#Motion Control Software In Robotics Market

Explore tagged Tumblr posts

Text

#Motion Control Software In Robotics Market#Motion Control Software In Robotics Market Share#Motion Control Software In Robotics Market Trends#Motion Control Software In Robotics Market Value

0 notes

Text

Hi, I'm Osaka

I'm a hobbyist designer, and I research esoteric concepts on the periphery of mecha to find new views nobody else is writing about. I also am obsesed with trying to push the genre forwards.

I also took up programming to build a game faster than ACFA, more airborne than Ace Combat, and more "art of the blade" than Zone of the Enders 2 by studying mecha games through the lens of published declassified military grade airwar and psywar human factors engineering and psychology concepts.

I want to make this game about mechposting and the trans experience, but I need your help: not money, but to speak with you about mecha.

The writing is simultaniously equal parts thesis to microfic a lot of the time, so your milage may vary.

Scroll through the mess below and find what suits you best.

Please.

Mecha Theory Writing

A comprehensive explanation of the evolutionary path from conventional ground and air vehicles, including a comprehensive outline of a functioning control-design based on the inceptor/software model seen in unmanned drones and 5th gen aircraft, complete with explanations.

The evolution of the walking thing called “mecha" (original)

Chapter 0: Establishing terminology & Concepts Part 1: Defining "the mechaness" of something: the 8 principles of mecha Part 2: Feisability: Mecha aren't realistic, but not for the reason you think

Chapter 1: How does "mecha" come into existence/why would you want one? Part 1: An evolution from ground vehicles of today Part 2: Skating, to walking, to running, to flight Part 3: “Why transform in the vacuum of space?”

Chapter 2: Cockpit & Software Design Control Theory Part 4: On Mecha Control Theory: Considerations Part 4a: On Mecha Control Theory II: OKAWARA Part 4b: On Mecha Control Theory III: TOMINO Part 4c: On Mecha Control Theory III: NAGANO

The World of Armored Core

An exploration of the world of Armored Core, using research into real phenomenon and engineering systems to infer how the world may itself function

Kojima particle physics (part 1): What are they? Kojima particle physics (part 2): The Human Consequences NEXT cockpit design (part 1): AMS and Lynx NEXT Cockpit Design (Part 2): G-force Tolerance Technocrat is SpaceX, and the legacy of Musk’s father (lmao) I am a 4th gen douchebag, and I love it (love-letter to ACFA) 4th gen shitpost: white gopnik

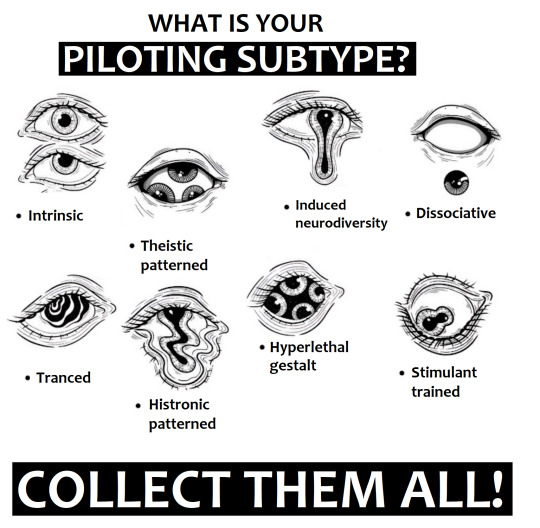

How To Domesticate Your Pilot

A husbandry guide for handlers, consisting of opinions and thoughts from various trainers and operators, as well as pilots. Includes practices, procedures, articles, stories and snippets.

I'm currently testing the waters with snippets and will likely be posting it out of order. I am extremely hungry for any and all possible feedback

If anybody knows the original source of the image of the eyes (which I first saw in a youtube ad) I'd love to know. I very much would like to commission them.

Inspired by mechposting

Chapter 3: Do not Abuse Your Wolves (Psychological patterning) Part 1: Action patterning (Initial Phases) Part 2: Action Patterning (Risks) Part 3: Once upon a mechanism

On mecha design: My personal thoughts on the assemblies of shape, form in the context of motion, action and function 1. Does anybody else have physical characteristics they find the most appealing? 2. Thoughts on self-altering dynamic form, and proportion designs 3. Shoji Kawamori and Armored Core: designers hallucinate, but do they hallucinate too? 4. Why is Gundam Gquuuuux called Gundam Gquuuuux?

Mechsploitation thoughts

#Mechposting

My personal thoughts on piloting culture, and mechanical design

1. The eroticism of the machine: Megastructures 2. Beyond pilebunker: The Grind-blade and the legacy of Overweapons 3. FLAT/Touchscreens are an act of hate: I will teach you love 4. You do not need to pick between a big hammer or daggers if you are a robot 5. O'Socks combat mix (tw: substance abuse) 6. Team dynamics, addiction, conflicts of interest and marketing 7. Commuication is hard, and mecha feet are cool 8. Morrigan Aensland is mecha and you cannot change my mind 9. re: Last Exile is not dieselpunk; its post-steampunk deleuzian dreams 10. Mecha PMC promotion is back, in pog form 11. Bodies, corporeal schema, and the body language of pilots 12. The blessing of the hounds; main system engaging combat mode 13. Exotic doctrine: Grappling & Booster-fu // torsion, aspect and control 14. Osaka, why do you always want to talk about ACFA? 15. You walk, so they can run

# Miscposting: Immacullate vibe-topia Pilot, for you: Love. Love. The sound of the ideal cockpit Left Hand/Right hand [gone]-- Mechposting vibes soundwall 🇸🇮🇨🇰🇧🇪🇦🇹🇸 🇹🇴 🇸🇪🇪🇰 🇦🇳🇩 🇩🇪🇸🇹🇷🇴🇾 🇹🇴: A #mechposting playlist [ongoing] Cicatrix: A writing playlist Sounds for violence: Mecha games vs FPS games

# Pilotcore: Dress & attire 1. Attire concept (includes #mechposting patch list) 2. Crew attire for things other than piloting a giant robot 3. Singleton over-jacket 4. Radios, straps and whips 5. Wearable keyboard for pilots 6. What color should a flight-suit be? (#AskOsaka from @siveine)

The Learning Tree

Reading this will help you grow as a person, or ask questions

"I experience depression as a failure of resource allocation systems" Adult social skills 101, because the world broke our ability to understand eachother Mental health: Things I wish I knew in my teens, my 20's or even my early 30's Sex-positivity, associations, critical thinking & deradicalization Crossing the hrt libido event horizon without libido heat-death by making biscuits Fool!: Your nostalgia isn't real: Your past has been stolen from you! Why Linux diehards are morons, and so is everybody else too On the ecology of slurs and the evolution of language Individualism can mean many things. The three fetishes of the human condition The real meaning of "you will not be an anime girl, you'll be your mom"

Nothing, but content for contented malcontents

Insightful, but stupid.

The collapse of the anime ecology's biodiversity Cycles of Nostalgia: Nobody is going to be nostalgic for Corporate Memphis Europe doesn't teach the Odyssey: Americentricism's fetishism is already its downfall Feeling used: The eternal disappointment of the Sawano Drop Lame? Bitch please: Clubbing deserves to go extinct every pmdd transmasc is that badass hot painting of satan crying The reviewer made a major error The Maid's Paradox Bread real

The horrors

Robo ComBAT: Cactus Jaque (original)

The Fear

Concerning plunges into the ne plus ultra culture of tomorrow

Humbert complex: When people prefer what they imagine to what's really there White Diamond, fascism, projection, ego, how Steven Universe botched its end. Sandwich names: the internet sucks now and smartphones are to blame! Gatekeeping is weird and knowledge-checks are arbitrary nonsense "The internet feels gross now", a trajectory of human events Providing feedback is also a skill and not everybody has it. AI isn't evil but it does embolden the worst people economics is just twitter brain for worth Do you?

