#Multilayer construct Design

Explore tagged Tumblr posts

Text

Multilayer pcb is circuit boards composed of two or more conductive layers (copper layers). The copper layer is pressed together by the resin layer (prepreg).

King Credie manufacture multilayer pcb up to 32 Layer ,We accept pure single material or mixed-press materials ( e.g., FR4,Rogers,Polymide,metal Core).

#Multilayer PCB Stackup Design#Multilayer PCB Design#Multilayer Stackup Design#Multilayer Stackup#PCB Stackup Design#Stackup Design#PCB Design#Multilayer Design#Multilayer PCB Stackup#Multilayer construct Design

0 notes

Text

prying off the shell

Hayama's friend Mihara makes a really trenchant observation in episode 7 of 25 Ji Akasaka de. First he points out that Shirasaki doesn't seem to have a "shell"--his way of talking about a social self, a persona that a person experiences as separate from their core self. Then he points out that Hayama not only has a "shell," he has multiple layers of shell, so many that it's essentially impenetrable. If you explore what's underneath his social persona, there's just another persona, and another under that, with no end in sight, like a seemingly neverending set of matryoshka dolls. At first Mihara says this to draw a parallel between the two, to claim they're similar. But when he elaborates, Hayama responds by saying it sounds like he's describing them as complete opposites. Mihara accedes to this and sums things up by pointing out that life is bound to be hard for someone in either of those positions.

Actually, both are true. These two ways of being have some significant overlap in their execution, and they also have huge fundamental differences at their cores.

One of the biggest things that Shirasaki and Hayama have in common is the fact that there's little difference between their public personas and their private selves. Shell-less Shirasaki is the same candid, sensitive person whether he's alone with someone he cares about or interacting in public with people he doesn't know very well, because he doesn't have a special persona for public settings. He's just Shirasaki inside and out and makes no bones about it--nor does it ever seem to cross his mind to do so. But he probably couldn't if he did want to.

Hayama's multilayered shell creates a similar effect for the opposite reason. Hayama has a carefully constructed social self. But if you bring him into a private setting, even if he sets aside his most public persona, you're just going to be presented with another carefully constructed persona designed to navigate a particular social situation. This means that public Hayama and private Hayama aren't that different. They may seem different at times, but that's only because he tailors his personas for different settings. He must be very skilled at it after all these years.

This opposite-yet-similar relationship is also present in how they both relate to acting in general, and more specifically to the idea of having a "fake" dating relationship with a costar for the purpose of improving a performance. For Hayama, acting is an opportunity to express emotions in a way that he can't otherwise. It's not just that acting provides a loophole from the system of rules he grew up with, though importantly, it does do that. He says that the way he learned as a young child not to express too much emotion around his mother was to make himself numb. Since he learned this lesson at such a young age, his ability to get in contact with his authentic emotions has atrophied. Acting provides him not only with permission to show emotion to portray in his performance, but also with ready-made words and actions he can use to do so. In other words, Hayama yearns for the freedom to express feelings, but if he had to express his own emotions he probably wouldn’t know how to access them. So it helps that acting comes with a script that can tell him how he's supposed to feel and how he's supposed to express that. When Hayama acts, he places a sort of veneer of a private self over his shell, and this allows him to experience something similar to being his authentic self.

Shirasaki doesn't tell us explicitly what he gets out of acting, the way Hayama does. But I think it must be the opposite of what Hayama gets out of it in a way. For Hayama, acting is a way of getting around his overactive system of control and gaining back some lost immediacy. For Shirasaki, for whom emotional immediacy is as natural as breathing, I think acting must provide a greater sense of control. It must be so taxing for Shirasaki to live in the world without a shell. He's buffeted about by social forces that he lacks resources to navigate and the unpredictable events that ensue hit him harder because of his unguarded authenticity. Acting could be a way of making these experiences predictable. He may not know what's going to happen to his shell-less self in his everyday life, but at work, the script tells him exactly what to expect. It must also be nice for Shirasaki to gain respect and validation for his authenticity after what I can only assume has been a lifetime of being criticized for that aspect of himself.

In a related way, Shirasaki's main challenge as an actor is also very different. He's great at the expressiveness part of acting. If he can feel something, he can portray it in his performance, because authenticity is so natural to him. If anything, he doesn't have a choice--he doesn't know how to stop being authentic. Issues come up, however, when he doesn't have an easily accessible emotion that maps onto how his character feels. He has an amazing delivery system for emotion that brings his feelings to the audience, but a delivery system only works if you have something to deliver. The situation that drives the story in 25 Ji is the fact that Shirasaki has to seek out these raw materials in order to perform.

One of the biggest issues I've had with this series from the beginning is the idea that a supposedly gifted actor like Shirasaki would think that he has to have firsthand experience with something in order to portray it (leading to his trip to the gay bar, his initial encounter with Hayama, and their pretend relationship). But this way of conceptualizing Shirasaki's personality goes a long way toward explaining that. If you don't know how to be fake in your private or your professional life, of course you'll have more of a need for firsthand experiences to draw from. It might also be a factor that Shirasaki is less likely than others to realize, and/or care, that this form of "rehearsal" generally isn't done.

Once Shirasaki and Hayama begin their pseudo-relationship, their distinct ways of relating to the world impact their experiences. For Hayama, there isn't that much difference between this pretend relationship and a supposedly real one. We don't know anything about his dating history, but it seems doubtful that any past relationships would have been appreciably more authentic than this one. After all, Hayama doesn't even know how he really feels half the time. How could he be emotionally present with another person under such circumstances? So their pseudo-relationship feels as authentic to him as any "real" one he's had, and quite possibly more so given the strength of his feelings for Shirasaki. This goes back to my first point--there's little difference between Hayama's public and private selves--and just puts it in a relationship context. Basically, a fake relationship and a real one are similar for him because both are equally fake.

Once again, Shirasaki's public and private selves are also remarkably similar, but in a different way and for different reasons. He welcomed the pseudo-relationship because he needed firsthand experience to fuel his performance, but his lack of a shell and lack of skill at pretending make it so that acting out a relationship and actually being in one are hard for him to distinguish. In other words, a fake relationship and a real one are similar for Shirasaki because both are equally real.

