#IndustrialIoT

Link

The Internet of Things (IoT), has become extensively popular in all aspects of technology today building solutions that revolve around IoT

#Theinternetofthings#IndustrialInternetofThings#IndustrialIot#InternetofthingsIoT#IoTApplications#IoTPlatform

2 notes

·

View notes

Text

#IoT#WiFiModules#BluetoothModules#IoTConnectivity#TechTrends#SmartDevices#Bluetooth5#WiFi6#ConnectedDevices#InternetOfThings#SmartHome#IndustrialIoT#TechInnovation#WirelessTechnology#5G#IoTMarket#TechInvestments#ConnectivitySolutions#CyberSecurity

0 notes

Text

#CommunicationModules#DeviceLevelCommunication#IndustrialAutomation#IoTDevices#SmartManufacturing#ConnectivitySolutions#WirelessCommunication#AutomationTechnology#IndustrialIoT#SmartDevices

0 notes

Text

Discover the transformative applications of the Internet of Things (IoT) across industries such as healthcare, agriculture, manufacturing, and smart cities. Learn how IoT is improving efficiency, safety, and convenience.

0 notes

Text

#IndustrialSmartSensors#SmartSensors#IndustrialAutomation#IoT#IIoT#SensorTechnology#IndustrialIoT#PredictiveMaintenance#SmartManufacturing#Industry40

0 notes

Text

youtube

Session 23 : Multi-Access Edge Computing (MEC) in Open RAN (ORAN) Explained for Beginners

Video Link -

https://youtu.be/q8uccjqTs8E

Subscribe to "Learn And Grow Community"

Follow #LearnAndGrowCommunity

#MEC#MultiAccessEdgeComputing#oran#openran#5g#edgecomputing#telecom#NetworkInnovation#techforbeginners#iot#smartcities#Telemedicine#industrialiot#NetworkEfficiency#techeducation#FutureOfNetworks#wirelesstechnology#techexplained#beginnerfriendly#TechOverview#techtalks#6g#5GNR#Youtube

1 note

·

View note

Text

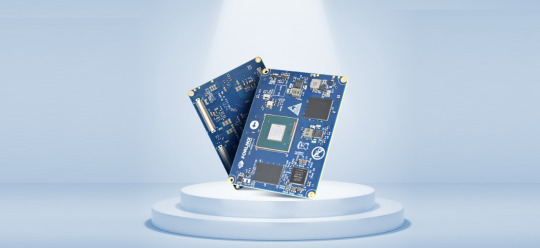

Announcing the new Forlinx FET-MX95xx-C SoM! Based on the NXP i.MX95 series flagship processor, it integrates 6 Cortex-A55 cores, Cortex-M7 and Cortex-M33 cores. With a powerful 2TOPS NPU, it offers excellent AI computing capability, ideal for edge computing, smart cockpits, Industry 4.0 and more.

The FET-MX95xx-C features rich interfaces including 5x CAN-FD, 1x 10GbE, 2x GbE, 2x PCIe Gen3, and an embedded ISP supporting 4K@30fps video capture with powerful GPU acceleration. It also has strong safety features compliant with ASIL-B and SIL-2 standards.

Want to learn more? Check out the Forlinx website

Let's explore Forlinx's latest technology together and power up your products!

#ForlinxEmbedded#NXPIMX95#EdgeComputing#IndustrialIoT#SmartCockpit#ComputerOnModule#AIAcceleration#FunctionalSafety#SoM

0 notes

Text

The Importance of Real-Time Energy Monitoring

In today's fast-paced world, energy management has become a critical concern for businesses and households alike. With rising energy costs, increasing environmental awareness, and the need for greater efficiency, monitoring energy consumption in real-time has emerged as a powerful tool for optimising usage and reducing waste. Real-time energy monitoring systems provide instant feedback on energy usage, allowing users to make timely adjustments to their consumption patterns.

Enhanced Efficiency: Real-time energy monitoring enables users to identify areas of high energy consumption immediately. By tracking energy usage in real-time, businesses can pinpoint inefficiencies and take corrective action promptly. For example, a manufacturing facility can detect equipment malfunctions or operational inefficiencies as they occur, preventing prolonged periods of energy waste.

Cost Savings: One of the most significant advantages of real-time energy monitoring is its potential for cost savings. By monitoring energy usage in real-time, businesses can identify opportunities to reduce consumption during peak hours when electricity rates are higher. Additionally, real-time monitoring allows for better load management, enabling users to schedule energy-intensive tasks during off-peak hours when electricity costs are lower.