My actual projects:

Art (I'm kind of private about my output and don't post often, sorry)

Pixelart: A very silly computer design that makes me smile idk

Games:

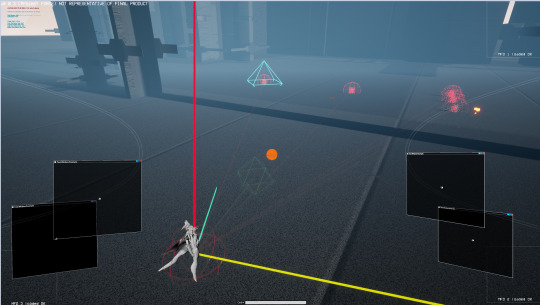

Project Force: 6dof aerodynamic high speed robot action [ongoing] Inspired by Armored Core For Answer, Freespace 2, Zone of the Enders 2 & Ace Combat 3, this game aims to merge their elements into a high speed mech sim.

e: yeesh this pinned post is getting kinda huge, I should break it into sub-pages or something so nobody can ever see any of it lol

110 notes

·

View notes

Text

Double Motors Market [2025] Size,Trends and Scope till 2033

Global “Double Motors Market” research report is a comprehensive analysis of the current status of the Double Motors industry worldwide. The report categorizes the global Double Motors market by top players/brands, region, type, and end-user. It also examines the competition landscape, market share, growth rate, future trends, market drivers, opportunities, and challenges in the global Double Motors market. The report provides a professional and in-depth study of the industry to help understand its current state and future prospects. What Are The Prominent Key Player Of the Double Motors Market?

Linak

TIMOTION

Jiecang Linear Motion

Zhejiang Ewelift

AMETEK

DewertOkin Technology Group

Qingdao Richmat

Moteck

Zhejiang Xinyi Control System

Lim-Tec

The Primary Objectives in This Report Are:

To determine the size of the total market opportunity of global and key countries

To assess the growth potential for Double Motors

To forecast future growth in each product and end-use market

To assess competitive factors affecting the marketplace

This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals.

Regional Segment of Double Motors Market:

Geographically, the report includes research on production, consumption, revenue, market share, and growth rate of the following regions:

United States

Europe (Germany, UK, France, Italy, Spain, Russia, Poland)

China

Japan

India

Southeast Asia (Malaysia, Singapore, Philippines, Indonesia, Thailand, Vietnam)

Latin America (Brazil, Mexico, Colombia)

Middle East and Africa (Saudi Arabia, United Arab Emirates, Turkey, Egypt, South Africa, Nigeria)

The global Double Motors Market report answers the following questions:

What are the main drivers of the global Double Motors market? How big will the Double Motors market and growth rate in upcoming years?

What are the major market trends that affecting the growth of the global Double Motors market?

Key trend factors affect market share in the world's top regions?

Who are the most important market participants and what strategies being they pursuing in the global Double Motors market?

What are the market opportunities and threats to which players are exposed in the global Double Motors market?

Which industry trends, drivers and challenges are driving that growth?

Browse More Details On This Report at - https://www.businessresearchinsights.com/market-reports/double-motors-market-104434

Contact Us:

Business Research Insights

Phone:

US: (+1) 424 253 0807

UK: (+44) 203 239 8187

Email: [email protected]

Web: https://www.businessresearchinsights.com

Other Reports Here:

Frisbees Market

CMMS Software Market

Point Machine Market

Canoe and Kayak Market

Grand Piano Market

Thermal Rototiller Market

Concentrated Solar Power (CSP) Market

Vinylene Carbonate Market

Boundary Scan Hardware Market

Ethyl Propenyl Ether Market

Other Reports Here:

Eccentric Press Market

Fluted Plastic Board Market

Instant Coffee Powder Market

B2B Fuel Cards Market

Portable Industrial Platforms Market

Semiconductor Fittings Market

Poultry Market

Semiconductor Wafer Transfer Robotics Market

Linear Alpha Olefins (LAO) Market

Magnetron Market

0 notes

Text

Robotic Platform Market driven by Automation Demand

The Robotic Platform Market encompasses a suite of advanced robotic systems designed to execute tasks ranging from material handling and assembly to inspection and packaging across diverse industries. These platforms integrate cutting-edge hardware components—such as robotic arms, end effectors, and vision systems—with sophisticated software for motion planning, simulation and real-time control. Key advantages include enhanced operational efficiency, improved precision, reduced human error and heightened workplace safety. As industries confront labor shortages and rising production costs, the need for scalable robotic platforms has soared, fueling demand for customizable and modular solutions.

In manufacturing, these systems optimize throughput and facilitate Industry 4.0 initiatives, while in healthcare, they support surgical assistance, telepresence and laboratory automation. Additionally, the ongoing trend toward collaborative robots (cobots) underlines the market’s focus on human-machine interaction and adaptive intelligence. Market research indicates that small and medium enterprises are increasingly adopting robotic solutions to maintain competitive cost structures. Robust market insights point to the pharmaceutical and food & beverage sectors as emerging segments for growth, driven by stringent quality standards and consumer expectations. Overall, continuous innovations in artificial intelligence and machine learning are expected to expand the Robotic Platform Market scope, enabling predictive maintenance and advanced analytics.

The Global Robotic Platform Market is estimated to be valued at USD 11.37 Bn in 2025 and is expected to reach USD 18.62 Bn by 2032, growing at a compound annual growth rate (CAGR) of 7.3% from 2025 to 2032. Key Takeaways Key players operating in the Robotic Platform Market are:

-ABB LTD.

-Amazon.com, Inc.

-Google LLC

-IBM Corporation

-KUKA AG

These market players dominate the industry size and contribute significantly to collectively over 40% of market share, leveraging robust market growth strategies such as strategic partnerships, acquisitions and extensive R&D spending. ABB LTD. continues to enhance its robotics portfolio through modular platforms, focusing on collaborative robots for light-duty tasks. Amazon.com, Inc. integrates robotic platforms in its fulfillment centers for automated order processing, boosting business growth and reducing operational costs. Google LLC and IBM Corporation invest heavily in AI-driven automation, offering cloud-based robotic solutions with advanced analytics and machine vision. Meanwhile, KUKA AG differentiates through high-precision industrial robots tailored for automotive and aerospace segments. Collectively, these leading companies drive market competition, develop new applications and influence market dynamics across global regions.

‣ Get More Insights On: Robotic Platform Market

‣ Get this Report in Japanese Language: ロボットプラットフォーム市場

‣ Get this Report in Korean Language: 로봇플랫폼시장

0 notes

Text

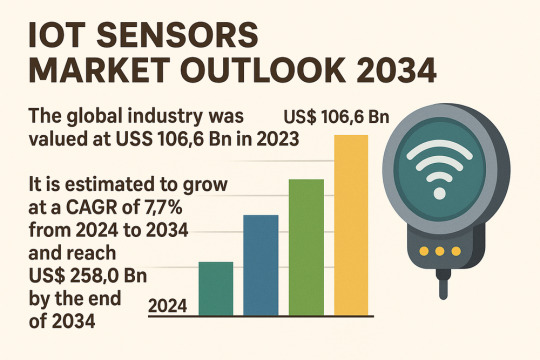

Internet of Things (IoT) Sensors Market to Hit US$ 258 Billion by 2034

The global Internet of Things (IoT) sensors market was valued at US$ 106.6 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 7.7% between 2024 and 2034, reaching US$ 258.0 billion by the end of the forecast period. IoT sensors, which convert physical parameters such as temperature, pressure, humidity, and motion into electrical signals, are key enablers of real-time data analytics across consumer electronics, healthcare, automotive, agriculture, transportation, and industrial sectors.

Market Drivers & Trends

Surge in Demand for Smart Sensors

Smart sensors provide digital data ready for immediate transmission, reducing latency in performance monitoring.

Adoption of automated predictive maintenance in smart factories is accelerating the shift toward intelligent sensor networks to prolong asset life and prevent unplanned downtime.

