#Modular Cleanroom Infrastructure

Explore tagged Tumblr posts

Text

Revolutionizing Clean Environments: Modular Cleanroom Infrastructure and Pharma Equipment Solutions

In the pharmaceutical and biotechnology industries, maintaining a contamination-free environment isn’t a choice — it’s a necessity. From drug manufacturing to precision electronics, every cleanroom must meet rigorous regulatory standards. That’s where modular cleanroom infrastructure, dedusting machines, and pharmaceutical isolators come into play.

What is Modular Cleanroom Infrastructure?

Modular cleanrooms offer a flexible, scalable, and cost-effective solution for controlled environments. Unlike conventional construction, these systems can be customized to suit specific cleanliness levels, processes, and space requirements. As a trusted modular cleanroom infrastructure manufacturer, Fabtechnologies delivers turnkey solutions that adhere to ISO and GMP standards.

Why Cleanroom Equipment Matters

Cleanrooms require specialized equipment to maintain particle-free air, stable temperature, humidity, and pressure levels. High-quality cleanroom equipment manufacturers like Fabtechnologies provide:

Air handling units (AHUs)

Laminar airflow systems

Pass boxes

Biosafety cabinets

All these systems work together to ensure product safety and process reliability.

The Role of Dedusting Machines in Pharma

Tablet manufacturing often generates dust, which poses contamination and health risks. This is where dedusting machines are essential. These machines clean and polish tablets post-compression, improving both quality and safety.

Fabtechnologies offers advanced dedusting solutions as part of their cleanroom and clean air application offerings, ensuring efficiency at every production stage.

Pharmaceutical Isolators: Safety Beyond Barriers

A pharmaceutical isolator creates a physical barrier between the operator and the product. This ensures ultra-clean working conditions during aseptic processes or when handling hazardous substances. As a reliable pharmaceutical isolator supplier, Fabtechnologies provides fully automated isolators with integrated HVAC and decontamination systems.

Pharma HVAC Systems: Breathing Life into Cleanrooms

A cleanroom is only as effective as its HVAC system. An expert pharma HVAC manufacturer like Fabtechnologies designs systems that maintain air purity, pressure differentials, and temperature control while ensuring energy efficiency.

Conclusion: Your Trusted Partner in Cleanroom Innovation

Whether you’re setting up a sterile manufacturing facility or upgrading your HVAC system, choosing the right partner is critical. Fabtechnologies stands out as a comprehensive solution provider for:

Modular cleanroom infrastructure

Cleanroom equipment

Dedusting machines

Pharmaceutical isolators

Pharma HVAC systems

🔗 Learn more about our solutions for cleanrooms and clean air applications.

📩 Ready to build your next-gen cleanroom facility? Contact us now to speak with our pharma turnkey experts.

#Modular Cleanroom Infrastructure#Cleanroom Equipment Manufacturer#Pharmaceutical Isolator Supplier#Pharma HVAC Systems#Dedusting Machines

0 notes

Text

Cleanroom, Modular Operation Theater & IVF Lab Solutions

Welcome to AUM Industries – your trusted partner for turnkey cleanroom and modular infrastructure solutions. We specialize in high-performance, precision-built modular environments that meet the strictest hygiene and quality standards across a variety of sectors.

🔧 Core Solutions Offered:

Cleanroom Design & Construction

Modular Operation Theater (OT) Solutions

IVF Laboratory Setup & Customization

🏭 Serving Diverse Industries:

Pharmaceutical Manufacturing

Food & Beverage Processing

Hospitals & Healthcare Facilities

Electronics & Semiconductor Industry

Plus: Cosmetics, Chemicals, and General Engineering

🛠️ Complete In-House Manufacturing & Design for:

PUF (Polyurethane Foam) Panel Partitions

Flush Doors & Airtight Hospital Doors

Modular Cleanroom Partitions & Walk-on Ceilings

Cleanroom Lights & Fixtures

Laminar Air Flow Units with 0.3 Micron HEPA Filters

Air Handling Units (AHUs) & Fabricated Ducting

Pass Boxes & Aluminium Coving

Antimicrobial Vinyl and Epoxy Flooring

🌟 Why Choose AUM Industries?

ISO 9001:2015 Certified

Turnkey Project Expertise in Cleanrooms, Modular OTs & ICUs

Customised, Quality-Driven, and Cost-Effective Solutions

Trusted by clients across India and beyond

Engineered for both National & International Standards

📞 Let’s Build Something Better – Together. 📧 Email: [email protected] 📱 Call: +91-9274313580

Turnkey Cleanroom, Modular OT & IVF Lab Solutions | AUM Industries

AUM Industries delivers ISO-certified turnkey cleanroom and modular OT/IVF lab solutions across pharma, healthcare, food, electronics, and more. In-house design, manufacturing, and international quality.

#vinyl flooring#ivf#cosmetics#hospital#medicine#architecture#cleanroomsolutions#modularot#ivflaboratory#icusetup#laminarairflow#madeinindia#ahu#pufpartitions#hepafilters#manufacturing#hospitalinfrastructure#pharmaprojects#turnkeycleanroom#cleanroom manufacturing#modular operation theater#IVF lab setup India#pharma cleanroom solutions#AHU and ducting#antimicrobial flooring#turnkey healthcare infrastructure#PUF panel partitions#laminar air flow#HEPA filters

1 note

·

View note

Text

Modularcleanroomindia - Modular Operation Theatre

What is a Modular Operation Theatre?

A modular operation theatre is a prefabricated, highly customizable surgical suite designed to meet the highest standards of hygiene, safety, and efficiency. These theatres are constructed using prefabricated modules that can be easily assembled, disassembled, and reconfigured to suit the specific needs of a healthcare facility. The modular approach allows for rapid installation, minimal disruption, and cost-effective scalability.

Key Features and Benefits of Modular Operation Theatres

1. Enhanced Sterility

Sterility is the cornerstone of any successful surgical procedure. Modular operation theatres from Modular Clean Room India are designed with advanced air filtration systems, including HEPA filters, to ensure a controlled and contaminant-free environment. These theatres also feature seamless wall and ceiling panels that prevent the accumulation of dust and pathogens, reducing the risk of surgical site infections.

2. Customizable Design

One of the most significant advantages of modular operation theatres is their customizable nature. Healthcare facilities can tailor the design of the theatre to meet their specific requirements. This includes the placement of medical equipment, lighting, and surgical workstations. Modular Clean Room India offers a range of customizable options to ensure that each theatre meets the unique needs of the surgical team.

3. Rapid Installation and Scalability

Traditional construction methods for operation theatres can be time-consuming and disruptive. Modular operation theatres, on the other hand, offer rapid installation with minimal downtime. The prefabricated modules can be assembled on-site quickly, allowing healthcare facilities to expand their surgical capacity without prolonged interruptions. Additionally, the modular design allows for easy scalability, enabling facilities to add or reconfigure theatres as needed.

4. Compliance with International Standards

Modular Clean Room India ensures that all modular operation theatres comply with international healthcare standards and guidelines. These theatres are designed to meet the stringent requirements of organizations such as the World Health Organization (WHO) and the International Organization for Standardization (ISO). This compliance guarantees that the theatres provide a safe and effective environment for surgical procedures.

5. Energy Efficiency and Cost Savings

Modular operation theatres are designed with energy efficiency in mind. Advanced HVAC systems, LED lighting, and energy-efficient materials help reduce the overall energy consumption of the theatre. This not only contributes to a more sustainable healthcare environment but also results in significant cost savings for healthcare facilities over time.

