#Inkjet Printing System

Explore tagged Tumblr posts

Text

Buy All in One Inkjet Printer at Discounted Price

Get the best deals on all in one inkjet printers at Monotech Systems! Shop now to enjoy discounted prices on top-rated models perfect for home and office use. With superior printing, scanning, and copying features, these printers offer excellent performance at a fraction of the cost. Don't miss out on these savings!

Contact Us :- Phone:-1 800 102 4567 Email :- [email protected] Visit Us: https://monotech.in/inkjet-printing-systems/canon/

#all in one inkjet printers#digital printing press#book scanner online#uv varnish machine#book printing machine#monotech systems

0 notes

Text

#carton inspection system#variable data printing#print inspection system#Variable data inkjet printing machines#Data Printing Retrofit#Digital Inkjet Printing Technology

1 note

·

View note

Note

So we all know printers are evil. But which type of printer (inkjet, laser, plotter, etc.) would you say is the most versatile, and therefore best? And do you have any specific recommendations? Thanks.

Specific recommendations: some cheap laser printer, see that Verge article, they're all roughly fine.

If you don't do photos, you want laser, or nowadays LED. They're much, much less evil than inkjet, and they can even do colour pretty well if all you need are colour documents and the basics. Toner is a solid powder that gets fused into ink by heat, so it can't really dry out like inkjet, and it's very resilient.

Laser printers (more generally "xerographic printers") are actually pretty reliable because they're relatively mechanically simple, and toner lasts years, so all the usual gripes about printers becoming useless when not used for more than a week don't apply.

Inkjet is really where the bad reputation of printers comes from. Liquid ink is a nightmare to work with in a machine, it's sticky, it dries out, it clogs, it needs complicated jet systems to spray it, and it's a pain to handle. The reason you deal with this is because inket is basically the only way to produce bright, colourful, detailed photo prints, but nowadays you don't have to print every photo you take, just ones you want, so you can go through a commercial printer, your local photo shop probably has a suite of nice inkjets available at reasonable rates.

50 notes

·

View notes

Text

My best corporate skill is emailing. I write emails so good and sum them up in the subject line so well. Im so adept at the proffessional intercourse that is the email delivery systems ill respond before you even think about emailing me. I know you so well I know your thoughts and i know you need to use Inkjet 2 to print that document not inkjet 2a

anyways my husband bought my diet pepsi and im gonna be so regular now.

6 notes

·

View notes

Text

Researchers leverage inkjet printing to make a portable multispectral 3D camera

Researchers have used inkjet printing to create a compact multispectral version of a light field camera. The camera, which fits in the palm of the hand, could be useful for many applications including autonomous driving, classification of recycled materials and remote sensing. 3D spectral information can be useful for classifying objects and materials; however, capturing 3D spatial and spectral information from a scene typically requires multiple devices or time-intensive scanning processes. The new light field camera solves this challenge by simultaneously acquiring 3D information and spectral data in a single snapshot. "To our knowledge, this is the most advanced and integrated version of a multispectral light field camera," said research team leader Uli Lemmer from the Karlsruhe Institute of Technology in Germany. "We combined it with new AI methods for reconstructing the depth and spectral properties of the scene to create an advanced sensor system for acquiring 3D information."

Read more.

9 notes

·

View notes

Text

Domino Presents New Monochrome Inkjet Printer at Labelexpo Southeast Asia 2025

Domino Printing Sciences (Domino) is pleased to announce the APAC launch of its new monochrome inkjet printer, the K300, at Labelexpo Southeast Asia. Building on the success of Domino’s K600i print bar, the K300 has been developed as a compact, flexible solution for converters looking to add variable data printing capabilities to analogue printing lines.

The K300 monochrome inkjet printer will be on display at the Nilpeter stand, booth F32, at Labelexpo Southeast Asia in Bangkok, Thailand from 8th–10th May 2025. The printer will form part of a Nilpeter FA-Line 17” hybrid label printing solution, providing consistent inline overprint of serialised 2D codes. A machine vision inspection system by Domino Company Lake Image Systems will validate each code to ensure reliable scanning by retailers and consumers whilst confirming unique code serialisation.

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,” explains Alex Mountis, Senior Product Manager at Domino. “Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands. We have developed the K300 with these variable data and 2D code printing opportunities in mind.”

The K300 monochrome inkjet printer can be incorporated into analogue printing lines to customise printed labels with variable data, such as best before dates, batch codes, serialised numbers, and 2D codes. The compact size of the 600dpi high-resolution printhead – 2.1″ / 54mm – offers enhanced flexibility with regards to positioning on the line, including the opportunity to combine two print stations across the web width to enable printing of two independent codes.

Operating at high speeds up to 250m / 820′ per minute, the K300 monochrome inkjet printer has been designed to match flexographic printing speeds. This means there is no need to slow down the line when adding variable data. Domino’s industry-leading ink delivery technology, including automatic ink recirculation and degassing, helps to ensure consistent performance and excellent reliability, while reducing downtime due to maintenance. The printer has been designed to be easy to use, with intuitive setup and operation via Domino’s smart user interface.