Rise in Investment in Industry 4.0

Industrial IoT (IIoT) sensors aggregate data centrally and feed it back to optimize processes, critical for factory automation and digital twin implementations.

Growth in collaborative robotics and autonomous guided vehicles has driven demand for Inertial Measurement Units (IMUs) comprising accelerometers, gyroscopes, and magnetometers to enable precise motion control.

Shift Toward Wireless Connectivity

Wireless IoT sensors are rapidly gaining traction due to simpler installation, scalability, and elimination of wiring constraints, essential for real-time asset tracking via GPS and network connectivity.

Latest Market Trends

Industrial IoT (IIoT) Proliferation: Manufacturing companies, post-pandemic, are heavily investing in digital and supply-chain technologies, fueling growth in IIoT sensor deployments for condition monitoring and quality control.

Industry 5.0 Foundations: Emerging trends see humans collaborating with robots, underscoring the need for sensors with embedded AI capabilities to interpret nuanced environmental cues and support safe, efficient cooperation.

Edge Computing Integration: Key players are developing edge-based network architectures that process sensor data locally, minimizing latency and bandwidth usage, and empowering real-time decision-making.

Key Players and Industry Leaders

The competitive landscape is marked by strategic investments and product innovations from leading semiconductor and sensor manufacturers:

Analog Devices, Inc.: Investing €630 million in its Limerick, Ireland facility for advanced semiconductor research in industrial and automotive sensors.

Bosch Sensortec GmbH: Unveiled the BHI380 Smart Connected Sensors platform at CES 2024, enhancing motion-tracking applications with ready-to-use hardware and software reference designs.

Honeywell International Inc.: Expanding its wireless sensor portfolio for building automation and aerospace applications.

Infineon Technologies AG: Focusing on low-power gas and environmental sensors for consumer electronics and healthcare monitoring devices.

Texas Instruments, Murata Manufacturing, STMicroelectronics, and TE Connectivity: Continuously broadening their IoT sensor lines across temperature, pressure, flow, and proximity sensing.

Recent Developments

January 2024: Bosch Sensortec launched the BHI380 platform, addressing wearable and motion-tracking needs with integrated AI support.

2023: ABB Ltd. entered a strategic partnership with Pratexo to co-develop edge-computing solutions for decentralized IoT networks.

2023: Siemens announced a US$ 150 million smart factory in Dallas–Fort Worth, leveraging Siemens-made IoT and AI tools for digital twin and factory automation.

2023: Momenta, backed by the European Commission, launched a US$ 100 million Industry 5.0 fund to support human-robot collaboration technologies.

Market Opportunities

Smart Factory Deployments: As Industry 4.0 adoption deepens, demand for temperature, vibration, and level sensors is set to accelerate, particularly in process-driven verticals like pharmaceuticals and petrochemicals.

Healthcare Monitoring: Wearable IoT sensors for continuous patient vitals tracking present a high-growth avenue amid digital health initiatives.

Agricultural IoT: Precision farming technologies, utilizing soil moisture and ambient condition sensors, offer substantial potential in optimizing crop yields and resource utilization.

Smart Buildings and Cities: Growth in building-management systems and urban infrastructure monitoring will escalate demand for environmental and occupancy sensors.

Future Outlook

Looking ahead to 2034, the IoT sensors market is poised for transformative growth driven by:

Advancements in AI-Embedded Sensors: On-sensor analytics will enable localized anomaly detection and autonomous decision-making.

Expansion of 5G and Beyond: Ultra-low latency networks will unlock new applications, from autonomous vehicles to remote surgery, demanding robust sensor ecosystems.

Sustainability Focus: Energy-harvesting and self-powered sensor technologies will reduce maintenance costs and environmental impact, aligning with corporate ESG objectives.

Market Segmentation

Segment

Sub-Segments

By Type

Temperature, Pressure, Humidity, Flow, Level, Image, Smoke, Hall Effect, Accelerometer, Vibration, Magnetometer, Gyroscope, Light, Gas, Others (Motion, Occupancy)

By Technology

Wired, Wireless

By End-Use Industry

Consumer Electronics, Healthcare, Automotive, Industrial, Building & Construction, Retail, Others (Agriculture, Transportation)

Regional Insights

Asia Pacific: Led the market in 2023, driven by accelerated technology investments in manufacturing. Indian manufacturers allocated 35% of operating budgets to tech investments above global averages to bolster IoT, automation, and AI integration.

North America: Strong uptake in smart building projects and automotive sensor applications, supported by major OEMs and tech giants.

Europe: Growing emphasis on sustainable manufacturing and Industrial Internet Consortium initiatives has catalyzed sensor adoption in Germany, France, and the U.K.

Latin America & MEA: Emerging infrastructure modernization and smart agriculture projects are creating greenfield opportunities for sensor deployment.

Why Buy This Report?

Comprehensive Analysis: Deep-dive quantitative and qualitative assessment covering 2020–2022 historical data and 2024–2034 forecast.

Actionable Insights: Detailed coverage of market drivers, restraints, opportunities, and Porter’s Five Forces to guide strategic decision-making.

Competitive Benchmarking: Profiles of 16 leading companies, including product portfolios, financial metrics, strategic initiatives, and recent developments.

Segmentation & Regional Breakdowns: Granular market sizing across types, technologies, end-use industries, and five key regions plus 12 major countries.

Customizable Format: Delivered in PDF and Excel formats with interactive data dashboards for further analysis.

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Precision in Motion: Machine Control System Market Nears $9B by 2034 🦾📐

Machine control system market is experiencing a dynamic transformation, projected to grow from $4.2 billion in 2024 to $8.9 billion by 2034, reflecting a strong CAGR of 7.8%. As industries pivot towards automation and precision, machine control systems have become integral to sectors like construction, mining, and agriculture. These systems, which incorporate technologies such as GNSS, GPS, laser scanners, and robotic total stations, are vital in reducing human error, enhancing safety, and optimizing operations.

With the need for real-time decision-making, data integration, and digital transformation, businesses are turning to these technologies to streamline workflows and improve project outcomes. The surge in infrastructure development and the evolution of smart cities are further propelling the demand for intelligent machine control solutions.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS20749

Market Dynamics

The market’s upward trajectory is largely influenced by the rising demand for precision in construction and farming applications, where human oversight alone is insufficient. Automation trends, particularly in heavy equipment, are reducing labor dependency while improving operational accuracy and safety.

At the same time, high initial investment costs and integration complexities act as restraints. Small to mid-sized enterprises often hesitate to adopt due to budget constraints and the steep learning curve. Moreover, the lack of skilled operators and concerns over data security in cloud-based systems also pose notable challenges.

Nevertheless, ongoing technological innovation, increasing government support for infrastructure projects, and the push for sustainability are creating vast opportunities for players in this market.

Key Players Analysis

The competitive landscape of the machine control system market is a blend of well-established giants and emerging innovators. Key market leaders include Topcon Corporation, Trimble Navigation, Leica Geosystems, MOBA Mobile Automation, and Carlson Software. These companies are constantly investing in R&D, forming strategic partnerships, and enhancing their software-hardware integration capabilities to stay ahead.

Emerging players like Geo Dynamics, Terra Track Systems, and Precision Pilot are making waves by offering niche innovations and customizable solutions for specialized applications. The market also sees increasing collaboration between technology developers and equipment manufacturers, allowing for seamless end-to-end solutions.

Regional Analysis

North America leads the global machine control system market, driven by strong technological adoption, robust infrastructure spending, and the presence of major players. The United States remains the largest contributor, thanks to its active smart city initiatives and large-scale construction activities.

Europe follows closely, with Germany and the United Kingdom at the forefront due to their focus on Industry 4.0 and sustainable development. These regions benefit from early adoption and government support for environmentally conscious construction practices.

The Asia-Pacific region is witnessing the fastest growth, led by China and India, where rapid urbanization and industrialization are fueling demand. Local government initiatives aimed at infrastructure modernization and precision agriculture are key market drivers.