6. Future-Proofing Healthcare Infrastructure

The healthcare industry is constantly evolving, with new technologies and surgical techniques emerging regularly. Modular operation theatres provide a future-proof solution that can adapt to these changes. The modular design allows for easy upgrades and modifications, ensuring that healthcare facilities can keep pace with advancements in surgical care without the need for extensive renovations.

Modular Clean Room India: Pioneering Excellence in Healthcare

Modular Clean Room India has established itself as a trusted provider of high-quality cleanroom solutions, including modular operation theatres. With a commitment to innovation, quality, and customer satisfaction, the company has delivered state-of-the-art surgical suites to healthcare facilities across the country.

Expertise and Experience

With years of experience in the cleanroom industry, Modular Clean Room India brings unparalleled expertise to the design and implementation of modular operation theatres. The company’s team of skilled professionals works closely with healthcare providers to understand their unique needs and deliver customized solutions that exceed expectations.

Commitment to Quality

Quality is at the heart of everything Modular Clean Room India does. The company uses only the highest quality materials and components in the construction of its modular operation theatres. Rigorous quality control processes ensure that each theatre meets the highest standards of safety, sterility, and functionality.

Comprehensive Service

Modular Clean Room India offers a comprehensive service that includes consultation, design, installation, and ongoing support. The company’s dedicated team is available to provide guidance and assistance at every stage of the project, ensuring a seamless and stress-free experience for healthcare providers.

Conclusion

Modular operation theatres represent the future of surgical excellence, offering a versatile, efficient, and cost-effective solution for modern healthcare facilities. With their enhanced sterility, customizable design, rapid installation, and compliance with international standards, these theatres are transforming the landscape of surgical care. Modular Clean Room India is proud to lead the way in delivering these innovative solutions, helping healthcare providers create safe and effective environments for life-saving surgeries.

For more information about Modular Clean Room India and their modular operation theatres, visit their website or contact their team of experts today.

2 notes

·

View notes

Text

Interior construction for hospitals, clinics, hotels and restaurants Delhi NCR

Interior Construction for Hospitals, Clinics, Hotels, and Restaurants in Delhi NCR – Delivered by way of dlhinfra In incredibly specialised environments like healthcare and hospitality, indoors creation is greater than just design—it’s about protection, capability, compliance, and the general enjoy. At dlhinfra, we concentrate on interior creation for hospitals, clinics, motels, and restaurants in Delhi NCR, delivering spaces that integrate shape with characteristic, design with sturdiness, and innovation with hygiene. Our group is professional in coping with the unique demands of those sectors, making sure that every assignment supports operational needs even as growing an inviting, efficient, and regulatory-compliant surroundings.

In the healthcare region, interiors directly impact no longer simply consolation however restoration and operational glide. Dlhinfra offers whole turnkey interior production for hospitals and clinics, integrating advanced scientific infrastructure with contemporary design principles. We apprehend that cleanliness, ventilation, ease of motion, and accessibility are vital in such settings. That’s why we use medical institution-grade materials like anti-bacterial vinyl floors, wipeable wall finishes, modular partitions, and laminar airflow-well suited ceiling systems. Our layouts prioritize affected person consolation, contamination control, and optimized movement of group of workers and system. Whether it’s OPDs, session rooms, ICUs, diagnostic facilities, or ready areas, each area is designed for maximum functionality and protection.

We additionally ensure strict adherence to NABH, fire safety, and constructing code rules all through the construction procedure. From electric load calculations to MEP integration and oxygen pipeline concealment, our crew brings engineering precision and enterprise-particular information. We additionally deploy custom designed cabinetry, handrails, cleanroom lighting, nurse stations, and signage answers to guide clinic-grade workflow. Our enjoy in working with each non-public clinics and massive multispeciality hospitals throughout Delhi NCR makes us a dependable partner for healthcare infrastructure development.

In parallel, dlhinfra brings a awesome set of talents and creativity to hospitality interior construction, which includes inns, lodges, cafes, and eating places. We recognize that inside the hospitality enterprise, ambiance and guest revel in are the whole lot. The indoors environment needs to captivate the senses whilst assisting smooth operations for the personnel. Our team collaborates with architects, cooks, F&B managers, and hospitality experts to construct areas which might be visually stunning and almost seamless. From elegant lodge lobbies to themed great-eating areas, high-footfall kitchens to luxurious guest rooms, we deliver turnkey construction answers that meet global hospitality requirements.

Every hospitality area is specific—and so is our method. For accommodations, we create grand receptions, spa regions, banquet halls, and contemporary visitor suites with attention to lights, acoustic manage, and top class finishes. We offer specified indoors production for back-of-house regions like laundry, kitchens, and carrier corridors to ensure complete operational readiness. For restaurants and cafes, our awareness is on idea-pushed layout, green kitchen-to-desk workflow, ambient lighting, and Instagram-worthy aesthetics. We additionally cope with bar counters, wood paneling, custom fixtures, and ceiling installations that align together with your logo identity.

What makes dlhinfra stand out in Delhi NCR’s competitive production space is our dedication to end-to-give up challenge shipping. From civil works and partitioning to floors, cladding, plumbing, HVAC, electricals, and false ceilings, we provide included solutions. This one-window technique simplifies conversation, avoids price overruns, and guarantees quicker assignment transport. We also provide unique 3-D layouts, BOQs, and site supervision to make sure every project stays heading in the right direction, both in phrases of time and excellent.

Another key location we cognizance on is fabric selection—especially essential in sectors like healthcare and hospitality in which wear-and-tear is high, hygiene is critical, and aesthetics need to impress. For medical interiors, we use high-stress laminates, anti-microbial paints, epoxy flooring, and SS fittings which can face up to rigorous cleansing and each day use. In lodges and eating places, we use a mix of natural stones, laminates, acoustic wall panels, fire-rated substances, and electricity-green lights that complement each safety and comfort.

Sustainability is also a growing priority. Dlhinfra integrates power-efficient HVAC structures, water-saving fixtures, LED lighting fixtures, and green substances anywhere feasible to reduce environmental impact and running charges. In both hospitals and hotels, we layout for herbal light, thermal consolation, and smart space zoning to limit power intake and enhance person nicely-being.

Beyond creation, our collaborative technique guarantees every stakeholder’s enter is heard and addressed. We work intently with healthcare professionals, hospitality experts, MEP specialists, and logo designers to translate vision into fact. Our submit-handover guide includes minor maintenance, format modifications, and machine optimizations—making sure your area stays operational and excessive-performing in the end.

Having finished multiple projects for clinics, diagnostic centers, cafes, price range motels, and four-star residences across Noida, Delhi, and Gurugram, dlhinfra has built a robust reputation for reliability, interest to element, and industry-specific execution. Clients admire our professionalism, technical knowledge, obvious pricing, and the high popular of finishes we supply throughout projects.

To sum up, dlhinfra offers specialised interior creation answers for hospitals, clinics, lodges, and eating places across Delhi NCR, combining enterprise know-how with execution excellence. Our potential to tailor each project to its intended use, person profile, and compliance requirements sets us apart. Whether you're planning to construct a brand new diagnostic lab, revamp an ageing guesthouse, or create a display-stopping restaurant indoors, dlhinfra is the associate you may believe.

Contact us today to discuss your task needs and discover how we assist you to create purposeful, beautiful, and compliant areas that deliver long-term price and unequalled experience.