“The K300 will open up new opportunities for converters. They can support their brand customers with variable data 2D codes, enabling supply chain traceability, anti-counterfeiting, and consumer engagement campaigns,” adds Mountis. “The versatile printer can also print variable data onto labels, cartons, and flatpack packaging as part of an inline or near-line late-stage customisation process in a manufacturing facility, lowering inventory costs and reducing waste.”

Code verification is an integral part of any effective variable data printing process. A downstream machine vision inspection system, such as the Lake Image Systems’ model showcased alongside the K300, enables converters and brands who add 2D codes and serialisation to labels and packaging to validate each printed code.

Mark Herrtage, Asia Business Development Director, Domino, concludes: “We are committed to helping our customers stay ahead in a competitive market, and are continuously working to develop new products that will help them achieve their business objectives. Collaborating with Lake Image Systems enables us to deliver innovative, complete variable data printing and code verification solutions to meet converters’ needs. We are delighted to be able to showcase an example of this collaboration, featuring the .”

To find more information about the K300 monochrome printer please visit: https://dmnoprnt.com/38tcze3r

#inkjet printer#variable data printing#biopharma packaging#glass pharmaceutical packaging#pharmaceutical packaging and labelling#Labelexpo Southeast Asi

2 notes

·

View notes

Text

The Art of Building Meat: Bioprinting Techniques in Cultured Meat Market Production

Introduction:

The future of food is taking shape in bioreactors and 3D printers. Cultured Meat Market, also known as clean meat or lab-grown meat, emerges as a revolutionary solution to the environmental and ethical concerns surrounding traditional meat production. This article delves into the fascinating world of bioprinting techniques, a key component in creating complex, delicious cultured meat products.

Download FREE Sample: https://www.nextmsc.com/cultured-meat-market/request-sample

Cultured Meat: A Sustainable Disruption

Traditional meat production carries a significant environmental burden, contributing to deforestation, greenhouse gas emissions, and water pollution. Cultured meat offers a promising alternative, growing meat from animal cells in a controlled environment.

Here's a simplified breakdown of the process:

Cell Collection: A small sample of muscle stem cells is obtained from an animal through a minimally invasive procedure.

Cell Culture: These cells are multiplied in a nutrient-rich medium within bioreactors.

Differentiation and Maturation: Controlled growth factors in the medium stimulate the cells to differentiate and mature into muscle tissue.

Bioprinting: This innovative step allows for precise arrangement of the cells to create the desired structure and texture of meat.

Maturation and Processing: The bioprinted meat undergoes further maturation and processing to achieve the final product.

Inquire before buying: https://www.nextmsc.com/cultured-meat-market/inquire-before-buying

Bioprinting: Engineering the Future of Meat

Bioprinting takes cultured meat production to a whole new level. Here's how it works:

Digital Design: A computer-aided design (CAD) model is created to define the desired structure of the meat product, such as a steak or a burger patty.

Bioink Preparation: A biocompatible material, often containing a mixture of cells, nutrients, and scaffolding materials, is prepared for printing.

3D Printing Process: The bioink is loaded into a bioprinter, which uses computer-controlled mechanisms to deposit the bioink layer-by-layer, replicating the designed structure.

Cell Culture and Maturation: Once printed, the bioprinted cells are allowed to mature and grow within a bioreactor, mimicking the natural development of muscle tissue.

Benefits of Bioprinting for Cultured Meat

Bioprinting offers several advantages in the production of cultured meat:

Complex Structures: Bioprinting allows for the creation of complex, multi-cellular structures that mimic the texture and marbling of traditional meat cuts. This is difficult to achieve with traditional culturing techniques.

Fat Distribution: Bioprinting enables precise control over fat distribution within the meat, allowing for the creation of leaner or marbled cuts as desired.

Customization: Bioprinting paves the way for personalized meat products tailored to specific dietary needs or preferences.

Vascularization: Bioprinting can potentially be used to create vascular networks within the cultured meat, promoting cell growth and mimicking the natural delivery of nutrients and oxygen.

Types of Bioprinting Techniques for Cultured Meat

Several bioprinting techniques are being explored for cultured meat production, each with its own advantages and limitations:

Extrusion-based Bioprinting: This common technique uses a pressurized system to deposit bioink through a nozzle, creating a filamentous structure. It's suitable for high-viscosity bioinks but may have limitations in resolution.

Inkjet Bioprinting: Similar to an inkjet printer, this technique uses a jet of bioink droplets to create a patterned structure. It offers high resolution but may be limited in the types of bioinks it can handle.

Stereolithography (SLA): This light-based technique uses a laser to solidify layers of bioink resin, building the desired structure layer-by-layer. It offers high accuracy but may require specialized biomaterials.

Challenges and Opportunities in Bioprinting for Cultured Meat

While bioprinting holds immense promise, some challenges need to be addressed:

Cost Reduction: Bioprinting equipment and bioink development are currently expensive, requiring cost optimization for large-scale production.

Bioink Development: Creating bioinks that are biocompatible, support cell growth, and allow for precise printing remains an ongoing area of research.

Scalability: Scaling up bioprinting processes to meet commercial production demands requires further advancements in technology and infrastructure.