Latin America, the Middle East, and Africa are emerging markets, with increasing investments in agriculture, mining, and urban development. Countries like Brazil, Saudi Arabia, and South Africa are investing in smart machinery to boost productivity.

Recent News & Developments

Recent years have seen rapid developments in machine control technology, particularly in GNSS and laser scanning systems. Integration of IoT, AI, and cloud computing into control systems is redefining performance standards. These innovations allow for remote monitoring, predictive maintenance, and data-driven project management.

Additionally, price dynamics remain competitive, with systems ranging from $5,000 to $50,000, depending on complexity and application scope. The increasing ROI and improved system affordability are encouraging broader adoption. Strategic alliances, such as between tech providers and OEMs, are also accelerating global expansion.

Browse Full Report : https://www.globalinsightservices.com/reports/machine-control-system-market/

Scope of the Report

This report provides an in-depth analysis of the machine control system market, spanning from 2018–2034, with a forecast period from 2025–2034. It covers segmentation by type, technology, component, application, end user, and more. Our scope extends to detailed regional forecasts, competitive benchmarking, value chain analysis, and PESTLE assessments.

Additionally, the report evaluates market trends, challenges, and opportunities, equipping stakeholders with the insights necessary to navigate and capitalize on market shifts. Whether you’re an investor, manufacturer, or policymaker, this comprehensive outlook will help align your strategy with emerging global trends.

Discover Additional Market Insights from Global Insight Services:

Printed Circuit Board Market : https://www.globalinsightservices.com/reports/printed-circuit-board-market/

Machine Control System Market : https://www.globalinsightservices.com/reports/machine-control-system-market/

Wires And Cables Market : https://www.globalinsightservices.com/reports/wires-and-cables-market/

Asset Integrity Management Market : https://www.globalinsightservices.com/reports/asset-integrity-management-market/

Gallium Nitride (GaN) Power Devices Market ; https://www.globalinsightservices.com/reports/gallium-nitride-gan-power-devices-market/

#machinecontrolsystems #constructiontech #agtech #smartinfrastructure #automationtechnology #gnss #laserscanning #iotintegration #precisionfarming #constructionautomation #heavyequipmenttech #digitalconstruction #smartfarming #roboticsystems #gpsnavigation #civilengineeringtech #infrastructuregrowth #earthmovingequipment #graderautomation #excavatortechnology #mininginnovation #agriculture4.0 #construction4.0 #geospatialtechnology #industrialautomation #remotesensingtech #lidarsolutions #digitalsite #siteautomation #buildingthefuture #smartcities2025 #jobsiteinnovation #machinelearningtech #constructionequipment #sustainabilitytech #techinconstruction #dataintelligence #fieldautomation #futureofconstruction #gnssapplications #constructionefficiency

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

What Key Factors Should You Consider When Choosing an Automation Products Supplier?

Understanding the Role of an Automation Products Supplier

In today’s fast-paced industrial landscape, businesses depend heavily on reliable Automation Products Supplier in Kuwait partners to streamline operations, improve productivity, and maintain a competitive edge. Automation has become essential across sectors such as manufacturing, logistics, healthcare, and more, driven by the need for efficiency, accuracy, and cost control. The right supplier not only provides advanced products but also delivers technical support, customization, and ongoing services that are crucial for long-term success.

Types of Automation Products Available

Automation products cover a wide range of technologies, each serving specific roles in industrial and commercial applications:

Programmable Logic Controllers (PLCs): These are ruggedized computers designed to control manufacturing processes, offering high reliability and ease of programming for tasks like assembly lines and robotic devices.

Human Machine Interfaces (HMIs): HMIs provide intuitive control panels for operators, enabling easy visualization and management of complex systems through touch screens and multi-touch interfaces.

Motion and Drives: Includes servo motors and stepper motors used for precise control of position, speed, and torque in automated systems.

I/O Systems: Inputs and outputs (I/O) connect various sensors and actuators to central controllers, supporting multiple communication protocols for distributed control.

Sensors and Vision Systems: Photoelectric, proximity sensors, and machine vision cameras are used for detecting objects, monitoring production lines, and ensuring quality control.

Accessories and Connectivity: Products such as cordsets, communication cables, and software for programming and troubleshooting are essential for seamless integration and maintenance of automation systems.

Why Supplier Selection Matters

Choosing the right automation products supplier is a strategic decision that impacts every aspect of your operations. Here are key factors to consider:

Product Range and Innovation: Leading suppliers offer a comprehensive portfolio, including the latest advancements in robotics, artificial intelligence, and IoT-based control systems. This ensures your business can adopt new technologies as they emerge.

Reliability and Support: A reputable supplier provides technical support, training, and after-sales services, helping you maximize the value of your investment and minimize downtime.

Customization and Scalability: As industries evolve, the demand for customized and scalable solutions grows. The best suppliers work closely with clients to tailor products that fit unique operational needs.

Global Reach and Local Presence: Top suppliers often have a global footprint with strong local support, ensuring timely delivery and service regardless of location.

Security and Compliance: With increasing digitalization, security is paramount. Suppliers should offer solutions with robust cybersecurity features and comply with relevant industry standards.

Market Trends and Growth Opportunities

The global industrial automation market is expanding rapidly, with a high growth rate projected for the coming years. This growth is driven by rising labor costs, a shortage of skilled workers, and government initiatives promoting automation for efficiency and sustainability. Companies are investing in technologies such as edge computing, 5G, and digital twin systems, which enable real-time monitoring and predictive maintenance for smarter operations.

Conclusion

Selecting the right Automation Products Supplier in Kuwait is critical for any business aiming to thrive in an increasingly automated world. By evaluating suppliers based on product offerings, innovation, support, and security, companies can ensure they are well-equipped to meet current demands and adapt to future challenges. As automation technology continues to evolve, partnering with a knowledgeable and reliable supplier will help your business achieve greater efficiency, productivity, and long-term growth.

Also Read: Rexroth Pumps and Valves Supplier in Kuwait

0 notes

Text

Revolutionizing Film Production: The Rise of Robotic Camera Systems

Technology always changes the scene in the fast-changing film and video production sector, providing new tools that increase operational efficiency and creative potential. Robotic camera systems are among the most revolutionary innovations of recent years. Epitomized by the BOLT Cinebot, these technologies change how visual effects teams, cinematographers, and directors record motion films. These robots' accuracy and quickness allow for very complicated and dynamic pictures, hence pushing the limits of what can be visually produced on screen.

Accuracy in Visual Effects and Cinematic Aesthetics

Precision is key in the field of visual effects; the BOLT Cinebot shines in this regard. Whether they are building CGI settings, motion tracking, or sophisticated composites, filmmakers may get a degree of precision that enables intricate visual effects with their ultra-precise control. The exact execution of repeating shots guarantees that visual effects companies have a strong basis to work from, hence producing breathtaking cinematic sequences that seem perfect on screen. The BOLT Cinebot is a great tool for filmmakers aiming to push the limits of visual imagination as it helps to provide that cinematic sheen.

Affordable Creativity for Smaller Studios

Studios may benefit from this advanced robotic camera system by renting rather than buying, therefore avoiding financial ruin. This strategy allows smaller production teams to produce top-tier, visually appealing material without significant upfront expenses. Rental services also provide technical assistance and maintenance, so guaranteeing that production teams may concentrate on their creative process instead of stressing about the technicalities of the tools.

Improving Visual Storytelling with BOLT Cinebot

Using the BOLT Cinebot in a studio environment offers unmatched filming accuracy. This robotic wonder can do fast, complicated camera motions with perfect reproducibility, hence enabling detailed and visually spectacular scenes that would be difficult to create with human operators alone. The camera's capacity to sync with motion control software opens doors for filmmakers to investigate new areas in visual storytelling, hence improving the aesthetic appeal and narrative depth of their works.

