#Inkjet Batch Coding Machine

Explore tagged Tumblr posts

Text

Boost Traceability and Compliance with an Inkjet Batch Coding Machine

Stay ahead of industry standards and meet regulatory demands effortlessly with an Inkjet batch coding machine. Designed for precision and adaptability, these machines provide fast, non-contact coding for a wide range of materials and packaging formats. Ideal for fast-moving consumer goods, pharmaceuticals, and industrial products, an Inkjet batch coding machine allows you to print detailed data—like manufacturing dates, expiry information, and serial numbers—directly onto your products. With features like quick-dry ink, variable font sizes, and customizable settings, it enhances traceability, prevents counterfeiting, and boosts brand credibility. Make your packaging smarter and your production line more efficient with this powerful tool.

1 note

·

View note

Text

Domino Presents New Monochrome Inkjet Printer at Labelexpo Southeast Asia 2025

Domino Printing Sciences (Domino) is pleased to announce the APAC launch of its new monochrome inkjet printer, the K300, at Labelexpo Southeast Asia. Building on the success of Domino’s K600i print bar, the K300 has been developed as a compact, flexible solution for converters looking to add variable data printing capabilities to analogue printing lines.

The K300 monochrome inkjet printer will be on display at the Nilpeter stand, booth F32, at Labelexpo Southeast Asia in Bangkok, Thailand from 8th–10th May 2025. The printer will form part of a Nilpeter FA-Line 17” hybrid label printing solution, providing consistent inline overprint of serialised 2D codes. A machine vision inspection system by Domino Company Lake Image Systems will validate each code to ensure reliable scanning by retailers and consumers whilst confirming unique code serialisation.

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,” explains Alex Mountis, Senior Product Manager at Domino. “Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands. We have developed the K300 with these variable data and 2D code printing opportunities in mind.”

The K300 monochrome inkjet printer can be incorporated into analogue printing lines to customise printed labels with variable data, such as best before dates, batch codes, serialised numbers, and 2D codes. The compact size of the 600dpi high-resolution printhead – 2.1″ / 54mm – offers enhanced flexibility with regards to positioning on the line, including the opportunity to combine two print stations across the web width to enable printing of two independent codes.

Operating at high speeds up to 250m / 820′ per minute, the K300 monochrome inkjet printer has been designed to match flexographic printing speeds. This means there is no need to slow down the line when adding variable data. Domino’s industry-leading ink delivery technology, including automatic ink recirculation and degassing, helps to ensure consistent performance and excellent reliability, while reducing downtime due to maintenance. The printer has been designed to be easy to use, with intuitive setup and operation via Domino’s smart user interface.

“The K300 will open up new opportunities for converters. They can support their brand customers with variable data 2D codes, enabling supply chain traceability, anti-counterfeiting, and consumer engagement campaigns,” adds Mountis. “The versatile printer can also print variable data onto labels, cartons, and flatpack packaging as part of an inline or near-line late-stage customisation process in a manufacturing facility, lowering inventory costs and reducing waste.”

Code verification is an integral part of any effective variable data printing process. A downstream machine vision inspection system, such as the Lake Image Systems’ model showcased alongside the K300, enables converters and brands who add 2D codes and serialisation to labels and packaging to validate each printed code.

Mark Herrtage, Asia Business Development Director, Domino, concludes: “We are committed to helping our customers stay ahead in a competitive market, and are continuously working to develop new products that will help them achieve their business objectives. Collaborating with Lake Image Systems enables us to deliver innovative, complete variable data printing and code verification solutions to meet converters’ needs. We are delighted to be able to showcase an example of this collaboration, featuring the .”

To find more information about the K300 monochrome printer please visit: https://dmnoprnt.com/38tcze3r

#inkjet printer#variable data printing#biopharma packaging#glass pharmaceutical packaging#pharmaceutical packaging and labelling#Labelexpo Southeast Asi

2 notes

·

View notes

Text

Hidden Costs of Choosing the Wrong Industrial Coding Machine

Understand the many applications of industrial coding with Technopack's inkjet coders. These machines deliver high-speed, accurate printing for batch numbers, expiration dates, and barcodes, supporting diverse production lines across food, pharma, and logistics sectors.

