#NX Software

Explore tagged Tumblr posts

Text

Day two of working in NX

I miss Inventor

#follow ivan-fyodorovich-k for more Relatable Content#supposedly NX is the superior software and that may be but man I really took that familiarity with Inventor/Solidworks for granted

6 notes

·

View notes

Text

When Should You Use NX CAD in Product Development?

In today’s competitive manufacturing industry, choosing the right CAD software is essential for efficient product development. Siemens NX is a widely used CAD software that provides advanced tools for design, simulation, and manufacturing. But when should you use NX CAD in product development? Let’s explore the key situations where NX CAD proves beneficial.

1. Complex Product Design

When working on intricate product designs that require precision, Siemens NX is a top choice. It offers powerful modeling features, allowing engineers to create detailed designs with high accuracy. Unlike traditional CAD software, NX provides a comprehensive set of tools to handle complex geometries efficiently.

2. Integration with Other Engineering Tools

Many industries use multiple software solutions for different stages of product development. NX CAD seamlessly integrates with SolidEdge CAD, CAE Software, and NX CAM, making it easier to transition from design to manufacturing. This eliminates data conversion issues and ensures a smooth workflow across departments.

3. Advanced Simulation and Analysis

Simulation plays a vital role in ensuring product durability and performance. Siemens NX includes built-in CAE software that allows engineers to test their designs under real-world conditions. This helps in reducing physical prototyping costs and improving product reliability.

4. Efficient Collaboration and Data Management

For teams working on large projects, managing design data efficiently is crucial. NX CAD works seamlessly with PLM software, ensuring secure storage, version control, and easy access to design files. This enhances collaboration and reduces errors caused by outdated file versions.

5. Streamlined Manufacturing with NX CAM

When transitioning from design to manufacturing, NX CAM helps in generating accurate tool paths for CNC machines. This feature is essential for industries like automotive, aerospace, and consumer electronics, where precision machining is required.

6. Shorter Development Cycles

Using NX CAD can significantly reduce product development time. Its intuitive interface, automation tools, and parametric modeling features help engineers create, modify, and validate designs quickly. Faster iterations mean quicker time-to-market for new products.

7. High-Quality 3D Modeling and Rendering

Visual representation of a product is crucial for both internal approval and customer presentations. Siemens NX provides high-quality rendering tools that help create realistic 3D models, making it easier to showcase design concepts before manufacturing.

8. Scalability for Different Business Sizes

Whether you are a small business or a large enterprise, NX CAD adapts to various project requirements. It offers different modules and licensing options to fit your needs, ensuring that companies of all sizes can benefit from its capabilities.

Conclusion

Choosing Siemens NX for product development is a smart decision for companies looking to improve design efficiency, enhance collaboration, and streamline manufacturing processes. Whether you need advanced CAE software, seamless integration with SolidEdge CAD, or manufacturing support through NX CAM, NX CAD offers a complete solution.

0 notes

Text

Why NX CAM Dealers in India Are Transforming Smart Manufacturing

NX CAM

In the evolving world of manufacturing, adopting advanced technologies has become essential. NX CAM, a leading Computer-Aided Manufacturing (CAM) software, is paving the way for smarter and more efficient production. This blog explores why NX CAM is the future of smart manufacturing and how authorized NX CAM dealers in India play a crucial role in driving this transformation.

Understanding NX CAM

NX CAM, developed by Siemens, is a powerful tool for automating and optimizing machining processes. It enables manufacturers to create precise and efficient toolpaths for CNC (Computer Numerical Control) machines. This software integrates seamlessly with the broader Siemens Digital Industries Software ecosystem, making it a preferred choice for manufacturers across industries.

The Importance of Smart Manufacturing

Smart manufacturing focuses on using data, automation, and advanced technologies to improve production efficiency, quality, and flexibility. NX CAM supports this approach by offering tools to:

Automate repetitive tasks.

Reduce production errors.

Optimize machining time and material use.

Connect seamlessly with other systems, enhancing collaboration.

These features make NX CAM a vital component for manufacturers seeking to stay competitive in the global market.

Why NX CAM Is the Future of Smart Manufacturing

1. Advanced Automation Features

NX CAM eliminates manual programming by automating toolpath creation. Its advanced algorithms generate optimized machining strategies for complex parts. This saves time and reduces errors.

