#MaintenanceEngineering

Explore tagged Tumblr posts

Text

Y Strainer Manufacturers in India

Speciality valve is top Y Strainer Manufacturers in India, A Y Strainer is the type of simple and efficient filter put in pipes to remove all forms of dirt, debris, or other particles from liquids, gases, or steam.

Description: 1.Body: Carbon Steel, CF8, CF8M, CF3M, Cast Iron, SS304, SS316 2.Nominal Diameter: DN25 to DN500 3.Nominal Pressure: Class150 to Class300 4.Inspection and Test: API 598 5.Size: ½” to 32” 6.Ends- Flanged, threaded, Buttweld, socket weld

Visit Us: https://www.specialityvalve.com/product-category/y-strainer/

#YStrainer#Strainer#PipeFitting#FluidFlow#WaterTreatment#IndustrialPiping#WaterFiltration#MechanicalEngineering#YStrainerFilter#PipingSystem#FiltrationTech#IndustrialEquipment#StrainerFilter#YShapeStrainer#FlowControl#PipeStrainer#FiltrationSystem#YStrainerInstallation#PipingSolutions#MaintenanceEngineering#FlowManagement#StrainerDesign#ProcessEngineering#FiltrationIndustry

0 notes

Text

Admissions Open for 2024-25 !

Kickstart your engineering career with our comprehensive polytechnic programs.

1-Civil Engineering

2-Computer Science Engineering

3-Electrical Engineering

4-Mechanical Engineering (Automobile)

5-Mechanical Engineering (Maintenance)

6-Mechanical Engineering (Production)

#PolytechnicAdmissions#EngineeringCourses#CivilEngineering#ComputerScienceEngineering#ElectricalEngineering#MechanicalEngineering#AutomobileEngineering#MaintenanceEngineering#ProductionEngineering#FutureEngineers#Admissions2024