1 note

·

View note

Text

Label Printer Machine: The Ultimate Guide for Efficient and Professional Product Labeling

What is a Label Printer Machine?

A label printer machine is a device that prints custom or standardized labels for products, containers, cartons, and shipping packages. It can print on paper, plastic, thermal material, or synthetic labels using technologies like thermal transfer, direct thermal, or inkjet. Label printer machines are essential in packaging, inventory management, retail, pharmaceuticals, logistics, and food processing.

Types of Label Printer Machines

1. Thermal Transfer Label Printers

These use heat to transfer ink from a ribbon onto the label. Ideal for long-lasting, waterproof, smudge-resistant labels, commonly used in pharmaceuticals, electronics, and industrial labeling.

2. Direct Thermal Label Printers

No ribbon is used; heat-sensitive label paper darkens when heated. Best for short-term applications like shipping labels, receipts, and food packaging.

3. Inkjet Label Printers

Produce high-resolution, colorful labels. Suitable for custom branding, marketing labels, and retail packaging.

4. Laser Label Printers

Offer speed and sharpness. Used when mass label printing is needed, especially for office or warehouse environments.

5. Portable Label Printers

Handheld or mobile devices used in field service, retail, logistics, and inventory control.

6. RFID Label Printers

Print and encode RFID tags and barcodes for real-time tracking and supply chain automation.

Common Applications Across Industries

1. Food and Beverage

Nutritional labels, expiry dates, batch codes

Tamper-evident and waterproof labels

2. Pharmaceuticals

Regulatory-compliant labels with dosage info, QR codes, batch numbers

High print precision and barcode clarity

3. Cosmetics

High-resolution brand and ingredient labels

Sleek, colorful, water-resistant finishes

4. Manufacturing

Asset labels, compliance tags, quality control stickers

5. Logistics and Warehousing

Shipping and barcode labels

SKU and inventory management tags

6. Retail

Price tags, promotional stickers, and shelf labels

Key Features of High-Quality Label Printer Machines

1. Print Resolution

Measured in DPI (dots per inch). For clear text and barcodes, 203 DPI is standard, while 300–600 DPI is used for high-definition images and small text.

2. Print Speed

Ranges from 2 to 14 inches per second (IPS). Higher speeds are ideal for bulk printing operations.

3. Connectivity Options

USB, Ethernet, Bluetooth, Wi-Fi—essential for integration with POS systems, warehouse management software, or industrial PLCs.

4. Media Compatibility

Should support a variety of label rolls: paper, PET, PP, BOPP, synthetic, glossy, and matte.

5. Software Integration

Compatibility with label design software like BarTender, NiceLabel, or ZebraDesigner.

6. Auto-Cutter and Peeler

Helps in high-speed workflows by automatically cutting or peeling off printed labels.

Advantages of Using a Label Printer Machine

Professional Packaging: Clean, precise labels reflect product quality

Customization: Easily print logos, barcodes, and QR codes on demand

Efficiency: Reduce dependency on pre-printed labels and minimize stockouts

Compliance: Meet legal labeling requirements effortlessly

Traceability: Boost product tracking across supply chains

Cost-Saving: In-house label printing reduces outsourcing costs

0 notes

Text

Sticker Label Roll Counting and Winding/Rewinding Machine – Precision, Speed & Smart Coding in One Compact Unit. Engineered for accuracy and efficiency, this high-speed machine not only counts label rolls but also enables on-the-go batch coding, pricing, and date marking using advanced inkjet technology.

For more details, visit - https://www.bhagwatilabeling.com/products/sticker-label-roll-counting-and-winding-rewinding-machine/

#bhagwatilabelling#StickerLabelMachine#LabelRollCounting#RewindingMachine#BatchCoding#InkjetCoding#LabelingSolutions#PrecisionLabeling#SmartLabeling

0 notes

Video

youtube

Auto L sealer machine with Shrink tunnel machine

Royal Inks & Equipments Pvt. Ltd.

Pioneering Excellence in Printing Inks & Industrial Machinery Since 1994.

