#Muratec

Explore tagged Tumblr posts

Text

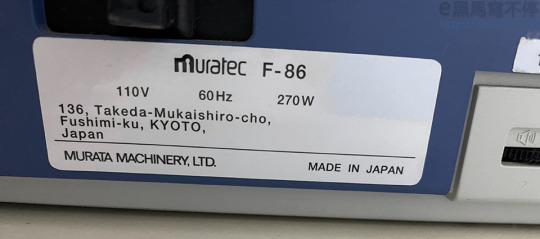

Murtec F-86 傳真機一直響 如何開啟自動接收傳真功能【教學】

有時工程師現場維修客戶電腦及ERP系統時,會突然問一些感覺好像有關卻與服務範圍無關的問題,客戶問:「我的傳真機一直響,無法自動接收傳真? 都要人來按才收,可以看一下嗎?」 剛好安排的工程師還真有接觸過傳統傳真機,順利協助客戶解決困擾並且收取服務費用… Continue reading Untitled

View On WordPress

0 notes

Text

Friction Spinning Machines Market Set to Hit $2,404.1 Million by 2035, Driven by Advanced Manufacturing Demands

According to recent research by DataString Consulting, the global Friction Spinning Machines market is expected to surge from $980.0 million in 2024 to $2,404.1 million by 2035, reflecting the rising importance of high-performance spinning systems across key sectors such as textile manufacturing, aerospace components, automotive parts, and metal fabrication.

Access detailed report insights here - https://datastringconsulting.com/industry-analysis/friction-spinning-machines-market-research-report

Expanding Applications in Textiles and Automotive

In the textile industry, friction spinning machines—particularly DREF systems—are in high demand for their versatility and ability to spin synthetic, natural, and blended fibers into high-quality yarn. These machines enable efficient production of specialty yarns while maintaining consistency and durability. Leading companies such as Rieter Group and Saurer are at the forefront, offering cutting-edge systems that dominate global market share through reliability and innovation.

Meanwhile, the automotive industry relies on friction spinning machines like the DREF-2 and DREF-3 for their precision, speed, and operational efficiency—crucial for component manufacturing. Key players including Oerlikon and Murata Machinery continue to lead this segment with robust designs and state-of-the-art technologies that meet stringent production demands.

Technology-Driven Transformation

A shift toward modernized and automated spinning systems marks a major transformation in the industry. These newer-generation friction spinning machines provide high-speed output, energy efficiency, and reduced manual intervention, making them indispensable in both textiles and industrial manufacturing.

The integration of automation, sensors, and Industry 4.0 frameworks is helping manufacturers lower operational costs, enhance product quality, and increase competitiveness. These advancements are accelerating the replacement of legacy equipment and setting new performance standards across the sector.

Competitive Landscape and Strategic Movements

The global market is fiercely competitive, with a strong presence in major demand hubs like the U.S., Germany, and China. Key players including Nakayama Iron Works Co. Ltd., Rieter AG, Trützschler GmbH & Co. KG, Lakshmi Machine Works, Saurer AG, Zinser Textile Systems, A.T.E. Enterprises, Savio Macchine Tessili, Schlafhorst, Marzoli S.p.A., Muratec, and SSM Textile Machinery are investing heavily in automation, customization, durability, and strategic innovation to expand market presence.

Notable strategic approaches include Oerlikon’s emphasis on customization, Makino’s focus on precision, Toyoda’s innovation alliances, and Haas Automation’s drive to enhance operational efficiency and quality control.

Regional Trends and Growth Opportunities

North America is a leading regional market, with sustained demand from both the textile and automotive sectors. The push for high-strength fiber products, coupled with modernized infrastructure, has positioned the region as a technology adopter. Rising investments in R&D, IoT integration, and the replacement of outdated machinery are contributing to market expansion.

At the same time, emerging economies such as India, Brazil, and China are becoming hotbeds for investment due to their rapidly growing manufacturing sectors and favorable policy landscapes.

