#MedicalGradeTitanium

Explore tagged Tumblr posts

Text

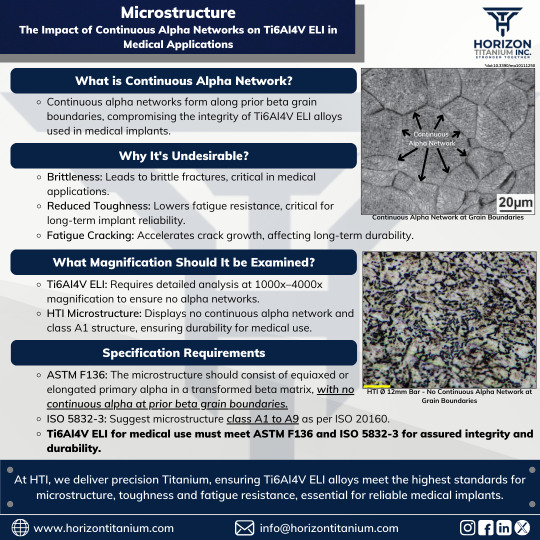

Microstructure Insights: Ti6Al4V ELI – Why Continuous Alpha Networks Matter

In industries like medical and aerospace, material performance is critical. The microstructure of Ti6Al4V ELI plays a crucial role in ensuring safety and durability. But have you ever wondered why continuous alpha networks can pose a significant issue? Here's why:

➡️ They create brittle points, increasing the risk of failure. ➡️ They reduce toughness and fatigue resistance. ➡️ They provide pathways for fatigue cracking, compromising durability.

Why is it important to examine the microstructure at higher resolutions?

Ti6Al4V ELI has a very fine microstructure in the annealed condition, making it difficult to assess the alpha network and phase distribution at lower magnifications (100x-500x). To accurately determine if a continuous alpha network has formed and to analyze the distribution of alpha and beta phases, it's essential to use magnifications of at least 1000x or higher.

Want to learn more about how detailed analysis can prevent material failures? Drop a comment or contact us at [email protected]. Let’s discuss your challenges!

#KnowYourTitanium#Titanium#TitaniumAlloys#Microstructure#Metallurgy#Ti6Al4VELI#MaterialScience#MedicalGradeTitanium#AlphaNetworkImpact#FatigueResistance#FractureToughness#FailurePrevention#HighResolutionAnalysis#AdvancedMaterials#EngineeringInsights#TitaniumFatigue#MicrostructureAnalysis#MaterialDurability#HorizonTitanium#StrongerTogether

0 notes

Text

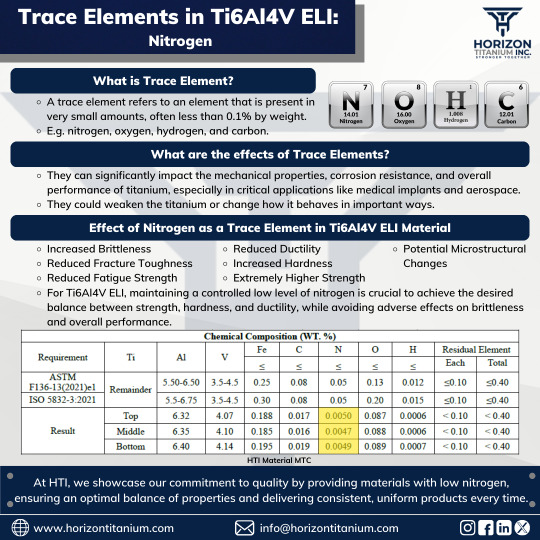

Trace Elements in Ti6Al4V ELI: The Impact of Nitrogen

When it comes to titanium alloys like Ti6Al4V ELI, trace elements such as nitrogen can have a significant impact on the material's mechanical properties. In this post, we dive deep into how trace amounts of nitrogen affect brittleness, fracture toughness, and strength.

Why does this matter?

1. Nitrogen can make your titanium alloy stronger, but there’s a balance! Too much can make it brittle. Too little, and you might lose strength. The key is finding that perfect balance. 2. In medical-grade titanium like Ti6Al4V ELI, precision is everything, and keeping nitrogen levels controlled ensures your material performs under the most demanding conditions.

Did you know? If the nitrogen content is low but your material still boasts high strength, you’re working with premium titanium! This means the strength is purely from the titanium and not from unwanted nitride phases like titanium nitride, which could weaken the material's long-term performance.

At HTI, we deliver consistent quality, ensuring that the material you get is optimized for strength, ductility, and durability—making it perfect for critical applications like medical implants.

For more technical insights, check out the composition chart in the post!

