#Industrial Magnetic Assemblies

Text

Principles And Applications of Electromagnetic Separator

Principles And Applications of Electromagnetic Separator

The electromagnetic separator, also known as a magnetic separator, plays a crucial role in diverse industries and permeates our everyday experiences.

Operating on the ingenious principle of magnetic separation, it efficiently segregates materials based on their magnetic properties.

This overview provides insight into electromagnetic…

View On WordPress

#electromagnetic separators#high performance magnetic separators#industrial application#Industrial Magnetic Assemblies#industrial magnetic equipment#Industry Magnetic Separators#Magnet Design#magnetic components#Magnetic device#Magnetic Liquid traps#magnetic permeable sheets#Magnetic pulley separator#Magnetic Pulleys#Magnetic Separation#magnetic separation assemblies#magnetic separation equipment#magnetic separation systems#Magnetic Separator#Magnetic Separator Conveyors#Magnetic Separators#Manual Magnetic Separators#Self-Cleaning Magnetic Separators#self-cleaning suspended magnets

0 notes

Text

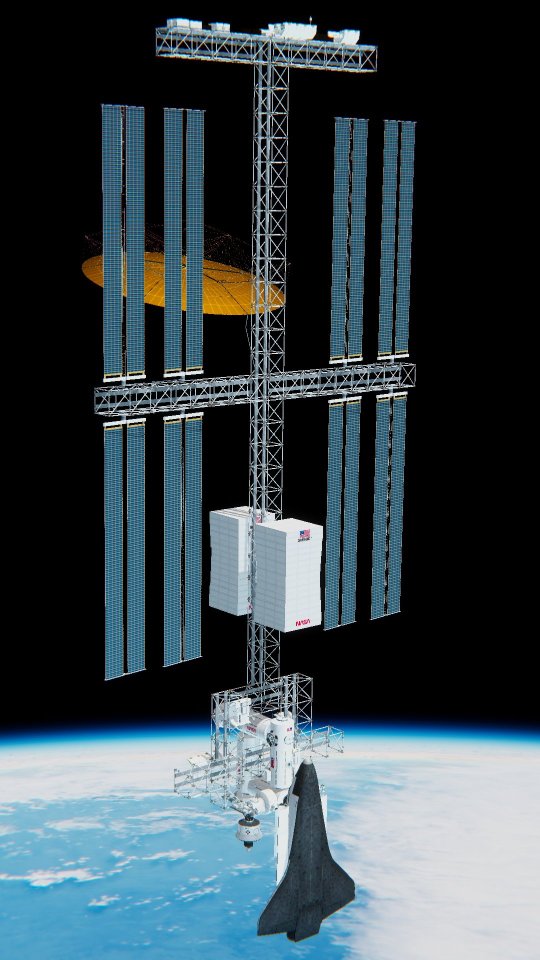

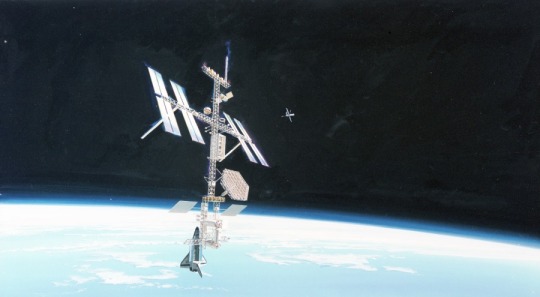

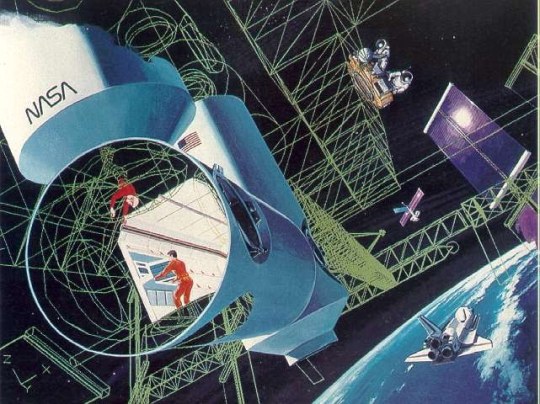

Space Station Concepts: Power Tower

"It would provide maximized user viewing opportunities, a clear area for Shuttle dockings and versatility in Station growth. The design was also less sensitive to changes in mass caused by the addition of modules to the Station. The 'Power Tower' station's main structure was to be 122 meters tall with 75 kW solar panels sticking 41 meters to either side of the centerline.

"This is an artist's conception of the proposed 'Power Tower' space station configuration, shown with the Japanese Experiment Module attached. This model and several others were examined before deciding on the Space Station Freedom structure that was later abandoned in favor of the International Space Station. Date: June 19, 1985."

There were nine articulated attachments for external payloads dedicated to Earth and space observation. The initial Station would have had a crew of six working on 12-hour shifts, and feature two US-developed laboratory modules plus two habitation modules.

A maximum of 18 hours/week of EVA 'spacewalks' would be permitted per astronaut. International modules had not yet been incorporated in the design. The 'Power Tower' assembly schedule would have required 12 Shuttle flights over a three-year period, starting in April 1992. The Space Station would support research in a man-tended capability from April 1993 onwards. But the schedule was already starting to slip as the Office of Management and Budget reduced the Fiscal 1985 budget from $235 million to $150 million. The slight reduction increased the total cost to $8.1 billion at 1984 rates ($11.4 billion in current-year dollars).

Some observers were critical of the contractors' lack of independent involvement in the design process. They felt Station contractors did nothing but ape NASA's configurations in order to win the contract. In May 1987, former Space Station engineer Oliver Harwood testified in the Senate. 'Aerospace industry resources and capabilities were being squandered by 'rubber stamping' NASA designs instead of seeking independent and competitive solutions to system problems. Why were the artist's conceptions of eight major corporations so nearly identical? In a real competition seeking real answers there would be a different version for each of them.'

NASA allocated all Space Station definition work between four 'Work Packages' managed by its Johnson, Marshall, Goddard and Lewis Space Centers in July 1984. Work Package 4, led by the Lewis Research Center, would investigate Space Station power options. The two leading contenders were photovoltaic solar arrays and solar thermodynamic generators. Solar thermodynamic generators would use huge parabolic dishes to heat a fluid, which then powered electric generators. They were more efficient than traditional photovoltaic solar panels, had a longer lifetime and generated less atmospheric drag. But they also had to be pointed to within 1.5 degrees of the Sun to generate electricity, and the concept had never been tried before. NASA awarded contracts worth a combined $144 million to six contractor teams in April 1985, including $20 million to Work Package 4 contractors TRW and Lockheed. The agency still had not decided whether solar thermodynamic generators or photovoltaic arrays would be chosen. Another concept from the late 1980s would generate auxiliary power from the Earth's magnetic field by connecting a generator to a long electrically conducting tether. The other end was attached to the Space Station.