Market Coverage and Research Scope

DataString Consulting’s comprehensive research covers the Friction Spinning Machines market across multiple dimensions, including:

Product Types: Single Rotor, Double Rotor

Applications: Textile, Automotive, Construction, Other Industrial Uses

Technology: Manual Operation, Semi-Automatic, Fully Automatic

Geographic Reach: Detailed insights across more than 20 countries

About DataString Consulting

DataString Consulting supports companies with tailored strategies to expand their total addressable market (TAM), diversify revenue, and enter new sectors through actionable market intelligence. With over 30 years of combined experience, the firm delivers results-driven insights by continuously tracking more than 15 industries and 60 sub-industries globally.

Whether targeting niche opportunities or planning a full-scale market entry, DataString offers precise, filtered strategies that reduce time to market and sharpen competitive positioning.

#FrictionSpinningMachines#TextileIndustry#AutomotiveIndustry#IndustrialManufacturing#MarketGrowth#TechInnovation#Automation#Industry40#TextileMachinery#ManufacturingTech#SustainableManufacturing#Rieter#Saurer#Oerlikon#MurataMachinery#SmartManufacturing#HighPerformance#GlobalMarket#FutureofTextiles#PrecisionEngineering#MarketResearch#BusinessInsights#DataStringConsulting#EmergingMarkets#MarketTrends#AdvancedManufacturing#Fibers#InnovationInManufacturing#IndustrialRevolution

0 notes

Text

Automated Guided Vehicle Market Trends and Forecast Analysis (2025–2030)

The Automated Guided Vehicle market is undergoing a transformative shift driven by rapid technological innovation, rising automation demands, and the evolution of smart factories across various industries. Between 2025 and 2030, the AGV market is expected to grow significantly, fueled by trends such as Industry 4.0 integration, labor cost optimization, and the booming e-commerce and logistics sectors.

Market Overview

AGVs are mobile robots used to transport materials in manufacturing facilities, warehouses, and distribution centers without human intervention. They use a combination of software, sensors, and guidance technologies such as laser navigation, magnetic strips, vision-based systems, and LiDAR to move autonomously.

According to recent market research, the global AGV market size is projected to surpass USD 5.5 billion by 2030, growing at a CAGR of over 10% from 2025 to 2030. This growth is largely driven by the need to improve operational efficiency, reduce labor costs, and enhance supply chain automation.

Key Market Trends (2025–2030)

1. Rising Adoption in E-Commerce and Warehousing

The explosive growth of e-commerce has led to an increased demand for efficient and scalable material handling systems. AGVs are now widely deployed in automated warehouses to support last-mile delivery, order picking, and inventory management. Companies like Amazon, Alibaba, and Flipkart are investing heavily in AGV systems to streamline their operations.

2. Integration with AI and IoT

The next generation of AGVs is being designed with AI algorithms, machine learning, and IoT connectivity. This enables real-time data sharing, predictive maintenance, and adaptive route planning. Smart AGVs can now learn from environments, avoid obstacles more efficiently, and collaborate with other machines in connected ecosystems.

3. Flexible Navigation Technologies

Modern AGVs no longer rely solely on fixed paths. The trend is shifting toward natural feature navigation and SLAM (Simultaneous Localization and Mapping), allowing AGVs to operate in dynamic environments with minimal infrastructure requirements.

4. Cost Reduction and ROI Focus

Manufacturers and warehouse operators are seeking solutions with a lower total cost of ownership (TCO). Advances in battery technology, including lithium-ion and wireless charging, along with modular AGV designs, are improving ROI and driving faster adoption.

5. Expansion in Emerging Markets

Countries like India, China, Brazil, and Southeast Asian nations are becoming hotbeds for AGV implementation. Government support for automation and smart manufacturing under initiatives like “Make in India” and “Made in China 2025” is playing a crucial role in market expansion.

Market Segmentation

The AGV market is segmented by:

Type: Tow Vehicles, Unit Load Carriers, Forklift AGVs, Pallet Trucks, and Hybrid AGVs

Navigation Technology: Laser Guidance, Magnetic Tape, Optical, Natural Navigation

Industry Vertical: Automotive, Food & Beverage, Healthcare, Retail, Aerospace, Logistics

Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

Key Players in the Market

Leading companies in the AGV market include:

Daifuku Co., Ltd.

KION Group (Dematic)

Toyota Industries Corporation

JBT Corporation

Swisslog Holding AG

Muratec

Seegrid Corporation

These players are focusing on strategic partnerships, R&D investment, and technological innovation to stay competitive.