0 notes

Text

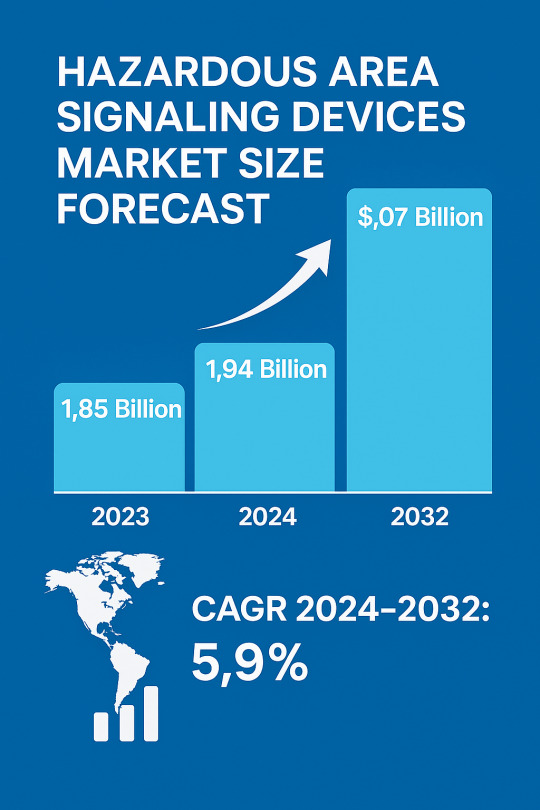

Hazardous Area Signaling Devices Market Set to Cross $3 Billion by 2032. Here’s What’s Powering the Rise

Just came across some compelling numbers on the hazardous area signaling devices industry — and if you’re in industrial safety, automation, or infrastructure, this one’s worth a deeper dive.

📊 Market Forecast (2024–2032)

💰 2023 Market Size: $1.85 billion 🔮 2024 Projection: $1.94 billion 🚀 2032 Forecast: $3.07 billion 📈 CAGR (2024–2032): 5.9%

That’s over 58% growth in just under a decade.

🌍 Safety First — And Everywhere

Hazardous area signaling devices are a critical piece of infrastructure in industries like oil & gas, mining, chemicals, and food processing — basically, anywhere explosive or dangerous environments require high-performance alerts and compliance with ATEX/IECEx norms.

🔑 Key Trends Fueling the Growth:

🚨 1. Industrial Safety Regulations Are Tightening

Governments and regulators worldwide are ramping up safety codes, especially in high-risk environments. That means more demand for reliable alarms, strobes, horns, and beacons designed for hazardous zones.

🏗️ 2. Expansion of Oil & Gas and Chemical Processing

As energy infrastructure expands — particularly in the Middle East, North America, and Asia — the need for certified signaling devices in explosive atmospheres is scaling accordingly.

⚙️ 3. Rise of Smart & Connected Devices

We're seeing the integration of IoT, diagnostics, and remote monitoring into signaling systems. These “smart alerts” improve incident response times and reduce maintenance downtime.

📦 4. Demand in Food & Pharma Cleanrooms

Signaling systems aren’t just for explosive zones — they’re increasingly deployed in sterile and contamination-sensitive spaces like pharmaceutical manufacturing and food processing, where audible/visual alerts ensure regulatory compliance.

🌐 5. Emerging Markets Are Catching Up

Developing economies are now building out their industrial safety frameworks. As factories and energy plants come online, the market for ATEX- and IECEx-compliant signaling devices is set to boom.

🧠 What Does This Mean for Industry Players?

We’re moving toward automation-ready, network-integrated safety ecosystems. Whether you’re a manufacturer or investor, now’s the time to focus on scalable, smart, and regulation-driven solutions.

🔧 If you’re building: Prioritize interoperability with PLC/DCS systems, cloud diagnostics, and fail-safe compliance certifications.

💼 If you’re investing: Long-term demand will favor companies innovating in smart industrial safety, modular device design, and emerging economy installations.

0 notes

Link

#AIinfrastructure#cross-regionallogistics#digitaltwindeployment#energy-efficientmanufacturing#precisionautomation#smartcityecosystems#sovereigncloudsolutions#thermalinnovation

0 notes

Text

The Role of Cleanroom Construction and Pharma Consultancy in Pharmaceutical Excellence

Pharmaceutical manufacturing is a high-stakes industry where quality, safety, and compliance are non-negotiable. As regulatory demands become stricter and the need for precision increases, companies are turning to specialized partners to ensure seamless operations. Two pillars supporting this infrastructure are cleanroom construction and pharma consultancy. These services are crucial for regulatory compliance, operational efficiency, and long-term growth.

Understanding the Importance of Cleanroom Construction

In the pharmaceutical sector, cleanrooms are controlled environments where contaminants like dust, airborne microbes, and chemical vapors are minimized. The quality of cleanroom construction plays a pivotal role in maintaining these sterile conditions.

Pharmaceutical companies rely on well-designed cleanrooms to ensure product integrity, prevent contamination, and meet GMP (Good Manufacturing Practice) requirements. From HVAC systems and HEPA filters to modular wall panels and automated airlocks, every element of cleanroom construction is engineered to support strict hygiene and environmental control standards.

Well-executed cleanroom construction ensures that temperature, humidity, air pressure, and particle count remain within permissible levels. Whether it’s for tablet manufacturing, sterile injectable production, or biotechnology processes, the cleanroom must meet exact specifications based on the product being manufactured.

The Strategic Role of Pharma Consultancy

Pharma consultancy services offer expert guidance across various phases of pharmaceutical operations, from R&D and regulatory affairs to facility design and process optimization. These consultants help pharmaceutical companies align with industry standards, obtain necessary certifications, and adopt best practices that improve efficiency and quality.

A reliable pharma consultancy firm brings in-depth industry knowledge and hands-on experience to guide companies through complex challenges. Whether launching a new manufacturing facility or scaling up an existing plant, pharma consultants play a strategic role in ensuring that every step complies with local and international regulations.

From preparing dossiers for regulatory submission to designing risk management frameworks, pharma consultancy covers both operational and strategic aspects. Their support is invaluable for companies seeking to avoid costly mistakes, minimize compliance risks, and accelerate time-to-market.

Integration of Cleanroom Construction and Pharma Consultancy

The intersection of cleanroom construction and pharma consultancy represents a holistic approach to pharmaceutical facility development. When these two services work in tandem, companies benefit from cohesive planning, reduced project delays, and optimal resource utilization.

Pharma consultants often collaborate with cleanroom engineers during the design phase to ensure the layout meets process flow and regulatory requirements. Their insights into manufacturing needs help inform decisions related to material selection, HVAC zoning, and workflow efficiency within the cleanroom environment.

By integrating pharma consultancy into cleanroom construction projects from the outset, companies can:

Reduce rework and delays through better planning

Ensure full GMP and FDA compliance

Optimize facility layout for efficiency and flexibility

Mitigate contamination risks through smart engineering choices

This synergy ensures that pharmaceutical companies are not just building compliant facilities—they're building high-performance environments that support innovation and scalable growth.

Cleanroom Construction Challenges and Solutions

One of the key challenges in cleanroom construction is balancing strict regulatory standards with cost-efficiency and operational needs. Every square meter of a cleanroom must be meticulously planned and validated. Moreover, maintaining the cleanroom over its lifecycle involves regular audits, revalidation, and continuous environmental monitoring.

To address these challenges, specialized cleanroom construction companies use modular designs, advanced airflow simulations, and energy-efficient systems. This not only ensures precision during the build phase but also facilitates easier maintenance and upgrades in the future.

A competent pharma consultancy partner can further enhance this process by advising on materials that meet regulatory standards, developing cleaning protocols, and aligning cleanroom classifications with product types.

Regulatory Compliance: A Shared Responsibility

Compliance with regulations like the US FDA, EU GMP, and WHO standards is mandatory for pharmaceutical companies. Non-compliance can lead to warning letters, production halts, and loss of reputation.

