategic business enabler.

Facility managers across sectors are reimagining how buildings and infrastructure are operated, maintained, and optimized. With economic pressures and heightened awareness around environmental and health concerns, the future of facility management will be guided by value creation, efficiency, and adaptability.

Smart Building Technologies and IoT Integration

One of the most significant future trends in the facility management market is the growing adoption of smart technologies and IoT (Internet of Things). These innovations are transforming buildings into intelligent ecosystems that provide real-time data on energy usage, equipment performance, occupancy levels, and environmental conditions.

IoT sensors embedded across HVAC systems, lighting, elevators, and plumbing systems allow for predictive maintenance, energy efficiency, and automated operations. Facility managers can monitor and control systems remotely, respond to issues faster, and reduce operational costs through data-driven insights. In the future, buildings will become more responsive and self-managing, making IoT a cornerstone of modern facility management.

Artificial Intelligence and Predictive Maintenance

Artificial Intelligence (AI) is playing a crucial role in enhancing facility operations. From automating work orders to identifying inefficiencies and predicting equipment failures, AI allows facilities to shift from reactive to predictive maintenance models. This reduces downtime, extends asset lifespans, and cuts maintenance costs significantly.

Future AI tools will not only interpret sensor data but also suggest optimal operational strategies and simulate scenarios to help managers make informed decisions. As AI becomes more intuitive and accessible, it will serve as a virtual assistant in day-to-day facility management tasks.

Sustainability and Energy Optimization

Sustainability is no longer optional—it’s a critical driver of facility management strategies. Future trends indicate increased emphasis on green buildings, carbon neutrality, and energy optimization. Facility managers will be expected to implement sustainable practices, reduce emissions, and support corporate environmental, social, and governance (ESG) goals.

Technologies such as energy management systems, solar installations, and eco-friendly materials will become standard. Certifications like LEED and WELL will also gain more importance, pushing organizations to adopt environmentally responsible facility operations. The growing regulatory and consumer pressure for sustainability will continue to shape facility management practices in the years to come.

Integrated Facility Management (IFM) Models

Another key future trend is the rise of Integrated Facility Management (IFM). Instead of relying on multiple vendors for individual services such as cleaning, security, maintenance, and energy management, organizations are moving toward unified service providers that offer all-in-one solutions.

IFM models streamline communication, reduce costs, and improve accountability through centralized coordination. They also enhance the user experience and allow for better performance tracking. In the future, more companies will partner with IFM providers to focus on core business objectives while ensuring facility excellence.

Health, Wellness, and Post-Pandemic Building Management

The COVID-19 pandemic redefined how workplaces and public buildings are managed. Future trends continue to emphasize health and wellness within facilities. Enhanced air filtration, contactless access systems, and occupancy monitoring will remain priorities for ensuring safety and confidence among occupants.

Facility managers will invest more in indoor air quality, cleanliness, and sanitation technologies. Additionally, wellness-focused design elements—such as natural lighting, ergonomic spaces, and biophilic environments—will be integrated into facility strategies to support occupant well-being.

Flexible Workplaces and Space Optimization

With the rise of hybrid work models and changing workplace dynamics, facility management must adapt to flexible space utilization. Companies are reconfiguring office spaces to accommodate fewer permanent desks, more collaborative zones, and shared resources.

Future facility management will involve dynamic space planning tools, sensor-based occupancy tracking, and real-time usage analytics. These tools help organizations make the most of available space while ensuring comfort, safety, and productivity for both remote and in-office staff.

Advanced Data Analytics and Business Intelligence

The future of facility management will be heavily influenced by advanced data analytics. As data becomes more accessible, facility managers will gain deeper insights into performance metrics, cost drivers, and improvement areas. Business intelligence tools will help forecast expenses, measure ROI on facility investments, and benchmark performance against industry standards.

This trend enables a proactive approach where decisions are based on evidence rather than intuition. As a result, facilities will become more agile, efficient, and aligned with organizational goals.

Cybersecurity and Data Protection

With the digitization of facility operations comes the increased risk of cyber threats. As buildings become more connected, ensuring the cybersecurity of building management systems will be critical. Future facility management will require robust cybersecurity strategies to protect sensitive data, operational systems, and occupant privacy.

Facilities will need to work closely with IT teams to monitor vulnerabilities, implement firewalls, and ensure compliance with data protection regulations. Cybersecurity training and risk assessments will become routine components of facility management protocols.

