#Heat exchanger

Text

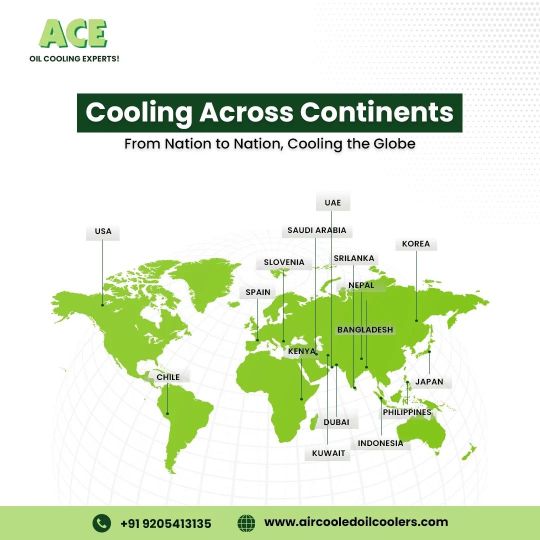

Ace Hydraulic Oil Cooler & Air Cooled Heat Exchanger Manufacturers in India.29+ years of Experience, Ex-Stock Delivery & Affordable Prices.

Hydraulic Oil Coolers & Air Cooled Heat Exchanger Manufacturers in India

2 notes

·

View notes

Text

Shell and Tube Heat Exchanger: An Introduction

Are you familiar with the concept of a heat exchanger? It's a device that transfers thermal energy between two fluids. And if you're particularly interested in this technology, then you've likely come across Shell and Tube Heat Exchangers. These types of heat exchangers have been around for over 150 years, but they're still widely used today due to their effectiveness and reliability. If you're looking to learn more about these amazing machines, then keep reading! This blog post is your definitive guide to the fascinating world of shell and tube heat exchangers - an introduction like no other.

What is a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger is a type of heat exchanger that is commonly used in industrial applications. It consists of a shell, which is a large cylindrical vessel, and a bundle of tubes that run through the shell. Heat is transferred between two fluids that flow through the shell and the tubes, respectively.

How Does a Shell and Tube Heat Exchanger Work?

In a shell and tube heat exchanger, the two fluids flow in opposite directions. The fluid that needs to be heated or cooled flows through the tubes, while the other fluid flows through the shell. As the fluids flow through the tubes and the shell, heat is transferred from one fluid to the other through the walls of the tubes.

Types of Shell and Tube Heat Exchangers

There are several types of shell and tube heat exchangers, including:

Fixed Tube Sheet Heat Exchanger: This is the simplest type of shell and tube heat exchanger, where the tube sheet is fixed and cannot be removed.

U-Tube Heat Exchanger: In this type of heat exchanger, the tube bundle is bent into a U-shape, allowing for easy maintenance and cleaning.

Floating Head Heat Exchanger: In a floating head heat exchanger, the tube bundle is removable, making it easy to clean and maintain.

Applications of Shell and Tube Heat Exchangers

Shell and tube heat exchangers are commonly used in a variety of industrial applications, including:

Chemical Processing: Shell and tube heat exchangers are commonly used in chemical processing plants to heat or cool fluids.

Oil and Gas: Shell and tube heat exchangers are used in oil refineries and gas processing plants to transfer heat between fluids.

HVAC: Shell and tube heat exchangers are used in HVAC systems to transfer heat between air and water.

Advantages of Shell and Tube Heat Exchangers

Efficient heat transfer

Can handle high-pressure applications

Can handle a wide range of fluids and temperatures

Conclusion

Why use a shell and tube heat exchanger? Shell and tube heat exchangers are an important component in many industrial applications. They provide efficient heat transfer between two fluids, making them ideal for use in chemical processing, oil and gas, and HVAC systems. While they can be expensive to manufacture and install and can be difficult to clean and maintain, the advantages of shell and tube heat exchangers make them a valuable asset in many industrial settings. So, whether you're designing a new industrial process or looking to improve an existing one, consider the benefits of a shell and tube heat exchanger.

4 notes

·

View notes

Text

Prover Tanks, Prover Tank Manufacturer, Supplier, Exporter, India

Prover Tanks, Manufacturer, Supplier, Exporter, Pune, Maharashtra, India, Saudi Arabia.