This is where pharma consultancy becomes invaluable. These consultants interpret evolving regulatory requirements and ensure that all aspects of facility planning, including cleanroom construction, align with current standards. From validating air handling units to preparing documentation for inspections, consultants play a critical role in maintaining compliance at every stage.

Long-Term Benefits for Pharma Companies

Partnering with a reputable cleanroom construction firm and a skilled pharma consultancy offers long-term value. These services ensure:

Faster project completion with minimal design errors

Future-proof facilities with scalable infrastructure

Seamless regulatory approvals and fewer audit findings

Enhanced product quality and safety

Whether launching a greenfield facility or upgrading an existing one, these partnerships are central to building resilient, efficient, and compliant pharmaceutical operations.

Conclusion

The pharmaceutical landscape is evolving rapidly, with an increased focus on quality, compliance, and operational efficiency. In this context, cleanroom construction and pharma consultancy are more than just support services—they are strategic enablers of success. By investing in expert partners, pharmaceutical companies can ensure that their facilities not only meet current regulatory requirements but also adapt to future innovations and expansions. Whether you are setting up a new plant or seeking to optimize an existing one, the collaboration between cleanroom construction experts and pharma consultancy professionals is key to achieving excellence in pharmaceutical manufacturing.

#pharma consultancy#cleanroom construction#biotech management consulting#biopharmaceutical consulting#pharma turnkey projects#cleanroom design#pharmaceutical consultant

0 notes

Text

Understanding the Growth Trajectory of the Cleanroom Technology Market

According to a recent report by Grand View Research, Inc., the global cleanroom technology market is projected to attain a value of USD 10.82 billion by 2030, expanding at a compound annual growth rate (CAGR) of 5.9% over the forecast period from 2025 to 2030. This growth reflects the increasing importance of contamination-free environments in highly regulated and precision-dependent industries.

Cleanroom technology encompasses a suite of advanced systems, equipment, and infrastructure specifically designed to create and maintain environments with controlled levels of airborne particles, chemical vapors, humidity, temperature, and other environmental variables. These clean environments are essential across a range of industries, including biotechnology, electronics, pharmaceuticals, and healthcare, where even microscopic contaminants can compromise the quality and reliability of products and processes.

Cleanrooms operate under stringent protocols that ensure precise control of temperature, humidity, air pressure, ventilation, and particulate levels. Central components of cleanroom systems include air filtration units (such as HEPA and ULPA filters), sophisticated HVAC systems, and automated monitoring and control systems to track and maintain cleanliness standards. Personnel working in cleanrooms must adhere to rigorous cleanliness procedures, often wearing specialized protective garments such as coveralls, gloves, masks, and hoods to minimize the introduction of contaminants.

The versatility of cleanroom technology enables its use in a variety of settings—from semiconductor fabrication plants to sterile hospital environments—where the risk of contamination must be minimized to maintain process integrity and product safety. As industries advance, cleanroom systems are evolving to meet more stringent quality and regulatory standards, offering improved efficiency, modularity, and energy performance.

A significant driver of market growth is the increased adoption of cleanroom environments by the pharmaceutical and biotechnology sectors, which face growing pressure to maintain product purity, ensure patient safety, and comply with rigorous global regulatory frameworks. Cleanroom technology supports these objectives by enabling controlled production environments that meet Good Manufacturing Practice (GMP) requirements.

Get a preview of the latest developments in the Cleanroom Technology Market? Download your FREE sample PDF copy today and explore key data and trends.

Cleanroom Technology Market: FAQs

1. What is the projected size of the global cleanroom technology market?

The global cleanroom technology market is expected to reach USD 10.82 billion by 2030, growing at a CAGR of 5.9% from 2025 to 2030.

2. What industries primarily utilize cleanroom technology?

Cleanroom technology is essential in industries such as pharmaceuticals, biotechnology, electronics, healthcare, and semiconductor manufacturing, where maintaining contamination-free environments is crucial for product quality and compliance.

3. Which cleanroom type holds the largest market share?

The hardwall cleanroom segment dominated the market with a share of 45.3% in 2024 and is expected to grow at the fastest CAGR of 6.6% during the forecast period.

4. What is the role of consumables in the cleanroom technology market?

Consumables, including gloves, apparel, wipes, disinfectants, and other safety and cleaning products, accounted for 55.2% of the market in 2024. This segment is projected to grow at a CAGR of 5.4% from 2025 to 2030.

5. Which region leads in cleanroom technology adoption?

North America led the market with a revenue share of 39.5% in 2024, driven by stringent regulatory requirements and advancements in automation and smart technologies.

6. How has the healthcare sector influenced the cleanroom technology market?

The healthcare sector accounted for 62.3% of the cleanroom technology market in 2024, with a projected CAGR of 6.3% during the forecast period. This growth is attributed to increasing demand for contamination-free environments in pharmaceutical manufacturing and medical device production.

Order a free sample PDF of the Cleanroom Technology Market Intelligence Study, published by Grand View Research.

#Cleanroom Technology Market#Cleanroom Technology Market Size#Cleanroom Technology Market Share#Cleanroom Technology Market Analysis

0 notes

Text

As a leading modular cleanroom infrastructure manufacturers, we specialize in innovating cutting-edge solutions for the pharmaceutical industry. Our state-of-the-art facilities and expert team ensure precision-engineered machines tailored to meet the evolving needs of pharmaceutical production. Explore our range of Pharmaceutical Machines today to elevate your manufacturing capabilities and streamline production processes.

1 note

·

View note

Text

In the fast-paced healthcare environment of New York, the quality and reliability of infrastructure are crucial. Hospital engineering suppliers in New York play a vital role in ensuring that hospitals, clinics, and medical centers operate smoothly, safely, and efficiently. From medical gas systems to stainless steel fabrications, trusted engineering suppliers provide the backbone of healthcare operations.

The Importance of Reliable Hospital Engineering Suppliers

Hospitals rely on a wide range of specialized equipment and systems that must meet strict health, safety, and regulatory standards. Partnering with experienced healthcare engineering suppliers in New York ensures access to products and services that are:

Compliant with Regulations: Meeting OSHA, HIPAA, and local NYC health codes.

Durable and Reliable: Engineered to withstand constant use in demanding environments.

Customizable: Tailored solutions to fit the unique needs of each facility.

Efficient: Supporting energy conservation and operational cost savings.

Choosing the right New York hospital supply company can directly impact patient outcomes, staff efficiency, and facility longevity.

Products Offered by Hospital Engineering Suppliers

Top hospital engineering companies in New York offer a wide array of specialized products and solutions, including:

1. Medical Gas Pipeline Systems

Medical gases such as oxygen, nitrogen, and vacuum systems are critical for patient care. Medical gas equipment suppliers ensure safe, reliable delivery with compliant pipeline installations and accessories.

2. Stainless Steel Fabrications

From surgical tables to wall protection panels, custom stainless steel hospital products ensure hygiene, durability, and ease of maintenance.

3. HVAC and Air Filtration Systems

Proper ventilation and air quality control are essential for infection prevention. Hospital HVAC suppliers provide HEPA filtration systems, negative pressure rooms, and cleanroom solutions.

4. Electrical and Communication Systems

Nurse call systems, backup generators, and specialized medical-grade electrical components are provided by hospital electrical engineering suppliers to maintain continuous facility operation.

5. Plumbing and Sanitary Equipment

Touchless sinks, anti-microbial fixtures, and emergency eyewash stations are available from trusted hospital plumbing supply companies in New York.

How to Choose the Best Hospital Engineering Supplier in New York

Finding the right New York healthcare engineering supplier is essential for the success of any hospital project or renovation. Key factors to consider include:

Industry Experience: Look for suppliers with a proven track record in healthcare projects.