BOLT Cinebot Studio Rental: A Game Changer

Choosing a BOLT Cinebot Studio Rental gives you access to a degree of technical sophistication once only accessible to top-tier film productions. This accessibility to a larger spectrum of filmmakers, including those in independent filmmaking and commercial advertising, democratizes high-end cinematic processes. Renting allows studios and production firms to play with cutting-edge technologies without the whole expenditure, hence enabling them to produce outstanding material that distinguishes themselves in a crowded market.

Simplifying Production Processes

Including a BOLT Cinebot in manufacturing processes greatly improves efficiency. The robot's speed and precision eliminate the need for many takes, hence saving time and lowering expenses connected with long shooting days. The Cinebot's consistency also helps to streamline post-production processes as editors get more accurate and cleaner film, hence facilitating the integration of visual effects and lowering the total time from production to post.

Advanced robotics: The future of filmmaking

Looking forward, the function of robots like the BOLT Cinebot in filmmaking will surely grow to affect not just how films are produced but also how viewers interact with cinema. The intention behind these technologies is to give filmmakers fresh methods to craft tales that fascinate and involve viewers on more profound levels. Creative exploration options are almost unlimited, hence starting a new age of cinematic quality powered by technical innovation.

Conclusion

Robotic technology's influence on the movie is clear; with services like BOLT Cinebot Studio Rental, this sophisticated equipment has become more reachable. Filmmakers wishing to exploit this technology may discover additional information and rental alternatives via companies such as pannyhire.com. Here, the union of technology and creativity opens up a universe of possibilities, guaranteeing that the future of filmmaking not only matches but surpasses the visionary standards of today’s cinematic environment.

For more info:-

ARRI Master Anamorphic rental Los Angeles

ARRI Signature Prime rental Los Angeles

0 notes

Text

What Is Automation and Control Engineering? How It’s Powering Rockford’s Industrial Growth

In today’s competitive and fast-paced industrial environment, companies are under immense pressure to increase efficiency, reduce downtime, and produce higher-quality output. One discipline that sits at the heart of this transformation is automation and control engineering. Across the manufacturing-heavy city of Rockford, Illinois, this field is driving innovation, operational excellence, and long-term sustainability.

From robotics to real-time data monitoring, automation and control engineering plays a critical role in modernizing factories, optimizing logistics, and ensuring safer, smarter processes. But what exactly does this field involve—and why is it becoming essential for companies in Rockford and beyond?

Let’s take a closer look.

Understanding Automation and Control Engineering

At its core, automation and control engineering is the integration of hardware and software systems to automate industrial processes, control machinery, and optimize operations. Engineers in this field design intelligent systems that make decisions, collect data, and execute actions with little to no human intervention.

Typical systems include:

Programmable Logic Controllers (PLCs)

Supervisory Control and Data Acquisition (SCADA)

Distributed Control Systems (DCS)

Human-Machine Interfaces (HMIs)

Sensors, actuators, and IoT devices

Robotics and motion control

These systems are crucial in industries like automotive manufacturing, aerospace, food processing, energy production, water treatment, and many more—all of which have a strong presence in Rockford.

Why Rockford Is an Automation Hotspot

Rockford has long been known as a powerhouse for manufacturing and aerospace engineering. Home to major players in precision machining, automation integration, and logistics, the city has embraced technological innovation to stay competitive in the global market.

Here's why automation and control engineering is such a perfect fit for Rockford:

1. Strong Manufacturing Base

With a high concentration of machine shops and OEMs (original equipment manufacturers), Rockford relies heavily on process efficiency and system reliability. Automation makes it easier to maintain consistent production and minimize waste.

2. Workforce Development

The city’s technical schools and engineering programs, including those at Rock Valley College and Northern Illinois University, are helping to prepare a new generation of automation-savvy engineers.

3. Modernization of Legacy Facilities

Many older manufacturing facilities in Rockford are upgrading to smart systems to meet today's standards for energy efficiency, data tracking, and remote operation.

4. Industry Diversification

Aside from aerospace and automotive, Rockford is seeing growth in renewable energy, food processing, and medical device manufacturing—all of which benefit greatly from advanced control systems.

Key Benefits of Automation and Control Engineering

Increased Efficiency

By reducing manual intervention, automated systems can streamline tasks like assembly, inspection, and material handling. This results in faster production cycles and lower labor costs.

Better Product Quality

Automated control systems can monitor quality metrics in real-time, ensuring products meet strict specifications. This is especially important for high-precision industries like aerospace and electronics.

Improved Safety

Sensors, alarms, and emergency shutdown systems help reduce the risk of accidents. Workers are kept away from hazardous zones, and automated safety protocols ensure fast response during equipment malfunctions.

Data-Driven Operations

With the integration of IoT and cloud technology, companies can collect and analyze vast amounts of performance data. This empowers smarter decision-making, predictive maintenance, and better resource management.

Scalability and Flexibility

Automated systems can be easily modified or scaled as production demands change—crucial for Rockford’s diverse and rapidly evolving manufacturing landscape.

Common Applications in Rockford Industries

Automation and control engineering is already making an impact across many sectors in Rockford. Some examples include:

Aerospace: Robotic welding, CNC automation, and torque control systems for precision parts

Automotive: Automated assembly lines, vision-guided inspection, and quality control systems

Food & Beverage: Temperature and pH monitoring, smart conveyors, and automated packaging

Logistics: Warehouse automation, conveyor control, and robotic material handling

Utilities: SCADA systems for water treatment and energy distribution

Choosing the Right Automation Partner

When upgrading or implementing automated systems, it's essential to work with professionals who understand both the technology and the unique challenges of your industry. Look for a partner with:

Proven experience in automation design and integration

Knowledge of Rockford’s industrial landscape

Ability to provide long-term support and training

A clear roadmap for system scalability

Companies across Illinois have found success by working with specialized automation providers who not only deliver hardware and software but also offer consulting, system optimization, and ongoing maintenance.

Final Words: Engineering Rockford’s Future

In a city like Rockford, where tradition meets innovation, automation and control engineering is not just a trend—it’s a transformation. Whether you’re modernizing an existing facility or building a fully smart production line, the key to success lies in engineering systems that are intelligent, adaptable, and aligned with your operational goals.

As industries continue to evolve, so must the tools they use. With the right automation strategies in place, Rockford's manufacturers can expect reduced costs, better performance, and stronger global competitiveness.

To explore automation solutions built for your industry, start your journey with trusted experts at Xtreme Automation LLC— your gateway to smarter systems and a more efficient future.

1 note

·

View note

Text

AI for Engineers: The Top Certifications Every Techie Needs

Artificial Intelligence (AI) is transforming industries worldwide, and engineers are at the forefront of this technological revolution. From robotics and automation to data-driven decision-making and smart systems, AI is reshaping how engineers approach problem-solving and innovation.

For engineers looking to enhance their careers, AI certifications provide structured learning, practical applications, and industry-recognized credentials. Whether you’re a software engineer, mechanical engineer, or robotics expert, understanding AI will give you a competitive edge in today’s job market.

Why Engineers Need AI Skills

1. AI is Revolutionizing Engineering Fields

From predictive maintenance in manufacturing to AI-driven simulations in civil engineering, AI enhances efficiency and accuracy across various disciplines.

2. AI-Powered Automation is Changing Workflows

Automation in engineering, such as AI-based design optimization and robotics control systems, requires engineers to develop AI expertise to remain relevant.

3. Demand for AI-Skilled Engineers is Growing

Industries such as automotive (self-driving technology), aerospace (AI-powered simulations), and energy (smart grids and predictive analytics) are actively hiring engineers with AI skills.

4. Competitive Edge & Career Growth

Engineers with AI certifications stand out in the job market, opening doors to leadership roles and cutting-edge projects.

Given these advantages, let’s explore the top AI certifications for engineers in 2025.

Top AI Certifications for Engineers

1. AI+ Engineer™ by AI Certs

The AI+ Engineer™ certification by AI Certs is designed for engineers specializing in robotics, automation, and intelligent systems. This course covers foundational and advanced AI techniques applied in robotics engineering.