3 notes

·

View notes

Text

10 Common John Deere 425 Problems Every Owner Should Know (And How to Fix Them)

https://autorepairlebanontn.com/?p=3887 10 Common John Deere 425 Problems Every Owner Should Know (And How to Fix Them) Are you facing frustrating issues with your John Deere 425 lawn tractor? You’re not alone. We’ve researched the most common 425 John Deere problems that owners encounter and compiled them into this comprehensive guide to help you troubleshoot effectively. From engine starting difficulties to transmission failures, the John Deere 425 can present several challenges even though its reputation for reliability. We’ll walk you through these common problems, their causes, and practical answers that can save you time and money on unnecessary repairs. Whether you’re a longtime owner or considering purchasing a used 425 model, understanding these potential issues is essential. Table of Contents Toggle Common John Deere 425 Problems: An OverviewTransmission and Drive System IssuesHydraulic Pump FailuresTransmission Slipping ProblemsEngine-Related ChallengesFuel Quality and Delivery ProblemsOil Pressure ComplicationsHydraulic System FailuresStarting DifficultiesOverheating ConcernsElectrical System FailuresBattery and Charging ProblemsFaulty Wiring and SwitchesSteering and Front End ProblemsPower Steering IssuesFront Axle and Wheel Bearing FailuresMower Deck ComplicationsClogging and Material Flow IssuesBelt and Spindle ProblemsUneven Cutting PerformanceMaintenance Tips to Prevent Common 425 IssuesFuel System MaintenanceIgnition System MaintenanceEngine MaintenanceAir Filter MaintenanceCarburetor MaintenanceRegular InspectionsCost Analysis of John Deere 425 RepairsEngine IssuesCooling System IssuesFuel System IssuesPTO and Deck ProblemsGeneral Repair Cost BreakdownConclusionFrequently Asked QuestionsWhat are the most common engine problems with the John Deere 425?How can I prevent transmission failures in my John Deere 425?What causes the John Deere 425 to overheat?Why is my John Deere 425 having starting problems?How do I fix electrical system failures in a John Deere 425?What should I do if my John Deere 425 has steering problems?How often should I perform maintenance on my John Deere 425?What causes mower deck issues on the John Deere 425?How much do repairs typically cost for a John Deere 425?Can I prevent brake system problems in my John Deere 425? Common John Deere 425 Problems: An Overview The John Deere 425 lawn tractor experiences several recurring issues that owners commonly encounter. Engine problems top the list, with starting difficulties often stemming from fuel system contamination or ignition system failures. Many users report transmission issues, particularly with the hydrostatic drive system that can develop leaks or lose pressure over time. Electrical system failures, including faulty solenoids and corroded connections, frequently plague these machines after extended use. Cooling system problems represent another important concern, with overheating occurring due to clogged radiators or malfunctioning cooling fans. Deck issues such as uneven cutting patterns or premature belt wear impact the 425’s primary function as a lawn maintenance tool. Steering complications emerge in older models, typically manifesting as difficulty turning or excessive play in the steering wheel. Brake systems on the 425 can deteriorate, resulting in reduced stopping power or complete failure in severe cases. PTO (Power Take-Off) malfunctions prevent implements from captivating properly, limiting the tractor’s versatility. Also, hydraulic system problems often develop in higher-hour units, with symptoms including slow or jerky carry out movement. Understanding these common issues helps owners perform preventive maintenance and address problems before they escalate into major repairs. Transmission and Drive System Issues The John Deere 425 tractor’s transmission and drive system can experience several performance issues that affect its overall functionality. These problems often manifest as reduced power delivery and operational inefficiencies that frustrate owners during daily use. Hydraulic Pump Failures Hydraulic pump failures represent a important concern for John Deere 425 owners. Contaminated hydraulic fluid stands as the primary culprit behind these failures, with dirt, debris, and water infiltration causing accelerated wear on critical components. Air leaks in the hydraulic system frequently lead to inconsistent machine behavior and noticeably reduced lift capacity, requiring proper bleeding to restore normal operation. High mileage machines face increased risk of hydraulic failure due to deteriorated seals and damaged hoses that allow oil leakage throughout the system. Regular maintenance practices, including scheduled fluid changes and filter replacements, prove essential for preventing catastrophic hydraulic pump issues and extending the service life of these components. Transmission Slipping Problems Transmission slipping in the John Deere 425 typically stems from oil pressure complications within the system. Worn oil pump gears or malfunctioning pumps create insufficient pressure conditions that prevent proper engagement of transmission components. These pressure issues manifest as slipping sensations during operation, particularly when the tractor encounters resistance or operates under heavy loads. Oil leaks from aging seals contribute to transmission fluid depletion, exacerbating slipping problems and potentially causing lasting damage. Monitoring transmission fluid levels, quality, and promptly addressing any visible leaks helps identify potential problems before they escalate into major repairs. Replacing worn components like the oil pump gear effectively resolves many transmission slipping issues, restoring proper functionality to the drive system. Engine-Related Challenges The John Deere 425 lawn tractor faces several engine-related issues that can impact performance and reliability. These challenges range from fuel delivery problems to oil pressure complications that require exact attention and answers. Fuel Quality and Delivery Problems Fuel quality significantly affects the John Deere 425’s engine performance. When the fuel is contaminated or the fuel line becomes clogged, the engine typically bogs down or loses power during operation. Checking the fuel line and carburetor helps diagnose this issue effectively. Users often notice performance