Quality Assurance: Ensure all products meet relevant certifications and standards.

Customization Capabilities: Hospitals often require tailored solutions rather than off-the-shelf products.

Installation and Support Services: Full-service suppliers offer delivery, installation, and ongoing maintenance support.

Local Expertise: Familiarity with New York City regulations and building codes is a major advantage.

A good hospital supply company in NYC acts as a partner, not just a vendor — supporting projects from concept to completion.

Trends in Hospital Engineering Supplies

The world of healthcare facility supplies is evolving rapidly. Modern hospitals are embracing:

Smart Building Integration: IoT-connected devices that monitor building performance in real time.

Green Initiatives: Eco-friendly HVAC, plumbing, and energy systems for sustainable hospital designs.

Modular Construction: Prefabricated components that speed up hospital expansions and renovations.

Enhanced Infection Control: New materials and technologies designed to reduce the spread of pathogens.

Leading hospital engineering suppliers in New York City stay at the forefront of these trends, offering solutions that meet today’s and tomorrow’s healthcare challenges.

Final Thoughts

When it comes to healthcare, every detail matters — and that includes the engineering supplies behind the scenes. Trusted hospital engineering suppliers in New York provide the critical infrastructure that keeps hospitals safe, efficient, and prepared for anything.

Whether you're constructing a new medical center, upgrading surgical suites, or maintaining essential systems, partnering with experienced New York hospital supply companies ensures your facility is built to last and ready to deliver exceptional care.

Choose quality. Choose compliance. Choose a hospital engineering supplier New York trusts.

0 notes

Text

What to Look for When Choosing a Cleanroom Solutions Provider

In sectors like pharmaceuticals, hospitals, electronics, and diagnostics, where hygiene, safety, and regulatory compliance are non-negotiable, choosing the right cleanroom solutions provider becomes a critical decision. A subpar installation can compromise not just product quality and patient safety, but also business continuity and compliance with regulatory bodies such as NABH, GMP, WHO, and USFDA.

Whether you’re setting up a modular OT in a private hospital, expanding a pharmaceutical unit, or upgrading a clean zone in an electronics plant, you need a provider who offers turnkey cleanroom infrastructure with deep domain expertise.

In this comprehensive guide, we will explore what buyers should look for in a cleanroom solutions provider, based on insights gathered from top-performing projects across India.

Why the Right Cleanroom Partner Matters

Cleanroom environments are highly sensitive and regulated. An error in design, materials, airflow control, or installation could result in:

Product contamination or rejection

Failed audits by NABH, GMP, or USFDA

Equipment malfunction

Costly retrofits or repairs

Delayed go-to-market timelines

Hence, your provider must offer not just components, but a fully integrated, future-ready solution—from design and engineering to fabrication and compliance support.

Key Factors to Consider When Choosing a Cleanroom Solutions Provider

1. Proven Experience in Regulated Sectors

Cleanroom construction is not like typical interior or civil work. It requires an understanding of environmental control, air changes per hour (ACH), clean zoning, and ISO classifications.

Choose a provider with verifiable experience in:

Pharmaceutical cleanrooms (GMP compliant)

Modular operation theatres (Class 100 or ISO 5)

IVF labs, ICUs, and diagnostic labs

Electronic assembly units (ESD-sensitive)

Food and cosmetic manufacturing clean zones

A provider with sector-specific experience will understand your industry's pain points and regulatory expectations.

2. Turnkey Capabilities

Is your provider offering only panels and doors? Or do they deliver end-to-end turnkey solutions?

Look for companies that can deliver:

Design & layout planning (AutoCAD/3D)

HVAC & AHU systems integration

Cleanroom paneling (PUF, HPL, SS)

Ceiling systems (walkable/non-walkable)

Flooring (epoxy, PU, vinyl)

HEPA filtration systems & LAF units

Electrical, lighting, and smart control panels

Validation documentation & compliance checklists

A turnkey approach ensures better coordination, single-point responsibility, and cost efficiency.

3. In-House Manufacturing Capability

Providers with their own manufacturing units for panels, doors, AHUs, and filters can ensure:

Faster project turnaround

Quality consistency

Custom-built components for unique site needs

Reduced dependence on third-party vendors

In contrast, contractors who only “buy and install” tend to lack control over timelines and quality.

4. Compliance With International & Indian Standards

Your provider should demonstrate strict adherence to major compliance standards:

NABH – For Indian hospitals and surgical units

WHO-GMP – For pharma and biopharma setups

USFDA & MHRA (UK) – For global export readiness

ISO 14644-1 – Cleanroom classification system

IEC & CE compliance – For electrical components and air handling units

Ask for certificates, project references, and third-party audit reports.

5. Technical Depth: HVAC, HEPA, and More

Air purity, pressure, temperature, and humidity control are central to cleanroom performance.

Ensure your provider has expertise in:

Air Handling Units (AHUs) – DX or chiller-based; single/double skin

HEPA Filters (0.3 Micron) – Terminal boxes, LAF units, and risers

Airflow design – Laminar flow, turbulence control, return air risers

Insulations – Thermocol, XLPE, nitrile rubber for Class ‘O’ fire ratings

Ducting systems – GI, SS, or aluminum with MS flange systems

6. Custom Engineering & Flexibility

Every site and use case is different. A good provider should offer tailor-made configurations, such as:

PUF panel thickness options (50mm / 80mm / 100mm)

Flush or glazed doors (single/double)

Manual or remote blinds for observation windows

Modular ICUs with nurse control stations

Touch panels to control lighting, oxygen, AHUs, etc.

Custom engineering ensures your cleanroom integrates seamlessly with existing infrastructure.

7. Project Management & Installation Team

Ask about the team who will execute the job.

A competent turnkey cleanroom provider should have:

On-site engineers and supervisors

Skilled fabricators and installers

NABH/GMP consultants

Commissioning and validation support team

Also verify whether the provider offers pan-India support—a must for large hospital chains and pharma units.

8. Post-Installation Support & AMC

Cleanrooms need ongoing maintenance. Ensure the provider offers:

Preventive Maintenance Contracts (PMC)

Annual Maintenance Contracts (AMC)

Replacement filters, lights, and wear parts

Emergency breakdown services

Validation and documentation support for audits

Frequently Asked Questions (FAQs)

Q1: How do I verify if a cleanroom provider is NABH compliant? Check for project case studies in NABH-accredited hospitals. Ask for documentation and site references.

Q2: What’s the difference between epoxy and PU flooring in cleanrooms? Epoxy is glossy, antimicrobial, and chemical-resistant—ideal for pharma and OTs. PU is matte, impact-resistant, and used in ICUs or food processing areas.

Q3: Are modular cleanrooms better than conventional construction? Yes. Modular cleanrooms are faster to install, easy to modify, and offer better contamination control.

Q4: How important is HEPA filtration in a cleanroom? HEPA filters remove 99.97% of airborne particles ≥0.3 microns. They are crucial for ISO-classified environments.

Q5: Can I get HVAC, cleanroom panels, and flooring from one vendor? Yes. Leading turnkey cleanroom companies offer all systems under one roof—design, manufacture, and install.

Final Thoughts: Build Clean with AUM Industries

When hygiene, efficiency, and compliance are paramount, partnering with a trusted provider like AUM Industries can make all the difference. With a state-of-the-art facility in Gujarat and a pan-India execution team, AUM Industries delivers turnkey cleanroom and modular OT solutions that meet the strictest global and Indian standards.

From cleanroom paneling and modular OT setups to HVAC, HEPA filtration, and epoxy flooring, AUM Industries offers everything under one roof—with unmatched customization, technical support, and post-installation service.

