#SmartFactory

Explore tagged Tumblr posts

Text

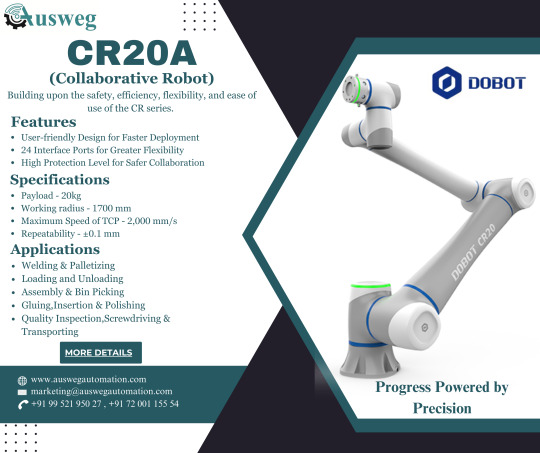

DOBOT CR20A Performance Unleashed With High Payload and Wide Radius

www.auswegautomation.com [email protected] +91 99 521 950 27, +91 72 001 155 54

#cobots#collabrativerobots#automation#industry40#robotics#manufacturing#ai#roboticstechno#digitaltransformation#innovation#techtrends#futureofwork#smartfactory#industrialautomation#productivity#workplacesafety#efficiency#humanrobotcollabration#roboticsindustry#advancedmanufacturing

2 notes

·

View notes

Text

A skilled engineer using augmented reality (AR) and digital twin technology to visualize and interact with advanced machinery in an electronic manufacturing setup. This smart factory approach represents the future of Industry 4.0 — combining virtual design, real-time data, and precision engineering for faster, smarter product development.

Explore how Auckam Technologies is powering the future of manufacturing: www.auckam.com

#ElectronicManufacturing#Industry40#SmartFactory#AugmentedReality#DigitalTwin#PCBDesign#EngineeringInnovation#IndustrialAutomation#ARinManufacturing#SmartManufacturing#Auckam

0 notes

Text

Unlocking Manufacturing Efficiency Through Data

Real-time dashboards. Smarter decisions. Streamlined output. 📊

Manufacturing Data analytics is the engine behind modern manufacturing success.

#smartfactory#manufacturing#manufacturing solutions#digitaltransformation#factory#techinmanufacturing

0 notes

Text

𝗗𝗼 𝗬𝗼𝘂 𝗞𝗻𝗼𝘄 𝗪𝗵𝗲𝗿𝗲 𝗙𝗿𝗮𝗻𝗰𝗲'𝘀 𝗡𝗲𝘅𝘁 𝗕𝗶𝗴 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗣𝗿𝗼𝗳𝗶𝘁 𝗣𝗼𝗼𝗹 𝗜𝘀? The 𝗙𝗿𝗮𝗻𝗰𝗲 𝗗𝗶𝘀𝘁𝗿𝗶𝗯𝘂𝘁𝗲𝗱 𝗖𝗼𝗻𝘁𝗿𝗼𝗹 𝗦𝘆𝘀𝘁𝗲𝗺 (𝗗𝗖𝗦) 𝗠𝗮𝗿𝗸𝗲𝘁 is not just growing — it's transforming the entire backbone of France's industrial automation.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

𝗗𝗿𝗶𝘃𝗲𝗻 𝗯𝘆 𝘀𝘂𝗿𝗴𝗶𝗻𝗴 𝗱𝗲𝗺𝗮𝗻𝗱 𝗶𝗻:

Smart manufacturing & Industry 4.0

Energy optimization across oil & gas, power, and chemical sectors

Government-backed decarbonization initiatives

𝗙𝗿𝗮𝗻𝗰𝗲 𝗶𝘀 𝗽𝗼𝘀𝗶𝘁𝗶𝗼𝗻𝗶𝗻𝗴 𝗶𝘁𝘀𝗲𝗹𝗳 𝗮𝘀 𝗮 𝗘𝘂𝗿𝗼𝗽𝗲𝗮𝗻 𝗮𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗽𝗼𝘄𝗲𝗿𝗵𝗼𝘂𝘀𝗲. 𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀 : Hitachi Ltd., Omron Corporation, Emerson Electric Co., Mitsubishi Electric Corporation, ABB Ltd., Rockwell Automation Inc., Honeywell International Inc., Valmet OYJ, Toshiba Corporation, Schneider Electric SE, General Electrics and others.