2. Integration with Digital Twins

NX CAM allows users to create and simulate digital twins of machining processes. These virtual models ensure that machining strategies are tested and optimized before production begins. This reduces downtime and material waste.

3. High Precision and Accuracy

Modern industries demand precision. NX CAM delivers this by enabling manufacturers to create detailed and accurate machining plans. This is especially valuable in industries such as aerospace, automotive, and medical devices.

4. Customizable and Scalable Solutions

NX CAM can adapt to the needs of small workshops and large factories alike. Its modular design allows manufacturers to start with basic features and expand as their requirements grow.

5. Seamless Integration with NX Software

As part of the broader Siemens NX software suite, NX CAM integrates with design and simulation tools. This ensures a smooth flow of data from design to production, enabling manufacturers to innovate faster.

Originally Published Corengg Technologies on December 9, 2024

0 notes

Text

Siemens NX is a cutting-edge, high-end CAD/CAM/CAE software package widely used for mechanical product design, engineering, and manufacturing. The NX CAD designing tools set industry benchmarks for speed, performance, and ease of use. CAD DESK’s NX CAD Training course is meticulously designed to offer in-depth learning, providing a flexible solution for product development.

NX CAD stands out for its seamless data integration compared to other CAD systems, enabling designers to achieve quick results by maximizing the use of virtual product models and minimizing the need for physical prototypes. CAD DESK delivers top-notch NX CAD CAM training and encourages students to participate in internships during their NX Training to gain practical experience. All training sessions are conducted on the latest version of NX CAD Training Institute in Maharashtra.

0 notes

Text

NX CAD Design Software: Career, Benefits, Uses

In today's rapidly evolving technological landscape, proficiency in Computer-Aided Design (CAD) software has become a cornerstone skill for aspiring engineers, designers, and architects. Among the plethora of CAD tools available, NX CAD stands out as a comprehensive and powerful solution that not only facilitates efficient design but also opens doors to diverse career opportunities. In this blog, we'll delve into the world of NX CAD, exploring its myriad benefits, versatile applications, and its pivotal role in shaping careers across various industries.

The Power of NX CAD

NX CAD, developed by Siemens Digital Industries Software, is a leading-edge CAD software renowned for its robust capabilities and advanced features. It offers a wide array of tools for 3D modeling, simulation, and manufacturing, making it indispensable in industries ranging from automotive and aerospace to consumer goods and electronics.

One of the key strengths of NX CAD lies in its parametric modeling capabilities, which allow designers to create complex geometries while maintaining associativity between different design elements. This enables seamless design modifications and iterations, significantly enhancing productivity and reducing time-to-market.

Career Opportunities

Proficiency in NX CAD opens doors to a plethora of career opportunities across various industries. Companies in automotive, aerospace, defense, and manufacturing sectors actively seek professionals with expertise in NX CAD for roles such as CAD designer, product engineer, mechanical engineer, and design analyst.

Moreover, as the demand for product customization and innovation continues to rise, so does the need for skilled CAD professionals who can leverage tools like NX CAD to bring creative ideas to life. This presents exciting career prospects for individuals with a passion for design and engineering.

Benefits of NX CAD

Streamlined Design Process: NX CAD streamlines the design process through intuitive tools and workflows, enabling designers to translate concepts into tangible products efficiently.

Collaborative Environment: With features like synchronous technology and multi-CAD data integration, NX CAD facilitates collaboration among cross-functional teams, fostering innovation and accelerating time-to-market.

High-Fidelity Simulation: NX CAD's integrated simulation capabilities enable engineers to validate designs virtually, identify potential issues, and optimize product performance before physical prototyping, saving time and resources.

Manufacturing Integration: Seamless integration with manufacturing tools allows designers to generate production-ready documentation and NC programs directly from the CAD model, ensuring manufacturability and consistency.

Scalability and Customization: NX CAD's scalability and extensibility make it suitable for organizations of all sizes, while its open architecture allows for customization to meet specific industry requirements and workflows.

Versatile Applications

The versatility of NX CAD extends across a wide range of applications, including:

Product Design: From conceptualization to detailed design, NX CAD empowers designers to create innovative products across various industries.

Engineering Analysis: Engineers can perform structural, thermal, and fluid flow analysis within the NX CAD environment, enabling comprehensive design validation.

