#SpongeGrade

Explore tagged Tumblr posts

Text

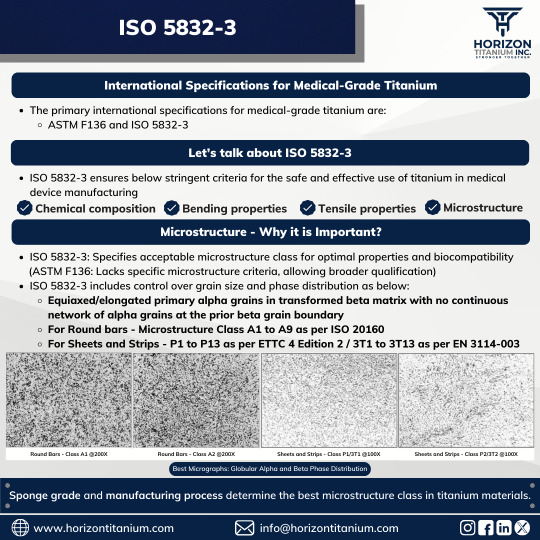

The properties of metals are determined by their metallurgy, and for applications such as medical use, these properties must be optimized. To achieve this, international standards specify the required microstructure. Two key standards for medical titanium materials are ASTM F136 and ISO 5832-3.

ISO 5832-3 defines microstructure classes with specific alpha and beta morphologies and phase distributions, detailed through micrographs. In contrast, ASTM F136 outlines microstructure requirements without specifying exact classes or providing micrographs, thus omitting precise details on alpha and beta phase distributions.

To illustrate this, consider the example of the color blue. ASTM F136 broadly accepts any shade of blue for medical applications. However, ISO 5832-3 specifies exact color codes, categorizing shades from Class Sr. No. A1 to A9, and thus sets rigorous microstructure requirements for medical grades. ASTM F136 lacks this level of detail and does not categorize shades of blue, merely stating that any blue is acceptable for medical use.

Therefore, adhering to the ISO 5832-3 standard is crucial for ensuring the precise microstructure requirements in Titanium materials needed for medical device manufacturing.

To know more about the importance of microstructure in titanium materials for medical applications, write us at [email protected]

#KnowYourTitanium#Titanium#Metallurgy#ISO5832_3#ASTMF136#Microstructure#MicrostructureClass#ISO20160#EN3114_003#SpongeGrade#TitaniumPurity#ManufacturingProcess#Biocompatibility#MaterialsScience#Standards#MedicalGradeTitanium#TitaniumImplants#PrecisionMicrostructure#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Photo

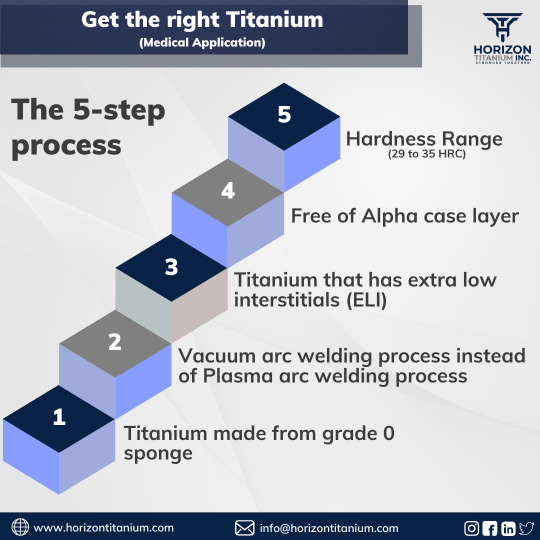

1. The Titanium sponge comes in six grades, i.e. level 0 to level 5. The level 0 grade Titanium sponge is the best material to produce Titanium raw materials because it has low impurities and lower hardness compared to other sponge grades.

2. As the Titanium reacts violently with oxygen and other gases, Vacuum welding, instead of plasma arc welding of compacted briquettes during the Titanium ingot manufacturing, prevents Titanium from reacting with ambient gases.

3. To assure reduced impurity levels, Titanium ingots must be melted three times in a vacuum arc re-melting furnace.

4. The Titanium alloy must be according to ASTM F136 & ISO 5832-3, and CP Titanium must be as per ASTM F67 & ISO 5832-2 standard, which doesn't permit an alpha case layer.

5. While the above standard doesn't define the hardness range of Titanium materials, our research shows that the hardness of Titanium alloy between 29 and 35 HRC should be ideal.

Are you looking to buy Titanium materials? Send us your requirements, and we will share our technical data sheet of Titanium materials based on your application. You can email us at [email protected]

#KnowYourTitanium#Titanium#RightTitanium#SpongeGrade#VaccumArcWelding#ELI#AlphaCase#HardnessRange#TitaniumRoundbar#TitaniumSheet#TitaniumImplant#MedicalImplants#OrthopedicImplant#MedicalDevices#StrongerTogether

0 notes