Conclusion

The Automated Guided Vehicle market is set for rapid expansion between 2025 and 2030. As industries continue to prioritize automation, efficiency, and smart logistics, AGVs will play a central role in reshaping modern supply chains. Businesses that adopt AGV technology early will not only optimize productivity but also gain a competitive edge in the evolving global market.

0 notes

Text

Lamiera 2023

Dal 10 al 13 maggio 2023 a Fieramilano Rho si terrà Lamiera, la manifestazione internazionale dedicata alle macchine per la deformazione e il taglio della lamiera e alle tecnologie ad esse connesse. Ideate da Ucimu-Sistemi, l’associazione dei costruttori italiani di macchine utensili, robot e automazione, e organizzata da Ceu-Centro Esposizioni Ucimu, Lamiera torna al suo posizionamento tradizionale negli anni dispari. Nei padiglioni, molto interessante sarà la proposta di tecnologie dedicate al taglio della lamiera, da sempre protagonista della manifestazione, mentre il mondo del laser sarà rappresentato da oltre 40 imprese, espressione della migliore produzione internazionale. Oltre alle tecnologie per il taglio laser, plasma e termico, per lamiere, barre, profilati e tubi, Lamiera proporrà una esaustiva offerta di prodotti consumabili e macchine, garantendo agli operatori presenti in mostra una completa ed esaustiva panoramica sul segmento del laser le cui applicazioni sono molto diffuse. Accanto all’ampia offerta di macchine stand alone e di impianti per la lavorazione e deformazione della lamiera, la manifestazione pone l’accento su fabbrica futura, saldatech, fastener industry, tts-il mondo dei trattamenti termici e di superficie, metrology & testingbl e ech italy service. Per l’evento Adh Italia, Alpemac, Amada Italia, Baykal Makina, Blm Group, Bodor, Comaf, Cutlite Penta, Cy-Laser, Dne Global, Eagle, Ermaksan, Ficep, Gweike Tech, Hpm High Performance Machinery, Hsg Laser, Hymson Italy, Kjellberg, Lag Machinery, Laserbergtech, Laser Plasma Systems, Laser Veronese, Laserisse, Le Macchine di Luca, L-Peak, Lvd, Mazak, Messer Cutting Systems, Mitsubishi Electric, Muratec, Optoprim, Prima Industrie, Prima Power, Salvagnini, Sei, Soitaab Impianti, Tecoi, Thermacut, Vd Industrial Equipments, Warcom, Zinetti Technologies/Schiavi Macchine International sono le aziende che aderito a Lamiera nel segno della piena rappresentatività di questo segmento produttivo. D’altra parte, l’esclusività di Lamiera, unico appuntamento espositivo in Italia dedicato al comparto, e il ruolo di primo piano che l’industria italiana delle tecnologie per la deformazione ha su scala internazionale e nei vertici delle graduatorie di produzione, export e consumo, contribuiscono a questo evento, di edizione in edizione, presso gli operatori del manifatturiero mondiale. A completamento dell’offerta in mostra, Lamiera proporrà l’appuntamento con Lamialamiera, l’arena all’interno del padiglione 13, per conferenze, convegni e incontri di approfondimento culturale e tematico. Tra i temi trattati una grande attenzione sarà riservata al taglio laser, plasma e termico e alle molteplici e variegate applicazioni che saranno illustrate dagli espositori presenti. Read the full article

0 notes

Photo

Highly qualitative, accurate dimensions & best price range Murata 21c machine spare parts manufacturer⚙️ and also customize spares as per client requirements.