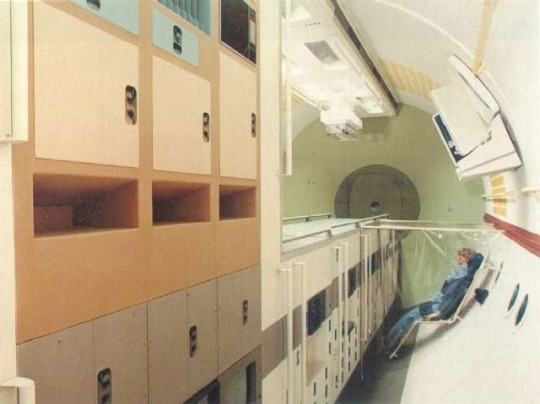

The McDonnell-Douglas 'Power Tower' Space Station crew modules were 10.7 meters long with docking ports at both ends. They would have been assembled end-to-end in a racetrack-like configuration. Some engineers felt this could have created dangerous dead-ends inside the Station if a module had to be depressurized. The contractors paid considerable attention to habitability issues since each crew would live and work on the Space Station for 90 days before returning to Earth. Rockwell's crew module proposal put all the equipment inside storage racks in the middle of the module rather than on the walls.

Article by Marcus Lindroos"

-Information from astronautix.com: link

NASA ID: 85-H-273

source, source, source

Mike Acs's Collection: link

NASA ID: C-1984-5784

SDASM Archives: 54059800

#Power Tower Space Station#Power Tower#Space Station Freedom#Space Station Concept#Space Station#Concept Art#NASA#Space#Earth

31 notes

·

View notes

Text

The Ambient Experimental Industrial Harsh Noise Musicians Just Don't Understand: May 26, 2024

listen to the show

Carole King - Pleasant Valley Sunday (Demo)

DJ speaks over The Battlefield Band - Ge Do Theid Mi Do M'Leabiadh

Zenda Jacks - Rub My Tummy

Vaguess - Turn it Off

The Vapors - Talk Talk

Fuera de Sektor - Solo Ves Lo Peor

Mdou Moctar - Oh France

Sally Skull - Tear Out

Kleenex - Ü

Clickbait - Pumpkin Spice

Abyecta - Nacer, Crecer, Morir

Patrik Fitzgerald - The Little Dippers

Chumbawamba - Isolation

A State of Mind - …Is Not Enough

Cyrnai - Sensitivity

Sadistic Exploits - Apathy

Trial - Is This to Be?

Cyrnai - Going Under Hypnosis

X-Ray Spex - Highly Inflammable

Gut Model - Angry Young Men

Spizzoil - Fibre

Bad Bangs - Philly

Retsu - 3 Years

Victimize - Baby Buyer

Wreckless Eric - Dizzy

Nusantara Beat - Mang Becak

Rouge - Images

XTC - Science Friction

Nag - In Effect

The Birthday Party - Blast Off

The Radiators from Space - Ripped and Torn

Tank - Turn Your Head Around

Armoured Flu Unit - Elsewhere Apartheid

The Drin - Lens of a Devotee

The Undertones - Billy's Third

Zoff - Sauerland

Puffer - Iron Hand

Naked - Frightened

The English Setters - Tragedy

Anti-Pasti - 1980

Ebba Grön - Turist I Tillvaron

Crucifix - Steel Case Enclosure

The Magnetic Fields - How to Say Goodbye

Double-O - Grey to Black

DBR - Displacement

Derya Yildirim & Grup Simsek - Darıldım Darıldım

Leyden Zar - Danger Zone

Hunger Project - Assembly

Crisis - Alienation

Zyfilis - P.I.A.

Death Culture Deprivation - Zitra

James Last - Tiger Feet / Radar Love / Jesus Loves Me

#radio#community radio#punk#music#playlist#schlager#hardcore punk#post-punk#anarchopunk#indie pop#new wave

3 notes

·

View notes

Text

Innovative Solutions in Magnetic Assemblies: Comprehensive Services for Precision and Performance

Magnetstek Engineering is one of the leading global suppliers of magnetic assemblies and manufacturers specialising in permanent magnets and rare earth magnetic products. Serving various industries such as wind power, medical technology and audio systems, we offer a wide range of products including neodymium magnets, samarium-cobalt, alnico and advanced magnetic assemblies. With more than two decades of industry experience, our professional team, including Ph.D. experts, provides unparalleled R&D support. We pride ourselves on our fast production times, high-performance materials and strict quality standards, ensuring our customers receive top-notch products designed to meet the exact requirements of their application.

For more information about Magnetic Assemblies click on this link: https://magnetstek.com/magnetic-assemblies/

2 notes

·

View notes

Text

How (Don’t Call ‘Em a Supergroup) L.S. Dunes Saved Its Own Members’ Lives

Words by Cassie Whitt

Photo by Mark Beemer

November 4, 2022

For anti-supergroup L.S. Dunes, the magnetism of friendship and love of their craft made coming together a no-brainer, especially during a particularly turbulent moment for the industry and within their personal lives.

In this excerpt from a conversation with drummer Tucker Rule (Thursday) and vocalist Anthony Green (Circa Survive) we learn just how much swapping sound files during a global pandemic helped heal their hearts and minds.

The band's lineup is a scene dream, also comprised of guitarist Frank Iero (My Chemical Romance), guitarist Travis Stever (Coheed & Cambria) and bassist Tim Payne (Thursday), and while fans may be quick to brand them a supergroup, that's not the sentiment these members harbor. It isn't about assembling an all-star band as the scene equivalent of the Justice League superheroes and more about bonding with like-minded musicians and, more importantly, dear friends.

Being cutoff from our regular social circles and points of contact helped frame a new perspective for us all amid the pandemic, and losing out on this essential element of the human experience led Green in particular down dark paths. Prioritizing mental health, and with the support of his L.S. Dunes bandmates, he confronted these issues and is grateful to have bettered his relationships as a result.

Get your copy of L.S. Dunes' 'Past Lives' album (out Nov. 11) here and follow the band on Instagram, Twitter, Facebook and Spotify.

They're not a supergroup, they're SUPER BUDS!

TUCKER RULE: All of us in our bands are the ones that are heads-down, want to write music and enjoy playing music. That's why we all have multiple bands.

When we get together, we joke about the "L.S." standing for "low stress" because we just want it to be fun. People love to throw around the term "supergroup," and we don't like that. We're a group of super buds, and this is just our circle of friendship. It's not like, "Oh, we've got to get the guy from Coheed and the guy from Circa and the guy from MCR..." These are my dudes and I know we get along musically.

Another thing with "supergroup" is that [people think], "Oh, they're just going do one show here and one show there." Why start a band if you're not going to go bring it out live? That's our goal — to play as much as we can. This is another full time job.

ANTHONY GREEN: I don't really get to have many friends that are outside of this business. It kind of sucks because you end up feeling kind of lonely when you're not working or when you're home.

Once we started connecting more, it was like, “Man, I'm talking to Tucker every other day.” I didn't realize how much I was lacking in my life. It's hard to even find two people that connect on a creative and personal way level so that they can make stuff, so when people have bands that are so good together, it's like, “These guys just bring out the best in each other!”

