#injectionmould

Text

Thin-wall injection molding is difficult, here is list of common problems!

Thin-wall injection molding is difficult, here is list of common problems!

Thin-wall injection molding is mainly used in:According to surveys, domestic thin-wall injection molding has been widely used in food containers, medical boxes, cosmetics, stationery and even multimedia packaging. For example: disposable packing boxes, cosmetics bottles and other daily necessities.

What is thin-wall injection

Thin-wall injection molding technology is also known as thin-wall…

View On WordPress

0 notes

Text

Ejector Plates

If an ejector plate does deflect to any extent, side forces are applied to the ejector elements which result in increased wear in the mold plate holes, bent ejector pins, and, in extreme cases, the complete seizure of the system.

During the injection part of the cycle, with certain pin and sleeve type ejector systems, the melt pressure acts directly on the ejector element. To prevent the ejector elements from being hobbed into the ejector plate by the applied force, reasonably tough steel must be specified for this member. General-purpose medium-carbon steel (BS 970-080 M40) is suitable.

Click here to read more.

Thank You

1 note

·

View note

Text

Mould Design in Plastic Injection Moulding

Injection Moulding is an extremely versatile procedure. It can be utilised for virtually any product. Injection moulding is the industry standard for manufacturing components for products.

There are some limitation needs to consider. Here are the rules to follow when designing your product to make sure quality and durability:

Wall Thickness

Keeping your walls thin will ensure a faster cooling rate and less materials used. Lower cooling rate and less material used will result in a shorter cycle time. This allows you more parts in a shorter amount of time, for less production cost

To strengthen parts, ribs are more effective than thicker walls. Adding ribs at right angles to a wall will add considerably to its overall strength. It is a common mistake to thicken the walls of a design to achieve this effect when ribs are a cheaper and more effective option.

Ribs should be about half the main wall thickness. There can be some leniency here, but not too much or the ribs will be completely ineffective. Half is the generally accepted standard and is more than enough to increase a wall’s strength.

Coherence

Try to make your design uniform throughout. That is, wall thickness, rib thickness and corner radii, for instance, should all be the same values. This will help the part to cool uniformly.

Corners & Edges

Corners could be an issue in a mould and will not come out flush. It is difficult to form plastic into a flawless corner. The outcome will look amateurish and messy, not to mention the power of the components can be compromised.

Corners and edges should be rounded wherever possible. Sharp edges do not always come out perfectly when the part is ejected from the mould.

Add a slight angle to the sides of your mould to allow easy release. A one- or two-degree angle should be applied to the mould on the face perpendicular to the parting line. This will allow for easy removal of the part from the mould.

Ribs

These are structural factors for your component, utilised for general stability control. Ribs are thin wall protrusions which extend vertically from a plane or wall. Adding ribs instead of thicker walls will provide greater structural support.

Bosses

These are empty, cylindrical protrusions. These are normally integrated in a style for accepting screws or other mating parts of your style. Making sure these are secured by attaching them a wall. Putting in ribs will means the bosses will stay straight as well as accommodate the part it was made for without an issue.

External Undercuts

A depression or protrusion in the exterior of the mould – the cavity half – could create issues if trying to divide parts from the mould. Adjust the parting line to lodge this.

Internal Undercuts and Overcuts

Related to external undercuts, these depressions or protrusions are within the mould – on the centre half. Adjust the parting line to lodge this.

Protrusions on the part that will snag on the mould core or cavity when it is opened can make it impossible to remove from the mould.

Threads

When your mould has a thread, always position it vertical to the parting column. This will make sure that the delicate thread isn’t damaged. It’s better, preferably, to not comprise a thread at all in the design. Making your design simple will lower the odd of something going wrong.

Injection mouldingdesign makes a superior product. The myriad possibilities far outdo the limitations. Designing for an excellent injection moulded part is the core of the design process. These restrictions are the guidelines for making a flexible end product.

Colour use

Where possible, use lighter colours for your moulds. The mould is already cool when the molten material is being injected. As such it begins the setting process immediately and will sometime leave setting patterns. Using lighter colours will help y.to hide these patterns.

Injection mouldingis the industry standard for creating lasting, quality parts. To be able to take advantage of this technology your design must meet its minimum requirements. Small considerations are all it takes and the result is a successful product that will meet all of your quality needs.