These opposite ways of relating bring the lead characters into somewhat similar positions at times, but for very different reasons. For a while, these opposites were so complimentary that they balanced each other out. That balance created stability. Their pseudo-relationship was easier to navigate then, but if it had continued that way, it would have been hard to topple in favor of something real.

There's one thing that keeps these opposing approaches from truly being mirror-image versions of each other, though: the fact that Hayama's feelings for Shirasaki are causing his authentic self to strain against the confines of his shell. If he could easily keep going the way he always has, and felt no need to change, any real relationship between him and Shirasaki would be pretty much doomed. But even the thickest shell has a center. There's a little nugget of authentic self that Hayama has had shuttered away inside his shell for most of his life. It hasn't seen light in a long time. It hasn't grown much since he was a child, because it hasn't been allowed to. But it has always been very responsive to contact with Shirasaki, even from afar. Now that Hayama has been able to get closer to Shirasaki, that little nugget of selfhood is growing exponentially, and as it grows it gets stronger and more insistent.

Hayama says that being with Shirasaki feels like having his shell "pried off." This is how that happens. It's bound to be scary, maybe even terrifying, to go through that. It's a kind of personal growth that Hayama probably couldn't find the motivation to push through if he didn't want so badly to be close to Shirasaki for real. But he does want that very deeply, enough to take this risk. So the different ways that Hayama and Shirasaki relate to the world, which had been such stable opposites, are on their way to becoming less perfectly balanced and thus more amenable to change.

There's a catalyst on the horizon: the love scene Hayama and Shirasaki are about to film for their drama. Hayama usually relies on a script to tell him what to feel and how to express that emotion in his work. His shell remains in place during that process because there's a difference between the little bit he can still feel of his real emotions and the emotions he portrays. But his role in the drama he's making with Shirasaki has been growing closer and closer to how he really feels. The love scene seems poised to bring him even closer to his own authentic experience. If the role he plays, the emotions he allows himself to show, sync up enough with the emotions of the little nugget of real self he still has, it could be a key to unlocking his shell. If he's able to speak from his authentic experience, he could find a way to tell Shirasaki how he feels. If he's able to show real emotion in the process, Shirasaki will be able to see the difference and understand what it means.

88 notes

·

View notes

Text

The Amazing World of Laminates: Style and Durability to Elevate Your Space

Hi there, lovers of design! Look no further than laminates, the unsung hero of interior design, if you're trying to turn your living area into a stylish, comfortable, and long-lasting sanctuary!

From their modest beginnings, these adaptable materials have gone a long way, and now they're taking centre stage in both offices and homes.

We're delving deep into the world of laminates in this blog post and learning what makes them a great option for your interior design.

Fundamentals of Laminates

Let's begin with the fundamentals. How are laminates different from other types of materials? Laminates, to put it simply, are composite materials that are usually created by pressing layers of paper or fabric that have been coated with resin and joined to an MDF (medium-density fiberboard) or particleboard core. The outcome? a robust, long-lasting surface that is not only aesthetically beautiful but also impervious to stains, scratches, and general wear and tear.

Appeal to the Eye

The amazing design adaptability of laminates is one of their most intriguing features. Laminates are available in a broad range of styles to suit every taste, whether you want brilliant colours, sleek modern patterns, or traditional wood finishes. Laminates provide you the freedom to express your individuality and design a place that accurately captures your sense of style, whether it's through strong and distinctive patterns or the imitation of natural materials like stone and wood.

Why Sturdiness Counts

Life occurs, as we all know, and furniture usually takes a beating. Let me introduce laminates, the unsung champions of toughness. Laminates are incredibly resistant to dents, scratches, and stains because of their multilayered construction and protective top layer. This makes them the perfect option for high-traffic spaces where furniture is constantly being used, like living rooms, offices, and kitchens.

Simple Upkeep

Low-maintenance options are ideal for busy lifestyles, and laminates fulfil this requirement admirably. Spills and accidents are easy to clean up; laminate floors often only require a quick wipe down with a moist cloth to maintain their pristine appearance. Embrace a stress-free, low-maintenance living environment and bid adieu to the days of worrying over every unintentional coffee spill or pet paw print!

Cost-Effective Choices

Though we all have a craving for luxury, our finances may not always concur. Laminates provide an affordable substitute for expensive materials without sacrificing design or quality. Laminates are a wise alternative for people who want to upgrade their area without going over budget because they can mimic the look of pricey stone or hardwood at a fraction of the cost.

Streamlining Installation

You may be asking yourself, "But what about the installation process?" at this point. Do not fear! Laminates are renowned for being easy to install. Options such as click-and-lock mechanisms make installation a do-it-yourself project that doesn't need a professional touch. This saves you money on installation fees and offers you the satisfaction of knowing that you were actively involved in the transformation of your space.

Environmental Friendliness

In an era where sustainability is a top priority, laminates have stepped up to the plate. Many laminate manufacturers are committed to environmentally friendly practices, using recycled materials in their production processes. Additionally, laminates are often more durable than some natural materials, reducing the need for frequent replacements and minimizing environmental impact.

In summary:

To sum up, laminates are a design powerhouse that successfully blend affordability, durability, and visual appeal. Laminates are a flexible option that meets all your needs, whether you're remodelling your kitchen, replacing your flooring, or giving your furniture a chic touch.

Why not give your room the makeover it deserves and join the laminate revolution? Your house will appreciate it!

2 notes

·

View notes

Text

Achieve Precision Motion Control with Robust Piezoelectric Bimorphs

A piezoelectric bimorph is a specialized bending actuator or sensor comprised of two bonded piezoelectric ceramic layers separated by an inner passive layer. When subjected to an electric field, one ceramic layer expands while the other contracts due to the converse piezoelectric effect, causing the composite to bend. This bending motion can be harnessed for precision actuation and vibration control applications.

The central passive layer, typically made of a metal or polymer, provides mechanical support and prevents electrical shorting between the two active piezo layers. The ceramic layers are poled during manufacturing to align their electric dipole moments in opposite axial directions. When an electric field is applied across the bimorph’s thickness, one layer expands longitudinally while the other contracts, resulting in a net bending displacement perpendicular to the field direction.