It’s hard to find people that creatively mesh well, and this is five people who fit together creatively just perfectly.

L.S. Dunes, "Permanent Rebellion" Music Video

youtube

It's not business, it's personal

AG: If at any moment Travis called us and was like, "Hey, I'm going through this and I need X, Y, and Z," that's the most important thing from the get-go. No matter what comes our way, we're able to deal with it because we're not looking at this like it's a business, we're looking at it like this big art project.

We all know from our other bands that when you have a business that's run cutthroat where it's about the bottom line or getting as many streams, or making as much money, it can become convoluted. Whereas, if you have a situation where everybody's just looking out for one another because of the fact that this is an emotionally driven band where we're processing a lot of really heavy shit together, you end up feeling so safe and secure and strong because you know that everybody has your back.

The most important thing is that everybody's mental health and personal relationships. Everybody's life is more important than just a song or a stream. That makes a project strong and fun... and no one's judging [personally or creatively].

Creativity is life-sustaining

TR: I would wake up or go to bed hoping somebody would write a riff so I could wake up in the morning and get to work on it [laughs]. And vice versa — I would write a drum beat and send it out and I'd be like, "Please, somebody work on this" and then I'd get something back. It [felt] like it was Christmas and it was during COVID, too, so there was very little to look forward to.

I think it saved all of our lives, to be honest with you.

It was a time where none of us knew what was going to happen with our industry. I know everybody had it rough and all industries suffered, but I can only speak for myself and the music industry was in shambles. We knew that it might not come back for a really long time and we had no idea how we were all going to make money. When you've done this for 20 years, you kind of get really good at it and not good at other things. For me, getting another job was not an option.

All of us are dads and at that time I had an infant. I was trying to figure out how to make money and was writing these songs with these dudes that I love, not thinking that we would make money from it.

So, why did it save our lives? It was like this was out of necessity to feel like we were a part of something, again.

L.S. Dunes, "2022" Music Video

youtube

Even so, life was still very challenging through all this

AG: We got laid off [amid the pandemic]. People were talking about when shows come back or when things reopened, but it was so scary [having the mindset of], "Okay, well let's save up until everything comes back," and then I was just like, "Hey, this is never going come back. It's never going to be like it was and we're going have to get used to playing through our computers." It was almost like a comforting thing for me to close the book on that chapter in my life.

I was so depressed. I had been going to AA and NA meetings where you make a pretty hardcore connection with other addicts and people who are struggling and that was gone. My therapist was not seeing people face to face. Yeah. [This band] was almost like an excuse to miss therapy a bunch.

I was also diagnosed as bipolar shortly after my my overdose. I was struggling with it, and I didn't want to admit that I was bipolar. I was really scared of even saying it. It's crazy to think about it now, but I just didn't want anybody to know. I wasn't medicating at all, and I was trying to figure out how to go through life without getting fucked up to deal with my problems, but also not doing any of the recommended things that you do to manage bipolar.

I was in this manic low, hallucinating, and this project coming to me at that moment... I hate saying this because your kids are the reason why you want to live... I thought my kids would be better off without me. I was convinced that I was just going to be a bad dad, and that I was going hurt them at some point.

That's what friends are for

If I didn't change my shit, I would've [wound up hurting them in some way], but the faith that Tucker, Tim, Frank and Travis had in me really did so much for my confidence and did so much for me in that moment and in those few months. It was like a fucking life preserver. I wasn't looking at my family, my life and my career as something worth fighting for. I was just so lost and there was so much joy anchored in the fact that I had this band that wanted to make songs with me, that believed in me, that wanted me to be in their group.

It really helped me see that my kids would be better if I got my shit together and went to therapy and figured out how to maintain. My family and my friendships would all be better—nobody'd be better off if I was dead.

When you don't see that yourself sometimes, it takes somebody else reminding you. And these guys did that and the songs did that. This band and these songs were like a little box of sanity. It became like a drug, almost. When I was feeling crazy, I would think about the fact that we had this thing that we were building and it would bring me back to earth every time.

Thanks to Tucker Rule and Anthony Green for the interview. Get your copy of 'Past Lives' album (out Nov. 11) here.

#ls dunes#m: anthony green#m: tucker rule#lsd: 2022#in: nov/22#t: photo#misc: interview#t: text#p: loudwire#archive[ane]

8 notes

·

View notes

Text

♪ "No push and pull, I'm running toward you now at lightning speed // Our chemistry got us immersed deeper into this scene" ♪

Welcome ILLIT to the K-pop industry! These girls assembled from the results of the survival show "R U Next?" (which I've never formally watched). "Magnetic" has a very dreamy concept like IZ*ONE's comebacks, & part of the pre-chorus reminds me of NewJeans's "Ditto". BUT LISTEN TO THE BRIDGE! THAT IS THE REAL HIGHLIGHT OF THIS SONG! There are 2 Japanese members in this 5-member group, so they might make their Japanese debut in late 2024 or early 2025 if all goes well... (I'm clearly thinking WAY too ahead XD)

Also, since ILLIT is short for "I will be it", there's a funny meme circulating online along the lines of this:

ILL-IT ❌

ILL-EAT ✅ (& leave no crumbs)

youtube

Full CD is here on YouTube Music!

1 note

·

View note

Text

Avalon Technologies Limited Is a Top EMS Industries In India

We Provide Services and Solutions Like:

Design

Engineering

NPI

Volume Production

Life Cycle Management

System Integration

PCB Assembly

Cable & Wire Harness

Sheet Metal

Aerospace Metal

Machining

Magnetics

Plastics

Supply Chain & Logistics

2 notes

·

View notes

Text

There's a lot going on in the world of fusion right now.

A lot of people are missing why ITER is so expensive and why fusion research is just now getting to the point where it seems feasible for a lot of other companies that aren't ITER. Like, surely we could have just waited a few more years for the technology to mature before diving headlong into this stuff right? Well, no. That's not how anything works, actually.

The ITER project is the Apollo program of fusion. NASA's Apollo project was fucking expensive okay? Tens of billions of dollars, in the sixties! ITER is $22 billion now, which is peanuts compared to Apollo which had a similar effect on industry. The whole point of Apollo, and the reason it was so expensive, is because all the technology it used was new.

Integrated circuit assembly was slow and expensive at the time, but after Apollo everyone saw how well they performed, so an entire new manufacturing process was invented to mass produce them. Fuel cells and solar panels were never going to be a thing without satellites; they were too damn expensive so no one bothered making them. New stitching methods were developed to make the spacesuits, which just so happened to have similar requirements as medical-grade machinery. Each of these industries already existed at the time, but the push to make more of them faster also led to their mass-production and reduced their cost and complexity.

So too with ITER today. Superconducting tape has been a thing, but the amount of tape ITER needs for its huge magnets is currently resulting in the development of new manufacturing methods for it. Superconductors that would have been prohibitively expensive just 10 years ago are in the realm of possibility today. And new superconductors that don't need fucking liquid helium are just starting to become available in the large quantity one needs to be useful.