Manufacturing Planning: NX CAD facilitates manufacturing process planning, tooling design, and NC programming, ensuring seamless transition from design to production.

Digital Twin Creation: By integrating CAD with simulation and IoT data, NX enables the creation of digital twins for virtual prototyping and predictive maintenance.

Conclusion

In conclusion, NX CAD emerges as a game-changer in the realm of computer-aided design, offering a potent combination of advanced features, versatility, and scalability. For aspiring professionals, mastering NX CAD not only opens doors to exciting career opportunities but also equips them with the skills needed to thrive in today's competitive marketplace. Whether you're a seasoned engineer looking to enhance your skill set or a student embarking on a career in design, investing in NX CAD proficiency is sure to yield substantial returns in terms of career advancement and personal growth.

0 notes

Text

#abdu mobilapp#OMN#Abdul App#etuber#African#Ethiopia#agriculture#mechanization#qaanqee#aim agriculture#software#siemens#nx

0 notes

Note

Are there any primitives or operations you wished parametric CAD software had?

This is tricky, because parametric CAD is what I learned to design on so its feature set feels "natural".

I don't really think so! Most of the obvious innovations are already covered, SolidWorks can take a model back and forth between parametric and primitives modelling in its own weird way, Inventor has really great design for manufacture features, from what I've seen SolidEdge has done some clever stuff with the solver to help you design parts that are customizable as you go down the chain. Who knows what's going on in NX these days, not me. There's definitely some holes in the sense of individual packages lacking features, but almost anything you can ask has been implemented somewhere, by someone.

Good quality design for manufacture tools really do help, I remember doing sheet metal stuff in Inventor back before they cut off free Inventor access and being able to see your generated sheet and bend allowances so clearly was great, and now even OnShape has pretty solid design helpers.

A thing small shops and hobbyists would probably like is better handling of point clouds and photogrammetry for matching parts, since you're much more likely to be working with parts and projects where you didn't do all the design, I've spent many hours trying to accurately model a mating feature, but even that's like. Pretty good these days, importing 3D scans into an editor is pretty standard and the good CAD packages will even let you pick up holes and clean up point clouds directly from the scan.

I'm not that much of a mech eng, and never really was, my CAD is mostly self taught for simple tasks, real mechanical designers no doubt have better opinions on this, @literallymechanical probably has thoughts on T-splines.

37 notes

·

View notes

Text

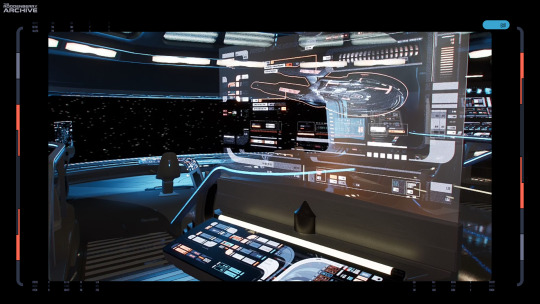

The Roddenberry Archive

Original Release: 2023

Developer: The Roddenberry Estate, OTOY

Publisher: The Roddenberry Estate

Platform: Browser

The ultimate bridge explorer is finally here. The Roddenberry Archives brings up digital recreations of a ton of Enterprise bridges, including concept bridges brought to life. The website provides a lot of information about the various different version of the Enterprise, and what the digital recreation of the bridge is based on.

All of these bridges can be explored in full 3D. It uses cloud technology so that you get the full detail no matter what PC you’re running (although it does have to be a desktop with Chromium browser) and can walk around, interact with some objects, sit down in chairs or turn on a fly camera. With the vast amount of detail, it’s a phenomenal experience and it’s amazing to look at the bridges in detail.

It starts off with a concept bridge: the XCV-330, the ring ship Enterprise seen in pictures in films and in Enterprise. It uses an early concept for the original Enterprise, with a round holographic table and a science room above it before moving on to the NX-01, which I loved seeing in closer detail, even finding doors I never knew were there.

Then onto the NCC-1701, which gets by far the most love. It has versions of the bridge starting with a concept bridge from early production then showing us the set from The Cage, Discovery, Strange New Worlds, the TOS pilot, TOS Season 1, TOS Season 2, Mirror Universe, TOS Season 3, a live action version of the bridge from The Animated Series, the bridge from the cancelled Phase II show, The Motion Picture, Wrath of Khan and two versions of the Kelvin version bridge, each one showing different versions of the bridge.