Environmental Sustainability: Real-time energy monitoring promotes environmental sustainability by helping users reduce their carbon footprint. By identifying areas of energy waste and implementing energy-saving measures, businesses and households can minimize their environmental impact. Moreover, real-time monitoring facilitates the integration of renewable energy sources such as solar and wind power by providing insights into energy generation and consumption patterns.

Predictive Maintenance: Real-time energy monitoring systems can also facilitate predictive maintenance by detecting abnormal energy usage patterns that may indicate equipment failures or malfunctions. By identifying potential issues early on, businesses can schedule maintenance tasks proactively, reducing downtime and preventing costly repairs.

Behavioral Insights: Real-time energy monitoring provides valuable insights into energy consumption patterns and behaviors. By visualizing energy usage data in real-time, users can gain a better understanding of how their actions impact energy consumption. This awareness can lead to changes in behavior, such as turning off lights or adjusting thermostat settings, to reduce energy waste.

Regulatory Compliance: In many industries, regulatory agencies impose strict guidelines on energy usage and emissions. Real-time energy monitoring helps businesses ensure compliance with these regulations by providing accurate and up-to-date data on energy consumption. By monitoring energy usage in real-time, businesses can identify areas of non-compliance and take corrective action to avoid penalties.

Remote Monitoring and Control: With the advancement of technology, real-time energy monitoring systems now offer remote monitoring and control capabilities. Users can access energy usage data and control devices from anywhere with an internet connection, allowing for greater flexibility and convenience. This remote accessibility is especially valuable for businesses with multiple locations or distributed assets.

#esp32development#esp32electronics#esp32innovation#energyusage#iiotinnovation#iiottechnology#esp32#esp32project#connecteddevices#industrialiot

0 notes

Text

Industrial Control and Factory Automation Market Size 2024 Research Report by Global Growth Rate, Development Strategy, Recent Trends, and Regional Demand till 2030

The qualitative report published by Exactitude Consultancy research on the “Industrial Control and Factory Automation Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Industrial Control and Factory Automation market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Industrial Control and Factory Automation Market from a Global and Regional perspective.

The Industrial Control and Factory Automation Market Is Expected to Grow At 10.5% CAGR From 2022 To 2029. It Is Expected to Reach Above USD 297.51 Billion By 2029 From USD 129.1 Billion In 2023.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/24982/industrial-control-and-factory-automation-market/

#FactoryAutomation#ManufacturingAutomation#IndustrialAutomation#AutomationTechnology#ControlSystems#ProcessAutomation#SmartManufacturing#IndustrialIoT#Industry40#SmartFactory#DigitalFactory#AutomatedManufacturing#PLC#SCADA#RoboticsAutomation#IoTinManufacturing#ProductionControl#MachineAutomation#FactoryFloor

0 notes

Text

Industrial IoT: Transforming Manufacturing through Connected Intelligence

The convergence of industrial processes with cutting-edge technology has given rise to the Industrial Internet of Things (IIoT), revolutionizing the landscape of manufacturing and industrial operations. This comprehensive exploration delves into the intricacies of Industrial IoT, examining its definition, key components, applications, benefits, and the transformative impact it has on optimizing efficiency, enabling predictive maintenance, and ushering in a new era of connected intelligence within the industrial sector.

Defining Industrial IoT

1. Overview of Industrial IoT

The Industrial Internet of Things (IIoT), also known as Industrial IoT, refers to the integration of internet-connected devices, sensors, and smart technologies into industrial and manufacturing processes. It leverages data analytics, machine learning, and real-time connectivity to enhance operational efficiency, monitor equipment health, and enable intelligent decision-making in industrial settings.

2. Key Components of Industrial IoT:

Sensors and Actuators: These devices capture real-time data from industrial equipment and processes, providing valuable insights into performance, conditions, and anomalies.

Connectivity Solutions: IIoT relies on robust communication protocols and networks to ensure seamless connectivity between devices and systems, enabling data transmission and analysis.

Edge Computing: Edge computing processes data locally near the source, reducing latency and enabling quick decision-making without relying solely on centralized cloud servers.

Cloud Platforms: Cloud-based platforms store and analyze vast amounts of data generated by IIoT devices, offering scalable and accessible solutions for data storage, analytics, and management.

