#PLC automation systems

Explore tagged Tumblr posts

Text

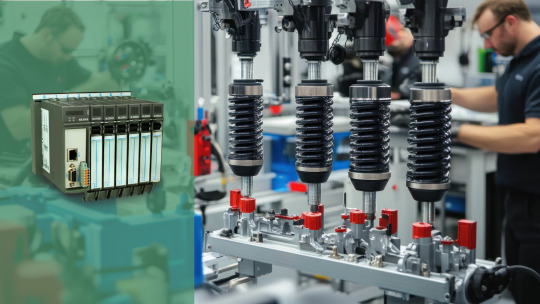

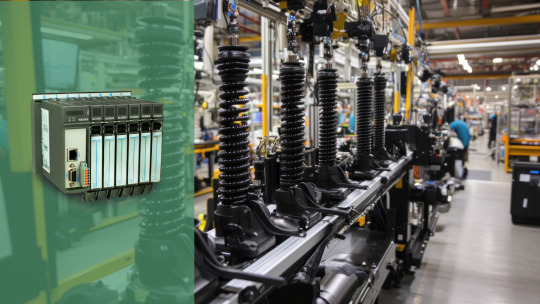

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

AVEVA (Wonderware) System Platform

SCADA, HMI, MES, and IIoT applications, AVEVA System Platform (previously Wonderware System Platform) is a unified operations center solution that offers an open, adaptable, and scalable architecture. In manufacturing and infrastructure operations, it provides a common basis for supervisory control, data collection, and real-time display.

Key Features of AVEVA System Platform

Object-Oriented Architecture

Scalability and Flexibility

Centralized Configuration and Deployment

Real-Time Data Handling

Integrated Historian

Security and User Management

Common Use Cases

Supervisory control and monitoring for manufacturing plants.

Energy and utilities operations management.

Water and wastewater facility control.

Oil & gas SCADA systems.

Smart buildings and infrastructure monitoring.

#automation#technology#tech#plc automation#aveva#scadatraining#scada systems#software programing#software#PLC#VFD#automotive

2 notes

·

View notes

Text

Understanding the meaning, applications, and advantages of control valves.

Control valves are devices that play an essential role in controlling and regulating the flow, pressure, and temperature in industrial processes and control systems. It is installed in the field-level area of the automation pyramid and connected to the control system and PLC through the PLC’s hardware. The global control valve consists of the body, actuator, Positioner, Valve trim, stem, and bonnet to prevent leakage. There are also the Gaskets and seals that are used when connecting the valve with other mechanical parts.

Control valves have many advantages such as Accurate Control of Process Parameters, Easy Automation Compatibility by integrating these items with the main Control systems (DCS and PLC), Energy saving and energy efficiency by optimizing the process condition and minimizing waste, maintaining safe operating conditions and increase process safety factors, Improve Process Efficiency and Increase Product Quality.

Control valves are used in many applications such as the Automotive Industry, Cement and steel, and Oil and Gas Industry, especially in gas valve trains, Renewable Energy, and HVAC Systems.

For full article check the following link:

For more articles about Renewable, Automation and Instrumentation, check the following link:

www.ecaico.com

#automation#instrumentation#renewable#control system#plc#sensors#pressure#gas valve#industrial valves

2 notes

·

View notes

Text

Eaton Plc Hardware

Hardware from Eaton Plc is a top option for automation and control. At PLC World, Eaton offers programmable logic controllers, operator interfaces, intelligent cabling, buttons and stacklights, relays, sensors, control, and motor protection.

2 notes

·

View notes

Text

Exploring the Innovations of Rabwellplc in the PLC Industry

The PLC industry is thriving with advancements, and Rabwellplc is at the forefront of this evolution. Their commitment to quality and innovation is truly inspiring. With products that integrate seamlessly into various automation systems, Rabwellplc is making a significant impact.

As we discuss the importance of reliable control systems, it's essential to highlight how Honeywell PLC products complement Rabwellplc's offerings. Together, they provide robust solutions that enhance operational efficiency and reliability.

