#InjectionMould

Explore tagged Tumblr posts

Text

Ashish Tools is a leading provider of injection moulds for PET preforms, offering exceptional design and engineering solutions for efficient preform production. Our injection moulds are crafted with high precision, ensuring uniformity and strength in every preform produced. Trust Ashish Tools for advanced moulds that support high-output production with minimal downtime.

#InjectionMoulding#PETPreformMould#InjectionMould#PreformMoulds#IndustrialManufacturing#PackagingIndustry

0 notes

Text

2 notes

·

View notes

Text

The Characteristics of Injection Molding: A Comprehensive Guide

Injection molding is a widely used manufacturing process that plays a crucial role in the production of a vast range of plastic products. From everyday household items to complex automotive parts, injection molding is the go-to method for creating high-quality, durable, and precise plastic components. In this blog, we’ll dive deep into the characteristics of injection molding, exploring its process, advantages, limitations, materials used, and applications across various industries.

1. The Injection Molding Process

Before delving into the specific characteristics of injection molding, it’s essential to understand the basic process. Injection molding involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired part. The process can be broken down into several key stages:

Clamping: The mold, which is composed of two halves, is clamped together by a machine, ensuring that it stays closed during the injection process.

Injection: The molten plastic material is injected into the mold cavity through a nozzle under high pressure. This material is usually heated and mixed within a barrel before being forced into the mold.

Cooling: Once the mold is filled, the plastic material begins to cool and solidify within the mold cavity. The cooling time can vary depending on the material and the complexity of the part.

Ejection: After the plastic part has cooled and solidified, the mold is opened, and the part is ejected using ejector pins or other mechanisms.

Post-Processing: Depending on the requirements, the part may undergo additional processes such as trimming, painting, or assembly.

2. Key Characteristics of Injection Molding

Injection molding is characterized by several features that make it a preferred method for producing plastic parts. These characteristics include:

2.1. High Production Efficiency

One of the standout characteristics of injection molding is its ability to produce large quantities of parts quickly and efficiently. Once the mold is created and the process is set up, injection molding can produce thousands or even millions of identical parts with minimal variation. This high production efficiency makes it an ideal choice for mass production.

2.2. Complex Geometries

Injection molding is capable of producing parts with intricate and complex geometries that would be difficult or impossible to achieve with other manufacturing methods. The ability to create detailed and precise shapes is due to the versatility of the mold design. Complex features such as undercuts, threads, and thin walls can be incorporated into the mold, allowing for the production of sophisticated parts.

2.3. Consistency and Precision

Consistency is a hallmark of injection molding. The process is highly repeatable, meaning that each part produced is virtually identical to the previous one. This consistency is crucial in industries where precision and accuracy are paramount, such as in medical devices and aerospace components. The precision of injection molding can achieve tolerances as tight as ±0.001 inches.

2.4. Material Versatility

Injection molding offers a wide range of material options, including thermoplastics, thermosetting plastics, and elastomers. Some of the most commonly used materials include:

Polyethylene (PE)

Polypropylene (PP)

Acrylonitrile Butadiene Styrene (ABS)

Polycarbonate (PC)

Nylon (PA)

Each material has its own set of properties, such as strength, flexibility, chemical resistance, and transparency, allowing manufacturers to choose the material that best suits the application.

2.5. Minimal Waste

Injection molding is an efficient process in terms of material usage. The process generates minimal waste, as any excess material (such as sprues, runners, and flash) can often be recycled and reused. This not only reduces material costs but also minimizes the environmental impact of the manufacturing process.

2.6. Fast Cycle Times

The cycle time in injection molding – the time it takes to complete one production cycle – is typically very fast, ranging from a few seconds to a few minutes, depending on the part size and complexity. This rapid production capability is one of the reasons why injection molding is favored for high-volume production runs.

2.7. Cost-Effectiveness

While the initial cost of designing and manufacturing a mold can be high, the per-unit cost of production is relatively low, especially when producing large quantities. This makes injection molding a cost-effective option for mass production. The ability to create multiple parts in a single cycle, known as multi-cavity molding, further enhances cost efficiency.

3. Limitations of Injection Molding

Despite its many advantages, injection molding is not without its limitations. Understanding these limitations is crucial for making informed decisions about whether injection molding is the right manufacturing process for a particular application.

3.1. High Initial Tooling Costs

One of the primary drawbacks of injection molding is the high cost of creating the mold. The mold must be custom-designed and machined from materials like steel or aluminum, which can be expensive. For small production runs or prototypes, these costs may be prohibitive.

3.2. Long Lead Times for Tooling

The process of designing, manufacturing, and testing the mold can take weeks or even months. This long lead time can be a disadvantage when rapid prototyping or quick time-to-market is required. However, once the mold is completed, production can proceed quickly.