For More Information Please visit, pzt bimorph

Bimorphs exhibit higher generative force compared to unimorphs, but slightly lower displacement range. The three-layer symmetric configuration also provides enhanced thermal stability. Bimorphs are engineered to resonance in desired frequency ranges from ~5 Hz up to hundreds of kHz depending on the materials and construction.

Key bimorph advantages:

Large bidirectional bending motions possible up to ±1 mm range.

Fast response times in milliseconds or less.

Generative force up to 100s of newtons.

Low operating voltages, often less than 30V.

Tailorable dynamics via materials selection and dimensions.

Compact, simple construction suitable for arrays.

Lower cost compared to stacks.

Consistent performance over billions of cycles.

Bimorph applications include:

Precision positioning stages and manipulators.

Piezoelectric motors and pumps.

Speakers and headphones due to good audio range response.

Vibration suppression and shock absorption.

Energy harvesting from vibrations and motion.

Overall, the bimorph configuration offers a balanced set of advantages for electromechanical transduction compared to other multilayer piezo options. With thoughtful design, bimorphs enable highly adaptable and robust motion control, acoustic, and sensor solutions.

2 notes

·

View notes

Text

Thursday 9th Nov.

8 - 10.30pm

Quasar

A---Z at Iklectik

Tickets: https://link.dice.fm/o0856a0ca324

A—Z comes back to Iklectik to present Quasar – Expect a night of live sets including immersive ambient sounds, from mystic, dark noise to electronic pulsar chaos. The event presents three acts that explore sensory/textural sounds, syncretism, displacement, cathartic tremors.

8.30 - 9pm Gisou Golshani (live)

9.15 - 9.45pm GAKKO (live)

10 - 10.30pm Manuka Honey (live)

Manuka Honey

Marissa Malik, best known by her stage name Manuka Honey, is a multi-disciplinary artist, DJ and producer at the forefront of Latinx-infused club music coming out of the UK. US-born and London-based, Manuka’s adoration of the Latinx diaspora’s sounds is exuded by her beautifully chaotic DJ sets that have pummeled the sound systems of clubs and festivals internationally.

GAKKO

Carolin Schnurrer is a London and Berlin-based artist, DJ (alias GAKKO), designer, and instrument builder, producing sensory experiences with a variety of media, from sound performance and installation art to moving images. In her artistic research, she creates electronic instruments that incorporate human skin into her music-making process: Providing a platform for the audience to actively shape and manipulate the sounds she produces in real time by engaging in tactile interactions with one another on a transformative odyssey through synthetic, sensual, and otherworldly sonic landscapes.

Delving into the depths of profound vulnerability and resilience, this approach allows her not only to investigate the potential of healing through the powers of human touch and sound, but also challenge traditional notions of music creation and club experiences – inviting listeners to embrace the symbiotic fusions between the organic and the synthetic, to forge a path towards a speculative and fictional future where these connections transcend the confines of borders, culture, language, and other categories of exclusion that we construct.

Operating under the name GAKKO, she has cultivated an unwavering passion for seamlessly blending genres spanning from 130 to 160 BPM, weaving together sets that pulsate with the raw energy of bass-heavy music, unexpected club edits, and thunderous drum breaks. Through radio shows on Foundation FM, Refuge Worldwide, and [sic]nal, she aims to showcase forward-thinking and marginalized electronic producers within the experimental and DIY realm. Carolin Schnurrer’s artistic journey is characterized by collaborative ventures with musicians, artists, writers, and dancers like KLEIN, AUDINT (Kode9, Eleni Ikon, Toby Heyes), Julie Cunningham, and Haroon Mirza; she has performed at events such as Tate Lates, Oram Awards at Kings Place, Hyperdub’s Night Ø at Corsica Studios, intonal in Malmö, the YARD theater, 925 in Colombo and the MIRA Festival in Barcelona.

Gisou Golshani

Gisou Golshani is a London-based Iranian artist. Their work depicts abstract narratives from seemingly disparate elements. Through multilayered editing and playful uses of sampling, they investigate the intimacy of the voice, the effects of sound on the body and their mother tongue Farsi’s complexities in translation. Looking into archival found material, Gisou creates multi-sensory, immersive installations and performances. Previous work has been shown at Disturbance (Ugly Duck), London, Studio/Chapple for Deptford X, London, Nottingham’s New Art Exchange, Mimosa House, London and internationally including their home country.

2 notes

·

View notes

Text

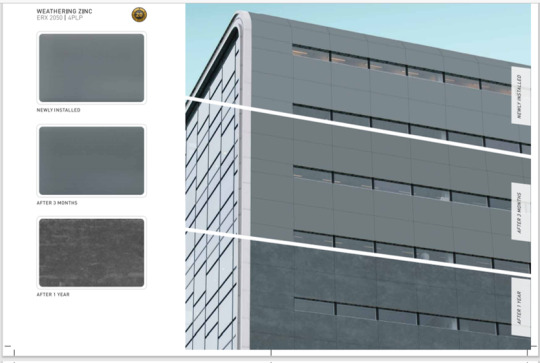

Euramax Interesting Facts about Zinc Finish ACPs

Zinc, Copper, Aluminium and Steel are some of the popularly used metals not only in construction but also in the décor of a building.

Roofing sheets, cladding of exterior & interior walls, false ceilings and decorative wall panels are some of the areas in which metal has replaced wood, stone, and more classic materials.

Gold, Silver, Zinc, Bronze, Copper and Brass finish in ACPs is even more fascinating with its majestic looks.

But what is Zinc Finish Aluminium Composite Panel?

Zinc ACP is a multilayered panel made up of two aluminium sheets with a composite core. It is 0.5 mm thick and thermo-glued on either side of an LDPE core for optimum reaction to fire.

What are the advantages of using zinc composite panels?

Zinc finish ACP Panels add awe-inspiring looks to both interiors and exteriors instantly.