Also, ITER is designed to react to fusion plasma as it changes, because when it was designed computers weren't fast enough to predict how it would act. While developing the systems needed to do this, much has been learned in terms of how plasma acts when there is fusion happening inside it. This in turn has led to better equations that predict the behavior of plasma, that can run on computers, which will likely lead to better systems for everything that handles plasma.

Basically, now that ITER has done most of the hard expensive research for fusion, smaller organizations are cropping up which will try to do each piece better. This leads to competition which, in the scientific world at least, is going to lead to a wave of rapidly-accelerating technological progress.

In short, a lot of cool stuff is about to happen in the world of fusion research in the next 5 years or so.

4 notes

·

View notes

Text

File: Assassin's Creed - Hnituðr

SCP#: ABJ

Code Name: Hnituðr

Object Class: Thaumiel

Special Containment Procedures: SCP-ABJ is stored within one of the lockers at the armory of Site-AM. The locker in question is owned by Agent Iris Clef and is guarded by AFA-1 units already assigned to guard all the lockers. All AFA units in question are armed with Foundation laser rifles including the AFA-2 unit hidden within the locker to act as a final defense against intruders. Agent Iris Clef is the only one able to access it through a fingerprint scanner, retina scanner, and a passcode known only to her. Only Foundation staff of Level 5 Clearance with permission from at least one O5 Council member are allowed or even able to bypass the security measures.

Description: SCP-ABJ is a golden arm ring that is actually made of seven pieces that can be assembled and disassembled like puzzle pieces. SCP-ABJ as a whole was created by Species of Interest: the ISU, though unlike normal ISU tech, SCP-ABJ regardless of it’s current form, does not hold memories of past users. The seven pieces of SCP-ABJ don't need to be assembled to have their anomalous properties activated and can be used to individually. However, by uniting all seven pieces of SCP-ABJ and wearing the golden arm ring they become, they give their wearer ultimate immunity to all forms of damage. The pieces that make up SCP-ABJ are known as SCP-ABJ-1 through SCP-ABJ-7.

SCP-ABJ-1 allows whoever holds this piece to heal from any wounds or physical disability. This includes cuts, bruises, scars, broken bones, necrosis and lost limbs. It’s even possible to reverses birth defects such as skin conditions, nutrient deficiencies, and even malformed body parts. SCP-ABJ-1 can give anyone perfect physical health and invulnerability to physical harm.

SCP-ABJ-2 cures any disease the holder may have, this includes bacteria, viruses, fungus, prions, parasites, and even advanced diseases or sickness like Alzheimer's, HIV, or cancer.

SCP-ABJ-3 Deflects all types of incoming damage such as melee weapons and even projectiles. So long as it's a physical attack, SCP-ABJ-3 can force it to bounce away from the holder and feel not even the force form the attack. Even accelerated physical attacks like a railgun round shot at Mach 7 will be deflected.

SCP-ABJ-4 Deflects all types of energy damage directed at the holder. Fire, electricity, magnetism, intense heat, radiation, plasma, and hard light construct weapons cannot harm the user.

SCP-ABJ-5 Protects the user form metaphysical and even magical threats such as thaumaturgic rituals, curses, enhanced poisons, enchanted weapons, anomalous humans, intense gravity, time manipulation, and even reality manipulation.

SCP-ABJ-6 Protects the user form subconscious threats or entities that exist on different plains of existence like spectral anomalies. SCP-ABJ-6 protection is even higher against mental alterations and threats such as memetics, amnestics and even anti-memetic anomalies.

SCP-ABJ-7 is actually useless on its own, it is instead the conduit and power source for all the other SCP-ABJ pieces when they combine into the golden bracelet. Through SCP-ABJ-7, the golden arm bracelet is able to create a perfect field that has the collected properties of all the other pieces so that one does not cancel out the other and they all equally protect the user. When worn, the user is invincible on all aspects, with no exploitable weaknesses to date.

SCP-ABJ was discovered in 2020, found in one of the transportation trucks owned by Group of Interest: Abstergo Industries. The raid leading to SCP-ABJ’s discover was conducted by Mobile Task Force Athena-1 "Assassin's Creed". The mission was originally declared a failure as seemingly noting of value was recovered. It was only by pure luck that SCP-ABJ’s anomalous properties were discovered. After only a month of testing it was concluded that SCP-ABJ possessed the ultimate capabilities of protecting its user.

SCP-ABJ was originally deemed too dangerous to use as a single misplace can allow it to fall into the wrong hands. It is for this reason none of the Captains or the Commander of Mobile Task Force Omega-45 “Street Samurai” received it. Instead, after her success against the [data expunged] The Foundation deemed it necessary to give SCP-ABJ to SCP-105 now known as Agent Iris Clef. Now thanks to SCP-ABJ Agent Clef ins considered indestructible and is now a spearhead of Mobile Task Force Alpha-9 "Last Hope".

.

SCP: Horror Movie Files Hub

#DZtheNerd#SCP: Horror Movie Files#SCP Foundation#scp fanfiction#scp au#SCP#SCP-ABJ#Assassin's Creed#Abstergo Industries#Group of Interest

3 notes

·

View notes

Text

Feature Of Brass Metal In The Manufacturing Of The Machines

Brass metal offers several key features and advantages in the manufacturing of machines, making it a popular choice for various applications. Here are some notable features of brass metal in machine manufacturing:

Excellent Machinability: Brass is known for its exceptional machinability, which means it can be easily shaped, cut, and formed into complex machine parts. Its relatively low melting point and good flow properties make it ideal for precision machining processes.

Corrosion Resistance: One of the most significant advantages of using brass in machine manufacturing is its excellent corrosion resistance. It is highly resistant to water, steam, and most non-oxidizing acids, which ensures the longevity and reliability of the machine components even in challenging environments.

Electrical Conductivity: Brass is a good conductor of electricity, making it suitable for electrical components and connectors within machines. Its conductivity is advantageous in transmitting electrical signals efficiently and reducing energy losses.

Thermal Conductivity: Brass also exhibits excellent thermal conductivity, making it useful in heat exchangers and components where heat dissipation is critical. It helps regulate the temperature of various machine parts and prevents overheating.

Low Friction: Brass has a relatively low coefficient of friction, making it an excellent choice for components that require smooth movement and minimal wear. Bearings, bushings, and gears made from brass help reduce friction and extend the lifespan of the machine.

Aesthetic Appeal: Apart from its functional properties, brass has an attractive golden appearance that adds an aesthetic appeal to machines and equipment. It is often used in decorative elements to enhance the overall appearance of the product.

Durability and Strength: Brass has good tensile strength and durability, which ensures that the machine parts can withstand mechanical stresses and loads. It resists deformation and maintains its structural integrity over time.

Non-Magnetic: Brass is non-magnetic, which can be advantageous in certain applications where magnetic interference needs to be minimized. It is used in equipment and devices where magnetic properties could negatively affect performance.