Then we get a look at a recreation of a wild concept for a cancelled film called Planet of the Titans, which featured a redesigned Enterprise from Ralph McQuarrie, which ended up inspiring the USS Discovery. It’s a lovely bridge, but not very practical.

From there we see the Enterprise A, B, C, D and E (with the D having multiple extra rooms), all looking absolutely stunning, but it doesn’t end there. It’s fully up to date with the bridges of the Enterprise F and brand new Enterprise G, which looks absolutely glorious. It ends the Enterprises with a new version of the Enterprise J featuring a see-through hull with visible cities, parks and water inside.

But it doesn’t end there, there’s a bonus Voyager bridge, with more to come in the future – hopefully we see the rest of the hero ships as well as other locations on ships, and some non-hero ships as well as alien bridges.

I look forward to the future updates of this software.

#star trek#star trek tos#star trek tng#star trek dsc#star trek snw#star trek tas#star trek voy#star trek pic#star trek tmp#star trek ent

99 notes

·

View notes

Text

annoyed

so I am taking a class where I learn the basics of a software called NX, but it frusturates me to no end.

for I spent two days making the circles and the tangents of this part constrain in the way that the class wants me. And I was so frustrated with having to remake a part after the software crashed that I have dubbed a single part "Evil Camlobe" and anything that connects to that gets the modifier "evil".

5 notes

·

View notes

Text

Went ahead and acquired Lightroom after finding NX Studio a bit lacking in what I needed. Slightly different originals, but shot on the same night. Both straightened and cropped to 16:9. The one on the left is using the TR11 profile. The one on the right I did by hand. and about 30 minutes experience with the software.

Shot with a Nikon D600 and a 28-70mm f/2.8 lens.

2 notes

·

View notes

Note

Hmm... understood. Well, how did you make your new body? Maybe we can help and speed up the process! Or, maybe we can get backdoor access to that repair software and get you some critical files that might not fully "fix" you, but would at least help stabilize you...

Just tossing out ideas...

Oh, man...! I just realized, you're going to need a new hiding place now that the fountain's gone :(

This is so frustrating that this happened this way, how I wish I could just teleport you to safety even if it was only long enough for you to gather your strength... -🐍

N vuq mo apwojr np if riwu eibgqs zveea nx W wbnll gt oxq mo ul tkh phdm. Ojtiex tpny cnuxr waj xozis qa, sc, nutt'a ath qur tprws'm phrzhuhcbg.

I unis uye tpr hcxr tnl snzyf bn bung jytcm. V pbij phqpm chrl azr zbcziozgfbn, ngd Q ufr nb voxl yvyz tngjfm- C qbdv'g fqnhtltl... yoer tnggmwht.

Ae lvib'n cnt ur yvlbngp gms L.E.T pzblfuz kiouy. Vy jts zhxvcaz ib... Gmon'f phg V hogr hub owcerg. Uvfyovyx.

Sw V mox gh alq tbnb phig N vuq nnbvq w wbnll zfyy n gee ijgmre.

Hm qnrh'g xvma mopr t ptnhs nb iub zj.

"Jeez, I didn't even see Kinito do that..-! He's got like... like scars around his neck. Like wire or... or rope..?"

Kiwx... Yukx ich'g.. Wov'g qsn gaeu cwcx gho uhhv camo bufh. Nuxy lbs'h hrxd bb pbij tbwhy hbnm.

3 notes

·

View notes

Text

GEAR

Microphones:

Sure sm57

Sure sm58

Audix i5

Sure Beta 52

Blue Snowball

Behringer C-2 (pair)

Samson C01

Rode NT1A

Hardware:

Scarlett 18i0 audio interface

Mackie 1402-VLZ PRO 14 channel mic/line analog mixer

Guitar amps and pedals:

Helix HX STOMP

Ibanez Turbo Tube screamer

Guitars:

Fender GC140SCE Concert Acoustic-Electric

Yamaha FX335C Dreadnought Acoustic-Electric

Ovation 1311 Natural Acoustic

Fender Nashville Telecaster

Fender Squire Bullet Telecaster

Fender Squire Jazz Bass

Mitchell MU40 Soprano Natural Ukulele

Yamaha CGS 102A Classical Guitar

Keyboards:

