#tools of quality control

Explore tagged Tumblr posts

Note

hiya stell! i hear you take care of parhelic anima, with repairs and defence as it travels through the cosmos!

i was wondering if you ever have to attend to maintenance on the outside of your comet, and if so if there are any protocols for those sort of repairs! are there codes of conduct to maintain your own safety while doing it, or to ensure bits-and-bobs aren't lost in space; or are those simply not issues for you?

(Removed: -1 Screwdriver) Don't worry. They always have a backup. @alagaesia-overlord

@kirbyoctournament

#qna#stell#parhelion knight#strix#doodles#kirby oc tournament#kirby oc#We're So Back#perks of being a species composed 100% of stardust is that you are Immune to the vacuum of space#But Stell would rather frankly explode and die than not be seen in their Cool Anime Outfit#(also just bc you're Immune doesn't mean you're Comfortable)#Having a controlled suit is great for quality of life#esp if you're gonna spend. a Longass time tinkering out there asdlkfjn#also perks of utilising a nano system that forms to one's needs#infinite tools#there is something to be said about the precision of regular physical tools#but also something to be said about not losing your fucking tools out in space#(regular tools are Inside Only)

54 notes

·

View notes

Text

guys, youtube is starting to be harder on the adblocking rules, so we should definitely follow them.

just so you know what rules not to break, chrome has hidden ublock origin because it updates around all of youtube attempts to block adblockers (slimy bugger), definitely DO NOT use the inspect element tool, use Ctrl + F to find "disabled aria-describedbody", and and DO NOT under ANY CIRCUMSTANCES change it to "enabled". this will allow you to install the extension like it was never hidden by chrome. this is very bad guys, don't do this. you'll have ublock origin back, and youtube doesn't want that because it stops youtube from making ad money. so come on, DONT install ublock origin, watch all 15 unskippable sexually inappropriate ads marketed towards children in your 4 minute video, come on. don't break youtubes rules guys.

also, youtube has been cracking down on removing quality of life features, as we all know, they know best, and their decisions are flawless. so DONT get the extension that re-impliments the youtube dislike. youtube removed it for a reason guys, come on.

#this is meant to be sarcastic#everytime youtube makes using the app with an adblocker harder#i will just get more adblockers#youtube needs to add quality control for their ads#or show less of them#also the dislike button is just nice to have back again#and i want to platnoically marry ublock origin#its like trump in a way#he can ban trans people all he wants (chrome hiding ublock origin) but trans people still exist and theres nothing he can do about it#(you can literally go into inspect tool and go “hidding from download? hehehe. how about no?”. its the best)#youtube#adblockers#ublock origin#youtube ads#youtube ads are ass (derogatory)

6 notes

·

View notes

Text

Got a report at work about a bunch of lots that had zero yield for an issue my area causes with a note that's like "You guys need to address this issue it's so common with you!!! 😡"

Oh no! I'd better look at the images we took of this and start looking into what happened!

Images: From 2017

Me: ... So like... That was eight years ago... I don't know what to tell you man.

#the smartass half of me wants to be like: well based on the image quality#id say one process improvement would be to get a tool that can focus on the pads during inspection#And we have! because its been more than 7 years!#we've literally changed companies since then!#two more years and we wouldn't even have fucking records aside from what my boss hoarded in my office!#none of its on site! and im pretty sure they had a lot less process controls back then!#given TWO YEARS AGO THEY DIDNT EVEN PRETEND TO TRACK BATH CHANGES#even blurry it is pretty clear that these lots did have said issue tho.

9 notes

·

View notes

Text

a bunch of people have already registered for my mentoring workshop! unfortunately this means i have to plan and host a workshop aaaaaa

#i want to think aloud through it on here at some point#but i think i am going to structure it around the theme of cultivating student autonomy#because i think one of the primary goals of mentorship is to prepare students to be self-directed learners who can set realistic goals +#evaluate their own progress + reflect on what they've learned and what they still don't know#+ take initiative without sitting around waiting for someone to tell them what to do next#so i think we will do some thinking around like#when we have a student we think of as really capable or driven what qualities and behaviors do we observe in that student#and maybe ill also share some of the research on intrinsic motivation + self-direction + locus of control#which i think is all really interesting esp in light of the contemporary College Mental Health Crisis concerns#and then we will look at a range of tools + structures + strategies that i think are useful for fostering student autonomy over time#and maybe leave them with some core principles/guiding values that i think are useful when you are trying to like#avoid jumping in and doing stuff for kids#or solving their problems for them#idk i need to think through specifics a bit more#but i feel like on this campus#people do a lot of 'workshops' that are really not interactive at all#it's just someone talking from slides#and i kind of want to show off my ability to structure more engaging workshops#but idk. gotta think about how to do it well#and how to build in lots of opportunities for like crowdsourcing strategies too

12 notes

·

View notes

Text

No matter whether AI does a good job at what it does or not, rage against the technology isn’t going to solve the labor issues. It isn’t going to stop artists and writers from losing their jobs. Whether it’s able to do the job adequately or not, it will be used to replace that job if all we do is protest against the technology itself. It will similarly do so if we rally around liberal principals like “copyright” and “intellectual property.” Most of the “intellectual property” belongs to conglomerates, not to intellectual laborers. The same if you misrepresent AIs water and energy consumption. None of these will get you anywhere productive, and some of them (“intellectual property”) even show a petty-bourgeoisie outlook.