𝗠𝗮𝗿𝗸𝗲𝘁 𝗚𝗿𝗼𝘄𝘁𝗵 𝗦𝗻𝗮𝗽𝘀𝗵𝗼𝘁:

Rapid DCS upgrades across aging infrastructures

Increased capital inflows in advanced control & monitoring technologies

High-margin service & maintenance contracts creating steady recurring revenue streams

𝗦𝗮𝘃𝘃𝘆 𝗶𝗻𝘃𝗲𝘀𝘁𝗼𝗿𝘀 𝗮𝗿𝗲 𝗮𝗹𝗿𝗲𝗮𝗱𝘆 𝗲𝘆𝗲𝗶𝗻𝗴:

Global DCS giants expanding French operations

Domestic system integrators grabbing niche segments

Long-term government digitalization funds

Miss this now, and you may be chasing it at a premium later. 𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁

The France DCS market is where control meets capital.

#FranceDCS#IndustrialAutomation#DistributedControlSystem#Industry40#SmartManufacturing#InvestmentOpportunity#PrivateEquity#VC#GrowthMarket#EnergyTransition#SmartFactory#AutomationRevolution#Decarbonization#FranceInvestment#TechStocks#InvestorAlert

0 notes

Text

The Future of Precision: Why Robot Calibration is a Game-Changer in Modern Manufacturing

The main purpose of robot calibration is to determine the location of the robot tools in their working environment to enable accurate movement, so the technology can be relied upon as it moves throughout the work zone.

Why is Robot Calibration Important?

As modern manufacturing improves and speeds up productivity and throughput, increased production demands can lead to more mistakes if robots are not correctly calibrated. The greatest risk of not performing calibration is rejecting defective product. Across industries, the overall cost penalty of rejecting defective product, one error, not a dozen errors that went through the system is enormous. Even just one part rejected, these decisions can cost upwards of hundreds of thousands, and even millions of dollars, depending on specific circumstances. In fact, some companies will even become more cost effective by performing complete calibration every day, because they know how many defective parts must be manufactured to break even, Their computer programs can inform the organization whether calibration applies to their robots every shift.

All of this said, the purpose of calibration is still to be able to in a physical sense measure the range of operational potential of the applications. And, if we know that the applications can operate with unreasonably high levels of precision, at all times, their efficacy or usefulness is supported by production reliability.

How is Dynalog Innovating the Automotive Industry

As a company evolving toward the Future of Precision, Dynalog is studying how the automotive sector is utilizing robots. These newer applications have boast numerous possibilities, but

Likewise, Dynalog continues to focus on advanced problem solving for existing and new applications outside the automotive sector, as well. Its pedigree in the automotive sector has allowed it to explore and take advantage of advanced machine learning algorithms and visualization applications.

In conclusion, with recent advances in robot calibration, the knowledge gained from the applications of robotics and advanced machine learning applications is exponentially increasing. This will lead to sweeping changes in how robots are used across all sectors. Looking ahead, Dynalog is leading the arena for organizational efficacy, as the ability for robots to make precise calibrated movements within the production ecosystem is changing.

Robotics has greatly increased the reliability and accuracy of manufacturing processes to a point where defects are few and far between. By leveraging the potential of robotics innovations in tandem with advanced calibration processes, manufacturers can expect less wasted time and resources on defective products.

Why Robot Calibration is Mandatory More often than not, industrial robots take the form of "repeatable" by default but not "accurate." In other words, they can produce the same motion over and over with minimal variability, but the motion can still be hundreds of millimeters off their intended path. In many cases this discrepancy can mean defects, down time, or wasted time and materials. This is where robot calibration is important.

increased accuracy: By calibrating the robot, you ensure the robot performs exactly as it was designed to in their digital twin or CAD model, which reduces offsets.

reduced downtime: The more accurate the robot, the less errors, less rework, and increased cycle time.

cost savings: Greater first-panel yield rates and efficient work processes will cut costs in the long run.

interchangeability: Calibrated robots can switch tasks and/or tooling quickly and with little recalibration.