However, these challenges offer exciting opportunities for innovation:

Advancements in Biomaterial Science: Development of affordable and efficient bioinks specifically tailored for cultured meat is crucial for large-scale adoption.

Bioprinter Design and Optimization: Improvements in bioprinter design can increase printing speed, resolution, and efficiency for cost-effective production.

Collaboration Between Researchers and Industry: Collaboration can accelerate research and development efforts to overcome technical hurdles and improve bioprinting techniques.

Conclusion: A Bite of the Future - Bioprinted Cultured Meat

Bioprinting represents a transformative leap in the world of cultured meat. This technology holds the potential to create delicious, sustainable, and ethical meat alternatives, replicating the textures and flavors we crave.

While challenges remain in terms of cost reduction, bioink development, and scalability, ongoing research and collaboration are paving the way for advancements. Bioprinting paves the way for a future where:

Cultured meat becomes readily available and affordable for consumers.

Bioprinting techniques can create a wider variety of meat products, from steaks to sausages.

Consumers can enjoy the taste and texture of meat while making a positive environmental impact.

2 notes

·

View notes

Text

Label Printer Machine: The Ultimate Guide for Efficient and Professional Product Labeling

What is a Label Printer Machine?

A label printer machine is a device that prints custom or standardized labels for products, containers, cartons, and shipping packages. It can print on paper, plastic, thermal material, or synthetic labels using technologies like thermal transfer, direct thermal, or inkjet. Label printer machines are essential in packaging, inventory management, retail, pharmaceuticals, logistics, and food processing.

Types of Label Printer Machines

1. Thermal Transfer Label Printers

These use heat to transfer ink from a ribbon onto the label. Ideal for long-lasting, waterproof, smudge-resistant labels, commonly used in pharmaceuticals, electronics, and industrial labeling.

2. Direct Thermal Label Printers

No ribbon is used; heat-sensitive label paper darkens when heated. Best for short-term applications like shipping labels, receipts, and food packaging.

3. Inkjet Label Printers

Produce high-resolution, colorful labels. Suitable for custom branding, marketing labels, and retail packaging.

4. Laser Label Printers

Offer speed and sharpness. Used when mass label printing is needed, especially for office or warehouse environments.

5. Portable Label Printers

Handheld or mobile devices used in field service, retail, logistics, and inventory control.

6. RFID Label Printers

Print and encode RFID tags and barcodes for real-time tracking and supply chain automation.

Common Applications Across Industries

1. Food and Beverage

Nutritional labels, expiry dates, batch codes

Tamper-evident and waterproof labels

2. Pharmaceuticals

Regulatory-compliant labels with dosage info, QR codes, batch numbers

High print precision and barcode clarity

3. Cosmetics

High-resolution brand and ingredient labels

Sleek, colorful, water-resistant finishes

4. Manufacturing

Asset labels, compliance tags, quality control stickers

5. Logistics and Warehousing

Shipping and barcode labels

SKU and inventory management tags

6. Retail

Price tags, promotional stickers, and shelf labels

Key Features of High-Quality Label Printer Machines

1. Print Resolution

Measured in DPI (dots per inch). For clear text and barcodes, 203 DPI is standard, while 300–600 DPI is used for high-definition images and small text.

2. Print Speed

Ranges from 2 to 14 inches per second (IPS). Higher speeds are ideal for bulk printing operations.

3. Connectivity Options

USB, Ethernet, Bluetooth, Wi-Fi—essential for integration with POS systems, warehouse management software, or industrial PLCs.

4. Media Compatibility

Should support a variety of label rolls: paper, PET, PP, BOPP, synthetic, glossy, and matte.

5. Software Integration

Compatibility with label design software like BarTender, NiceLabel, or ZebraDesigner.

6. Auto-Cutter and Peeler

Helps in high-speed workflows by automatically cutting or peeling off printed labels.

Advantages of Using a Label Printer Machine

Professional Packaging: Clean, precise labels reflect product quality

Customization: Easily print logos, barcodes, and QR codes on demand

Efficiency: Reduce dependency on pre-printed labels and minimize stockouts

Compliance: Meet legal labeling requirements effortlessly

Traceability: Boost product tracking across supply chains

Cost-Saving: In-house label printing reduces outsourcing costs

0 notes

Text

VIDEOJET PRINTING INK Compatibility with Modern Coding Technologies

In today’s fast-paced industrial environment, reliable coding and marking solutions are essential for maintaining efficiency, compliance, and product traceability. One of the leading names in this space is VIDEOJET PRINTING INK, known for its outstanding performance across a wide range of production needs. As modern coding technologies continue to evolve, the compatibility of VIDEOJET PRINTING INK with these advanced systems plays a crucial role in enhancing operational workflows and ensuring high-quality output.

Let’s explore how VIDEOJET PRINTING INK seamlessly integrates with modern coding technologies and why it remains a preferred choice across industries.

Meeting the Demands of Evolving Coding Systems

Modern coding technologies have rapidly advanced to support higher production speeds, diverse substrates, and more stringent compliance requirements. Whether it's continuous inkjet (CIJ), thermal inkjet (TIJ), laser marking, or large character printing (LCP), every technology demands ink formulations that are optimized for specific applications.