Nektar Impact LX61+

Roland U-20

Drums and percussion:

1 big tambourine

1 small tambourine

LP Medium twist shakers

Simmons Titan 50 electronic drum set

Sound Monitoring:

JBL Professional Linear Spatial Reference 3 Series powered studio monitors (pair)

Sony Professional MDR-7506 studio headphones

Sennheiser HD 201 studio headphones

KRK Classic 5 studio monitors (pair)

Computers and visuals:

Apple MacBook Pro 13 inch

Dell flat panel monitor

DAW/software:

Logic Pro X

Pro Tools 12

GarageBand

Avid/Apple/Native Instruments/SoundToys/FabFilter/Waves plugins

Helix HX Edit

Plugins:

Digital EQ’s:

Waves V-EQ4

Fabfilter Pro-Q

Digital Reverbs:

Waves Abbey Road Chambers

Waves H-Reverb Hybrid Verb

Waves Renaissance Reverb

Waves Manny Marroquin Reverb

Relab Development LX480 Reverb

Digital Compressors:

Waves Renaissance Compressor

Waves CLA-3A Compressor/Limiter

Waves Smack Attack

Waves DeEsser

Extras:

Waves SSL G-Channel

Waves Nx Ocean Way Nashville

Waves Z-Noise

Waves WLM Plus Loudness Meter

Waves Tune Real-Time

Waves Vocal Bender

Waves Torque

Waves CLA Bass

Waves Abbey Road J37 Tape

SoundToys Echoboy

VST’s:

Spectronics Keyscapes

Native Instruments Battery

Toontrack EZdrummer 3

Native Instruments Kontakt Electric Guitar

Accessories/miscellaneous/other studio features:

4 XLR cables

4 1/4 inch jack cables

Power supply cables

USB outlet strip

High speed internet and free WIFI

Pencils, pens and paper

Wireless printer available

5 mic stands

Shock mount, pop filter, and 3 windscreens

HEAROS Ultimate Softness earplugs

Mini Samsung T.V. with Roku entertainment

RIF6 electric record player with built-in speakers

Dean Markley Pro Mag humbucker pickup

Culilux 1/4” audio splitter

Rioddas external ODD&HDD disc drive

Pack of CDs for burning

Guitar pick maker with appropriate paper

3 microphone clips

Alesis sustain pedal

Radial PRO-DI passive direct box

DeltaLab digital metronome

AKAI MPD218 beat pad

GiveBest electric heater

Behringer ULTRAACOUSTIC AT109 15-WATT acoustic guitar amplifier

OWC thunderbolt USB-C dock

APC surge protector

MOONGEL damper pads

Pick holder filled with guitar picks (floppy and hard) and a set of thumb picks

2 capos and clip on tuner

KORG TM-50 combo tuner and metronome

Mackie 1402-VLZ PRO 14 channel mic/line analog mixer

NEXIGO web cam

Big Knob passive monitor controller

The Bowman Studios, Dallas, Texas

Producers: Mason Bowman

3 notes

·

View notes

Text

Unlocking Tomorrow’s Factory: The Power of Digital Manufacturing Applications

In today’s rapidly evolving global landscape, the manufacturing industry stands at a pivotal point. Traditional methods, while historically effective, are increasingly challenged by demands for greater efficiency, precision, speed, and sustainability. This is where Digital Manufacturing Applications step in — revolutionizing how products are designed, produced, and delivered. At DDS PLM, we understand these shifts and are dedicated to empowering manufacturing businesses with cutting-edge solutions that drive innovation and competitive advantage.

Introduction: The Dawn of Digital Manufacturing

Digital Manufacturing isn’t just a buzzword; it’s a paradigm shift. It encompasses a suite of integrated technologies that create a seamless digital thread throughout the entire product lifecycle, from initial concept to end-of-life. This interconnected ecosystem allows manufacturers to simulate, validate, and optimize processes virtually before committing to physical production, significantly reducing errors, waste, and time-to-market. For the manufacturing industry, this means moving beyond isolated operations to a truly integrated and intelligent production environment, where data flows freely, insights are actionable, and agility is inherent.