Conclusion

The future of the facility management market is dynamic, forward-thinking, and technology-driven. As organizations strive to become more efficient, sustainable, and occupant-friendly, facility managers will play an increasingly strategic role. From smart buildings and AI-powered maintenance to wellness initiatives and integrated services, tomorrow’s facility management will prioritize adaptability, intelligence, and long-term value. Companies that embrace these future trends will position themselves for operational excellence in an ever-changing business landscape.

#FacilityManagementMarket#SmartBuildings#SustainableFacilities#FutureOfFM#IntegratedFacilityManagement

0 notes

Text

Is the Fondis Winemaster C25 the Best Wine Cellar Cooling Unit for Homes in Altona North?

If you're serious about storing wine at home, you’ve probably heard of the Fondis Winemaster range. Known for their European design and long-term performance, these cooling systems are gaining popularity across Australia — especially in growing lifestyle suburbs like Altona North, VIC 3025.

In this blog, we’ll look at the Fondis Winemaster C25, answering common questions Australians ask about wine cellar cooling, and helping you decide whether it’s the right fit for your cellar project.

What is a Fondis Winemaster and Why Does It Matter?

The Fondis Winemaster is a brand of wine cellar cooling units designed in France to simulate natural underground wine storage conditions. Unlike regular air conditioners or split systems, Fondis units regulate not only temperature but also humidity, which is key to preventing cork damage and wine spoilage.

Wine storage isn’t just about keeping bottles cold — it’s about consistency. That’s why wine enthusiasts and collectors are turning to dedicated cooling systems like the Winemaster range.

What Makes the Fondis Winemaster C25 So Popular?

The Fondis Winemaster C25 is one of the most recommended models for home wine cellars up to 25m³. It's compact, efficient, and easy to install in both new and retrofitted spaces.

Here’s why it stands out:

Built-in temperature and humidity control

Low energy consumption

Quiet operation — ideal for indoor spaces

Plug-and-play system (wall-mounted with minimal installation fuss)

Whether you have a small under-stair cellar or a dedicated wine room, the C25 offers enough power to keep your collection protected year-round.

Is It Worth Getting a Wine Cellar Cooling Unit in Melbourne’s Climate?

One of the most common questions from homeowners in areas like Altona North is whether they really need a wine cooling unit. After all, Melbourne has cooler winters, right?

True — but it also has hot, dry summers, and wine doesn’t handle fluctuating temperatures well. A proper cooling and humidity control unit ensures wine ages slowly and evenly, no matter the outside weather.

Even if your wine cellar is located in a cooler part of the home (like a basement or garage), temperature swings can still occur. That’s where the Fondis Winemaster C25 makes a big difference.

How Much Does the Fondis Winemaster C25 Cost in Australia?

In Australia, the Fondis Winemaster C25 typically retails for between $3,200 and $3,800 AUD, depending on the supplier and whether installation is included.

Many local HVAC or wine cellar specialists in Melbourne’s western suburbs (including Altona North) offer package deals with installation, venting, and maintenance.

For the investment, you’re getting a professional-grade unit built to run quietly and efficiently for years, with minimal upkeep.

Where Can I Buy a Fondis Winemaster C25 Near Altona North, VIC?

There are several distributors and wine cellar design companies in the Melbourne area that supply the Fondis Winemaster C25. Some even offer site inspections and can custom design your cellar space for optimal airflow and insulation.

If you're based in Altona North, you're in a great spot — with easy access to both residential HVAC specialists and wine cellar builders servicing western suburbs like Yarraville, Newport, and Williamstown.

Final Thoughts: Is the Fondis Winemaster C25 Right for You?

If you’re planning to build or upgrade a wine cellar at home in Altona North, the Fondis Winemaster C25 is definitely worth considering. It’s compact, energy-efficient, and tailored for cellars of up to 25m³ — making it perfect for many Australian homes.

By investing in a quality cooling system, you’re not just storing wine — you’re preserving value, enhancing flavour, and protecting your collection for years to come.

Need advice or installation support? Reach out to a local wine cellar specialist who knows the climate in Altona North and can help you make the most of your space.

1 note

·

View note

Text

Engineering That Builds Confidence: How Advantage Engineering Technologies, PLLC Delivers Premier Mechanical and MEP Engineering Services

In the fast-paced and increasingly complex world of construction and product development, success hinges on more than vision—it depends on precise, practical, and coordinated engineering solutions. At Advantage Engineering Technologies, PLLC, clients gain access to a highly skilled team of professionals offering dependable mechanical engineering services and integrated MEP engineering services that help turn great ideas into structurally sound, efficient, and code-compliant realities.