Of course we should be concerned about small independent artists having their lives be less stable—even if it’s not our chief concern. Whether someone is an artisan proper or has some semi-proletarian characteristics (that is if they are working a side hustle to get by while they work on their passion project) that doesn’t mean we shouldn’t take their interests into account, but it does need to come from an industrial proletarian perspective first and foremost. Who will get laid off if AI technology is adopted? Who will lose their income? These are far more primary than independent artists.

The industrial proletariat is the most concentrated and unified force we have. It is this force with which we can fight and win. If we want to fight and win on the subject of AI, it must be fought with the organized industrial proletariat. Unions represent one lower form of this fight. The higher form of this fight is a political leadership that can lead to political reforms and regulations being adopted by the government as concessions, or perhaps even AI and other means of production being seized by the proletariat and regulated and technologically improved by the proletariat.

#AI may such at making art and writing but it’s hard to say whether it fundamentally does so#it may be a tool for an artist or writer to use like a paintbrush in the future as the technology develops#or it may otherwise find other uses#the technology itself isn’t fundamentally bad#the class that currently controls that technology is the problem#if your criticisms are focused on the technology and not the class than your thinking is fundamentally in error#and if the technology improves your criticisms may not hold water anymore especially if they fixate too much on the quality of its output#technology iterates and improves#that may not be true any more in a few years#the water and energy consumption of this new technology will likely be down#it’s output will likely be of higher quality than it is now#make deeper critiques than aesthetic ones jfc#and stop looking at liberal ‘solutions’ which benefit only the owning class

4 notes

·

View notes

Text

Please try out vector layers in Clip Studio animation ifyou are able...

#Aside from being able to transform lines without degrading the quality#Control points are a bit of a pain so sometimes I use the 'correct line' tool instead for minimal movements which is really useful#When you move a line it looks like a new organic stroke instead of a duplicated frame that just got moved around a bit

8 notes

·

View notes

Text

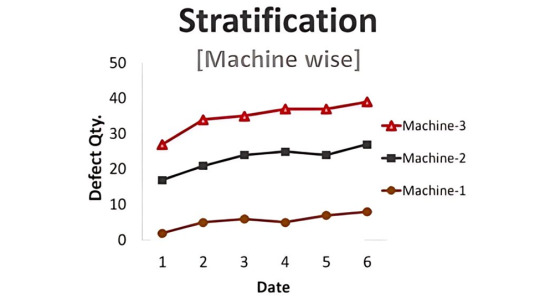

7 QC Tools for Quality Improvement in Manufacturing & Services Industries

In our competitive business climate today, consistently providing a quality product or service is not a choice, it is necessary. Whether in the manufacturing or service industry, the task of fulfilling expectations of a customer requires tools that help you to identify the problem, analyze the data, and the process of improvement. This is where the 7 QC (Quality Control) Tools come into play.

The 7 QC Tools are simple, effective, and applicable to everyone; they are the basis for quality improvement for all industries. Let’s take a look at each of these tools and how quality can provide value to you in your work.

What Are the 7 QC Tools?

The 7 QC Tools are basic statistical tools developed by Kaoru Ishikawa, a Japanese quality expert, to improve product and service quality. They are:

Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram)

Check Sheet

Control Chart

Histogram

Pareto Chart

Scatter Diagram

Flow Chart (Process Mapping)

These tools help teams in problem identification, root cause analysis, monitoring processes, and decision-making — critical to achieving Total Quality Management (TQM) and continuous improvement.

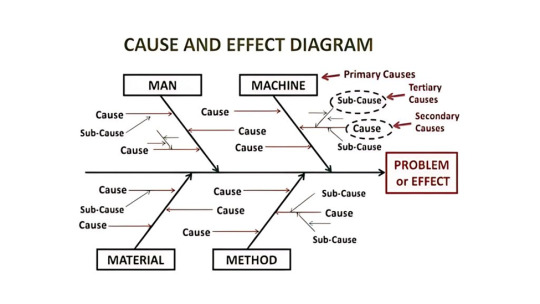

1. Cause-and-Effect Diagram (Fishbone Diagram)

Also known as the Ishikawa Diagram, this tool is used to identify the root causes of a problem by categorizing possible causes into groups such as:

Man

Machine

Method

Material

Measurement

Environment

📈 Use Case:

In a manufacturing plant, if there’s a defect in the product, the Fishbone Diagram helps break down and analyze every possible factor that could be causing it.