Zinc finish ACP is flexible, easy to bend, strong and hence is the choice for architects and designers

Zinc finish ACP is weather-resistant

Zinc finish ACP is available in fire-retardant sheets

Zinc finish ACP is very environmentally friendly can be reused and is 100 per cent recyclable metal.

Why should you use zinc composite panels?

Zinc finish aluminium composite panels are aesthetically pleasing

Building facades, building elevation designs, exterior wall panelling, roofing, cladding, etc. are some of the areas for the application of Zinc finish aluminium composite panels

Zinc finish acp sheets are easier to install and manage. It does not require special and expensive machinery that are usually required for cutting and grooving.

It has a low maintenance cost and can be easily done with the help of washing and cleaning

Zinc finish ACP panels are a long-lasting and beneficial alternative for building cladding.

While delivering extraordinary style, these ACP Panels are fire-retardant also. It restricts fire spread and no smoke and toxic fumes are released which is the main cause of death in a fire accident.

The architectural appeal is continually growing for this material. Zinc ACP is more than a piece of the panel; it comes with assurity of adding beauty at a cost-effective price & is environmentally friendly at the same time. Choose your colour and texture in to suit your design and application.

For more details on the product, visit the company website https://www.eurobondacp.com/zinc

2 notes

·

View notes

Text

Top Trends in PCB Assembly for 2025

PCBs are the heart of the modern world. Whether it’s household equipment, industrial equipment, or defense ordnance, printed circuit boards are running everything. With new developments, the global scene of PCB manufacturing is changing rapidly. Using the newest technologies is not only a great concept, but staying competitive depends on it as well. From downsizing to AI-driven manufacturing, 2025 promises to bring major breakthroughs along with making advancements in current technologies that will change the way Printed Circuit Boards (PCBs) are manufactured.

This article will walk you through some key industry trends that will sketch the future of PCB assembly.

5 Key Trends in PCB Assembly to Follow in 2025

As the world is moving towards manufacturing more complex products and adopting advanced technologies, the PCB assembly industry is also observing several key trends. Here are a few noteworthy trends to follow.

1. Shrinking is in High-Density Interconnections: HDI and Miniaturization

Think about our daily gadgets, such as wearables, Internet of Things devices, and sophisticated medical electronics. These devices need robust and small PCBs, and therefore, in these spaces, High-Density Interconnect (HDI) technology excels. HDI lets electronic gadgets be more powerful despite their compact stature. In what manner? For high-speed applications, it increases signal integrity, lowers component spacing, and permits smaller trace lengths, hence enhancing electrical performance. And it will change the entire PCB manufacturing market.

According to a forecast [1], the HDI PCB market is expected to rise rapidly and, by 2032, will reach almost $40 billion. That makes the direction in which things are heading quite obvious.

2. Smart Factories: Artificial Intelligence and Automation

Like in every other industry, PCB assembly is becoming significantly faster, smarter, and more efficient. Industry 4.0 and manufacturing driven by artificial intelligence lead the push. Think about robotic soldering and pick-and-place robots for fast, more perfect component installation. Artificial intelligence and machine learning have found their way into quality control, that is, for error reduction and flaw detection done automatically. Imagine the Internet of Things, connected production lines, allowing real-time monitoring and predictive maintenance.

3. Bendable and Adaptable: Rigid-flexible PCBs

Flexible and rigid-flex printed circuit boards are becoming more popular in industries such as transportation, aircraft, and healthcare electronics. But you may think, why so? Because of their small size and lightweight nature, they are ideal for manufacturing small, portable electronic devices. They can withstand significant external force and resist bending and vibration. They endure longer with fewer interconnect failures, making them more reliable.

4. Green is Good: Manufacturing Sustainable Circuit Boards

Growing worries about e-waste and carbon footprints force sustainability to the front stage in PCB production. Lead-free soldering, biodegradable and reusable substrates, recyclable materials, and energy-efficient manufacturing procedures will become the focal points in the near future. It’s about matching global laws and customer demand as much as it is about environmental responsibility.

5. Printing the Future: 3D Printing in PCB Assembly

Additive manufacturing is revolutionizing PCB manufacturing and streamlining complex multilayer design construction. From this, faster prototyping, reduced material waste, and more customization for specific uses follow. This is a breakthrough for design and development; it will only get more so.

The Final Thought

There are a lot of exciting new possibilities in the PCB assemblyand PCB manufacturing industries. Miniaturization, automation, sustainability, and developments in AI-driven manufacturing will enable you to produce premium printed circuit boards (PCRs) that satisfy future electronics needs. Survival in a dynamic industry depends on keeping ahead of the competitors. By following these trends and wise technology investments, you could set yourself up for success in 2025 and beyond.

Know More : https://www.pcbpower.us/blog/top-trends-pcb-assembly

0 notes

Text

Material Structure and Selection in Rigid-Flex PCBs

Rigid-Flex PCBs combine the stability of rigid boards with the adaptability of flexible circuits. But the key to a successful design lies in material selection and stack-up structure. Choosing the right materials impacts everything from electrical performance and mechanical flexibility to cost and manufacturability.

Below is a breakdown of essential materials used in Rigid-Flex PCBs and considerations for selecting them.

1. Rigid Section Materials

The rigid part of a Rigid-Flex PCB usually serves as the component-mounting area. It uses materials similar to traditional multilayer PCBs.

Common rigid materials:

FR-4 (Standard epoxy-glass laminate) Cost-effective and widely available, suitable for most applications with moderate thermal and electrical requirements.

High-Tg FR-4 Used in designs with higher operating temperatures or lead-free soldering.

Halogen-free FR-4 Chosen for environmental compliance (RoHS, REACH) and flame retardance.

Key properties to consider:

Glass transition temperature (Tg)

Coefficient of thermal expansion (CTE)

Dielectric constant (Dk) and loss tangent (Df)

Thickness tolerance and layer uniformity

2. Flex Section Materials

The flexible part of the PCB must endure bending, folding, and vibration without failure. Flex materials must be thin, strong, and highly resistant to cracking.

Core flex materials:

Polyimide film (PI) The most commonly used dielectric material in flex sections, due to excellent thermal, chemical, and mechanical properties.