VIDEOJET PRINTING INK is designed with compatibility in mind. It works effectively across multiple coding systems, especially with CIJ and TIJ printers, which are widely used in industries like food & beverage, pharmaceuticals, cosmetics, and electronics. Its superior adhesion properties and quick-drying characteristics make it suitable for a variety of materials such as glass, plastic, cardboard, and metals — all without compromising print clarity.

Precision and Consistency Across Substrates

The success of any modern coding solution relies heavily on consistent, legible prints — even on complex or irregular surfaces. VIDEOJET PRINTING INK is specially formulated to deliver high-contrast codes on challenging substrates, including slick plastic bottles, coated cartons, and flexible packaging.

For instance, when used with thermal inkjet printers, VIDEOJET PRINTING INK can produce high-resolution prints suitable for detailed information like QR codes, barcodes, and batch numbers. This level of precision ensures products meet regulatory and supply chain requirements without costly rework or delays.

Compatibility with Automation and Smart Production Lines

As Industry 4.0 and smart manufacturing trends continue to reshape factories, VIDEOJET PRINTING INK proves its adaptability by integrating seamlessly with automated systems. Today’s coding technologies often feature built-in software for remote monitoring, predictive maintenance, and real-time data tracking.

Whether integrated into robotic arms or smart conveyors, VIDEOJET-compatible printers and ink cartridges can work in sync with automated lines to minimize downtime and improve traceability. The chemical stability of VIDEOJET PRINTING INK ensures that the ink does not dry out or clog the printer even during extended idle times — a key advantage in automated environments.

Supporting Eco-Friendly and Regulatory Needs

Sustainability and compliance have become top priorities in modern manufacturing. VIDEOJET PRINTING INK is available in a range of formulations, including low-VOC (Volatile Organic Compounds) and MEK-free options, making it environmentally safer while still delivering strong performance.

Moreover, these inks comply with international safety and packaging regulations, including FDA, RoHS, and REACH standards, making them ideal for food, beverage, and pharmaceutical packaging. Modern coding technologies often come equipped with ink usage monitoring features, and VIDEOJET’s efficient ink formulations help reduce waste and operating costs over time.

Easy Integration with a Wide Range of Printers

One of the greatest strengths of VIDEOJET PRINTING INK is its wide printer compatibility. It is engineered to work perfectly with Videojet’s own series of printers, including the popular 1000 Line CIJ printers, 8510 TIJ printers, and more. This ensures plug-and-play functionality and optimal performance from the first print to the last.

For companies using a mix of legacy and new printing equipment, the versatility of VIDEOJET PRINTING INK provides a unified solution without the need for multiple ink inventories. This not only simplifies operations but also reduces maintenance and training time for machine operators.

Why Manufacturers Trust VIDEOJET PRINTING INK

Manufacturers around the globe rely on VIDEOJET PRINTING INK for its unmatched reliability, durability, and adaptability. Whether it's high-speed bottling lines or precise electronics labeling, this ink continues to deliver consistent results that keep operations running smoothly.

At SH HITECH SOLUTIONS, we understand how critical it is to choose the right ink for the right technology. That’s why we recommend VIDEOJET PRINTING INK for businesses looking to future-proof their production lines with high-performance, compatible ink solutions.

Final Thoughts

As coding technologies become smarter, faster, and more complex, the demand for high-performance inks that can keep up has never been greater. VIDEOJET PRINTING INK rises to the challenge, offering exceptional compatibility with modern coding technologies, from CIJ to TIJ and beyond.

For manufacturers seeking to streamline operations, maintain compliance, and ensure reliable product identification, VIDEOJET PRINTING INK remains a leading solution that supports both today’s needs and tomorrow’s innovations.

0 notes

Text

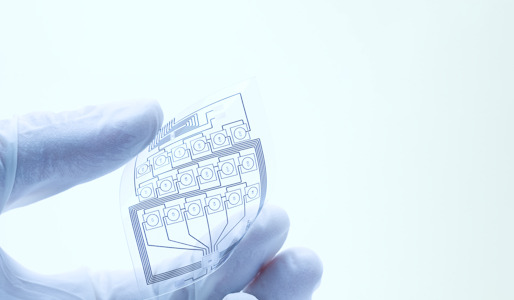

Printed Sensors Market Emerging Trends Driving Future Innovations and Growth

The printed sensors market is undergoing a transformative shift driven by rapid advancements in printing technologies, the Internet of Things (IoT), and the growing demand for smart, flexible, and low-cost sensing solutions. Printed sensors, manufactured using various printing methods such as screen, inkjet, and gravure printing, offer lightweight, cost-effective, and scalable alternatives to conventional sensors. Their adoption is expanding across industries including healthcare, automotive, electronics, and environmental monitoring. As businesses and researchers focus on innovation and sustainability, several emerging trends are reshaping the dynamics of the printed sensors market.

Advancements in Flexible Electronics One of the most prominent trends in the printed sensors market is the integration of printed sensors with flexible electronics. Flexible substrates such as PET (polyethylene terephthalate) and polyimide are being increasingly used to develop bendable, stretchable sensors. This advancement is particularly beneficial for wearable technology and healthcare monitoring devices where comfort, durability, and form factor are crucial. The synergy between flexible electronics and printed sensors is paving the way for the development of smart textiles, electronic skin, and unobtrusive health monitoring patches.