What are your thoughts on the future of PLC technology and how brands like Rabwellplc and Honeywell PLC are shaping this landscape?

0 notes

Text

Liebherr PCB Card 925086914 0002555 0601004 | High-Quality Control PCB Board | Ram Automations

Enhance your machinery’s performance with the Liebherr PCB Card 925086914 0002555 0601004, available now at Ram Automations. This high-quality Printed Circuit Board (PCB) offers exceptional reliability, precision engineering, and durability for a wide range of industrial and marine applications.

Designed for maximum performance and efficiency, this Liebherr PCB Card ensures seamless integration with complex control systems, making it ideal for critical automation environments and high-demand applications.

🛒 Buy Now from Ram Automations 👉 https://ramautomations.com/products/pcb-card-925086914-0002555-0601004-liebherr-new

🌐 Explore 1000+ Genuine Automation Components 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Liebherr • 🔹 Model: 925086914 / 0002555 / 0601004 • 🔹 Type: PCB Card • 🔹 Category: PCB Card / Industrial Electronics / Automation PCB • 🔹 Application: Industrial Automation, Marine Systems, Control Panels, Process Systems

✅ Key Features

✔️ Precision-engineered PCB for reliable performance ✔️ Seamless integration with industrial systems ✔️ High-quality materials and craftsmanship ✔️ Essential for complex machinery and automation units ✔️ Ideal for industrial, marine, and manufacturing environments

💡 Typical Applications

• Marine Electronic Control Systems • Industrial Automation Panels • SCADA and HMI System Boards • Heavy Equipment Automation • Process Automation Systems • Robotics Control Panels • Industrial Machinery Systems

🌟 Why Choose Ram Automations?

✅ 100% Genuine Products Only ✅ Best Prices with Worldwide Delivery ✅ Trusted Industrial Automation Supplier ✅ Large Inventory of Hard-to-Find Components

🛍️ Visit Us: https://ramautomations.com

In This Video You Will Discover:

🔎 Close-up View of Liebherr PCB Card 🔧 How It Integrates with Complex Systems 💡 Importance of High-Quality PCBs in Industrial Automation 🌐 Why Ram Automations is the Go-To Source for Industrial Parts

📣 Get Involved!

🔔 Subscribe for Automation & Electronics Updates 👍 Like to Show Support for Quality Electronics 💬 Comment Your Queries — We’re Happy to Help! 🛒 Visit our Online Store: https://ramautomations.com

#Liebherr PCB Card#PCB Card for Automation#Industrial PCB Card#Automation PCB Card#Marine Control PCB#Automation System Board#Ram Automations#Control Panel PCB Card#Process Control PCB#Marine Automation Electronics#Industrial Electronic PCB#Automation Equipment PCB Card#Marine Systems PCB Card#Factory Automation Parts#Robotics Control Panel Card#Data Transmission PCB Card#PLC Control PCB Card#High Quality PCB Card#SCADA System PCB Card#Electronic Connectivity PCB Board

1 note

·

View note

Text

Trend Iq221-400008 Controller Module Iq221/Unb/230V - Auto2mation

The Trend IQ221-400008 Controller Module IQ221/UNB/230V is a reliable and compact solution for smart building control systems. Designed to deliver efficient energy management, this module supports seamless integration with HVAC and other building automation applications. Its user-friendly setup makes installation and maintenance simple. Operating at 230V, it ensures stable performance and long-term durability. Ideal for commercial and industrial use, the IQ221 controller helps optimize energy usage while maintaining comfort. Trusted by professionals, it’s a smart choice for modern automation needs. Buy the Trend IQ221-400008 Controller Module now from Auto2mation – your trusted source for industrial automation products.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Trend#Controller Module#plc system

0 notes

Text

Exploring the PLC Industry with Rabwellplc

Hello everyone! I am excited to share my thoughts on the PLC industry, particularly focusing on the Rabwellplc brand and its integration with Fanuc PLC technology.

Rabwellplc has made significant strides in providing reliable and efficient programmable logic controllers that cater to various industrial needs. Their commitment to innovation ensures that users experience seamless automation processes.