At Royal Inks & Equipments Pvt. Ltd., we are a trusted manufacturer and supplier of high-quality printing inks and industrial coding & marking solutions. With over 25 years of industry expertise, we have been at the forefront of innovation, precision, and reliability in the printing and packaging industry, catering to both domestic and international markets.

Our Product Range 🔹 Printing Inks: ✔️ Marking Inks – Ensuring long-lasting impressions and superior adhesion. ✔️ Water-Based Flexographic Inks – Ideal for eco-friendly, high-speed printing applications. ✔️ Solvent-Based Poly Inks – Designed for flexible packaging and high-quality prints. ✔️ Lino Inks & Offset Inks – Delivering sharp, vibrant, and consistent color output. 🔹 Industrial Coding & Packaging Machinery: ✔️ Handy Coder Machines – Reliable for batch coding and marking. ✔️ Batch Coding & Inkjet Coding Machines – Enabling seamless product labeling and traceability. ✔️ Auto Coder Machines – Designed for automated, high-speed printing requirements. ✔️ Filler & Packing Machines – Enhancing efficiency in packaging operations.

0 notes

Text

Batch Coding Machine: Revolutionizing Efficiency in Manufacturing

In today’s rapidly evolving manufacturing landscape, batch coding machines have become indispensable tools for businesses striving to maintain accuracy, efficiency, and compliance. These machines ensure that products are labeled with critical information, such as batch numbers, expiration dates, and barcodes, which is essential for both consumers and regulatory agencies. Below, we dive deep into the world of batch coding machines, exploring their types, functionalities, benefits, and how they are transforming industries worldwide.

What is a Batch Coding Machine?

A batch coding machine is a device designed to print or emboss essential information on products or packaging. This information includes manufacturing dates, expiration dates, batch numbers, and other identifiers that help track products throughout the supply chain. These machines are widely used across industries such as pharmaceuticals, food and beverages, cosmetics, and electronics.

With advancements in technology, batch coding machines now incorporate features like high-speed printing, automated adjustments, and error detection, making them more reliable and efficient than ever.

Types of Batch Coding Machines

1. Inkjet Batch Coding Machines

Inkjet printers are among the most common batch coding solutions. They use tiny nozzles to spray ink onto surfaces, creating clear and precise codes. These machines are suitable for high-speed production lines and can print on a variety of surfaces, including paper, plastic, glass, and metal.

Advantages:

High-speed printing

Suitable for various surfaces

Low maintenance requirements

2. Laser Batch Coding Machines

Laser coding machines use focused laser beams to etch information onto surfaces. These machines are ideal for industries requiring permanent and tamper-proof markings.

Advantages:

Permanent markings

No need for consumables like ink

Eco-friendly and cost-effective over time

3. Thermal Transfer Batch Coding Machines

Thermal transfer printers use heat to transfer ink from a ribbon onto the surface of a product or label. These machines are commonly used in industries where high-resolution printing is required.

Advantages:

High-quality prints

Ideal for flexible packaging

Durable codes resistant to smudging

4. Contact Coding Machines

Contact coders use a stamping mechanism to transfer ink onto a product. Though older than other methods, they are still used in industries where simplicity and cost-effectiveness are priorities.

Advantages:

Simple operation

Low initial cost

Reliable for low-volume production

Key Features of Modern Batch Coding Machines

1. Versatility

Modern batch coding machines are designed to handle a wide range of materials, including cardboard, plastic, glass, and metal. This versatility makes them suitable for diverse industries.

2. Integration with Production Lines

Advanced models can seamlessly integrate with production lines, ensuring that coding operations do not disrupt workflow.

3. User-Friendly Interfaces

Most machines now come equipped with touchscreen interfaces and intuitive software, allowing operators to easily adjust settings and monitor performance.

4. Compliance with Regulations

Batch coding machines ensure adherence to regulatory standards, such as those set by the FDA, ensuring that products meet legal requirements.

Benefits of Using Batch Coding Machines

1. Improved Traceability

Batch coding ensures that products can be tracked from production to distribution, which is critical for quality control and recall management.

2. Enhanced Brand Reputation

Accurate and professional-looking batch codes enhance the perceived quality of a product, boosting customer confidence and brand loyalty.