#BhartiIndustry#manufacturer#Autoconer#spareparts#supplier#textile#textileindustry#textilemachinery#sparemanufacturer#schlafhorst#savio#murata#muratec

0 notes

Text

DOWNLOAD MURATEC F-114 DRIVER

File Size: 23 Mb Operating Systems: Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X File Format: exe Uploader: Jelly Downloads: 5466 File Name: muratec f-114 driver Download Type: http Price: Free Date Added: 24 October, 2019 File Version: 515171660

What's New: - Fixed remove battry,(muratec f-114 driver battry,) system will hang on C1. - Fixed(muratec f-114 driver Fixed) a bug where the UPS sync settings were not applied. - Fixes a(muratec f-114 driver a) processing error in relation to the leap second for the "Geotag information appended to image" and "Log data" GPS functions. - Fixed execute awdflash.exe and system hang on when entering wrong file name or no file name. - -(muratec f-114 driver -) Fixed PPTP and PPPoE don’t work issue. - Fixes LAN wake up S1 disable can't be disabled issue. - Fixed shutter settings issue for support anti-flicker series. - Fixed firmware upgrade issue when AP mode switches to Router mode. - Fixed(muratec f-114 driver Fixed) hang on post 96h with intel 6XX CPU.# Removed some items to add USB Storage support. - Fixed battery capacity does not report correctly in Dell Support Center. Users content: Download the BIOS Package (ZIP archive file). - Extract archive file to root folder. (for e.g. This update installs the latest Brother printing and scanning software for OS X Lion and Mac OS vX 10. Issues were observed whereby attempting to save configured labels for various softkey types would initially fail. Fix the issue “Cannot established PPTP session to PPTP server” Enhancements: 1. This issue is known to occur under all supported operating system. Updated SATA ROM to version 1.09. USB HID device class spec. Fix Bluetooth sometimes cannot be detected after S4 long run. A display similar to what is shown on the following page will appear. Add multi-language in some character string. DOWNLOAD COMPAQ EVO N610C USB 2.0 DRIVER Supported OS: Windows Server 2003 64-bit Windows Vista 32-bit Windows Server 2012 R2 Microsoft Windows 8.1 Pro (64-bit) Windows XP 64-bit Windows 7 64-bit Microsoft Windows 8.1 (32-bit) Windows Server 2008 Notebook 8.1/8/7 32-bit Microsoft Windows 8.1 Pro (32-bit) Windows Server 2003 32-bit Microsoft Windows 8 Pro (32-bit) Microsoft Windows 10 (64-bit) Windows XP 32-bit Windows 7 32-bit Windows Server 2016 Microsoft Windows 8 Enterprise (64-bit) Microsoft Windows 8 Enterprise (32-bit) Windows 8.1/8/7/Vista 64-bit Windows Server 2008 R2 Windows 8.1 Microsoft Windows 8.1 Enterprise (64-bit) Windows 10 Windows 8 Microsoft Windows 8 (32-bit) Microsoft Windows 8 (64-bit) Notebook 8.1/8/7 64-bit Microsoft Windows 8.1 (64-bit) Microsoft Windows 8 Pro (64-bit) Windows 8.1/8/7/Vista 32-bit Microsoft Windows 8.1 Enterprise (32-bit) Windows 2000 Windows Server 2012 Microsoft Windows 10 (32-bit) Windows 7 Windows Vista 64-bit Searches: muratec f-114 R RN258-2; muratec f-114 driver for Windows Server 2012 R2; muratec f-114 driver; muratec f-114 driver for Windows Server 2003 64-bit; muratec f-114 RN2589; muratec f-114 Rlz258-lzj; muratec f-114 driver for Windows Server 2012; muratec f-114 R25l; muratec f-114 driver for Windows Vista 64-bit; muratec f-114 driver for Microsoft Windows 8 Pro (64-bit); muratec f-114 RNBGO2589 Compatible Devices: Computer Cable Adapters; Scanner; Keyboards; Monitor; USB Hubs; Wifi router To ensure the integrity of your download, please verify the checksum value. MD5: 5399cc67ccdb5a5227343cfb3f0b4380 SHA1: 15e45d1eaa22d28b35819c114367b1605191562e SHA-256: 96571644f5d617b185e41b4b805f8cf47daa905d7d57edfef5b3efacae55a419

1 note

·

View note

Text

Murata reveals mini-load automated storage and retrieval system

New Post has been published on https://supplychainmanagementcertificate.com/2023/03/22/murata-reveals-mini-load-automated-storage-and-retrieval-system/

Murata reveals mini-load automated storage and retrieval system

Murata Machinery USA (Muratec; Booth 2703a) announced its latest addition to Muratec’s range of automated material handling solutions for small product storage and retrieval – the new Ledger A3 mini-load is a high-density, four-tote carriage automated storage and retrieval system (AS/RS).