Anti-Bacterial Properties: Brass has inherent antimicrobial properties, which makes it a suitable choice for machine parts in healthcare and food processing industries. It helps inhibit the growth of bacteria on surfaces, contributing to better hygiene and cleanliness.

Easy Joining and Welding: Brass can be easily joined and welded, allowing for seamless integration of different components during the manufacturing process. This simplifies assembly and reduces production time.

Overall, the combination of excellent machinability, corrosion resistance, electrical and thermal conductivity, low friction, and other advantageous properties makes brass metal a versatile and reliable material for use in the manufacturing of machines across various industries.

2 notes

·

View notes

Text

Become the Night part 8: Tech Expression Lab

Proto seemed pleased with himself as he and Elec Man sat in the back of a cab taking them to the other side of the city.

"Remember, this is a one-time thing," Elec Man hissed out of the corner of his mouth as he glared out the window.

Proto was reclined in his seat with his arms folded behind his head. "Sure boss—whatever you say."

The cab dropped them off within a dirty industrial lot.

"So this is it, huh?" Proto commented as they overlooked Tech Expression Lab. It was a squat, boxy building with dull gray bricks like a giant collection of poorly assembled building blocks.

"Yes," Elec Man replied with a wrinkled nose. "It's a legitimate office—but it's owned by the Peacekeeping Collective, who are primarily a racketeering ring—i.e. mobsters force civilians to pay them money for their 'protection'."

Proto raised an eyebrow at Elec Man, the afternoon sunlight flashing off his aviators. "I know you think I'm a moron, but I know what a racketeering ring is."

"This will be quick," Elec Man informed him. "You're just the lookout—we do not want anyone to notice what we're up to. Just act like you belong and leave the rest to me."

"Get in, find out what the Collective stole, and get out," Proto rattled off airily, smirking at Elec Man, "Got it, boss."

Elec Man rolled his eyes and shook his head. "…I can tell if you had your own way, you'd pull every alarm just for the thrill of fighting off security drones."

"Got that right!"

The inside of Tech Expression Lab was as dull and shabby as the outside, and smelled depressingly of dust and old plastic, like being stuck inside a floppy disk. Human workers were slumped at computers slowly typing entries into spreadsheets, while a supervisor drone hovered in lazy circles overhead. No one seemed to care as they slipped through the cubicles toward stairs that led toward the basement.

The smell of old plastic increased. So did the dust. Both Proto and Elec Man's noses wrinkled as they stepped into a dark basement lined with refrigerator-sized data storage devices topped with whirling magnetic-tape reels. An old computer terminal with a massive CRT monitor sat in one corner.

Proto and Elec Man gawked incredulously around the equipment.

"Gee, how old is this place?" murmured Proto.

"Easily five times our combined age," Elec Man muttered back dryly. He crossed over to the computer terminal and booted it on. It greeted him with glowing green text across a black screen.

"DOS, huh? Have fun," Proto remarked with a small smirk. He gave Elec Man a sarcastic salute, then headed toward the stairs.

Elec Man gave a disdainful sniff. Pathetic. Perhaps Pharaoh Man had been right to say this was beneath the Syndicate's notice, perhaps investigating and ending the Peacekeeping Collective really was overkill—but Elec Man never liked leaving loose ends. Besides, it was just as well that this would be a boring mission as promised—it would be prudent to show Proto that Syndicate work was not 'fun and games' as Proto had apparently found Wily's schemes to be, discouraging him from asking to go on future missions.

It did not take significant hacking skills to break into the Peacekeeping Collective's mainframe—the password was 'password.' Now, to figure out what the Collective had stolen. Elec Man ran a query for recently installed software—

Suddenly, all characters cleared from the screen, and the monitor went completely black for a moment. Then, in slow increments, new green text scrolled at the top of the screen.

Hello, Spanner.

Elec Man froze with narrowed eyes. The computer appeared to be addressing him by the slang term other mobs used for Syndicate members.

My name is C.R.O.R.Q.

CRORQ? Elec Man thought. What the hell is that?

"Boss…"

Elec Man ignored Proto, for another message was scrolling across the black screen at an excruciatingly slow rate, no doubt due to the slow processing rate of the 80s technology.

I am the leader of the Peacekeeping Collective. You must be the hacker that is dismantling the other mobs. I have been waiting for you to find me.

"Hey, Boss…"

You will be terminated. Goodbye.

Proto appeared by Elec Man's elbow. "Boss, those really ugly scraps-bots are here."

With a dull whine, all lights within the basement cut out. Only the soft green glow from the old CRT monitor remained, the cursor flashing at the end of 'Goodbye.' At the same time, a tall scrapper emerged from the dark opening of the staircase.

Elec Man rolled his eyes at the dumb theatrics and fired a Thunder Beam at the advancing scrapper.

But when the Thunder Beam hit the scrapper's body, the white forks of electricity gave a dull crackle and fizzled out—the scrapper maintaining its advance.

To be continued…

#fic updates#become the night#recut au#Syndicate!Proto Au#proto man#elec man#CRORQ#robot masters#syndicate#megaman#ruby spears mega man#rockman#Mega Man (DOS)#Mega Man PC games#obscure video games

17 notes

·

View notes

Text

Detailed Introduction About Cross Belt Magnetic Separators

Detailed Introduction About Cross Belt Magnetic Separators

Cross Belt Magnetic Separators are a remarkable innovation in material handling and separation technology. These versatile devices play a crucial role in various industries, ensuring the purity and quality of materials. Whether you’re in mining, recycling, food processing, or construction, understanding how crossbelt magnetic Separators…

View On WordPress

#high performance magnetic separators#industrial application#Industrial Magnetic Assemblies#industrial magnetic equipment#Industry Magnetic Separators#Magnet Design#magnetic components#Magnetic device#Magnetic Liquid traps#magnetic permeable sheets#Magnetic pulley separator#Magnetic Pulleys#Magnetic Separation#magnetic separation assemblies#magnetic separation equipment#magnetic separation systems#Magnetic Separator#Magnetic Separator Conveyors#Magnetic Separators#Manual Magnetic Separators#Self-Cleaning Magnetic Separators#self-cleaning suspended magnets

0 notes

Text

Killswitch

In the spring 1989 the Karvina Corporation released a curious game, whose dissemination among American students that fall was swift and furious, though its popularity was ultimately short-lived.

The game was "Killswitch".

On the surface it was a variant on the mystery or horror survival game, a precursor to the Myst and Silent Hill franchises. The narrative showed the complexity for which Karvina was known, though the graphics were monochrome, vague grey and white shapes against a black background. Slow MIDI versions of Czech folksongs play throughout. Players could choose between two avatars: an invisible demon named Ghast or a visible human woman, Porto. Playing as Ghast was considerably more difficult due to his total invisibility, and players were highly liable to restart the game as Porto after the first level, in which it was impossible to gauge jumps or aim. However, Ghast was clearly the more powerful character he had fire-breath and a coal-steam attack, but as it was above the skill level of most players to keep track of where a fire-breathing, poison-dispensing invisible imp was on their screens once the fire and steam had run out, Porto became more or less the default.