3. Cost Savings

By automating the coding process, manufacturers can reduce labor costs and minimize errors, leading to significant cost savings over time.

4. Increased Efficiency

Modern machines operate at high speeds and require minimal supervision, allowing businesses to optimize their production workflows.

Applications of Batch Coding Machines

1. Pharmaceutical Industry

In the pharmaceutical sector, batch coding is crucial for ensuring product safety and compliance. Machines print batch numbers, expiration dates, and barcodes on medicine bottles, blister packs, and cartons.

2. Food and Beverage Industry

Batch coding machines help maintain food safety by providing essential information, such as expiry dates and batch details, on packaging.

3. Electronics Industry

In the electronics industry, batch coding is used to label components with serial numbers and manufacturing details, ensuring proper assembly and quality control.

4. Cosmetics Industry

Batch coding machines play a vital role in labeling cosmetic products with lot numbers and expiration dates, meeting both consumer demands and regulatory requirements.

Choosing the Right Batch Coding Machine

When selecting a batch coding machine, consider the following factors:

Type of Material: Ensure the machine is compatible with the materials used in your products.

Production Speed: Choose a model that matches your production line’s output.

Budget: Factor in both initial costs and long-term operational expenses.

Regulatory Compliance: Opt for machines that meet industry-specific standards.

Ease of Use: Look for user-friendly features like touchscreen interfaces and automated adjustments.

Future Trends in Batch Coding Technology

1. AI Integration

Artificial Intelligence is being integrated into batch coding systems to enhance error detection and predictive maintenance.

2. Sustainability

Manufacturers are focusing on eco-friendly solutions, such as laser coding and biodegradable inks, to reduce their environmental impact.

3. IoT Connectivity

The Internet of Things (IoT) allows machines to be connected to central systems, enabling real-time monitoring and data analysis.

Conclusion

Batch coding machines are essential for modern manufacturing, offering unparalleled efficiency, accuracy, and compliance. By investing in the right batch coding solution, businesses can streamline their operations, enhance product traceability, and build consumer trust.

0 notes

Text

A Comparative Analysis for Variable Data Printing vs. Traditional Printing

The printing industry has seen significant advancements over the years, particularly with the introduction of variable data printing (VDP). This technology allows for the printing of individualized information on each sheet, such as alphanumeric characters, addresses, barcodes, QR codes, and logos.

What is Variable Data Printing?

Variable data printing (VDP) involves printing unique data on each sheet, which is crucial for applications requiring personalized information. This technology supports high-speed printing on various substrates like Colour Wove, Maplitho, Art Paper, Duplex Board up to 350 gsm, and NCR Sheet. The Autoprint Reckoner VDP65 is an example of a machine that leverages HP Inkjet Technology to offer efficient numbering, barcoding, mail addressing, and online perforation.

Traditional Printing

Traditional printing methods, such as offset and digital printing, produce identical copies of a print job. These methods are cost-effective for large volumes of the same print material but do not offer the flexibility of VDP. Traditional printing is best suited for mass production where the content remains consistent across all copies.

Advantages of Variable Data Printing

1. Personalization: VDP allows for the customization of each printed piece, making it ideal for direct mail, marketing materials, and personalized invitations.

2. Efficiency: By printing variable information directly, VDP eliminates the need for pre-printed stock and separate personalization steps, reducing production time.

3. Cost-Effectiveness: Although the initial setup cost may be higher, VDP can be more cost-effective in the long run by reducing waste and inventory costs.

4. Versatility: VDP can be applied to various substrates and formats, offering flexibility for different applications.

Autoprint Reckoner VDP65

The Autoprint Reckoner VDP65 is an offline sheetfed variable data printing machine using HP Inkjet Technology. It is designed for high-speed, accurate printing of variable data such as numbers, barcodes, and addresses. As an authorized oil-free air compressor dealer, AS Equipment ensures that customers receive top-quality products along with exceptional support and service, maximizing the performance and reliability of their compressed air systems.

Batch Coding Systems

A batch coding system is crucial for marking products with unique codes or batch numbers, ensuring traceability throughout the supply chain. These systems are vital for industries like food and beverage, pharmaceuticals, and cosmetics, where product safety and quality are paramount. Batch coding can be integrated with VDP machines to streamline processes and ensure accurate, consistent coding.