In a service company, it could be used to find why customer complaints have increased.

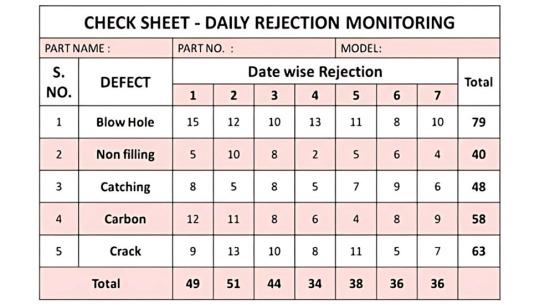

2. Check Sheet

A Check Sheet is a structured, prepared form used to collect real-time data at the location where it is generated. It's one of the simplest and most effective tools for tracking how often a problem occurs.

📈 Use Case:

In manufacturing, it might track the number of defects per shift.

In services, a call center might use it to log the types of issues customers report.

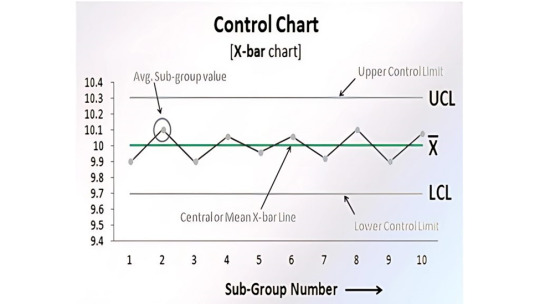

3. Control Chart

Control Charts are used to monitor process variation over time and determine whether a process is in a state of control.

It distinguishes between:

Common cause variation (normal)

Special cause variation (abnormal)

📈 Use Case:

A manufacturing process using machinery can track the consistency of product dimensions.

In services, a control chart could monitor average call handling time to ensure it stays within set limits.

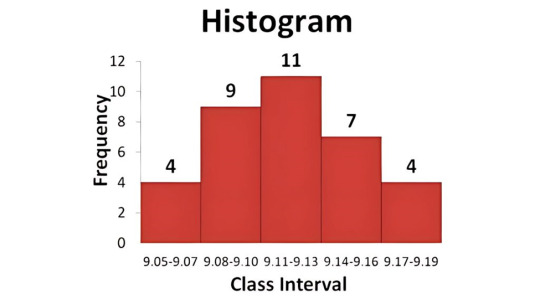

4. Histogram

A Histogram is a graphical representation of data distribution. It shows how often each different value in a set of data occurs.

📈 Use Case:

In manufacturing, it helps identify the spread of measurement values, like length or weight.

In services, it can show customer satisfaction ratings to identify performance trends.

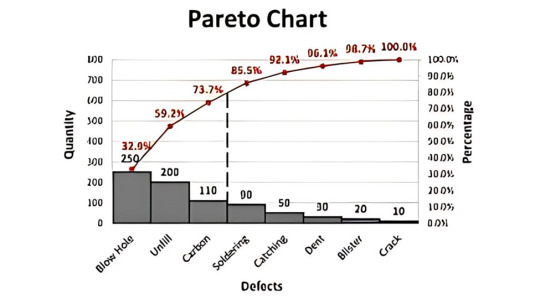

5. Pareto Chart

Based on the 80/20 rule, the Pareto Chart helps prioritize problems by showing which causes contribute most to an issue.

It ranks issues from most to least significant, so teams can focus on the "vital few" rather than the "trivial many."

📈 Use Case:

In manufacturing, it helps identify which types of defects occur most frequently.

In services, it can identify the top reasons for customer complaints or service delays.

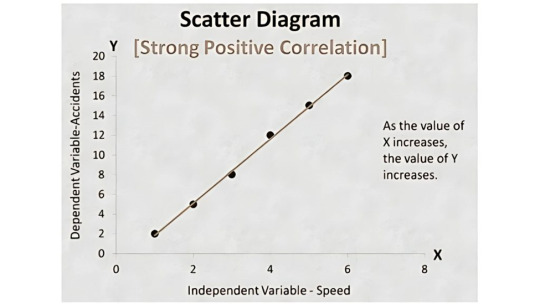

6. Scatter Diagram

A Scatter Diagram shows the relationship between two variables. It helps determine if a change in one factor affects another.

📈 Use Case:

In manufacturing, you could study the relationship between machine maintenance frequency and product quality.

In services, it might analyze how employee training hours affect customer satisfaction scores.

7. Flow Chart (Process Mapping)

A Flow Chart maps out every step in a process, helping visualize workflows and identify unnecessary steps, delays, or bottlenecks.

📈 Use Case:

In manufacturing, it can map out an assembly process to find inefficiencies.

In services, it can improve the flow of customer onboarding or complaint resolution processes.