Adhesive-based vs adhesiveless polyimide laminates Adhesiveless: Thinner, better dimensional stability, and higher reliability. Adhesive-based: Slightly lower cost, but more prone to delamination under heat or flexing.

Copper types used in flex:

Rolled Annealed (RA) copper High ductility, ideal for repeated bending applications.

Electrodeposited (ED) copper Lower cost, better suited for static flex or one-time folding designs.

3. Coverlay vs Solder Mask

The flexible solder resist layer is typically made from polyimide-based coverlay, not traditional solder mask.

Coverlay: A polyimide film laminated with adhesive, providing insulation and mechanical protection in flex areas.

Flexible solder mask: Can be screen-printed like in rigid boards, but less durable in dynamic bending conditions.

Use coverlay in all bend zones for improved reliability and better protection against cracking or delamination.

4. Stiffener Materials

Stiffeners are added under flex areas to provide mechanical support for connectors or SMT components.

Common stiffener options:

FR-4: Adds thickness and support under connector pads.

Polyimide film: Maintains flexibility while giving local stiffness.

Stainless steel or aluminum: Used when high rigidity is needed in limited space.

Stiffeners are not part of the electrical structure, but must be specified accurately in mechanical drawings.

5. Adhesive Systems

The adhesives used in Rigid-Flex PCBs bond copper to polyimide and help laminate multiple layers together. Adhesive performance directly affects heat resistance, delamination resistance, and bend lifespan.

Adhesives must:

Be compatible with lead-free processing temperatures

Withstand dynamic mechanical stress

Maintain integrity under humidity and thermal cycling

For better thermal and mechanical stability, adhesiveless constructions are preferred in high-reliability or dynamic-flex designs.

6. Material Matching and CTE Compatibility

In Rigid-Flex designs, mismatched materials can lead to mechanical stress, warping, or cracking during lamination or soldering.

Tips for compatibility:

Use materials with similar CTEs across rigid and flex zones

Avoid combining low-Tg and high-Tg materials in one board

Choose laminates tested for multilayer Rigid-Flex constructions

Final Thoughts

The materials chosen for a Rigid-Flex PCB form the backbone of the entire structure — influencing everything from mechanical durability to signal integrity and cost.

A well-designed material stack-up:

Supports complex bending and 3D assembly

Ensures thermal and electrical stability

Reduces risk of failure in critical environments

Enables long-term reliability even under stress

0 notes

Text

Primal Omniverse. GPM. Can also be found on Pinterest.

Len Alwen Foska, formerly known as The Unnamed and The First Enemy, is the creator of all curses, blessings and the ruler of all beasts and monsters. He serves as the overarching antagonist of the Sapiens Cinematic Verse, particularly in the War of the Kingdoms and Legends of the Cosmos, as well as the main final arc antagonist in "The First Ever Evil We Return."

In the War of the Kingdoms, he operates as the unseen antagonist throughout Seasons 1 to 5, becomes the primary villain in Season 6, and culminates as the final adversary in Season 7. In Legends of the Cosmos, he is the unseen antagonist of Season 1 and the primary antagonist of Season 2.

As one of the first creations of the Origin of All Origins—though not a product of its concept—Len is also the creator of demons, Eldritch gods, and void sapiens. Despite being immobile and imprisoned for many generations, he manipulates events from the shadows, even driving Corian, a creator of an infinite multilayer universe, to a genocidal warpath.

As the source of all evil, magic, and sorcery—encompassing all physical and metaphysical realms—the First Curse is regarded as the second strongest being in the universe, surpassed only by The Origin of Origins, but only outside of his own infinite verse of endless verses. Unlike other characters, the First Curse/Len is not a living entity; he embodies the first curse and magical source that ever existed. He invented the concepts of curses, magic, evil alchemies, sciences, witchcraft, arts, godhoods, powers,endless infinities of haxs and unfair, uncountable haxs and haxeds, haxs, absolute haxs, absolutes, Omnis, Metas, concepts, and Outer-concepts.

Biography

Early Life

In the beginning, the Origin of Origins, the first creator, sought to gain more power by manifesting a physical form of the First Blessing. His goal was to bestow upon himself the grace of Omni-Meta, an unlimited power. However, the First Blessing developed sentience and free will, defying his creator's wishes and earning the name "the First Curse" or "The Fallen."

Embodying overwhelming godly energy, he waged war against his creator. During this time, a regular Indigo Sapien named Galactic rose to challenge the First Curse upon hearing about him. In retaliation, the First Curse cursed Galactic, transforming him into an abomination—a colossal mass of souls bound for the ascending megaverse, unable to speak.

At another point, the First Curse constructed a massive castle in a vast swamp within an infinite Omniverse and claimed it as his home, where demons dwelled. He initially created the Prism Sapiens as an army to assist in his battles, but ironically, they rebelled against him due to their own free will and disobedience. To correct this, he designed a race of Sapiens meant for absolute obedience, which he named the Meteorite Sapiens, instilling in them the concepts of complete loyalty.

Additionally, he created the Dreaded One, a singular Sapien capable of delving into others' minds to confront them with their deepest fears. In response, the First Creator crafted Purge to counter the Dreaded One, who also created the Light Sapiens to aid in this ongoing battle.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the brand Add D&V Engg to your life. We have a professional team and we are committed to bringing the best products to you and your home. D&V Engineering TV Stand Multilayer Plant Stands HANGING POT STANDS & HOOKS KITCHEN PRODUCTS OTHER HOUSE HOLD PRODUCTS CLOTH HANGERS Single Planter Stands EASY TO ASSEMBLE & CLEAN: just a couple of minutes then your open shelf will be assembled and installed, and easy to wipe dirty stain from the smooth surface DIMENSIONS: L 55 cm X W 41 CM X H 43 cm MULTI USE: Use this metal storage rack for anything and anywhere. It is perfect as a microwave table stand or other small appliances such as toasters. It is also useful as pantry risers. Use it anywhere to create more space with vertical storage STURDY & DURABLE: Sturdy construction with durable steel tube support frame to ensure durability in storage and decoration SPACE SAVER : Put a microwave oven or other kitchen appliances on the sturdy top shelf, you can store toaster, spice, dishes and any other utensils below the shelf FLOOR PROTECTION: You have no worries about Kitchen countertop scratching, this black metal microwave oven stand is designed with the smooth Bushes at feet, so your kitchen shelf will be Scratch free [ad_2]

0 notes

Text

PVC Tarpaulin: Essential for Temporary and Permanent Shelters

In shelter design, one material that consistently meets the demands of structural integrity and climate resistance is PVC Tarpaulin fabric , widely recognized for its adaptability in both permanent and mobile construction applications. From high-altitude expedition tents to industrial-grade warehouse roofs, its role has become indispensable in settings that require rapid installation and lasting performance.