Dynalog: The Premier Robot Calibration Company

Dynalog is the name manufacturers trust when it comes to world-class robot calibration.

Based out of the U.S. , Dynalog (dynalog-us.com) provides robotic system calibration, robot TCP (Tool Center Point) calibration, and dynamic robot performance monitoring. Dynalog has worked with just about every major robot brand including FANUC, ABB, KUKA , and Yaskawa, and has helped world-class manufacturers achieve levels of robotic accuracy that

Here are a few of the main products and services provided by Dynalog:

1. Robot Calibration Systems

Dynalog’s DynaCal system is a complete mechanism which calibrates a robot's kinematic model by measuring its actual joint and end-effector positions across the kinematic model with the use of external sensors and then comparing those to theoretical values.

Once calibrated, the robot's internal kinematic model is updated to align with its real-world performance and positioning accuracy improves substantially.

2. TCP Calibration (Tool Center Point)

Tool accuracy is as vital as robot positioning. Dynalog’s DynaTCP system accurately measures the position and orientation of any tool, accordingly to the robot flange, which is important for any application requiring welding, painting or material handling, where the smallest misalignment can create errors.

3. Robot Performance Monitoring

Robots may drift out of alignment, over time. Dynalog offers systems which provide the ability to continuously monitor robot performance and allow engineers to identify and rectify problems before they affect production. This proactivity leads to improved time savings, lowers maintenance costs and increased uptime.

4. Robot Simulation and Validation

Dynalog also offers high precision simulation and validation products which ensure the robot path that was created during offline programming or pathing is congruent when implemented in the factory environment. This "what you see is what you get" process is very important to companies approving towards

Why Work With Dynalog?

When you think about Dynalog, it’s not all about the technology. It’s all about knowledge, support and continuing to innovate.

We support the future today: You’ll see Dynalog solutions on the factory floors of the leading manufacturers from around the globe.

Calibration solutions tailored to you: Dynalog scaling is never an issue, whether you want to calibrate one robot or an entire fleet of them.

Calibration accuracy you can rely on: Dynalog systems will consistently provide you with submillimeter accuracy - that’s why we are the trusted choice for high precision applications.

Support from the U.S: Headquartered in Michigan, Dynalog is there to provide your ongoing support, quickly and reliably - whether you’re in North America or across the globe.

In summary: the future is calibrated

As automation continues to evolve and robots become essential for manufacturing success, the need for precision will become ever more important each day we operate. Organizations who embrace robot calibration products now will position themselves for the future of smart factories ahead.

So, if you are committed to ensuring robotic accuracy, and want to make sure your systems are performing to their full capabilities, it’s time to explore robot calibration with Dynalog - your ideal partner.

Check out dynalog-us.com today to learn more how our state-of-the-art calibration solutions can help with your robotic operations.

#robotcalibration#dynalog#industrialrobotics#manufacturingautomation#smartfactory#Industry40#robotaccuracy#robotTCP

0 notes

Text

Engineered for extreme reliability, Lanmus Industrial Switches deliver seamless plug-and-play performance in the harshest conditions. Built tough for industrial environments, they offer stable, rugged connectivity where it matters most. Ideal for factories, outdoor setups, and mission-critical systems. Available now at New Trend Computer Networks — your trusted industrial networking partner.

For more information, Visit:https://newtrend.ae/product-category/dlink/ Live chat: +971 507542792

#IndustrialNetworking#RuggedSwitches#LanmusSwitch#EdgeConnectivity#SmartFactory#IndustrialSolutions#PlugAndPlay#NetworkReliability#NewTrendNetworks#HeavyDutyNetworking

0 notes

Text

Standard machines may seem convenient — until they fall short of your production goals. 🚧 In today’s competitive landscape, businesses need more than just functionality — they need precision, flexibility, and scalability.