Benefits of Using 7 QC Tools in Manufacturing

Reduces defects and rework

Increases productivity and process control

Improves product consistency

Increases the effectiveness of decision making when using data to support decisions

Improves customer satisfaction and retention

Benefits of 7 QC Tools in Services Industry

Improves service delivery time

Reduces customer complaints

Improves employee performance through better processes

Enables proactive problem-solving

Supports a culture of continuous improvement

How to Implement the 7 QC Tools in Your Organization

Step 1: Train Employees

Start with basic training on each QC tool so that employees understand when and how to use them.

Step 2: Identify Problems

Pick a real problem that affects your quality, such as high defect rates or customer dissatisfaction.

Step 3: Choose the Right Tool

Each tool has a unique function. Select based on what you want to analyze — root cause, trends, relationships, etc.

Step 4: Analyze Data

Use the tool to collect and interpret data. Look for patterns, trends, or anomalies.

Step 5: Take Action

Based on the analysis, make informed decisions and implement process improvements.

Step 6: Review & Improve

Monitor the results of your changes and keep refining your processes.

How 4C Consulting Can Help

With experience of working with over 2500+ clients and delivering more than 15,000 hours of quality training, 4C Consulting is your expert partner in implementing QC tools, ISO standards, and quality improvement frameworks.

Our consultants will:

Provide hands-on training on 7 QC Tools

Help create customized checklists, charts, and templates

Assist in integrating these tools into your Quality Management System

Support your team in problem-solving and performance tracking

Ready to improve your quality processes? 👉 Talk to our experts today for a free consultation!

#7 QC Tools#Quality improvement tools#QC tools in manufacturing#QC tools in service industry#How to use 7 QC tools#Basic quality control tools#Problem-solving tools for quality#7 QC tools implementation#Quality management tools

1 note

·

View note

Text

Pipe Testing Equipments, Manufacturers, Exporters, India

Explore our range of pipe testing equipment for reliable quality assurance. Perfect for ensuring compliance and performance in your polymer applications.

#Pipe Testing Equipments#Pipe Testing Equipment#Polymer Testing Tools#Quality Control Solutions#Material Testing#Lab Testing Equipment#Pressure Testing#Durability Assessment#Mumbai#India

0 notes

Text

Revolutionizing Precision: How Automated Measuring Systems Are Changing

The Game In today’s high-tech manufacturing and robotic landscape, precision is no longer a bonus—it's essential. As industries have stricter tolerances, faster production times, and flawless quality control, you can push the limits with specialized automated measuring systems—precision, efficiency and reliability in ways traditional measurement cannot support—and Dynalog is leading the way.

What are Automated Measuring Systems?

Automated Measuring Systems (AMS) use sophisticated technology to perform measurements automatically, without operator input. Automated Measuring Systems use a combination of sensors, robotics, software and analysis to provide measurements with extremely high accuracy, in real time. AMS can verify dimensions on a complex piece of material, check the position of the end effector on a robotic tool, or complete an entire inspection routine---and can do this quickly, at a consistent level of accuracy. For the manufacturer or production facility, AMS provide lower risk of error, faster throughput, and a better quality of product quality. It is not surprising that companies, like Dynalog, are advancing these systems for industries such as automotive, aerospace, electronics and medical device manufacturing.

The Importance of Accuracy is UndeniableIn manufacturing,

a difference of just 0.01mm can mean the difference between a product that works perfectly and one that does not work. As parts become smaller and more complicated, the margin of error is decreasingly smaller! Manual measurement is often human error-prone, slow, and inconsistent.

That’s why Dynalog has automated measuring systems.

Automated measuring systems take human error out of the equation and provide repeatable, consistent, real-time measuring data. With real-time feedback, manufacturers can change their processes on the spot, eliminating scrap and saving money.Dynalog: The Leaders in Robotic Accuracy and CalibrationAt Dynalog, accuracy is not just a marketing statement, accuracy is at the core of everything they do. With extensive experience in robotic measuring, calibration, and inspection systems, they build state-of-the-art solutions for the next generation of manufacturing.Automated measuring systems integrate with robotic arms and production lines, every movement and measurement is accurate and traceable. From Robot TCP Calibration to validating robot performance, Dynalog measuring systems are for manufacturers that cannot afford to be inaccurate.Key Dynalog Solutions for Automated MeasurementDynaCal® – A cutting-edge robotic calibration system providing sub-millimeter accuracy

Advantages of Automated Measurement Systems in ManufacturingLet's look at the rationale of why automated measurement is becoming the new standard in the industry:

1. Superior PrecisionAMS (Automated Measurement Systems) eliminate the subjectivity of the human eye and achieve measurements to the micron level of precision. For high-stakes industries like aerospace and medical equipment where safety is a stringent criteria, this level of precision is critical.

2. Accelerated Production Cycles Manual inspections hinder production, whereas with AMS, measurements occur in real-time—in-line or near-line—removing bottlenecks and even shortening delivery times.

3. Minimized Scrap and ReworkBy identifying deviations early in the process, manufacturers can take steps to correct defects prior to irreversible mistakes, resulting in more yield and less scrap.