Key Topics Covered:

AI-driven robotics and autonomous systems

Machine learning for robotics applications

Computer vision & sensor integration

Deep learning for control systems & automation

Ethical considerations & safety in AI-powered robotics

This certification is perfect for engineers working in robotics, automation, industrial rrengineering, and mechatronics.

Use the coupon code NEWCOURSE25 to get 25% OFF on AI CERTS’ certifications. Don’t miss out on this limited-time offer! Visit this link to explore the courses and enroll today.

2. AI for Engineers by Stanford University (Coursera)

Stanford’s AI for Engineers course on Coursera provides a comprehensive foundation in machine learning, deep learning, and AI applications tailored for engineering disciplines.

Key Topics Covered:

AI-powered design & manufacturing

Machine learning for engineering applications

Optimization techniques using AI

Real-world AI projects for engineers

This certification is ideal for engineers in mechanical, electrical, and software engineering who want to integrate AI into their work.

3. Artificial Intelligence for Robotics by Udacity

This Udacity program, developed in collaboration with Sebastian Thrun, the founder of Google’s self-driving car project, focuses on AI applications in robotics and autonomous vehicles.

Key Topics Covered:

Path planning & localization for autonomous robots

Probabilistic robotics & motion planning

Computer vision for robot perception

AI-driven control systems for automation

This certification is ideal for engineers in robotics, self-driving car technology, and industrial automation.

4. AI for Manufacturing & Industrial Engineering by MIT (edX)

Offered by MIT, this course focuses on AI applications in smart manufacturing, predictive maintenance, and industrial automation.

Key Topics Covered:

AI-driven production planning & scheduling

Machine learning for predictive maintenance

Computer vision for quality control

AI-powered supply chain optimization

This certification is perfect for engineers in manufacturing, industrial automation, and supply chain management.

How AI Certifications Benefit Engineers

1. AI Enhances Engineering Efficiency & Innovation

Engineers can leverage AI for automated design processes, real-time simulations, and AI-driven optimization techniques.

2. Expands Career Opportunities Across Industries

AI-certified engineers can transition into high-demand roles in robotics, automation, self-driving cars, aerospace, and manufacturing.

3. Competitive Edge in AI-Driven Engineering Projects

Professionals with AI expertise lead innovation in smart systems, autonomous robots, and intelligent control mechanisms.

4. Increases Salary & Career Advancement

AI-skilled engineers are highly sought after, earning higher salaries and securing leadership positions in AI-driven projects.

Choosing the Right AI Certification for Engineers

When selecting an AI certification, consider:

Industry Relevance: Choose a certification that aligns with your engineering discipline (mechanical, electrical, software, or robotics).

Hands-On Learning: Courses with real-world AI projects and simulations are crucial for practical applications.

Recognition & Accreditation: Certifications from top universities, AI-focused training providers, or industry leaders carry more weight.

Flexibility: Online, self-paced courses help engineers balance learning with their work schedules.

The Future of AI in Engineering

AI is rapidly evolving, with key trends shaping engineering fields:

AI-powered predictive maintenance will reduce downtime and enhance efficiency in manufacturing.

Autonomous robots and drones will revolutionize logistics, construction, and industrial automation.

AI-driven simulations and modeling will optimize engineering designs for aerospace and automotive industries.

Smart infrastructure and IoT-powered AI will enhance urban planning and energy management.

Conclusion

AI is no longer just for data scientists — engineers across disciplines must master AI to stay competitive. AI-powered automation, robotics, and intelligent systems are driving the future of engineering.

The AI+ Robotics™ certification by AI Certs, Stanford’s AI for Engineers course, Udacity’s AI for Robotics program, and MIT’s AI for Manufacturing course are among the top AI certifications for engineers in 2025.

By investing in AI education, engineers can boost their careers, drive innovation, and shape the future of technology. Now is the time to embrace AI and advance your expertise in this transformative field.

0 notes

Text

Future of Collaborative Robots: Automation and AI Integration

The global collaborative robot market size is anticipated to reach USD 11.64 billion by 2030, exhibiting a CAGR of 31.6% over the forecast period, according to a new report published by Grand View Research, Inc. The growth can be credited to the growing inclination of industries toward collaborative robots or cobots to automate manufacturing processes.

Over the past few years, the growing interest in robot technology across various industries has positively impacted the collaborative robots industry. Unlike conventional industrial robots, cobots are developed to operate at par with their human counterparts. They are mobile and can be easily moved from one area of a manufacturing facility to another. Moreover, they can be programmed with ease, are more cost-effective than their fixed counterparts, and can be used in a wide range of low-speed, repetitive applications.

Collaborative Robot Market Report Highlights

By payload capacity, the up to 5kg segment accounted for the largest market share of over 43% in 2024. The growth is attributable to the increasing demand for enhanced in-building wireless connectivity catalyzed by the burgeoning number of smartphone users and data-intensive applications.

The assembly segment accounted for the largest market share in 2024, driven by the increasing adoption of collaborative robots (cobots) for tasks such as nut driving, bolting, and part fitting.

The automotive segment dominated the market in 2024, owing to its extensive adoption of automation technologies. Collaborative robots are particularly valuable in this sector for tasks such as assembly, welding, and painting, where they enhance productivity and ensure precision.

The European collaborative robots is expected to grow at the significant CAGR of over 30% from 2025 to 2030, driven by government initiatives promoting industrial automation and sustainability.

For More Details or Sample Copy please visit link @: Collaborative Robots Market Report

The increasing need for highly efficient and user-friendly robots that do not require highly skilled experts for deployment and functioning has created a significant demand for software platforms. These platforms allow the integration of robots, motion control, and the generation of an interface that enables the programming of such robots. For instance, Mitsubishi Electric Corporation has launched a cobot named MELFA ASSISTA equipped with RT VisualBox, the company’s engineering software. This software allows the intuitive creation of operating sequences by connecting block diagrams in a chain of events, including linking with other devices, such as cameras and the hands of the robot.

The increasing demand from industrial customers, researchers, and engineers further strengthens the outlook of the collaborative robots industry. These robots are being deployed across various industries and have been highly influential in addressing the challenges faced by the logistics sector, such as complex work processes, and managing several tasks in different combinations and compact spaces.

List of Key Players in Collaborative Robot Market

ABB Group

DENSO Corporation

Epson America Inc.

AUBO (BEIJING) ROBOTICS TECHNOLOGY CO., LTD

Comau S.p.A.

Energid Technologies Corporation

Fanuc Corporation

KUKA AG

Rethink Robotics GmbH

Robert Bosch GmbH

We have segmented the global collaborative robot market report based on payload capacity, application, industry vertical, and region

#CollaborativeRobots#Cobots#RoboticsMarket#Automation#IndustrialRobots#SmartManufacturing#AIinRobotics#CobotsIndustry#RobotAutomation#Industry40#ManufacturingTrends#RobotTechnology#FutureOfWork#IoTRobotics#GlobalMarket

0 notes

Text

Best Robotic Arm Applications Transforming Modern Industries

One Millionth Industrial Robot - recently FANUC achieved this successful milestone in the global industrial robotics market. For more than 50 years, FANUC has provided innovative solutions for various needs of industries, such as automotive, aerospace, agriculture, and many more. Transformation through innovation FANUC India is right at the forefront of this revolution with solutions that dramatically improve efficiency and productivity. Using a variety of industrial robots, such as Welding Robots, Painting Robots, Assembly Robots, Quality Control Robots, Material Handling Robots, and Packaging Robots, for certain operations in a production line, the company streamlines processes, saves valuable time, and makes cost control more effective. Above all, making use of industrial robot accessories optimizes all the different applications for a maximum use and effectiveness of the robot’s arms. This technology allows companies to create value-added jobs by removing risky jobs from the manual process, thus lowering the dangers of human errors. With this in mind, companies are able to produce more without using more-lessons that FANUC repeats through the processes of its quest towards operational excellence. This blog will delve into well-crafted topics that would outline the best possible applications of the use of robotic arms and pays homage as well to FANUC's tenet of innovation, precision, and sustainability.