3.3. Design Constraints

While injection molding is capable of producing complex geometries, there are certain design constraints that must be considered. For example, the need for uniform wall thickness, avoidance of sharp corners, and careful consideration of draft angles are essential to ensure successful molding. Parts with very thin walls or deep undercuts may be challenging to produce.

3.4. Material-Specific Limitations

Not all materials are suitable for injection molding. Some materials may degrade under the high temperatures and pressures required for the process, while others may be difficult to mold due to their viscosity or flow characteristics. Additionally, certain materials may require specialized molds or equipment.

3.5. Potential for Defects

Injection molding, like any manufacturing process, is susceptible to defects. Common defects include warping, sink marks, flow lines, and short shots. These defects can result from improper mold design, incorrect material selection, or issues with the injection parameters. However, with proper design and process control, many of these defects can be minimized or eliminated.

4. Applications of Injection Molding

Injection molding is a versatile process that finds applications in a wide range of industries. Some of the most common applications include:

4.1. Automotive Industry

Injection molding is extensively used in the automotive industry to produce a variety of components, including dashboards, bumpers, door panels, and interior trims. The ability to produce large, complex parts with high precision makes it an ideal choice for automotive manufacturers.

4.2. Consumer Goods

Many of the plastic products we use daily, such as containers, toys, and household appliances, are produced using injection molding. The process is well-suited for creating consumer goods that require a high level of detail, durability, and aesthetic appeal.

4.3. Medical Devices

The medical industry relies on injection molding for the production of components such as syringes, surgical instruments, and diagnostic equipment. The precision and consistency of injection molding are critical in ensuring the safety and effectiveness of medical devices.

4.4. Electronics

Injection molding is widely used in the electronics industry to manufacture components such as connectors, housings, and enclosures. The process allows for the integration of multiple features into a single part, reducing the need for assembly and improving product reliability.

4.5. Packaging

The packaging industry utilizes injection molding to produce items such as caps, closures, and containers. The ability to produce lightweight, strong, and cost-effective packaging solutions is a key advantage of injection molding in this sector.

5. Innovations in Injection Molding

As technology advances, so too does the field of injection molding. Several innovations are shaping the future of this manufacturing process, including:

5.1. Micro Injection Molding

Micro injection molding is a specialized form of injection molding used to produce extremely small and precise components, often with dimensions in the micrometer range. This technology is particularly valuable in industries such as medical devices, electronics, and microelectronics.

5.2. Multi-Material Injection Molding

Multi-material injection molding allows for the production of parts made from two or more different materials. This can be achieved through processes such as co-injection molding or overmolding, where one material is injected over another. This technique is used to create parts with different properties, such as hard-soft combinations or multi-colored components.

5.3. 3D Printing and Injection Molding Integration

The integration of 3D printing with injection molding is an emerging trend that offers new possibilities for rapid prototyping and low-volume production. 3D printing can be used to create molds or inserts for injection molding, reducing lead times and costs associated with traditional mold-making.

5.4. Advanced Materials

The development of advanced materials, such as bioplastics, high-performance polymers, and nanocomposites, is expanding the range of applications for injection molding. These materials offer enhanced properties such as improved strength, thermal resistance, and sustainability.

6. Conclusion

Injection molding is a versatile and highly efficient manufacturing process with a wide range of characteristics that make it suitable for producing a vast array of plastic parts. Its ability to create complex geometries, maintain consistency, and offer material versatility makes it a preferred choice for many industries. While there are some limitations, such as high initial tooling costs and design constraints, the benefits of injection molding often outweigh these challenges, particularly for large-scale production.

As technology continues to evolve, so too will the capabilities of injection molding. Innovations such as micro injection molding, multi-material molding, and the integration of 3D printing are pushing the boundaries of what can be achieved with this process. Whether you’re manufacturing automotive components, medical devices, or consumer goods, injection molding remains a cornerstone of modern manufacturing, offering the precision, efficiency, and flexibility needed to meet the demands of today’s market.

This comprehensive understanding of the characteristics of injection molding should provide you with the insights needed to make informed decisions about its use in your manufacturing projects. Whether you’re a seasoned engineer or new to the field, the principles and practices of injection molding will continue to play a pivotal role in the production of high-quality plastic parts for years to come.

0 notes

Text

They are the pre-shaped forms that get blown into the final bottles and containers we use every day. To ensure consistent quality and meet ever-evolving industry demands, selecting the right PET preform injectionmoulding machine manufacturers is vital.

0 notes

Video

youtube

greedaikin precision mold #machine #cnc #precision #factory #manufacturi...

0 notes

Text

Why Is 1.2311 Plastic Mould Steel Important?

