#MicrostructureClass

Explore tagged Tumblr posts

Text

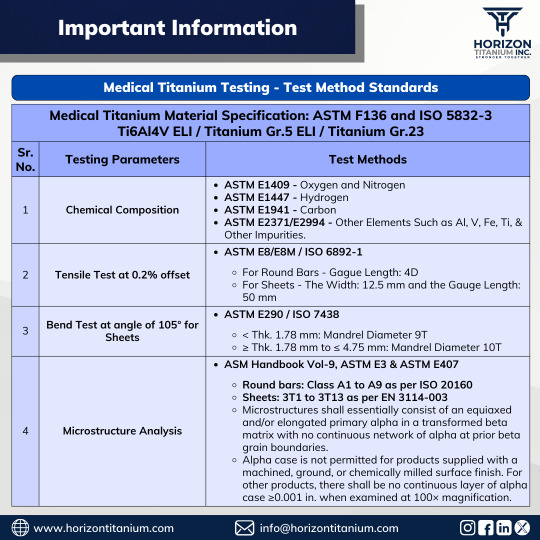

At Horizon Titanium, we believe in the importance of accurate testing for medical-grade titanium. We're sharing essential insights on the correct testing methods and standards to ensure the highest quality.

Need more information? We're here to help—just reach out to us at [email protected]

#KnowYourTitanium#TitaniumTesting#MedicalGradeTitanium#Ti6Al4VELI#Grade5ELI#Grade23#ASTMF136#ISO5832_3#QualityAssurance#Specification#TestMethod#ChemicalComposition#ASTME1409#ASTME1447#ASTME1941#Aluminium#Vanadium#ASTME2371#Mechanical#TensileTest#ASTME8#BendTest#ASTME290#MicrostructureAnalysis#ASMHandbookVol_9#MicrostructureClass#ISO20160#EN3114_003#HorizonTitanium#StrongerTogether

0 notes

Text

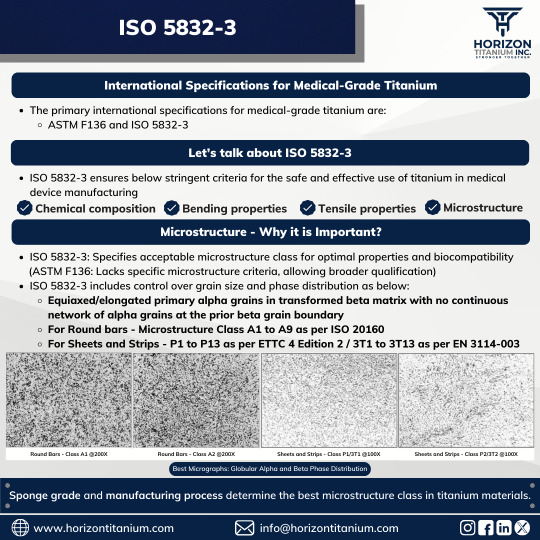

The properties of metals are determined by their metallurgy, and for applications such as medical use, these properties must be optimized. To achieve this, international standards specify the required microstructure. Two key standards for medical titanium materials are ASTM F136 and ISO 5832-3.

ISO 5832-3 defines microstructure classes with specific alpha and beta morphologies and phase distributions, detailed through micrographs. In contrast, ASTM F136 outlines microstructure requirements without specifying exact classes or providing micrographs, thus omitting precise details on alpha and beta phase distributions.

To illustrate this, consider the example of the color blue. ASTM F136 broadly accepts any shade of blue for medical applications. However, ISO 5832-3 specifies exact color codes, categorizing shades from Class Sr. No. A1 to A9, and thus sets rigorous microstructure requirements for medical grades. ASTM F136 lacks this level of detail and does not categorize shades of blue, merely stating that any blue is acceptable for medical use.

Therefore, adhering to the ISO 5832-3 standard is crucial for ensuring the precise microstructure requirements in Titanium materials needed for medical device manufacturing.

To know more about the importance of microstructure in titanium materials for medical applications, write us at [email protected]

#KnowYourTitanium#Titanium#Metallurgy#ISO5832_3#ASTMF136#Microstructure#MicrostructureClass#ISO20160#EN3114_003#SpongeGrade#TitaniumPurity#ManufacturingProcess#Biocompatibility#MaterialsScience#Standards#MedicalGradeTitanium#TitaniumImplants#PrecisionMicrostructure#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Photo

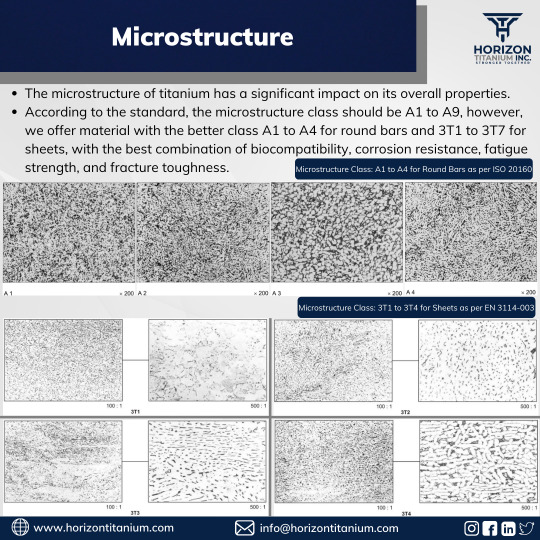

The microstructure is the most significant aspect of any material. Titanium's overall properties are determined by how the phases, grain size, and constituent particles are distributed within the Titanium. The ISO standard recommends Microstructure class A1 to A9 for Titanium Round bars, while the EN standard recommends class 3T1 to 3T13 for sheets. For any information regarding Titanium metallurgy, its grades, standards, or applications, you can write us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#TitaniumSheets#Metallurgy#Microstructure#MicrostructureClass#Mechanical#FatigueStrength#FractureToughness#CorrosionResistance#Biocompactibility#Properties#MedicalImplants#OrthopaedicImplants#LongLastingImplants#HorizonTitanium#StrongerTogether

0 notes