Let’s build clean. Let’s build smart. Let’s build together.

#CleanroomSolutions#ModularOT#TurnkeyProjects#PharmaInfrastructure#HealthcareConstruction#HEPAFilters#HVACSystems#EpoxyFlooring#NABHCompliance#AUMIndustries

0 notes

Text

Understanding The Global Cleanroom Technologies Market : Key Findings From The Latest Report

The global Cleanroom Technologies Market was valued at USD 8.1 billion in 2023 and is projected to reach USD 14.6 billion by 2032, growing at a Compound Annual Growth Rate (CAGR) of 6.8% during the forecast period 2024 to 2032, according to the latest industry insights.

Get Free Sample Report on Cleanroom Technologies Market

Cleanroom technologies are critical to maintaining controlled environments that minimize contamination during production and research processes. These solutions are increasingly in demand across sectors such as pharmaceuticals, biotechnology, semiconductors, medical devices, and aerospace, where strict hygiene and quality standards are essential.

Cleanroom Technologies: Enabling Precision, Safety, and Compliance

Cleanrooms are specialized environments with controlled levels of airborne particles, temperature, humidity, and pressure, making them essential in industries where even the smallest contaminant can compromise product integrity or patient safety. Cleanroom technologies include equipment, consumables, design and construction services, and maintenance solutions that help organizations meet Good Manufacturing Practice (GMP) and ISO standards.

“Cleanrooms are no longer optional—they’re essential for quality assurance, especially in regulated industries,” said a senior analyst from a leading market research firm. “As demand for high-quality and sterile production environments increases, cleanroom technologies will play a central role in enabling innovation and regulatory compliance.”

Key Drivers Fueling Market Growth

Several significant factors are propelling the cleanroom technologies market forward:

Growth in the Pharmaceutical and Biotechnology Industries The global pharmaceutical and biotech sectors continue to expand rapidly, particularly with the rise in biologics, vaccine production, and personalized medicine. These processes require stringent contamination control, boosting demand for modular cleanrooms, HEPA filters, laminar airflow systems, and specialized cleaning equipment.

Stringent Regulatory Requirements Government and regulatory bodies such as the U.S. FDA, EMA, and WHO are enforcing more rigorous guidelines for cleanroom operations. As compliance becomes more complex, companies are investing heavily in advanced cleanroom solutions to ensure they meet the required environmental and sterility standards.

Semiconductor and Electronics Sector Growth The microelectronics industry, which requires particle-free environments to manufacture semiconductors and integrated circuits, continues to be a major consumer of cleanroom technologies. With the increasing demand for smaller, faster, and more powerful electronic devices, cleanroom specifications have become even more stringent.

Surge in Healthcare and Medical Device Manufacturing Post-pandemic healthcare infrastructure development, coupled with rising demand for sterile medical devices, has significantly contributed to the expansion of cleanroom requirements in healthcare manufacturing.

Increased Demand for Modular and Flexible Cleanroom Designs Modular cleanrooms are gaining traction due to their scalability, cost-effectiveness, and ease of installation. This trend is particularly evident in contract manufacturing organizations (CMOs) and smaller biotech firms that require quick deployment of cleanroom capabilities.

Key Market Segments:

By Product

By Type

By End User

Key Players

Key Service Providers/Manufacturers

Future Outlook

As industries become more specialized and regulations become stricter, cleanroom technologies are expected to evolve in sophistication and application. Innovations such as energy-efficient HVAC systems, AI-driven monitoring, and modular mobile cleanrooms are expected to shape the future of this market.

Make Enquiry about Cleanroom Technologies Market

Moreover, sustainability is emerging as a key consideration. Manufacturers are seeking eco-friendly materials, energy-saving equipment, and recyclable consumables to meet their environmental goals without compromising sterility standards.

“The cleanroom technologies market will continue to thrive as precision, sterility, and compliance become non-negotiable across industries,” said a leading market analyst. “Cleanrooms are no longer just infrastructure—they are strategic assets enabling innovation, safety, and market competitiveness.”

About the Report

This report provides a comprehensive analysis of the global cleanroom technologies market, including segmentation, growth drivers, challenges, opportunities, and competitive intelligence. It serves as a strategic resource for investors, manufacturers, regulatory professionals, and decision-makers in healthcare, pharma, and tech-driven sectors.

About US

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Cleanroom Technologies Market#Cleanroom Technologies Market Trend#Cleanroom Technologies Market Share#Cleanroom Technologies Market Growth#Cleanroom Technologies Market.

0 notes

Text

Air Handling Units Market Analysis: Key Players and Competitive Landscape

Growing Focus on Energy Efficiency and Indoor Air Quality Drives Expansion in the Air Handling Units Market.

The Air Handling Units Market Size was valued at USD 12.64 billion in 2023, and is expected to reach USD 20.10 billion by 2032, and grow at a CAGR of 5.29% over the forecast period 2024-2032.

The Air Handling Units (AHU) Market is driven by the increasing demand for energy-efficient HVAC systems, improved indoor air quality, and rising construction activities across commercial, residential, and industrial sectors. Air handling units play a crucial role in ventilation, heating, and cooling systems, ensuring efficient air circulation and filtration in hospitals, commercial buildings, data centers, and industrial facilities. The focus on sustainable building solutions, green energy initiatives, and stringent air quality regulations is further fueling market expansion.

Key Players

Systemair AB

Trox GmbH

Daikin Industries Ltd.

Lennox International, Inc.

Carrier Corporation

Flakt Woods Group

Trane Inc.

Johnson Controls Inc

GEA Group AG

Hitachi Ventus

Future Scope

The future of the AHU market looks promising, with advancements in smart HVAC technology, automation, and energy-efficient air handling solutions. The increasing adoption of modular and custom-designed air handling units is expected to cater to specific industry needs, such as pharmaceutical cleanrooms, data center cooling, and hospital ventilation. Additionally, government policies promoting sustainable construction and carbon footprint reduction will further drive the adoption of high-performance AHUs.

Emerging Trends

The AHU market is evolving with technological innovations in energy recovery, IoT-enabled monitoring, and HEPA filtration systems. The integration of smart sensors and AI-driven HVAC controls is improving efficiency, predictive maintenance, and real-time air quality management. Additionally, the push for eco-friendly refrigerants and hybrid ventilation solutions is reshaping the industry, making AHUs more environmentally sustainable and cost-effective. The growing demand for decentralized HVAC systems in commercial buildings and high-performance air filtration in healthcare facilities is also driving market growth.

Key Points

Rising demand for energy-efficient air handling units in commercial and industrial buildings.

Adoption of smart AHUs with IoT and AI-driven monitoring capabilities.

Growing emphasis on indoor air quality and HEPA filtration in healthcare and data centers.

Government regulations promoting sustainable HVAC solutions and carbon reduction.

Increased demand for modular and custom-designed AHUs across industries.

Conclusion

The Air Handling Units Market is set for significant growth, driven by advancements in HVAC technology, sustainability initiatives, and increased demand for smart, efficient air ventilation solutions. As businesses and industries prioritize energy conservation, air quality improvement, and regulatory compliance, the AHU market will continue to expand, innovate, and evolve to meet the changing demands of modern infrastructure.