From HVAC systems in high-rise buildings to industrial piping layouts and electrical system planning, the firm’s multidisciplinary expertise ensures that every detail is engineered for success.

Mechanical Engineering Services Designed for Performance

Mechanical systems are the backbone of building performance. Whether managing indoor climate, moving fluids, or powering industrial equipment, the design and execution of these systems must be precise. That’s where Advantage Engineering Technologies excels—with expert mechanical engineering services that support a broad spectrum of industries and project types.

Their capabilities span:

HVAC system design and analysis

Piping and ductwork layout optimization

Equipment selection and sizing

Energy efficiency modeling and sustainability compliance

System performance simulations and diagnostics

Each mechanical system is engineered with a balance of efficiency, reliability, and cost-effectiveness. Using state-of-the-art design tools such as AutoCAD MEP, Revit, and energy modeling software, the firm ensures that every design is technically sound and installation-ready.

Mechanical solutions are tailored to each project’s unique goals—whether that’s improving airflow in a school, designing low-noise systems for a hospital, or maximizing energy savings in a LEED-certified commercial facility.

Comprehensive MEP Engineering Services for Integrated Building Design

Building systems are rarely independent. Electrical, plumbing, and mechanical systems must work together seamlessly to ensure building functionality, occupant comfort, and long-term sustainability. That’s why Advantage Engineering Technologies offers fully integrated MEP engineering services, giving clients a single source for coordinated design and documentation.

Their MEP engineering services include:

Mechanical (HVAC) system design

Electrical system planning and lighting design

Plumbing and piping design, including water and gas systems

Fire protection systems layout and coordination

Load calculations and utility coordination

The firm’s MEP engineers use a coordinated design approach, ensuring that systems are developed in parallel—not in silos. By leveraging advanced Building Information Modeling (BIM) tools, the team identifies conflicts early in the design process, reducing costly changes during construction and enhancing project delivery timelines.

Serving Diverse Sectors with Scalable Engineering Expertise

From complex healthcare facilities to high-rise residential developments, Advantage Engineering Technologies brings a scalable and flexible engineering approach to every engagement. Their mechanical and MEP engineering services are customized to support projects of any size or complexity.

Industries served include:

Commercial and Corporate Offices

Healthcare and Medical Facilities

Higher Education and K-12 Schools

Industrial and Manufacturing Plants

Retail and Hospitality

Government and Military Buildings

Whether working as part of a large design-build team or supporting a developer with early-stage concept engineering, the firm adapts to project needs while maintaining high standards of quality, documentation, and coordination.

Energy Efficiency and Code Compliance Built In

Today’s construction standards require more than functionality—they demand efficiency, environmental responsibility, and compliance with local and national codes. Advantage Engineering Technologies incorporates these priorities into every project through thoughtful engineering and best practices.

The firm’s engineers are well-versed in:

ASHRAE standards

IECC energy codes

NFPA fire protection guidelines

ADA compliance for mechanical spaces

Green building certifications such as LEED and WELL

By embedding code compliance into their workflows and coordinating with jurisdictional authorities, Advantage Engineering Technologies helps clients avoid costly redesigns and accelerate project approvals.

Why Clients Choose Advantage Engineering Technologies, PLLC

With a solid reputation for technical depth and responsive service, Advantage Engineering Technologies is a trusted partner for developers, architects, general contractors, and facility owners alike.

What sets them apart:

Multidisciplinary Expertise: A team that understands the full spectrum of MEP systems, from mechanical HVAC design to electrical distribution and plumbing detailing.

Technology-Driven Design: Utilization of BIM, energy modeling, and drafting tools that enable detailed, collaborative design development.

Tailored Solutions: No two projects are the same—neither are the firm’s engineering solutions. Everything is custom-designed to meet performance, budget, and schedule goals.

Clear Communication: Clients benefit from ongoing communication, transparent timelines, and proactive issue resolution at every stage of the process.

Value Engineering: The firm prioritizes practical, cost-conscious design choices without sacrificing performance or compliance.

Engineering the Future with Confidence

As buildings become smarter and systems more interconnected, the need for intelligent, collaborative engineering is greater than ever. Advantage Engineering Technologies, PLLC delivers the technical knowledge, tools, and responsiveness needed to help clients meet today’s challenges—and build for tomorrow.