Our latest blog breaks down the key reasons why investing in a custom machine design can give you a true competitive edge — from optimizing performance and reducing downtime to ensuring your equipment grows with your business.

If you're facing production bottlenecks, high maintenance costs, or struggling to adapt to evolving product demands, this read is for you.

🔍 Discover how custom-designed machinery could be the smartest long-term move for your operations.

👉 Read the full blog here.

#Manufacturing#Automation#CustomMachinery#IndustrialDesign#LeanManufacturing#SmartFactory#Industry40#EngineeringInnovation#ProcessImprovement#MachineDesign

1 note

·

View note

Text

Smart Factory: Rivoluzione o Apocalisse Lavorativa?

Scopri il futuro delle fabbriche nel nostro docu-fiction “Smart Factory: Rivoluzione o Apocalisse Lavorativa?”.

Ti porteremo nel 2030, in un mondo dominato da robot e intelligenza artificiale, dove l'essere umano è sempre più superfluo. Attraverso casi reali dalla Cina e dall'Occidente, esploreremo la crescente automazione e le sue conseguenze.

Qual è il lato oscuro di questa rivoluzione? Cosa significa per il lavoro e la società? Attraverso dati tangibili e dilemmi etici, questo video stimolerà la tua riflessione sul futuro del lavoro.

Se questo viaggio ti ha colpito, metti un like e condividilo! ✨

youtube

0 notes

Text

Introducing the FCU3501, our rugged, next-gen embedded computer powered by the Rockchip RK3588 SoC. Designed for industrial AI at the edge, it delivers up to 32 TOPS of AI performance via onboard NPU + Hailo-8 M.2 accelerator.

🔧 Key Features:

Dual NPU Architecture – 6 TOPS onboard + 26 TOPS via Hailo‑8

Supports 8K Video Encoding/Decoding – Perfect for smart vision applications

Wide Temp, Fanless Design (–40 °C to +85 °C)

Certified for Industrial Use – CE, FCC, RoHS, EMC-compliant

Modular Storage & Expansion – M.2 SSD, TF card, 4G/5G optional

Rich I/O for Smart Factories, Transportation, Buildings & more

📩 Want a spec sheet or evaluation sample? Contact us: [email protected]

#EdgeAI#RK3588#Hailo8#EmbeddedComputer#IndustrialAutomation#AIAccelerator#SmartFactory#MachineVision#ProductLaunch

0 notes

Text

Discover how digital Permit to Work software is transforming workplace safety and compliance.

#workplacesafety#ehs#smartfactory#digitaltransformation#softdesigners#artificialintelligence#productivity#manufacturing

0 notes

Text

#ASRockIndustrial#EdgeAI#SmartAutomation#COMPUTEX2025#IndustrialIoT#AIoT#SmartFactory#Innovation#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

Manufacturing Sector Trends & Innovations - BizzBuzz

Discover the latest in manufacturing including Industry 4.0 technologies, supply chain optimization, and global production trends. Our coverage spans automotive, electronics, pharmaceuticals, and consumer goods manufacturing. Learn about smart factories, sustainable production methods, and workforce development strategies. Essential reading for manufacturing executives, operations managers, and investors tracking the transformation of global production networks in the digital age.

0 notes

Text

PROLIM at Hannover Messe 2025! We’re excited to announce that Prabhu Patil (Founder & CEO) and Srinath Koppa (Managing Director, India) will be representing PROLIM at Hannover Messe 2025! Meet us as we showcase PROMIS™ Digital Manufacturing, a game-changer in AI, IoT, and automation for the future of smart factories. 📍 Hannover, Germany 📅March 31 – April 4, 2025 Don’t miss out on this innovation-packed event! 🔗 Read More : https://lnkd.in/gMTR2W48

0 notes

Text

𝗗𝗼 𝗬𝗼𝘂 𝗞𝗻𝗼𝘄?