degradation when using old fuel that has begun to break down or when debris enters the fuel system. Regular fuel filter replacement and using fresh, high-quality fuel prevents many of these problems from developing. Oil Pressure Complications Low oil pressure represents a common yet serious issue in the 425 model. The primary culprits include faulty plastic gears in the oil pump or improper spring alignment within the system. Replacing the original plastic gear with a more durable steel alternative provides a long-term solution to this recurring problem. Proper spring adjustment during maintenance ensures consistent oil pressure throughout engine operation. Monitoring oil pressure gauges helps detect these issues before they cause catastrophic engine damage. Hydraulic System Failures Hydraulic system leaks frequently plague the John Deere 425 and directly impact engine performance. Overfilling the hydraulic reservoir or operating with split hoses leads to fluid loss and reduced system efficiency. Correct oil level maintenance and prompt replacement of damaged hoses prevent these issues from affecting engine operation. Many owners report improved engine performance after addressing hydraulic leaks that previously created back pressure in the system. Starting Difficulties The John Deere 425 commonly experiences starting problems related to fuel delivery and electrical components. Fuel pump failures manifest when the pump doesn’t produce the characteristic ticking sound when turning the key, often caused by bad electrical contacts or blown fuses. PTO switch issues create another starting obstacle, with faulty contacts interrupting the electrical flow necessary for ignition. Running the gas tank completely dry leads to difficult restarts and rough initial operation as air enters the fuel system. Regular electrical connection cleaning and maintaining adequate fuel levels minimize these starting challenges. Overheating Concerns Overheating issues frequently affect the John Deere 425 engine, particularly during extended operation. The engine typically runs rough and struggles to restart once it reaches high temperatures, indicating potential cooling system deficiencies. Finding coolant in the engine oil signals a serious internal problem that requires immediate attention to prevent permanent engine damage. Regular cooling system maintenance, including radiator cleaning and proper coolant levels, helps prevent these temperature-related concerns. Many owners report improved performance after addressing cooling system blockages that restricted proper heat dissipation. Electrical System Failures Electrical system failures represent a important challenge for John Deere 425 owners, often leaving tractors inoperable without warning. The complex electrical network powering these machines can develop several issues over time, particularly in older models or those exposed to harsh environmental conditions. Battery and Charging Problems Battery issues rank among the most common electrical problems faced by John Deere 425 owners. Extended periods of inactivity frequently result in discharged batteries that fail to start the tractor when needed. Proper battery maintenance becomes essential, as old or consistently discharged batteries typically require complete replacement rather than recharging. The charging system itself can develop faults, with components like the alternator or voltage regulator failing to maintain proper battery charge during operation. Checking these components regularly helps ensure the battery receives appropriate charging current while the tractor runs. Many electrical problems manifest first as intermittent starting issues before progressing to complete failure, making early diagnosis crucial for preventing more extensive damage. Faulty Wiring and Switches Wiring problems create many electrical failures in the John Deere 425, ranging from annoying power interruptions to complete system shutdown. Inspecting all wiring harnesses for signs of wear, rodent damage, or corrosion helps identify potential failure points before they cause operational issues. Switch malfunctions, particularly with the ignition switch, commonly prevent tractors from starting even though having fully charged batteries. Cleaning switch contacts with electronic cleaner often resolves intermittent starting problems without requiring component replacement. The ignition coil contacts also frequently develop corrosion or wear in these tractors, leading to starting failures that can be remedied by applying lubricants like WD-40 or electronic cleaner to the affected areas. Damp operating conditions accelerate electrical system deterioration through increased corrosion, making regular cleaning and maintenance especially important for tractors used in humid environments or stored outdoors. Steering and Front End Problems The John Deere 425 garden tractor can develop several steering and front end issues as it ages, particularly in models with higher operating hours. These problems often manifest gradually and may significantly impact the tractor’s maneuverability and overall performance. Power Steering Issues Power steering functionality on the John Deere 425 requires regular maintenance to prevent operational problems. Many 425 owners experience increased steering difficulty over time, which often indicates deteriorating hydraulic pressure in the steering system. Leaks in the power steering lines can cause fluid loss, resulting in stiff or inconsistent steering response when operating the tractor. Damaged O-rings and seals are common culprits behind these leaks, especially in tractors that have been operated for extended periods. Air trapped in the hydraulic system might also create erratic steering behavior, requiring a proper bleeding procedure to restore normal function. Front Axle and Wheel Bearing Failures Front axle components on the 425 John Deere frequently develop wear patterns that compromise steering precision and front-end stability. Wheel bearings typically show signs of failure through unusual noises when turning or a noticeable wobble in the front wheels during operation. Excessive play in the front axle assembly makes precise maneuvering difficult, particularly when handling around landscaping features or obstacles. Corrosion from moisture exposure often accelerates bearing deterioration, especially in tractors stored outdoors or used in wet conditions. Regular greasing of front