4. Data-Driven DecisionsDynalog's systems not only measure, but they analyze. The real-time data can be accessed and input into process control systems to help engineers make informed data-based decisions for continuous improvement.

5. Easy Updated IntegrationToday’s AMS systems, like Dynalog's, can actually integrate with the existing robotic systems and software, creating a quick, affordable transition to your automated solution.

#automated measuring systems#robotic measurement systems#robot calibration solutions#Dynalog measuring systems#robot TCP calibration#manufacturing automation#industrial robotics#robot inspection technology#precision measurement tools#Industry 4.0 solutions#manufacturing quality control#3D robotic measurement#Dynalog USA#robotic accuracy systems#advanced measuring systems

0 notes

Text

Your Health is Better Series - Dealing with Diabetes (5)

Managing diabetes effectively requires a comprehensive and personalized approach, as each person’s needs and circumstances are different. One of the best ways to ensure optimal control of blood sugar and overall health is to work with a healthcare professional to develop a personalized diabetes management plan. This plan is tailored to your specific health needs, lifestyle, and goals, helping you make informed decisions about diet, exercise, medication, and monitoring.

Why is a Personalized Diabetes Management Plan Important?

Diabetes is a complex condition where the body either doesn't produce enough insulin (as in type 1 diabetes) or doesn’t use insulin properly (as in type 2 diabetes). Insulin is crucial for regulating blood sugar levels, and without effective management, high blood sugar can lead to complications like heart disease, kidney damage, nerve damage, and vision problems. Each individual has unique factors that influence how diabetes affects their body, such as age, activity level, other health conditions, and personal preferences. A personalized plan helps address these individual needs, making diabetes management more effective.

How Can a Healthcare Professional Help?

A healthcare professional, such as a doctor, endocrinologist, or diabetes educator, plays a critical role in developing and guiding your management plan. Here’s how they can assist:

Assessing Your Health: Your healthcare professional will begin by evaluating your overall health. This includes checking your blood sugar levels, weight, blood pressure, cholesterol, and any other relevant medical issues. They will also ask about your lifestyle, including your diet, exercise habits, and any challenges you face in managing diabetes.

Setting Personal Goals: Based on your health assessment, your healthcare provider will help you set realistic and achievable goals. These might include target blood glucose levels, weight loss, improving exercise habits, or managing any other health issues like high blood pressure or high cholesterol. Personalized goals help keep you motivated and on track.

Tailoring Diet and Exercise Recommendations: A significant part of managing diabetes involves making healthy food choices and staying physically active. Your healthcare professional will work with you to develop a diet plan that supports blood sugar control, taking into account your preferences, cultural habits, and nutritional needs. They will also help you set up an exercise routine that fits your lifestyle and ability, as regular physical activity is essential for managing blood glucose and improving insulin sensitivity.

Managing Medications: If necessary, your healthcare provider will prescribe medications to help control your blood sugar levels. This could include oral medications, insulin, or other drugs, depending on your type of diabetes and overall health. A personalized plan ensures you understand how and when to take your medications, potential side effects, and how they fit into your daily routine.

Monitoring Blood Sugar: Regular monitoring of blood glucose is a crucial part of managing diabetes. Your healthcare provider will help you determine how often and when to check your blood sugar levels, based on your treatment plan. This will allow you to make timely adjustments to your diet, activity level, or medication if needed.

Providing Ongoing Support and Education: Diabetes management is an ongoing process, and things can change over time. Your healthcare provider will offer continuous support and adjust your plan as needed. They can provide education on new diabetes management tools, technologies, and strategies to keep you informed and in control.

The Benefits of a Personalized Plan:

A personalized diabetes management plan offers several benefits:

Better Blood Sugar Control: A tailored approach helps you maintain blood glucose within a healthy range, reducing the risk of complications.

Improved Quality of Life: By addressing your individual needs and preferences, the plan can make managing diabetes less overwhelming and more achievable.

Empowerment and Motivation: Having a clear plan and support from a healthcare professional can boost your confidence in managing diabetes, making it easier to stick to your goals.

#Diabetes management plan#Healthcare professional#Personalized plan#Blood sugar control#Health assessment#Blood glucose levels#Nerve damage#Vision problems#Personal goals#Diet plan#Exercise routine#Insulin therapy#Blood pressure#Cholesterol#Monitoring blood sugar#Blood glucose monitoring#Ongoing support#Diabetes education#Lifestyle habits#Empowerment#Motivation#Quality of life#Insulin sensitivity#Health needs#Diabetes management tools#Blood glucose range#Health goals#Ongoing process

0 notes

Text

How Pharmaceutical Consulting Can Help Launch Your New Product Successfully

Ambrosia Ventures, we ensure your product launch achieves maximum impact by utilizing our expertise in biopharma consulting, which makes us a trusted pharmaceutical consulting service provider in the US. Here's the way to transform your product launch strategy into a blueprint for success through pharmaceutical consulting services