Growth of Wearable and Health Monitoring Devices The rising consumer preference for personal health tracking is accelerating the adoption of printed sensors in wearable devices. These sensors can monitor parameters such as temperature, heart rate, hydration levels, and glucose levels in real-time. Their low-profile and skin-conforming properties make them ideal for integration into wearable platforms. The trend is gaining further momentum due to the increasing focus on remote healthcare and telemedicine, particularly in the post-pandemic era. Printed biosensors are also being explored for use in diagnostics, contributing to personalized medicine.

Integration with IoT and Smart Systems Printed sensors are becoming critical components of IoT-enabled systems, enabling real-time data collection and communication in smart homes, industrial automation, agriculture, and environmental monitoring. Their adaptability and affordability allow widespread deployment in areas where traditional sensors may be impractical. For instance, printed humidity and temperature sensors are being used in smart farming applications to optimize irrigation and crop yield. As IoT ecosystems expand, the demand for compact and efficient sensing solutions is propelling the growth of the printed sensors market.

Sustainability and Green Manufacturing Sustainability is an emerging focus in the printed sensors landscape. Manufacturers are increasingly adopting eco-friendly materials and energy-efficient printing techniques to reduce the environmental impact of sensor production. Organic and biodegradable materials are being researched for use in substrates and inks. Furthermore, additive manufacturing methods, which minimize material waste, are gaining traction. These efforts align with global initiatives toward reducing electronic waste and promoting circular economy practices in the electronics sector.

Emergence of Printed Chemical and Gas Sensors The need for real-time environmental monitoring and workplace safety has led to the development of printed chemical and gas sensors. These sensors are used to detect hazardous gases, pollutants, and toxins in industrial environments, urban areas, and enclosed spaces. Their lightweight, low-cost nature makes them suitable for mass deployment. Innovations in nanomaterials and conductive inks are enhancing their sensitivity and selectivity, broadening their application scope in smart cities and environmental management.

Advances in Materials and Nanotechnology Nanotechnology is playing a vital role in enhancing the performance of printed sensors. Advanced materials such as graphene, carbon nanotubes, and silver nanowires are being utilized to improve the conductivity, sensitivity, and durability of sensor components. These materials enable the development of highly responsive sensors suitable for complex and demanding applications. Moreover, research into hybrid materials that combine organic and inorganic elements is opening up new avenues for multi-functional and high-performance printed sensors.

Automotive Applications Gaining Momentum The automotive sector is increasingly integrating printed sensors into vehicle components for applications such as touch interfaces, tire pressure monitoring, and in-cabin climate control. As vehicles become smarter and more connected, the demand for lightweight, energy-efficient sensors is rising. Printed sensors can be embedded into non-flat surfaces, dashboards, and seats, providing manufacturers with design flexibility and cost efficiency. This trend aligns with the broader shift toward autonomous and electric vehicles.

Conclusion The printed sensors market is poised for significant growth, driven by technological advancements, industry demand, and a push toward sustainability. Emerging trends such as the integration with flexible electronics, expansion in healthcare wearables, IoT synergy, and environmental monitoring are transforming the landscape of sensor technology. Continued innovation in materials and printing methods will further unlock new applications and drive adoption across various sectors. As the world becomes increasingly connected and data-driven, printed sensors are set to play a pivotal role in enabling smart, responsive, and sustainable systems.

0 notes

Text

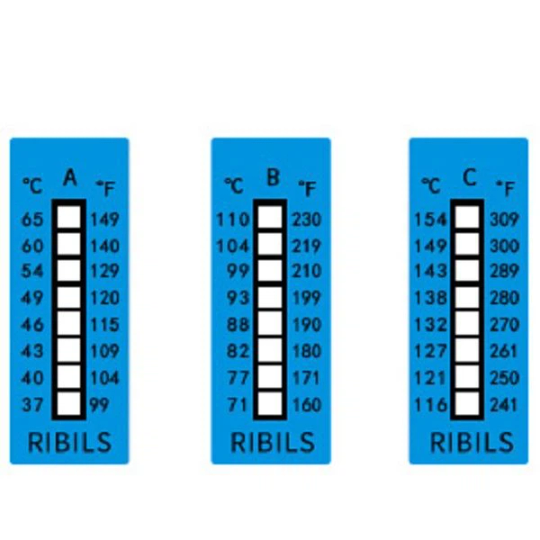

Time Temperature Indicator Labels Market Future Trends Driven by Food Safety and Cold Chain Expansion

The time temperature indicator (TTI) labels market is witnessing transformative growth, fueled by heightened awareness around food safety, pharmaceutical integrity, and cold chain reliability. These smart labeling solutions, designed to monitor and visually communicate exposure to temperature over time, are gaining traction as critical components in ensuring product quality and safety from production to consumption.

With the global movement toward more traceable and accountable supply chains, TTIs are evolving from basic indicators to sophisticated tools integrated with digital platforms. As a result, the market is on the cusp of numerous exciting trends that will redefine its scope, utility, and technological sophistication over the coming years.