end components helps extend their service life, though bearings eventually require replacement as preventative maintenance to avoid more serious mechanical failures during operation. Mower Deck Complications The John Deere 425 mower deck presents several maintenance challenges that can impact overall performance. These complications often develop gradually and may significantly affect cutting quality when left unaddressed. Clogging and Material Flow Issues Debris accumulation represents one of the most common mower deck problems affecting the John Deere 425. Grass clippings and yard debris frequently build up underneath the deck, obstructing proper material flow and reducing cutting efficiency. Regular deck cleaning prevents this clogging issue that many owners report. The deck design, while generally praised for its cut quality, requires consistent maintenance to prevent performance degradation. Flooding issues also plague some 425 models, particularly after the engine reaches operational temperature and is shut down. This complication makes restarting difficult and indicates potential problems with the fuel system or carburetor. Cleaning fuel components and ensuring proper ventilation helps mitigate these flooding concerns. Belt and Spindle Problems Belt deterioration occurs frequently on aging John Deere 425 tractors, leading to performance problems and unexpected breakdowns. Worn or stretched belts slip during operation, causing inconsistent blade speeds and poor cutting results. Inspecting belt tension and condition during routine maintenance prevents catastrophic failures during operation. Spindle assemblies experience wear over time due to constant rotational forces and exposure to debris. Damaged spindles create vibration that transfers throughout the mower deck, causing uneven cutting and accelerated component wear. Lubrication of spindle bearings extends their service life, while regular inspection identifies developing issues before complete failure occurs. Uneven Cutting Performance Deck leveling problems constitute a major cause of uneven cutting with the 425 model. The Exact Adjust deck-leveling system, while designed for precision, requires proper adjustment to maintain an even cutting plane. Incorrect deck height settings result in scalped areas or missed grass patches across the lawn surface. Engine power fluctuations contribute significantly to cutting performance issues. When the tractor bogs down under load, blade speed decreases and cutting quality suffers immediately. Poor fuel quality, clogged fuel lines, or air filter restrictions commonly cause these power deficiencies that impact cutting consistency. Corrosion damage affects older 425 models, particularly in humid climates or when stored outdoors. Rust formation on deck components creates rough surfaces that collect debris more readily and interfere with grass discharge. Applying protective coatings and storing the tractor properly minimizes corrosion damage to the mower deck assembly. Maintenance Tips to Prevent Common 425 Issues Fuel System Maintenance Regular fuel system maintenance keeps your John Deere 425 running smoothly. Check fuel quality frequently and ensure fuel lines remain clear of debris and contaminants. Replace the fuel filter according to manufacturer recommendations to prevent power loss and performance issues. Clean fuel systems deliver consistent power and help avoid the common problem of engines bogging down under load. Ignition System Maintenance Ignition contacts require periodic cleaning to prevent corrosion-related starting problems. Apply lubricants like WD-40 or electronic cleaners to maintain good contact conditions. Store your tractor in a dry environment whenever possible to minimize moisture exposure. Properly maintained ignition systems eliminate frustrating no-start conditions that plague many 425 owners. Engine Maintenance Engine oil maintenance directly impacts your 425’s performance and longevity. Use only the manufacturer-recommended oil type and viscosity as specified in the service manual. Check oil levels before each use and change oil at prescribed intervals. Proper engine maintenance prevents low oil pressure issues and reduces wear on critical internal components. Air Filter Maintenance Air filters need regular inspection and replacement to maintain optimal engine performance. Clogged filters restrict airflow, causing the engine to bog down or lose power during operation. Clean or replace filters more frequently when operating in dusty conditions. Fresh air filters ensure proper combustion and fuel efficiency in your 425. Carburetor Maintenance Carburetor adjustments and cleaning prevent common issues like flooding after shutdown. Inspect the carburetor regularly for signs of varnish buildup or debris. Clean or rebuild the carburetor when performance deteriorates or flooding occurs, especially after reaching operational temperature. Properly functioning carburetors eliminate rough running conditions and improve fuel economy. Regular Inspections Comprehensive inspections catch potential problems before they cause major failures. Examine electrical systems, PTO connections, and hydraulic components during routine maintenance. Follow the service manual’s inspection schedule to maintain reliability. Document any changes in performance or unusual noises during operation to identify developing issues early. Cost Analysis of John Deere 425 Repairs Engine Issues Engine problems represent some of the most common repair needs for John Deere 425 tractors. Bogging down and power loss typically stem from fuel quality issues, clogged fuel lines, or carburetor problems. Addressing these issues costs between $50-$200 depending on which parts need replacement. Starting problems caused by corroded electrical contacts or worn ignition components are relatively inexpensive to fix, with cleaning answers costing minimal amounts, while replacement ignition parts range from $20-$100. Cooling System Issues Cooling system problems often manifest as unexplained coolant loss without visible leaks. These issues frequently indicate internal engine problems or failing cooling system components. Repairs for cooling system components typically cost $100-$500 depending on the severity of the damage and which parts require replacement. Fuel System Issues Fuel flooding after engine shutdown points to fuel system or carburetor malfunctions. Fixing these problems involves adjusting or