0 notes

Video

youtube

Muratec Process Conner 21C sale / Winders Murata 21C Round Magazine typ...

0 notes

Text

WYS Hinge Coil Forming Tooling

For over 20 years, WYS Machinery Tooling combined with user experience to produce tools tailored to customer requirements.

Customized and can provide OEM service Axis precision: ±0.02mm

And our tooling products suitable for most machine brand as: AMADA, Muratec, Tailift, Trumpf, Prima Power, Strippit, Accurpress, Finnpower, LFK, LVD, Salvagnini, Yawei, JFY, Yangli

Discover More: https://lnkd.in/gte9vTRj WhatsApp:+86 153 7014 1857 Email: [email protected] #pressbrake#pressbraketooling#pressbraketools#sheetmetal#sheetmetalfabrication#sheetmetalforming#wysmachinery#Amada#Bystronic#Baykal#Aliko#Trumpf#Adira#Durmazlar#Ermaksan#Dener#primapower#Salvagnini#Yawei#LVD#YSD#JFY#Yangli

0 notes

Text

Global Air Jet Cotton Spinning Machines Powerhouses: Top 5 Countries Driving Growth

According to a recent research, Industry revenue for Air Jet Cotton Spinning Machines is expected to rise to $1331.6 million by 2035 from $680.0 million of 2024. China, India, U.S., Germany and Brazil are the top 5 markets and combinely holds substantial demand share. The revenue growth of market players in these countries is expected to range between 4.1% and 6% annually for period 2025 to 2035.

Industry transition including automation enhancement and digital integration, are transforming the supply chain of Air Jet Cotton Spinning Machines market. The textile sector has experienced a shift towards automation in recent times. A change that is clearly seen in the development of air jet cotton spinning machines. These machines have been upgraded with automation features to boost efficiency and lessen the strain required during production. This significant transition has not only accelerated the pace and enhanced the quality of cotton spinning but also brought about substantial cost savings in manufacturing. Thanks to automation advancements the dependence on labor, for air jet cotton spinning machines has decreased, reducing errors and increasing productivity significantly. This shift has also resulted in a consistent production of yarns that meet the increasing need for high quality fabrics, in the textile industry worldwide.

Potential Application Areas

Cotton Processing: In the cotton processing sector specialized versions of air jet cotton spinning machines are used for ginning and spinning operations to clean the cotton fibers while maintaining their structure intact to create top notch lint for various textile uses. Key players in this field consist of companies, like Trtzschler known for their reliable production of performance improving processing equipment that enjoys a solid market standing.

Apparel Production: In the apparel production sector air jet cotton spinning machines play a role. These machines are known for their ability to create consistent yarns, which are essential for producing top notch comfortable clothing items. Savio, a player in this industry holds a significant market share thanks to its cutting edge machines that deliver excellent yarn quality along, with fast performance and adaptability.

Industry Leadership and Strategies

The Air Jet Cotton Spinning Machines market is characterized by intense competition, with a number of leading players such as Rieter AG, Truetzschler GmbH & Co. KG, Lakshmi Machine Works Limited, Saurer AG, Zhejiang RIFA Textile Machinery Co. Ltd., Muratec USA Inc., Marzoli SpA, Toyota Industries Corporation, Jingwei Textile Machinery Co. Ltd., Savio Macchine Tessili SpA, Luwa Air Engineering AG and Qingdao Textile Machinery Co. Ltd.. These players are pushing the boundaries of innovation & technological advancements and forging strategic partnerships to expand the existing reach of the market. Below table briefs about adopted market strategies by leading players.

Access detailed report insights here - https://datastringconsulting.com/industry-analysis/air-jet-cotton-spinning-machines-market-research-report

About DataString Consulting

DataString Consulting assist companies in strategy formulations & roadmap creation including TAM expansion, revenue diversification strategies and venturing into new markets; by offering in depth insights into developing trends and competitor landscapes as well as customer demographics. Our customized & direct strategies, filters industry noises into new opportunities; and reduces the effective connect time between products and its market niche.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

0 notes

Photo

Buy Autoconer spares 238,338,x5⚙️ and related components in the best price and quality.