Steps Involved in Batch Coding

1. Prepare the Design: Create the design for the batch code, including relevant information such as the date of manufacture and product batch number.

2. Set Up the Machine: Calibrate the batch coding machine and load the necessary ink or ribbon.

3. Load the Product: Position the product or packaging correctly on the machine’s conveyor.

4. Set Parameters: Configure printing speed, number of copies, and other settings.

5. Start Coding: Activate the machine to print the batch code.

6. Verify Codes: Check the printed codes for accuracy and legibility.

Both variable data printing and traditional printing have their unique advantages and are suited to different applications. VDP offers unparalleled flexibility and efficiency for personalized printing needs, while traditional printing remains the best choice for large-scale, uniform print jobs. By understanding the strengths of each method, businesses can choose the right technology to optimize their production processes. For high-quality VDP solutions, the Autoprint Reckoner VDP65 stands out as a reliable choice, supported by AS Equipment’s excellent service as an authorized dealer.

Read more posts Maximizing Efficiency with Automatic UV Coating Machines: Tips and Best Practices Role of prepress in offset printing

0 notes

Text

The Importance of Batch Coding in Manufacturing

What is Batch Coding?

Batch coding is printing unique identifiers on products or their packaging. These identifiers can include:

Batch numbers: A unique code identifying a specific group of products made during the same production run.

Manufacturing dates: The date when the product was made.

Expiration dates: The date the product should be used or sold.

Serial numbers: Unique codes assigned to individual items for tracking purposes.

These codes are essential for keeping track of products as they move through the supply chain—from production to distribution and retail.

Why is Batch Coding Important?

Traceability and Recall Management

One of the most significant benefits of batch coding is its ability to help companies quickly identify products in case of a recall. If a safety issue arises—such as contamination or defects—batch codes allow manufacturers to trace affected products back to their source. This quick response helps protect consumers and maintain the company’s reputation.

Quality Control

Batch codes provide valuable information that helps manufacturers monitor product quality. By analyzing data related to specific batches, companies can spot trends or issues in their production process. For example, if multiple complaints arise about a particular batch, manufacturers can investigate and resolve any underlying problems.

Regulatory Compliance

Many industries, especially food and pharmaceuticals, are subject to strict regulations that require accurate labeling and traceability. Batch coding ensures that companies comply with these laws, reducing the risk of fines or legal issues.

Inventory Management

Effective batch coding helps businesses manage their inventory more efficiently. By tracking production and expiration dates, manufacturers can minimize waste and ensure that products are sold while they are still fresh.

Consumer Trust

Clear and accurate batch coding fosters transparency with consumers. When customers see detailed information about a product’s origin and freshness, it builds trust and confidence in the brand.

Choosing the Right Batch Coding Machine

Choosing a reliable batch coding machine manufacturer is essential to implement effective batch coding. Here are some key factors to consider when selecting a machine:

Technology Type: Different machines use various technologies such as inkjet printing, laser marking, or thermal transfer printing. Choose a technology that fits your production needs.

Speed and Efficiency: Look for machines that can print quickly without slowing down your production line.

Versatility: Select machines that can handle different materials (like plastic, glass, or cardboard) so you can use them for various products.

Ease of Use: A user-friendly interface will make it easier for your staff to operate the machine without extensive training.

Support and Maintenance: Partnering with a manufacturer like SH Hitech Solutions, known for excellent customer support and maintenance services, ensures your machine runs smoothly over time.

Conclusion

The importance of batch coding in manufacturing cannot be overstated. It plays a vital role in ensuring traceability, maintaining quality control, complying with regulations, managing inventory effectively, and building consumer trust. By investing in high-quality batch coding machines from reputable manufacturers such as SH Hitech Solutions, businesses can streamline their operations and uphold high standards in product management.

In summary, adopting effective batch coding practices not only protects your brand but also meets the expectations of today’s informed consumers who value transparency and quality assurance. As you consider enhancing your manufacturing processes, remember that effective batch coding is key to achieving operational excellence.