Rising Adoption Across Cold Chain Applications

Cold chain logistics—especially for food, beverages, and pharmaceuticals—has emerged as a major driver of TTI label demand. Ensuring that temperature-sensitive products maintain optimal storage conditions from production facilities to end consumers is vital for health, compliance, and brand reputation. TTIs are increasingly being employed across frozen foods, dairy, seafood, vaccines, biologics, and other perishable items to maintain quality assurance throughout the chain.

The future will likely see an increased preference for TTIs with broader temperature sensitivity ranges, multi-threshold indicators, and clear, irreversible visual cues. Businesses are also showing interest in bulk implementation to cover secondary and tertiary packaging layers.

Integration With Smart Packaging Technologies

One of the most prominent future trends is the integration of TTIs with broader smart packaging solutions. As the Internet of Things (IoT) continues to penetrate logistics and retail, TTIs are being embedded with digital sensors and QR codes for real-time data capture and sharing.

Smart TTIs that can communicate directly with mobile apps or centralized monitoring systems are beginning to replace passive indicators. These labels not only show visual color changes but also log data that can be analyzed for inventory management, quality control, and predictive analytics. This integration offers transparency, faster decision-making, and greater control over supply chain variables.

Demand From E-Commerce and Direct-to-Consumer Models

With the rise of online food delivery and direct-to-consumer pharmaceutical services, TTIs are becoming more essential in smaller packaging formats. Consumers are now more aware of freshness indicators and often demand proof of proper handling during transit.

TTI labels are expected to play a bigger role in boosting consumer trust in online food platforms, meal kits, and prescription deliveries. Companies that include these indicators on packaging enhance perceived value and demonstrate their commitment to safety and transparency, creating competitive differentiation in the market.

Innovation in Label Materials and Printing Techniques

As sustainability becomes a growing concern, future TTI development will also focus on eco-friendly materials, non-toxic indicator inks, and recyclable adhesives. Biodegradable substrates and compostable labels are in demand, especially among companies pursuing green certification and reducing packaging waste.

Innovative printing technologies like inkjet and roll-to-roll digital printing are being explored to reduce costs and enhance the scalability of TTI labels. This evolution in production methods also enables greater customization, allowing companies to design TTI labels suited for specific use-cases and branding needs.

Expansion Into Emerging Markets

As cold chain infrastructure improves in emerging economies such as India, Brazil, and Southeast Asia, the demand for TTIs is expected to surge. Governments and regulatory agencies are tightening food and pharma handling laws, encouraging local businesses to adopt TTIs for compliance and export-readiness.

The future will likely see wider adoption across local meat markets, dairy cooperatives, vaccine storage facilities, and agricultural exporters in these regions. Local manufacturing of TTIs in these markets will also help reduce costs and increase penetration.

Regulatory Influence and Compliance Standards

Global food and drug regulatory bodies such as the FDA, EFSA, and WHO are increasingly encouraging or mandating the use of time temperature monitoring tools. TTIs are being viewed as crucial evidence in compliance audits, recalls, and quality assurance practices.

In the coming years, expect TTIs to become standard in packaging across high-risk products. As new legislation emerges focusing on traceability and consumer protection, more companies will proactively integrate TTIs into their packaging processes to stay ahead of regulatory requirements.

Personalized and Customizable Indicator Solutions

As industries diversify, the need for customizable TTI labels will increase. Companies are requesting indicators tuned to specific time-temperature thresholds that reflect the perishability and stability of individual products. For example, the temperature tolerance of a fresh salad kit differs significantly from a vial of insulin.

Label providers that offer personalization options, on-demand printing, and integration with digital platforms will gain a significant edge in the evolving market. This shift towards tailored solutions will define the next wave of innovation in the TTI space.

Enhanced Focus on Consumer Awareness

Consumer education about freshness and safety indicators is expected to grow, further influencing demand for TTIs in retail packaging. Packaging that visibly shows freshness status builds brand trust and enhances product appeal. As shoppers become more informed, TTI-labeled products will increasingly become a deciding factor at the point of sale.

Brands that actively promote their use of TTIs in marketing campaigns are likely to strengthen their value proposition, especially in health-conscious and premium product segments.

Conclusion

The future of the time temperature indicator labels market lies in its adaptability, integration with digital ecosystems, and alignment with global safety standards. As cold chains grow more complex and consumers demand greater transparency, TTIs will evolve into intelligent tools offering insights beyond simple temperature tracking. Players in this space who innovate in technology, sustainability, and user experience are poised to lead the next phase of growth in this essential and rapidly expanding market.

#TimeTemperatureIndicatorsMarket#SmartPackaging#ColdChainLogistics#FoodSafetySolutions#PharmaPackaging

0 notes

Text

How Digital Textile Printing is Revolutionizing the Fabric Industry

The Need for Innovation in Textile Printing

Historically, fabric printing relied on methods like screen printing or rotary printing. These techniques are cost-effective for large runs but are inefficient for small batches or designs requiring intricate detail. Enter the digital textile printing revolution. This method allows for direct-to-fabric printing using inkjet technology, providing limitless design freedom without the setup costs of conventional techniques.