Prover Tanks, Loading Arm, Loading Arms, Unloading Arm, Unloading Arms, Loading Arms System, Loading Arms Systems, Unloading Arms System, Unloading Arms Systems, Swivel Joint, Swivel Joints, Floating Suction Assemblies, Floating Suction Assembly, Prover Tank, Prover Tanks, Storage Tank, Storage Tanks, Storage Tank, Storage Tanks, Rotary Joint, Rotary Joints, Mechanical Seal Support System, Mechanical Seal Support Systems, Thermosyphon, Thermosyphons, Heat Exchanger, Heat Exchangers, Test Aider, Test Aiders, Fluid Handling System, Fluid Handling Systems, Manufacturer, Supplier, Exporter, Pune, Maharashtra, India, Saudi Arabia.

#Prover Tanks#Loading Arm#Loading Arms#Unloading Arm#Unloading Arms#Loading Arms System#Loading Arms Systems#Unloading Arms System#Unloading Arms Systems#Swivel Joint#Swivel Joints#Floating Suction Assemblies#Floating Suction Assembly#Prover Tank#Storage Tank#Storage Tanks#Rotary Joint#Rotary Joints#Mechanical Seal Support System#Mechanical Seal Support Systems#Thermosyphon#Thermosyphons#Heat Exchanger#Heat Exchangers#Test Aider#Test Aiders#Fluid Handling System#Fluid Handling Systems#Manufacturer#Supplier

0 notes

Text

Advancing Biofuel Efficiency: Precision Equipments' Shell and Tube Heat Exchangers

Shell and Tube Heat Exchangers

As the global focus shifts toward energy transition and decarbonization, developing countries like India face the dual challenge of rapidly growing energy demand and dwindling fossil fuel resources. To address this, the Government of India is promoting the production of biofuels such as ethanol, aiming for energy self-sufficiency and reduced reliance on fossil fuels.

The Role of Biofuel in Modern Energy Solutions:

Biofuels, including ethanol, can be utilized directly or blended with fossil fuels to reduce emissions and fossil fuel dependency. Notably, biofuels like ethanol boast a higher octane number than gasoline, ensuring complete combustion within engine cylinders and contributing to lower emissions.

Innovative Production Techniques:

Biofuel production leverages a novel, sulfur-free bio-solvent in a closed-loop cycle with water, enhancing sustainability through full recovery and minimal chemical input. This process not only offers significant cost savings but also aligns with sustainable practices by minimizing environmental impact.

Precision Equipment's Contribution to Biofuel Industry:

Precision Equipments specializes in manufacturing top-quality biofuel heat exchangers for cooling, reheating processes, and handling exhaust or flue gases. Our products serve a broad range of industries, including:

Biodiesel

Bioethanol

Biogas

And more biofuel production sectors.

Benefits of Bio-Fuels Heat Exchangers:

Our bio-fuels heat exchangers offer numerous advantages:

Reduction in CO2 emissions, supporting global decarbonization goals.

Production of bio-chemical byproducts that lessen environmental impact.

More energy-efficient than fossil fuels with fewer chemical processes.

Non-food-based production that does not affect human habitation.

Critical Role in Biofuel Production Processes:

Heat exchangers are crucial in various stages of biofuel production, including pre-treatment, fermentation, distillation, dehydration, stillage dewatering, and evaporation. Precision Equipments designs shell and tube heat exchangers specifically for biofuels, capable of handling hazardous fluids like bio-solvents and furfural. Constructed from materials such as duplex and super duplex stainless steels & non-ferrous metals, these exchangers often feature fixed tube sheets or thick wall expansion bellows for critical operating conditions.

Expertise and Reliability:

Since 1981, Precision Equipments has been a leader in manufacturing shell and tube heat exchangers for biofuels, adhering to international codes and standards like ASME, API, & TEMA, and meeting strict quality control measures. Our extensive experience ensures that we continue to deliver high-quality and high-performance heat exchangers for nationally important projects.

Conclusion:

Shell and tube heat exchangers from Precision Equipments play a pivotal role in enhancing the efficiency and sustainability of biofuel production processes. By improving operational reliability and reducing environmental impact, our solutions help propel the biofuel industry forward. For those in the biofuel industry looking to upgrade their production capabilities, Precision Equipments offers a range of solutions tailored to meet diverse needs.