Fanuc PLC, known for its advanced capabilities, pairs wonderfully with Rabwellplc systems, allowing businesses to optimize their operations. The combination of these two brands can lead to enhanced productivity and improved performance in manufacturing environments.

If you are considering upgrading your automation systems, I highly recommend looking into Rabwellplc and Fanuc PLC solutions. Together, they can empower your business to reach new heights!

What are your experiences with these brands? Let's discuss!

#innovation#Rabwellplc#manufacturing#Fanuc PLC#automation systems#PLC industry#industrial needs#automation

0 notes

Text

What is Python Programming? Learn the Basics of Python

Python is one of the most beginner-friendly programming languages available today. It’s widely used across industries and has become the go-to language for those just stepping into the world of programming. Whether your goal is to build websites, analyze data, or explore artificial intelligence, Python provides a solid foundation to begin your journey.

Why Python is Ideal for Beginners

One of the biggest reasons Python is favored by newcomers is its simplicity. Python's syntax is clean and easy to read, which means you can quickly understand what your code is doing without needing a background in computer science. Unlike some other languages that require strict formatting or complex structures, Python keeps things minimal and intuitive.

Another strong advantage is its wide usage. Python is used in a variety of fields such as software development, automation, data science, machine learning, and web development. This versatility means that once you learn the basics, you can apply your knowledge to countless real-world scenarios.

Python also boasts a massive global community. This means that if you ever get stuck, there are thousands of tutorials, forums, documentation pages, and learning resources available online. Beginners benefit greatly from such a supportive environment.

Understanding the Basics of Python

To begin your Python journey, it’s essential to grasp a few fundamental concepts. These include understanding how to store information using variables, working with different types of data, performing calculations, and writing logic to make decisions in your code.

Another important area is learning how to repeat tasks using loops, and how to organize your code into reusable blocks called functions. These basics form the building blocks of almost every program you'll write in Python.

As you progress, you’ll also explore how to work with data collections like lists and dictionaries, handle user input, and structure your projects to be readable and efficient.

Real-World Applications of Python

Python’s appeal goes far beyond its simplicity. It’s a powerful tool used in professional environments to build a variety of applications. In web development, Python is behind many dynamic websites and platforms, thanks to frameworks like Django and Flask.

In the world of data analysis and visualization, Python offers libraries that help professionals process large volumes of information and extract meaningful insights. From creating charts to building predictive models, Python powers much of what we see in business intelligence and research today.

Another exciting domain is machine learning and artificial intelligence. With Python’s frameworks and libraries, developers can build systems that learn from data, make decisions, and even understand natural language.

Python also excels in automation. If you’ve ever had a repetitive task on your computer, like renaming files or processing data, Python can be used to automate those tasks, saving time and effort.

How to Start Learning Python

The best way to begin learning Python is to start small and stay consistent. You don’t need any expensive software, many online platforms allow you to write and test Python code right in your browser. There are also free tutorials, beginner courses, and video lessons available to help guide your learning step-by-step.

It’s helpful to set small goals, such as writing a simple calculator or building a personal planner. These projects may seem small, but they help reinforce core concepts and make learning more engaging.

As you improve, you can challenge yourself with more complex projects and begin exploring specific fields like web development or data analysis. Python’s broad range of applications means there’s always something new to learn and try.

Conclusion

Python is more than just a beginner’s language, it’s a tool that professionals use to build innovative technologies and solve real-world problems. By mastering the basics, you open the door to endless possibilities in the tech world.

Whether you're a student, a working professional, or someone simply curious about coding, Python is the perfect language to get started. With dedication and practice, you’ll be amazed at how quickly you can go from a beginner to a confident programmer.

#What is PLC#What is SCADA#Industrial automation#PLC SCADA tutorial#plc scada system 2025#role of plc in automation

0 notes

Text

#Advanced PLC and HMI Training Kit Pune#Advanced PLC HMI Kits Pune#Advanced Siemens PLC Kits Pune#Advanced Mitsubishi PLC Training Pune#PLC and HMI Systems Pune#Industrial Automation Training Kits Pune#PLC and HMI Training Solutions Pune#Professional PLC Training Kits Pune#Advanced Automation Training Kits Pune#Best PLC and HMI Training Kits Pune.