Porto’s singular ability was seemingly random growth– she expanded and contracted in size throughout the game. A Kansas engineering grad claimed to have figured out the pattern involved, but for reasons which will become obvious, his work was lost. Porto awakens in the dark with wounds in her elbows, confused. Seeking a way out, she ascends through the levels of a coal mine in which it is slowly revealed she was once an employee, investigating its collapse and beset on all sides by demons similar to Ghast, as well as dead foremen, coal-golems, and demonic inspectors from the Sovatik corporation, whose boxy bodies were clothed in red, the only color in the game. The environment, though primitive, becomes genuinely uncanny as play progresses. There are no bosses in any real sense– Porto must simply move physically through tunnels to reach subsequent levels while her size varies wildly through inter-level spaces.

The story that emerges through Porto’s discovery of magnetic tapes, files, mutilated factory workers who were once her friends, and deciphering an impressively complex code inscribed on a series of iron axes players must collect (This portion of the game was almost laughably complex,and defeated many players until Porto881 posted the cipher to a Columbia BBS. Attempts to contact this player have been unsuccessful, and the username is no longer in use on any known service.) is that the foremen, under pressure to increase coal production, began to falsify reports of malfunctions and worker malfeasance in order to excuse low output, which incited a Sovatik inspection.

Officials were dispatched, one for each miner, and an extraordinary story of torture unfolds, with fuzzy and indistinct graphics of red-coated men standing over workers, inserting small knives into their joints whenever production slowed. (Admittedly, this is not a very subtle critique of Soviet-era industrial tactics, and as the town of Karvina itself was devastated by the departure of the coal industry, more than one thesis has interpreted Killswitch as a political screed.)After solving the axe-code, Porto finds and assembles a tape recorder, on which a male voice tells her that the fires of the earth had risen up in their defense and flowed into the hearts of the decrepit, pre-evolution equipment they used and wakened them to avenge the workers. It is generally assumed that the fires of the earth are demons like Ghast, coal fumes and gassy bodies inhabiting the old machines.

The machines themselves are so big that the graphics elect to only show two or three gear-teeth or a conveyor belt rather than the entire apparatus. The machines drove the inspectors mad, and they disappeared into caverns with their knives (only to emerge to plague Porto, of course). The workers were often crushed and mangled in the onslaught of machines, who were neither graceful nor discriminating. Porto herself was knocked into a deep chasm by a grief-stricken engine, and her fluctuating size, if it is real and not imagined, is implied to be the result of poisonous fumes inhaled there.

What follows is the most cryptic and intuitive part of the game. There is no logical reason to proceed in the correct way, and again it was Porto881 who came to the rescue of the fledgling Killswitch community. In the chamber behind the tape recorder is a great furnace where coal was once rendered into coke. There are no clues as to what she is intended to do in this room. Players attempted nearly everything, from immolating herself to continuing to process coal as if the machines had never risen up.

Porto881 hit upon the solution, and posted it to the Columbia boards. If Porto ingests the raw coke, she will find her body under control, and can go on to fight her way out of the final levels of the mine, which are impassable in her giant state, clutching the tape containing this extraordinary story. However, as she crawls through the final tunnel to emerge above ground, the screen goes suddenly white. Killswitch, by design, deletes itself upon player completion of the game. It is not recoverable by any means, all trace of it is removed from the user’s computer. The game cannot be copied. For all intents and purposes it exists only for those playing it, and then ceases to be entirely.

One cannot replay it, unlocking further secrets or narrative pathways, one cannot allow another to play it, and perhaps most importantly, it is impossible to experience the game all the way to the end as both Porto and Ghast. Predictably, player outcry was enormous. Several routes to solve the problem were pursued, with no real efficacy. The first and most common was to simply buy more copies of the game, but Karvina Corp. released only 5,000 copies and refused to press further editions. The following is an excerpt from their May 1990 press release:

"Killswitch was designed to be a unique playing experience: like reality, it is unrepeatable, unretrievable,and illogical. One might even say ineffable. Death is final; death is complete. The fates of Porto and her beloved Ghast are as unknowable as our own. It is the desire of the KarvinaCorporation that this be so, and we ask our customers to respect that desire. Rest assured, Karvina will continue to provide the highest quality of games to the West, and that Killswitch is merely one among our many wonders."

This did not have the intended effect. The word beloved piqued the interest of committed, even obsessive players, as Ghast is not present in any portion of Porto’s narrative. A rush to find the remaining copies of the game ensued, with the intent of playing as Ghast and discovering the meaning of Karvina’s cryptic word. The most popular theory was that Ghast would at some point become the fumes inhaled by Porto, changing her size and beginning her adventure. Some thought this was wishful thinking, that if only Ghast’s early levels were passable one would somehow be able to play as both simultaneously. However, by this time no further copies appeared to be available in retail outlets. Players who had not yet completed the game attempted Ghast’s levels frequently, but the difficulty of actually playing this enigmatic avatar persisted, and no player has ever claimed to have finished the game as Ghast. One by one, the lure of Porto’s lost, unearthly world drew them back to her, and one by one, they were compelled towards the finality of the vast white screen. To find any copy usable today is an almost unfathomably rare occurance; a still shrink-wrapped copy was sold at auction in 2005 for $733,000 to Yamamoto Ryuichi of Tokyo.

It is entirely possible that Yamamoto’s has the last remaining copy of the game. Knowing this, Yakamoto had intended to open his play to all enthusiasts, filming and uploading his progress. However, to date, the only film which has surfaced is a one minute and forty five second clip of a haggard Yamamoto at his computer, the avatar selection screen is visible over his right shoulder.

Yamamoto is crying.

#killswitch game#killswitch#its so annoying to find the original story that im just posting it here for future reference

9 notes

·

View notes

Text

Different Types Of Bearings

The machinery in the industries is constructed from extremely small parts. These components are put together to create functional equipment. Today, we'll discuss one of the significant minor components of such machinery. We'll speak about bearings today.

Bearings are a little but significant component. Depending on our needs, many bearing types are offered. It is employed to limit any part's degree of freedom. It provides a specific component with the specified direction. The drawer on your computer table is the most straightforward example, where a bearing allows a component to move linearly. Bearings reduce friction between two pieces by removing direct contact between them. Additionally, it takes less power or energy to remove a part as a result. Let's now talk about the many sorts of bearing.

Types of Bearings:

Ball Bearings

The most popular kind of bearing is the ball bearing. It is made up of tiny metal balls called Races that are positioned between two metal rings. The Cage assembly is used to maintain the location of balls as well. Ball bearings lose less energy because of the lower rolling friction compared to sliding friction. The outside races are immobile, but the inner races and balls can freely revolve. The outer races are attached to a motor, and the shaft is placed inside the inner races.

Advantages:

Reduce your resistance.

Simple to replace components

Less expensive

Manage heavy loads

Lengthy life

Disadvantages:

Shocks could cause it to break.