𝗨𝗻𝗹𝗼𝗰𝗸𝗶𝗻𝗴 𝗚𝗿𝗼𝘄𝘁𝗵: 𝗧𝗵𝗲 𝗕𝗼𝗼𝗺𝗶𝗻𝗴 𝗡𝗲𝘁𝗵𝗲𝗿𝗹𝗮𝗻𝗱𝘀 𝗗𝗶𝘀𝘁𝗿𝗶𝗯𝘂𝘁𝗲𝗱 𝗖𝗼𝗻𝘁𝗿𝗼𝗹 𝗦𝘆𝘀𝘁𝗲𝗺 (𝗗𝗖𝗦) 𝗠𝗮𝗿𝗸𝗲𝘁 𝗬𝗼𝘂 𝗖𝗮𝗻’𝘁 𝗜𝗴𝗻𝗼𝗿𝗲

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

𝗪𝗶𝘁𝗵 𝘁𝗵𝗲 𝗡𝗲𝘁𝗵𝗲𝗿𝗹𝗮𝗻𝗱𝘀 𝗮𝗰𝗰𝗲𝗹𝗲𝗿𝗮𝘁𝗶𝗻𝗴 𝗶𝘁𝘀 𝗶𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗮𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻, 𝘁𝗵𝗲 𝗗𝗖𝗦 𝗺𝗮𝗿𝗸𝗲𝘁 𝗶𝘀 𝗽𝗿𝗼𝗷𝗲𝗰𝘁𝗲𝗱 𝘁𝗼 𝗴𝗿𝗼𝘄 𝘀𝗶𝗴𝗻𝗶𝗳𝗶𝗰𝗮𝗻𝘁𝗹𝘆 𝗶𝗻 𝘀𝗲𝗰𝘁𝗼𝗿𝘀 𝗹𝗶𝗸𝗲:

Oil & Gas

Power Generation

Water Treatment

Chemical Processing

Pharmaceuticals

𝗪𝗵𝘆 𝘁𝗵𝗲 𝗡𝗲𝘁𝗵𝗲𝗿𝗹𝗮𝗻𝗱𝘀?

Strategic location in the EU

Government push toward Industry 4.0

Focus on sustainability & smart infrastructure

High-tech manufacturing & energy transition support

𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀 : Toshiba Corporation, Schneider Electric SE, General Electrics, Ingeteam Corporation S.A, Azbil Corporation, Siemens AG and others.

𝗠𝗮𝗿𝗸𝗲𝘁 𝗜𝗻𝘀𝗶𝗴𝗵𝘁: The shift towards digitalized, centralized control systems is not just a trend—it's a transformation. Dutch industries are demanding real-time monitoring, predictive maintenance, and seamless integration, fueling a robust DCS adoption wave.

𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁

𝗦𝗺𝗮𝗿𝘁 𝗶𝗻𝘃𝗲𝘀𝘁𝗼𝗿𝘀 𝗮𝗿𝗲 𝗮𝗹𝗿𝗲𝗮𝗱𝘆 𝘄𝗮𝘁𝗰𝗵𝗶𝗻𝗴 𝘁𝗵𝗶𝘀 𝘀𝗽𝗮𝗰𝗲—𝗮𝗿𝗲 𝘆𝗼𝘂? Stay ahead of the curve. Explore opportunities in automation infrastructure and next-gen industrial control systems.

#Netherlands#DCS#DistributedControlSystem#IndustrialAutomation#InvestSmart#Industry40#ProcessControl#SmartFactory#InvestorAlert#TechTrends#AutomationMarket

0 notes

Text

Pinakastra Computing Private Limited

Founded in 2021 in Bangalore, Karnataka, India, Pinakastra Computing specializes in Private cloud infrastructure and hyperconverged infrastructure (HCI), offering innovative cloud solutions for enterprises, academia, and research organizations. Our Pinaka ZTi™ cloud platform integrates advanced hardware and software to deliver scalable, efficient, and secure private cloud solutions. Pinakastra aims to fill the gap in India’s enterprise tech ecosystem by offering alternatives to global cloud providers. We focus on addressing the growing demand for VM & Container based AI/ML workloads with modular, cost-efficient, and scalable solutions, aspiring to become a global leader in cloud infrastructure.