Understanding Robotic Arms Imagine a mechanical arm doing the same task day after day, with amazing accuracy. That's exactly what an industrial robotic arm is. These exciting machines usually have a number of joints and links, like humans, so they can operate in versatile ways. They perform several operations; welding, painting, assembling, and packaging. That is why, without robotic arms, manufacturing would not be producing at the scale it does today to meet all the demands for goods. Types of Industrial Robots There are several types of industrial robots, and they are designed for specific types of jobs in a variety of sectors. Let's have a closer look at some of the most common types: Articulated Robots: Multiple rotating joints gives articulated robots flexibility in motion. Therefore, it is best used for applications requiring specificity in painting and assembly. SCARA Robots: SCARA stands for Selective Compliance Assembly Robot Arm. SCARA robots typically excel in horizontal motions. Speed and accuracy win the day in pick-and-place operations and other assembly applications. Delta Robots: Due to their unique geometry, delta robots were meant to be fast. Often utilized in packaging and sorting, among other applications their high-speed handling is well regarded. Cobots: A short form of the term collaborative robots, cobots have been designed to work along with humans. Their functionality is all about improving productivity but with an emphasis on safety, making them ideal for applications that require just a bit of human touch.

Heavy Machinery Construction and Mining: Robots are applied in the building of very massive parts for construction and mining machines. The materials used for welding are high-strength and result in high-quality welds that withstand extreme operational conditions.

FANUC India’s Expertise in Robotic Arm Systems

Robot System Engineering is at the very heart of upgrading industrial robotic arm capabilities to make them even more universal, accurate, and efficient across industrial applications. It blends the arm with control systems, sensors, and AI-driven software to generate highly sophisticated automated solutions that simplify production, minimize the possibility of human error, and maximize operational efficiency on the whole. These solutions are most essential for industries such as automotive, heavy machinery, and electronics, in which precision and scalability play a critical role.

FANUC India is a leading company in the Robot System Engineering line, from conceptualizing designs to meet specific industrial requirements. The systems are developed, operational algorithms are crafted, and even the performance of the robots is evaluated to ensure that desired outcomes are accomplished. FANUC India excels at pinpointing ways to make improvements, strict testing protocols, and writing control software with smooth operations being ensured. This approach enables FANUC India's robotic arms to not only function efficiently but also reach new heights in automation with industrial applications.

Welding Robots: An Important Manufacturing Aspect In production, welding robots play a very significant role, mostly in the automotive and heavy machinery industries. They produce welds of incredibly high quality and accuracy while working at incredible speeds to further drive the pursuit of higher efficiency rates in production.

Major Applications in Industry

· Automobile Manufacturing: Welding robots have revolutionized the assembling of automobiles completely. The automobile firms are now delivering more outputs with accurate welds and therefore fewer defects and safer, reliable automobiles.

· Heavy Machinery Production: Welding robots are instrumental in fabricating large components, such as those used in construction and mining equipment. They can handle tough materials and deliver strong, durable welds that meet stringent industry standards.

Advantages of Welding Robots

Enhanced Precision and Quality: Welding robots deliver consistent results, reducing the chances of errors and ensuring high-quality welds.

Cost Reduction: By automating welding processes, companies can reduce labor costs while increasing throughput.

Increased Safety: Welding robots handle hazardous tasks, minimizing risks for human workers and promoting a safer working environment.

Industrial Robot Accessories: Enhancing Efficiency Industrial robot accessories are very important since they make the robotic arm complete and enhance the overall efficiency and versatility. Accessories of a Robot: As such, there exist several categories of industrial robot accessories. Grippers and End Effectors: Such accessories allow pick-and-place operations with a robotic arm, thus allowing for interaction with different objects. Sensors and Cameras: They provide robots with the ability to sense environments in real-time, hence providing much accuracy and safety. Power Supplies and Control Systems: Reliable power supplies and sophisticated control systems ensure correct operation of robots, demands of assembly line, and fit perfectly in current processes of manufacturing. Improving Operational Performance By utilizing various strategies and technologies Fanuc India empowers its robotic systems. They are aimed at enhancing the capabilities of robotic systems as a whole. This maximizes uptime and optimizes operational performance to ensure continued competitiveness in the market. Such versatility is what companies interested in improving operations and enhancing productivity seek. Maximize Uptime with Lifetime Support FANUC India's commitment to service and sustainability reflects FANUC's philosophy towards operational systems, like robotics. Almost 50% of engineers at the site in India are into services, wherein almost every client receives personal attention. Comprehensive Service Solutions FANUC India offers solutions in the area of predictive, preventive, and breakdown maintenance solutions to build an enhanced customer experience while minimizing downtime. The Service Resource Center is manned by highly experienced product line experts well prepared to assist customers throughout the country. Parts Sales and Inventory Management The importance of proper maintenance for robotic systems cannot be overstated. FANUC India is a key component of FANUC's global service and support network, maintaining an extensive inventory of original spare parts worth USD 15 million. The Logistics Network FANUC India guarantees that 99% of spare parts and consumables are available ex-stock, allowing for prompt breakdown support. Effective inventory planning and logistics ensure timely deliveries, enabling customers to keep operations running smoothly. Repair and Maintenance Services FANUC India offers comprehensive repair management solutions. They have been doing so for over 30 years now. Their service covers full inspection, major overhauls, and also software upgrades. Customers can expect all the lifecycles to be serviced.

Long-term Support for Legacy Equipment The majority of spares are available as an exchange; this lets companies continue to use their older equipment and save money. This long-term strategy ensures returns on investments through optimum usage.

Transformational Applications Beyond Industries Industrial robotic arms are redesigning the industrial scenario beyond automotive manufacturing. Some of the most useful applications are:

Food and Beverage Industry: Robotic arms enable packaging and sorting, making food production much more efficient with respect to hygiene.

Electronics: Robotic arms in assembly lines of electronic manufacture ensure precise, rapid production of even the most complex devices.

Construction Industry: The robotic arms for bricklaying and site management improve processes and safety practices.

Logistics and Warehouse Management: These machines play a very big role in inventory control and, therefore, improve materials management and optimize supply chains. Future of Industrial Robotic ArmsWith the emergence and acceptance of newer technologies, the future of industrial robotic arms is brighter than ever. Overall, AI and IoT integration will make things much more efficient and responsive.

Discover how robotic arm technology may improve your business operations and find how you can boost efficiency, enhance quality, or cut down on operational costs. Our observations may serve as a compass in the complex landscape of automation. We invite you to connect with us today and discover the options that could keep you ahead in this rapidly evolving industry.

0 notes

Text

Functional Safety Companies - Schneider Electric (France) and ABB (Switzerland) are the Key Players

The global functional safety market is expected to be USD 5,883.3 million in 2024 to USD 7,896.7 million by 2029; it is expected to register a CAGR of 6.1% during the forecast period. Rising enforcement of stringent regulations to ensure personnel and process safety, Increasing investment in oil and gas plants to meet energy demand, Mounting adoption of advanced safety solutions to prevent accidents in industrial facilities are attributed to the ever-increasing demand for functional safety systems.

Schneider Electric (France), ABB (Switzerland), Honeywell International Inc. (US), Emerson Electric Co. (US), Rockwell Automation (US), Yokogawa Electric Corporation (Japan), HIMA (Germany), Omron Corporation (Japan), Siemens (Germany), and General Electric (US) are some of the key players in the functional safety market.