replacing the carburetor and checking fuel line connections. Repair costs for these issues generally fall between $50-$200, making them moderately expensive to address compared to other maintenance items. PTO and Deck Problems Power Take-Off (PTO) issues stem from component wear and damage after extended use. Replacing or repairing these critical parts costs between $50-$200, depending on the exact components affected and their availability. General Repair Cost Breakdown Repair Category Parts Cost Labor Cost (hourly) Total Cost Range Minor Repairs $20-$100 $50-$200 $20-$100 Moderate Repairs $100-$300 $50-$200 $100-$500 Major Repairs $300-$500+ $50-$200 $500-$1,500+ Replacement parts vary significantly in price, from simple items like fuel lines to more complex components such as cooling system parts, ranging from $20-$500. Professional labor adds substantial cost to repairs, with rates typically running $50-$200 per hour based on mechanic expertise and repair complexity. Minor repairs like cleaning electrical contacts or replacing simple components generally cost $20-$100 total. Moderate repairs involving carburetor replacements or basic cooling system work range from $100-$500 all-inclusive. Major system overhauls or complex component replacements can reach $500-$1,500 or more when combining parts and professional labor. Understanding these cost ranges helps John Deere 425 owners budget appropriately for maintenance and make informed decisions about whether to perform DIY repairs or seek professional assistance for more complex issues. Conclusion The John Deere 425 remains a capable lawn tractor even though its share of challenges. With proper maintenance and timely intervention we’ve outlined throughout this guide owners can significantly extend their machine’s lifespan and avoid costly repairs. Understanding these common issues isn’t just about troubleshooting they’re opportunities to develop preventative maintenance habits that protect your investment. Regular fluid checks fuel system maintenance and electrical system inspections are your best defense against major failures. While no machine is perfect the 425’s problems are generally manageable with the right knowledge and care. By implementing our recommended maintenance practices and staying alert to early warning signs you’ll enjoy more reliable performance from this classic John Deere model for years to come. Frequently Asked Questions What are the most common engine problems with the John Deere 425? The most common engine problems include fuel system contamination, ignition failures, and starting difficulties. These issues often stem from poor fuel quality, clogged fuel lines, or worn electrical components. Regular fuel system maintenance and monitoring oil pressure can prevent many of these problems and ensure optimal performance. How can I prevent transmission failures in my John Deere 425? Prevent transmission failures through regular hydraulic fluid changes and filter replacements. Monitor fluid levels and quality regularly, and address any leaks immediately. Air leaks and contaminated fluid are primary causes of hydraulic pump failures. Proper maintenance can prevent inconsistent performance and reduced lift capacity, avoiding costly repairs. What causes the John Deere 425 to overheat? Overheating typically occurs due to cooling system issues such as clogged radiators, faulty thermostats, or low coolant levels. Extended operation in high temperatures can exacerbate these problems. Regular inspection of the cooling system components and maintaining proper coolant levels are essential to prevent overheating and potential engine damage. Why is my John Deere 425 having starting problems? Starting problems usually result from fuel delivery issues, discharged batteries, or faulty electrical components. Check the battery connections, fuel quality, and ignition switch for proper function. Cold weather can amplify these issues. Regular battery maintenance and ensuring clean fuel can prevent most starting difficulties. How do I fix electrical system failures in a John Deere 425? Address electrical failures by regularly inspecting the battery, charging system, and wiring harnesses for corrosion or damage. Maintain battery terminals and connections, and check for loose or damaged wires. Replace faulty switches promptly. Regular electrical system maintenance can prevent unexpected power interruptions and system shutdowns. What should I do if my John Deere 425 has steering problems? For steering issues, check hydraulic pressure and inspect power steering lines for leaks. Grease front-end components regularly and inspect wheel bearings for wear. Increased steering difficulty often indicates deteriorating hydraulic systems. Regular maintenance can extend component life, though eventual replacement may be necessary for older models. How often should I perform maintenance on my John Deere 425? Perform basic maintenance every 50 operating hours, including oil checks, air filter inspections, and greasing essential components. Change engine oil every 100 hours, hydraulic fluid annually, and inspect fuel system components regularly. Comprehensive inspections should be conducted at least twice yearly to catch potential problems early. What causes mower deck issues on the John Deere 425? Mower deck issues typically stem from debris accumulation, worn belts, damaged spindles, or improper leveling. These problems lead to uneven cutting, reduced efficiency, and material flow issues. Regular deck cleaning, belt inspections, spindle maintenance, and proper leveling can prevent most cutting performance problems. How much do repairs typically cost for a John Deere 425? Repair costs vary by system: minor engine repairs range from $100-$300, while major overhauls can exceed $1,500. Cooling system repairs typically cost $150-$600, fuel system repairs $50-$400, and PTO repairs $200-$800. Costs depend on whether you choose DIY repairs or professional service, with labor significantly increasing expenses. Can I prevent brake system problems in my John Deere 425? Yes, prevent brake system deterioration by regularly inspecting brake components for wear and adjusting as needed. Check brake fluid levels in hydraulic systems and replace worn pads or discs promptly. Regular testing of brake effectiveness can identify issues before they compromise safety or require extensive repairs. https://autorepairlebanontn.com/?p=3887 Absolute Auto Repair