1.2311 is a type of Plastic Mold Steel that holds significance in various Industrial Applications, especially in the manufacturing of Plastic Injection Molds. Here's why it's important:

1. Good Machinability: 1.2311 Plastic Mold Steel possesses good machinability properties, which means it can be easily machined into desired shapes and forms using conventional machining techniques. This attribute is crucial in mold making where precision is key.

2. Excellent Wear Resistance: It offers excellent wear resistance properties, which is essential for Plastic Molds that undergo repeated cycles of molding and demolding. This ensures that the mold maintains its shape and functionality over a long period of time.

3. High Hardness: 1.2311 Steel can be hardened to a high level, providing the necessary hardness required for withstanding the pressures and stresses encountered during the injection molding process.

4. Good Polishability: The Steel is capable of being polished to a smooth finish, which is important for achieving high-quality surface finishes on Molded Plastic Parts.

5. Good Dimensional Stability: It exhibits good dimensional stability under high temperatures and pressures, ensuring that the molds retain their shape and dimensions throughout the molding process.

6. Cost-Effective: Compared to some other mold steels, 1.2311 Steel is relatively cost-effective while still offering good mechanical properties, making it an attractive choice for many mold-making applications.

In summary, 1.2311 Plastic Mold Steel is important due to its combination of machinability, wear resistance, hardness, polishability, dimensional stability, and cost-effectiveness, all of which are critical factors in the production of high-quality plastic components through injection molding processes.

Sandeep Enterprises reputation as a respected entity within the Steel Industry is well-earned and reflects its unwavering dedication to excellence, quality, and customer satisfaction. By consistently prioritizing these core values, Sandeep Enterprises has solidified its position as a trusted partner for clients across diverse sectors.

The company's commitment to delivering superior Products and Services is evident in its adherence to stringent quality control measures. By maintaining high standards throughout the production process, Sandeep Enterprises ensures that its steel products consistently meet or exceed industry requirements and customer expectations.

#SandeepEnterprises hashtag#Steel hashtag#PlasticMoulding hashtag#InjectionMoulding hashtag#MouldMaking hashtag#SteelAlloy hashtag#Manufacturing hashtag#IndustrialEngineering hashtag#ToolAndDie hashtag#MouldSteel hashtag#InjectionMoulds hashtag#PrecisionMachining

0 notes

Video

youtube

RAYING MOULD Professional mould maker2023

#youtube#Having no selfishness with the best motive. RAYINGMOULD Helping you succeed. diecastings injectionmoulds toolingmaker in china injectionmold

0 notes

Text

Because the plant extension, the mold factory chagnged the new name as: Rost mold! We will be your reliable partner in China!

#injectionmold #plastmold #plasticmould #injectionmould #injectionmoulding #imm #inyeccionmold #bucketmold #chairmold #petmold #householdmold #dailyusemold #electricmold #autopartsmold #doublecolormold #irrigationmold

#injection molding#plastic molding#plastic#injection moulding machine#injection manufacturing company#injection mold

0 notes

Text

Injection Moulding Machine Manufacturers

Shivam Engitech is one of the most trusted InjectionMoulding Machine Manufacturers & Suppliers in Ahmedabad, India. our plastic injection moulding machines have been praised by potential clients all over the world.

Visit to know more.https://shivamengitech.com/

0 notes

Text

Welcome old customers of Algeria for ten years to haituo to continue to discuss orders. #haituo #haituomachine #haitian #haitai #bole #iran #turkey #Pakistan #Algeria #Brazil #Egypt #Korea #Dubai #Thailand #India #Iraq #China #4sale #agent #plastics #used #injectionmolding #machine

#moldes #highquality #maquinaria #export #injectionmould #mouldmanufacturer #moldmaker

0 notes

Text

Adapt and innovate with Moulds Conversion services from Ashish Tools. Whether you need to upgrade, modify, or convert your existing moulds, Ashish Tools offers expert solutions to meet your evolving needs. Their conversion services help optimize your production processes, increase efficiency, and reduce costs. Rely on Ashish Tools for seamless and effective mould conversion.

#MouldConversion#AshishTools#Manufacturing#IndustrialSolutions#InjectionMoulding#ProductionEfficiency

0 notes

Text

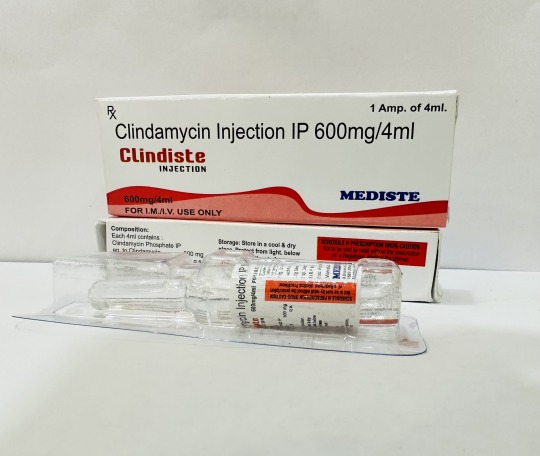

INJ. CLINDAMYCIN 600MG 4ML

.