#textile#textilemanufacturer#textileindustry#textilemachinery#spareparts#Schlafhorst#Savio#supplier#spares#exporter#murata#muratec

0 notes

Text

Automotive Industry AGV Market Comprehensive Research Study, Regional Growth, Business Top Key Players Analysis

Global Automotive Industry AGV Market report emphasizes on the detailed understanding of some decisive factors such as size, share, sales, forecast trends, supply, production, demands, industry and CAGR in order to provide a comprehensive outlook of the global market. Additionally, the report also highlights the challenges impeding market growth and expansion strategies employed by leading companies in the “Automotive Industry AGV Market”.

Global Automotive Industry AGV Market research report analyzes top players in the key regions like North America, South America, Middle East and Africa, Asia and Pacific region. It delivers insight and expert analysis into key consumer trends and behavior in market place, In addition to an overview of the market data and key brands. It also provides all data with easily digestible information to guide every businessman’s future innovation and move business ahead.

Global Automotive Industry AGV Market Segmentation Analysis:

Major Players in Automotive Industry AGV market are: JBT Meidensha CSG Muratec DS Automotion KION Group Daifuku Ek Automation Siasun Atab Toyota Corecon Aichikikai Oceaneering International Scott Group Most important types of Automotive Industry AGV products covered in this report are: Unit Load Type Automated Forklift Type Tugger Type Others Most widely used downstream fields of Automotive Industry AGV market covered in this report are: Warehouse Production Line

Click the link to get a free Sample Copy of the Report @ https://crediblemarkets.com/sample-request/automotive-industry-agv-market-313328?utm_source=Kaustubh&utm_medium=SatPR

Automotive Industry AGV Market, By Geography:

The regional analysis of Automotive Industry AGV market is studied for region such as Asia pacific, North America, Europe and Rest of the World. The North America is one of the leading region in the market due to numerous cross industry collaborations taking place between automotive original equipment manufacturers and mobile network operators (MNOs) are taking place for continuous internet connectivity inside a car to enhance the user experience of connected living, while driving. Asia-Pacific region is one of the prominent player in the market owing to large enterprises and SMEs in the region are increasingly adopting Automotive Industry AGV solutions.

Some Points from Table of Content

Global Automotive Industry AGV Market 2022 by Company, Regions, Type and Application, Forecast to 2030

1 Automotive Industry AGV Introduction and Market Overview

2 Industry Chain Analysis

3 Global Automotive Industry AGV Market, by Type

4 Automotive Industry AGV Market, by Application

5 Global Automotive Industry AGV Consumption, Revenue ($) by Region (2018-2022)

6 Global Automotive Industry AGV Production by Top Regions (2018-2022)

7 Global Automotive Industry AGV Consumption by Regions (2018-2022)

8 Competitive Landscape

9 Global Automotive Industry AGV Market Analysis and Forecast by Type and Application

10 Automotive Industry AGV Market Supply and Demand Forecast by Region

11 New Project Feasibility Analysis

12 Expert Interview Record

13 Research Finding and Conclusion

14 Appendix

Direct Purchase this Market Research Report Now @ https://crediblemarkets.com/reports/purchase/automotive-industry-agv-market-313328?license_type=single_user;utm_source=Kaustubh&utm_medium=SatPR

Reasons to Purchase this Report

Qualitative and quantitative analysis of the market based on segmentation involving both economic as well as non-economic factors

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players

The current as well as the future market outlook of the industry with respect to recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Includes in-depth analysis of the market of various perspectives through Porter’s five forces analysis

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

About US

Credible Markets is a new-age market research company with a firm grip on the pulse of global markets. Credible Markets has emerged as a dependable source for the market research needs of businesses within a quick time span. We have collaborated with leading publishers of market intelligence and the coverage of our reports reserve spans all the key industry verticals and thousands of micro markets. The massive repository allows our clients to pick from recently published reports from a range of publishers that also provide extensive regional and country-wise analysis. Moreover, pre-booked research reports are among our top offerings.

The collection of market intelligence reports is regularly updated to offer visitors ready access to the most recent market insights. We provide round-the-clock support to help you repurpose search parameters and thereby avail a complete range of reserved reports. After all, it is all about helping you reach an informed strategic decision about purchasing the right report that caters to all your market research demands.