Contact Precision Equipments today to explore our biofuel treatment systems and discover how our expertise can benefit your production requirements.

0 notes

Text

The Role of Heat Exchangers in Modern HVAC Systems: Key Insights

Heat exchangers are pivotal in modern HVAC systems, enabling efficient heat transfer between fluids. They help regulate indoor temperatures by transferring heat from hot to cold fluids or vice versa, enhancing energy efficiency and reducing operational costs. Their design and performance are crucial for maintaining optimal climate control and improving overall system effectiveness.

0 notes

Text

Rixens Enterprises Inc- Plumbing Kits & Parts

0 notes

Text

#hvac systems#hvac design#building design#thermostat#furnace#blower motor#heat exchanger#indoor evaporated coil#outside condensing unit#ducts#hvac system design

1 note

·

View note

Text

KRYSTAL GLOBAL ENGINEERING LIMITED AT HEAT EXCHANGER WORLD AMERICAS - 2024

HEAT EXCHANGER WORLD AMERICAS - 2024

Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024

Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions in high-performance Stainless Steel, Duplex, Super Duplex, Nickel Alloy, and Exotic-Grade Material Tubes, Pipes, and U-Tubes.

Event Details:

Date: 16 – 17 October 2024

Venue: Houston, Texas, USA

Booth Number: Stand 2110

Event Hours: 10:00 AM – 5:00 PM

Event Link: https://heat-exchanger-world-americas.com

KRYSTAL X HEAT EXCHANGER

2024

Manufacturer and Exporter of Seamless Stainless Steel, Duplex, Super Duplex, Nickel Alloy Tubes, Pipes & U Tubes.

At the trendsetting, ultimate networking event for the process industry, you will have an opportunity to connect with Krystal experts, tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics include the path beyond blue to green hydrogen, the latest decarbonization innovations, advances in electrolyser technologies with ITM Power and the role of services in future-proofing your plant.

About Krystal Global Engineering Limited:

Krystal Global Engineering Limited is your premier destination for top-quality tubes and pipes, serving industries worldwide including petrochemical, oil and gas, chemical processing, and power generation. We prioritize excellence and innovation, delivering superior products tailored to global standards.

What to Expect:

Extensive Product Showcase: Explore our comprehensive range of high-performance tubes, pipes, and U-tubes designed to endure extreme temperatures, corrosive environments, and high-pressure conditions.

Expert Consultation: Meet our team of industry specialists available to discuss your specific needs and provide tailored solutions.

Networking Opportunities: Connect with professionals, engineers, and industry leaders to exchange ideas, insights, and business opportunities.

Live Demonstrations: Witness live demonstrations highlighting the durability, reliability, and performance of our products in real-world applications.

Why Visit Us?

Quality Assurance: Our products undergo stringent quality control measures, ensuring compliance with international standards and specifications.

Customization: Benefit from our flexible manufacturing capabilities, allowing for customized solutions to meet your unique project requirements.

Global Reach: With a vast network of distributors and partners, we offer prompt delivery and comprehensive support worldwide.

Innovation: Stay ahead with our continuous investment in research and development, delivering cutting-edge solutions to address evolving industry challenges.

#heat exchanger#exhibition 2024#krystalgeltd#Krystal Global Engineering Limited#steels#tubes#pipes#metals#mining#worldwide 2024#bright annealed tubes#buy seamless tubes and pipes#capillary tubes#heat exchanger tubes manufacturers#inconel alloy#instrumentation tubes#seamless tube suppliers#seamless heat exchanger tubes#hydraulic tube manufacturer#manufacturer of instrumentation tubes

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/new-cts-turbo-heat-exchanger-for-bmw-s58-g8x-m3-m4-platforms/

NEW: CTS Turbo Heat Exchanger for BMW S58 Platforms

Introducing the CTS Turbo High-Performance Heat Exchanger for BMW S58 Platform:

CTS Turbo has unveiled their latest innovation for BMW enthusiasts – the High-Performance Heat Exchanger designed specifically for the S58 platform. This includes the highly anticipated models such as the M2 G87, M3 G80, M3C G80, M4 G82, and M4C G82. Engineered to perfection, this heat exchanger is a must-have upgrade for those looking to elevate their vehicle’s performance and reliability.

Why Upgrade Your BMW’s Heat Exchanger?