If you would like to find out more or have any questions please do not hesitate to get in touch, contact details can be found below:

Email: [email protected] or [email protected]

Tel: 01455 558825

Mob: 07754 857071

Our Socials can also be found below:

LinkedIn: https://www.linkedin.com/company/dudley-associates-ltd/

Instagram: https://www.instagram.com/dudleyassociates

Twitter: Dudley Associates (@DALPlastics) / Twitter

Facebook: https://www.facebook.com/DudleyAsssociates

#plastic injection molding#plastic injection moulding#injectionmoulders#injection moulding#injectionmouldtooling#injection mould toolmaking#toolmaking#tool making#toolmakers#tooling#rapid prototyping#productdevelopment#product design#productdesign#made in uk#made in britain

2 notes

·

View notes

Text

Explore precision crafting with our pet preform injection moulding machine manufacturer. With state-of-the-art technology and meticulous craftsmanship, we deliver high-quality machines tailored to your needs.

#pet preform injectionmoulding machine manufacturers#injection moulding machine manufacturers in ahmedabad

0 notes

Text

Why Is 1.2311 Plastic Mould Steel Important?

1.2311 is a type of Plastic Mold Steel that holds significance in various Industrial Applications, especially in the manufacturing of Plastic Injection Molds. Here's why it's important:

1. Good Machinability: 1.2311 Plastic Mold Steel possesses good machinability properties, which means it can be easily machined into desired shapes and forms using conventional machining techniques. This attribute is crucial in mold making where precision is key.

2. Excellent Wear Resistance: It offers excellent wear resistance properties, which is essential for Plastic Molds that undergo repeated cycles of molding and demolding. This ensures that the mold maintains its shape and functionality over a long period of time.

3. High Hardness: 1.2311 Steel can be hardened to a high level, providing the necessary hardness required for withstanding the pressures and stresses encountered during the injection molding process.

4. Good Polishability: The Steel is capable of being polished to a smooth finish, which is important for achieving high-quality surface finishes on Molded Plastic Parts.

5. Good Dimensional Stability: It exhibits good dimensional stability under high temperatures and pressures, ensuring that the molds retain their shape and dimensions throughout the molding process.

6. Cost-Effective: Compared to some other mold steels, 1.2311 Steel is relatively cost-effective while still offering good mechanical properties, making it an attractive choice for many mold-making applications.

In summary, 1.2311 Plastic Mold Steel is important due to its combination of machinability, wear resistance, hardness, polishability, dimensional stability, and cost-effectiveness, all of which are critical factors in the production of high-quality plastic components through injection molding processes.

Sandeep Enterprises reputation as a respected entity within the Steel Industry is well-earned and reflects its unwavering dedication to excellence, quality, and customer satisfaction. By consistently prioritizing these core values, Sandeep Enterprises has solidified its position as a trusted partner for clients across diverse sectors.

The company's commitment to delivering superior Products and Services is evident in its adherence to stringent quality control measures. By maintaining high standards throughout the production process, Sandeep Enterprises ensures that its steel products consistently meet or exceed industry requirements and customer expectations.

#SandeepEnterprises hashtag#Steel hashtag#PlasticMoulding hashtag#InjectionMoulding hashtag#MouldMaking hashtag#SteelAlloy hashtag#Manufacturing hashtag#IndustrialEngineering hashtag#ToolAndDie hashtag#MouldSteel hashtag#InjectionMoulds hashtag#PrecisionMachining

0 notes

Video

youtube

RAYING MOULD Professional mould maker2023

#youtube#Having no selfishness with the best motive. RAYINGMOULD Helping you succeed. diecastings injectionmoulds toolingmaker in china injectionmold

0 notes

Text

Features of Syringe Mould!

Allied Way India top a leading manufacturer and supplier of Syringe Mould machine. This machine operates different parts of the syringe, such as the syringe barrel mold, and syringe gasket mould of different sizes and spaces. Get in touch with us, for further information.

#syringemould#syringemouldSupplier#syringemouldexporter#Treatment#Syringe#syringemouldmanufacturer#injectionmoulding#plasticinjectionmoulding#Medical#Faridabad#Haryana#India#AlliedWayIndia#quality

0 notes

Text

Extract the Plastic Products Manufacturers, Suppliers, and Exporters' data

Our experts will help you to get accurate and well-managed scraped data such as Company name, Address, Contact information, Website Url, Activities, Products and their descriptions, etc.