0 notes

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

We at Messung Industrial Automation are not just manufacturing PLC automation systems. We engineer intelligence. Smart PLC control is our ambition, and we aim to revolutionize the way AHU controllers operate, using a range of technologies, including Modbus, MQTT, compact PLCs, or IOT-enabled PLC.

What is a PLC-Based AHU Control System?

A PLC-based AHU control system is the ultimate HVAC master conductor. The flow, cooling, heating, and energy consumption of air are all controlled by real-time logic and precision through automation controllers.

Decision-making is the primary responsibility of a IoT enabled PLC (programmable logic controller), not just following instructions. Your AHU is designed to respond to data, adjust to changing surroundings, and function like a finely tuned machine with the help of intelligent controllers.

Whether it’s a mini PLC for a compact setup or a modular PLC for a multi-zone building, this IEC 61131-3 standard controller is the heartbeat of your air management system.

Core Functions of PLC Automation in AHU Controllers Applications

Sensor Integration

Temperature, humidity, CO2, and differential pressure are all sensors that your AHU controllers are equipped with. When it comes to Energy management systems, PLC control systems are necessary for reading, interpreting, and operating raw data.

Our intelligent PLCs work together with sensors to capture every detail of your indoor environment.

Data Analysis & Decision Making

After submitting the data, the PLC Automation magic begins. Our IEC 61131 based PLCs utilize advanced logic and maintain monitoring of variables such as:

Room occupancy

Outdoor air quality

Return air temperature

The intelligence in this scenario is not confined to automation alone it expands to the action of the PLC Control Systems.

Control Actions via Actuators

Now let's talk about the muscle of the operation. By utilizing PLC and Modbus TCP/IP, your automation controllers can dynamically control VFDs (Variable Frequency Drives) to regulate fan speeds while minimizing energy usage.

Actuated Dampers

Want zoned cooling in your building? Each damper is given precise guidance on when and where it should be opened or closed by our compact PLC, down to the second.

Valves

Our PLC automation system manages both hot and chilled water circuits, ensuring thermal comfort with accuracy.

Humidifiers & Dehumidifiers

System Overview: The NX-ERA JET Advantage

NX-ERA JET PLC is a digital command centre that is agile, adaptive, and always on alert as the AHU controllers. We have developed an intelligent and IEC 61131-3 standard PLC Control Systems that combine advanced logic, seamless connectivity, and flexible scalability. The NX-ERA JET is the key to ensuring that every component of your AHU system, including sensors and actuators, operates in perfect harmony.

Features of this IoT enabled PLC at a Glance

Modular PLC architecture is flexible and can be easily scaled for multi-zone management in large or changing infrastructure

The utilization of PLC with TCP/IP facilitates fast and secure communication between devices, including devices connected to remote systems

The integration of MODBUS RTU, Modbus TCP, and MQTT with BMS, SCADA, or cloud-based IoT platforms is facilitated by the native support provided by these protocols.

An integrated HMI that provides real-time, intuitive monitoring, diagnostics, and manual overrides.

Benefits of IoT enabled PLC for AHUs

In modern air handling, the focus isn’t just on moving air but moving it forward. Why? Integrating PLC control systems into AHUs can offer a transformative advantage in performance, sustainability, and adaptability for buildings. We should examine why PLC automation is the primary driving force behind intelligent HVAC solutions.

Improved Energy Efficiency

The value of energy is high, and PLC for energy systems with IEC 61131-3 standards optimizes every kilowatt. We can use our IoT enabled PLCs to save energy - up to 30% a time with intelligently controlled fan speeds, valve positions and damper angles that are real-time. Measurable reductions through these intelligent controllers help to reduce operational costs and greener footprints are not just numbers.

High Precision Control

AHU controllers equate performance with precision. Why? Our IEC 61131-3 compliant PLCs provide precise control over airflow, temperature and humidity. The result? Consistent comfort, efficient performance and strict environmental regulations.