Analytics and Machine Learning: Advanced analytics and machine learning algorithms interpret the collected data, providing actionable insights, predictive maintenance predictions, and optimization recommendations.

Applications of Industrial IoT

1. Predictive Maintenance

IIoT enables predictive maintenance by continuously monitoring equipment conditions. By analyzing data from sensors, manufacturers can predict when machinery is likely to fail, allowing for proactive maintenance and minimizing downtime.

2. Asset Tracking and Management

Tracking the location and status of assets within a manufacturing facility becomes efficient with IIoT. RFID tags and sensors provide real-time visibility, optimizing inventory management and reducing the risk of asset misplacement.

3. Supply Chain Optimization

IIoT facilitates end-to-end visibility in the supply chain. From raw material sourcing to product delivery, manufacturers can track and optimize each step, reducing lead times, minimizing disruptions, and improving overall supply chain efficiency.

4. Energy Management

Smart sensors and meters integrated with IIoT systems help monitor energy consumption in real time. Manufacturers can identify energy inefficiencies, implement energy-saving measures, and reduce operational costs.

5. Quality Control and Monitoring

IIoT enhances quality control by continuously monitoring production processes. Real-time data analysis ensures that products meet quality standards, reducing defects, and improving overall product quality.

6. Worker Safety and Health

Wearable devices equipped with IIoT capabilities enhance worker safety by monitoring environmental conditions, detecting potential hazards, and providing real-time alerts. This contributes to a safer working environment.

Benefits of Industrial IoT

1. Improved Operational Efficiency

IIoT optimizes operational processes by providing real-time insights into equipment performance, production efficiency, and resource utilization. This leads to streamlined operations, reduced waste, and increased overall efficiency.

2. Cost Reduction

Predictive maintenance, energy optimization, and efficient resource management enabled by IIoT contribute to significant cost reductions. Manufacturers can minimize downtime, extend equipment lifespan, and make informed decisions to optimize spending.

3. Enhanced Productivity

IIoT empowers manufacturers to make data-driven decisions that positively impact productivity. Automation, real-time monitoring, and predictive analytics contribute to smoother production processes and higher output.

4. Strategic Decision-Making

The data generated by IIoT devices provides valuable insights for strategic decision-making. Manufacturers can make informed choices regarding production schedules, resource allocation, and overall business strategies.

5. Innovation and Agility

The adoption of IIoT fosters innovation within the industrial sector. Companies that embrace connected technologies can quickly adapt to changing market demands, introduce new products, and stay ahead of the competition.

6. Customer Satisfaction

By optimizing production processes, ensuring product quality, and minimizing delays, IIoT contributes to higher customer satisfaction. Timely delivery of high-quality products enhances the reputation of manufacturers in the market.

Challenges and Considerations in Industrial IoT Implementation

1. Security Concerns

The interconnected nature of IIoT devices raises cybersecurity concerns. Safeguarding sensitive data, protecting against cyber threats, and ensuring secure communication between devices are critical considerations.

2. Interoperability Issues

Compatibility between different IIoT devices and systems can be a challenge. Establishing industry standards and protocols is essential to ensure seamless integration and interoperability.

3. Data Privacy and Compliance

With the vast amount of data generated by IIoT, ensuring compliance with data privacy regulations and standards is crucial. Manufacturers must implement robust data governance practices to protect customer and operational data.

4. Initial Investment Costs

The upfront costs associated with implementing IIoT infrastructure, including sensors, connectivity solutions, and analytics platforms, can be a barrier for some organizations. However, the long-term benefits often outweigh the initial investment.

Future Trends in Industrial IoT

1. 5G Integration

The rollout of 5G networks will enhance connectivity and enable faster data transmission for IIoT devices. This will further improve real-time monitoring, decision-making, and overall efficiency in industrial settings.

2. Edge Computing Advancements

Continued advancements in edge computing technologies will enable more processing capabilities at the device level. This reduces reliance on centralized cloud servers and enhances the speed of data analysis for critical applications.

3. AI and Machine Learning Integration

The integration of artificial intelligence (AI) and machine learning (ML) with IIoT will enable more advanced predictive analytics, anomaly detection, and optimization capabilities, further enhancing the intelligence of industrial processes.

4. Digital Twins for Simulation

The use of digital twins – virtual replicas of physical assets or systems – will become more prevalent. Manufacturers can simulate and analyze the behavior of assets in a virtual environment before implementing changes in the physical world.