0 notes

Text

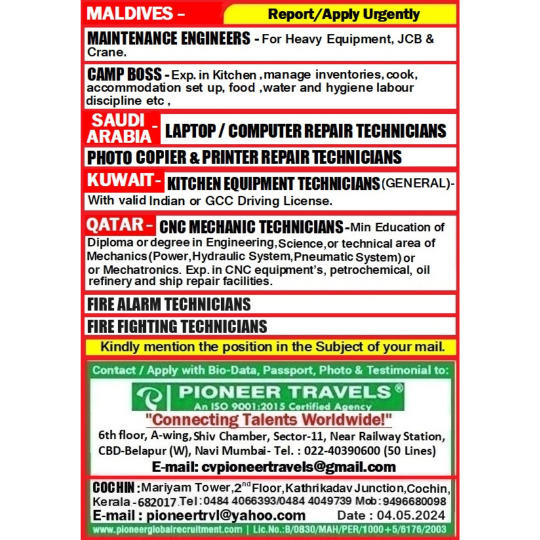

𝐖𝐞 𝐡𝐚𝐯𝐞 𝐚𝐧 𝐔𝐫𝐠𝐞𝐧𝐭 𝐑𝐞𝐪𝐮𝐢𝐫𝐞𝐦𝐞𝐧𝐭 𝐟𝐨𝐫 𝐭𝐡𝐞 #Maldives #SaudiArabia #Kuwait & #Qatar 𝐥𝐨𝐜𝐚𝐭𝐢𝐨𝐧.