One of the reasons PVC Tarpaulin fabric is favored in shelter construction is its multilayer composition, typically involving a polyester mesh core encased in weather-resistant PVC coatings. This design not only enhances tensile and tear strength but also offers excellent insulation against heat, cold, and moisture. It performs reliably in regions with extreme climates—from desert heat to sub-zero mountain environments—ensuring protection for both people and stored materials.

Shanghai MSD is a trusted name when it comes to manufacturing PVC-coated textiles for demanding environments. With years of experience and cutting-edge production capabilities, the company supplies tarpaulin materials to clients across military, humanitarian aid, and commercial sectors. Their commitment to quality assurance, including rigorous testing for UV resistance and dimensional stability, ensures the materials perform under pressure without degradation.

In areas where climate control within the shelter is essential—such as in medical tents or livestock enclosures—tarpaulin's thermal insulation capabilities are a standout feature. The material limits solar heat gain during hot seasons and reduces heat loss in colder months. For users, this translates to more stable interior temperatures without heavy reliance on mechanical climate systems, lowering both operational costs and energy consumption.

Fire safety is another critical consideration, especially in densely packed temporary shelter setups or in industrial zones. Shanghai MSD offers flame-retardant options that comply with international fire safety standards, allowing end users to meet regional compliance requirements without sacrificing fabric performance. Combined with its resistance to most industrial chemicals, the tarpaulin remains safe and functional even in hazardous surroundings.

Installation of tarpaulin-based shelter systems is also cost-efficient. The fabric is lightweight enough for manual handling yet strong enough to span wide structural areas with minimal support. It can be tensioned securely over metal frames or modular paneling, and can be replaced in sections without dismantling the entire structure. This modularity is critical for operations that require fast setup and potential redeployment.

Aesthetic flexibility is another reason designers and architects favor PVC tarpaulin in semi-permanent structures. It can be produced in a range of colors and finishes—matte, glossy, or textured—and is compatible with digital printing for branding, zoning, or informational graphics. Whether for commercial event domes or emergency relief signage, the fabric enables shelters to serve both practical and visual functions.

From sustainability to customization, Shanghai MSD has invested in research and development to offer PVC tarpaulins that meet modern expectations. Their environmentally aware production processes use low-VOC coatings and recyclable base materials to reduce the ecological impact. This focus on green manufacturing aligns with growing global preferences for eco-conscious solutions in temporary infrastructure.

Shelter designers, construction engineers, and logistics teams looking for a high-performing, versatile solution will continue to rely on PVC tarpaulin for its proven reliability across a spectrum of use cases. As construction timelines shrink and environmental challenges grow, durable and adaptive fabrics will remain vital to shelter innovation.To learn more about Shanghai MSD's PVC tarpaulin fabric offerings, visit https://www.shanghaimsd.com .

#PVC Tarpaulin Fabric#shelter design#Shanghai MSD#climate resistance#fire safety#insulation#modular shelters#eco-friendly fabric

0 notes

Text

The Role of Polyimide Fibers in Next-Gen Electronics and Wearables

In 2025, the polyimide fibers market sales are projected to generate revenue exceeding USD 574.89 Million. By 2035, it is projected to reach USD 954.44 million, reflecting a compound annual growth rate (CAGR) of 5.2%.

Polyimide fibers are increasingly used in the manufacture of protective apparel due to their outstanding flame-retardant potential. Polyimide fibers are now widely utilized in the production of protective equipment, such as the outer shell of army uniforms, firefighters’ jackets, industrial protective gear, and others.

According to NASA, ISRO, and other space research organizations, several space launches are expected to increase significantly during the forecast period, creating a huge demand for portable, superior materials that can withstand high temperatures. Moreover, polyimide fibers are employed for multilayer insulations of space shuttles and astronaut space suits due to their outstanding heat resistance property, which is projected to drive demand throughout the forecast period.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨��𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/REP-GB-13755

The increase in the number of space research activities and space launches throughout the world has continually boosted polyimide fiber sales. Growth in the number of space launches necessitates the production of tones of materials and components for rockets and space shuttles.

The existence of numerous space organizations such as NASA, as well as their substantial plans to launch various space shuttles, are projected to drive demand for polyimide fibers. As a result, the market value in the United States is estimated to rise during the projection period.

Key Takeaways

In the last five years, the market has expanded at a CAGR of 5.2%.

It is projected to reach USD 954.44 million by 2035

In 2035, the United States polyimide fibers market is predicted to rise 5.3% CAGR, with Germany accounting for about 30% of the income earned by polyimide fiber sales in Europe.

Filter media is the large user of polyimide fibers by application, accounting for 60% of total polyimide fiber output globally.

Filter Media and Protective Clothing Drive Market Growth.

Construction and Power & Utilities Sectors Drive Market Expansion

To Gain More Insights about this Research, Visit! Polyimide Fibers Market Growth - Trends & Forecast 2025 to 2035

Competitive Landscape

The key players have focused on increasing their manufacturing units in their respective regions. Innovation, cooperation with important actors, partnerships, strategic alliances, and the strengthening of regional and worldwide distribution networks are examples of strategies. Among the significant developments are:

In May 2025, Solvay, a global market leader in specialized materials, introduced KetaSpire�� KT-857, a revolutionary polyetheretherketone (PEEK) extrusion substance designed exclusively for copper magnet wiring insulation in electric motors.

In April 2022, Kolon Industries, a chemical company in South Korea, partnered with SKC to supply polyimide sheets to Taiwan’s Asus for its folding notebook, Zenbook 17-Fold OLED. In exchange for support in the development of Asus’s device, the companies agreed to supply PI to the Chinese display panel manufacturer BOE.