Little loud

Roller Bearings

Similar to ball bearings, which are engineered to support a load while minimizing friction, are roller bearings, often referred to as rolling-element bearings. Instead of employing balls to keep the bearing's moving sections apart, roller bearings transmit loads using cylinder-shaped rolling elements. Single or several rows of rolling elements may be present in these adaptable bearings; numerous rows can greatly increase radial load capacity. Additionally, the use of various roller shapes can lessen friction even more while supporting radial and axial loads.

Advantages:

Low resistance

High capacity for load

Simple to maintain

Disadvantages:

Very expensive

Noisy

Linear Bearings

The linear bearing is used to provide linear motion to any component and has balls or rolling components between two races. Sliding doors, cabinet drawers, etc. are some examples of linear bearings in their most basic form.

Jewel Bearings

It is employed in applications where there are tiny shafts, such as in timepieces and meters. It is much smaller than other bearings and operates much more efficiently. It is made of particular components.

Plain Bearings

It is the most basic kind of bearing. It does not have any rolling components and only has a bearing surface. In the bearing hole, the shaft is turning. More sliding friction than rolling friction is provided by it. Shaft rotation inside the bearing surface is an illustration of it.

Fluid Bearings

These revolutionary bearings are currently taking the place of metal bearings. Here, two elements that reduce friction come into touch with the fluid. Due to fluid pressure, two elements never come into touch and always remain separated. Compared to other metal bearings, it offers extremely quiet operation and extremely little vibration.

Magnetic Bearings

Magnetic bearings utilize the principle of magnetic levitation to maintain the airborne position of moving parts. The fact that the speed of the spinning element has no upper limit makes this bearing highly well-liked.

There are two different kinds of magnetic bearings:

Active Magnetic Bearings

In the Active kind, we employ an electric magnet to pull the shaft back to the center as it travels out of place.

Passive Magnetic Bearings

We employ permanent or fixed magnets, which are challenging to design, in the passive kind.

#Ball bearings#roller bearings#linear bearings#fluid bearings#plain bearings#jewel bearings#magnetic bearings

2 notes

·

View notes

Text

Nickel 200 Forged Fittings Suppliers

Nickel 200 is a commercially pure nickel alloy (with a minimum of 99% nickel content), known for its excellent mechanical properties, outstanding corrosion resistance, and high electrical and thermal conductivity. Nickel 200 forged fittings are widely used in industries where purity, corrosion resistance, and operational integrity are essential, especially in extreme temperatures and harsh chemical environments.

Key Properties of Nickel 200 Forged Fittings

High Purity and Corrosion Resistance: Nickel 200 is highly resistant to a wide range of corrosive environments, particularly in reducing environments such as acids and alkalis. Its resistance to caustic soda, sulfuric acid, and other aggressive chemicals makes it ideal for the chemical and food processing industries.

Thermal and Electrical Conductivity: The high thermal and electrical conductivity of Nickel 200 makes it useful in applications requiring good heat transfer and electrical performance. This is why it is frequently used in electrical and electronic components.

Magnetic and Ductile: Nickel 200 retains its magnetic properties even at low temperatures and exhibits good ductility, allowing for easy fabrication and forming, making it suitable for many types of forged fittings.

Excellent Mechanical Properties: Even at elevated temperatures (up to 600°F or 315°C), Nickel 200 maintains its mechanical strength, while also performing well in low-temperature and cryogenic applications.

Applications of Nickel 200 Forged Fittings

Nickel 200 forged fittings are used in a variety of industries due to their excellent corrosion resistance, high thermal conductivity, and durability. Common applications include:

Chemical Processing: Nickel 200 is widely used in the handling of caustic alkalis, chlorine, and other aggressive chemicals in chemical processing plants. The fittings are used in pipe systems, reactors, and heat exchangers.

Food Processing: Due to its non-toxic and non-contaminating properties, Nickel 200 is used in food processing equipment, especially in environments where sodium hydroxide or other caustic solutions are present.

Electrical and Electronics: Nickel 200’s high electrical conductivity makes it ideal for electrical and electronic components like connectors, terminals, and batteries.

Aerospace and Marine: Its resistance to saltwater corrosion makes Nickel 200 fittings suitable for marine environments and aerospace applications that involve high-performance requirements.

Pharmaceutical and Petrochemical Industries: Nickel 200 fittings are used in pharmaceutical manufacturing and petrochemical processing, where chemical purity and corrosion resistance are paramount.

Types of Nickel 200 Forged Fittings

Nickel 200 forged fittings are available in various types and configurations to accommodate different piping systems and operational needs. Some common types include:

Elbows: Used to change the direction of flow in piping systems.

Tees: Facilitate the branching of pipe sections to redirect flow.

Couplings: Join two pipes together, often used for easy pipe assembly.

Unions: Provide easy assembly and disassembly in piping systems, allowing for quick maintenance or replacement of parts.

Reducers: Help transition between different pipe sizes while maintaining flow efficiency.

Crosses: Enable a four-way junction for complex piping systems.

Specifications of Nickel 200 Forged Fittings

Nickel 200 forged fittings must adhere to specific industry standards and specifications to ensure their reliability in demanding applications. Below are some of the key specifications:

Chemical Composition

Nickel 200 has a simple and highly pure composition:

Nickel (Ni): 99.0% minimum

Cobalt (Co): 0.25% maximum

Manganese (Mn): 0.35% maximum

Carbon (C): 0.15% maximum

Sulfur (S): 0.01% maximum

Silicon (Si): 0.35% maximum

Iron (Fe): 0.40% maximum

This composition ensures the high purity of Nickel 200, which is key to its performance in corrosive environments.

Mechanical Properties

Tensile Strength (MPa): 415 MPa minimum

Yield Strength (MPa): 103 MPa minimum

Elongation: 40% minimum

Hardness: 110 HB (Brinell Hardness)

These properties allow Nickel 200 forged fittings to maintain strength and flexibility even under high-stress conditions.

Standards and Grades

Nickel 200 forged fittings are produced according to internationally recognized standards to ensure reliability in various industrial applications:

ASTM B564: This standard outlines the specifications for nickel alloy forgings.

ASME SB564: This is the corresponding ASME standard for nickel forgings used in pressure piping systems.

ASME B16.11: Specifies the dimensional standards for forged fittings used in pressure systems.

MSS-SP-79, MSS-SP-83, MSS-SP-95: Cover socket weld and threaded forged fittings.

Dimensional Specifications

Nickel 200 forged fittings are available in various pressure classes and sizes, depending on the requirements of the piping system:

Sizes: 1/8" NB to 4" NB

Pressure Classes: Class 2000, 3000, 6000, and 9000

Connection Types: Available in socket weld and threaded connection types.

Corrosion Resistance of Nickel 200 Forged Fittings

Nickel 200 exhibits excellent resistance to a variety of corrosive media, making it a superior choice for demanding environments:

Caustic Alkalis: Nickel 200 is particularly resistant to alkalis such as caustic soda, even at high concentrations and temperatures.