For more information, visit our official page https://www.linkedin.com/company/hir-infotech/ or contact us at [email protected]

#plasticmanufacturers#exporter#importer#suppliers#datascraping#hirinfotech#webscraping#industrialautomation#injectionmoulding#foodpackaging#plasticmoldmaker#india#usa#canada

1 note

·

View note

Photo

06 Ekim 2022 Workshop (13.00 - 15.00) . Bora Korkut . Anterior Estetik Restorasyonlarda ‘Injection Moulding’ Tekniği . ➡️ Daha fazlası EDAD 2022 Kongresinde! Kayıt için www.edad2022.org . @dr.borakorkut @gencedad gcturkiye #borakorkut #edad #gençedad #dishekimi #disteknisyeni #anterior #estetikrestorasyon #injectionmoulding #gaenialuniversalinjectable #restorativedentistry #gc #gctürkiye https://www.instagram.com/p/ChwNmSPqqq2/?igshid=NGJjMDIxMWI=

#borakorkut#edad#gençedad#dishekimi#disteknisyeni#anterior#estetikrestorasyon#injectionmoulding#gaenialuniversalinjectable#restorativedentistry#gc#gctürkiye

0 notes

Photo

Playing with 2 new injection molds. . #belitzdesign #belitz #design #enginreeng #molds #injectionmoulding https://www.instagram.com/p/Cf5pidMOJrM/?igshid=NGJjMDIxMWI=

0 notes

Text

6 heat treatment issues to help you understand heat treatment!

6 heat treatment issues to help you understand heat treatment!

First, what is annealing of steel? What are types of annealing and what are its uses?

Annealing of steel:

Annealing is a heat treatment process in which steel is heated to a temperature above or below critical point AC1 and then slowly cooled with furnace after a certain period of time to obtain a near-equilibrium structure.

Annealing type:

According to heating temperature, it can be divided…

View On WordPress

0 notes

Text

The purpose of this member is to transmit the ejector force from the actuating system of the injection machine to the molding via an ejector element.

The force required to eject a molding is appreciable, particular with those moldings which are deep and which incorporate little draft. Most ejector plates that fail in operation do so in fact because too thin a plate is specified in the design. The ejector plate must be sufficiently thick not to deflect to any significant extent. Deflection tends to occur at the beginning of the ejector stroke when there is maximum adhesion between the molding and the core. The deflection of any beam is inversely proportional to the cube of its depth and, therefore, a relatively small increase in plate thickness will decrease the deflection of the plate.

1 note

·

View note

Text

Injection Moulding & Toolmaking – A Little Bit More About Us

How Can We Help?

Design and Development:

We can help you achieve your goal of production injection moulded parts from any starting point. Whether you already have the design & drawings or have an idea & need us to do the designing for you.

We can offer full product design services using the latest CAD software to produce your components, with all part designs optimised for injection moulding. We can advise on material choice and work closely with many material suppliers to ensure that you get the right material for your job. When the design is complete we can supply prototypes for design validation.

Rapid Prototyping:

We can manufacture your prototype at the very early stages of design and testing to ensure that the finished products fit requirements & specifications exactly.

At Dudley Associates, we offer this service to our customers because we believe in providing the very best level of service and are dedicated to getting the project right every time. So if a project needs a little more help to get there, then rapid prototyping is a more cost effective & faster solution. Producing premium quality but low cost prototypes from CAD data sources.

Injection Moulding:

Injection Moulding is a manufacturing process for producing identical plastic parts. It is suitable for low to high volumes and small to large parts. Plastic polymers are available to suit every application for the final component, according to the need for strength, durability, conductivity, aesthetic finish, fire rating, ect.

Before we can make the plastic components, we need an injection mould tool. An injection mould tool can be design to produce a single part at a time or it can have multiple impressions of identical, mirrored or different components.

Toolmaking:

An injection mould tool is effectively the mould into which molten plastic polymer material is injected. The polymer then cool inside the mould, solidifies and forms the unique shape mandated by the design, after the designated cooling time, the tool is automatically separated into the the two halves and the components are ejected and removed.

When we are initially discussing a project with a client, we will establish the key facts around the final application. this will lead to the most suitable material for both the mould tool and moulded components, and the structure of the tool.

#injectionmoulding#plasticinjectionmoulding#rapidprototyping#productdesign#productdevelopment#tooling#toolmaking#toolmaker#madeinbritain#ukmanufacturing#ukmfg#manufacturing

2 notes

·

View notes

Text

What are the key properties and applications of P20 Steel Grade, and how does it compare to other tool steel grades in terms of performance and versatility?

P20 Steel, also known as P20 tool steel, is a versatile and widely used mold steel with several key properties and applications:

Key Properties of P20 Steel:

1. Excellent Machinability: P20 Steel exhibits good machinability, allowing for easy shaping and fabrication of molds and components.