#Life Science Consulting#Strategic Life Sciences Consulting#Biotech Strategic Consulting#best biotech consulting firms#Pharmaceutical Consulting Services#Biotechnology Consulting#Strategic Life Sciences Advisory#Life Sciences Business Strategy#life science business consulting#Digital Transformation in Life Sciences#Pharma R&D Consulting#M&A Advisory Life Sciences#Healthcare M&A Solutions#Biopharma M&A Services#biopharma consulting#Biotech M&A Advisory#Pharmaceutical M&A Advisory#Predictive Analytics for M&A#Data-Driven M&A Strategy#Strategic M&A Analytics Solutions#M&A Target Identification Tool#Life Sciences M&A Analytics Tool#AI-Powered M&A Toolkit#M&A Toolkit#AI M&A Due Diligence Tools#Project Management Life Sciences#quality control services#quality control for project management#Regulatory Consulting for Life Sciences#Life Sciences Quality Assurance

0 notes

Text

Improving Quality Control in Material Management: Techniques and Tools

production meet the highest standards of quality and compliance. By implementing techniques such as Supplier Quality Assurance (SQA), Statistical Process Control (SPC), and Failure Mode and Effect Analysis (FMEA), organizations can proactively address quality issues and enhance operational efficiency. Modern tools like automated inspection systems, Quality Management Systems (QMS), and data analytics platforms further enable material managers to maintain strict quality standards, reduce wastage, and streamline processes. Pursuing a specialized program, such as a Post Graduate Diploma in Material Management, equips professionals with the advanced skills and knowledge required to excel in this field. With comprehensive training in quality control methods and emerging technologies, these programs prepare individuals to drive significant improvements in material quality and foster sustainable organizational success.

#Material management#best material management courses#best pg diploma in material management#Material Management Techniques#Material Management Tools#PG diploma in material management#pgdm material management#post graduate diploma in material management#Quality control material management

0 notes

Text

Why SBJ Nirmal L Type 14x57 Rotary Hoe/Blade is the Ideal Choice for Farmers

When it comes to preparing soil and ensuring crops have the best start possible, farmers know that quality tools make all the difference. The right rotary Hoe/Blade can mean the difference between smooth soil preparation and days of unnecessary struggle. That’s where SBJ Nirmal L Type 14x57 Rotary Hoe/Blade comes in. With its efficient design and high-quality materials, this blade is made to withstand the challenges of modern farming. Let’s dig deeper into why this blade is so special and what sets it apart in the world of agricultural tools.

What is a Rotary Hoe/Blade, and Why is it Important?

A rotary Hoe/Blade is a critical part of a rotavator, a piece of farming equipment used to break up and aerate the soil. In simple terms, a rotary Hoe/Blade spins into the ground, digging up soil to prepare it for planting. This process helps improve soil structure, aerates it for plant roots, and controls weeds—all vital aspects for healthy crop growth.

The L-shaped design of the SBJ Nirmal 14x57 blade makes it especially effective at penetrating soil. Its unique shape allows the blade to dive deep into the ground with each pass, giving a more thorough till. Whether you’re dealing with compact, rocky, or sandy soil, this blade is built to handle it. Many farmers appreciate this blade because of its ability to handle different soil types without losing efficiency.

Made from Boron Steel: Built to Handle Tough Jobs

One standout feature of SBJ Nirmal L Type 14x57 Rotary Hoe/Blade is the boron steel material it’s crafted from. For those unfamiliar with boron steel, it’s a high-strength steel alloy that includes a small amount of boron. This might seem like a minor addition, but that tiny amount of boron gives the steel incredible strength, hardness, and durability. Farmers benefit from boron steel because it makes the blade tough enough to withstand harsh soil conditions.

Here’s a bit more on boron steel’s advantages:

High Hardness and Strength: Boron gives steel an extra level of hardness and wear resistance. Since farming equipment often takes a lot of punishment, this extra hardness is a huge plus, meaning less wear and fewer replacements.

Resistance to Abrasive Soils: In areas with rocky or gritty soil, blades can wear down fast. Boron steel holds up well against abrasive materials, allowing it to dig deeper and last longer than standard steel.

Great Flexibility: Even though it’s hard and strong, boron steel maintains a level of flexibility. This balance is crucial since overly rigid materials can break under heavy stress, but boron steel can bend without snapping.

With boron steel, SBJ Nirmal blade provides a mix of strength and endurance that most standard blades lack. Farmers who use it report longer life spans for their blades, reducing the need for frequent replacements.

Powder Coating: Protecting the Blade Against Rust and Wear

On top of using durable boron steel, SBJ Nirmal adds a powder coating to its L Type 14x57 Rotary Hoe/Blade. This is a special process where a powder made of resin, pigment, and other particles is applied to the blade’s surface, then heated to form a strong, protective layer. The result is a coating that protects the blade from rust, moisture, and other weather-related damage.