Acid Resistance: The alloy shows good resistance to neutral and mildly acidic environments.

Seawater Resistance: Nickel 200 performs well in marine environments due to its ability to resist saltwater corrosion.

Oxidizing Environments: In oxidizing conditions, Nickel 200 forms a protective oxide layer that prevents further corrosion.

Temperature Range

Nickel 200 forged fittings are designed to withstand a wide range of temperatures:

Operational Temperature Range: From cryogenic temperatures to around 600°F (315°C), Nickel 200 maintains its mechanical integrity and corrosion resistance.

Testing and Quality Control

To ensure the highest quality and safety standards, Nickel 200 forged fittings undergo rigorous testing, including:

Hydrostatic Testing: Ensures the fittings can withstand pressure without leaks or structural failures.

Non-Destructive Testing (NDT): Techniques such as ultrasonic or radiographic inspection ensure there are no internal defects.

Mechanical Testing: To verify tensile strength, yield strength, and elongation properties.

Chemical Composition Testing: Verifies the purity and chemical makeup of the alloy to ensure compliance with standards.

0 notes

Text

The Role of Automated Guided Vehicles in Automotive Manufacturing by Experts like Peter Gregory Striker

In the rapidly evolving automotive industry, the integration of advanced technologies is reshaping manufacturing processes. One such technology making significant strides is Automated Guided Vehicles (AGVs). These sophisticated systems are revolutionizing the way automotive manufacturers handle materials and components, enhancing efficiency, precision, and safety on the production floor. As manufacturers strive to meet increasing demand and adapt to new production techniques, Automated Guided Vehicles offer a solution that aligns with the industry's need for greater automation and streamlined operations. This blog explores the pivotal role of AGVs in automotive manufacturing, examining their benefits, applications, and future prospects.

Understanding Automated Guided Vehicles

Automated Guided Vehicles are mobile robots used in manufacturing settings to transport materials and components from one location to another. Unlike traditional forklifts or conveyor belts, AGVs operate autonomously, navigating through predefined paths or using sophisticated navigation systems like lasers or magnetic strips. This technology allows Automated Guided Vehicles to perform tasks such as delivering parts to assembly lines or moving products between different stages of production with minimal human intervention.

The fundamental advantage of Automated Guided Vehicles lies in their ability to reduce human labor while increasing operational efficiency. By automating repetitive and time-consuming tasks, AGVs help to streamline workflows and minimize errors associated with manual handling as highlighted by experts like Peter Gregory Striker. Their autonomous nature also enhances safety by reducing the likelihood of accidents caused by human oversight, making them an invaluable asset in modern automotive manufacturing environments.

Benefits of AGVs in Automotive Manufacturing

The deployment of Automated Guided Vehicles in automotive manufacturing brings numerous benefits, starting with increased operational efficiency. AGVs can operate 24/7 without the need for breaks or shifts, leading to significant improvements in production throughput. Their ability to navigate autonomously also reduces the time required for material handling, allowing for faster turnaround times and more streamlined production processes.

In addition to efficiency, Automated Guided Vehicles contribute to cost savings. Leaders such as Peter Gregory Striker mention that by minimizing the need for manual labor and reducing workplace accidents, manufacturers can lower labor costs and decrease expenses related to workplace injuries. Furthermore, AGVs are equipped with advanced sensors and software that ensure precise material handling, reducing the risk of damage to components and thereby cutting down on waste and rework costs.

Applications of AGVs in Automotive Manufacturing

AGVs are versatile and can be applied across various stages of automotive manufacturing. In the assembly line, Automated Guided Vehicles are used to transport parts and components to different workstations, ensuring a steady flow of materials and reducing downtime. They are also utilized in warehousing operations, where they manage inventory and deliver parts to assembly lines as needed.

In addition to these traditional applications, Automated Guided Vehicles are increasingly being used in just-in-time (JIT) manufacturing systems. In JIT systems, AGVs help synchronize the delivery of components with production schedules, reducing inventory levels and minimizing the need for storage space. This application enhances the overall efficiency of the production process and aligns with the industry's focus on lean manufacturing principles as pointed out by industry leaders including Peter Gregory Striker.

Integration Challenges and Solutions

While AGVs offer substantial advantages, their integration into existing manufacturing systems can present challenges. One primary concern is the initial cost of implementation, which includes purchasing the Automated Guided Vehicles, installing the necessary infrastructure, and training staff to operate and maintain the systems. Despite the upfront investment, the long-term benefits often outweigh these costs through improved efficiency and reduced operational expenses.

To address these challenges, manufacturers can take a phased approach to AGV integration. Starting with a pilot program allows for testing and adjustment before full-scale deployment. Additionally, selecting Automated Guided Vehicles with scalable and flexible designs can ease integration into existing systems. Experts like Peter Gregory Striker convey that collaborating with technology providers for comprehensive support and training can also help ensure a smooth transition and maximize the benefits of AGV technology.

Future Trends in AGV Technology

The future of AGV technology is marked by advancements that promise even greater capabilities and integration within automotive manufacturing. Emerging trends include the development of more advanced navigation systems, such as those using artificial intelligence (AI) and machine learning, which enhance the flexibility and adaptability of AGVs. These advancements enable Automated Guided Vehicles to navigate more complex environments and make real-time decisions based on changing conditions.

Another trend is the integration of Automated Guided Vehicles with other automation technologies, such as robotic arms and Internet of Things (IoT) systems. This integration allows for more seamless coordination between different automated systems, improving overall production efficiency and enabling more sophisticated manufacturing processes. As technology continues to evolve, AGVs will likely become an even more integral part of automotive manufacturing, driving innovation and enhancing operational capabilities.

Case Studies and Industry Examples

Several automotive manufacturers have successfully integrated Automated Guided Vehicles into their production processes, showcasing the technology's potential. For example, major automotive brands like BMW and Toyota have implemented AGVs to enhance their assembly lines and material handling operations. These case studies highlight the benefits of Automated Guided Vehicles, including increased production efficiency, reduced labor costs, and improved safety.

In addition to these examples, smaller and mid-sized manufacturers are also adopting Automated Guided Vehicles to stay competitive in the industry. By leveraging AGV technology as suggested by leaders such as Peter Gregory Striker, these companies can achieve similar efficiencies and cost savings as their larger counterparts, making Automated Guided Vehicles a valuable investment across various scales of operation. These industry examples underscore the versatility and effectiveness of AGVs in modern automotive manufacturing.

Automated Guided Vehicles are transforming the automotive manufacturing landscape by offering increased efficiency, cost savings, and improved safety. Their ability to operate autonomously and integrate with existing production systems makes them a valuable asset in streamlining material handling and assembly processes. As technology continues to advance, Automated Guided Vehicles will play an increasingly crucial role in shaping the future of automotive manufacturing. Embracing AGV technology allows manufacturers to enhance their operational capabilities, reduce costs, and maintain a competitive edge in an evolving industry. Through effective implementation and ongoing innovation, Automated Guided Vehicles will continue to drive progress and efficiency in automotive production.

0 notes