#Batch coding machine#Batch coding machine manufacturer#Batch coding machine supplier#Batch coding machine in india

0 notes

Text

📦 Portable Handheld Inkjet Printer - 42% OFF! Print Logos & Expiry Dates On-the-Go 📦

Streamline your packaging and labeling process with the S1730 12.7mm Printing Gun Batch Coding Machine. This portable handheld inkjet printer allows you to easily print logos, batch codes, expiry dates, and other important information directly onto products, packaging, and more. With its compact design and user-friendly interface, it's ideal for businesses on the go. Save time and enhance your workflow with this efficient, easy-to-use printing solution.

Special Offer: Price Now: $76.09 (Original Price: $131.81) - Save 42% OFF!

🔗 Click to Buy Now: S1730 Handheld Inkjet Printer

#InkjetPrinter#HandheldPrinter#PortablePrinter#BatchCodingMachine#PrintingSolutions#PortableTech#ProductLabeling#BusinessTools#TechDeals#AliExpressDeals#PackagingPrinter#CodingMachine#LabelPrinting#EfficiencyBoost#TechSale#PrintingOnTheGo#PackagingEssentials#BusinessTech

0 notes

Text

Automatic Label Roll Winding and Counting Machine

Automatic Label Roll Winding and Counting Machine is quite useful for label roll counting and printing of various data such as batch no., date, and price etc. by using inkjet coding or any other non-contact coding provided by the packager. It is a useful machine that with an in-built sensor and electronic counter that can be used for label counting. The machine also features a robust A.C variable drive system for proper speed control. Whether it is pouch film counting or any other packaging material, this stainless steel construction comprising machine utilizes variable speeds for 400 mm size label spool.

Automatic Label Roll Winding and Counting Machine is almost maintenance free and performs at its best even with the basic maintenance. It is easy to use and labeling becomes a cake-walk. Also, it has an in-built self-protection system to safeguard the machine against voltage fluctuations. You can achieve high speed rolling with 45 measures per minute. This one of its kind machine is very commonly used across various industries for labeling purposes.

For more information related to automatic label roll winding and counting machines, feel free to get in touch with team Adinath International today.

0 notes

Text

Discover the cost-effective solution for precise product marking. Techno-Me's laser batch coding machines offer superior quality and c.

0 notes

Text

Frequently Asked Questions(FAQs) about Ink Pumps for Continuous Inkjet Printers(CIJ)

You will find the following information here:

What is CIJ?

What is the primary application of continuous inkjet printers?

How does continuous inkjet printing work?

How is a continuous inkjet system formed?

Common issues with ink pumps in continuous inkjet printers

TOPSFLO CIJ ink pumps Solution

How to Get in Touch with TOPSFLO for Expert Assistance?

What is CIJ?

CIJ stands for Continuous Inkjet, CIJ is a small character inkjet printing technology that uses a single inkjet nozzle to rapidly spray ink into tiny droplets, forming printed images or text. CIJ printers are widely used worldwide and are a non-contact printing method, making them suitable for marking on both flat and curved surfaces. They are primarily used in industrial applications for product packaging, labeling, and coding.

What are the Main Applications of Continuous Inkjet Printers?

Continuous inkjet printers are primarily used to mark production dates, batch numbers, barcodes, and other information on the surfaces of various materials such as plastic, metal, glass, cardboard, and wood. Typical applications include beverage cartons, cans, and bags, pharmaceuticals, small cardboard boxes, cables, and components. Virtually any product or packaging that moves on a conveyor belt or extrusion machine is suitable for continuous inkjet printing.

How does Continuous Inkjet Printers Work?

Continuous inkjet printers create a continuous stream of ink, which is broken down into numerous ink droplets through high-frequency vibrations. Once the ink droplets are formed, the selected ones are charged by electrodes and then directed by a deflection plate that generates an electrostatic field.

Charged ink droplets pass through the deflection plate, causing them to deviate at a specific angle before being sprayed from the print head onto the product to create the desired printed information. Uncharged ink droplets remain unaffected and return directly to the CIJ ink system.