Read Full Report: https://www.snsinsider.com/reports/air-handling-units-market-2134

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Air Handling Units Market#Air Handling Units Market Size#Air Handling Units Market Share#Air Handling Units Market Report#Air Handling Units Market Forecast

0 notes

Text

MOBATIME Analogue Clocks: Precision, Reliability, and Style for Every Environment

In today's fast-paced world, precise timekeeping is essential across various sectors, from transportation hubs to educational institutions. MOBATIME, a renowned brand of Moser-Baer Ltd., Switzerland, stands at the forefront of delivering high-quality analogue clock solutions that seamlessly blend accuracy, reliability, and aesthetic appeal. With a diverse range of products and services, MOBATIME caters to both indoor and outdoor environments, ensuring synchronized time displays that meet the unique demands of each setting.

Indoor Analogue Clocks: Precision Meets Elegance

MOBATIME's indoor Analogue Clocks are designed to enhance the ambiance of any interior space while providing precise timekeeping. These clocks are available in both illuminated and non-illuminated versions, catering to various aesthetic preferences and functional requirements. Engineered to operate with multiple standard time codes, from traditional wired systems to advanced network packet synchronization, these clocks ensure seamless integration into existing infrastructures.

Key models in the indoor analogue clock lineup include:

FLEX: Known for its versatility, the FLEX model adapts to diverse technical requirements, installation conditions, and design preferences, making it suitable for a wide range of applications.

SLH OP: Specifically crafted for environments with stringent hygiene standards, such as operating theaters, cleanrooms, and laboratories, the SLH OP model offers optimal performance in specialized settings.

MODERNA: Featuring a modern design with a transparent cover and robust metal casing, the MODERNA clock combines aesthetics with durability, making it a perfect fit for contemporary interiors.

ECO: Offering cost-effective solutions, the ECO series provides conventional one-minute pulse time systems, ensuring high professional standards without compromising on quality.

TREND: With its slim and modern design, the TREND model is available in double-sided configurations, making it ideal for large spaces where visibility from multiple angles is crucial.

FLEX LN: Designed with integrated noise dampening, the FLEX LN model is perfect for environments where minimal noise exposure is a priority, such as recording studios and broadcasting stations.

Each of these models is engineered to deliver accurate time displays, contributing to the efficiency and punctuality of operations in various indoor settings.

Outdoor Analogue Clocks: Durability and Visibility

For outdoor environments, MOBATIME offers a range of analogue clocks built to withstand diverse weather conditions while ensuring optimal visibility. These clocks come in both illuminated and non-illuminated versions, with IP65 protection ratings, making them suitable for various outdoor applications. They are compatible with multiple standard time codes, facilitating seamless synchronization and integration.

Notable models in the outdoor analogue clock range include:

METROLINE: Featuring an attractive aluminum lightweight housing and modular design, the METROLINE clock is available in single- and double-sided configurations. It comes in various sizes (50cm, 60cm, and 80cm diameters) and offers options for second hands and illumination, catering to diverse outdoor settings.

PROFILINE: This professional clock line boasts a modern design with a weatherproof aluminum profile case. The PROFILINE series is built to high professional standards, ensuring easy commissioning and maintenance.

PROFILINE QUAD: Designed with a square dial, the PROFILINE QUAD model offers a unique aesthetic appeal while maintaining the robustness required for outdoor installations.

PROFILINE 4 SIDED: Ideal for spaces requiring visibility from multiple directions, the PROFILINE 4 SIDED clock features a four-sided cube design, ensuring time is easily readable from any angle.

FLEX OUTDOOR: Built with IP65 protection, the FLEX OUTDOOR clock is suitable for various outdoor applications, offering both single-sided and double-sided designs to meet specific installation needs.

These outdoor clocks are engineered to provide accurate time displays, enhancing the efficiency and coordination of operations in public spaces, transportation hubs, and other outdoor environments.

Customization and Technical Features

Understanding that different environments have unique requirements, MOBATIME offers customization options across its analogue clock range. Clients can select from various sizes, dial types, and mounting arrangements to ensure the clocks align with their specific needs. Whether it's wall mounting, pole mounting, or ceiling suspension, MOBATIME provides flexible installation solutions.

From a technical standpoint, MOBATIME's analogue clocks support a variety of time code variants, including:

Polarized Impulses

MOBALine

NTP (Network Time Protocol)

Serial

IRIG / AFNOR

DCF 77, DCF active

GPS (DCF current loop)

Quartz

WTD (Wireless Time Distribution)

This versatility ensures seamless integration with existing time synchronization systems, providing accurate and reliable time displays across all connected clocks.

Applications Across Diverse Sectors

MOBATIME's analogue clocks find applications in a wide array of sectors, including:

Transportation: Ensuring synchronized time displays in airports, train stations, and bus terminals to facilitate smooth operations and punctuality.

Healthcare: Providing precise timekeeping in hospitals and laboratories, which is crucial for medical procedures and research activities.

Education: Enhancing time management in schools, colleges, and universities, aiding in the efficient scheduling of classes and events.

Corporate Offices: Promoting punctuality and time awareness in business environments, contributing to improved productivity.

Public Spaces: Offering reliable time displays in libraries, museums, and community centers, serving the general public's need for accurate time information.

By delivering precise and synchronized time displays, MOBATIME's analogue clocks play a pivotal role in enhancing operational efficiency and time management across these sectors.

1 note

·

View note

Text

How Construction Management Drives Efficiency in Life Science Facilities Development

The demand for cutting-edge life science facilities is rapidly increasing as the biotechnology, pharmaceutical, and medical research industries continue to expand. Efficient construction management plays a crucial role in delivering high-performing, compliant, and future-ready facilities that support innovation and growth.

From navigating complex regulatory requirements to integrating the latest technology, construction managers ensure that life science facility development meets industry standards while optimizing cost, time, and sustainability.

This article explores the key challenges, innovative solutions, and the impact of diversity and inclusion in life science construction.

Key Challenges in Life Science Construction

Building life science facilities is more complex than standard commercial construction due to strict regulatory compliance, specialized infrastructure needs, and evolving industry demands. Some of the major challenges include:

1. Regulatory & Compliance Requirements

Life science buildings, such as laboratories and cleanrooms, must adhere to FDA, GMP (Good Manufacturing Practices), ISO, and other stringent industry regulations. Construction managers must ensure that materials, airflow, contamination controls, and waste management systems meet these standards.

2. Advanced Infrastructure Needs

Life science facilities require specialized infrastructure, including HEPA filtration systems, controlled environments, vibration-resistant structures, and high-power lab equipment support. Managing these components while maintaining project timelines is a challenge.

3. Sustainability & Energy Efficiency

With increasing focus on sustainable construction, life science facilities must integrate energy-efficient HVAC, water conservation systems, and environmentally friendly materials. Balancing sustainability with cost-effectiveness is a key consideration.

Innovative Solutions in Construction Management

Effective construction management drives efficiency by integrating advanced planning, technology, and industry best practices. Here’s how:

Building Information Modeling (BIM) BIM technology allows construction teams to create a digital twin of the facility, enabling real-time collaboration, clash detection, and precise planning. This minimizes costly errors and accelerates project completion.

Modular & Prefabricated Construction To improve efficiency many life science developers are leveraging modular construction and off-site prefabrication of lab components, cleanroom panels, and mechanical systems. This speeds up installation while maintaining quality.

Lean Construction Methods Applying lean principles reduces waste, inefficiencies, and project delays by streamlining workflows, optimizing resource allocation, and ensuring just-in-time material delivery.

Sustainable & Smart Technologies

Innovative solutions such as smart HVAC systems, automated lighting, and IoT-based facility monitoring enhance operational efficiency and sustainability, making facilities future-ready.

The Role of Diversity & Inclusion in Life Science Facility Construction

A diverse and inclusive workforce brings fresh perspectives and innovative solutions to life science construction. Women-owned construction management firms, like Stelic, are making a significant impact by promoting diversity, equity, and collaboration in a traditionally male-dominated industry.