For enthusiasts who enjoy spirited canyon driving and occasional track days, upgrading to the CTS Turbo High-Performance Heat Exchanger is essential for maintaining peak engine performance and reliability, all season long. The stock heat exchanger can struggle to keep up with the increased thermal demands of aggressive driving, leading to higher charge air temperatures and reduced performance. The CTS Turbo unit, with its superior cooling efficiency and high-quality construction, ensures your engine stays cool even under the most demanding conditions. This means more consistent power delivery, less stress on your engine, and the confidence to push your BMW G8X to its limits without compromise. What more could you ask for?

Let’s dive into other aspects that make this heat exchanger an excellent option for all BMW G8x drivers.

Check Out All The Lastest Parts From CTS Turbo – HERE

What Makes The CTS Turbo S58 G8X Heat Exchanger A Good Upgrade?

Direct Fitment

The heat exchanger is crafted for a seamless fitment on BMW G8X models, including the M2, M3, and M4. Installation is straightforward with no modifications needed.

❄️ Superior Cooling Efficiency:

Equipped with a dual-pass high-efficiency core, this heat exchanger significantly reduces charge air temperatures. This improvement translates to better engine performance and increased reliability, especially under demanding conditions.

🛠️ High-Quality Construction:

Made from high-grade materials, the CTS Turbo heat exchanger boasts a robust aluminum core coupled with advanced cooling fins. This ensures durability and longevity, making it a solid investment for your BMW.

📈 Optimal Performance:

Ideal for both street and track use, the heat exchanger maintains consistent cooling to keep your engine running at its best. Whether you’re spirited daily driving or pushing your car to its limits on the track, this upgrade ensures peak performance.

👨💻 Enhanced Design:

With an optimized fin pitch and high-density core, the heat exchanger maximizes heat dissipation. This design enhancement is crucial for maintaining lower temperatures and enhancing overall engine efficiency.

🪶 Lightweight:

Despite its durable construction, the heat exchanger is lightweight. This not only aids in vehicle handling but also contributes to better fuel efficiency.

🤝 Plug-and-Play Installation:

The product comes with all the necessary hardware for an easy installation process. The plug-and-play design allows for a hassle-free upgrade that can be installed in the driveway.

Fitment

2021+ BMW G80 M3 (including Competition)

2021+ BMW G82/G83 M4 (including Competition)

2022+ BMW G81 M3 (including Competition)

2022+ BMW G87 M2 (including Competition)

This CTS Turbo High-Performance G8X M2/M3/M4 Heat Exchanger is engineered to provide the ultimate cooling solution for your high-performance BMW. With its superior construction and design, it ensures your engine runs cooler and more efficiently, allowing you to push your vehicle to its limits without compromise.

Pricing

Retail Price: $499.99

Sale Price: $424.99 (At Vivid Racing during sale periods)

Upgrade your BMW with the new CTS Turbo High-Performance Heat Exchanger and experience the difference in performance and reliability. Don’t miss out on this essential modification for your S58-powered vehicle.

Let us help!

There is no doubt this all-new heat exchanger for the S58 is a no-brainer upgrade for your G8X. As always, if you have any questions regarding upgrades for your vehicle or this CTS Turbo part specifically, we are enthusiasts who genuinely believe in supplying fellow enthusiasts with the best mods to meet your driving goals! We have almost 12,000 5-star reviews and a 4.6/5 review on Google to prove it 😏

You can chat with us – HERE (Live Chat). We’ll get back to you like, spooky fast.

Reach out to us at [email protected] or give us a call at (480) 966-3040 📞 and we’ll be happy to help with your questions or be a shoulder to cry on.

0 notes

Text

"Optimize your heat exchanger performance with Vinssco's stainless steel tube solutions! 🌡️ Our latest blog delves into the crucial role of stainless steel tubing in heat exchanger systems, highlighting Vinssco's premium quality and durability. Whether you're in the HVAC, chemical, or food processing industry, trust Vinssco to provide the ideal tubing for your heat transfer needs. Click the link to learn more and revolutionize your heat exchanger efficiency today.

0 notes

Text

youtube

Barnacle Buster How to use? Sailboat Engine Flush Heat Exchanger

Are you facing engine overheating issues on your sailboat? Learn a simple and effective method to describe your Yanmar Diesel engine's heat exchanger using Barnacle Buster without the need for an external pump. This procedure, recommended by the manufacturer but often needs to be better explained, involves leaving the solution inside the engine's raw water system overnight for optimal results.