During this printing process, the solvent base of the ink evaporates, and the viscosity of the ink changes accordingly. To ensure the optimal droplet formulation, viscosity must be strictly controlled within specified values.

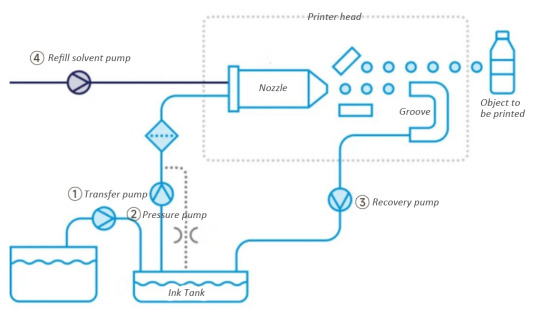

How is a Continuous Inkjet System Formed?

In continuous inkjet (CIJ) printing, ink circulates continuously throughout the printer, from the fluid system to the printhead, and then back to the fluid system. The entire ink path system involves several pumps working in coordination.

Initially, ink is transported from a large container to an ink reservoir using a transfer pump (①).

Subsequently, the ink is pressurized and transferred to the printhead using a pressure pump (②). Inside the printhead, the ink flows through nozzles, forming a continuous array of small ink droplets, each of which can be individually charged. Charged droplets are deflected by electrodes and hit the object to be printed.

Additionally, uncharged ink droplets fly in a straight line into a gutter, and excess ink is recirculated from this point back to the ink reservoir using a recirculation/suction/recovery pump (③).

To prevent the ink from drying and damaging the system when the printer is not in use, a refill solvent pump (④) is typically included in the continuous inkjet system. This pump delivers solvent to the nozzles to flush out any residual ink.

Through these steps, a continuous inkjet system can continuously supply ink and achieve high-speed, efficient inkjet printing.

Common Issues with Ink Pumps in Continuous Inkjet Printers

1. In the current market, there is a wide variety of ink types used in CIJ printers, each with different viscosities. These different ink compositions may contain additives, some of which can be corrosive, leading to compatibility issues with pump materials that can cause malfunctions or a very short lifespan.

2. Instability in the liquid circuit pressure and ink flow during the operation of the inkjet printer can affect the printing results.

Continuous inkjet printing requires prolonged periods of operation. Over time, continuous use may result in wear and tear, potentially leading to a decline in performance or malfunctions, thus compromising the printer's lifespan.

TOPSFLO CIJ ink pumps Solution

Diverse Pump Materials

Topsflo printer ink pumps offer a variety of pump material configurations to accommodate common CIJ ink types, such as MEK, dye-based inks, pigment inks, and soft pigment inks. The pump head materials for diaphragm pumps can be selected from PA, PPS, or PP, while membrane materials can be chosen from EPDM or PTFE. For valve materials, options include EPDM, FKM, or FFKM. YT alloy gear pumps are mainly used for pigment inks, while PEEK gears can be used for dye-based inks.

Carefully Selected Pump Types for Precise Applications

Topsflo offers two pump options tailored for printer applications: diaphragm pumps and gear pumps.

- Diaphragm liquid pumps, especially those designed for low-flow rates, provide relatively stable flow and pressure output. They are more suitable for handling liquids containing solid particles or particulate matter because their design is better suited for handling suspended particles. However, in high-flow applications, diaphragm pumps may produce larger pulses, which could lead to vibration or noise issues.

- Gear pumps are suitable for printers that require a large volume of ink. They offer stable flow and pressure output with lower pulsation. Compared to ordinary gear pumps on the market, TOPSFLO gear pumps use high-precision gears and component control to ensure smooth flow, minimal pulsation, and adjustable output pressure stability.

TOPSFLO engineers can determine which pump is better suited for your application based on your printing requirements, including the desired flow rate, accuracy, pulsation, noise level, ink properties, and whether they contain solid particles, among other factors.

Long-lasting Lifetime for Stable Printing Assurance

Both Topsflo diaphragm pumps and gear pumps are equipped with high-performance brushless motors developed in-house.

The coreless brushless motor in the diaphragm pump boasts a lifespan of up to 15,000 hours, while the gear pump utilizes a high-performance, in-house designed and manufactured brushless three-phase motor with a lifespan exceeding 30,000 hours, requiring no maintenance.