2. High Hardenability: It has high hardenability, meaning it can be hardened throughout its cross-section when properly heat-treated, resulting in excellent wear resistance.

3. Good Polishing Ability: P20 Steel can be polished to a high surface finish, making it suitable for applications requiring fine detail and aesthetic appeal.

4. Good Toughness: P20 Steel offers good toughness, which helps prevent cracking and chipping during use, enhancing the durability of molds and components.

5. Excellent Dimensional Stability: It maintains its shape and size even under high temperatures and pressures, ensuring precision and consistency in molded products.

Applications of P20 Steel:

1. Injection Molding: P20 Steel is widely used for manufacturing injection molds for plastic components due to its excellent polishability, wear resistance, and dimensional stability.

2. Extrusion Dies: It is also used in the production of extrusion dies for plastic and rubber processing, where high wear resistance and toughness are required.

3. Die Casting: P20 Steel finds applications in die casting dies for non-ferrous metals, providing good thermal conductivity and resistance to thermal fatigue.

4. Forming Tools: P20 steel is used to manufacture forming tools, such as bending and stamping dies, where high wear resistance and toughness are essential.

Comparison with Other Tool Steel Grades:

1. Compared to H13 Steel: While H13 Steel offers higher heat resistance and hardness retention at elevated temperatures, P20 steel is preferred for applications requiring polishability, ease of machining, and excellent wear resistance at lower temperatures.

2. Compared to D2 Steel: D2 Steel offers higher wear resistance and edge retention compared to P20 steel, but it may be more difficult to machine and polish. P20 steel is often chosen for applications where polishability and machinability are critical.

3. Compared to S7 Steel: S7 Steel provides superior impact resistance and toughness compared to P20 steel, but P20 steel offers better wear resistance and dimensional stability, making it more suitable for applications requiring high precision and surface finish.

In summary, P20 Steel stands out for its excellent combination of machinability, polishability, wear resistance, toughness, and dimensional stability, making it a preferred choice for a wide range of tooling and mold-making applications in the manufacturing industry.

Sandeep Enterprises stands as a respected entity within the Steel Industry, underscored by its unwavering dedication to excellence, quality, and customer satisfaction. With a steadfast commitment to delivering superior products and services, Sandeep Enterprises has established itself as a trusted partner for clients across various sectors. From stringent quality control measures to innovative solutions tailored to meet diverse industry needs, Sandeep Enterprises consistently strives to exceed expectations. This dedication to excellence permeates every aspect of its operations, cementing its reputation as a leader in the Steel Industry.

#SandeepEnterprises#P20Steel#ToolSteel#Engineering#MoldMaking#InjectionMolding#ExtrusionDies#DieCasting#FormingTools#SteelIndustry#Manufacturing#PrecisionEngineering#P20PlasticMouldSteel#MouldMaking#Tooling#InjectionMoulding#PlasticManufacturing#SteelAlloy#MouldDesign#P20#PlasticIndustry

0 notes

Text

Welcome old customers of Algeria for ten years to haituo to continue to discuss orders. #haituo #haituomachine #haitian #haitai #bole #iran #turkey #Pakistan #Algeria #Brazil #Egypt #Korea #Dubai #Thailand #India #Iraq #China #4sale #agent #plastics #used #injectionmolding #machine

#moldes #highquality #maquinaria #export #injectionmould #mouldmanufacturer #moldmaker

0 notes

Text

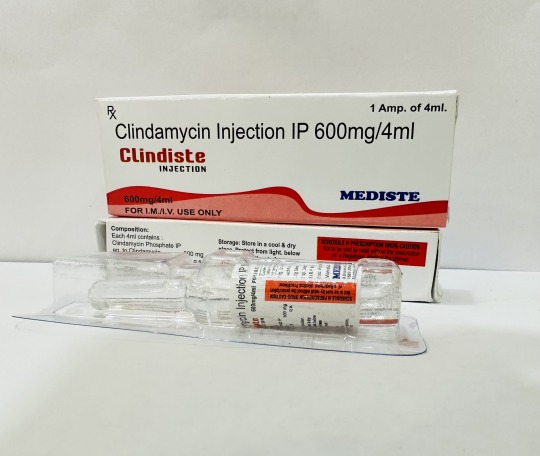

INJ. CLINDAMYCIN 600MG 4ML

.

.

injectionputihmalaysia #injectionevent #injectionbooster #injectionmoulding #injectionph #injectiontooling #injectionmachine #injectionstoronto #injectionstemcell #Injectionday #injectionmold #injectioncars #injectionmoldingparts

1 note

·

View note