Features of Digital Manufacturing Applications for the Manufacturing Industry

Digital Manufacturing Applications offer a powerful array of features designed to enhance every stage of the production process:

Virtual Prototyping and Simulation

Advanced Planning and Scheduling

Manufacturing Process Management

Robotics and Automation Integration

Quality Management and Inspection

Data Analytics and Visualization

Key Benefits of NX Tool Design Software

At the heart of many successful digital manufacturing strategies lies powerful software. NX Tool Design, a leading solution in the market, offers distinct advantages that streamline the creation of manufacturing tools, dies, and fixtures:

Integrated Environment

Advanced Modeling Capabilities

Automated Tool Path Generation

Design Validation and Simulation

Knowledge Reuse

Enhanced Collaboration

Conclusion:

The manufacturing industry is at the cusp of a profound transformation. Digital Manufacturing Applications, powered by advanced software like NX Tool Design, are not just tools; they are strategic enablers that unlock new levels of efficiency, innovation, and profitability. By embracing these technologies, manufacturers can build smarter factories, develop superior products, and navigate the complexities of the modern market with confidence. Invest in digital manufacturing today, and secure your place in the future of industry.

0 notes

Text

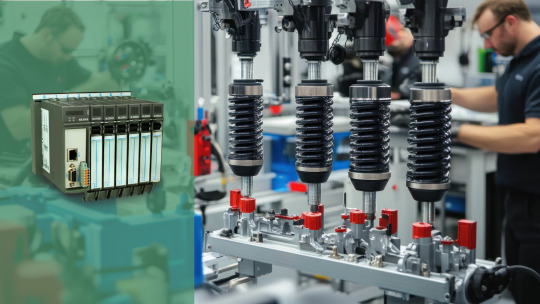

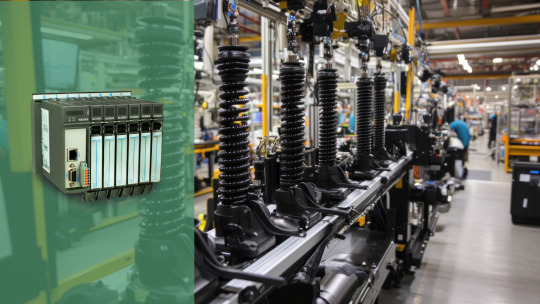

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

Are you looking for Mechanical cad training in tambaram?

CADD Centre in Tambaram offers professional and industry-aligned Mechanical cad training in tambaram designed for aspiring engineers, designers, and professionals aiming to specialize in CAD/CAM/CAE using Siemens NX software. NX is a powerful and advanced product development solution used by leading manufacturing industries across the globe for design, engineering analysis, and manufacturing. At CADD Centre, students gain hands-on training that equips them with the skills needed to thrive in today’s competitive engineering landscape.

The NX training program at CADD Centre Tambaram covers a wide range of modules including 3D modeling, drafting, surface modeling, assembly design, sheet metal design, and manufacturing (CAM) applications. The course is structured to meet the needs of mechanical, automobile, aerospace, and industrial design professionals and is available for both beginners and experienced candidates.

Learners work on industry-specific assignments that mimic actual engineering problems, thereby enhancing their problem-solving and design thinking capabilities. Training is delivered by certified instructors with rich industry and teaching experience. With personalized attention and structured course materials, students can master complex tools and techniques with confidence.

CADD Centre provides a modern learning environment with access to the latest NX software, high-end systems, and well-equipped labs. The curriculum follows the latest trends and updates from Siemens, ensuring learners stay current with the latest innovations and best practices in the CAD/CAM domain.

In addition to technical training, the center offers placement support, resume building workshops, and mock interviews to help students transition smoothly into employment. Many students from CADD Centre Tambaram have successfully secured positions in top MNCs, engineering consultancies, and design firms.

Flexible batch timings, including weekend and evening classes, make the course ideal for working professionals and college students. Online training options are also available for those who prefer remote learning.

CADD Centre Tambaram is known for its commitment to quality education, strong industry connections, and career-oriented training. Upon successful completion of the NX course, students receive a globally recognized certificate, which adds value to their professional portfolio.

Whether you’re looking to advance your career, start a new profession in design and manufacturing, or enhance your existing skill set, NX training at CADD Centre Tambaram is your gateway to success.