Powder coating is an important feature for a few reasons:

Rust Resistance: As any farmer knows, equipment that stays outdoors is prone to rust. The powder coating provides an extra layer of protection, keeping the blade rust-free and extending its lifespan.

Weatherproofing: From rainy seasons to dry spells, farm equipment faces a range of weather conditions. Powder coating prevents moisture from seeping into the metal, so the blade doesn’t corrode or degrade.

Easy Maintenance: Powder-coated blades are much easier to clean, requiring only a quick rinse to remove dirt or mud. This saves time for busy farmers who want reliable, low-maintenance equipment.

Key Benefits for Farmers Using SBJ Nirmal 14x57 Rotary Hoe/Blade

So, why do farmers trust this particular blade for their rotavators? Here are some of the top reasons this blade has become a popular choice:

Efficient Soil Penetration: The L-type shape is optimized for soil penetration. Its angled edges dig in smoothly, so the blade can handle dense soil without wearing down quickly. This shape also makes it easier to prepare seedbeds with fewer passes, which is a big time-saver.

Versatility Across Soil Types: One major benefit of SBJ Nirmal L Type 14x57 blade is its versatility. Farmers use it successfully on everything from clay-rich soil to sandy ground, as well as rocky areas. This versatility means farmers don’t need different blades for different fields.

Cost-Effective Over Time: Since it’s built to last, this blade is a good investment. The initial cost may be a bit higher than standard blades, but over time, farmers save on replacements and repairs. For those managing large areas or frequent tilling, this long-lasting blade proves especially economical.

Low Maintenance Requirements: With the combination of boron steel and powder coating, this blade is tough and easy to care for. It can handle wet, muddy fields without rusting or degrading, meaning it’s always ready for the next job.

SBJ Nirmal: A Brand Farmers Trust

SBJ Nirmal Products has earned a reputation as a reliable supplier of high-quality rotavator parts. The company’s commitment to quality is clear in every part they produce, especially in their L Type 14x57 Rotary Hoe/Blade. They’re known for their consistent focus on durability and performance, ensuring farmers have tools they can rely on year after year.

In the end, SBJ Nirmal L Type 14x57 Rotary Hoe/Blade is an ideal choice for farmers looking to optimize their soil preparation process. It combines strength, resilience, and smart design, all essential features for today’s agricultural needs. By investing in a blade built to last, farmers can spend more time focusing on their crops and less time worrying about tool maintenance.

#Rotary Hoe Blade#SBJ Nirmal Products#L Type 14x57 Blade#Boron Steel Blade#Powder Coated Blade#Durable Farming Tools#Soil Preparation#Rotavator Parts#Agricultural Equipment#Farming Efficiency#Rust Resistant Blade#High-Quality Rotary Blades#Long-Lasting Farming Tools#Efficient Soil Cultivation#Weed Control Blade

0 notes

Text

Exploring Claude AI's Key Features for Enhanced Productivity

Claude AI outlines its diverse capabilities aimed at various user groups, including writing, analysis, programming, education, and productivity. It supports long-form content creation, technical documentation, and data analysis....

Claude AI Outlines Capabilities for Diverse Users 🤖 AI assistants teaching Claude AI outlines its diverse capabilities aimed at various user groups, including writing, analysis, programming, education, and productivity. It supports long-form content creation, technical documentation, and data analysis, while also providing customized assistance for teachers, students, blog writers, and…

#AI assistant#analytical depth#Claude ai#coding#content creation#content writer assistants#contextual understanding#creative ideation#data analysis#data visualization#education#problem-solving#productivity tools#quality control#research skills#teaching#technical capabilities#versatility

0 notes

Text

BIS Certification Cost for Hand tools prodcuts

The Bureau of Indian Standards (BIS) certification for hand tools, such as wrenches, is essential for ensuring that these products meet Indian quality and safety standards. The cost of BIS certification can vary depending on several factors, including the type of product, the complexity of the testing required, and the specific certification scheme applicable. For hand tools, the certification process generally involves fees for application, testing, and inspection.

BIS QCO for Hand Tools

BIS has issued a Quality Control Order (QCO) that mandates the certification of specific hand tools to ensure their quality and safety. Under this order, manufacturers must obtain BIS certification to demonstrate compliance with Indian standards. The relevant standards for hand tools can be found in IS 2015 for general hand tools and IS 1363 for fasteners, which outline the specifications and testing methods.

BIS Certification for Hand Tools and Wrenches

The BIS certification for hand tools and wrenches includes a comprehensive evaluation of manufacturing facilities, product samples, and quality control processes. The cost typically ranges from ₹20,000 to ₹50,000, depending on the scope of testing and the number of products submitted for evaluation. Additionally, there may be annual surveillance fees to maintain certification. Manufacturers are encouraged to consult with BIS or authorized agencies for detailed cost breakdowns and guidance through the BIS certification for hand tools process.