The Role of the Modern Printing Machine

At the heart of this innovation lies the printing machine itself. Today’s advanced machines come equipped with high-resolution nozzles, AI-based controls, and specialized software that ensure sharp, vibrant prints. These machines can handle complex designs, multiple colors, and even print on various types of fabrics—from cotton and silk to synthetic blends.

More importantly, digital textile printers enable on-demand production. This means that designers can now test patterns, release limited collections, or even allow customers to personalize products—without worrying about inventory waste or long lead times.

Delivering on True Colour Accuracy

One of the standout features of digital textile printing is its ability to maintain true colour accuracy across batches. Traditional methods often suffer from color bleeding or tone shifts due to manual ink mixing and inconsistent application. But with digital technology, color management systems ensure consistency and precision.

This fidelity is crucial for fashion brands where brand identity depends heavily on specific color palettes. Interior designers also benefit, as they can now match fabrics precisely to walls, furnishings, or other décor elements.

Sustainability and Efficiency Go Hand-in-Hand

In an era where environmental responsibility matters, digital textile printing scores high on sustainability. It uses less water, reduces chemical waste, and minimizes leftover stock—making it a greener choice for both small and large textile businesses.

Traditional dyeing methods consume vast amounts of water and produce effluents that are difficult to treat. Digital systems, however, print only what is needed, drastically cutting down pollution and energy usage. A modern textile printing machine can now create hundreds of designs per day with minimal environmental impact.

Applications Beyond Fashion

While fashion remains the most visible industry adopting this technology, digital textile printing also plays a pivotal role in sportswear, accessories, interior décor, and even technical textiles. Whether it’s vibrant cushions, printed upholstery, or personalized yoga mats, the possibilities are endless.

For startups and indie brands, this levels the playing field. High-quality, custom products can be created with relatively low capital investment—thanks to compact printing machines suited for studio-scale operations.

Final Thoughts

The rise of digital textile printing marks a shift from mass production to mass customization. With capabilities that ensure true colour, faster turnaround times, and eco-conscious operations, the modern textile printing machine is more than just a tool—it’s a gateway to the future of design and manufacturing. As technology advances further, the textile industry can only expect better precision, scalability, and creative freedom.

0 notes

Text

THE ULTIMATE GUIDE TO PRINT SHIPPING LABELS

In today’s fast-paced business environment, efficient shipping is crucial for customer satisfaction and operational success. Print shipping labels are an essential tool for businesses of all sizes, ensuring that packages reach their destinations accurately and on time. At Label Power, we provide a range of high-quality labels that can enhance your shipping process. Let’s explore the benefits and best practices of using print shipping labels.

Why Use Print Shipping Labels?

1. Streamlined Shipping Process

Using print shipping labels simplifies the shipping process significantly. By printing labels directly from your computer, you eliminate the need for handwritten labels, which can lead to errors and delays. This streamlined process ensures that your shipping operations run smoothly and efficiently.

2. Improved Accuracy

Mistakes in shipping can be costly. Printed labels reduce the risk of human error associated with handwritten information. With the ability to print shipping labels directly from your order management or shipping software, you can ensure that all necessary details — such as addresses, barcodes, and tracking numbers — are accurate and legible.

3. Professional Appearance

Printed shipping labels convey professionalism. When you use high-quality labels, your packages not only look more appealing but also give customers confidence in your business. A professional presentation can enhance your brand’s reputation and foster customer loyalty.

4. Easy Integration with Shipping Software

Many shipping software solutions allow you to design and print labels directly from their platforms. This integration makes it easy to generate labels in bulk and saves time when processing orders. You can also customize labels to include your branding, ensuring a consistent look across all shipments.

5. Cost-Effective Solution

Investing in print shipping labels can save your business money in the long run. By streamlining the shipping process and reducing errors, you can avoid costly shipping mistakes and delays. Additionally, buying labels in bulk can further lower your costs.

Choosing the Right Shipping Labels

When selecting shipping labels, consider the following factors:

Label Size and Type: Choose a size that fits your packages and is compatible with your printer. Consider whether you need thermal labels, direct thermal labels, or standard adhesive labels.

Durability: Ensure the labels can withstand various shipping conditions. Waterproof and tear-resistant labels are ideal for long-distance shipping.

Printer Compatibility: Make sure the labels are compatible with your existing printers, whether they are inkjet, laser, or thermal printers.

Best Practices for Using Print Shipping Labels

1. Test Print Before Bulk Printing

Always test print a few labels before bulk printing to ensure that everything aligns correctly and that the information is accurate.

2. Keep Labels Organized

Organize your labels in a way that allows for quick access. Whether you store them in a drawer or on a label dispenser, having an organized system will save you time during busy shipping periods.

0 notes

Text

Revolutionizing Print: Solimar Systems & RISO Unveil Cutting-Edge Inkjet Workflows at IPMA 2025

Solimar Systems, a prominent provider of workflow automation and PDF optimization solutions, is set to collaborate with RISO to exhibit at the 2025 In-Plant Printing and Mailing Association (IPMA) Annual Educational Conference. The event will take place from June 8 to 12 at the Davenport Grand Hotel in Spokane, Washington. This conference is the largest gathering of in-house print and mail…

0 notes

Text

This 3D printer can watch itself fabricate objects

Computer vision enables contact-free 3D printing, letting engineers print with high-performance materials they couldn’t use before.