𝐂𝐚𝐥𝐥 𝐔𝐬: +(91)-(22)-40390600 (50 Lines) 𝐄𝐦𝐚𝐢𝐥: [email protected] 𝐖𝐞𝐛𝐬𝐢𝐭𝐞: https://shorturl.at/inuKO Walk in for an Interview/Apply Now! Or if you know someone who's a perfect fit for the roles described below, kindly share this with them too. 𝐕𝐚𝐜𝐚𝐧𝐜𝐲 𝐇𝐢𝐠𝐡𝐥𝐢𝐠𝐡𝐭𝐬: Competitive Salaries Exciting Abroad Opportunities Dynamic Work Environments _ #gulfjobs #jobvacancy #hiringnow #newvacancy #jobvacancy #abroadjobs #jobseeker #careeropportunities #jobseekersindia #gccjobs #jobs #saudiarabiajobs #kuwaitjob #Qatarjobs #firealarmtechnician #cncmechanictechnicians #kitchenequipmenttechnician #campboss #maintenanceengineer

0 notes

Text

Temperature sensor

A temperature sensor is a device used to measure temperature. This can be air temperature, liquid temperature or the temperature of solid matter. There are different types of temperature sensors available and they each use different technologies and principles to take the temperature measurement.

.

.

.

#sensors #plastic #plasticmodel #PlasticManufacturing #temperaturecontrol #temperaturesensor #temperaturemonitoring #temperature #temperaturecontrolled #electrician #maintenanceengineering #electricalinstallation

0 notes

Text

How to reduce Grease Bleeding?

New grease cartridges, tubes or containers should be stored upright in the vertical position with the plastic cap up at all the time. This helps to prevent oil from leaking out of the vessel. To learn more, read our blog.

#greasebleeding#greaseseperation#greasestorage#maintenanceandrepair#maintenanceengineering#lubrication

0 notes

Photo

#DOEPKE Switch-disconnectors and main switches are able to separate #electrical devices or even system parts from the mains completely at all poles for #maintenance purposes, even under load or overload. Suitable for use in main distribution boards in power supplies in large areas such as campsites, marinas, allotment gardens, and showrooms www.jiselectric.com #switches #maintenanceandrepair #maintenanceengineering #distributionboards #switchboards #switchgear #panelbuilding #electricalsafety #electricalcontractor #jiselectric #doepkedubai #uae #dubaiexpo2021 (at JIS Electrical Trading LLC) https://www.instagram.com/p/CQxi6P9ht21/?utm_medium=tumblr

#doepke#electrical#maintenance#switches#maintenanceandrepair#maintenanceengineering#distributionboards#switchboards#switchgear#panelbuilding#electricalsafety#electricalcontractor#jiselectric#doepkedubai#uae#dubaiexpo2021

0 notes

Photo

#Spendanalytics #service by #CyspaceGlobal for more details visit Cyspaceglobal.com # #reliable #deliver #servicecenter #specialized #delivery #maintenance #availability #maintenanceengineering #datamanagement #datagovernance #dataintegration #datavirtualization #dataintelligence #datalake #informationtechnology #informationsecurity # #infosec #cybersecurity #security #cyberdefense #datawarehouse #infosecurity #computersecurity #datasecurity #networksecurity #cyberattack https://www.instagram.com/p/CAwOaOhAVO4/?igshid=gkcpno9w9ht7

#spendanalytics#service#cyspaceglobal#reliable#deliver#servicecenter#specialized#delivery#maintenance#availability#maintenanceengineering#datamanagement#datagovernance#dataintegration#datavirtualization#dataintelligence#datalake#informationtechnology#informationsecurity#infosec#cybersecurity#security#cyberdefense#datawarehouse#infosecurity#computersecurity#datasecurity#networksecurity#cyberattack

0 notes

Photo

Book appointment for Air conditioner Repair Service in Surprise, USA on Global B2B2C Portal NearMeTrade.com Register your every type of #business #products or #professional services for #free with instant approval and get free #lead and #enquiry. https://nearmetrade.com/air-conditioner-repair-service/p/surprise/arizona #b2b #b2c #nearmetrade #airconditioner #airconditioning #aircompressors #aircompressor #repair #repairs #maintenanceandrepair #maintenancemanagement #maintenance #maintenanceengineering #maintenanceengineer #maintain #electronics #electronic https://www.instagram.com/p/B_hgBrnpXvt/?igshid=1i7vgl0vrykp4