.

injectionputihmalaysia #injectionevent #injectionbooster #injectionmoulding #injectionph #injectiontooling #injectionmachine #injectionstoronto #injectionstemcell #Injectionday #injectionmold #injectioncars #injectionmoldingparts

1 note

·

View note

Text

Thin-wall injection molding is difficult, here is list of common problems!

Thin-wall injection molding is difficult, here is list of common problems!

Thin-wall injection molding is mainly used in:According to surveys, domestic thin-wall injection molding has been widely used in food containers, medical boxes, cosmetics, stationery and even multimedia packaging. For example: disposable packing boxes, cosmetics bottles and other daily necessities. What is thin-wall injection Thin-wall injection molding technology is also known as thin-wall…

View On WordPress

0 notes

Text

Explore precision crafting with our pet preform injection moulding machine manufacturer. With state-of-the-art technology and meticulous craftsmanship, we deliver high-quality machines tailored to your needs.

#pet preform injectionmoulding machine manufacturers#injection moulding machine manufacturers in ahmedabad

0 notes

Video

youtube

Taiwan Daqian five axis machining center

#youtube#Zhuhai Gree Daikin Precision Mold (GDM) Taiwan Daqian five-axis machining center for injectionMold,injectionMould,injectionMolding,injectio

0 notes

Text

What are the key properties and applications of P20 Steel Grade, and how does it compare to other tool steel grades in terms of performance and versatility?

P20 Steel, also known as P20 tool steel, is a versatile and widely used mold steel with several key properties and applications:

Key Properties of P20 Steel:

1. Excellent Machinability: P20 Steel exhibits good machinability, allowing for easy shaping and fabrication of molds and components.

2. High Hardenability: It has high hardenability, meaning it can be hardened throughout its cross-section when properly heat-treated, resulting in excellent wear resistance.

3. Good Polishing Ability: P20 Steel can be polished to a high surface finish, making it suitable for applications requiring fine detail and aesthetic appeal.

4. Good Toughness: P20 Steel offers good toughness, which helps prevent cracking and chipping during use, enhancing the durability of molds and components.

5. Excellent Dimensional Stability: It maintains its shape and size even under high temperatures and pressures, ensuring precision and consistency in molded products.

Applications of P20 Steel:

1. Injection Molding: P20 Steel is widely used for manufacturing injection molds for plastic components due to its excellent polishability, wear resistance, and dimensional stability.

2. Extrusion Dies: It is also used in the production of extrusion dies for plastic and rubber processing, where high wear resistance and toughness are required.

3. Die Casting: P20 Steel finds applications in die casting dies for non-ferrous metals, providing good thermal conductivity and resistance to thermal fatigue.

4. Forming Tools: P20 steel is used to manufacture forming tools, such as bending and stamping dies, where high wear resistance and toughness are essential.

Comparison with Other Tool Steel Grades:

1. Compared to H13 Steel: While H13 Steel offers higher heat resistance and hardness retention at elevated temperatures, P20 steel is preferred for applications requiring polishability, ease of machining, and excellent wear resistance at lower temperatures.

2. Compared to D2 Steel: D2 Steel offers higher wear resistance and edge retention compared to P20 steel, but it may be more difficult to machine and polish. P20 steel is often chosen for applications where polishability and machinability are critical.

3. Compared to S7 Steel: S7 Steel provides superior impact resistance and toughness compared to P20 steel, but P20 steel offers better wear resistance and dimensional stability, making it more suitable for applications requiring high precision and surface finish.

In summary, P20 Steel stands out for its excellent combination of machinability, polishability, wear resistance, toughness, and dimensional stability, making it a preferred choice for a wide range of tooling and mold-making applications in the manufacturing industry.

Sandeep Enterprises stands as a respected entity within the Steel Industry, underscored by its unwavering dedication to excellence, quality, and customer satisfaction. With a steadfast commitment to delivering superior products and services, Sandeep Enterprises has established itself as a trusted partner for clients across various sectors. From stringent quality control measures to innovative solutions tailored to meet diverse industry needs, Sandeep Enterprises consistently strives to exceed expectations. This dedication to excellence permeates every aspect of its operations, cementing its reputation as a leader in the Steel Industry.

#SandeepEnterprises#P20Steel#ToolSteel#Engineering#MoldMaking#InjectionMolding#ExtrusionDies#DieCasting#FormingTools#SteelIndustry#Manufacturing#PrecisionEngineering#P20PlasticMouldSteel#MouldMaking#Tooling#InjectionMoulding#PlasticManufacturing#SteelAlloy#MouldDesign#P20#PlasticIndustry

0 notes