Conclusion

The Industrial Internet of Things stands at the forefront of a transformative wave, reshaping the manufacturing and industrial landscape. As organizations continue to embrace connected intelligence, the benefits of IIoT in terms of efficiency, productivity, and innovation become increasingly evident. While challenges such as security and interoperability must be addressed, the potential for optimized operations, predictive maintenance, and enhanced decision-making positions IIoT as a cornerstone of the fourth industrial revolution. The ongoing evolution of IIoT promises not only to connect machines but also to empower industries with the intelligence needed to thrive in an ever-evolving, interconnected world.

Read More: Smart Manufacturing: A Revolution in Industry 4.0

#IIoT#industrialiot#connectedintelligence#manufacturing#predictivemaintenance#iotapplications#SmartManufacturing

0 notes

Text

📢 #Elecrow Lora Series Product #NewArrival 👋

⭐ Introducing the LR1302 #LoRaWAN Long Range Gateway Module, which supports 8-channel data transmission for the connection and data transmission of more devices.🔥

📌https://www.elecrow.com/lr1302-lorawan-gateway-module-spi-eu868-sx1302-long-range-gateway-module-support-8-channels.html?utm_source=tumblr&utm_term=idd=2

#WirelessCommunication#InternetOfThings#SmartCity#IoTDevices#LPWAN#SensorNetworks#SmartHome#IndustrialIoT

1 note

·

View note

Text

#IndustrialNetworking#IIoT#SmartManufacturing#5G#Cybersecurity#Industry40#CloudNetworking#Automation#SmartFactory#DigitalTransformation#IndustrialAutomation#NetworkSolutions#DataConnectivity#EdgeComputing#IndustrialIoT#TechInnovation#IndustrialGrowth#NetworkingInfrastructure

0 notes

Text

Innovating the connected future with our IoT application development services. From prototypes to production, our experts deliver smart, scalable IoT solutions. Let's discuss your project!

🛠️ Services We Offer:

✅ Prototyping

✅ Custom Development

✅ Data Analytics

✅ Security & Privacy

✅ Full-scale Production

Ready to embark on your IoT journey? Let's discuss your project and shape the future together! 💬

👉 Visit Us-: www.digitalbrain.co.in

👉 Email Us-: [email protected]

#IoT#InternetOfThings#ConnectedDevices#Sensors#Wearables#IIoT#IndustrialIoT#MachineLearning#AI#SmartCity#SmartHome#Tech#Innovation#Engineering#IoTDevelopment#SmartTechnology#IoTSolutions#TechExperts

0 notes

Text

We are excited to announce Keysight as one of our prestigious Gold Partners. Booth # E-17

𝗦𝗽𝗼𝗻𝘀𝗼𝗿 𝗔𝗻𝗻𝗼𝘂𝗻𝗰𝗲𝗺𝗲𝗻𝘁📢

We are excited to announce Keysight as one of our prestigious Gold Partners. Booth # E-17

Keysight empowers automotive industry designers and manufacturers with the latest innovations in design and test solutions to help create high-quality and high-performance products while mitigating safety risks.

Join them & Explore the testing solutions for Automotive & Electric Vehicles . Get your visitor pass now - autoevexpo.com

#keysight#keysighttechnologies#automotivetesting#electricvehiclestesting#industrialiot#evtesting#automotiveindustrydesigners#automotiveindustrymanufacturers#automotiveinnovations#latestevinnovations#emobilitytesting#automotive#automotiveindustry#automotiveelectronics#automotiveengineering#evtechnology#electricvehicles#electricvehicletechnology#evcharging#technology#batterytechnology#batterymanagementsystems#powertrain#semiconductors

0 notes

Text

IoT-based healthcare systems make remote monitoring of patients a reality. We deliver IoT healthcare solutions that will undoubtedly transform the way you run your hospitals.

Give us a call now to learn about harnessing digital power in your healthcare operations.

WhatsApp: https://wa.me/919535555225

#IoT#InternetOfThings#SmartDevices#ConnectedWorld#IoTInnovation#SmartCities#IoTSolutions#IoTTechnology#IndustrialIoT#IoTSecurity#SmartHomes#IoTAnalytics#IoTData#SmartGrid#IoTApplications#IoTPlatform#IoTIndustry#IoTDevices#IoTConnectivity#IoTDevelopment#june#softwarecompany#digital#healthcare#power#hospitals

0 notes