#business#products#professional#free#lead#enquiry#b2b#b2c#nearmetrade#airconditioner#airconditioning#aircompressors#aircompressor#repair#repairs#maintenanceandrepair#maintenancemanagement#maintenance#maintenanceengineering#maintenanceengineer#maintain#electronics#electronic

0 notes

Photo

#tlbscorporarion E-SM Industrial Division Engineering and Maintenance Services Line Services We carry out Inspection, test and certifications of non-destructive and metalographic testting #maintenanceengineering #inspection #metalworking #metalographic #nondestructive #houston #texas #api #astm #ansi #metalwork #radiographystudent #welding (at Houston Tomball Tx) https://www.instagram.com/p/B3ilw6bAJ_P/?igshid=fk59s5ayxyvj

#tlbscorporarion#maintenanceengineering#inspection#metalworking#metalographic#nondestructive#houston#texas#api#astm#ansi#metalwork#radiographystudent#welding

0 notes

Text

Best Electrical Operations & Maintenance Services Tamil Nadu

PR Power Engineers is a Power Operations and Maintenance service that provides the top best operations and maintenance services to energy assets across generation technologies. Best Power Operations and Maintenance services are essential to making sure that your project is under regulations, along with having safety and emergency procedures in place. With dedicated Expert engineering in Tamilnadu, we operate & maintain all possible power plants, process industries, and substation equipment on a 24 X 7 basis.

Our services more visit - https://www.prpowerengineers.com/operation-maintenance/

#OperationServiceChennai#powermaintenanceservice#powerassetmanagementserviceschennai#industrialandmaintenanceengineeringchennai#itmaintenanceengineer#operationandmaintenancesystemchennai#technical maintenance engineer#maintenanceengineer#operationandmaintenanceengineerinchennai

0 notes

Photo

We Are Hiring Maintenance Engineer

0 notes

Text

KG Multi Speciality Hospital and research centre

HIRING!!!

1. Pharmacy Assistant

2. Maintenance Engineer - Technical

3. MRD Assistant

Qualification: Diploma/DMLT/BSc (MLT)/Degree

Contact: +91 7094441666

Drop Your CV @: [email protected]

Location: Thanjavur, Tamil Nadu

For more details click here:

https://www.jobslink.in/viewjob/294300/

https://www.jobslink.in/viewjob/294303/

https://www.jobslink.in/viewjob/294304/

#jobslink #jobseekers #jobsinindia #jobvacancies #jobsearching #career #jobs #workfromhome #hiringnow #latestjobs #jobs2022 #jobopenings #chennaijobs #thanjavurjobs #pharmacyassistant #maintenanceengineer #mrdassistant

0 notes

Text

Temperature sensor

A temperature sensor is a device used to measure temperature. This can be air temperature, liquid temperature or the temperature of solid matter. There are different types of temperature sensors available and they each use different technologies and principles to take the temperature measurement.

.

.

.

#sensors #plastic #plasticmodel #PlasticManufacturing #temperaturecontrol #temperaturesensor #temperaturemonitoring #temperature #temperaturecontrolled #electrician #maintenanceengineering #electricalinstallation

1 note

·

View note

Photo

Figured its about time i share this. The building i maintain. Brand new 303 unit resident building. What i do. #workmode #dayjob #maintenanceengineer (at Brooklyn, New York)

0 notes

Photo

Multiple #opportunities in a Leading Company in Abu Dhabi. Send Resumes - [email protected] & Visit - www.sundus.jobs #recruitment #executivesearch #outsoucing #engineerjobs #technicaljobs #economists #planningjobs #programdevelopment #operationsjobs #analyst #tariffs #watermanagement #powerengineering #watermanagement #engineer #electrical #abudhabijobs #connections #followers #maintenanceengineer #vacancy #jobsearch #careers #recruiting #hiring #hr #resume #cv #lookingforjob #abudhabi #jobs #jobseekers

#recruitment#outsourcing#executive search#technical jobs#program development#economist#abu dhabi jobs#abu dhabi#maintenance engineer#hot jobs#careers#resume#cv#job search#water management#vacancy#electrical jobs#power jobs#power engineer

0 notes