With 3D inkjet printing systems, engineers can fabricate hybrid structures that have soft and rigid components, like robotic grippers that are strong enough to grasp heavy objects but soft enough to interact safely with humans. These multimaterial 3D printing systems utilize thousands of nozzles to deposit tiny droplets of resin, which are smoothed with a scraper or roller and cured with UV light. But the smoothing process could squish or smear resins that cure slowly, limiting the types of materials that can be used. Researchers from MIT, the MIT spinout Inkbit, and ETH Zurich have developed a new 3D inkjet printing system that works with a much wider range of materials. Their printer utilizes computer vision to automatically scan the 3D printing surface and adjust the amount of resin each nozzle deposits in real-time to ensure no areas have too much or too little material.

Read more.

13 notes

·

View notes

Text

Conductive Inks Market Drivers: Key Forces Powering Growth in the Printed Electronics Era

The conductive inks market is rapidly expanding, underpinned by technological advancements and the rising adoption of printed electronics. Conductive inks—formulated with silver, copper, graphene, or carbon—are used to print circuits on flexible substrates, enabling lightweight and cost-effective electronic solutions. This article delves into the major market drivers propelling the global conductive inks market, highlighting key trends across end-use sectors and materials.

Rising Demand for Flexible and Wearable Electronics

One of the strongest drivers of the conductive inks market is the surge in demand for flexible and wearable electronics. As consumers seek more compact, lightweight, and flexible electronic devices, manufacturers are turning to conductive inks to produce bendable circuits, sensors, and displays. Applications range from smartwatches and fitness bands to medical wearables that monitor vital signs in real time.

Conductive inks offer the unique advantage of enabling printed electronics on flexible substrates like plastic, textiles, and paper. This property aligns perfectly with the design needs of the wearable tech segment, supporting growth in both consumer electronics and healthcare.

Expanding Internet of Things (IoT) Ecosystem

The global proliferation of IoT devices is creating a robust demand for low-cost, printed sensors and antennas—core applications of conductive inks. With billions of IoT devices expected to connect everything from home appliances to industrial machinery, the need for scalable and economical circuit printing has never been greater.

Conductive inks enable the fabrication of components such as RFID tags, touch panels, and smart labels, which are integral to data capture and wireless communication in the IoT infrastructure. This rapidly growing ecosystem represents a long-term growth engine for the conductive inks market.

Advancements in Printed Electronics and Manufacturing Techniques

The evolution of printing techniques such as inkjet, screen, gravure, and flexographic printing has significantly enhanced the functionality and application scope of conductive inks. These methods allow precise, high-resolution circuit fabrication on diverse substrates at lower costs than traditional manufacturing.

Moreover, improvements in ink formulations—such as nanoparticle silver inks and graphene-based alternatives—are enabling better conductivity, adhesion, and printability. As printed electronics mature, conductive inks are seeing increased adoption in applications like OLED displays, photovoltaic cells, and printed circuit boards.

Strong Demand from the Automotive and Aerospace Sectors

Conductive inks are also gaining traction in the automotive and aerospace industries, where the push for lightweight, fuel-efficient vehicles and advanced electronics is prominent. Automakers are incorporating printed sensors, touch controls, and heater elements in car interiors, while aerospace manufacturers use conductive inks for de-icing systems and lightweight electrical components.

These industries benefit from the weight reduction, design flexibility, and cost efficiencies that conductive inks offer, reinforcing their role in next-generation mobility solutions.

Sustainability and Environmentally Friendly Manufacturing

As environmental sustainability becomes a key concern across industries, conductive inks provide an eco-friendly alternative to conventional etching and wiring techniques. Printed electronics consume fewer materials and generate less waste, while newer ink formulations are being designed with reduced toxicity and recyclability in mind.

Green electronics initiatives across consumer goods, energy, and automotive segments are thus fueling the transition toward conductive ink-based production, positioning the market favorably amid rising regulatory and consumer scrutiny.

Government Support and Strategic R&D Investments

Governments worldwide are supporting research and innovation in printed electronics, which directly boosts the conductive inks market. Funding initiatives, academic collaborations, and public-private partnerships are driving the development of new materials, scalable manufacturing processes, and commercial applications.

Additionally, industry stakeholders are increasingly investing in R&D to improve ink conductivity, reduce material costs (especially with silver alternatives), and expand usability across emerging applications such as bioelectronics and smart packaging.

Conclusion

The conductive inks market is being driven by a confluence of dynamic factors, including the rapid expansion of wearable tech, the IoT boom, advancements in printing technologies, and the growing emphasis on sustainable manufacturing. With diverse applications across consumer electronics, automotive, healthcare, and industrial sectors, conductive inks are positioned as a critical enabler of the future electronics landscape.

As companies innovate to meet the evolving needs of flexible, cost-effective, and green electronics, these market drivers will continue to shape the growth trajectory of the global conductive inks market.

0 notes