Whether you need high-performance mechanical engineering services for a commercial facility or full-scope MEP engineering services for a multi-use development, Advantage Engineering Technologies has the capabilities to engineer with purpose and precision.

0 notes

Text

Safety Standards Followed by Leading Plate Heat Exchanger Manufacturers in Pune

In the evolving industrial landscape, safety is no longer just a checkbox—it’s a non-negotiable priority. This holds especially true in thermal system manufacturing, where heat, pressure, and complex engineering converge. Among the key players in this space, plate heat exchanger manufacturers in Pune have emerged as leaders, not just in innovation and performance, but also in following strict safety standards.

Pune, known for its robust engineering ecosystem, houses several reputable manufacturers that design and supply plate heat exchangers for industries like chemical processing, pharmaceuticals, food and beverage, HVAC, and more. What sets a trusted plate heat exchanger manufacturer in Pune apart is their unwavering commitment to safety across every stage—design, fabrication, assembly, testing, and delivery.

Let’s explore the various safety standards followed by the top manufacturers in Pune and how these practices contribute to long-term equipment reliability and user safety.

1. Compliance with International Design Codes

Every leading plate heat exchanger manufacturer in Pune adheres to globally recognized design codes such as ASME (American Society of Mechanical Engineers), TEMA (Tubular Exchanger Manufacturers Association), and PED (Pressure Equipment Directive). These standards ensure that each heat exchanger can handle its intended pressure, temperature, and operating conditions without failure.

For manufacturers, following these codes isn't just about passing an inspection—it reflects engineering integrity. Pune-based manufacturers frequently invest in advanced design software and simulation tools that ensure every design meets these regulatory benchmarks with precision.

2. Material Safety and Traceability

Raw materials play a vital role in the performance and safety of a plate heat exchanger. Reliable plate heat exchanger manufacturers in Pune source certified materials with proper documentation, including chemical composition and mechanical properties.

High-grade stainless steel, titanium, and other corrosion-resistant alloys are used depending on the application. These manufacturers maintain full traceability, so if any issues arise post-installation, the specific material batch can be tracked and analyzed. This traceability is a cornerstone of ISO 9001 and other quality systems followed by Pune-based companies.

3. Pressure Testing and Leak-Proof Assurance

Before leaving the factory, every unit undergoes rigorous hydrostatic and pneumatic testing. These tests are done under pressure conditions that exceed actual operating parameters to ensure the system can withstand extreme conditions.

This is a routine but essential practice for any professional plate heat exchanger manufacturer in Pune. It prevents unexpected system failures, especially in industries like oil and gas or chemical processing where safety risks are higher.

4. Welding and Assembly Safety Protocols

Precision welding is critical to the performance of plate heat exchangers, especially in gasketed and brazed models. Pune manufacturers employ certified welders and follow welding standards such as ASME Section IX and ISO 9606. In addition, many manufacturers implement cleanroom conditions for final assembly, ensuring that no contaminants affect sealing surfaces.

By maintaining strict welding procedures, these companies reduce the risk of joint failures, leakage, or structural compromise—all of which can have serious safety consequences.

5. Regular Staff Training and Certification

Safety begins with the people on the shop floor. Top plate heat exchanger manufacturers in Pune ensure that every technician, engineer, and production worker is regularly trained on workplace safety, quality protocols, and handling of high-pressure components.

Many companies also participate in third-party audits and safety workshops to stay updated with evolving safety standards. Employee safety gear, SOPs for emergency handling, and regular mock drills are standard practices.

6. Environmental and Workplace Safety Compliance

Environmental safety is another area where Pune’s manufacturers excel. Compliance with local and international environmental norms ensures that no harmful by-products are released during manufacturing. Proper waste disposal, use of eco-friendly cleaning agents for plates, and energy-efficient processes all contribute to both worker and environmental safety.

Factories are routinely inspected for fire safety, electrical hazard prevention, and ventilation control. This not only safeguards workers but also ensures uninterrupted and clean production environments.

Conclusion

When selecting a plate heat exchanger manufacturer in Pune, safety should be one of your top evaluation criteria. From global design compliance to pressure testing, from material traceability to employee training—these manufacturers invest heavily in building safe, reliable, and high-performing products. Their dedication to maintaining world-class safety standards not only enhances the quality of the equipment but also ensures peace of mind for clients across various industries.

Choosing a manufacturer that prioritizes safety is not just a smart business decision—it’s a long-term investment in operational stability and human well-being.

0 notes