Major Functional Safety companies include:

Schneider Electric (France)

ABB (Switzerland)

Honeywell International Inc. (US)

Emerson Electric Co. (US)

Rockwell Automation (US)

Yokogawa Electric Corporation (Japan)

HIMA (Germany)

Omron Corporation (Japan)

Siemens (Germany)

General Electric (US)

Schneider Electric

Schneider Electric offers energy and automation digital solutions. The company provides hardware, software, and services related to energy management and automation. Schneider Electric offers functional safety solutions under its Industrial Automation business segment. The company’s product offerings include emergency shutdown systems, burner management systems, fire & gas monitoring controls, turbomachinery controls, high integrity pressure protection systems (HIPPS), supervisory control and data acquisition (SCADA) systems, distributed control systems (DCS), safety sensors and switches, safety modules, and safety controllers. It also provides SIL 3 function safety solutions that ensure the fail-safe performance of controllers for energize-to-trip and de-energize-to-trip applications. The company has a strong portfolio of functional safety-certified emergency stop devices and safety instrumented systems (SIS). It holds expertise in DCS and offers various safety solutions.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=146773188

ABB

ABB is a leading power and automation technology company. The company mainly operates through four business segments: Electrification Products, Robotics and Discrete Automation, Motion, and Industrial Automation. For the functional safety market, ABB offers ABB Ability System 800xA, which is a DCS, an electrical control system, a safety system, and a collaboration enabler. This system can improve engineering efficiency, asset utilization, and operational performance. Moreover, the company offers burner management systems, emergency shutdown systems, safety sensors, safety switches, fire & gas protection systems, safety relays, programmable safety controllers, SCADA, and emergency and stop devices. All these products are highly used in the functional safety market.

Honeywell International Inc.

In the realm of industrial automation, Honeywell International Inc. holds a prominent position. Aerospace goods and services, performance materials, safety and productivity solutions, and control, sensing, and security technologies for homes, buildings, and industries are all provided by the corporation. Honeywell Building Technologies, Performance Materials and Technologies, Aerospace, and Safety and Productivity Solutions are its four business segments. It also offers automotive products, specialty chemicals, turbochargers, and electronic materials, including electronic chemicals and polymers, targets, coil sets, metals, and advanced materials, such as environmentally preferable refrigerants, and chemical and analytical reagents.

Honeywell International Inc. offers various solutions related to functional safety through its Safety and Productivity Solutions segment. It also provides personal protection equipment, footwear, apparel, gas detection technology, and cloud-based apps for worker safety. Furthermore, this segment includes switches and controls for sensing and productivity solutions and software-based data and asset management productivity solutions.

Emerson Electric Co.

Emerson Electric Co. manufactures and develops process controls, systems, valves, and analytical instruments. The company offers industrial, commercial, automation, and residential solutions worldwide. It operates through two business segments: Intelligent Devices and Software and Control

Emerson Electric Co. provides functional safety solutions under the Intelligent Devices. The company offers safety solutions to its customers operating in the process and discrete industries. Its robust technological and engineering capabilities give it a competitive advantage in the functional safety market. It offers a range of safety components for functional safety solutions, including actuators, valves, digital valve controllers, solenoid valves, and pressure transmitters. These products completely meet the requirements mentioned by the safety requirements specification (SRS), and the SIL level is maintained throughout the lifetime of the installation.

Rockwell Automation

Rockwell Automation is a leading provider of industrial automation and information solutions. The company offers diverse products and services, including industrial control components, information software, sensing devices, and industrial security services.

Rockwell Automation operates through three business segments: Intelligent Devices, Software & Control, and Lifecycle Services. The company offers drives, motion controls, sensors, switches, industrial components, and safety and configured-to-order products through its Intelligent Devices segment. It offers information software, control and visualization software and hardware, and network and security infrastructure through the Software & Control segment.

Rockwell Automation offers functional safety solutions through its Intelligent Devices segment. The company offers functional safety products such as safety connection systems, safety drives, safety I/O modules, emergency stop devices, presence-sensing safety devices, safety programmable controllers, safety relays, safety switches, and others.

0 notes

Text

Which Type of Automation is Preferred for the Packaging Industry?

The packaging industry has seen a rapid evolution over the years, driven by increasing demand for efficiency, precision, and sustainability. Automation has become a cornerstone of this transformation, providing solutions that streamline production, reduce waste, and ensure consistent quality. But with several types of automation technologies available, which is most suitable for the packaging industry? The answer depends on the specific needs of a business, but certain types of automation stand out as preferred choices in this dynamic sector.

The Role of Automation in Packaging

Automation in packaging involves the use of advanced machinery and software to handle repetitive tasks such as filling, sealing, labeling, and palletizing. These systems enhance productivity by minimizing human intervention, ensuring accuracy, and reducing operational costs. With the advent of technologies like robotics, sensors, and artificial intelligence, packaging processes are becoming more efficient and adaptable to varying product demands.

Among these innovations, Packaging Machine Automation has emerged as a leading solution, tailored specifically for the complexities of the packaging industry. This technology integrates smart machinery with data-driven systems to automate entire production lines, offering unparalleled speed and consistency.

Types of Automation in Packaging

1. Fixed Automation

Fixed automation, also known as hard automation, involves machinery designed for high-volume, repetitive tasks. These systems are ideal for production environments where the product types and packaging requirements remain consistent over time. Fixed automation excels in processes like bottle filling or labeling, where speed and precision are paramount. However, its inflexibility makes it less suitable for businesses with frequent changes in packaging designs or sizes.

2. Programmable Automation

This type of automation offers more flexibility compared to fixed automation. Programmable automation systems allow businesses to reprogram machinery to accommodate different tasks, such as switching between product sizes or packaging types. This adaptability makes it a preferred choice for manufacturers who deal with diverse product lines. For instance, Oracle Robotics offers customizable programmable solutions that enable seamless transitions between packaging operations, ensuring efficiency without compromising quality.

3. Robotic Automation

Robotic automation represents the pinnacle of versatility and efficiency in the packaging industry. Robots equipped with advanced motion control and vision systems can perform tasks like carton loading, palletizing, and product sorting with high precision. These systems can handle various product shapes and sizes, making them ideal for industries like food and beverage, pharmaceuticals, and consumer goods. Robotic automation, often integrated with Packaging Machine Automation, provides businesses with the ability to scale operations and meet dynamic market demands.

4. Integrated Automation

Integrated automation combines various systems and processes into a unified platform, allowing seamless coordination across the entire production line. This type of automation leverages IoT (Internet of Things) and AI technologies to monitor, analyze, and optimize packaging operations in real time. Integrated automation is especially beneficial for large-scale manufacturing facilities aiming to improve efficiency and reduce downtime.

Why Packaging Machine Automation is Preferred

Packaging Machine Automation stands out as a preferred choice in the packaging industry due to its ability to address key challenges and enhance overall operational efficiency. Here are some of the reasons why businesses prioritize this type of automation:

Increased Speed and Accuracy: Automated packaging machines operate at high speeds without compromising on accuracy, ensuring consistent output and reducing the risk of errors.

Flexibility: These systems are designed to adapt to varying product specifications and packaging designs, making them ideal for industries with diverse needs.

Cost-Effectiveness: By reducing labor dependency and minimizing material waste, packaging machine automation significantly lowers operational costs.

Enhanced Quality Control: Advanced sensors and vision systems integrated into automated machines enable precise quality checks, ensuring that only compliant products reach the market.

Scalability: As businesses grow, packaging machine automation can easily scale to accommodate higher production volumes, maintaining efficiency at all levels.

How Oracle Robotics Enhances Packaging Automation

At Oracle Robotics, we specialize in delivering cutting-edge packaging automation solutions tailored to meet the unique needs of our clients. Our systems integrate robotics, IoT, and AI technologies to create smart, efficient production lines that maximize productivity and minimize downtime. Whether it’s robotic cartoning, automated palletizing, or quality inspection, our solutions are designed to ensure seamless operations and exceptional results. With a focus on innovation and sustainability, Oracle Robotics helps businesses stay ahead in a competitive market.

Future Trends in Packaging Automation

The future of packaging automation is driven by advancements in technology and changing consumer demands. Here are some emerging trends that will shape the industry:

Sustainability: Automation systems are being designed to reduce material waste and energy consumption, aligning with the global push for sustainable practices.

Smart Packaging: IoT-enabled packaging systems that provide real-time data about product conditions and supply chain performance are becoming increasingly popular.