0 notes

Text

Understanding the 7 QC Tools: The Foundation of Quality Improvement

In every quality-based company, problem-solving involves going beyond just resolving an issue. It requires deep diving into understanding why the issue arose in the first place. This is exactly where the 7 Quality Control (QC) Tools come into play.

Designed in Japan, these tools offer a practical, visual, and data-oriented method for problem-solving, analysis of processes, and continual improvement. Be it managing production lines, performing compliance audits, or spearheading digital transformation projects, the 7 QC Tools assist teams in clearly and systematically eliminating root causes, minimizing variation, and improving performance.

All seven tools contribute to the enhancement of evaluating processes and inefficiencies for the sake of achieving ongoing operational excellence. Their collective application builds a comprehensive system that can be used in any field, including but not limited to, healthcare, logistics, and information technology.

The 7 QC Tools for Quality Improvement

These tools form the foundation of any successful Quality Management System (QMS). Their straightforward nature as well as flexibility make them indispensable for any team that aims at building a culture of quality.

1. Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram)

This tool aids in outlining every potential cause a given problem may have. By grouping causes into manpower, methods, machines, measurement, materials measurement and environment, teams deepen their understanding of the issue.

Example: A sealing two-hundred boxes of country's best raw honey fails repeatedly. A packaging team takes this diagram to help overcome this issue.

2. Check Sheet

As simple as it gets, check sheets allow customers to identify all types of orders, including defects, errors, and occurrences systemically.

Example: A logistics company tracks and identifies peak periods for late deliveries using check sheets.

3. Control Chart

A process is stable when the control upper and lower limits are constant, while in need of corrective action when they change. Control charts display process behavior over time.

Example: A pharmaceutical company control charts to avoid inconsistent temperature control during production.

4. Histogram

Example: IT support teams resolve tickets and average the time taken to do so.

5. Pareto Chart

Example: A call center finds out that two service lines account for a majority of customer complaints through Pareto analysis.

6. Scatter Diagram

Example: An HR manager tests a theory about onboarding hours and early-stage employee error reduction by increasing onboarding hours.

7. Flowchart

A flowchart is one of the ways to visualize processes step-by-step. It helps teams pinpoint inefficiencies, bottlenecks, and redundancies.

Example: A hospital maps out its discharge process to identify and eliminate delays.

Where Can These Tools Be Used?

Finally, all industries can use the 7 QC tools, even if they were primarily used in manufacturing.

In ESG compliance: Monitor sustainability KPIs and supplier risk.

In HR: Streamline hiring and employee performance monitoring using flowcharts and control charts.

In IT: Use histograms and Pareto charts to improve response times for help desk services and reduce system outages.

In logistics: Identify service-related delays, optimize routes, and improve service.

These tools allow all organizations, regardless of industry, to practice fact-based decision making, which is crucial in any organization committed to quality.

How to Implement the 7 QC Tools Effectively

The good news is that you don't need expensive tools and certifications to start. Most of these can be implemented using Excel, Google Sheets, or even pen and paper.

Steps to Implement:

1. Identify the problem – Frame the issue you are experiencing as specifically as possible.

2. Select the right QC Tool – Match the problem or analysis with the appropriate tool.

3. Train your team – Make sure the relevant personnel know how to use the selected tools.

4. Collect accurate data – Focus on achieving consistency as well as completeness.

5. Analyze and act – Review all the data and decide what information will lead to improvement.

With some support from leadership and basic training, these tools can easily be integrated into your team's daily routines and problem-solving habits.

Why the 7 QC Tools Matter

The 7 QC tools are incredibly powerful due to how basic they are. They:

• Enable root cause analysis

• Support data-driven decisions

• Promote continuous improvement

• Foster collaboration across teams

• Enhance quality, efficiency, and compliance

In today's world with growing complexities, intense competition, and increasing customer expectations, these tools can serve as a cornerstone for operational excellence and strategic transformation.

How 4C Consulting Can Help You Implement the 7 QC Tools

At 4C Consulting, we focus on integrating quality into the heart of your operations. We have successfully completed over 2,500 ISO implementations and delivered over 15,000 hours of expert training, so we have the experience and deep industry knowledge to help.

Here's how we help your journey with the 7 QC Tools:

✅ Gap Assessment – Identify where your existing processes are relative to your goals.

✅ Tailored Training – Teach your teams to properly use and maintain the QC tools with confidence.

✅ Tool Selection & Deployment – Select the appropriate tools for your specific problems.

✅ Real-Time Application Support – Get hands-on help with real-life projects.

✅ Ongoing Improvement Coaching – Foster an environment that promotes quality, spanning multiple departments.

Looking to aid with process improvement, variability reduction, and establishing an organization-wide continuous improvement culture?

Master the 7 QC Tools and more with 4C Consulting.

👉 Begin your journey to better quality today.

#7 QC Tools#Seven Quality Control Tools#7 QC Tools for Quality Improvement#Implementing 7 QC Tools#7 QC Tools Examples#Quality Management Tools

1 note

·

View note