Contact Us

Credible Markets Analytics

99 Wall Street 2124 New York, NY 10005

Email: [email protected]

0 notes

Link

Find the best document scanning solutions with the help of Nyccopierguy.com! We know that NYC business moves quickly so we quickly deliver what we sell.

0 notes

Text

Data explosion driving demand for Japanese company that moves chips in factories

For close to four decades, one Japanese company has been trusted to move silicon wafers around the factories of the world’s biggest chip manufacturers.

Now it is going back to the drawing board and redesigning its ubiquitous overhead conveyors to handle an exponential surge in data use and global chip demand.

Daifuku has, over its 85 years in business, gone from ferrying documents between offices and hospital wards to handling the world’s most delicate microelectronics, making the conveyor belts and boxes that zip across the ceilings of modern semiconductor plants.

Those containers and rails, which shuttle chips to different parts of the fabrication process at speeds of more than five 5 metres per second, will within years need to bear 100 kilograms — or five times their current load — chief executive Hiroshi Geshiro said.

“Many in the industry are optimistic that growth is here to stay, as the amount of data that society must deal with has increased exponentially,” he told Bloomberg News.

“Our system is like blood vessels connecting all the important organs” and will need to handle that explosion in demand. The company stockpiled materials at the start of the pandemic, but may face challenges if global supply shortages intensify or prolong, he said.

The 63-year-old’s remarks underscore the bullishness of global chip-manufacturing leaders such as Intel and Taiwan Semiconductor Manufacturing (TSMC), which have been spending unprecedented sums of money to capture a wave of new demand from industries such as electric vehicles, connected home devices and internet servers.

Between them, the two companies have committed to spending about $70 billion on new manufacturing equipment and facilities this year. Intel announced two giant new chipmaking campuses — one in Ohio and another in Germany — in recent months, as it joins rivals in preparing for a doubling of the $550bn industry over the next decade.

At the heart of that impending explosion will be Osaka-based Daifuku, founded in 1937 as a maker of forging machines before scoring its first big break 20 years later when Toyota Motor came calling.

Today, analysts say its systems power everything from Amazon.com fulfilment centres to the plants of Intel and TSMC.

Its factory conveyance systems are among the world’s most sophisticated. Its overhead vehicles are powered wirelessly and can cover 320 metres in a minute without shaking or disturbing their contents. A routing system aided by artificial intelligence helps plot paths for hundreds of containers across a complex intertwined network without creating a jam.

Daifuku’s closest rival is Muratec Automation, and together they have become critical in the manufacturing of most chips, from basic microcontroller units to the most advanced semiconductors in servers, laptops and game consoles, said Tokyo-based Bain & Co partner Jean-Philippe Biragnet.

Their systems and other highly automated processes mean “human hands never touch the product and humans are really only there to maintain the tools”.

“There are no competitors that can match Daifuku when it comes to speed in meeting customer requests for production lines,” said Omdia analyst Akira Minamikawa.

The company’s long track record has “built a high level of trust and confidence among semiconductor makers. In chipmaking, minimising travel time between processes is key to maximising output”.

While Mr Geshiro declined to disclose the names of his customers, SMBC Nikko Securities analyst Satoshi Taninaka wrote in a report this month that Daifuku’s transport system is used in almost every factory making chips with the most advanced fabrication processes of 7nm and smaller.

Mr Geshiro, who joined Daifuku a year before it got into chipmaking in 1984, sees demand for its transports expanding to include the so-called back-end of chip manufacturing — which features heavier, less sensitive loads. This push has been driven in part by the increasing adoption of stacked-chip manufacturing techniques that put more silicon into every module. Daifuku’s current systems carry loads of about 20kg, but customers have been asking for systems that can work with loads between 70kg and 100kg and the company is developing new rails and carriers to handle such weight.

The entire transport system for a given fab (manufacturing plant) is less costly than a single unit of the most advanced semiconductor-making machines, but Mr Geshiro considers his machinery every bit as essential to the final product. Chipmaker fabs are more demanding than other industries, the chief executive said, asking for installations to be completed in half the time that others, such as auto makers, would allow.

“There won’t be a day when semiconductor makers will be completely satisfied with what we offer because they constantly ask us for more,” he said.

0 notes