These brushless motors do not produce sparks, static electricity, or electromagnetic interference during operation, ensuring safety and allowing the pumps to run continuously in high-demand inkjet printing tasks.

How to Get in Touch with TOPSFLO for Expert Assistance?

Maintaining a consistently stable flow and using ink fluids with the appropriate viscosity are crucial for overall printing quality. Any abnormalities in the ink supply system can lead to poor printing quality, error messages, and even costly product recalls. Therefore, choosing the right ink pump for your continuous inkjet printer is of utmost importance.

TOPSFLO specializes in the development and production of various micro pumps for printers. They have extensive experience and pump solutions, and they offer customized services to meet different customer needs. Please contact their sales engineers for printer pump application cases and pump information! Email: [email protected] or [email protected]

youtube

0 notes

Link

Krishna Engineering Works are leading manufacturer, of Conveyor for Inkjet Printing machine. Heavy duty Conveyor for Inkjet Printing for different industries with high-quality parts, Conveyor for Inkjet Printing manufacturer. Our esteemed clients can benefit from us the most preferred range of Conveyor for Inkjet Printing Machine. This Belt Conveyor for Inkjet Printing machine works like feeding and conveying equipment, used for transferring nature rubber.

#Conveyor for Inkjet Printing machine#Heavy duty Conveyor for Inkjet Printing#Inkjet Printing Belt Conveyor#Inkjet Batch Coding Machine#Automatic Batch Coding Machine#Semi-Automatic Batch Coding Machine#Industrial inkjet printer#Customized Inkjet Printer Conveyor Belt#Automatic Mild Steel Inkjet Printing Conveyor

1 note

·

View note

Link

0 notes

Text

What is a Batch Coding Machine? | Creature Industry

In the world of manufacturing and packaging, keeping track of product information is crucial. One essential tool that helps with this is the batch coding machine. But what exactly is a batch coding machine, and how can it benefit your business? Let's find out.

What is a Batch Coding Machine?

A batch coding machine is a device used to print important information, like manufacturing dates, expiry dates, batch numbers, and other data on products and packaging. This information helps with tracking products, ensuring quality, and meeting regulations.

Key Features of Batch Coding Machines

High Precision: Accurate and clear printing on various surfaces.

Versatility: Can print on plastic, metal, glass, paper, and more.

Ease of Use: Simple to operate.

Speed and Efficiency: Works quickly without sacrificing print quality.

Benefits of Using a Batch Coding Machine

Adding a batch coding machine from Creature Industry to your business can bring several benefits:

Regulatory Compliance: Easily meet industry standards and legal requirements.

Enhanced Traceability: Track products through every stage of the supply chain.

Improved Quality Control: Quickly identify and address production issues.

Brand Protection: Deter counterfeiting by adding unique batch codes.

Types of Batch Coding Machines

At Creature Industry, we offer different types of batch coding machines to meet various needs:

Inkjet Printers: Ideal for non-contact printing on uneven surfaces.

Thermal Transfer Overprinters: Perfect for high-quality prints on flexible packaging.

Laser Coders: Provide permanent marking solutions without the need for consumables.

Special Offers from Creature Industry

Take advantage of our exclusive offers on batch coding machines:

Free Consultation: Get expert advice on the best batch coding solution for your business.

Extended Warranty: Enjoy peace of mind with our extended warranty options.

Bulk Discounts: Save more when you purchase multiple units.

Why Choose Creature Industry?

Quality Products: We provide reliable and durable batch coding machines.

Exceptional Support: Our dedicated support team is always ready to assist you.

Competitive Pricing: Get the best value for your investment.

Contact Us Today!

Ready to improve your production process with a batch coding machine? Visit Creature Industry or contact us at:

Email: [email protected]

Phone: +123-456-7890

Address: 123 Industrial Area, City, Country

Investing in a batch coding machine is a smart move for any business looking to improve product identification and traceability. With Creature Industry, you get top-notch machines, exceptional support, and unbeatable value. Don’t miss out on our special offers—contact us today to find the perfect batch coding solution for your needs!

0 notes