Let’s talk titanium! Have questions about material quality or trace elements? Drop a comment or reach out at [email protected]

#KnowYourTitanium#Titanium#Ti6Al4VELI#MaterialScience#TraceElements#NitrogenImpact#ChemicalComposition#MedicalGradeTitanium#Metallurgy#EngineeringExcellence#AdvancedMaterials#QualityControl#TitaniumStrength#TitaniumAlloys#PrecisionEngineering#HorizonTitanium#StrongerTogether

0 notes

Text

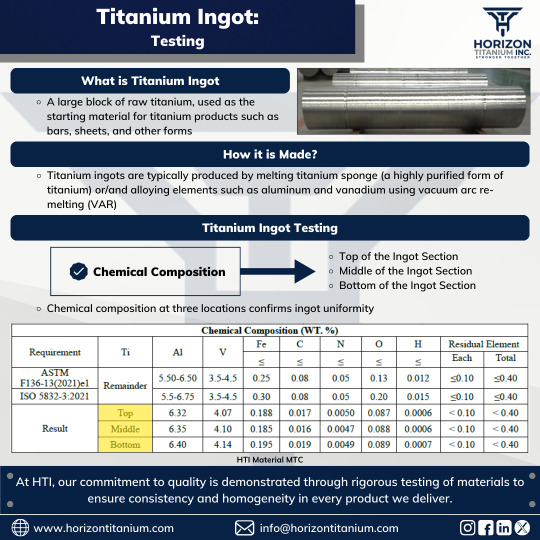

Titanium ingots play a crucial role as the starting material for producing bars, sheets, and other forms of titanium products used in medical devices and orthopedic implants.

What makes HTI titanium bars perfect for medical applications?

Quality and consistency are non-negotiable. That's why we ensure that every ingot undergoes rigorous testing, with special attention to key quality parameters such as:

1. Chemical Composition: Ensured uniformity through testing at the top, middle, and bottom sections. 2. Alloying Elements: Optimal levels of aluminum and vanadium for strength and durability. 3. Purity: Low levels of residual elements to meet medical standards, adhering to ASTM F136-13 and ISO 5832-3 guidelines. These parameters ensure the material's strength, reliability, and compatibility for medical implants and devices.

At Horizon Titanium Inc., we source top-grade titanium bars to meet the stringent demands of the medical field.

For more information, contact us at [email protected]

#KnowYourTitanium#TitaniumIngot#Homogenous#Uniform#ChemicalComposition#MedicalGradeTitanium#OrthopedicImplants#MaterialQuality#MedicalIndustry#SupplierExcellence#HorizonTitanium#StrongerTogether

0 notes

Text

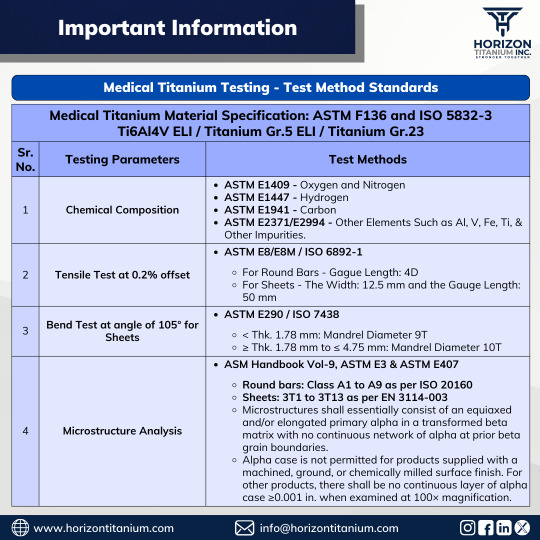

At Horizon Titanium, we believe in the importance of accurate testing for medical-grade titanium. We're sharing essential insights on the correct testing methods and standards to ensure the highest quality.

Need more information? We're here to help—just reach out to us at [email protected]

#KnowYourTitanium#TitaniumTesting#MedicalGradeTitanium#Ti6Al4VELI#Grade5ELI#Grade23#ASTMF136#ISO5832_3#QualityAssurance#Specification#TestMethod#ChemicalComposition#ASTME1409#ASTME1447#ASTME1941#Aluminium#Vanadium#ASTME2371#Mechanical#TensileTest#ASTME8#BendTest#ASTME290#MicrostructureAnalysis#ASMHandbookVol_9#MicrostructureClass#ISO20160#EN3114_003#HorizonTitanium#StrongerTogether

0 notes

Text

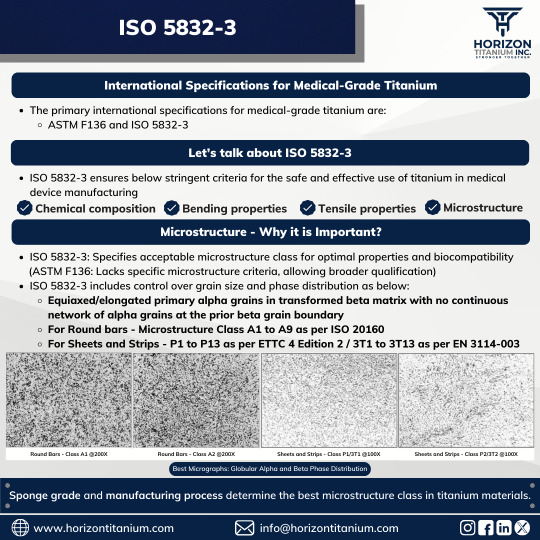

The properties of metals are determined by their metallurgy, and for applications such as medical use, these properties must be optimized. To achieve this, international standards specify the required microstructure. Two key standards for medical titanium materials are ASTM F136 and ISO 5832-3.