Enhanced Problem-Solving & Innovation: Diverse teams approach challenges from multiple perspectives, leading to more creative problem-solving and optimized construction strategies.

Stronger Community & Client Relationships: Inclusive teams foster better communication, collaboration, and adaptability, ensuring that client expectations and industry demands are met efficiently.

A More Resilient Workforce: With talent shortages in construction, diversity strengthens the industry by attracting and retaining top professionals from different backgrounds.

Our Expertise in Life Science Facilities Construction

Whether you are building a new state-of-the-art research laboratory, upgrading an existing manufacturing plant, or implementing a cGMP-compliant production facility, our life science construction management team has a proven track record of delivering life sciences projects of various scales. From small-scale R&D labs to large-scale biomanufacturing complexes, we ensure precision, efficiency, and compliance at every step.

Final Thoughts

The success of life science facility construction depends on expert management, cutting-edge technology, and inclusive collaboration. By addressing regulatory challenges, leveraging innovative solutions, and promoting diversity, construction management firms can drive efficiency and deliver state-of-the-art facilities that support scientific and medical advancements.

For expert life science construction management, trust Stelic to lead your project with precision, innovation, and inclusivity.

Essential FAQs

1. What makes life science facility construction different from commercial construction?

Life science facilities require specialized infrastructure, advanced HVAC systems, cleanroom technology, and strict regulatory compliance, making their construction more complex than traditional commercial projects.

2. How does construction management improve efficiency in life science facility development?

Effective construction management leverages BIM technology, lean methods, prefabrication, and sustainability-focused strategies to reduce delays, optimize costs, and ensure compliance.

3. What are the benefits of modular construction for life science buildings?

Modular construction speeds up installation, enhances quality control, reduces waste, and minimizes on-site disruptions, making it a preferred approach for life science projects.

4. How does diversity impact construction management in life science projects?

Diverse teams bring innovative ideas, improved decision-making, and stronger client relationships, leading to more effective construction management and successful project outcomes.

Get in Touch.

#Life Science Facilities Construction Management Washington DC#Life Science Project Management Washington DC#Life Science Construction Washington DC#Life Science Buildings Construction Washington DC

0 notes

Text

PUF Panel Supplier in India | High-Quality PUF Sandwich Panels by EPACK Prefab

Introduction

As industries expand and modern infrastructure demands energy-efficient, durable, and cost-effective construction solutions, PUF Panels have become the preferred choice across various sectors. Whether it's cold storage, warehouses, industrial sheds, or commercial buildings, the use of PUF Sandwich Panels ensures excellent insulation, structural strength, and long-term durability.

If you are searching for a trusted PUF Panel Supplier in India, EPACK Prefab provides premium-quality PUF Insulated Sandwich Panels, designed for thermal efficiency, weather resistance, and sustainability.

What is a PUF Panel?

A PUF Panel (Polyurethane Foam Panel) is a lightweight, high-performance insulation panel used for walls, roofing, and cold storage applications. It consists of a rigid polyurethane foam (PUF) core sandwiched between two durable metal sheets, providing superior thermal insulation and structural stability.

✔ Highly durable and lightweight ✔ Excellent thermal and sound insulation ✔ Fire-resistant and weatherproof ✔ Energy-efficient, reducing cooling & heating costs ✔ Quick and easy installation ✔ Environmentally friendly and recyclable

Why Choose EPACK Prefab as Your PUF Panel Supplier?

EPACK Prefab is a leading manufacturer and supplier of PUF Panels in India, offering customized, high-quality, and cost-effective insulation solutions. Our expertise in prefabrication technology enables us to deliver durable and efficient PUF Sandwich Panels for various industrial and commercial applications.

1. Premium-Quality PUF Sandwich Panels

🔹 Manufactured using high-grade materials for long-lasting durability. 🔹 Available in different thicknesses & sizes to meet diverse project needs. 🔹 Customizable insulation panels for varied temperature requirements.

2. Wide Range of PUF Panel Solutions

We offer a comprehensive range of PUF Panels designed for multiple industrial applications, including:

🏗 PUF Roofing Panels – Ideal for industrial & commercial roofing solutions. 🏢 PUF Wall Panels – Suitable for exterior & interior walls. ❄ PUF Cold Storage Panels – High-performance insulation for temperature-controlled environments. 🛠 PUF Partition Panels – Used in modular offices, cleanrooms, and laboratories.

3. Advanced Manufacturing Facility

🔹 State-of-the-art production units ensuring high-precision manufacturing. 🔹 ISO-certified quality standards for unmatched product reliability. 🔹 Eco-friendly production with minimal material wastage.

4. Cost-Effective & Energy-Efficient

🔹 Superior insulation properties reducing energy consumption. 🔹 Quick installation minimizes project timelines and labor costs. 🔹 Long-lasting performance, reducing maintenance expenses.

5. PAN India Delivery & Installation Support

🔹 Nationwide presence, ensuring prompt supply across all locations. 🔹 Professional installation services for seamless project execution. 🔹 Custom-made solutions tailored to client requirements.

Applications of PUF Panels

PUF Insulated Sandwich Panels are widely used across multiple industries for thermal insulation, energy efficiency, and structural durability. Some common applications include:

🏢 Industrial & Commercial Buildings – Offices, factories, warehouses. ❄ Cold Storage & Refrigerated Warehouses – Ensuring temperature control. 🏗 Prefabricated Structures – Modular housing, site offices, clean rooms. 🌡 HVAC Ducting & Insulated Rooms – Maintaining controlled environments. 🚧 Healthcare & Laboratories – Hospitals, pharma units, research centers.

Why PUF Panels are the Best Choice for Insulated Construction?

With the increasing demand for energy-efficient and eco-friendly construction, PUF Panels have become the go-to solution for modern buildings. Here’s why:

✅ Thermal Insulation – Minimizes heat transfer, reducing cooling & heating expenses. ✅ High Strength-to-Weight Ratio – Lightweight yet structurally robust. ✅ Quick Installation – Prefabricated for faster and hassle-free assembly. ✅ Fire & Weather Resistance – Provides protection against fire hazards and extreme weather conditions. ✅ Long-Term Durability – Resistant to corrosion, moisture, and UV radiation.

Why EPACK Prefab is India’s Most Trusted PUF Panel Supplier?

🔹 25+ years of expertise in the prefabrication industry. 🔹 100+ ongoing projects across India. 🔹 Turnkey PUF panel solutions – From manufacturing to on-site installation. 🔹 Serving diverse industries – Cold storage, industrial sheds, cleanrooms, and more.

📌 Client Satisfaction: EPACK Prefab has successfully delivered high-performance insulation solutions for industries, ensuring top-quality, cost-efficiency, and long-lasting performance.

Get in Touch with EPACK Prefab – India’s Leading PUF Panel Supplier!

Looking for high-quality PUF Panels for your next project? EPACK Prefab is your one-stop solution for PUF Insulated Sandwich Panels, Roofing Panels, and Cold Storage Panels at competitive prices.

📩 Email: [email protected] 📞 Call: +91 8130444466 🌐 Website: www.epack.in/puf-panels

🚀 Build faster, smarter, and more energy-efficient with EPACK Prefab – India’s leading PUF Panel Manufacturer & Supplier!

Related Blog - What is a PUF Panel and Why Choose It Over Traditional Construction Materials?

#PUF Panels#PUF Panel Supplier#PUF Sandwich Panels#PUF Roofing Panels#PUF Insulated Panels#PUF Panel Manufacturer#PUF Cold Storage Panels#Prefabricated Insulated Panels#Industrial PUF Panels#Insulated Roofing Sheets#EPACK Prefab

0 notes