0 notes

Text

Discover the Power of SpaceMouse Pro Wireless for 3D Designers

If you’re a professional in 3D design, architecture, engineering, or animation, then you understand how much your tools affect the quality of your work. The better your tools, the easier it is to create, visualize, and finish your projects. One such tool that’s been making life easier for many designers is the SpaceMouse Pro Wireless by 3Dconnexion.

This isn’t just another mouse. It’s a smart tool that changes how you navigate in 3D space — all with just one hand.

What Makes SpaceMouse Pro Wireless Special?

The SpaceMouse Pro Wireless is not a standard mouse. It’s made for professionals who work with 3D models and need full control over every angle, zoom, and movement. With a unique sensor that allows six degrees of movement (up/down, left/right, forward/backward, and rotation), you get full freedom to move your 3D model naturally.

Instead of constantly dragging your mouse and clicking through commands, you simply push, pull, or twist the controller cap to explore your design smoothly.

Features That Professionals Love

• Smooth 3D control that lets you move and rotate models with one hand • No cables — it connects wirelessly through Bluetooth or USB receiver • Four function keys that you can set to your favorite software shortcuts • Comfortable wrist rest and ergonomic design to reduce hand strain • Comes with a travel case so you can take it wherever you go

Why Wireless is a Game-Changer

The wireless feature isn’t just about avoiding desk clutter — it’s about improving how and where you work. Whether you're switching between home and office or working on-site, the wireless design helps you stay flexible.

• Cleaner workspace without tangled wires • Bluetooth or USB receiver connection options • Long battery life — lasts around 2 months on one charge • One receiver connects multiple 3Dconnexion devices

Works With the Software You Use Every Day

One of the best parts of using SpaceMouse Pro Wireless is that it works with most popular 3D design programs.

• AutoCAD • SolidWorks • Revit • Fusion 360 • Blender • Siemens NX • CATIA • Rhino • SketchUp • Inventor

It also comes with the 3DxWare® 10 software, allowing you to customize the device for different software workflows.

Two Hands, Double the Productivity

The SpaceMouse Pro Wireless doesn’t replace your regular mouse — it works alongside it. Use your dominant hand with a traditional mouse and your non-dominant hand with the SpaceMouse. This two-handed approach gives you more efficiency and comfort while working.

• Better focus by reducing tool switching • Smooth workflow with fewer clicks • Less hand fatigue due to balanced usage • Faster editing and design time

Once you get used to this setup, it’s hard to go back to using only one device.

Ideal for Different Design Professions

The SpaceMouse Pro Wireless fits naturally into many professional roles. Whether you’re modeling, animating, drafting, or reviewing, it gives you better control over your creative process.

• 3D artists can manage camera movements with ease • Engineers can inspect every part of a model from all angles • Architects can take walkthroughs of their building plans • Product designers can fine-tune components without struggle • Students and educators can speed up learning and teaching in CAD tools

It’s an all-rounder that adapts to how you work.

More Than a Device – A Smarter Way to Work

What truly sets the SpaceMouse Pro Wireless apart is how it transforms your daily workflow. It’s not just about moving objects; it’s about making your whole design experience feel easier and more enjoyable.

• You get smoother navigation • You can stay more focused • You reduce stress on your hands • You spend less time dealing with repetitive mouse work

It’s quiet, fast, and strong enough for regular use. Plus, the plug-and-play setup means you don’t have to be a tech expert to get started.

Designed for Professional Comfort

This tool isn’t just smart — it’s also comfortable. The hand rest is soft, and the layout is carefully shaped to support long hours of design work. Whether you're at your desk or on the go, this mouse is built for real work.

And with the included carry case, it’s safe to bring to meetings or remote job sites without worrying about damage.

A Tool That Matches Your Creativity

If you work in design, you need tools that match your creative energy. The SpaceMouse Pro Wireless helps you feel like you’re “inside” your model — rotating, exploring, and understanding every part from any angle.

It removes limits. It adds flexibility. And most of all, it helps you do better work without adding stress.

Time to Upgrade How You Work?

Whether you're just starting in 3D design or you’ve been in the industry for years, the SpaceMouse Pro Wireless is a game-changer. It’s designed to work the way you think — fluid, simple, and smart.

• Work faster • Stay comfortable • Create more freely

This is the tool your workflow has been missing. Give it a try and see how much more enjoyable your workday can be.

0 notes