The video presents two ways to utilize Barnacle Buster for sailboat engine flush. First, run the engine to expel water from the system, followed by placing a bucket as a water source. The crucial step of mixing Barnacle Buster is demonstrated, ensuring the correct preparation for the flush. Finally, the video shows the process of flushing the system to complete the maintenance.

If you're seeking a straightforward solution to maintain your sailboat's engine health, this guide on using Barnacle Buster for sailboat engine flush and heat exchanger maintenance is a valuable resource. Remember, a well-maintained engine ensures smooth sailing on your nautical adventures!

#sailing shanti#shanti#shanti sailing#sailing vlog#sailing series#barnacle buster#sea flush#sea flush and barnacle buster#barnacle buster engine flush#heat exchanger#boat maintenance#barnacle buster r301#barnacle buster heat exchanger#barnacle buster concentrate#heat exchanger maintenance#barnacle buster flush#barnacle buster sea flush kit#raw water pump#flush heat exchanger#boat maintenance tips#exhaust elbow cleaning#exhaust elbow yanmar#yanmar diesel#Youtube

1 note

·

View note

Text

Floating Suction Assemblies Manufacturer, Supplier, India

Floating Suction Assemblies, Manufacturer, Supplier, Exporter, Pune, Maharashtra, India, Saudi Arabia.

Floating Suction Assemblies, Loading Arm, Loading Arms, Unloading Arm, Unloading Arms, Loading Arms System, Loading Arms Systems, Unloading Arms System, Unloading Arms Systems, Swivel Joint, Swivel Joints, Floating Suction Assemblies, Floating Suction Assembly, Prover Tank, Prover Tanks, Storage Tank, Storage Tanks, Storage Tank, Storage Tanks, Rotary Joint, Rotary Joints, Mechanical Seal Support System, Mechanical Seal Support Systems, Thermosyphon, Thermosyphons, Heat Exchanger, Heat Exchangers, Test Aider, Test Aiders, Fluid Handling System, Fluid Handling Systems, Manufacturer, Supplier, Exporter, Pune, Maharashtra, India, Saudi Arabia.

#Floating Suction Assemblies#Loading Arm#Loading Arms#Unloading Arm#Unloading Arms#Loading Arms System#Loading Arms Systems#Unloading Arms System#Unloading Arms Systems#Swivel Joint#Swivel Joints#Floating Suction Assembly#Prover Tank#Prover Tanks#Storage Tank#Storage Tanks#Rotary Joint#Rotary Joints#Mechanical Seal Support System#Mechanical Seal Support Systems#Thermosyphon#Thermosyphons#Heat Exchanger#Heat Exchangers#Test Aider#Test Aiders#Fluid Handling System#Fluid Handling Systems#Manufacturer#Supplier

0 notes

Text

Plate and Frame Heat Exchangers Repair and Service: Ensuring Efficiency and Reliability

Plate and frame heat exchangers are essential components in various industrial processes, facilitating efficient heat transfer between two fluids. However, like any mechanical system, they require regular maintenance and occasional repairs to ensure optimal performance and longevity. Recognizing this need, Ring Heat Exchanger offers a comprehensive maintenance and repair service tailored specifically for plate and frame heat exchangers, guaranteeing that they function as efficiently as when they were new.

Understanding Plate and Frame Heat Exchangers

Plate and frame heat exchangers operate on the principle of transferring heat between two fluids through metal plates. These plates, arranged in a frame, create parallel flow channels for the fluids, allowing for a significant increase in surface area contact. This design promotes a more efficient heat exchange process, enabling rapid temperature changes. However, over time, various factors can lead to performance issues and even failure of the heat exchanger.

#heat exchanger service#heat exchanger#heat exchanger service and repair#radiator maintenance#plate and frame heat exchangers

0 notes

Text

Top 5 Common Problems with Heat Exchangers and How to Fix Them

Heat exchangers are vital components in many industrial processes, but they can encounter common issues that affect performance. This guide highlights the top five problems: fouling, leakage, corrosion, inadequate heat transfer, and improper flow distribution. Each issue is accompanied by effective solutions to restore efficiency and ensure reliable operation. By addressing these challenges promptly, you can enhance the longevity and effectiveness of your heat exchanger systems.

0 notes