Key Companies Profiled

Jiangsu Shino New Materials Technology Co., Ltd.

Jiangsu Aoshen Hi Material Co.

Changchun Hipolyking Co., Ltd.

Ningbo Yide Fine Chemical Co., Ltd.

Lirsot Ltd.

Swicofil

Shandong Xingye Environmental Technology Corp.

Jiangsu Jinqiao Salt International Trade Co. Ltd.

Baoding Sanyuan Textile Technology Co. Ltd.

Shanghai Easun Group Imp & Exp Co., Ltd.

Xiamen Meidasi Environmental Protection Industry Co. Ltd.

Evonik Industries AG

Valuable Insights

Future Market Insights, in its new offering, presents an unbiased analysis of the global Polyimide Fibers market presenting a historical analysis from 2020 to 2024 and forecast statistics between 2025 and 2035.

The study reveals essential insights By Application(Filter Media, Protective Clothing, Insulation Material), End Use(Construction, Power & Utilities, Chemical & Processing), & Region.

Textiles, Fabrics, Yarn & Fibres: https://www.futuremarketinsights.com/industry-analysis/textiles-fabrics-yarn-and-fibres

Polyimide Fibers Market Segmentation by Category

By Application:

Filter Media

Protective Clothing

Insulation Material

Others

By End Use:

Construction

Power & Utilities

Chemical & Processing

Mining

Others

By Region

North America

Latin America

Western Europe

Eastern Europe

South Asia and the Pacific

East Asia

The Middle East and Africa

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc. Christiana Corporate, 200 Continental Drive, Suite 401, Newark, Delaware - 19713, USA T: +1-347-918-3531 For Sales Enquiries: [email protected] Website: https://www.futuremarketinsights.com LinkedIn| Twitter| Blogs | YouTube

0 notes

Text

Comprehensive Guide to Shielding & Blocking Fabrics: EMF, Anti-Radiation, RFID & RF

In an increasingly connected world, the need to protect ourselves, our devices, and our sensitive data from electromagnetic interference and unauthorized scans has never been more critical. Shielding and blocking fabrics—engineered with conductive fibers capable of attenuating or reflecting electromagnetic waves—offer versatile solutions across consumer, industrial, and medical applications. This article explores four key categories of these performance textiles: EMF shielding fabric, anti-radiation fabric, RFID blocking fabric, and RF shielding fabric.

1. EMF Shielding Fabric

Electromagnetic Field (EMF) shielding fabric is specifically designed to protect against the broad spectrum of electromagnetic radiation emitted by power lines, mobile devices, routers, and other electronics.

Materials & Construction

Conductive fibers such as silver-plated nylon, copper-infused polyester, or stainless-steel blends

Knitted or woven structures to maintain flexibility, breathability, and drapeability

Key Benefits

Reduces exposure to low-frequency (ELF) and high-frequency (RF) EMF

Maintains fabric softness and durability for apparel and home textiles

Washable for long-term use

Typical Applications

Protective clothing and undergarments for EMF-sensitive individuals

Curtains, window screens, and tent linings to create “quiet zones” in homes and offices

Enclosures for electronic equipment, medical devices, and laboratory spaces

2. Anti-Radiation Fabric

Anti-radiation fabric overlaps with EMF shielding textiles but is often marketed toward general “radiation protection,” including both electromagnetic and ionizing radiation shielding.

Material Variations

Silver or copper coated textiles for non-ionizing EMF

Metal-foil laminates (e.g., aluminum or stainless steel foils sandwiched in fabric layers) for enhanced barrier performance

Core Advantages

Broader spectrum attenuation, potentially including X-rays and gamma rays when laminated with dense metal foils

High tensile strength and tear resistance for industrial or medical shielding curtains

Customizable in multilayer composites for capsule or enclosure applications

Use Cases

Protective aprons and lab coats for radiology departments

Wall and ceiling panels in radiotherapy rooms

Consumer garments and bedding marketed to EMP enthusiasts

3. RFID Blocking Fabric

Radio Frequency Identification (RFID) blocking fabric specifically targets the prevention of unauthorized reading of RFID chips embedded in passports, credit cards, ID badges, and access cards.

Shielding Mechanism

Conductive fibers create a Faraday cage effect around RFID antennas

Blocks common RFID frequencies (125 kHz, 13.56 MHz, and UHF 860–960 MHz)

Standout Features

Lightweight and ultra-thin, enabling integration into wallets, passport covers, and bags

Durable through repeated flexing and laundering

Available in rolls, sheets, and customizable cut-to-size pieces

Practical Applications

Travel accessories: wallets, passport holders, ticket sleeves

Fashion and accessories: jackets, purses, hats with embedded blocking lining

Industrial ID management: badge holders for secure facilities

4. RF Shielding Fabric

Radio Frequency (RF) shielding fabric is engineered to attenuate or reflect radio waves across a specified frequency range, from VHF/UHF television bands up to microwave and millimeter-wave frequencies.

Common Fabric Types

Stainless steel® woven mesh fabrics for broad-band RF shielding

Copper-nylon blends for targeted attenuation at specific frequencies (e.g., Wi-Fi at 2.4 GHz and 5 GHz)

Advantages & Performance Metrics

High shielding effectiveness (SE) ratings, often exceeding 60 dB—meaning over 99.9999% signal reduction

Flexibility and conformability for complex shapes and enclosures

Often supplied with grounding options to safely dissipate intercepted energy

Typical Uses

EMI/RFI gaskets and seals in aerospace, telecommunications, and defense equipment

Shielded rooms and enclosures for EMC testing labs

Protective covers and drapes for antennas and radar installations

Choosing the Right Fabric for Your Needs

When selecting between EMF, anti-radiation, RFID blocking, and RF shielding fabrics, consider the following factors:

Frequency Range & Shielding Effectiveness (SE):

Match the fabric’s tested SE to the frequencies you need to block.

Form Factor & Flexibility:

Apparel and soft furnishings require knitted or woven textiles, while rigid foil laminates suit panel applications.