Advanced Diagnostics

The use of intelligent PLCs with IoT systems means that problems can be prevented rather than delayed. With real-time monitoring and fault detection, teams can receive predictive maintenance insights to minimize downtime and maximize up time.

Scalability and Modularity

Our modular PLCs are designed to accommodate the growth of your building, offering compact systems and multi-zone installations. Do you require an immediate upgrade or expansion? These intelligent controllers can scale without complexity.

BMS Integration

Our PLC Control Systems with IEC 61131-3 standard integrates seamlessly with Building Management Systems, creating one intelligent ecosystem. Whether it’s HVAC, lighting, fire alarms, or access control—everything talks to everything for smoother operations.

In a world where data and efficiency are the primary drivers of change, PLC-controlled AHU controllers provide more than just automation; they also offer confidence. Our IoT enabled PLCs enable buildings to thrive rather than just functioning.

Intelligent PLC Control Systems for Smart Buildings

HMI with PLC Controllers - An HMI with PLC controller enables the observation of invisible areas. The entire package, including fan speed and filter life, is conveniently located at your fingertips.

MQTT based PLC and IoT Systems - The integration of IoT enabled PLC and MQTT support enables your AHU to communicate with the cloud, apps, and analytics platforms, simplifying the process of achieving predictive control and remote access.

Real-World Applications

Through PLC-based AHU control systems, we at Messung are changing the possibilities of environments from sterile labs to busy malls. With precision, adaptability, and unparalleled reliability, our intelligent automation controllers tackle the challenges associated with every application.

Pharma Cleanrooms - The precision of pharmaceutical products is essential in their application. The strict GMP standards are adhered to by our PLC control systems, which involve managing temperature, humidity, pressure differentials. The result? Zones that are sterile, upholding drug integrity and safety.

Commercial Buildings - Employee comfort drives efficiency. Our HVAC automation enables seamless climate management of all floors and departments. By utilizing intelligent design, efficient air circulation, and real-time monitoring, our IoT enabled PLCs enhance the productivity and satisfaction of customers in spaces.

Data Centers - Servers demand a stable climate 24/7. Even minor temperature fluctuations can compromise data. Our intelligent PLC Control Systems with IEC 61131-3 standard ensure uninterrupted cooling performance, reducing thermal risk and operational downtime.

Energy-Efficient Manufacturing - Today's manufacturers must strike a balance between sustainability and production. Without compromising comfort or compliance, our PLCs maximize AHU performance to reduce energy footprints, reduce emissions, and guarantee stable internal environments.

Wherever there's air to manage and performance to perfect, our Compact PLCs lead the way with intelligent control.

Messung’s Expertise in HVAC Automation

We at Messung lead the way in HVAC automation innovation for organizing smart air movement. Our legacy is created on trust, performance, and innovative control systems that transform indoor environments, not only on technology

Why Choose Messung PLC Automation?

We design smart automation systems rather than only selling PLC Control Systems. With more than four decades of engineering expertise, our PLCs are the favoured option of architects, MEP consultants, HVAC contractors, and facility managers across India and globally. Our internal R&D, field-tested dependability, and quick support system turn us into a progress partner rather than just a supplier.

Built on IEC 61131-3 Standard

To ensure every Messung programmable logic controller is consistent, dependable, and compatible with worldwide systems—today and tomorrow — our automation controllers follow this internationally recognized IEC 61131-3 standard.

Flexible Form Factors

Whether you are managing many air zones throughout a smart high-rise or automating a small rooftop AHU, our compact and modular PLCs meet every architectural and functional requirement.

Comfort, control, and conservation are not optional but rather vital in the quickly changing realm of smart infrastructure of today. Furthermore, realizing this potent triad calls for smart, adaptive control rather than just automation. That is what Messung's PLC-based AHU systems precisely provide. Our programmable logic controllers redefine air handling performance for buildings of all sizes with real-time responsiveness, easy BMS integration, IoT readiness, and IEC 61131-3 standard. Our intelligent controllers offer precision, dependability, and next-generation energy efficiency from sterile zones to skyscrapers. Should excellence be your goal, our IoT enabled PLC guarantees you lead rather than merely follow. Why settle for fundamentals when you may automate brilliance with our smart automation controllers?