https://pinakastra.com/

#PrivateCloud#CloudComputing#IoT#DataSecurity#HyperConvergedInfrastructure#HCI#SecureData#HealthcareIT#FinTech#EdTech#biotech#GovernmentIT#ManufacturingTech#RetailSolutions#smartfactory

1 note

·

View note

Text

The Evolution of Lean Manufacturing in the Digital Era

Lean Manufacturing is built on the foundation of continuous improvement, focusing on efficiency, waste reduction, and value creation. Over the years, its principles have evolved significantly, especially with the rise of Industry 4.0. The introduction of digital technologies has reshaped Lean methodologies, enabling manufacturers to make smarter, data-driven decisions.

Let’s explore how modern advancements like automation, real-time data, and AI have transformed Lean Manufacturing.

1. The Shift to Digital-Driven Lean Manufacturing Traditional Lean Manufacturing focused on streamlining workflows, reducing waste, and optimizing production. However, the rise of Industry 4.0 has introduced powerful tools like the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and data analytics, which allow manufacturers to move beyond conventional methods.

These technologies provide real-time insights, helping businesses make more precise decisions and continuously improve their operations. With real-time machine communication and AI-driven analysis, manufacturers can achieve levels of efficiency that were previously unattainable.

A key factor in this transformation is the ability to reduce changeover time, ensuring production lines switch between tasks seamlessly without unnecessary downtime.

Key Advancements: • Real-time data collection through IIoT and smart sensors. • AI-driven decision-making to improve accuracy and efficiency. • Optimized workflows that help reduce changeover time and increase uptime.

2. Automation and Smart Factories in Lean Manufacturing Automation is at the core of modern Lean Manufacturing. By integrating machine connectivity, predictive maintenance, and AI-powered optimization, smart factories can now self-adjust production speeds, minimize downtime, and reduce human error.

One of the most impactful benefits of automation is its ability to reduce changeover time between production runs. By automating setup processes and leveraging data-driven scheduling, manufacturers can ensure smoother transitions with minimal disruption.

Key Advancements: • Machines now communicate in real-time to optimize production. • Automated systems help reduce changeover time, eliminate errors, and improve efficiency.

3. Enhancing Efficiency with MOM Systems Manufacturing Operations Management (MOM) systems play a critical role in modern Lean environments. These systems connect every aspect of production, from scheduling and inventory tracking to quality control. With real-time visibility across operations, manufacturers can ensure smooth workflows and prevent bottlenecks.

By integrating MOM systems, manufacturers gain greater control, efficiency, and responsiveness—key factors in today’s fast-paced production environments. Additionally, MOM systems help reduce changeover time by optimizing production schedules and ensuring that materials and resources are available when needed.

Key Advancements: • Improved real-time visibility and control across production lines. • Seamless integration of scheduling, quality control, and workflow management. • Data-driven scheduling to reduce changeover time and enhance productivity.

4. The Role of OEE & Takt Time in Lean Optimization

Optimizing Overall Equipment Effectiveness (OEE) and Takt Time has become a priority for manufacturers looking to streamline production. With real-time monitoring and advanced analytics, factories can quickly identify inefficiencies and adjust their production schedules accordingly.

A major contributor to low OEE is excessive downtime during product switches. By focusing on strategies to reduce changeover time, manufacturers can improve machine utilization, increase throughput, and maintain consistent production flow.

Key Advancements: • AI and data-driven insights help optimize OEE and reduce waste. • Takt Time adjustments ensure a balanced production flow. • Faster setup and transition processes help reduce changeover time and minimize disruptions.

Final Thoughts

Lean Manufacturing is no longer just about eliminating waste—it’s about leveraging technology to drive smarter, more efficient production. The integration of automation, AI, IIoT, and MOM systems is revolutionizing the way manufacturers approach continuous improvement.

By focusing on strategies to reduce changeover time, manufacturers can enhance productivity, improve quality, and stay ahead in an increasingly competitive industry.

0 notes