ISO 5832-3 defines microstructure classes with specific alpha and beta morphologies and phase distributions, detailed through micrographs. In contrast, ASTM F136 outlines microstructure requirements without specifying exact classes or providing micrographs, thus omitting precise details on alpha and beta phase distributions.

To illustrate this, consider the example of the color blue. ASTM F136 broadly accepts any shade of blue for medical applications. However, ISO 5832-3 specifies exact color codes, categorizing shades from Class Sr. No. A1 to A9, and thus sets rigorous microstructure requirements for medical grades. ASTM F136 lacks this level of detail and does not categorize shades of blue, merely stating that any blue is acceptable for medical use.

Therefore, adhering to the ISO 5832-3 standard is crucial for ensuring the precise microstructure requirements in Titanium materials needed for medical device manufacturing.

To know more about the importance of microstructure in titanium materials for medical applications, write us at [email protected]

#KnowYourTitanium#Titanium#Metallurgy#ISO5832_3#ASTMF136#Microstructure#MicrostructureClass#ISO20160#EN3114_003#SpongeGrade#TitaniumPurity#ManufacturingProcess#Biocompatibility#MaterialsScience#Standards#MedicalGradeTitanium#TitaniumImplants#PrecisionMicrostructure#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Text

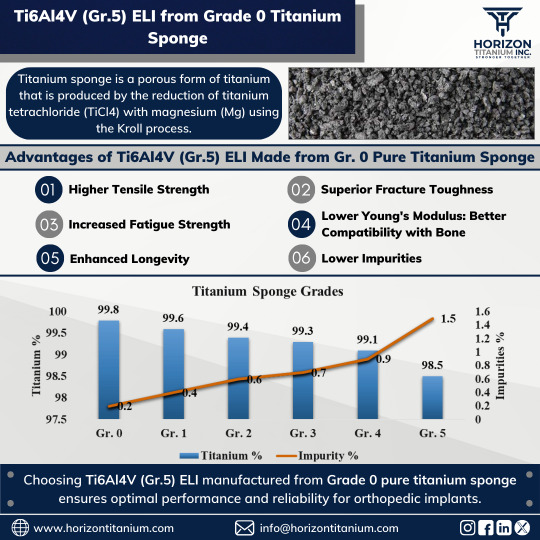

Titanium is vital in the medical field due to its biocompatibility, strength, and corrosion resistance. However, the quality of medical-grade titanium depends on the grade of titanium sponge used in production. Let's explore how titanium sponge impact the quality of titanium for medical devices and implants.

What is Titanium Sponge? Titanium sponge, made through the Kroll process, is a porous, brittle form of titanium. It needs further processing and alloying with elements like aluminum and vanadium (Ti6Al4V (Gr.5) ELI) to be used in manufacturing medical devices. Its quality and purity are critical for the final titanium properties.

Importance of Choosing the Right Grade The grade of titanium sponge used to manufacture titanium material for medical applications has a profound impact on the quality and performance of the final product. By selecting the right grade, manufacturers can ensure that medical devices made from high-purity Sponge Gr. 0 material will meet the stringent standards required for medical use, providing safe and effective solutions for patients.

If you need any further information, reach out at [email protected]

#KnowYourTitanium#Titanium#TitaniumSponge#TitaniumSpongeGrade0#TitaniumManufacturing#KrollProcess#Ti6Al4VELI#Grade5ELI#HigherTensileStrength#SuperiorFractureToughness#IncreasedFatigueStrength#LowerYoungModulus#EnhancedLongevity#LowerImpurities#MaterialScience#TitaniumQuality#MedicalGradeTitanium#TitaniumImplants#OrthopaedicImplants#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Photo

Titanium sponge is the primary raw material used in the manufacture of Titanium round bars and sheets for medical applications, and the quality of Titanium sponge influences the qualities of the end products.

For more information, write us at [email protected]

#KnowYourTitanium#TitaniumSponge#Impurities#Biocompatibility#CorrosionResistance#FatigueStrength#FractureToghness#MedicalGradeTitanium#TitaniumRoundbars#TitaniumSheets#MedicalImplants#OrthopaedicImplants#Orthopaedic#HorizonTitanium#StrongerTogether

0 notes

Photo

Discover the superior strength and exceptional quality of our titanium materials at Horizon Titanium Inc. The advanced VAR process ensures high purity, homogeneity, and tighter control for increased durability and performance. Perfect for high-stress applications in aerospace, defense, medical, and nuclear industries, our titanium alloys offer corrosion resistance, lightweight design, high heat resistance, and biocompatibility. Trust in us to deliver the highest quality titanium materials for your critical applications. Contact us today to learn [email protected]

#KnowYourTitanium#TitaniumIngot#VacuumArcRemelting#TitaniumProductions#TripleMelting#HighPurityTitanium#HomogenousMicrostructure#EcofriendlyTitanium#HighQualityTitanium#MedicalGradeTitanium#MedicalImplants#OrthopedicImplants#HorizonTitanium#StrongerTogether

0 notes