Durability & Maintenance:

Ensure the fabric withstands laundering, UV exposure, or chemical cleaning if used in demanding environments.

Customization & Integration:

Look for suppliers offering roll goods, die-cut shapes, or laminated composites tuned to your project specifications.

Conclusion

Conductive-fiber fabrics offer versatile solutions to modern challenges of electromagnetic exposure, data privacy, and signal interference. Whether you’re designing protective garments, travel accessories, secure enclosures, or industrial shielding, the right choice among EMF shielding, anti-radiation, RFID blocking, and RF shielding fabrics will deliver both performance and practicality. Explore specialized products at Conductive-Fabric.com to find tailored options that balance shielding effectiveness, comfort, and durability.

For samples, technical datasheets, and custom fabric runs, visit Conductive-Fabric.com.

#RFID Blocking Fabric#RF Shielding Fabric#Anti-Radiation Fabric#EMF Shielding Fabric#china emf protection fabric manufacturers

0 notes

Text

Top Trends in PCB Assembly for 2025

Top Trends in PCB Assembly for 2025

PCBs are the heart of the modern world. Whether it's household equipment, industrial equipment, or defense ordnance, printed circuit boards are running everything. With new developments, the global scene of PCB manufacturing is changing rapidly. Using the newest technologies is not only a great concept, but staying competitive depends on it as well. From downsizing to AI-driven manufacturing, 2025 promises to bring major breakthroughs along with making advancements in current technologies that will change the way Printed Circuit Boards (PCBs) are manufactured.

This article will walk you through some key industry trends that will sketch the future of PCB assembly.

5 Key Trends in PCB Assembly to Follow in 2025

As the world is moving towards manufacturing more complex products and adopting advanced technologies, the PCB assembly industry is also observing several key trends. Here are a few noteworthy trends to follow.

1. Shrinking is in High-Density Interconnections: HDI and Miniaturization

Think about our daily gadgets, such as wearables, Internet of Things devices, and sophisticated medical electronics. These devices need robust and small PCBs, and therefore, in these spaces, High-Density Interconnect (HDI) technology excels. HDI lets electronic gadgets be more powerful despite their compact stature. In what manner? For high-speed applications, it increases signal integrity, lowers component spacing, and permits smaller trace lengths, hence enhancing electrical performance. And it will change the entire PCB manufacturing market.

According to a forecast [1], the HDI PCB market is expected to rise rapidly and, by 2032, will reach almost $40 billion. That makes the direction in which things are heading quite obvious.

2. Smart Factories: Artificial Intelligence and Automation

Like in every other industry, PCB assembly is becoming significantly faster, smarter, and more efficient. Industry 4.0 and manufacturing driven by artificial intelligence lead the push. Think about robotic soldering and pick-and-place robots for fast, more perfect component installation. Artificial intelligence and machine learning have found their way into quality control, that is, for error reduction and flaw detection done automatically. Imagine the Internet of Things, connected production lines, allowing real-time monitoring and predictive maintenance.

3. Bendable and Adaptable: Rigid-flexible PCBs

Flexible and rigid-flex printed circuit boards are becoming more popular in industries such as transportation, aircraft, and healthcare electronics. But you may think, why so? Because of their small size and lightweight nature, they are ideal for manufacturing small, portable electronic devices. They can withstand significant external force and resist bending and vibration. They endure longer with fewer interconnect failures, making them more reliable.

4. Green is Good: Manufacturing Sustainable Circuit Boards

Growing worries about e-waste and carbon footprints force sustainability to the front stage in PCB production. Lead-free soldering, biodegradable and reusable substrates, recyclable materials, and energy-efficient manufacturing procedures will become the focal points in the near future. It's about matching global laws and customer demand as much as it is about environmental responsibility.

5. Printing the Future: 3D Printing in PCB Assembly

Additive manufacturing is revolutionizing PCB manufacturing and streamlining complex multilayer design construction. From this, faster prototyping, reduced material waste, and more customization for specific uses follow. This is a breakthrough for design and development; it will only get more so.

The Final Thought

There are a lot of exciting new possibilities in the PCB assemblyand PCB manufacturing industries. Miniaturization, automation, sustainability, and developments in AI-driven manufacturing will enable you to produce premium printed circuit boards (PCRs) that satisfy future electronics needs. Survival in a dynamic industry depends on keeping ahead of the competitors. By following these trends and wise technology investments, you could set yourself up for success in 2025 and beyond.

Know More: https://www.pcbpower.us/blog/top-trends-pcb-assembly

0 notes

Text

“People are quick to assert themselves as good or evil, when in reality their pathos, logos, and ethos multifaceted, multilayered constructs of their own design and the machinations of those around them. Even the most evil of souls is capable of producing good, just as the kindest soul is capable of unleashing unspeakable evil. When you perceive the world from a shallow, narrow point of view you ultimately loose sight of what truly exists.”

1 note

·

View note

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the brand Add D&V Engg to your life. We have a professional team and we are committed to bringing the best products to you and your home. D&V Engineering TV Stand Multilayer Plant Stands HANGING POT STANDS & HOOKS KITCHEN PRODUCTS OTHER HOUSE HOLD PRODUCTS CLOTH HANGERS Single Planter Stands SPACE SAVER : Put a microwave oven or other kitchen appliances on the sturdy top shelf, you can store toaster, spice, dishes and any other utensils below the shelf. STURDY & DURABLE: Sturdy construction with durable steel tube support frame to ensure durability in storage and decoration. MULTI USE: Use this metal storage rack for anything and anywhere. It is perfect as a microwave table stand or other small appliances such as toasters. It is also useful as pantry risers. Use it anywhere to create more space with vertical storage. EASY TO ASSEMBLE & CLEAN: just a couple of minutes then your open shelf will be assembled and installed, and easy to wipe dirty stain from the smooth surface. FLOOR PROTECTION: You have no worries about Kitchen countertop scratching, this black metal microwave oven stand is designed with the smooth Bushes at feet, so your kitchen shelf will be Scratch free. DIMENSIONS: L 55 cm X W 41 CM X H 43 cm [ad_2]

0 notes