FAQs

What makes a PLC suitable for AHU control?

Real-time processing, sensor compatibility, actuator control, and smooth BMS integration define good automation controllers. Messung's smart PLCs with IoT systems check every box

Can a modular PLC (Programmable logic controllers) handle multiple AHU zones?

Absolutely. Modular PLCs like Messung’s NX-ERA JET are great for big buildings since they can span levels and zones.

How does Messung's IoT enabled PLC enhance building performance?

Connecting to cloud systems and providing remote access help our IoT enabled PLCs to maximize energy efficiency and real-time maintenance cycles.

Why is Messung’s NX-ERA JET the ideal, affordable PLC choice for midscale operations compared to traditional compact or mini PLCs?

Messung’s NX-ERA JET offers advanced performance at an affordable price, making it perfect for midscale operations. It outperforms mini PLCs with better speed, scalability, and flexibility, without breaking the budget.

Are MQTT based Programmable logic controllers better than traditional protocols?

MQTT-based PLCs offer faster, lighter, and more effective communication than conventional systems like MODBUS RTU for remote and IoT-intensive applications.

#messing 1st blog ahu link#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#AHU controllers#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#AHU controllers systems#NX-ERA JET#HVAC solutions#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#Pharma Cleanrooms#Commercial Buildings#Data Centers#smart automation systems#programmable logic controller#BMS integration#smart PLCs#Modular PLCs

0 notes

Text

Other communication options are available in PowerFlex 525 AC Drives

The PowerFlex 525 AC Drives provide a variety of connection options in addition to typical EtherNet/IP connectivity to guarantee smooth integration with different industrial networks. These drives provide various networking setups by supporting optional dual-port EtherNet/IP, DeviceNet, and Modbus RTU protocols. Communication adapter modules allow them to interact with protocols including ControlNet, BACnet, and Profibus DP. Because of its adaptability, users may connect to various control systems without requiring significant hardware modifications, making the PowerFlex 525 perfect for a variety of automation scenarios. Easy configuration and connectivity are further improved by embedded Ethernet and built-in USB programming.

#automation#technology#tech#technical#AVEVA#PLC#HMI#SCADA#scada systems#industrial#industries#Allen Bradley#Rockwell Automation#Tech#Automotive

2 notes

·

View notes

Text

139537 Eaton – DILM185A/22(RAC240)

DILM Contactor, 380 V 400 V 90 kW, 2 N/O, 2 NC, RAC 240: 190 – 240 V 50/60 Hz, AC operation, Screw connection.

For a more information click here

#plc world#industrial automation parts#plc hardware buy#plc equipment#allen bradley plc systems#buy eaton products#industrial automation equipment#plc system hardware#allen bradley plc parts#the three-step guide to buying automation

0 notes

Text

Maintenance Officer (Instrumentation) at Cotton Company of Zimbabwe - February 2025

The Cotton Company of Zimbabwe is seeking a qualified and experienced Maintenance Officer specializing in instrumentation to join their team. This role is crucial for ensuring the smooth operation of their ginning sites. About the Role: The Maintenance Officer will be responsible for the maintenance, repair, and calibration of instrumentation and control systems at the Cotton Company of…

View On WordPress

#Automation#Control Systems Jobs#Cottco#Cotton Company Zimbabwe#Electrical Engineering Jobs#Employment ZW#Engineering Careers#Engineering Jobs#Ginning#Harare Jobs#Hot Zimbabwe Jobs#Industrial Maintenance#Instrumentation Jobs#Instrumentation Technician#Job Opportunities ZW#Job Search ZW#Maintenance Jobs#Maintenance Technician#Manufacturing Jobs#PLC#Technician Jobs#Zim Jobs#Zimbabwe Careers#Zimbabwe Jobs

0 notes